Formula of plastic building template

A construction formwork and formula technology, applied in the field of formwork, can solve the problems of corrosion resistance, acid resistance, poor wear resistance, heavy construction formwork operation, high production cost, etc., and achieve the effects of good stability, good plasticizing fluidity and ultra-low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

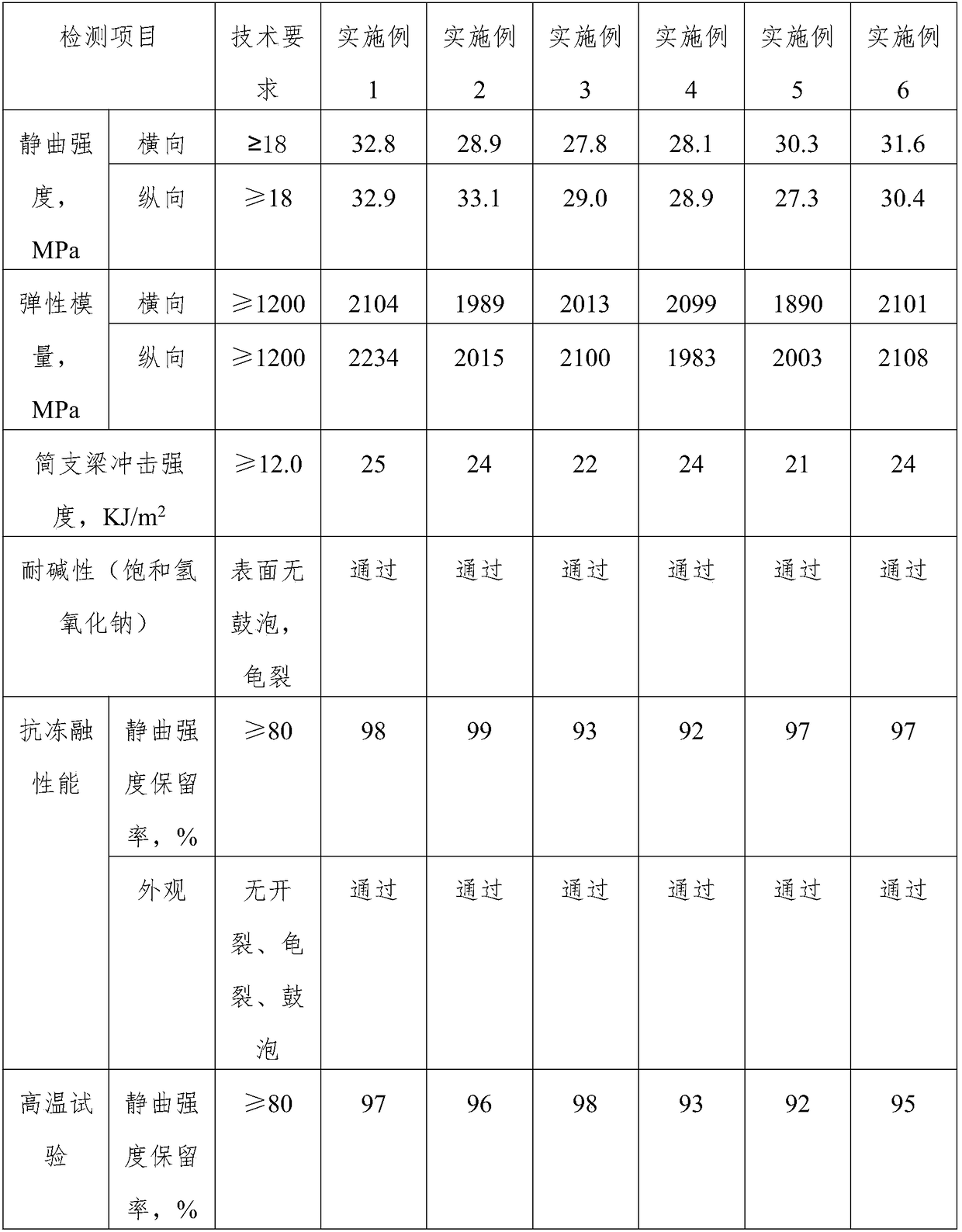

Examples

Embodiment 1

[0027] This embodiment provides a formula for a plastic building formwork, the building formwork is prepared from the following raw materials: 100kg of polyvinyl chloride PVC, 3.5kg of heat stabilizer, 10kg of chlorinated polyethylene CPE, 2kg of ACR processing aid , light calcium 15kg, titanium dioxide 2.5kg.

[0028] The heat stabilizer is a calcium-zinc composite stabilizer.

[0029] The titanium dioxide is rutile titanium dioxide.

[0030] The model of the ACR processing aid is 401A.

[0031] The preparation method of above-mentioned formula is as follows:

[0032] Step 1: weighing each raw material of corresponding parts by weight;

[0033] Step 2: mix each raw material evenly through a mixer;

[0034] Step 3: Extrude through a twin-screw extruder at 180-200°C;

[0035] Step 4: After vacuum adsorption by the forming mold, cooling by water circulation, forming;

[0036] Step 5: pull out the tractor;

[0037] Step 6: The cutting machine cuts according to the specifie...

Embodiment 2

[0040] This example provides a formula for plastic building formwork, which is prepared from the following raw materials: 100kg of polyvinyl chloride PVC, 3kg of heat stabilizer, 12kg of chlorinated polyethylene CPE, and 1.5kg of ACR processing aid , light calcium 20kg, titanium dioxide 2kg.

[0041] Other content is identical with embodiment 1.

Embodiment 3

[0043] This embodiment provides a formula for plastic building formwork, which is prepared from raw materials including the following weights: polyvinyl chloride PVC 100kg, heat stabilizer 4kg, chlorinated polyethylene CPE 8kg, ACR processing aid 2.5kg , light calcium 10kg, titanium dioxide 3kg.

[0044] Other content is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com