Patents

Literature

84results about How to "Meet different performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

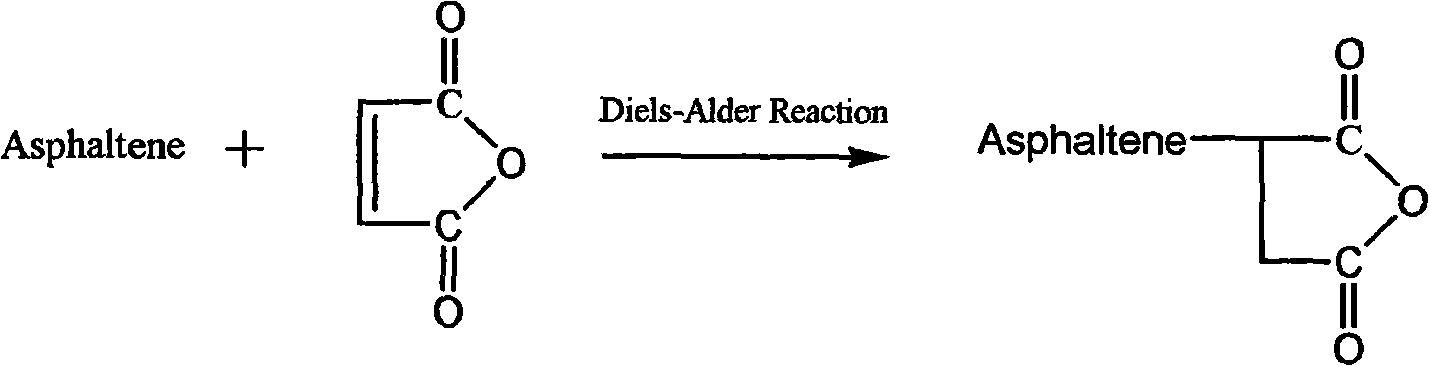

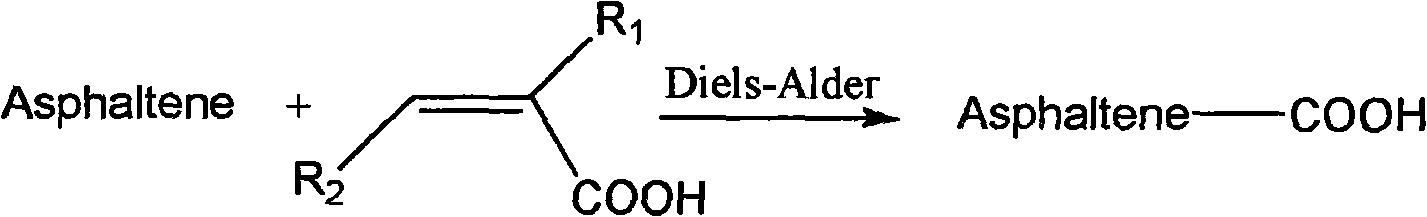

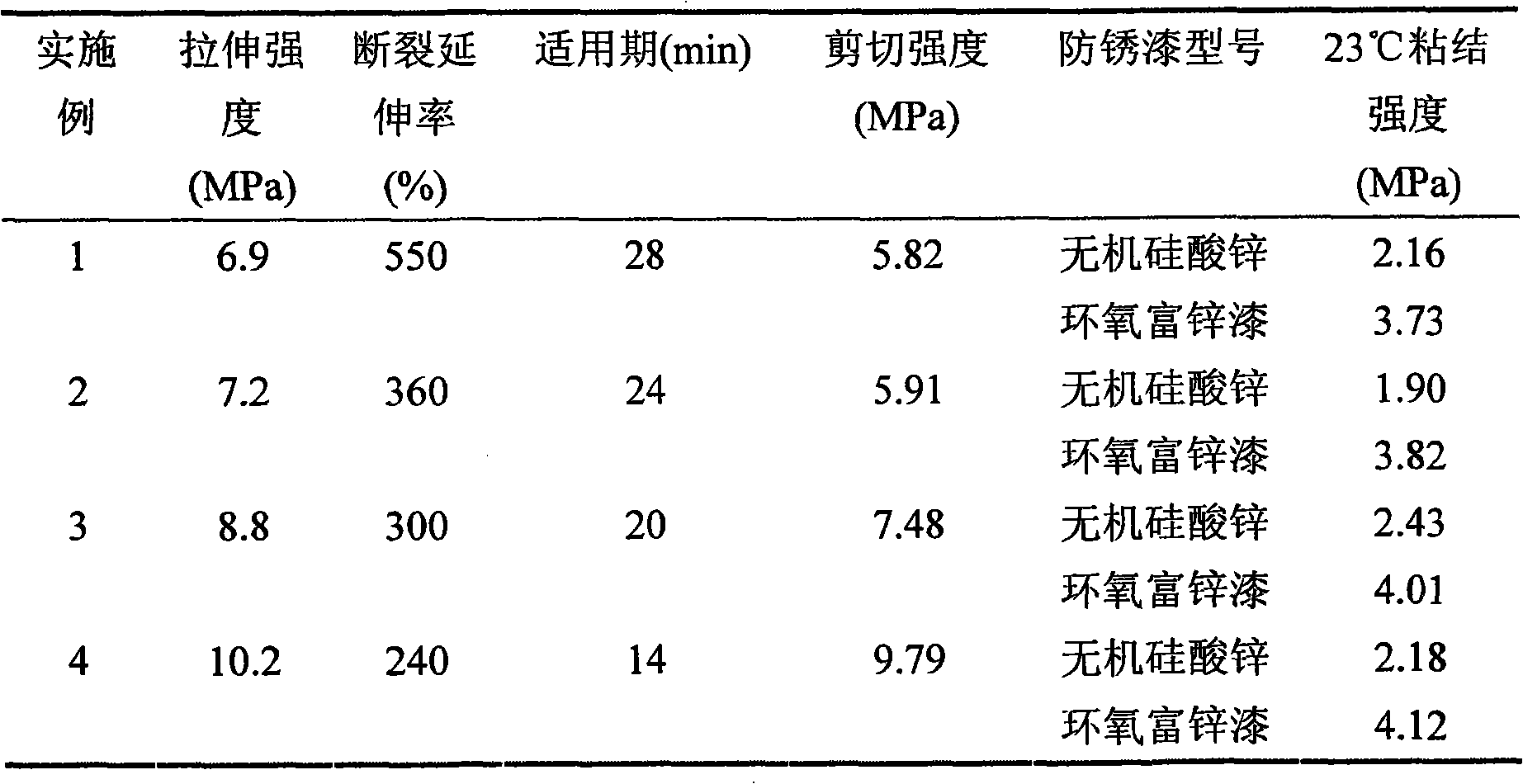

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

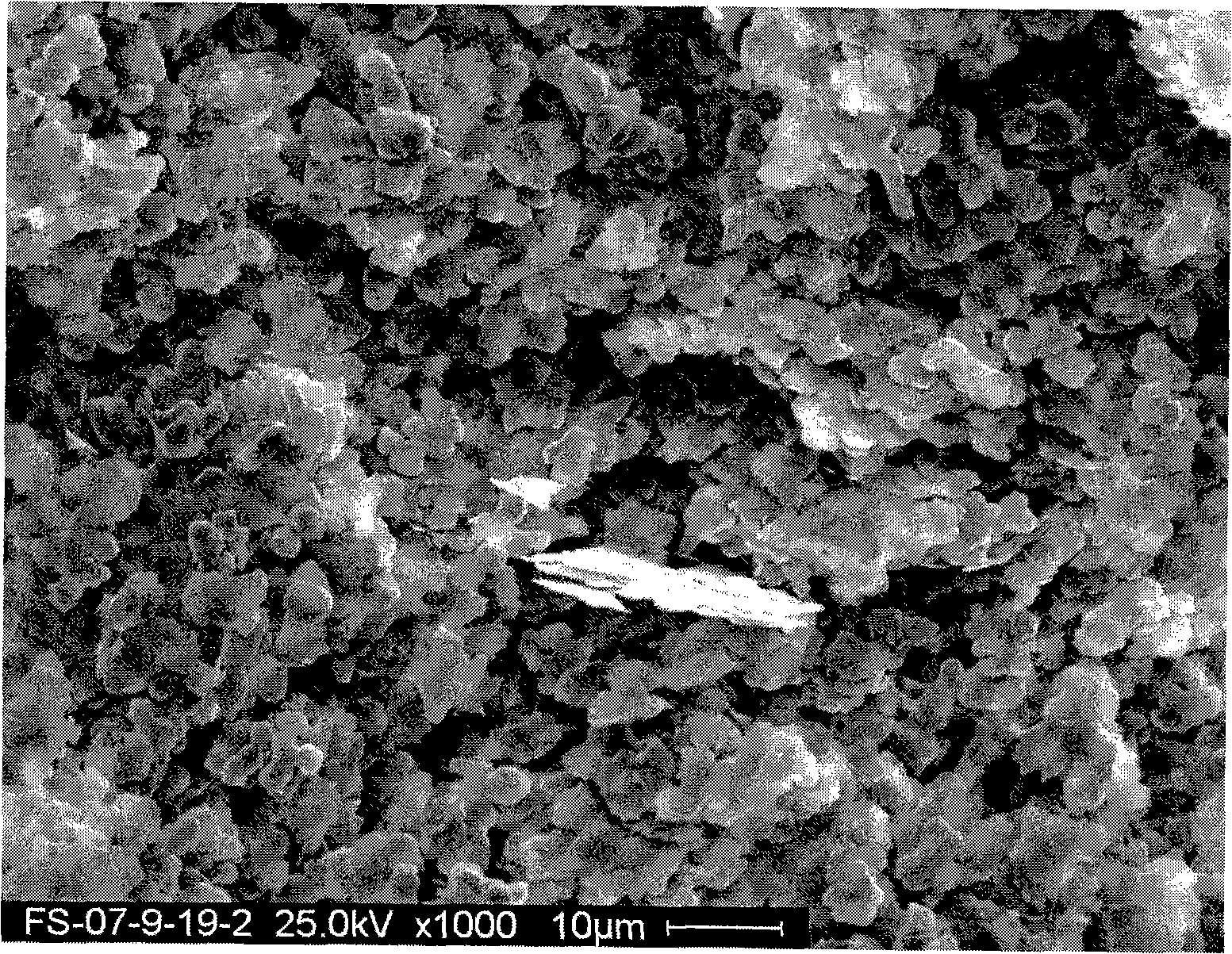

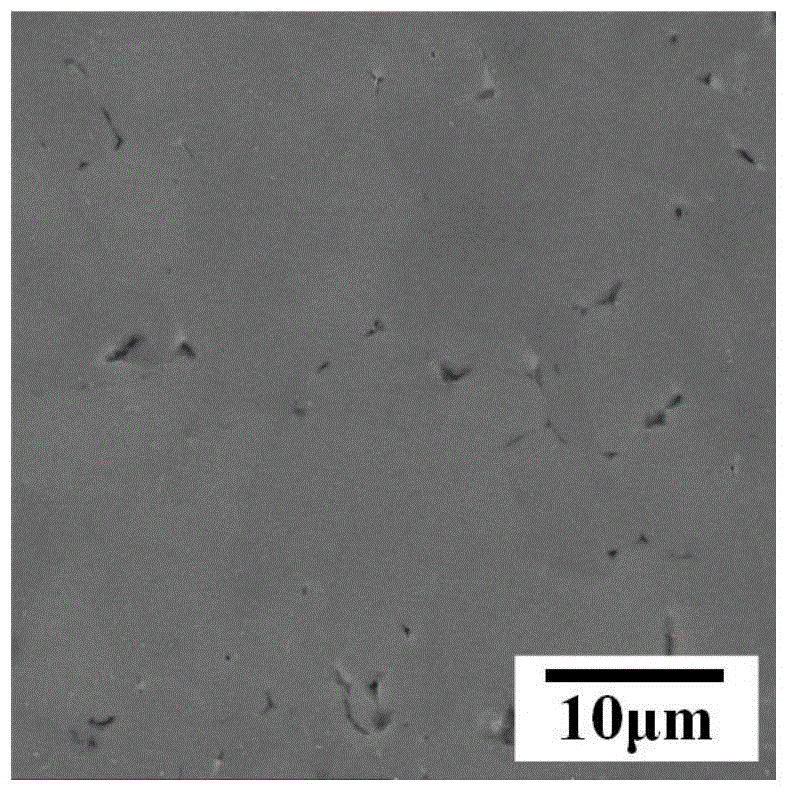

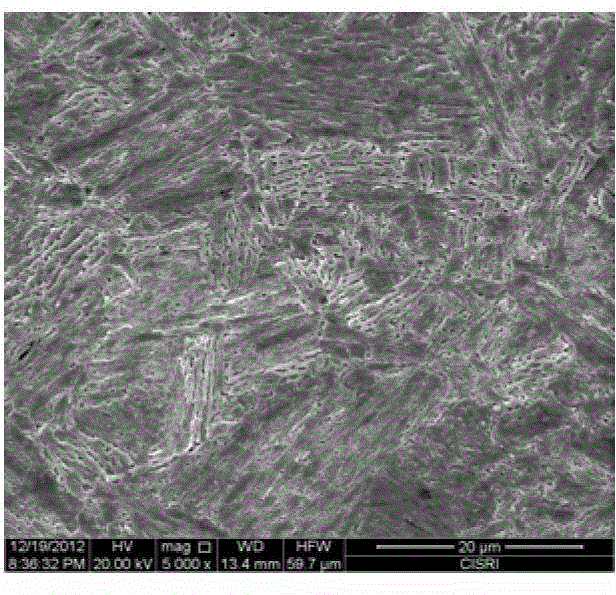

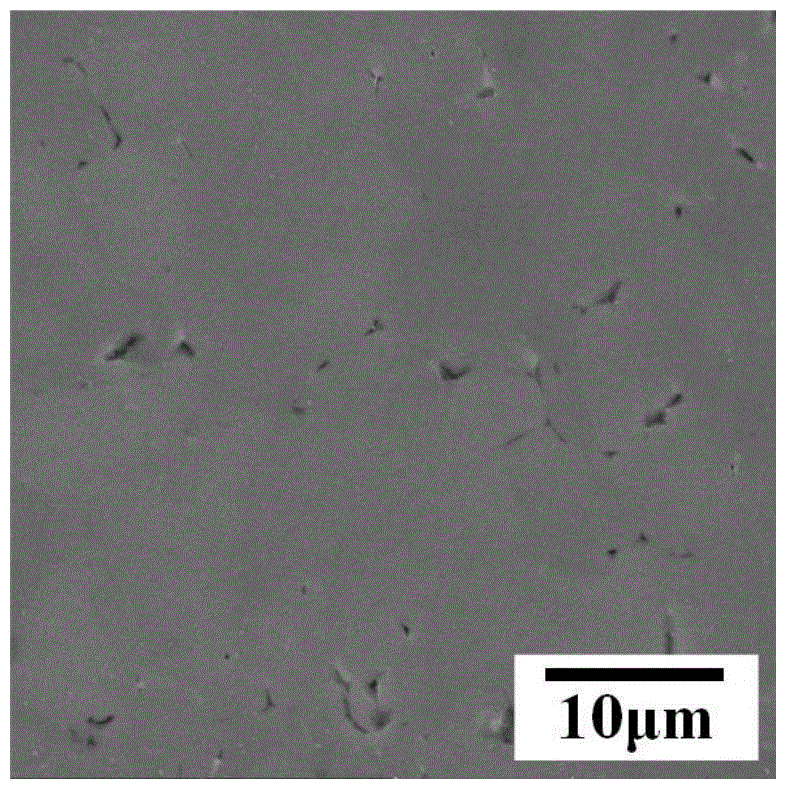

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

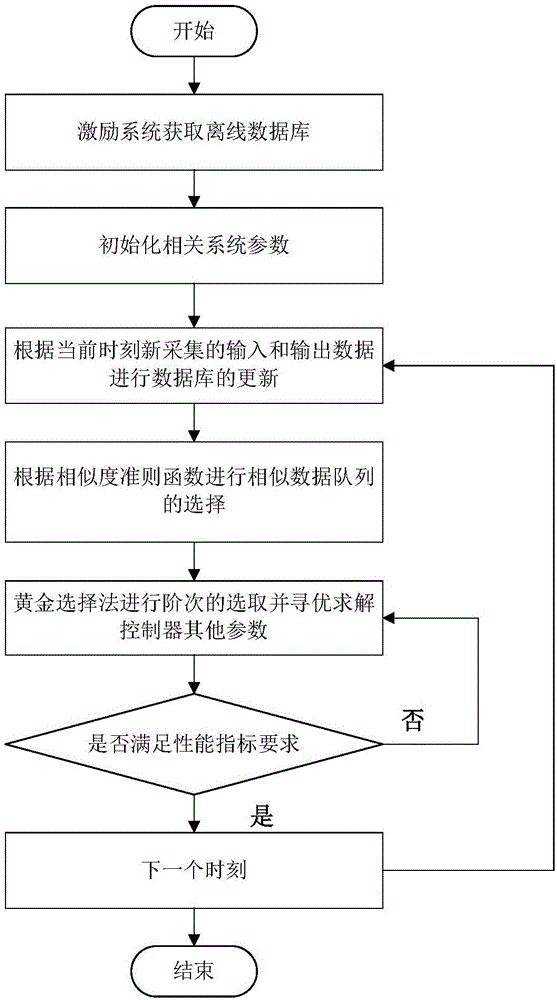

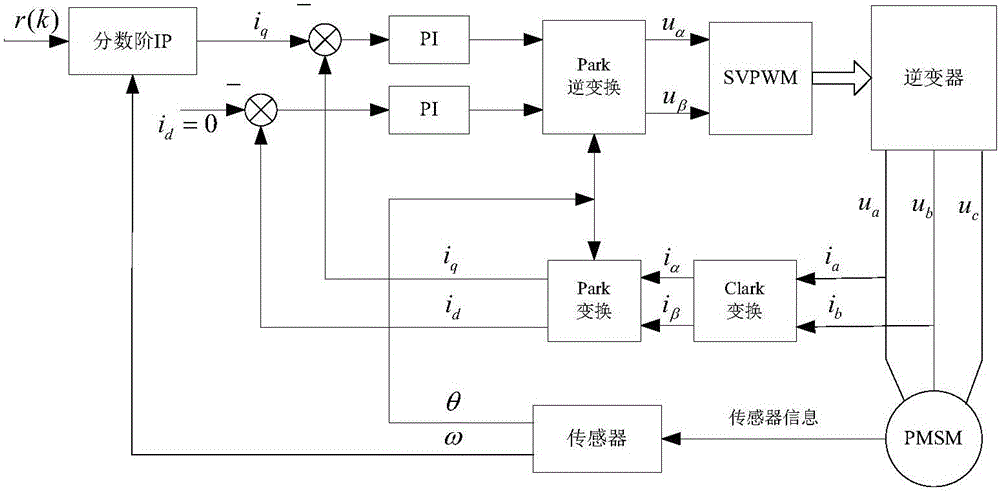

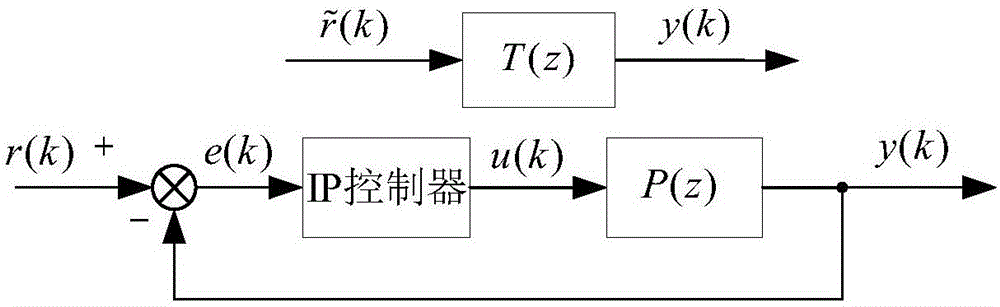

Servo system position IP controller model-free self-correcting method based on fractional order

ActiveCN106325073AChoose flexibleMeet the requirements of different performances in different occasionsAdaptive controlReference modelFractional-order control

The invention discloses a servo system position IP controller model-free self-correcting method based on fractional order. The method includes: setting a reference model, exciting a system to obtain an offline database, initiating the related parameters of the system, updating the database according to input and output data newly collected at a current moment, selecting similar data queues according to a similarity criterion function, selecting the order of a fractional order controller, and using particle swarm optimization algorithm to perform self-correcting on fractional-order IP controller parameters. The method has the advantages that the fractional order feature of the system is considered, performance such as overshoot, rising time, error convergence speed and controller parameter variation is appraised comprehensively, the instantaneity of the system is guaranteed by using the similarity criterion function, the method is unaffected by unmodeled dynamics, and the robustness, disturbance rejection ability and control precision of the system are increased.

Owner:HUAZHONG UNIV OF SCI & TECH +1

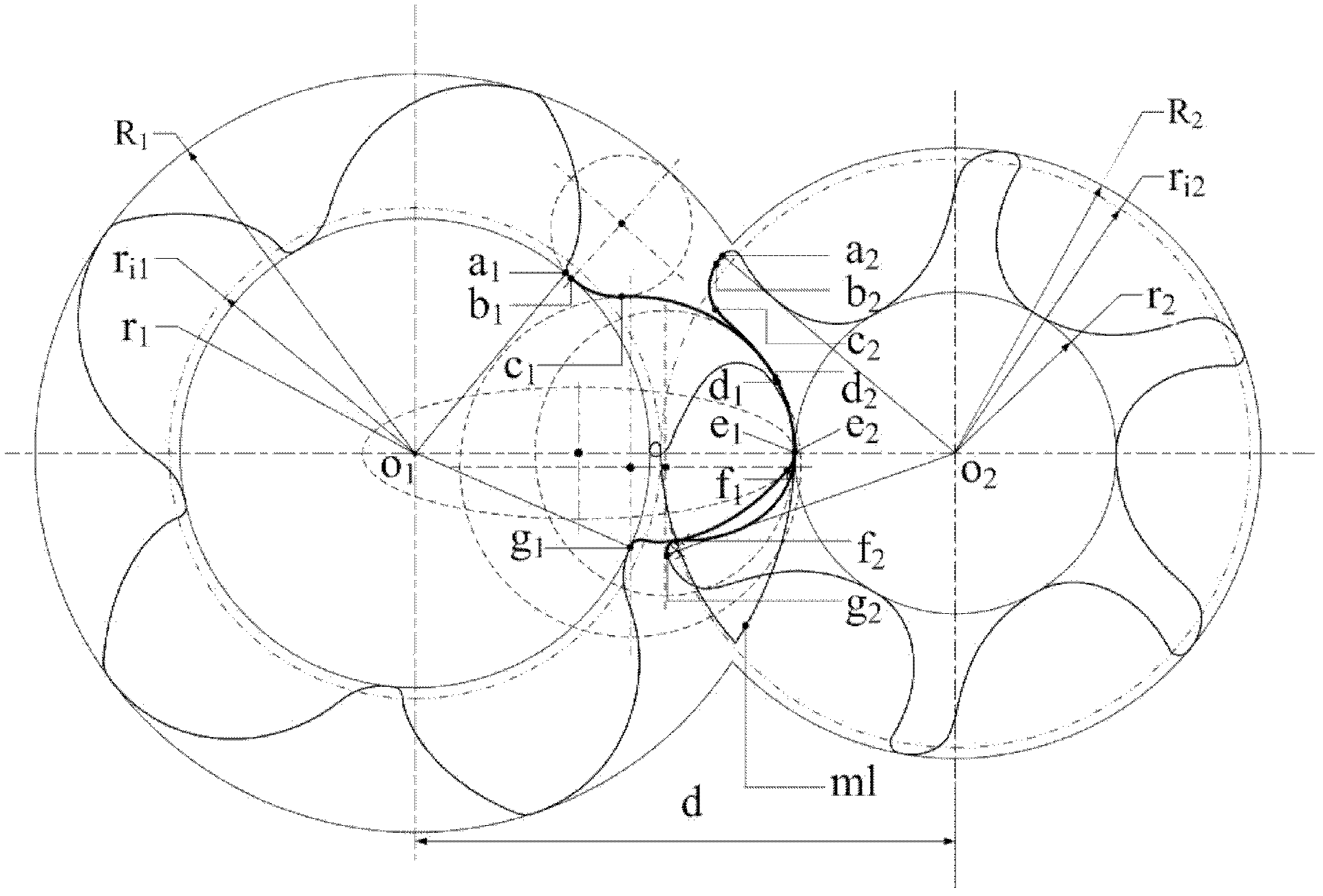

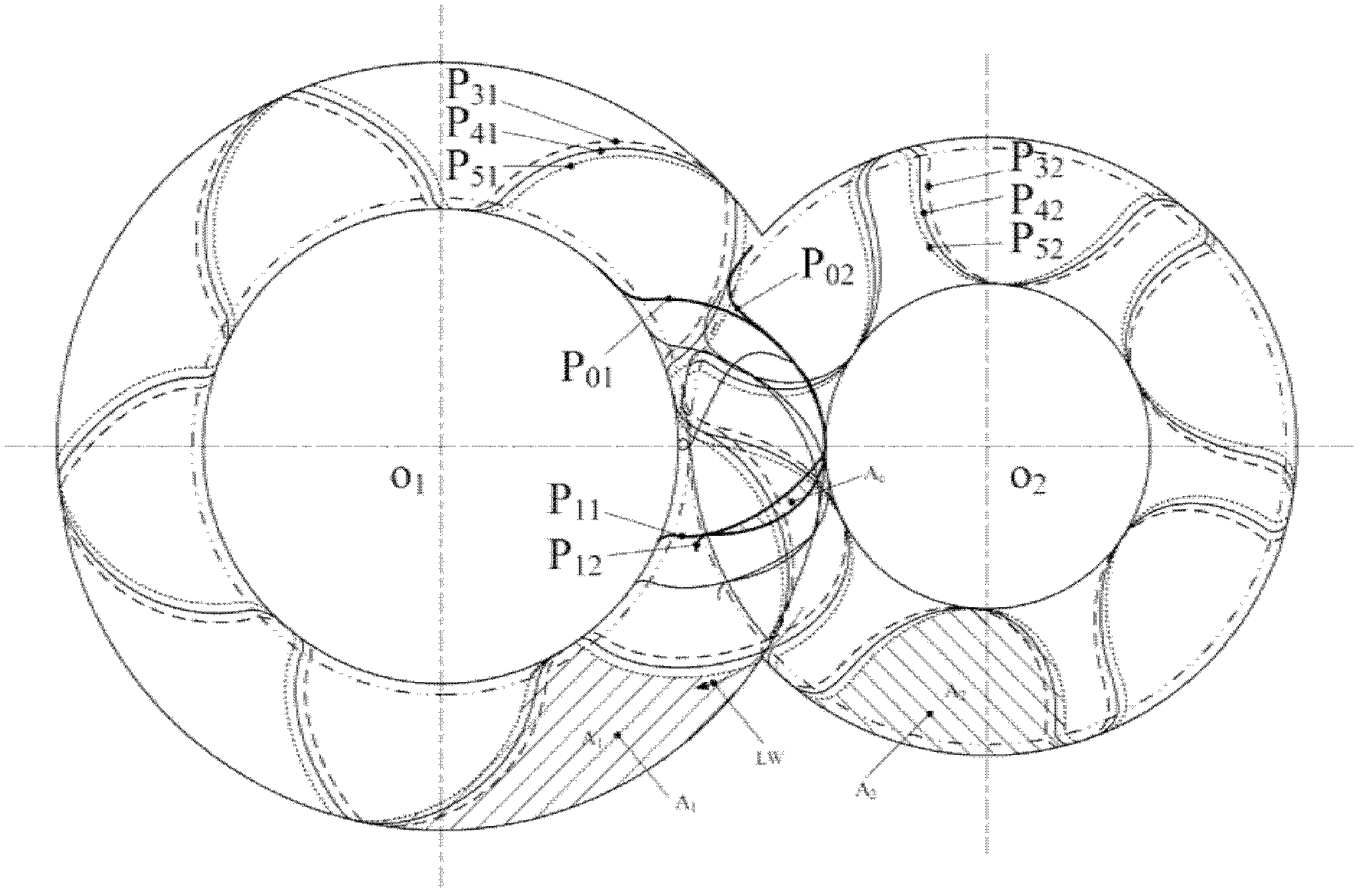

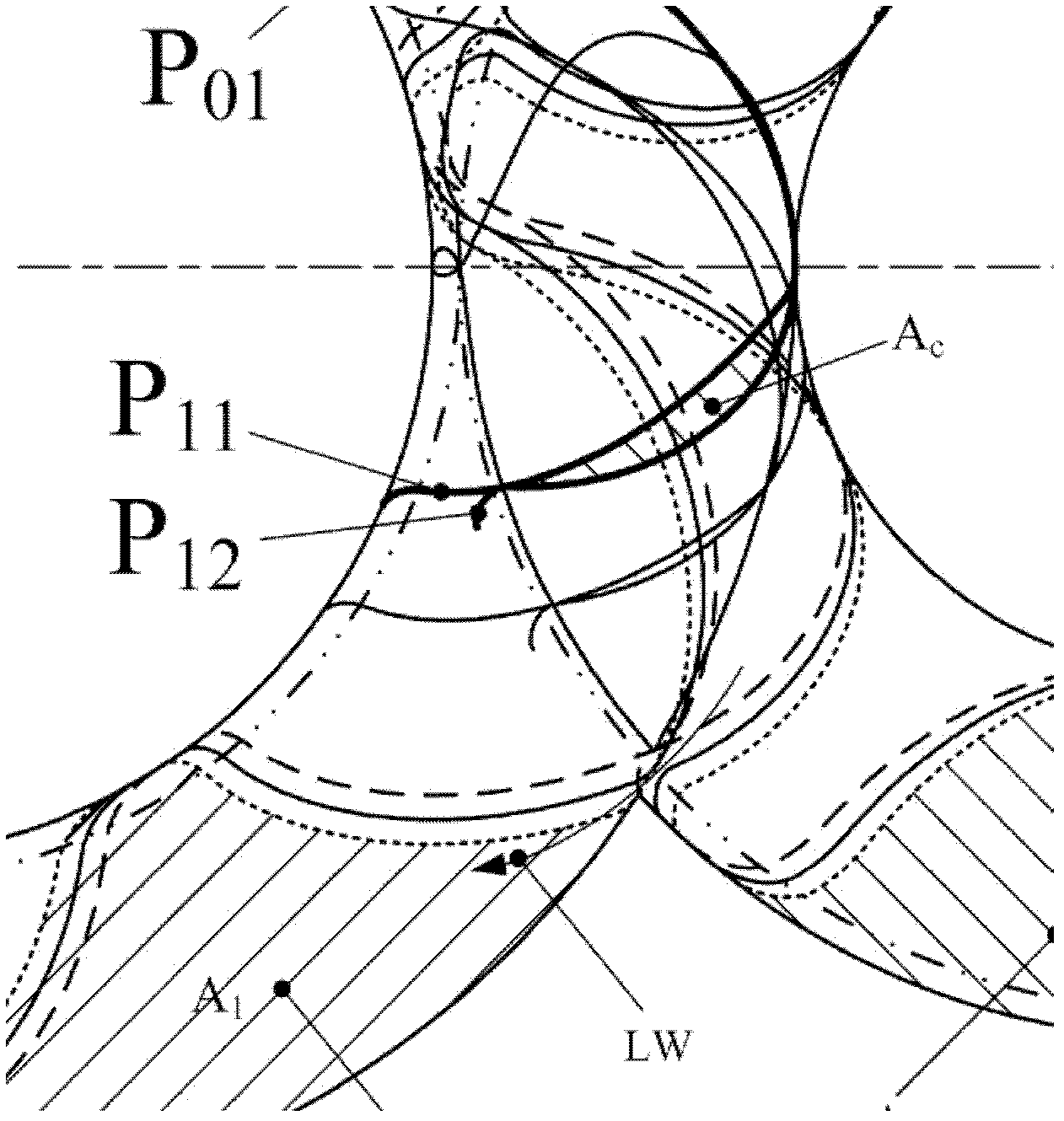

Screw rotor end face profile pair and construction method thereof

ActiveCN102352840AImprove machinabilitySmooth meshingRotary piston pumpsRotary piston liquid enginesEllipseMechanical engineering

The invention provides a screw rotor end face profile pair and a construction method thereof. The screw rotor end face profile pair comprises a pair of conjugated male rotor profile and female rotor profile, wherein each tooth profile in the male rotor profile and the female rotor profile is formed by six curves in a smooth connection mode; segmented curves of the male and female rotors are first-order continuous, rotor profiles formed by the segmented curves and envelope curves of the segmented curves are not interfered each other; and each curve comprises four segments of elliptical arcs, two segments of arcs and envelope curves of the arcs. According to the invention, tooth crests of driven edges of the male and female rotors are in an elliptical arc transition, and the tooth root and the tooth crest of a driving edge of the male rotor are in an elliptical arc transition, so that the construction of the profile is flexible, the machinable performance of the rotor can be improved, more importantly, the torque generated by the gas pressure on the driven edge of the female rotor can be adjusted, thus the smooth mesh of the rotors can be ensured; no pin tooth arcs are used, thus the meshing stability can be improved; the adjustable construction parameters are more, thus different performance requirements can be satisfied; the combination of the rotor tooth profile pair is diversified, thus the tooth profile pair can be applied to different occasions.

Owner:SHAANXI FENGZE ELECTROMECHANICAL TECH

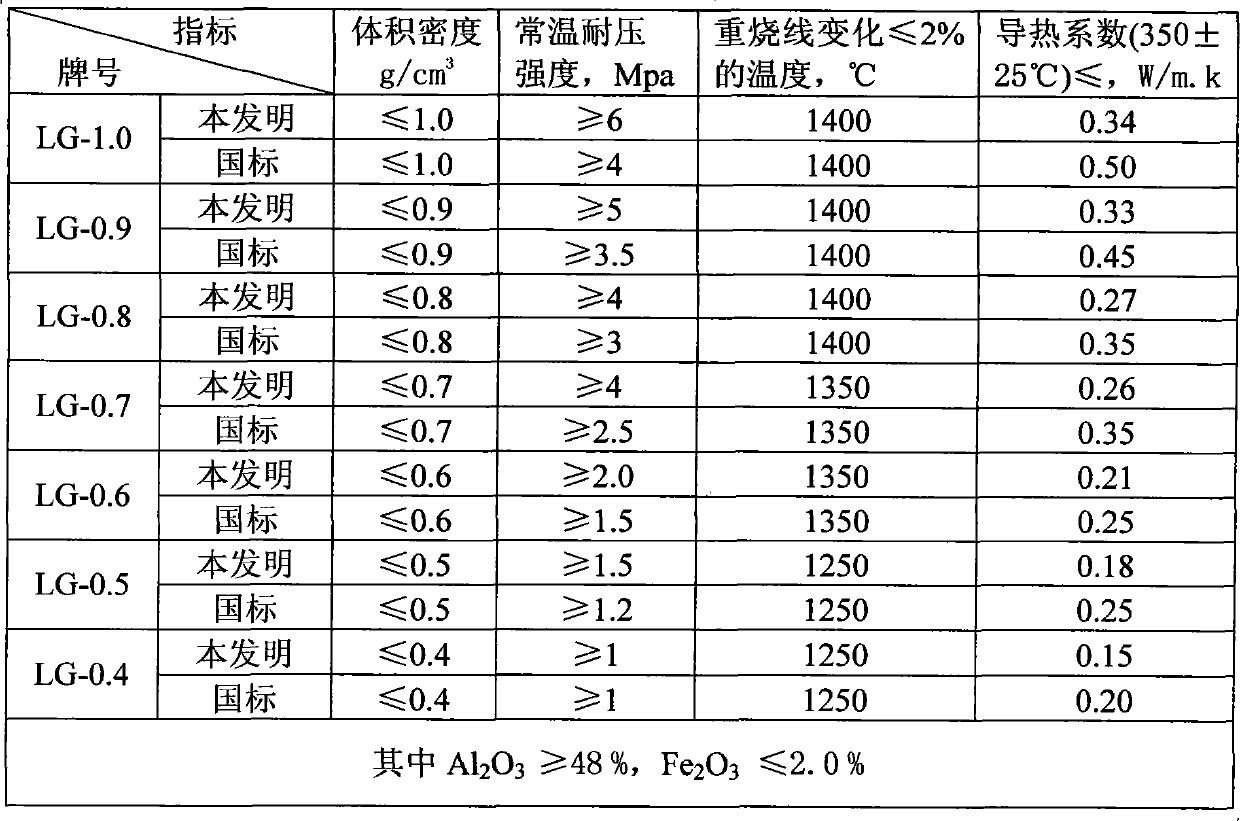

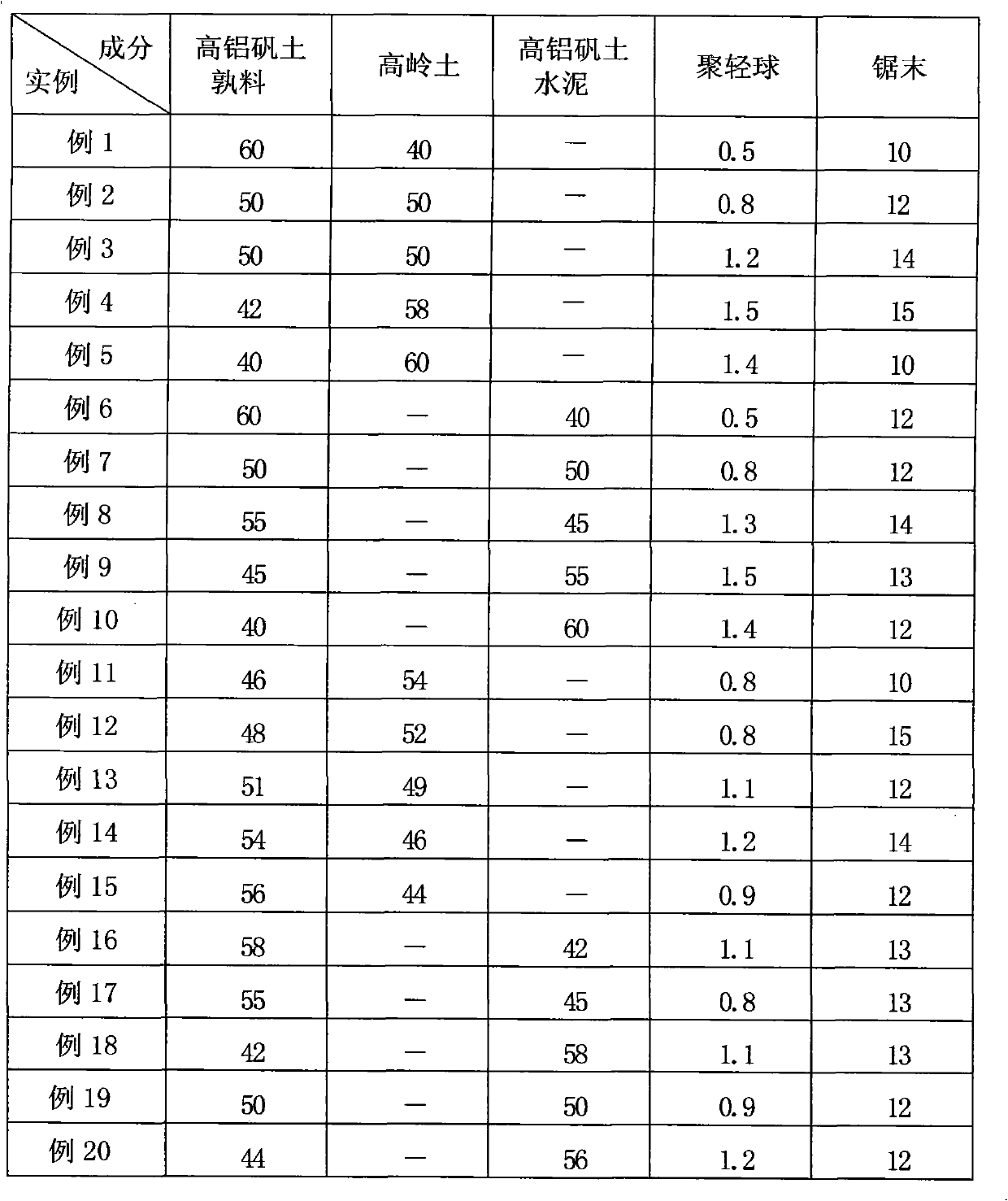

Light high-alumina insulating firebrick and preparation method thereof

The invention discloses a light high-alumina insulating firebrick and a preparation method thereof used for insulating layers of thermal equipment. The firebrick comprises the raw materials in percent by weight: 40% to 60% of high-alumina bauxite clinker and 40% to 60% of binder, polymeric light ball and sawdust respectively account 0.5% to 1.5% and10% to 15% of the total weight of the high-alumina bauxite clinker and the binder and are also added. The preparation method comprises the steps of: mixing the high-alumina bauxite clinker with the binder; then adding the polymeric light ball and the sawdust; adding water with the proportion of the dry mixed powder and the water of 1.0 to 1.75: 1; stirring into slurry-shaped materials; casting into brick blanks; drying; filling into a kiln; heating to 1270 DEG C to 1350 DEG C; and keeping the temperature for preparing the firebrick by burning. The firebrick has the advantages of simple formulation, easy acquirement of the raw materials, good compatibility, high compressive strength, low thermal conductivity, low change rate of high-temperature heavy firing line and the like, and achieves the national standards of relative products. The firebrick has simple preparation method and lower cost, can be used for the insulating layers and fireproof layers of all kinds of thermal equipment, and is beneficial to popularization and application.

Owner:郑州东方炉衬材料有限公司

Method for manufacturing high-strength direct-spreading knife-scraping tarpaulin

ActiveCN101117772AWaterproofOil-resistantLiquid surface applicatorsFibre treatmentPlasticizerHigh intensity

The present invention discloses a manufacturing method of tarpaulin with high strength and direct coating knife scraping, and the method is performed as per the following steps: (1)a composition with a certain weight including PVC paste resin, plasticizer, stabilizer, filling, fire resistant agent and painting is mixed to form coating agent; (2)the mixed coating agent is grinded and filtrated; (3)1-5kg cross-linking agent is added into each 100kg coating agent, and are evenly coated on a base cloth, and drying is executed; (4)after plasticizing and forming, surface treatment agent is used for treating. The tarpaulin manufactured with the method in the present invention has the advantages of waterproof, oil resistance, dirt resistance, fireproof, aging resistance, stripping resistance, etc., which can be used for carriage tarpaulin, carriage side curtain cloth and cloth for a container with the top opened; train tarpaulin and ship tarpaulin; building material, applied for building material for soft roof, such as a supermarket, a stadium and a sightseeing building; for military use, for temporary rest of the field army, headquarters during wartime, etc.

Owner:浙江锦达新材料股份有限公司

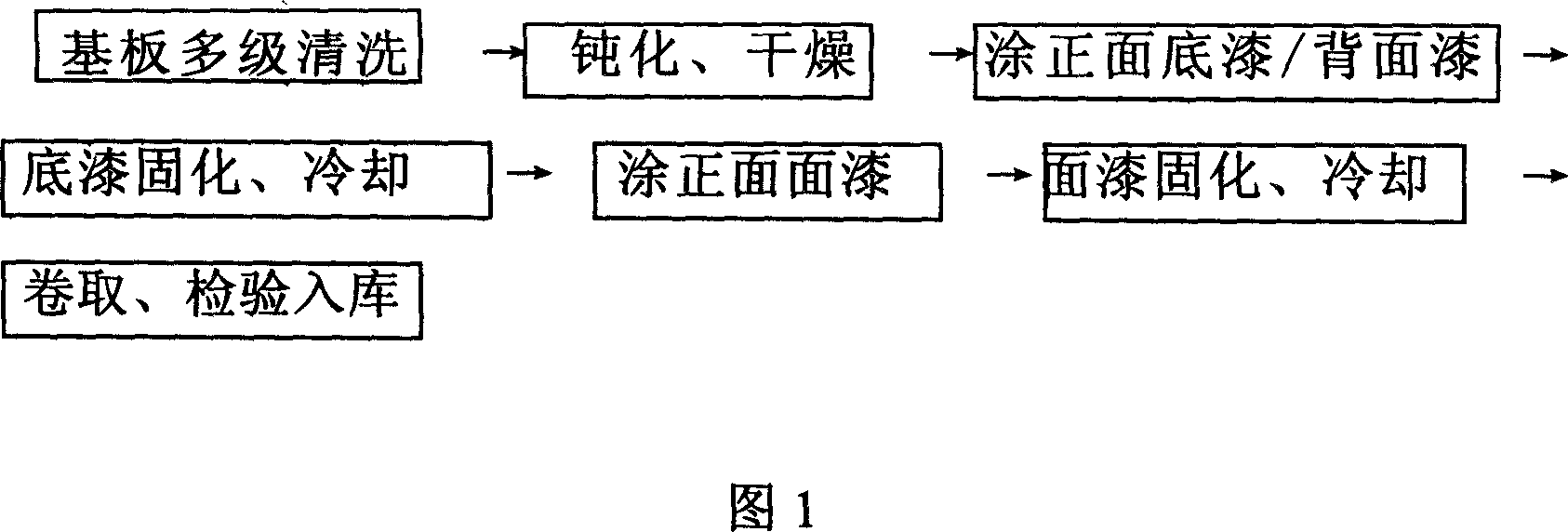

Multi purpose color coating boards, and preparation method

ActiveCN1958284AMeet different performance requirementsEasy to useSynthetic resin layered productsSpecial ornamental structuresEpoxyPollution

A multi-purpose coated color plate used to prepare corrugated plate or sandwich plate is composed of a coated layer on front surface, a basic plate, and a coated layer on back, which uses high-purity (90-99%) epoxy resin as its filming resin. Its preparing process is also disclosed, which features that the Ti-Ni pigments are used to replace Cr-Sr yellow pigment for improving its corrosion resistance and decreasing environmental pollution.

Owner:MAANSHAN IRON & STEEL CO LTD

High-strength and high-aluminum light heat-insulation and fire-resistant brick and production method thereof

The invention relates to a high-strength and high-aluminum light heat-insulation and fire-resistant brick, which is used in a heat-insulation layer in thermal equipment, and a production method thereof. The fire-resistant brick includes following basic raw materials: 30-35% of a high-aluminum alumina clinker, 10-20% of an expansion agent and 45-55% of a bonding agent and additionally includes 0.1-0.15% of engineering fibers and 0.15-0.2% of a water reducer on the basis of the total amount of the basic raw materials above. In addition, each ton of the basic raw materials is added with 0.7-2.0 m<3> of expandable polystyrene spheres. The bonding agent is kaolin or high-aluminum alumina cement and is 200-320 meshes in granularity. The production method includes the steps of stirring the raw materials to form a sludge material, preparing the sludge material into green bricks, drying the green bricks, and sintering the green bricks at 1350-1400 DEG C with heat insulation. The fire-resistant brick is high in pressure resistance strength, is low in heat conductivity and is low in change rate of a high temperature reburning curve. The normal-temperature pressure resistance strength of the fire-resistant brick is higher than that of a common fire-resistant brick by more than two times. The fire-resistant brick can be used in a heat insulation layer and a fireproof layer in all thermal equipment, achieves both energy-saving and fireproofing effects and is beneficial to popularization.

Owner:郑州东方炉衬材料有限公司

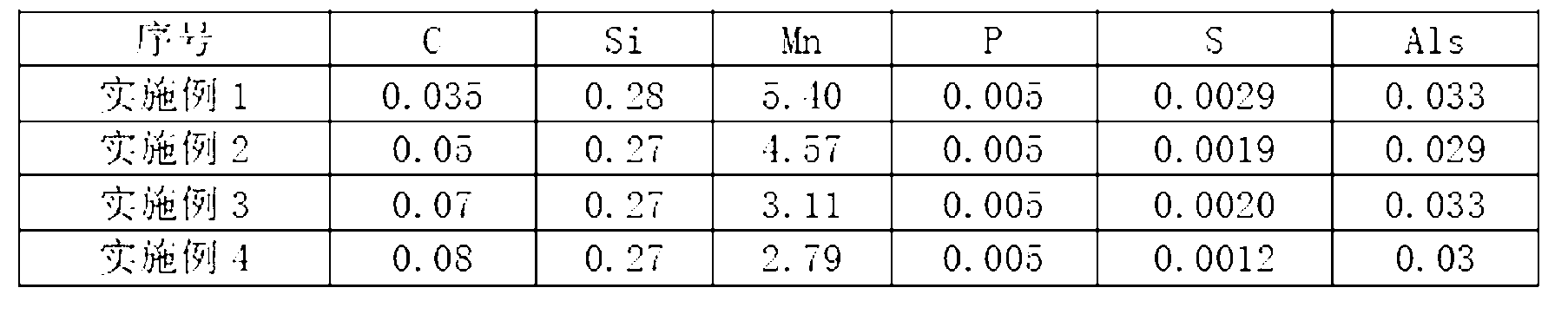

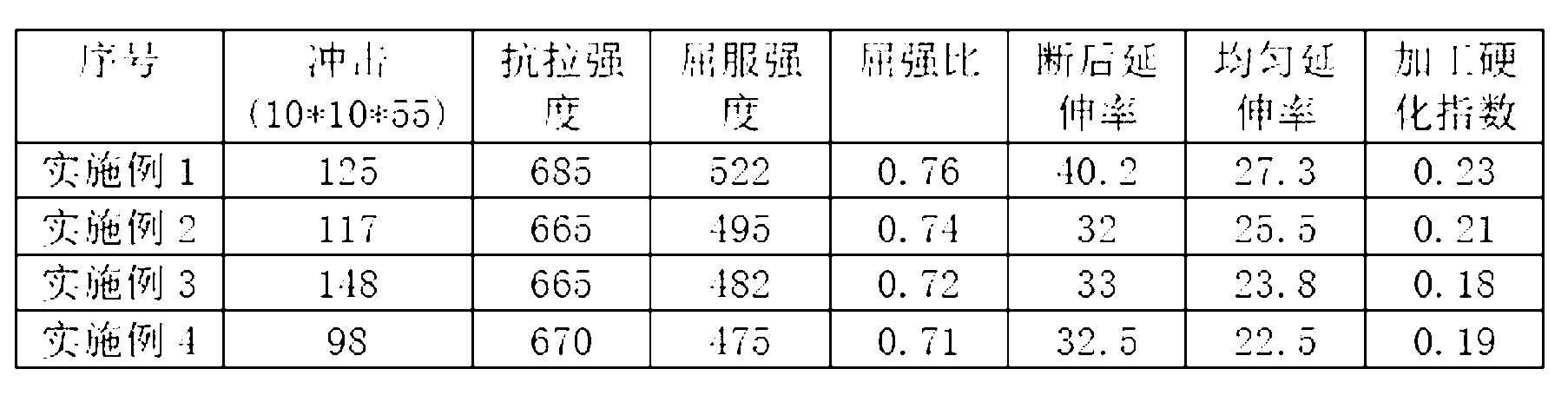

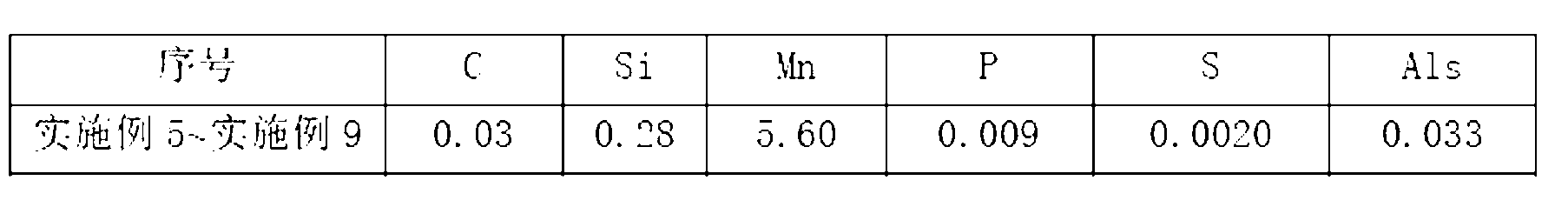

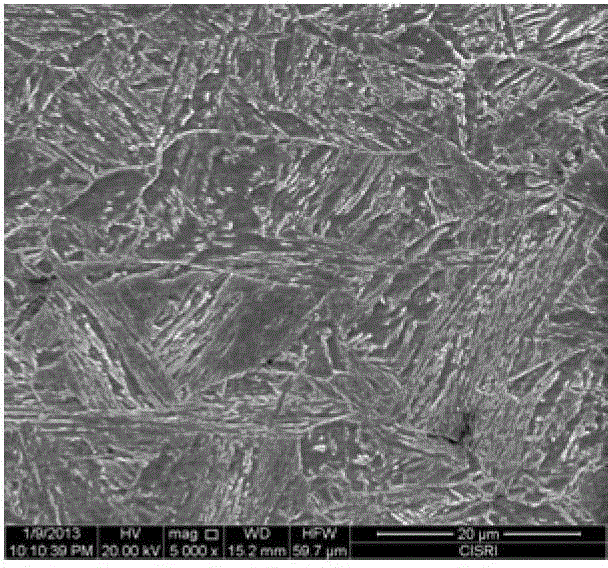

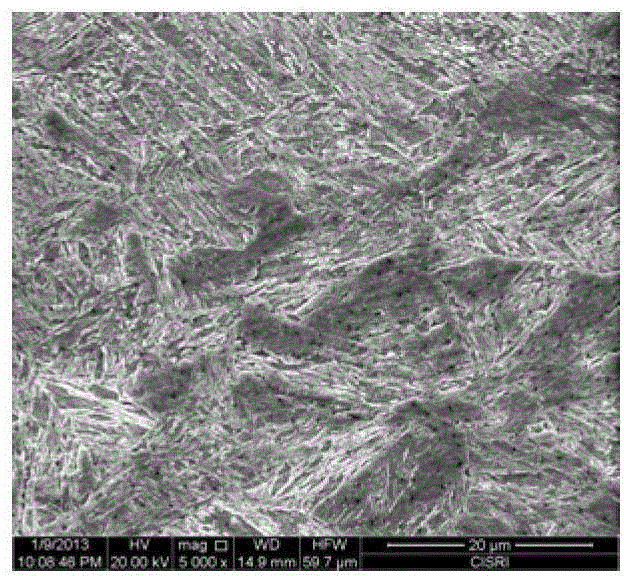

Large-swelling-amount welded tube and manufacturing method thereof

ActiveCN103160730ARaise the ratioMeet different performance requirementsFurnace typesHeat treatment furnacesChemical compositionPerformance index

The invention relates to a large-swelling-amount welded tube and a manufacturing method thereof, belonging to the technical field of welded tube steel. The welded tube contains the following chemical components in percentage by mass: 0.02-0.10wt% of C, 2.0-6.0wt% of Mn, 0.2-1.0wt% of Si, less than 0.01wt% of S, less than 0.02wt% of P and the balance of Fe and inevitable impurities, and can also contain the following one or more chemical components: 0.1-0.6wt% of Ni, 0.1-0.6wt% of Cr, 0.1-0.5wt% of Cu, 0.01-0.1wt% of Nb, 0.01-0.1wt% of V and 0.01-0.02wt% of Ti. The manufacturing method comprises the following steps: performing converter steel making, controlled rolling and controlled cooling; then performing crimping plate processing on steel strips; forming a swollen blank tube through high frequency welding (HFW); and finally performing heat treatment to obtain residual austenite of which the volume fraction is larger than 5% in the structure. The invention ensures that the material has high strength level and simultaneously has high plasticity, the uniform elongation rate is up to 20% or above, and all the mechanical performance indices meet the requirements of API and other relevant standards.

Owner:CENT IRON & STEEL RES INST

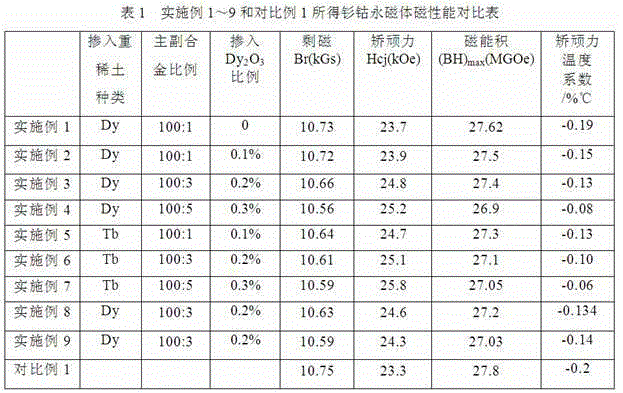

High-coercivity samarium-cobalt permanent magnet material and preparation method thereof

The invention discloses a high-coercivity samarium-cobalt permanent magnet material and a preparation method thereof. The high-coercivity samarium-cobalt permanent magnet material comprises a main alloy and an auxiliary alloy, wherein a chemical formula of the main alloy is Sm<x>Co<y>Fe<z>Cu<w>Zr<bal>; x is smaller than or equal to 27% and greater than or equal to 24%; y is smaller than or equal to 55% and greater than or equal to 45%; z is smaller than or equal to 20% and greater than or equal to 15%; w is smaller than or equal to 10% and greater than or equal to 4%; the chemical formula of the auxiliary alloy is NMFe<c>; N represents one or a mixture of light rare earth elements Sm, Pr and Nd; M is one or the mixture of heavy rare earth elements Dy and Tb; a is smaller than or equal to 25% and greater than or equal to 20%; b is smaller than or equal to 65% and greater than or equal to 60%; c is smaller than or equal to 20% and greater than or equal to 15%; and meanwhile, Dy<2>O<3> powder which is equivalent to 0.1%-0.5% of the weight of the main alloy is added. According to the high-coercivity samarium-cobalt permanent magnet material, growth of crystal particles in a sintering process can be prevented; the crystal particles of a samarium-cobalt alloy are refined; and improvement of the coercivity is facilitated; and continuously adjustable coercivity can be achieved by proportioning the main alloy and the auxiliary alloy with different ratios.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

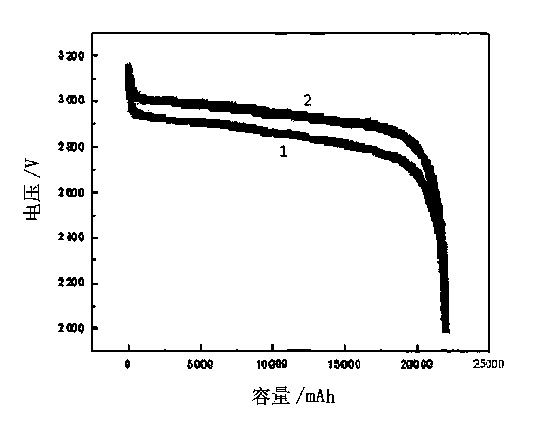

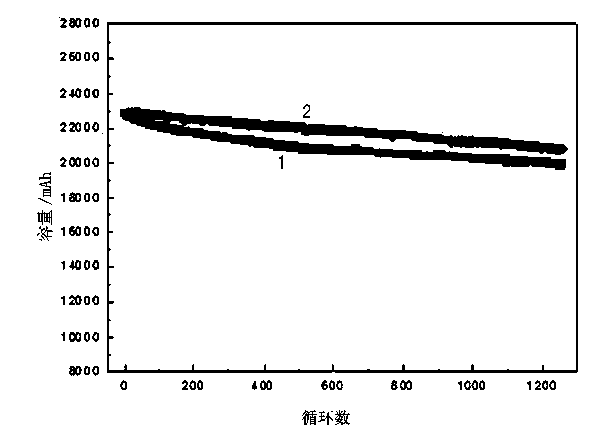

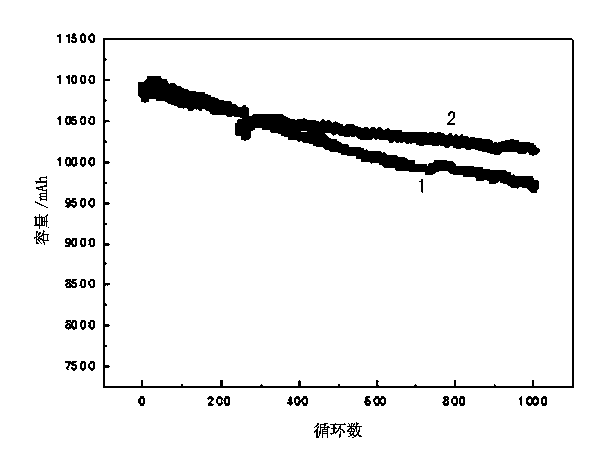

Positive electrode piece of lithium-ion power battery and preparation method thereof

InactiveCN103515616ATightly boundImprove uniformityElectrode carriers/collectorsElectrode collector coatingCarbon layerPower battery

The invention relates to a lithium ion battery and particularly relates to a positive electrode piece of a lithium-ion power battery and a preparation method of the electrode piece. The positive electrode piece comprises a current collector and a positive electrode material, wherein a carbon layer is arranged between the current collector and the positive material and is formed by adopting a magnetron sputtering method, using a graphite target as a carbon source under an inert atmosphere and carrying out sputtering on the surface of the current collector; the carbon layer is 10nm-3mum in thickness. The preparation method comprises the following steps: (1) preparing the carbon layer; (2) preparing slurry of the positive electrode material; (3) coating a positive electrode; (4) rolling the positive electrode. The positive electrode piece has the advantages that the positive electrode material and a current body are bonded closely, so that the resistance of the electrode piece is small.

Owner:万向电动汽车有限公司 +1

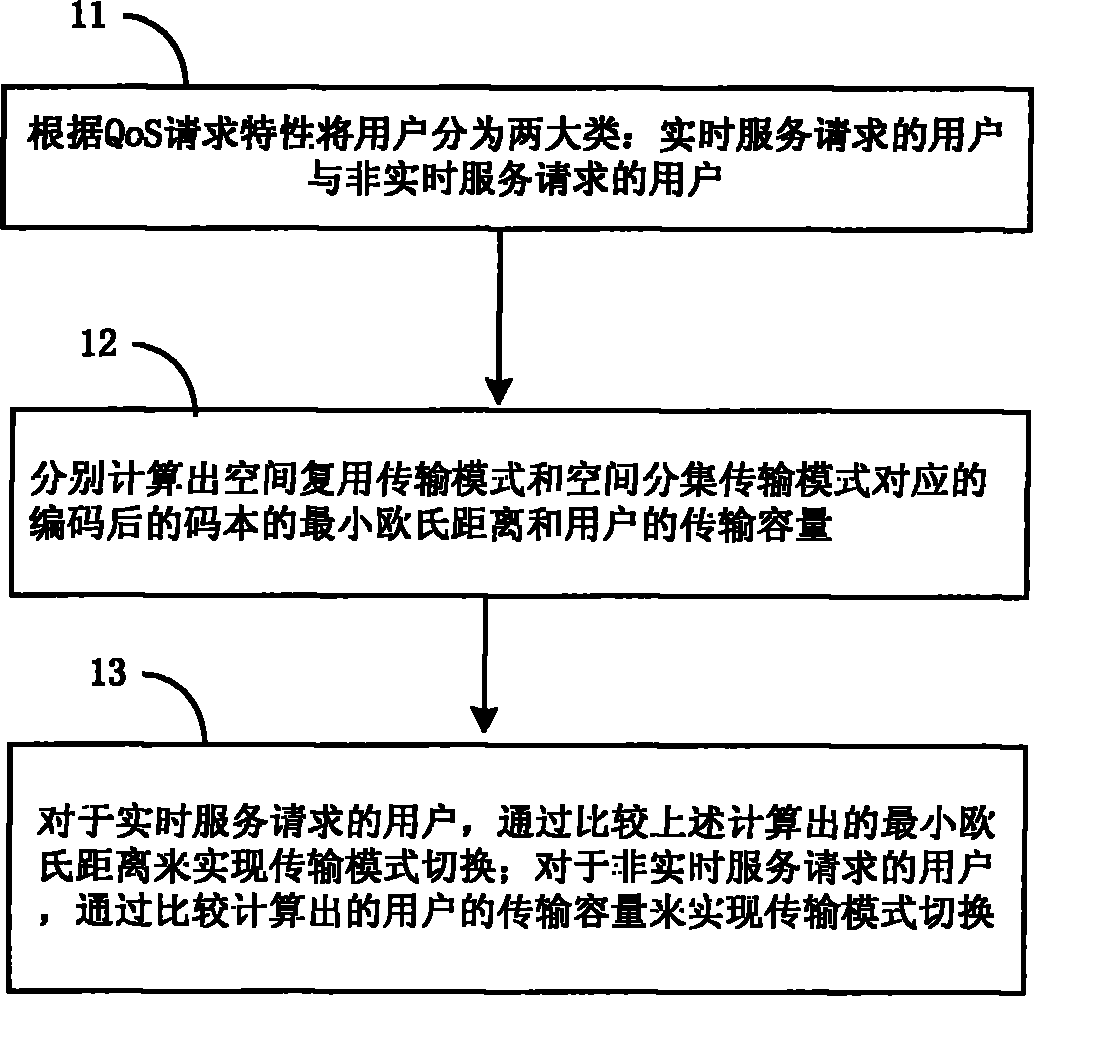

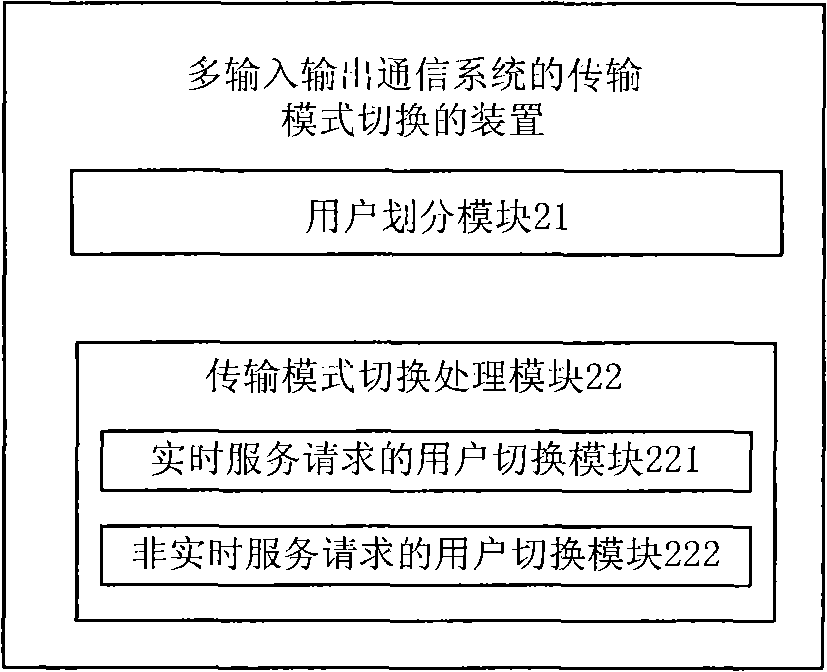

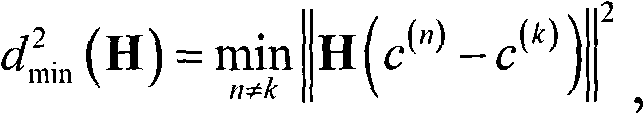

Method and device for switching transmission mode of MIMO communication system

InactiveCN102025460AMeet different performance requirementsImprove performanceError prevention/detection by diversity receptionMulti inputNon real time

The embodiment of the invention provides a method and a device for switching the transmission mode of a multi-input multi-output (MIMO) communication system. The method comprises the following steps of: dividing users into two types, namely real-time service request users and non-real-time service request users according to the quality of service (QoS) request characteristics of the users; for the real-time service request users, switching between a spatial multiplexing transmission mode and a spatial diversity transmission mode according to the minimum Euclidean distance of a coded codebook;and for the non-real-time service request users, switching between the spatial multiplexing transmission mode and the spatial diversity transmission mode according to the transmission capacity of theusers. By the method and the device, the switching criterion of switching the MIMO mode is dynamically selected for the real-time service request users or the non-real-time service request users on the basis of QoS requests of the users.

Owner:BEIJING UNIV OF POSTS & TELECOMM

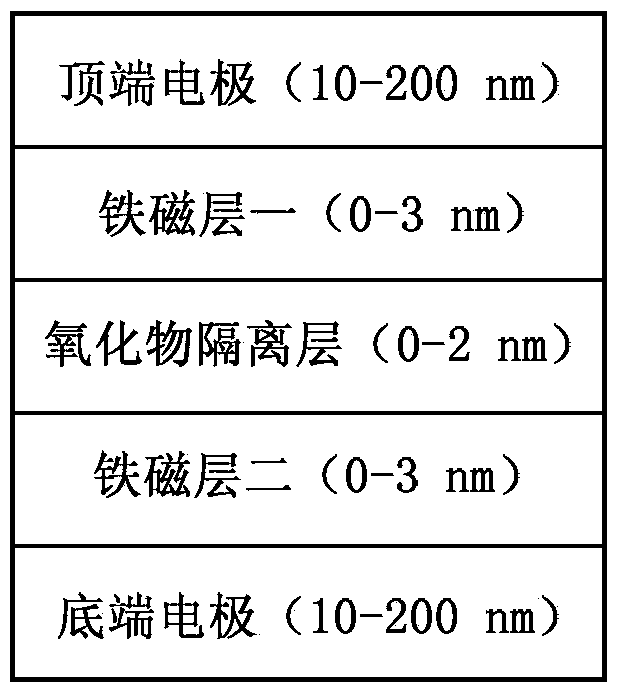

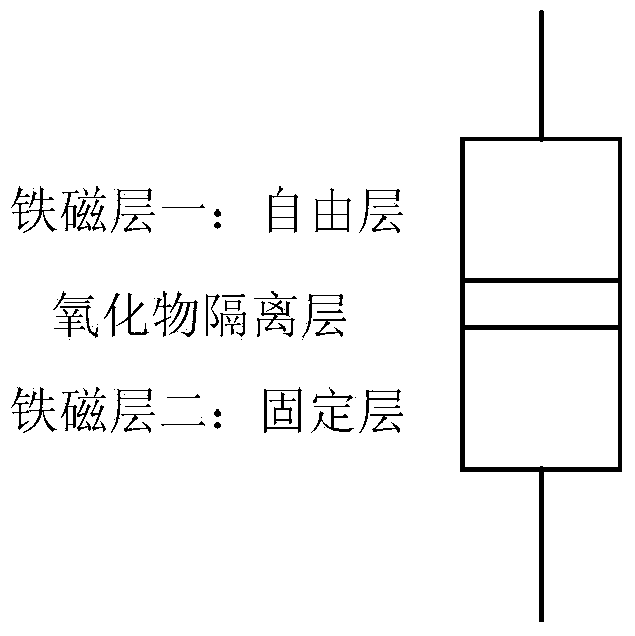

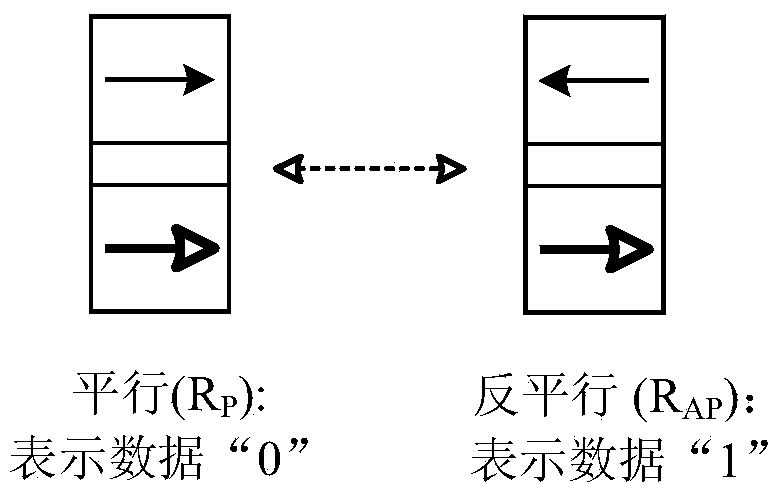

Double-function storage unit with high reliability and multi-bit storage

ActiveCN103811045AImprove reliabilityMeet different performance requirementsSolid-state devicesDigital storageBit lineData information

The invention discloses a double-function storage unit with high reliability and multi-bit storage. The storage unit consists of a complex number of MTJs (Magnetic Tunnel Junction), wherein the MTJs are connected in series and are stacked to form an MTJ cluster; the MTJ cluster is further connected in series with an NMOS (N-Metal Oxide Semiconductor) transistor; the structure is called as an mMTJ1T structure; the MTJ cluster is used for storing data information; the NMOS transistor is used for access control on the storage unit; a bit line, namely BL, is connected with the top end of the MTJ; the drain of the NMOS transistor is connected with the bottom end of the MTJ; the grid of the NMOS transistor is connected with a word line, namely, WL; the source of the NMOS transistor is connected with a source line, namely, SL. The storage unit has two different working modes, namely, a high-reliability mode HR-Mode and multi-bit storage mode MLC-Mode, and a relatively flexible design scheme is provided for a novel storage system, so that the working modes of the storage unit can be reasonably configured according to different performance requirements in practical use, and then different demands of users are met.

Owner:致真精仪(北京)科技有限公司

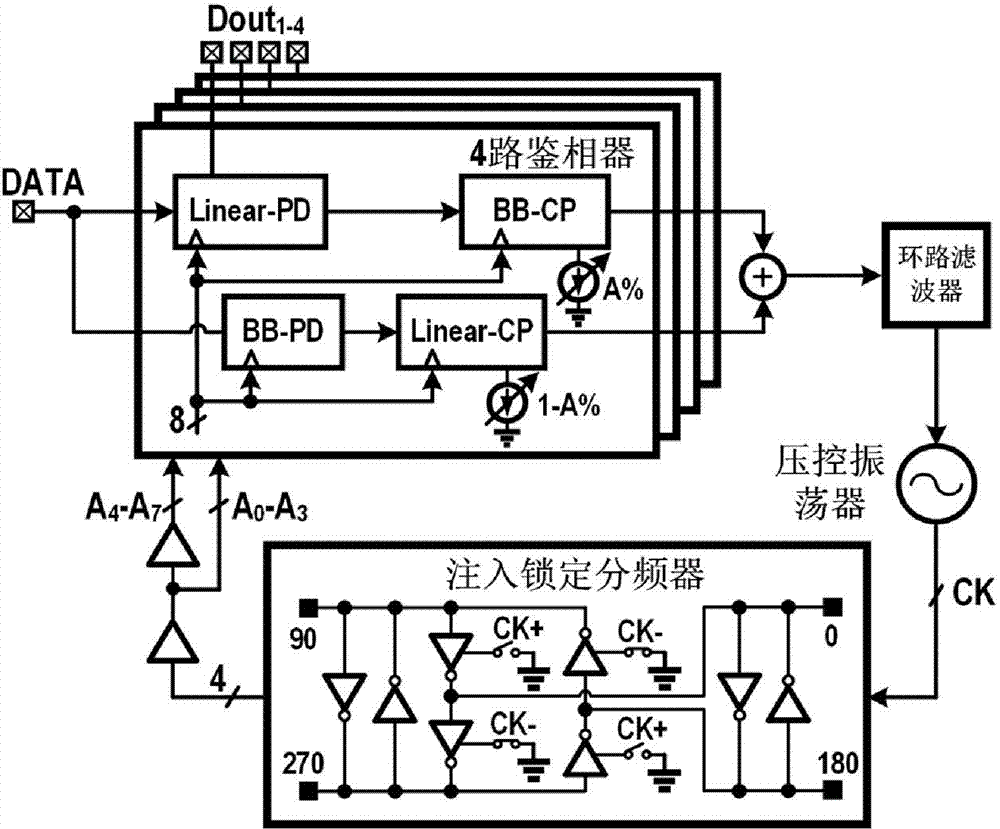

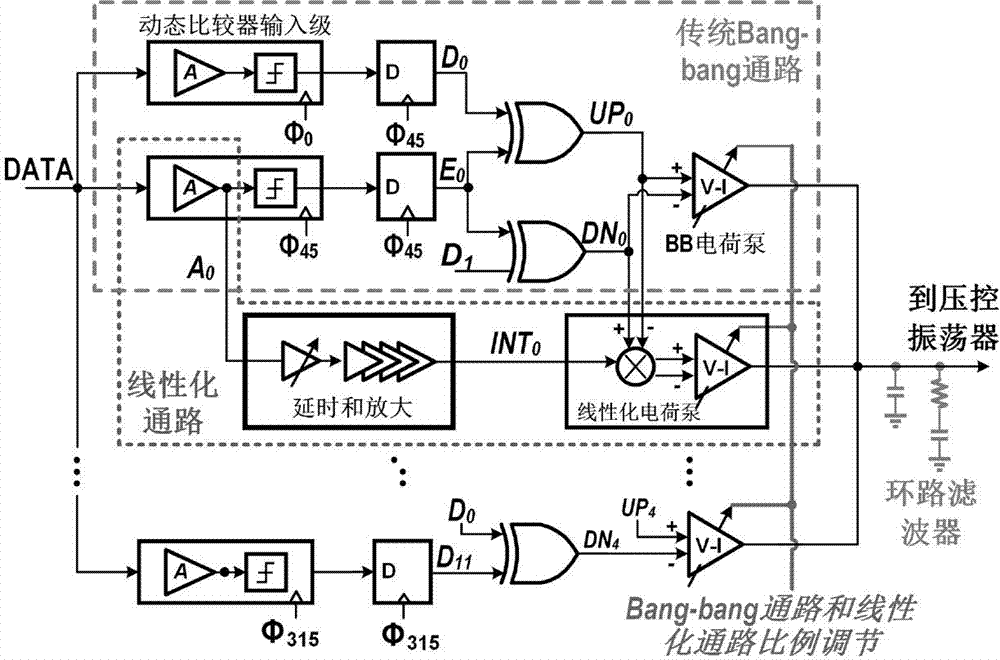

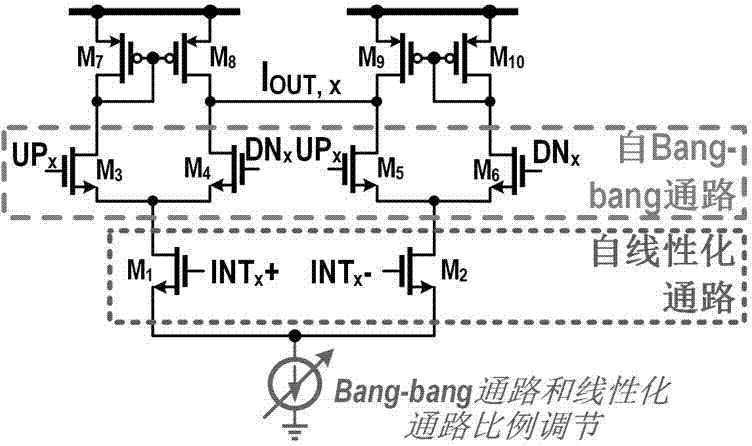

25Gbps data clock restoring circuit based on edge linearization technique

InactiveCN103684434AReduce power consumptionReduce gain requirementsPulse automatic controlSynchronising arrangementDiscriminatorInjection locked

The invention belongs to the technical field of communications, and particularly relates to a 25Gbps data clock restoring circuit based on the edge linearization technique. The circuit comprises a charge pump, a voltage-controlled oscillator, a loop filter, an injection locking frequency divider and a phase discriminator adopting edge linearization. A 12.5GHz differential clock is generated by the voltage-controlled oscillator, and an eight-phase 6.25GHz clock is generated through frequency division of the injection locking frequency divider and delay of an adjustable delay unit; the phase discriminator carries out oversampling on data through the eight-phase clock and controls the charge pump to generate a pulse current through synchronization and logical operation; after being filtered by the loop filter, the pulse current controls the control end of the voltage-controlled oscillator. By means of the 25Gbps data clock restoring circuit, four 6.25Gbps data and corresponding clocks can be generated through 25Gbps input data with low power consumption, and the requirement for good jitter performance and good locking features can be met as well.

Owner:FUDAN UNIV

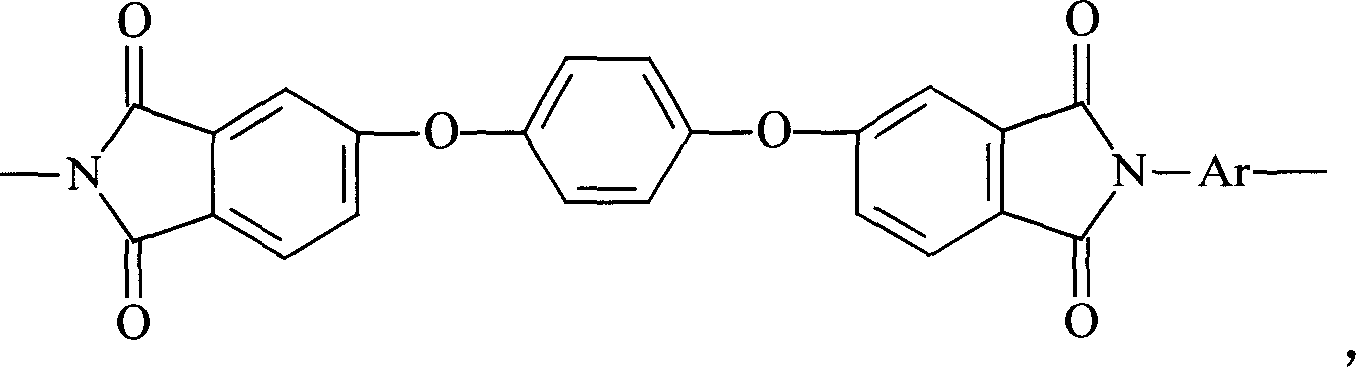

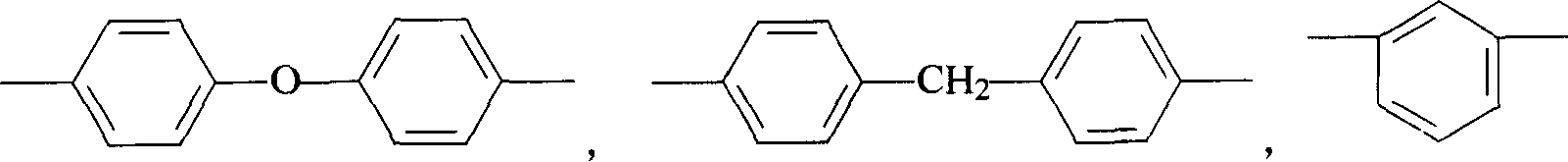

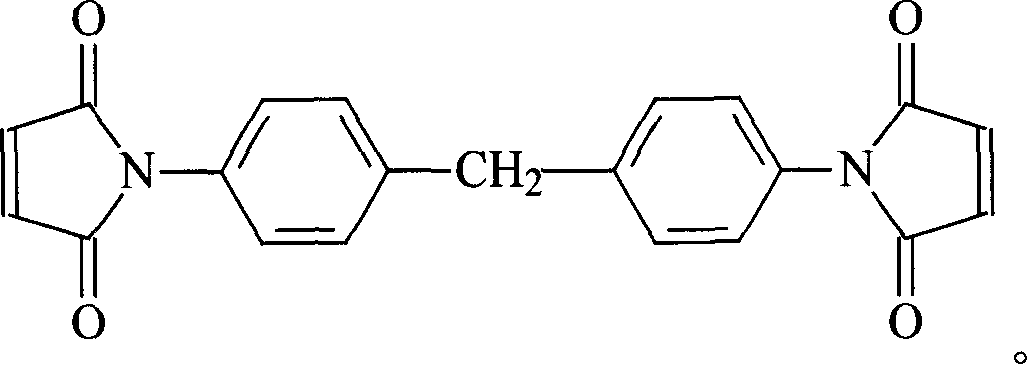

Polyimide semi-interpenetrating network resin and its prepn. method

The invention belongs to the domain of the polymers technology and is the polyimide half interpenetrating networks pitch and the producing process. With the method of the dry mixing, the wet mixing or the melt mixing, the tri-benzene bis ether polyimide with thermal plasticity is combined with the thermoset bi-smaleimide, then the half interpenetrating networks is formed by the hot pressing. The dosage of the tri-benzene bis ether polyimide is 5-90 percentage and 10-70 percentage optimally. The mixed pitch can be shared with other filler material such as the fraphite, the supramoly, the silicon dioxide, the titanium dioxide, the polyetrafluoroethylene, the carbon fiber and the fibergals in order to improve the ability of the engineering plastic and to satisfy the consumer. Using the high tenacity of the tri-benzene bis ether polyimide with thermal plasticity to reinforce the rigid cross linked structure of the bismaleimide, we can gain the half interpenetrating of the high tenacity and the intension; the material requirement of the different capability needed by a vatiety of purpose can be satisfied by the different mixing methods.

Owner:CHANGCHUN HIPOLYKING

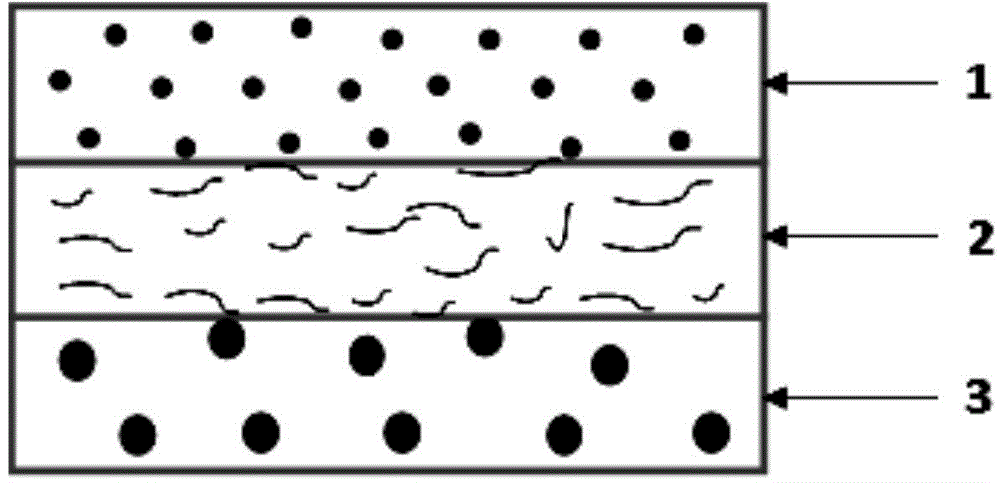

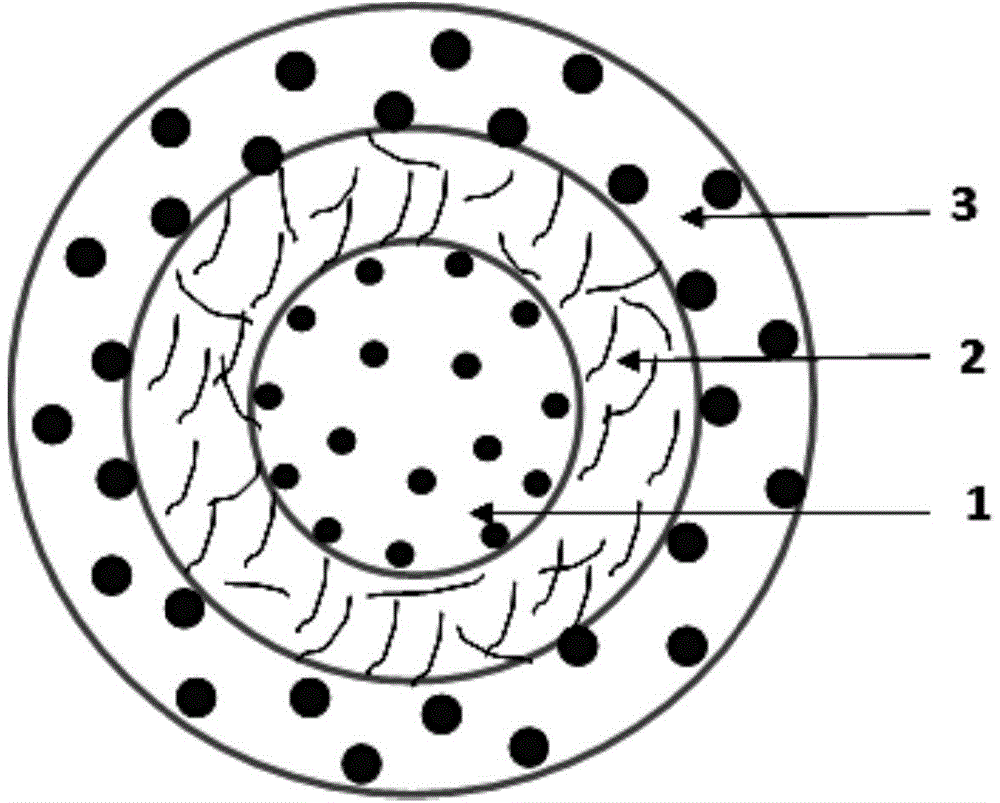

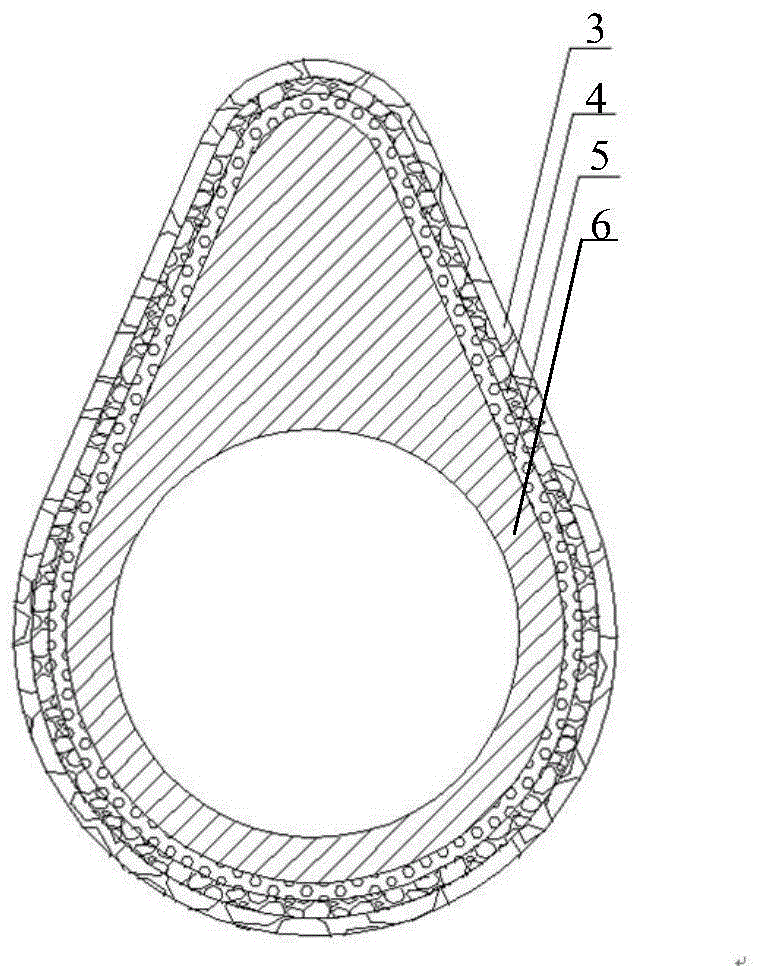

Multilayer modified casting nylon material

InactiveCN106146830AImprove performanceLow costSynthetic resin layered productsTougheningMultiple layer

The invention relates to a multilayer modified casting nylon material. The multilayer modified casting nylon material comprises at least two of an anti-abrasion layer, a toughening layer and a reinforcing layer. The anti-abrasion layer is made of anti-abrasion casting nylon. The toughing layer is made of toughening casting nylon. The reinforcing layer is made of reinforced casting nylon. The multilayer modified casting nylon material has different properties on different levels and can meet the requirements of different use positions of parts for different properties.

Owner:XCMG CONSTR MACHINERY

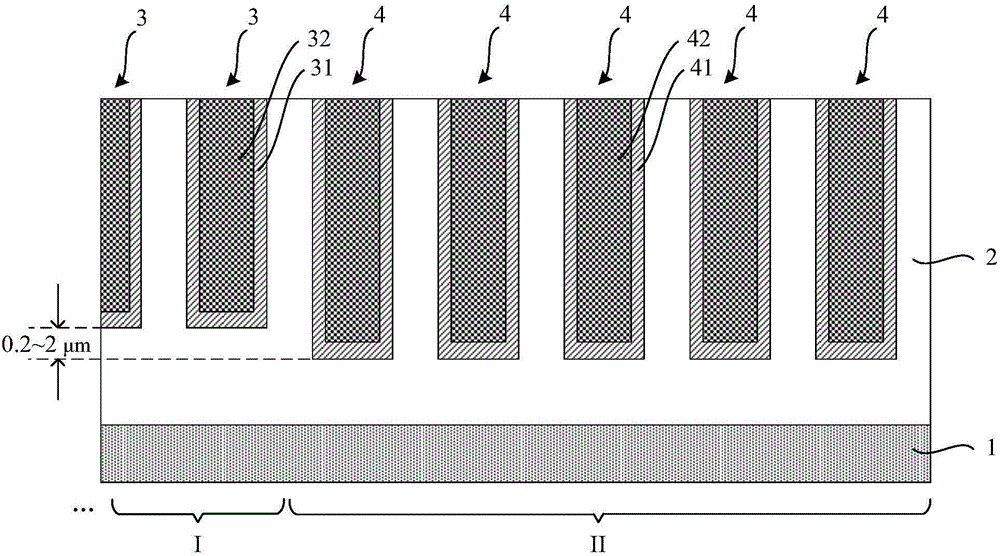

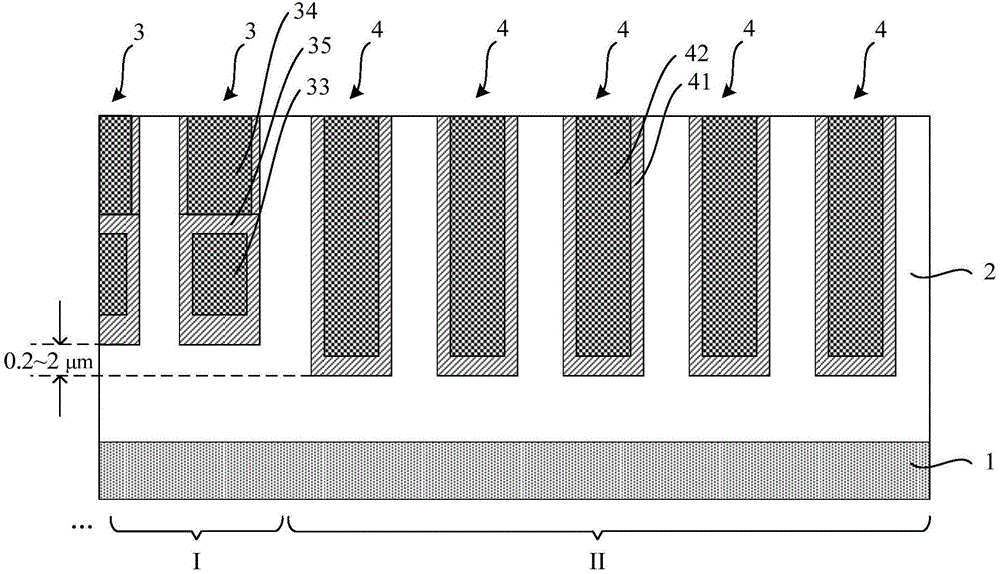

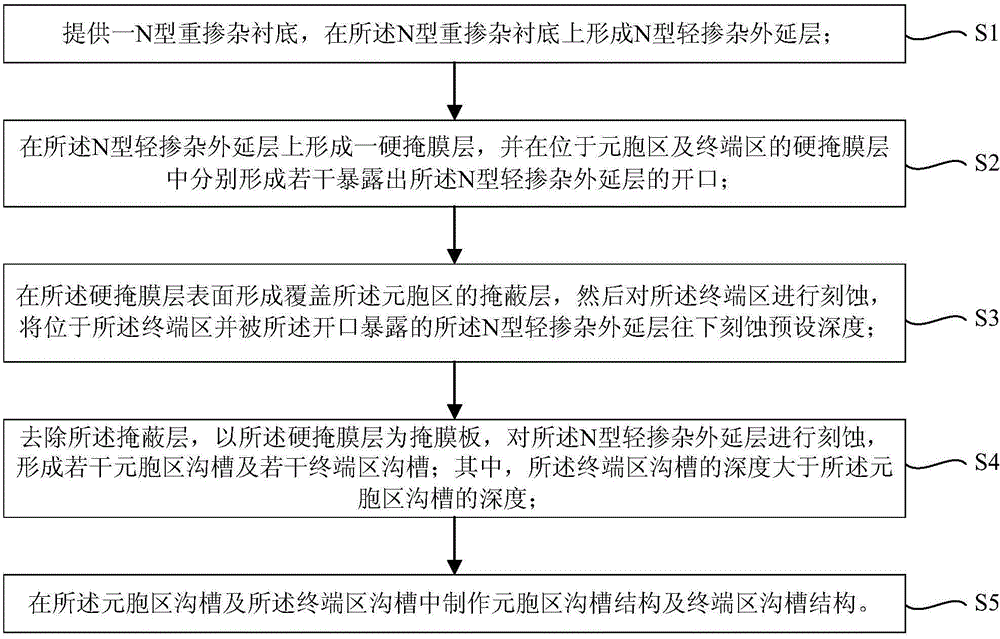

Trench MOSFET (Metal Oxide Semiconductor Field Effect Transistor) device and manufacturing method thereof

ActiveCN104638011AImprove pressure resistanceEnhanced depletionSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

The invention provides a trench MOSFET (Metal Oxide Semiconductor Field Effect Transistor) device and a manufacturing method thereof. The device comprises an N-type heavily doped substrate and an N-type lightly doped epitaxial layer which is formed on the N-type heavily doped substrate, wherein a plurality of cellular area trench structures and a plurality of terminal area trench structures are formed in the N-type lightly doped epitaxial layer; the depth of the terminal area trench structures is greater than the depth of the cellular area trench structures. Since an inversion layer is formed on the surface of a trench gate when the device is in work, the length of the inversion layer can be lengthened by the deeper terminal area trench structures, the depletion degree around the terminal area trench structures is higher; thus the voltage endurance capability of a medium pressure MOSFET terminal area is favorably improved.

Owner:WUXI TONGFANG MICROELECTRONICS

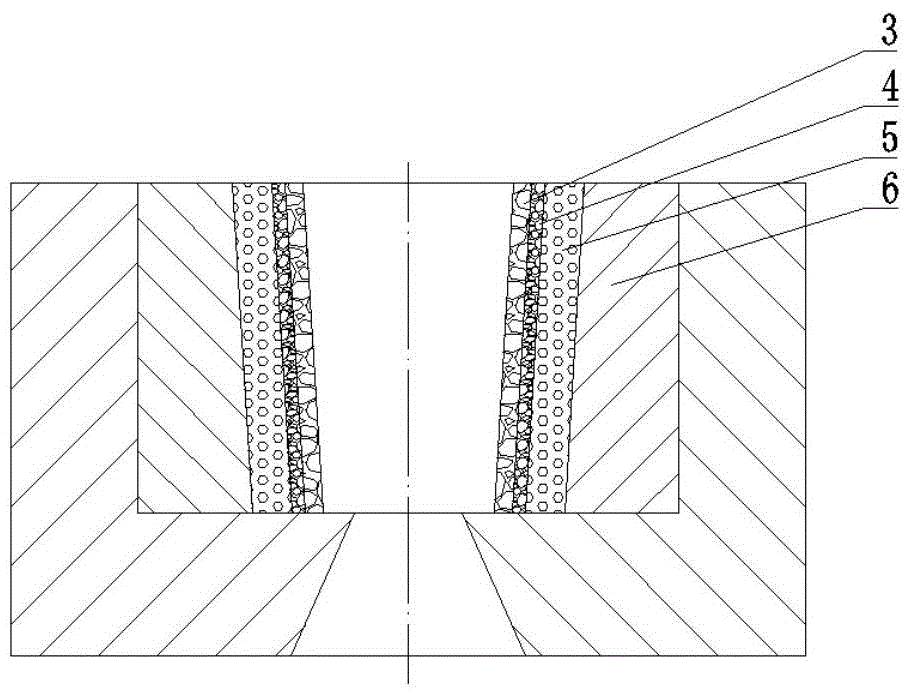

Wire drawing die and production method thereof

ActiveCN104525593AImprove mechanical propertiesOvercome the problem of easy sheddingDrawing diesCarbide coatingMicrometer

The invention discloses a wire drawing die and a production method thereof. The surface of each of work positions of the wire drawing die is provided with a carbide coating. The work positions of the upper surface and the lower surface of the wire drawing die are respectively provided with the carbide coating. A quasi monocrystalline TiC dense ceramic layer, a micrometer TiC ceramic layer and a TiC-matrix composite layer are sequentially distributed in a gradient manner from outside to inside, and are applied to the surface of carbon steel. The carbide coating can be applied to the surface of the carbon steel. The carbide coating is formed on the surface of the above matrix through the cast matrix-titanium complex, the introduction of an external carbon source, heating and heat insulation, the coating and the matrix are metallurgically bonded, and the bonding force is very strong, so the problems of non-metallurgic bonding between present hard particles and the steel substrate, very weak bonding force and easy shedding of the particles are overcome, and the wear resistance of the work surfaces of the wire drawing die is greatly improved.

Owner:XIAN UNIV OF TECH

Windshield adhesive tape and manufacturing method thereof

PendingCN108394380AMeet different performance requirementsTightly bondedVehicle cleaningRubber materialEngineering

The invention discloses a windshield adhesive tape. The windshield adhesive tape comprises an adhesive main body which is made from a first rubber material and a blade part which is made from a secondrubber material; the blade part and the adhesive tape main body are subjected to co-extrusion forming integrally. The adhesive tape main body and the blade part are made from different materials to meet the requirements of the adhesive tape main body and the blade part for the respective using performance. The invention further provides a manufacturing method of the windshield adhesive tape.

Owner:XIAMEN METO AUTO PARTS IND

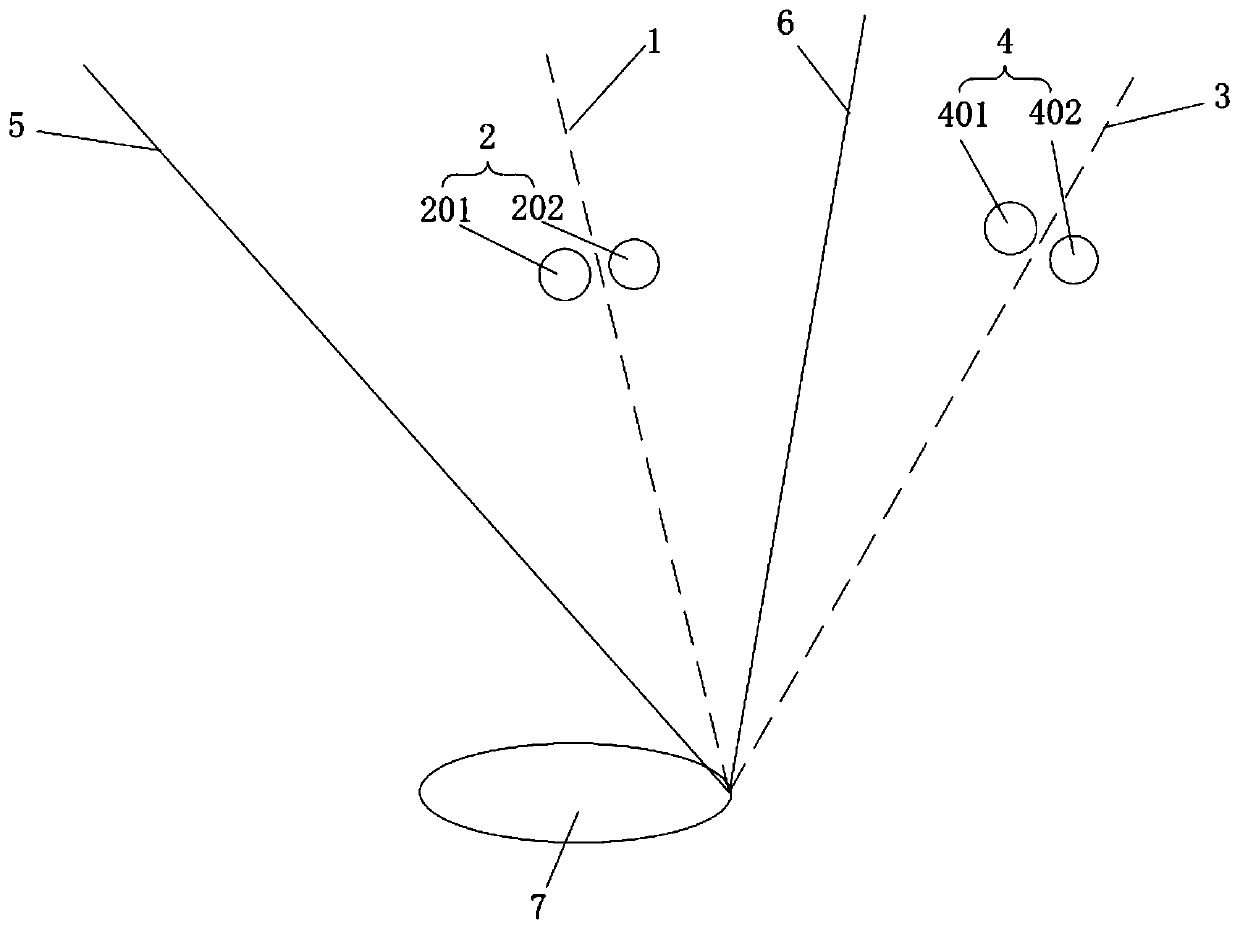

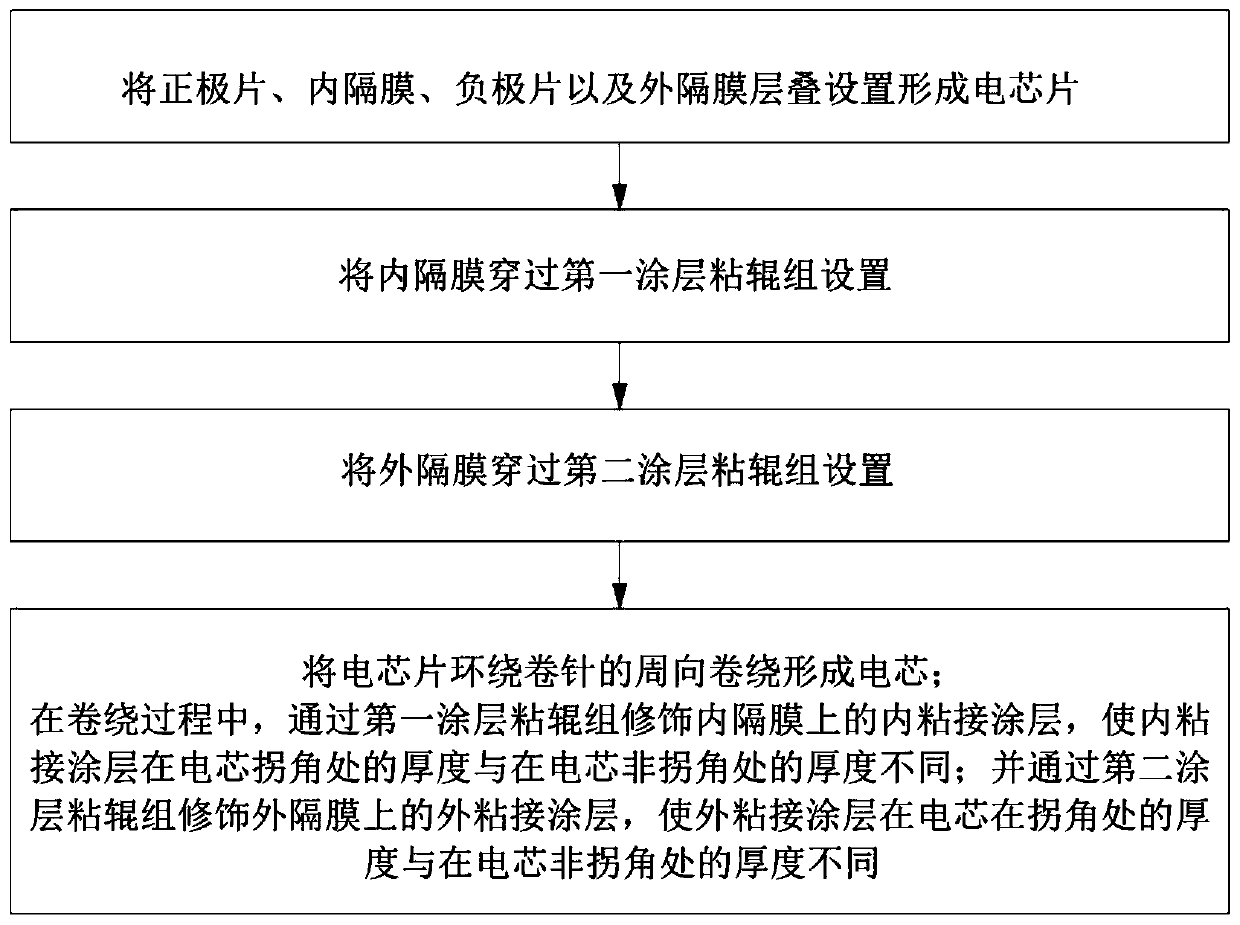

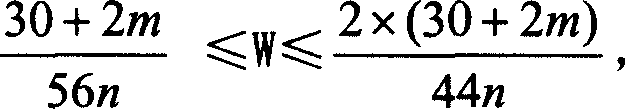

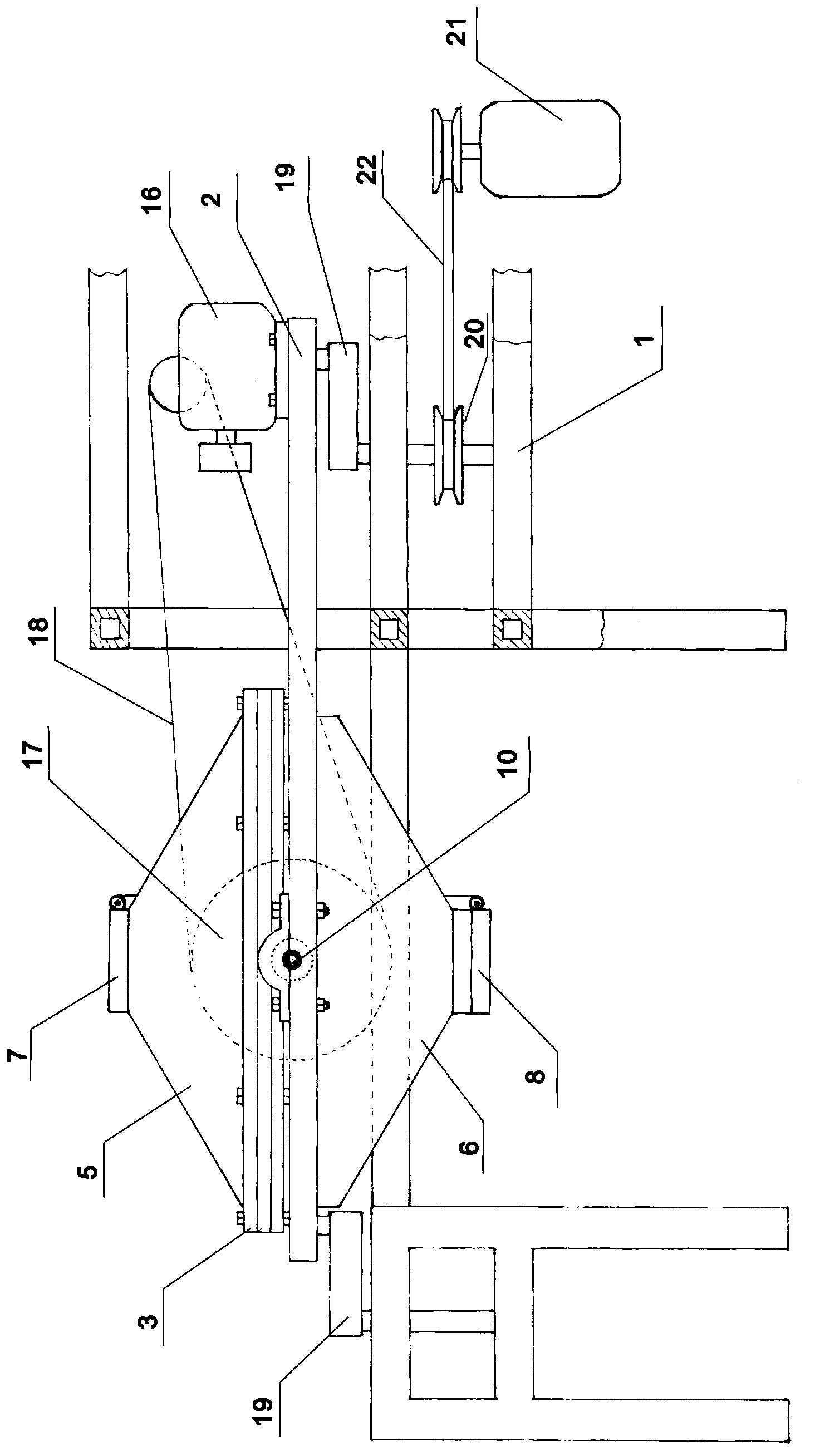

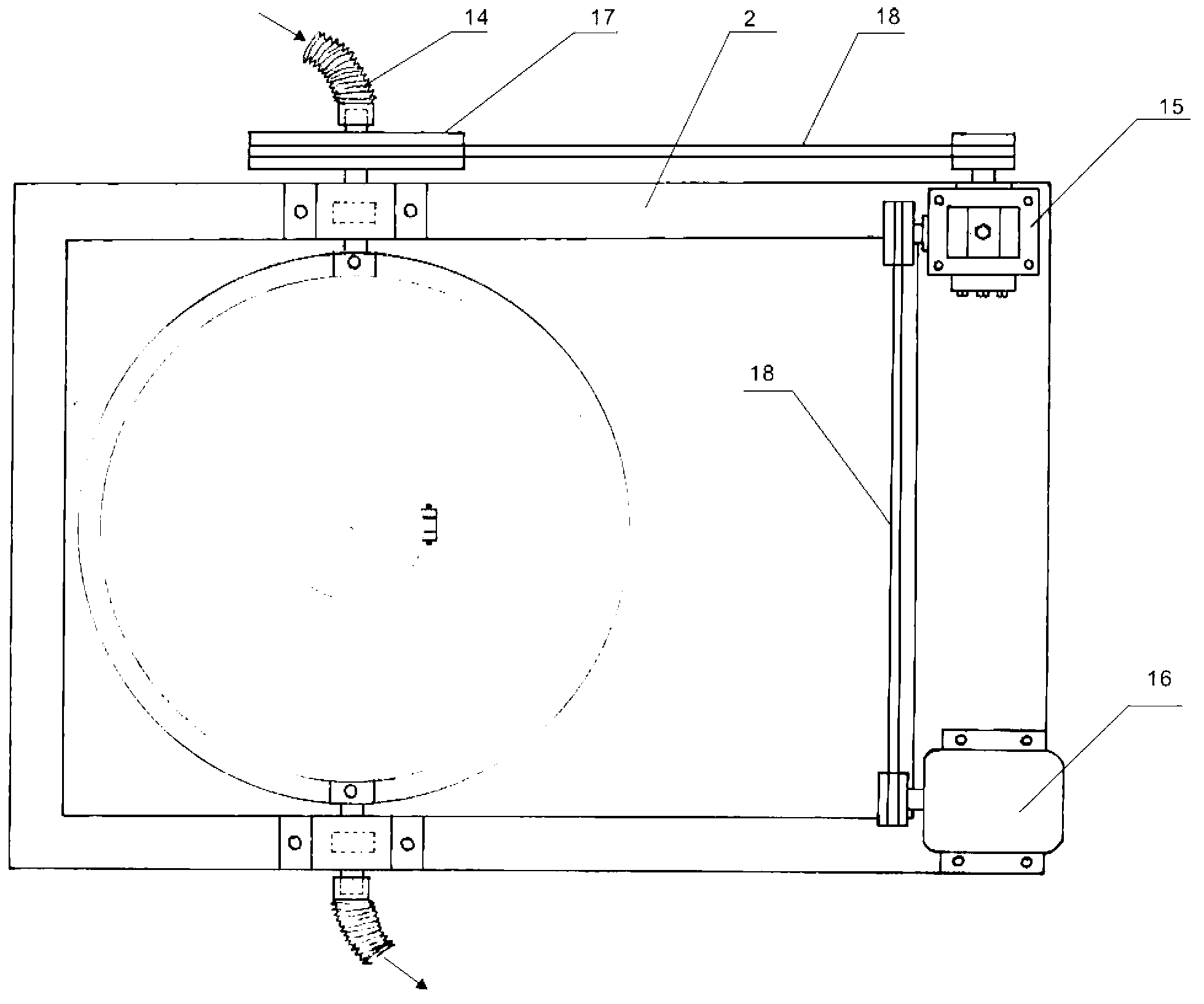

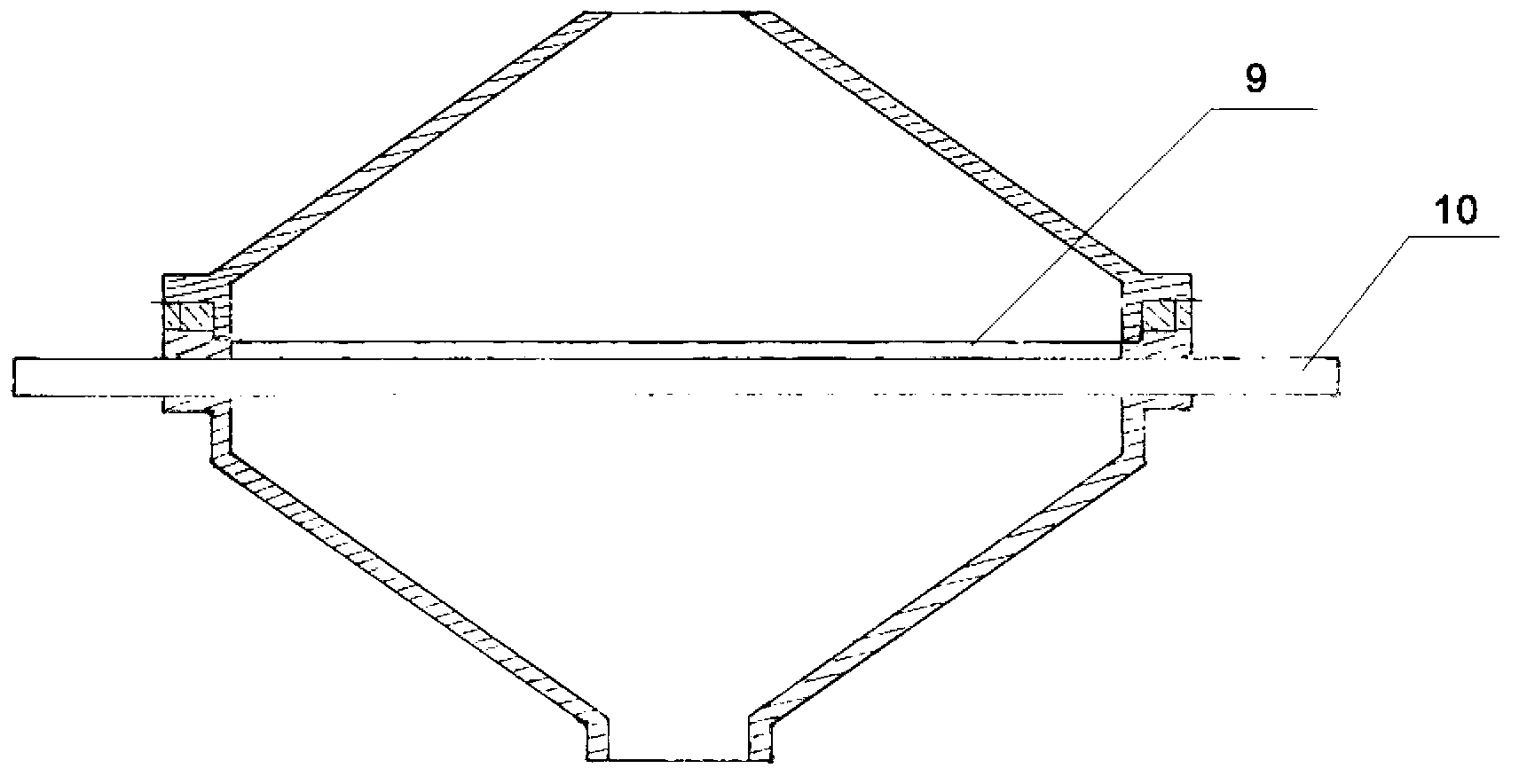

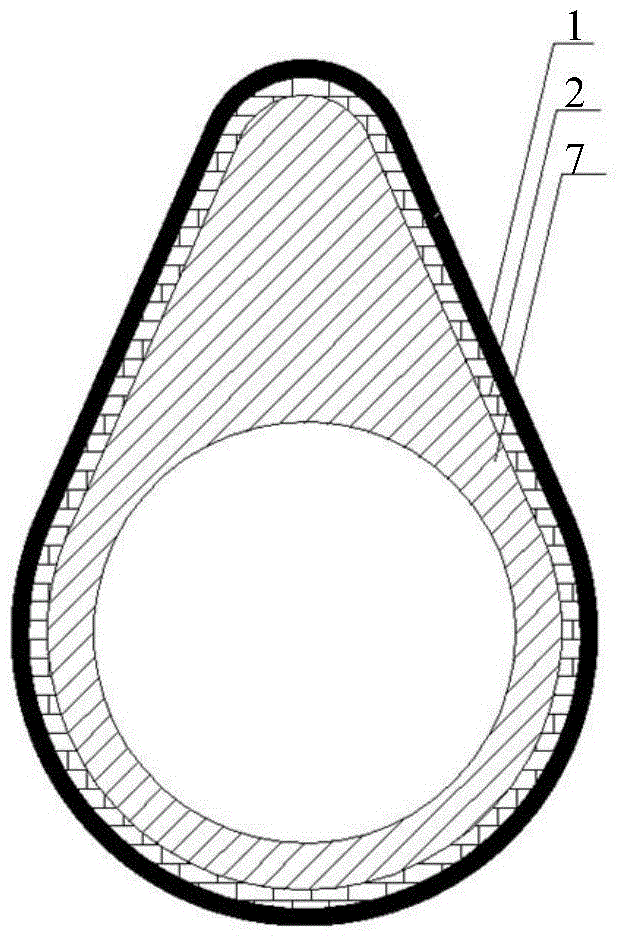

Battery cell winding device, battery cell production method and power battery

ActiveCN110165287AIncrease flexibilityMeet different performance requirementsFinal product manufactureWound/folded electrode electrodesElectricityPower battery

The invention discloses a battery cell winding device, a battery cell production method and a power battery, and belongs to the technical field of battery production and manufacturing. The battery cell winding device provided by the invention comprises a first coating adhesive roller group, a second coating adhesive roller group and a winding needle, wherein the first coating adhesive roller groupcan modify the thickness of an inner adhesive coating on an inner diaphragm, the second coating adhesive roller group can modify the thickness of an outer adhesive coating on an outer diaphragm, andthe winding needle can wind a battery cell piece to form a battery cell. Through the arrangement of the first coating adhesive roller group, the thickness of the inner adhesive coating on the inner diaphragm can be modified before the battery cell is wound, thereby forming the inner adhesive coating with the uneven thickness on the inner diaphragm; through the arrangement of the second coating bonding roller group, the thickness of the outer adhesive coating on the outer diaphragm can be modified before the battery cell is wound, thereby forming the outer adhesive coating with the uneven thickness can be formed on the outer diaphragm. The battery cell wound by the battery cell winding device can meet the demands of various power batteries with different performance requirements, and is high in flexibility and wide in application range.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Process of preparing oxyalkylene-base unsaturated ester polymer

InactiveCN101089028AMeet different performance requirementsSynthesis conditions are easy to controlMolecular sieveCopolymer

The present invention discloses process of preparing polyoxyalkylene-base unsaturated ester. The process is a one-step active anionic polymerization process including three steps of dewatering the reactant with molecular sieve, reaction and separating side product. The polyoxyalkylene-base unsaturated ester has controllable molecular weight for different requirements, and the process has easy control in the synthesis condition, easy application in industrial production and short reaction period. The polyoxyalkylene-base unsaturated ester may be copolymerized with hydrophilic and lipophilic monomer to form amphiphilic graft copolymer with polyoxyalkylene-base long branched chain, with the ratio between the hydrophilic groups and the lipophilic groups being adjustable for obtain products with different performances.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

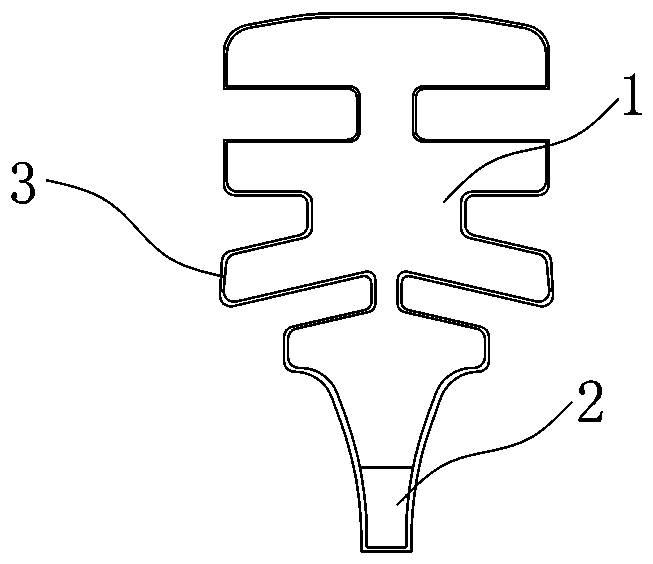

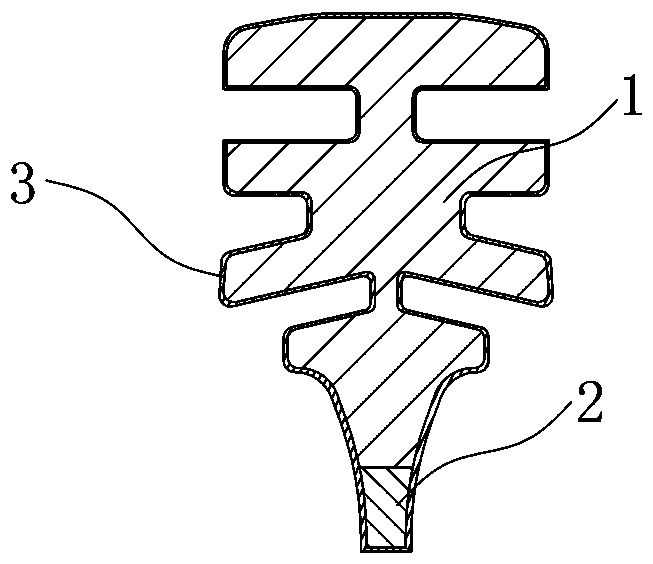

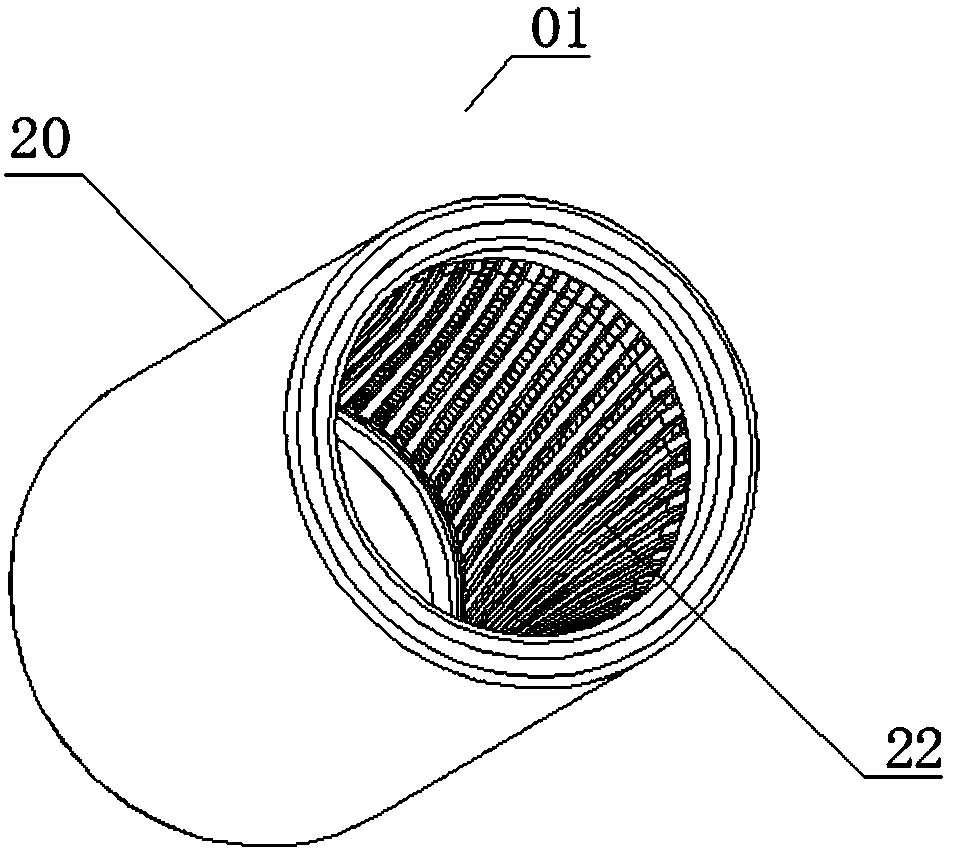

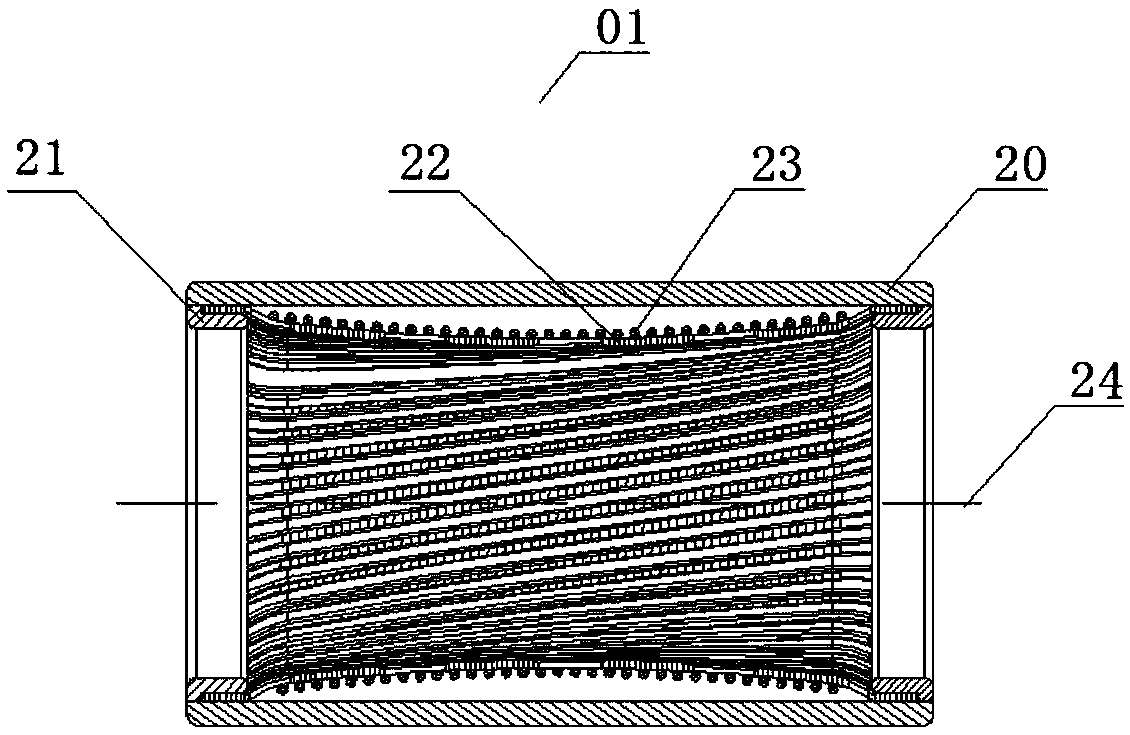

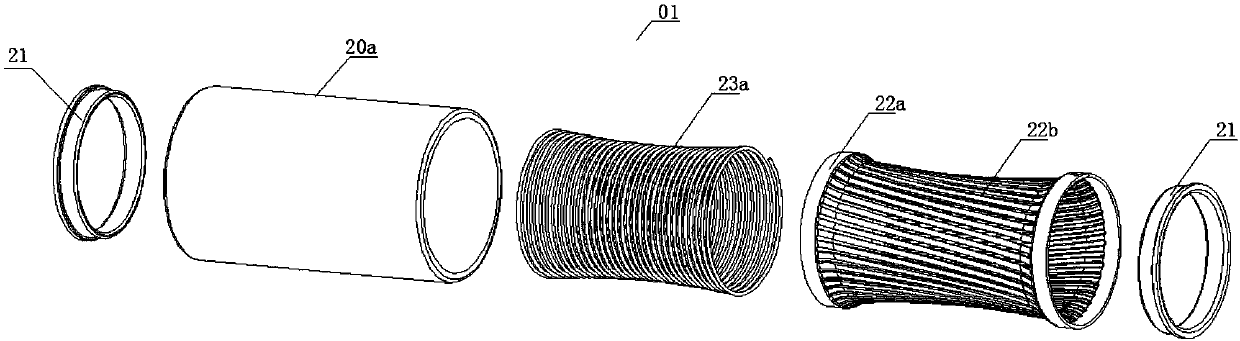

Jack connector assembly

PendingCN107845870AHigh conductivityReduce heatCoupling device detailsElectrical connectionExternal pressure

The invention provides a jack connector assembly, and the connector assembly comprises a jack sleeve which comprises a cylindrical contact sleeve; a round-cage-type cylindrical contact part which is made of a high-conductivity material, is installed in the cylindrical contact sleeve, is of a line spring or leaf spring structure, and comprises a fixed contact part in electrical connection with thecylindrical contact sleeve, and a separable contact part which is separated with or makes contact with a pin; and a pressure part which is corresponding to the separable contact part, wraps the separable contact part, is installed between the round-cage-type cylindrical contact part and the cylindrical contact sleeve, and provides an external pressure when the pin makes contact with the round-cage-type cylindrical contact part. The round-cage-type cylindrical contact part and the cylindrical contact sleeve are connected electrically to form a current channel, and the pressure part wrapping theexterior is used for providing the external pressure, thereby enabling the round-cage-type cylindrical contact part to give partial consideration or no consideration to a function of providing an elastic force, and to select the high-conductivity material. The conductivity of the line spring or leaf spring contact part is improved, and the dedicated pressure part is used for providing the required external pressure.

Owner:SHENZHEN QILIAN TECH CO LTD

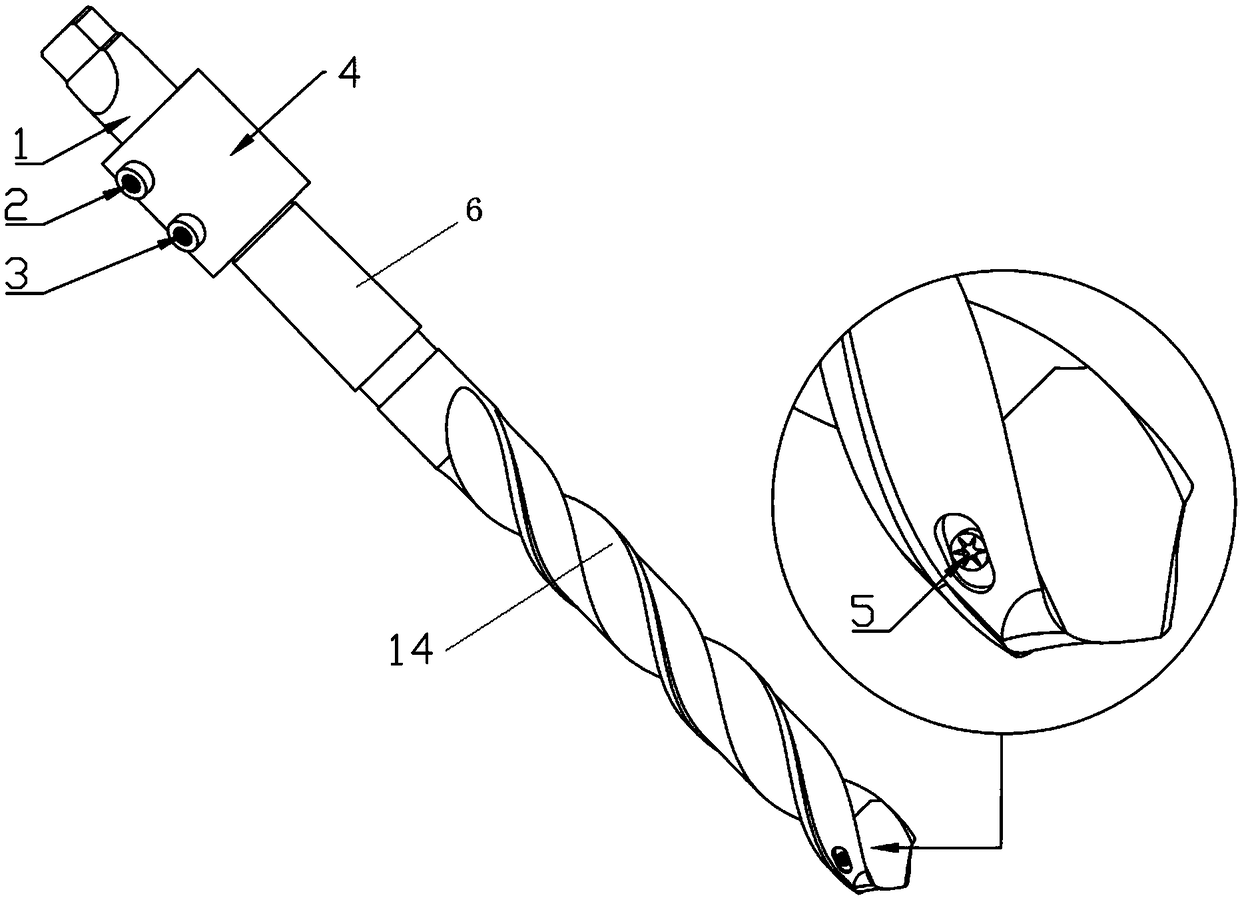

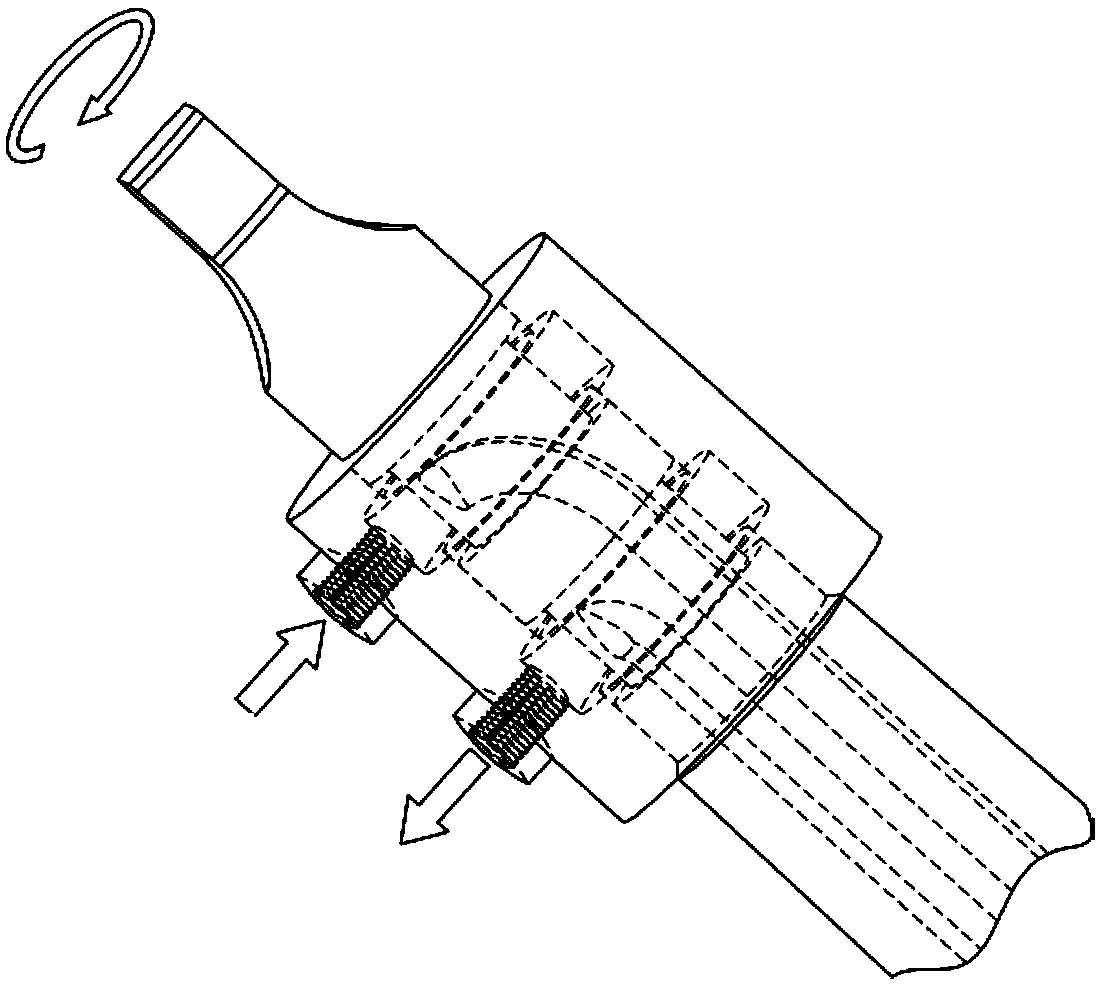

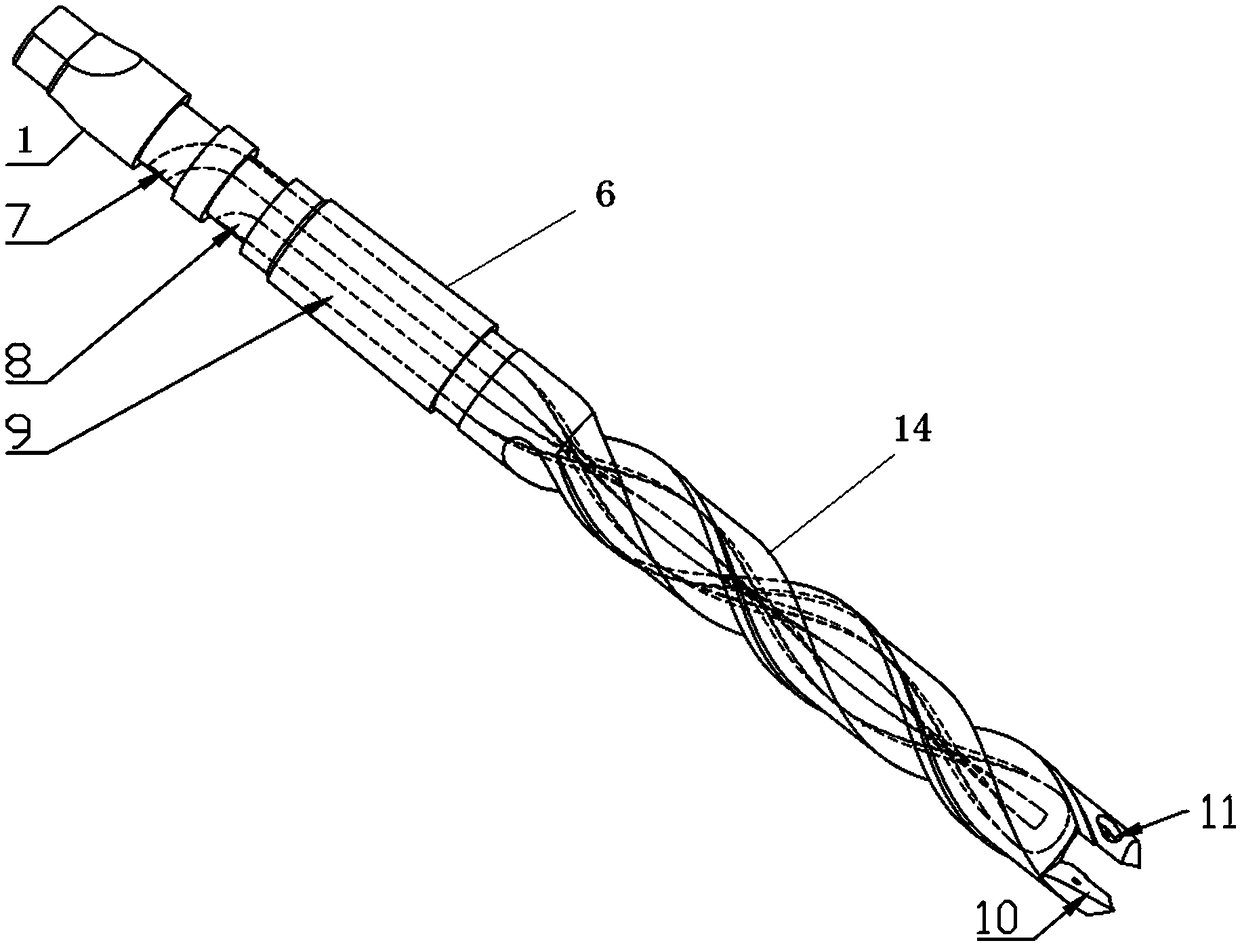

Embedded rapid cooling orthopedic twist drill and manufacturing method

PendingCN108969053AStructural parameter freedomHeat dissipation fastSurgeryBiomedical engineeringCooling fluid

The invention discloses an embedded rapid cooling orthopedic twist drill and a manufacturing method. Two cooling water ring grooves are formed in the outer circumferential wall of a connecting sectionof the orthopedic twist drill, a sleeve ring is additionally arranged outside the orthopedic twist drill, and a closed rotating connector capable of rotatably conveying liquid media by 360 degrees isformed among the cooling water ring grooves and the sleeve ring. External cooling liquid is led into an internal circulation spiral cooling water channel in a drill body to cool the drill body, and the drill body and a cutting portion thereof are of split detachable structures. According to the orthopedic twist drill, by the aid of the external conveyed cooling liquid, the internal circulation spiral cooling water channel rapidly cools the bone drill without polluting a wound of a patient. A tool no longer needs to be sharpened by experienced staff after the cutting portion is abraded, and awear-out part is directly replaced. Key components of the orthopedic twist drill adopt selective laser melting, used materials can be same or different metal powder materials, and the orthopedic twistdrill has a certain economic benefit advantage in terms of waste tool recovery and reuse.

Owner:SOUTH CHINA UNIV OF TECH

Formula of plastic building template

InactiveCN108752797AMeet environmental health requirementsGood dispersionPolyvinyl chlorideChlorinated polyethylene

The invention discloses a formula of a plastic building template. The building template is prepared by the following raw materials by weight: 100 parts of polyvinyl chloride PVC, 3-4 parts of heat stabilizer, 8-12 parts of chlorinated polyethylene CPE, 1.5-2.5 parts of ACR processing aid, 10-20 parts of light calcium and 2-3 parts of titanium dioxide. The plastic building template prepared by theformula has the following advantages of being (1) light in weight; (2) convenient to construct; (3) ultralow in cost and multiple in recycling times; (4) low in cost of mobilization and transition; (5) good in stability, high in bearing capability, cold-resistant, heat-resistant, free of deformation and good in flame retardant performance; (6) vertical and flat and capable of achieving a smooth wall body and serving as a clear water concrete panel; (7) capable of being reused, environmentally friendly, clean and high in plastic residual value.

Owner:FUYUAN FUJIAN ENVIRONMENTAL PROTECTION TEMPLATE

Large-expansion steel for seamless steel tube and preparation method thereof

The invention discloses large-expansion steel for a seamless steel tube and a preparation method thereof, and belongs to the technical field of the seamless steel tube. The large-expansion steel comprises the chemical ingredients by mass percent: 0.02-0.10wt% of C, 2.0-8.0wt% of Mn, 0.2-1.0wt% of Si, less than 0.01wt% of S, less than 0.02wt% of P, the balance of Fe and inevitable impurities; and one or more other chemical elements can be added on the basis, including 0.1-0.6wt% of Ni, 0.1-0.6wt% of Cr, 0.1-0.5wt% of Cu, 0.01-0.1wt% of Nb, 0.01-0.1wt% of V, and 0.01-0.02wt% of Ti. The preparation process comprises the steps of smelting and condensing steel, heating and perforating a tube blank, controlling cooling, and annealing a two-phase area. The retained austenite of which the volume fraction is greater than 5% is finally obtained in the tissue. The large-expansion steel has the advantages that the large-expansion steel has high plasticity when ensuring that the material has high strength level; the uniform elongation achieves over 20%; and each mechanical performance index meets the American Petroleum Institute (API) and other related standard requirements.

Owner:CENT IRON & STEEL RES INST

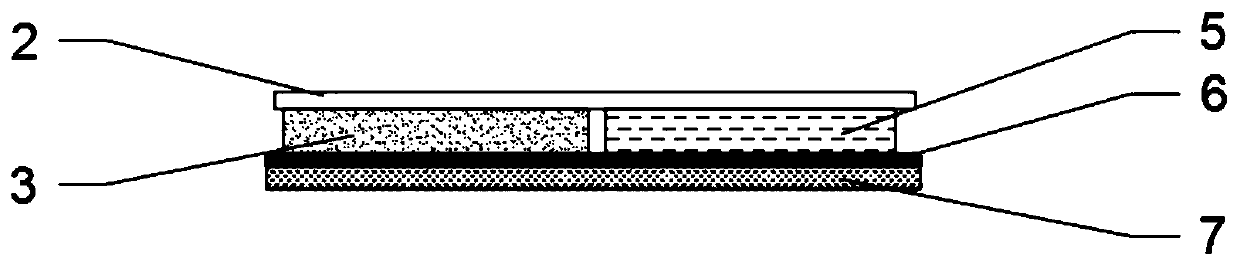

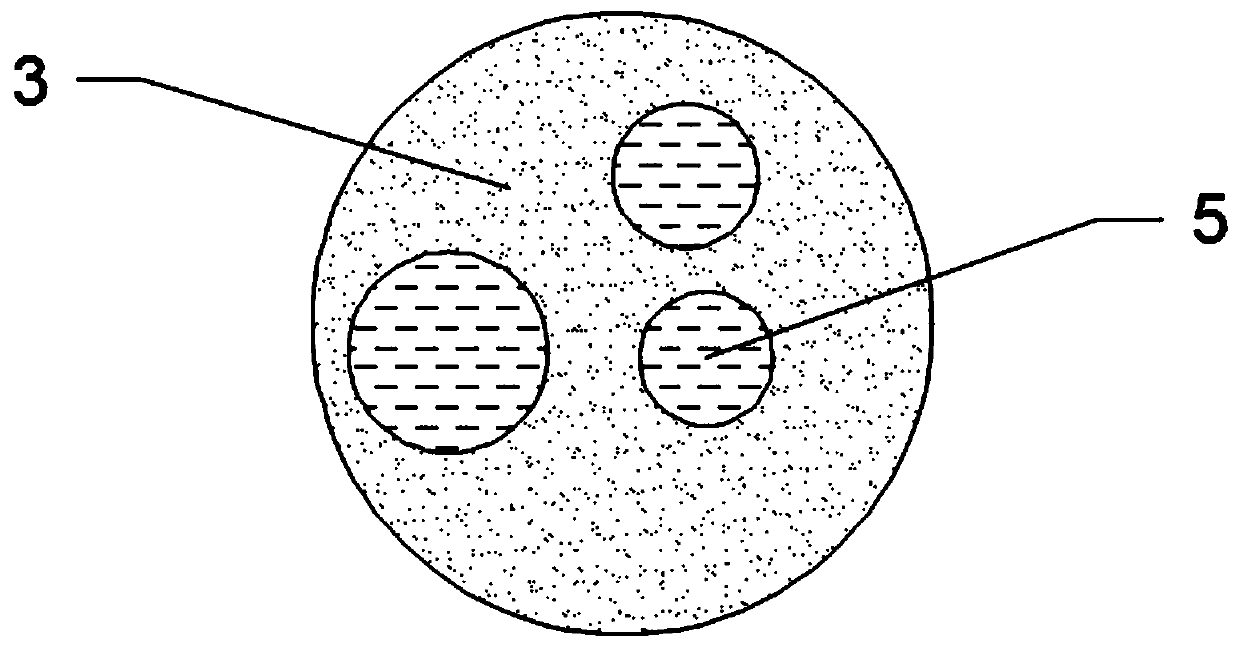

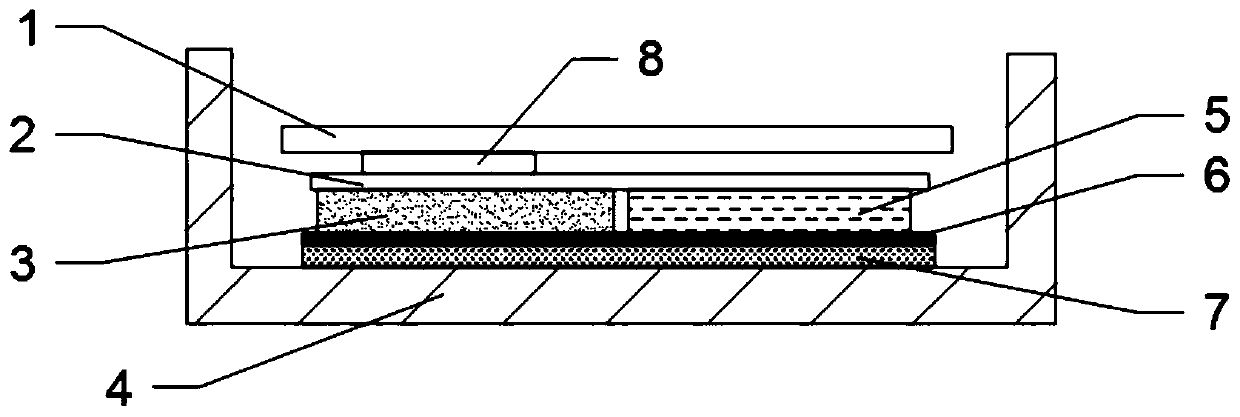

Smartwatch heat management composite

InactiveCN109743865AAchieving soakingFast heat conductionMagnetic/electric field screeningProtection against external influencesHeat managementMetal foil

The invention discloses a smartwatch heat management composite. The smartwatch heat management composite comprises a shielding layer, a heat management layer, a heat conduction layer and super glue, wherein the bottom face of the heat management layer is attached to the top face of the heat conduction layer, the bottom face of the shielding layer is attached to the top face of the heat managementlayer, and the super glue is spread on the bottom face of the heat conduction layer. According to the smartwatch heat management composite, core materials, namely metal foil, a heat insulation material layer, a heat storage material layer and a graphite layer made of a material with high heat conductivity are made into the composite which can achieve conduction shielding, a good heat conduction effect and a local hotspot elimination function, heat is transferred quickly and uniformly, the heat dissipation area is enlarged, the attachment to a bottom case of a smartwatch can be enhanced throughthe super glue on the bottom layer, and the heat conduction effect can be brought into full play.

Owner:东莞市珀信电子有限公司

Firework powder automatic screening and device

The invention discloses a firework powder automatic screening and a device. A screen net is arranged in a sealed powder mixing container of the device and performs circle rotation and overturning. A seal type mechanical automatic mixing method can improve production efficiency and avoids dust environment pollution and occupation disease harm, automatic control and remote control can be achieved to perform human-machine separation, and personal injury is completely avoided. Movement of the screen net and firework powders accords with manual screening mixing, a mixing method is mild, and no movement heat-producing part is arranged in the powder mixing container. Compared with other mixing methods, the possibilities that the firework powders are triggered are small, the powder is evenly mixed, powder mixing quality is good, screen nets of different meshes are matched according to particle size of the firework powder to achieve different screening and mixing effects, different performance requirements of the firework powders are met, and impurities and caking possibly existing in the powders can be further discharged. The device is simple and convenient to maintain, and flow is concise.

Owner:浏阳鑫兵机械厂

Engine cam and production method thereof

ActiveCN104525861AAvoid replacementImprove wear resistanceValve drivesFoundry mouldsCarbide coatingMicrometer

The invention provides an engine cam and a production method thereof. The surface of the work position of the engine cam is provided with a carbide coating, The work position of the surface of the cam is provided with the carbide coating. A quasi monocrystalline TiC dense ceramic layer, a micrometer TiC ceramic layer and a TiC-matrix fusion layer are sequentially distributed in a gradient manner from outside to inside, and are applied to the surface of carbon steel. The carbide coating can be applied to the surface of the carbon steel. The carbide coating is formed on the surface of a matrix through the cast matrix and titanium complex, the introduction of an external carbon source, heating and heat insulation, the coating and the substrate are metallurgically bonded, and the bonding force is very strong, so the problems of non-metallurgic bonding between present hard particles and the steel substrate, very weak bonding force and easy shedding of the particles are overcome, and the wear resistance of the work surface of the cam is greatly improved.

Owner:XIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com