Patents

Literature

58results about How to "Improve initial whiteness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat resistant polyamide composite and applications thereof

ActiveCN102372921AImprove reflectivityImprove initial whitenessSemiconductor devicesFiberGlass fiber

The invention discloses a heat resistant polyamide composite and applications thereof. The composite comprises the following components by weight percent: 40%-90% of heat resistant polyamide resin, 5%-35% of mineral fiber A, 0-35% of mineral filler B, 0.1%-1% of light stabilizer, 0.1%-1% of flow modifier and 0.1%-1% of antioxidant. The heat resistant polyamide resin of which concentration ratio of amino end groups to carboxyl end groups is 0.1-0.8, as well as the irregular glass fiber of which thickness-breadth ratio is 2-6, the mineral filler B and the flow modifier, is selected to prepare the heat resistant polyamide composite; and the composite has high original brightness and reflectivity, excellent heat resistance, good formability and good dimensional stability and can be used to prepare the reflection supports of light sources such as the backlights, vehicle headlights, instrument panels and illuminating implements of liquid crystal displays such as portable phones, computers, televisions and the like.

Owner:KINGFA SCI & TECH CO LTD +1

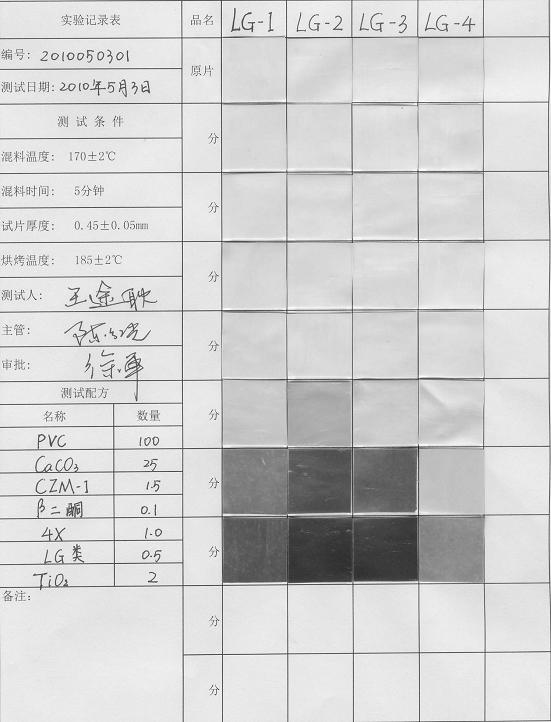

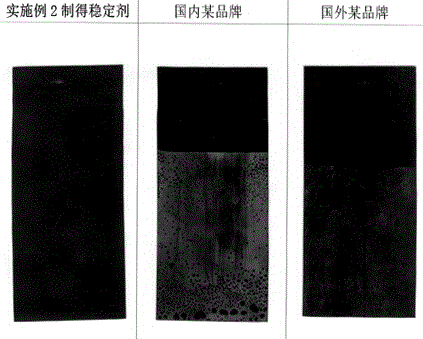

Magnesium-aluminum-zinc environment-friendly stabilizer special for U-PVC calendered sheet

The invention discloses a special environment-friendly stabilizer for U-PVC calendered sheet, which is prepared from the following components in weight ratio: 260-300 kg of magnesium-aluminum-zinc composition, 50-150 kg of zinc stearate, and 1010-15-15 kg of antioxidant. 20kg, calcium acetylacetonate 40~68kg, tris(2-hydroxyethyl) isocyanurate 80~130kg, oxidized polyethylene wax 50~250kg, polyethylene wax 30~100kg. The stabilizer of the invention is suitable for continuous calendering and extrusion production of U-PVC sheet, and has moderate dosage, low cost, good production process stabilization effect, good rolling effect, smooth processing, smooth sheet surface, good plasticization, and satisfactory mechanical properties. The requirements of the national standard also have the advantages of non-toxicity and high environmental protection performance; the U-PVC sheet prepared by the stabilizer of the present invention has stable chemical properties, no rust, good impact resistance, and good transparency. Good insulation and low thermal conductivity; good formability and colorability, and low processing cost; the PVC sheet produced conforms to GB / T15267 "PVC Rigid Sheets and Films for Food Packaging" and conforms to YBB00212005 Polyethylene Vinyl chloride solid medicinal tablet.

Owner:广东森德利环保新材料科技有限公司

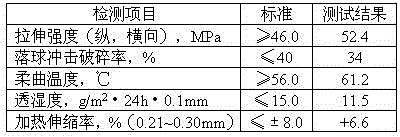

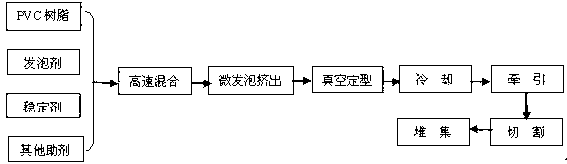

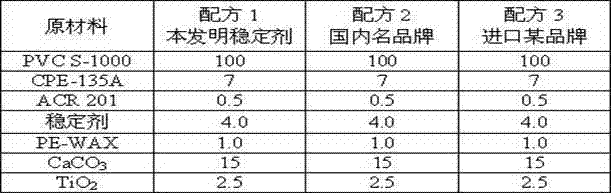

Magnesium-aluminum-zinc modified non-toxic compound stabilizing agent for PVC (Polyvinyl Chloride) foaming material

The invention relates to a magnesium-aluminum-zinc modified non-toxic compound stabilizing agent for a PVC (Polyvinyl Chloride) foaming material. The stabilizing agent is prepared from a fatty acid calcium zinc composition, an antioxidant, acetylacetone calcium or acetylacetone magnesium, hydrotalcite, dehydroacetic acid or sodium dehydroacetate, trihydroxyethyl isocyanurate, macromolecular ester-group calcium, calcium carbonate or talcum powder according to a weight ratio. A formula of the stabilizing agent adopts the trihydroxyethyl isocyanurate so that a product has good whiteness and machining stability; the fatty acid calcium zinc composition and the macromolecular ester-group calcium in the formula can improve the product machining performance and the product compatibility so that the product comprehensive performance is the best; the stabilizing agent is used for extruding a PVC foaming sheet material and has the advantages of good stabilizing effect, smooth machining and good whiteness; the mechanical property meets various international requirements and the difficulty that an AC (Azodicarbonamide) foaming agent is added and is easily subjected to a color reaction with a substance with the high activity is overcome; and the magnesium-aluminum-zinc modified non-toxic compound stabilizing agent has the advantages of no toxin and environmental friendliness.

Owner:广东森德利环保新材料科技有限公司

Dedicated Mg-Al-Zn modified non-toxic compound stabilizer for PVC (Poly Vinyl Chloride) pipes

The invention relates to a dedicated Mg-Al-Zn modified non-toxic compound stabilizer for PVC (Poly Vinyl Chloride) pipes. The stabilizer comprises the following raw materials according to the weight percent: a fatty acid calcium-zinc combination, calcium stearate, an antioxidant 1076, stearoyl benzoyl methane, calcium acetylacetonate or magnesium acetylacetonate, hydrotalcite, dehydroacetic acid or sodium dehydroacetate, high-polymer ester-based calcium g, and calcium carbonate or talcum powder. The stabilizer is suitable for continuous extrusion production of the pipes, small in use amount and low in cost, can be used for extrusion production of hard pipes, and are excellent in stabilizing effect, smooth to process, non-toxic, and high in environmental-friendly performance; the inner surfaces and the outer surfaces of the pipes are smooth, and the mechanical property meets various requirements of the national standard; and PVC products manufactured by the stabilizer are excellent in compatibility, processing stability and long term stability.

Owner:广东森德利环保新材料科技有限公司

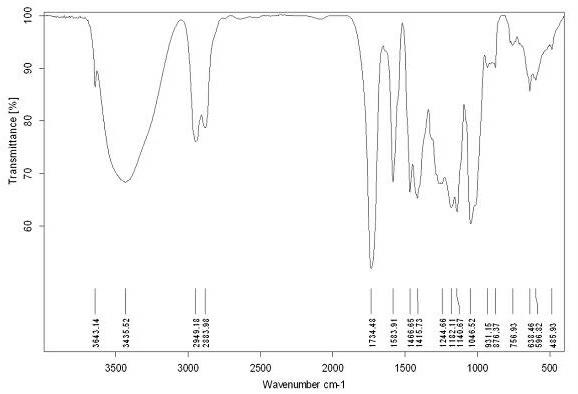

High polymer ester calcium and synthesis method thereof

The invention relates to high polymer ester calcium and a synthesis method thereof. According to the invention, the high polymer ester calcium is calcium salt of pentaerythritol adipate formed by carrying out esterification reaction on adipic acid and pentaerythritol, adding a solid superacid as a catalyst and adding calcium oxide or calcium hydroxide to neutralize. The high polymer ester calcium, provided by the invention, has excellent comprehensive performance, when the high polymer ester calcium is used for a PVC (Polyvinyl Chloride) stabilizing system, the initial whiteness of obtained products, Congo red times, system compatibility, stability and the like are very outstanding, and the preparation method is simple so as to achieve industrial productions, and the high polymer ester calcium can be used for preparing a PVC stabilizing agent.

Owner:广东森德利环保新材料科技有限公司

Preparation method of cotton pulp and preparation method of viscose fiber

ActiveCN106283786AQuality improvementReactiveArtificial filaments from viscosePulping with inorganic basesPapermakingViscose

The invention provides a preparation method of cotton pulp. The preparation method comprises the following steps: sequentially performing dry impurity removal and wet impurity removal on cotton linter to obtain impurity-removed cotton linter; mixing the impurity-removed cotton linter with cooking liquor, heating to 85-95 DEG C, and preserving heat for 50-70 min; continually heating to 110-125 DEG C, and preserving heat for 120-300 min to obtain a cooked slurry; sequentially pulping, desanding, chlorinating and alkalizing, bleaching, performing acid treatment and a papermaking process on the cooked slurry to obtain the cotton pulp, wherein the cooking liquor comprises alkali and hydrogen peroxide. By the preparation method, hydrogen peroxide is added in the cooking process, and cooking is carried out by two stages at low temperature, so that a role of hydrogen peroxide in destroying colored groups of cotton fiber is fully played, the initial whiteness of the cooked slurry is improved, and the alpha cellulose content of the cotton pulp is increased; meanwhile, by the preparation method, the quality of the cotton pulp is greatly improved, and paper pulp pollution of the cotton pulp is reduced. The invention further provides a preparation method of viscose fiber.

Owner:ANHUI SNOW DRAGON FIBER TECH

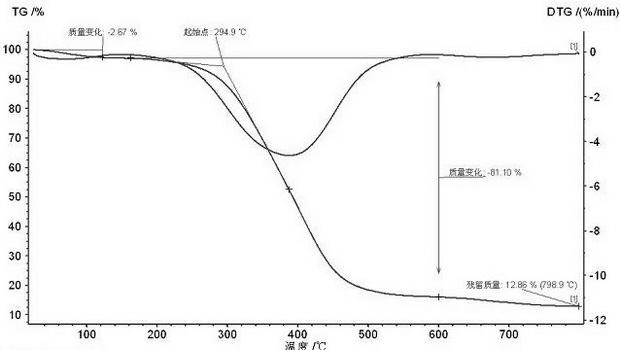

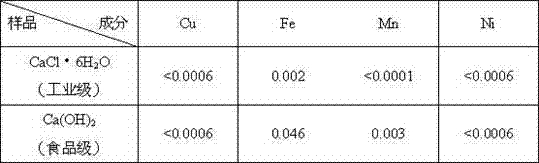

Preparation method for high-brightness calcium acetylacetonate for PVC (Polyvinyl Chloride) heat stabilizer

ActiveCN103086857AImprove initial whitenessLow costCalcium/strontium/barium chloridesPreparation of aldehyde/ketone chelatesFerric hydroxideCalcium hydroxide

The invention discloses a preparation method for high-brightness calcium acetylacetonate for PVC (Polyvinyl Chloride) heat stabilizer. A report about the preparation of high-brightness calcium acetylacetonate is not provided at present. The preparation method comprises the following steps of: oxidizing divalent iron ion and divalent manganese iron in a calcium chloride aqueous solution into trivalent iron ion and tetravalent manganese by oxidant, respectively; adjusting the pH value of the solution, so that iron and manganese are separated from the liquid phase in the forms of ferric hydroxide precipitates and hydrated manganese dioxide precipitates; filtering the solution to obtain calcium chloride solution free of iron and manganese impurities after the solution is treated by an adsorbent; preparing calcium chloride into calcium hydroxide by a conventional method; and enabling calcium chloride and acetylacetone to react to generate high-brightness calcium acetylacetonate. The preparation method disclosed by the invention is low in cost, good in quality and high in cost performance; and the obtained high-brightness calcium acetylacetonate is compounded with other additives to form the PVC heat stabilizer, so that the PVC product has good initial brightness during the processing process.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

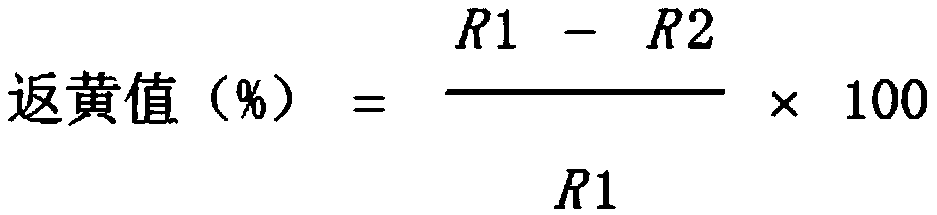

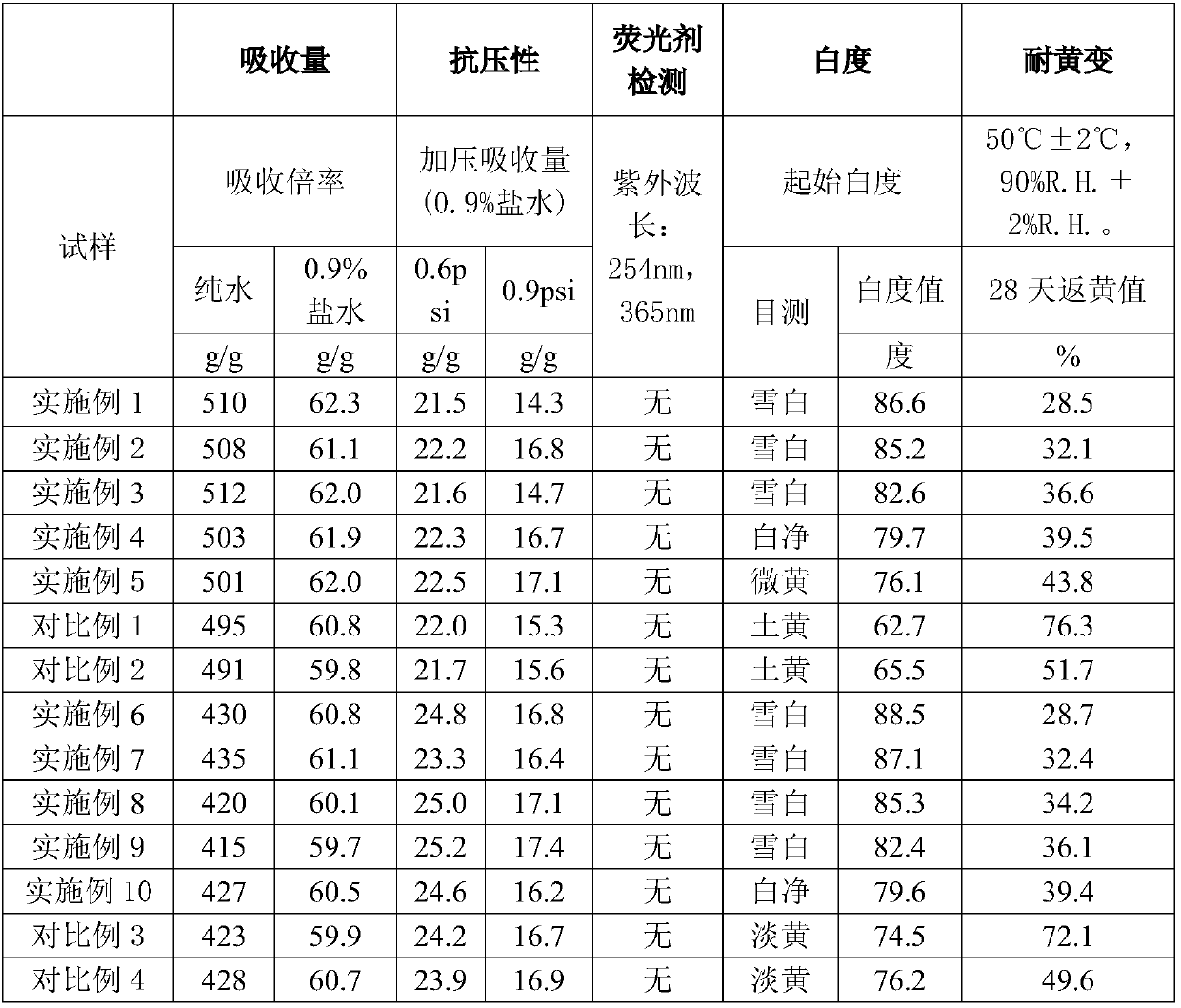

Preparation method of white and yellowing resistant water-absorbent resin

The invention discloses a preparation method of a white and yellowing resistant water-absorbent resin. The preparation method is a pre-neutralization method or a post-neutralization method, wherein the pre-neutralization method comprises the following steps: adding acrylic acid into a neutralization solution to be neutralized, carrying out a radical polymerization reaction to obtain sodium polyacrylate and polyacrylic acid hydrogel of a certain neutralization degree, performing squeezing granulation on the hydrogel in the presence of a soluble reducing agent, and performing after-treatment toobtain a super absorbent resin; and the post-neutralization method comprises the following steps: carrying out a radical polymerization reaction on an aqueous solution of acrylic acid so as to obtainpolyacrylic acid gel, and adding a neutralization solution into the polyacrylic acid gel to carry out a neutralization reaction; and adding the soluble reducing agent to perform squeezing granulation,and performing after-treatment, thereby obtaining the super absorbent resin. According to the preparation method disclosed by the invention, the initial whiteness of the product can be effectively improved, and the yellowing resistance of the product can also be effectively enhanced.

Owner:刘常红

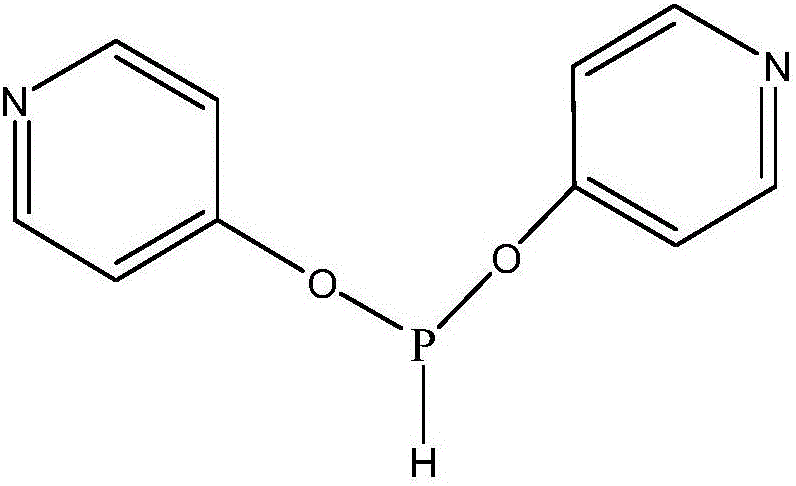

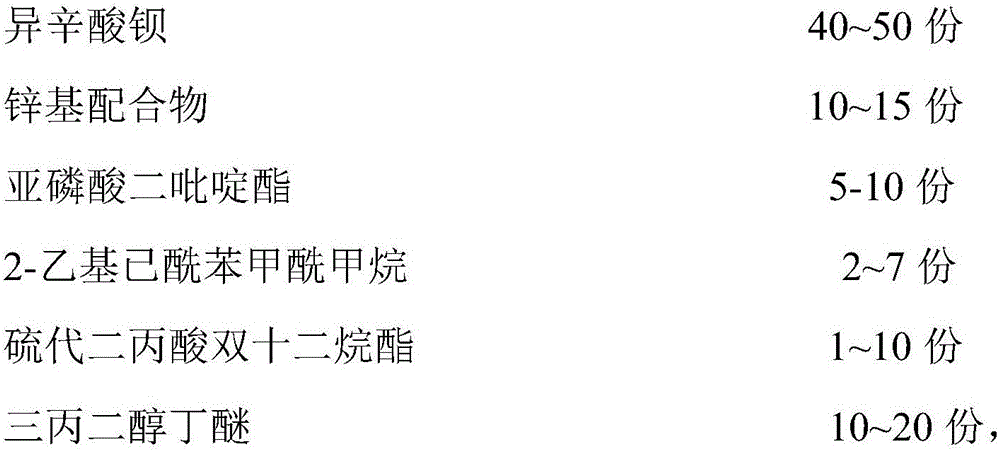

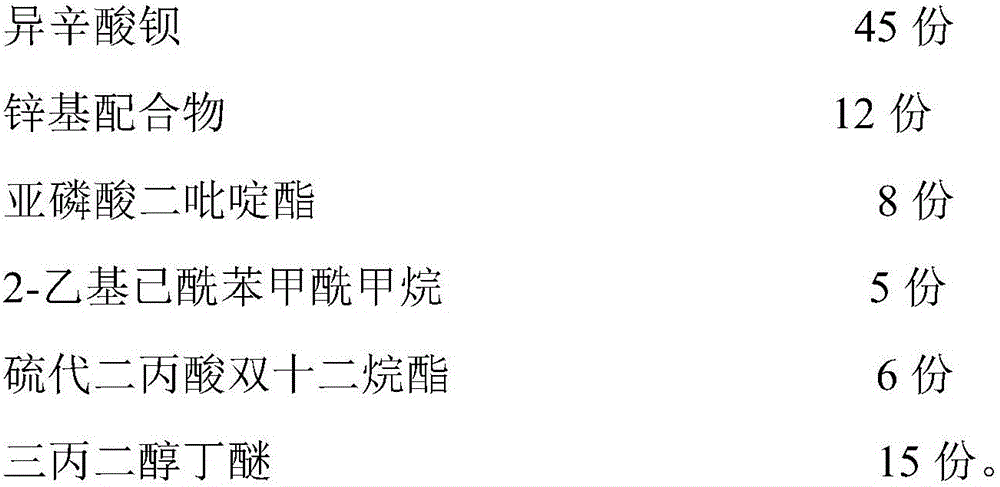

Application of bipyridine ester phosphite to PVC heat stabilizer

ActiveCN106046618AExcellent resistance to precipitationAuxiliary Stabilization ImprovementNitrogen atomEther

The invention relates to the application of bipyridine ester phosphite to a PVC heat stabilizer. bipyridine ester phosphite can be applied to preparation of a liquid barium-zinc stabilizer, a liquid barium-cadmium-zinc stabilizer and a liquid calcium-zinc stabilizer. The liquid barium-zinc stabilizer is prepared from, by weight, 40-50 parts of barium isotanoate, 10-15 parts of zinc-based complex, 5-10 parts of bipyridine ester phosphite, 2-7 parts of 2-ethyl acetyl benzoyl methane, 1-10 parts of thiodipropionicacid dilauryl ester and 10-20 parts of tripropylene glycol n-butyl ether. The bipyridine ester phosphite compound has a higher anti-precipitation property than aliphatic or aromatic phosphite ester by means of a novel heterocyclic perssad replacing the aliphatic or aromatic perssad during preparation of the liquid barium-zinc stabilizer, the liquid barium-cadmium-zinc stabilizer and the liquid calcium-zinc stabilizer. By introducing nitrogen atoms to the heterocyclic ring, the auxiliary stabilization effect on phosphite ester is improved remarkably, and then the printing performance and stability of a modified PVC product are improved.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

Flame-retardant reinforced high-temperature-resistant nylon composite material

The invention discloses a flame-retardant reinforced high-temperature-resistant nylon composite material which is prepared from the following raw materials in parts by weight: 30 to 45 parts of high-temperature nylon resin, 30 to 55 parts of glass fibers, 10 to 20 parts of flame retardant and 0.1 to 2.0 parts of polyvinylpyrrolidone. According to the material, the polyvinylpyrrolidone is introduced into a formula system of the flame-retardant reinforced high-temperature-resistant nylon composite material, so that the initial whiteness of the composite material can be remarkably improved, titanium dioxide is not required to be added when a light-color product is prepared, the initial whiteness L value of an obtained molded product is greater than 80, and the prepared molded product has an excellent visual effect, the reduction of the cost is facilitated, and the molded product is smooth in surface, so that the problem of fiber floating on the surface of the product is effectively solved.

Owner:BENSONG ENG PLASTICS HANGZHOU

Synthesis method and application of polyhydroxy stearate

ActiveCN104478692AReduce the risk factorReduce corrosionOrganic compound preparationCarboxylic acid salt preparationSynthesis methodsPolyvinyl chloride

The invention discloses a synthesis method of polyhydroxy stearate and application of the polyhydroxy stearate in PVC (polyvinyl chloride) resin heat stabilizers. The existing alkaline process for preparing 9,10-bis-hydroxystearic acid is complex in after-treatment, and no one has applied bis-hydroxystearate to PVC heat stabilizers. The invention is characterized in that in the polyhydroxy stearic acid synthesis, fatty acid, acetic acid and 40 wt% hydrochloric acid are added into the reaction vessel, wherein the fatty acid is one or mixture of more of oleic acid, linoleic acid and linolenic acid; in the system, the mass ratio of fatty acid to anhydrous acetic acid 30% to oxydol is 1:(0.5-2):(1-3.5); and in the reaction system, the mass ratio of anhydrous acetic acid to water is 1:(2.0-3.0). In the synthesis method, the product can be directly precipitated from the system, thereby simplifying the after-treatment.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

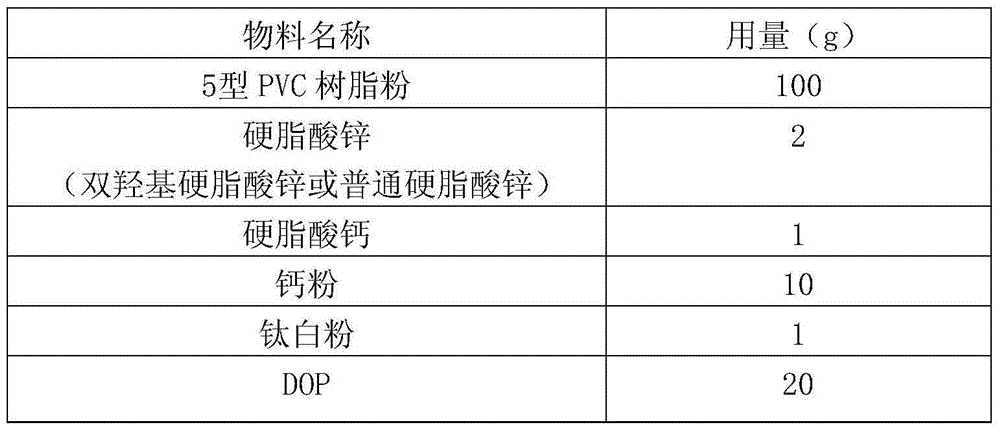

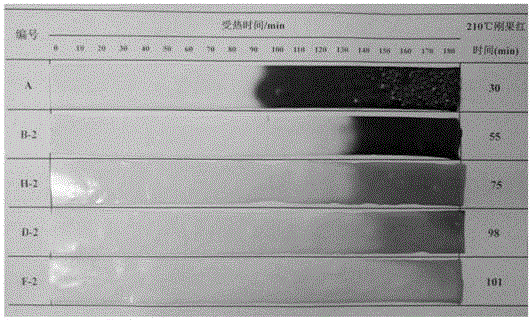

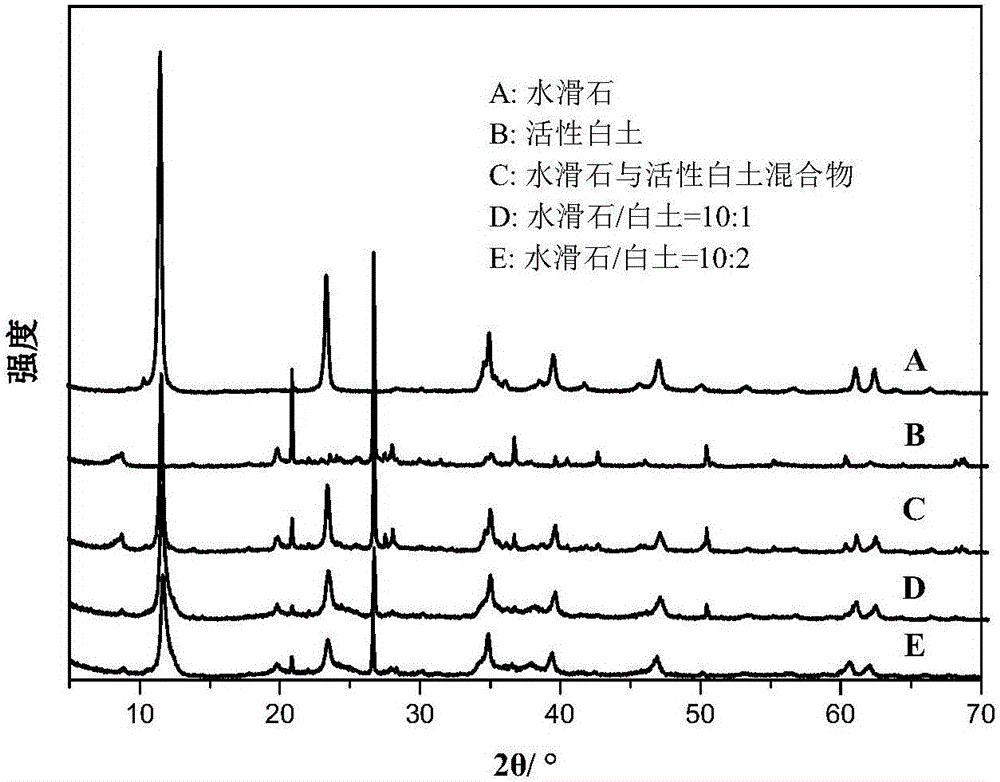

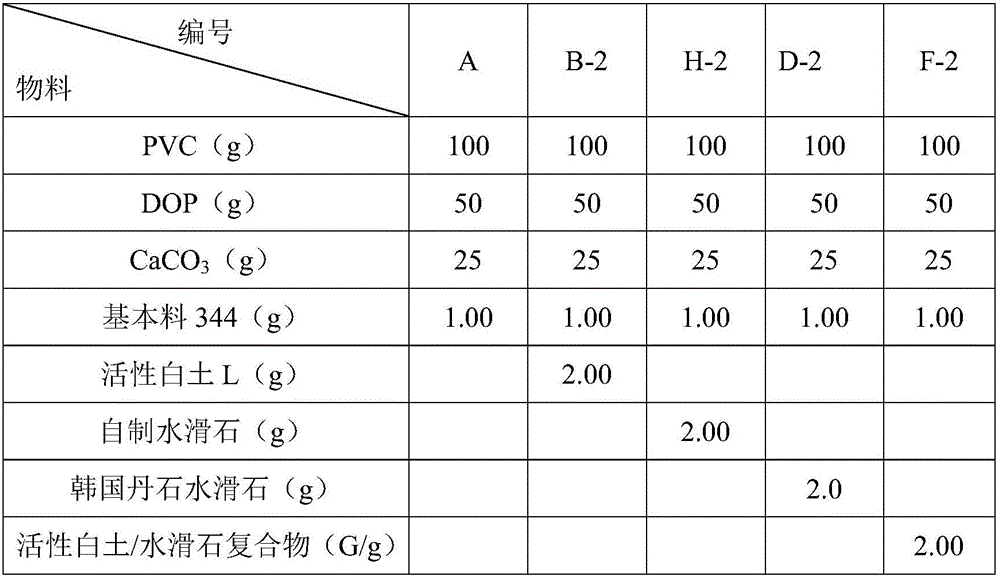

Composite material used for PVC heat stabilizers, and preparation method thereof

The invention relates to a composite material used for PVC heat stabilizers. The novel composite material Hangjin 2# soil / hydrotalcite is produced from Hangjin 2# soil with abundant reserves and low price and self-made hydrotalcite through using a silane coupling agent grafting technology, and has a good effect when used in the PVC heat stabilizers. Adoption of the cheap Hangjin 2# soil as a raw material reduces the production cost of the composite material and makes the composite material have better performances than imported DANSUK hydrotalcite.

Owner:ZHAOQING UNIV

Modified hydrotalcite and preparation method thereof, PVC heat stabilizer and application

The invention relates to the technical field of PVC (polyvinyl chloride) heat stabilizers, and provides modified hydrotalcite and a preparation method thereof as well as a PVC heat stabilizer and application thereof in order to solve the problem that zinc salt is invalid after hydrotalcite and zinc salt are compounded in a traditional PVC heat stabilizer, and the modified hydrotalcite is obtained by in-situ synthesis of uracil, epoxy acid, metal salt and other auxiliaries. Urea pyrimidine epoxy acid with excellent HCl absorption and instable chlorine atom substitution is intercalated between hydrotalcite layers, so that the HCl absorption and instable chlorine atom substitution capabilities of modified hydrotalcite can be improved, by-products, such as AlCl3 and MgCl2, capable of replacing Zn after metal strong oxides in the layers absorb HCl can be complexed, and zinc ions in the zinc salt heat stabilizer are prevented from being replaced by AlCl3, MgCl2 and the like; and the modified hydrotalcite and the zinc salt can be used as a PVC heat stabilizer to be applied to a PVC product after being compounded, and the obtained product has excellent initial whiteness and long-term heat stability.

Owner:浙江宏天新材料科技有限公司

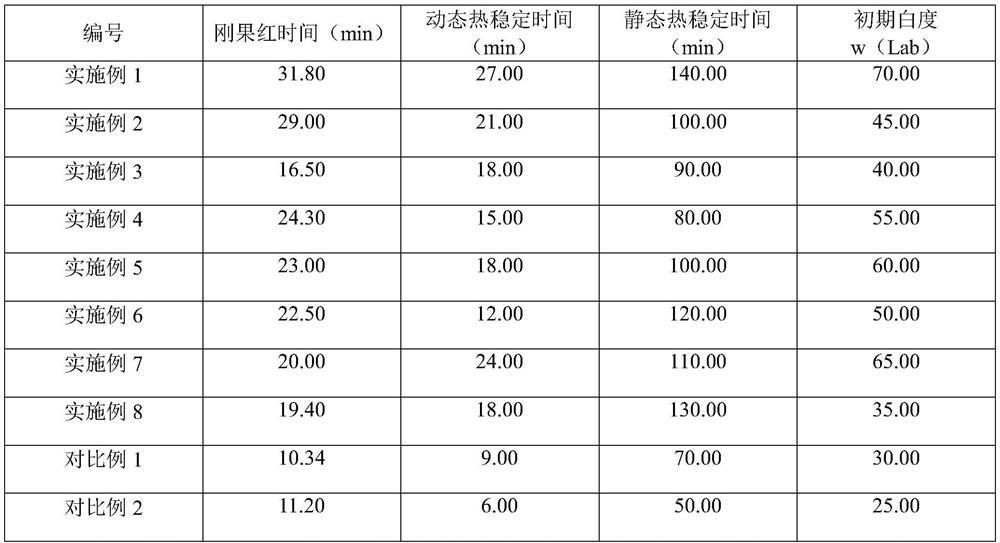

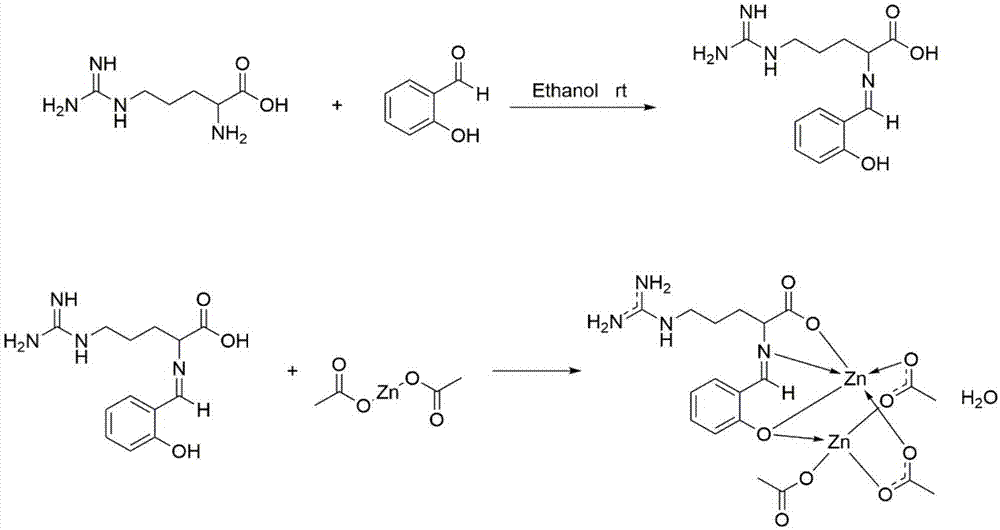

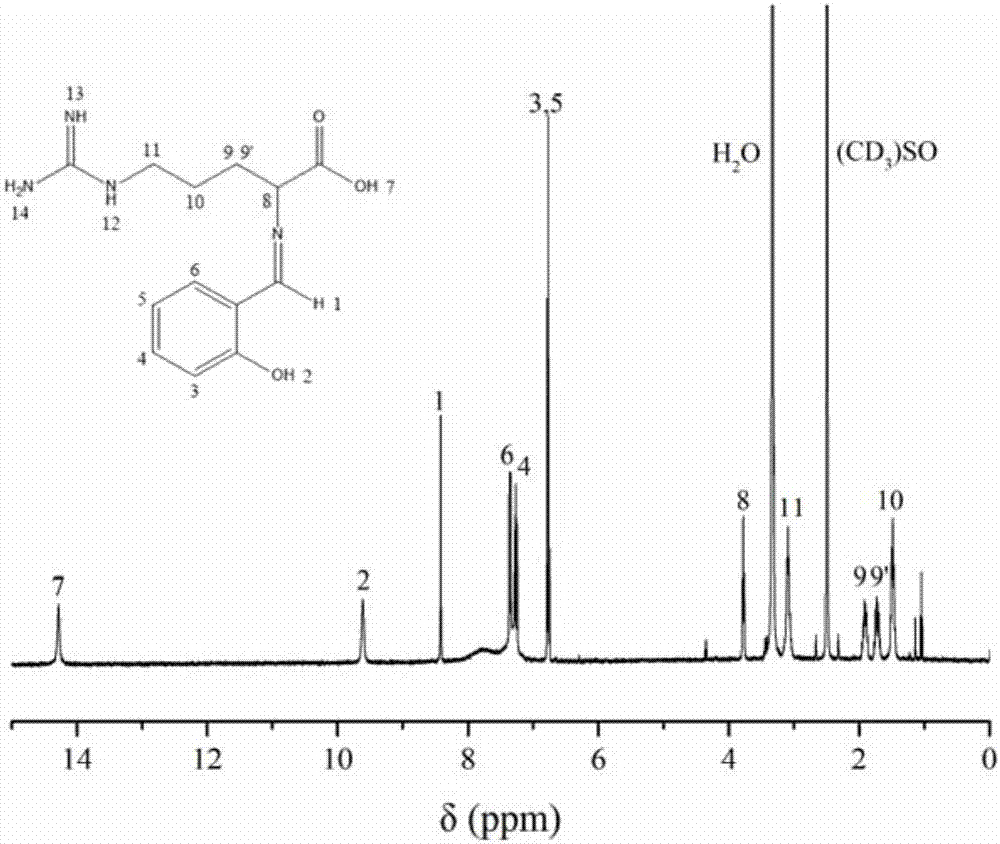

Zinc-based heat stabilizer, preparation method thereof and heat stabilizer compound

ActiveCN107337876AImprove stabilityGood resistance to "zinc burning" phenomenonPolymer scienceChemical composition

The invention provides a zinc-based heat stabilizer, a preparation method thereof and a heat stabilizer compound containing the zinc-based heat stabilizer. The zinc-based heat stabilizer is a zinc-containing product as shown in the structural formula II, and chemical composition of the zinc-based heat stabilizer is Zn2(HL)(CH3COO)3.xH2O (x=0-1.0) in the description. The zinc-based heat stabilizer and the compound of the zinc-based heat stabilizer have excellent initial stain resistance and long-term heat aging resistance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

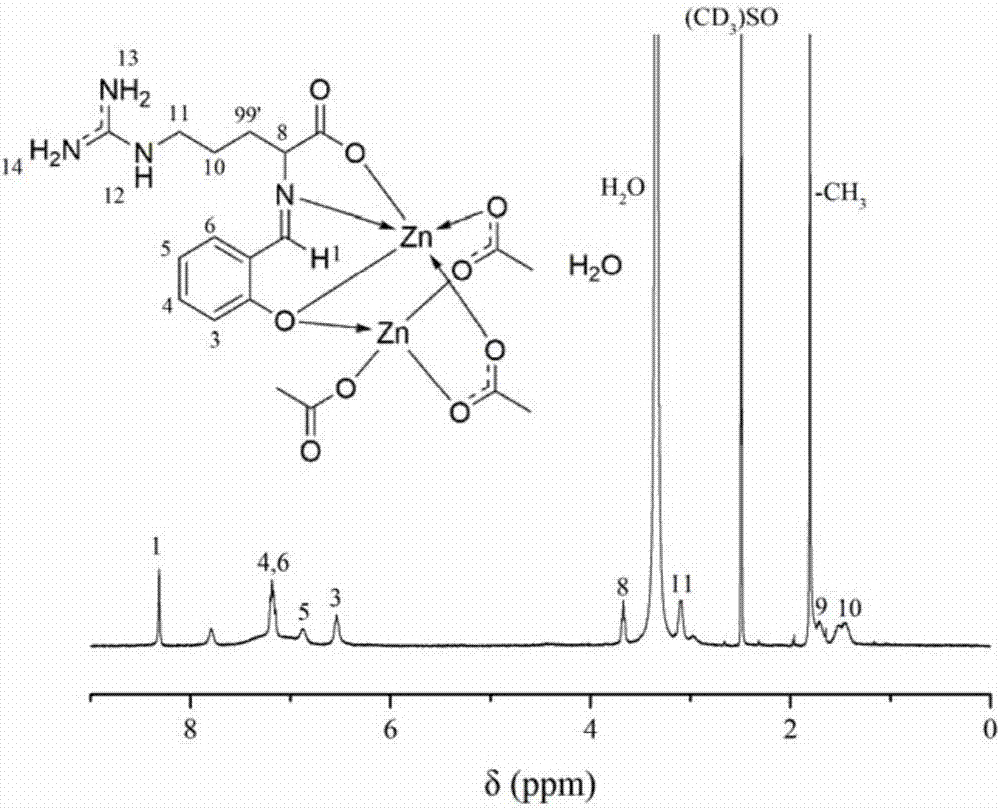

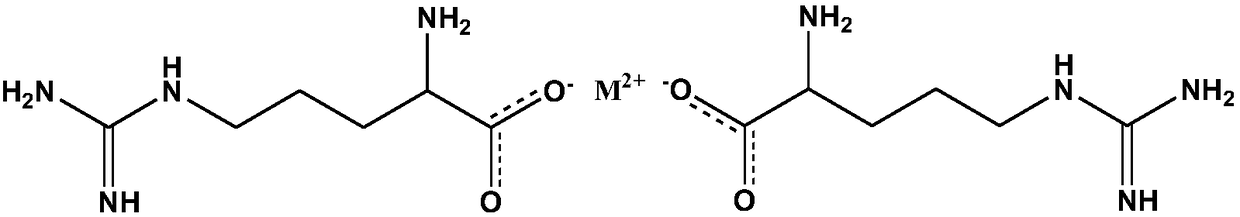

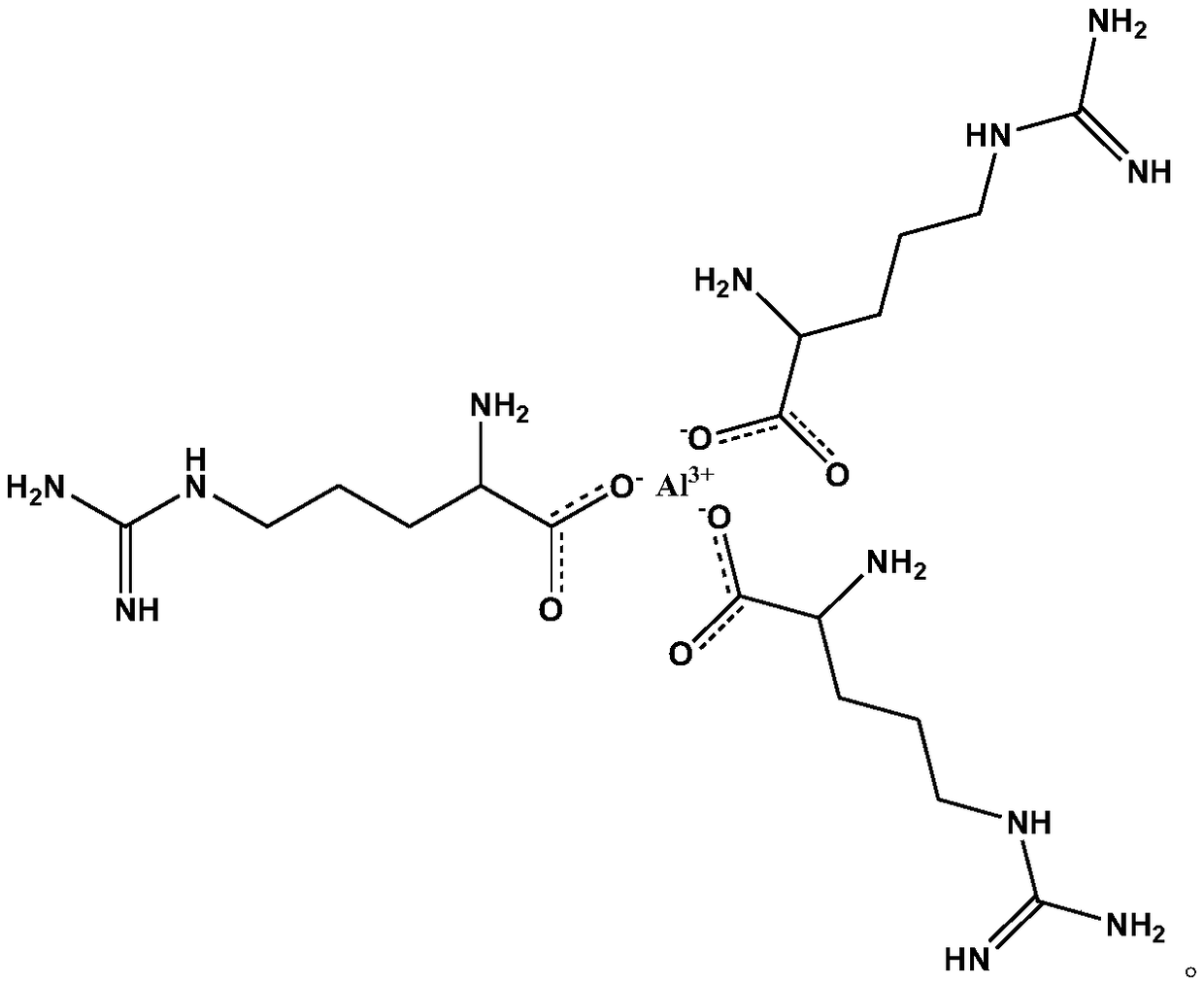

Arginine metal complex, compound heat stabilizer and application thereof

ActiveCN109294114AThe preparation process is simple and environmentally friendlyPreparation Process GreenArginineAntioxidant

The invention relates to the technical field of polyvinyl chloride heat stabilizers, in particular to an arginine metal complex, a compound heat stabilizer and an application thereof. The compound heat stabilizer comprises components as follows: 2-6 phr of an arginine metal complex, 0-0.9 phr of arginine, 0.3-0.9 phr of an auxiliary stabilizer, 0.4-1.2 phr of a lubricant and 0.4-1.2 phr of an antioxidant. The arginine metal complex is used as a main stabilizer of the compound heat stabilizer for PVC and has good initial whiteness and long-term stability, and the mechanical performance and apparent quality of a PVC product can be improved. The PVC product using the compound heat stabilizer has good initial whiteness and long-term stability, excellent heat stabilization effect and good industrial prospects.

Owner:ZHEJIANG UNIV OF TECH

Formula of plastic building template

InactiveCN108752797AMeet environmental health requirementsGood dispersionPolyvinyl chlorideChlorinated polyethylene

The invention discloses a formula of a plastic building template. The building template is prepared by the following raw materials by weight: 100 parts of polyvinyl chloride PVC, 3-4 parts of heat stabilizer, 8-12 parts of chlorinated polyethylene CPE, 1.5-2.5 parts of ACR processing aid, 10-20 parts of light calcium and 2-3 parts of titanium dioxide. The plastic building template prepared by theformula has the following advantages of being (1) light in weight; (2) convenient to construct; (3) ultralow in cost and multiple in recycling times; (4) low in cost of mobilization and transition; (5) good in stability, high in bearing capability, cold-resistant, heat-resistant, free of deformation and good in flame retardant performance; (6) vertical and flat and capable of achieving a smooth wall body and serving as a clear water concrete panel; (7) capable of being reused, environmentally friendly, clean and high in plastic residual value.

Owner:FUYUAN FUJIAN ENVIRONMENTAL PROTECTION TEMPLATE

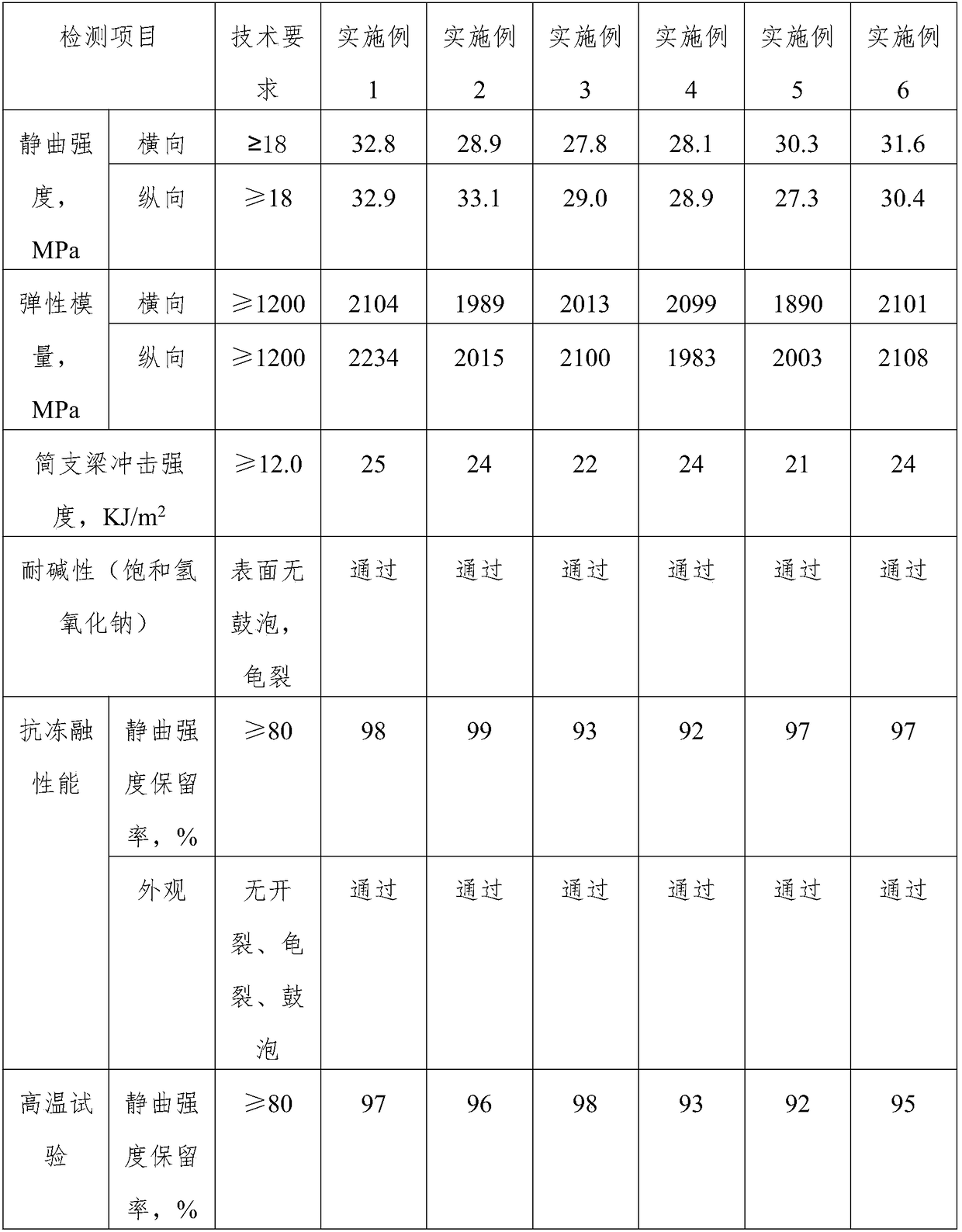

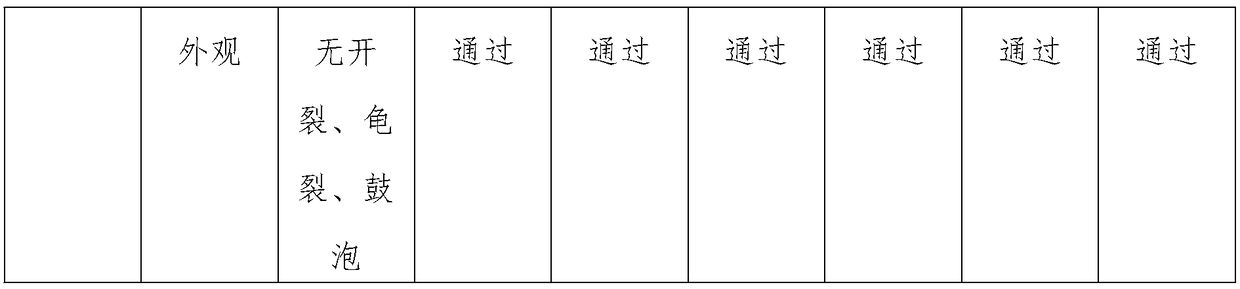

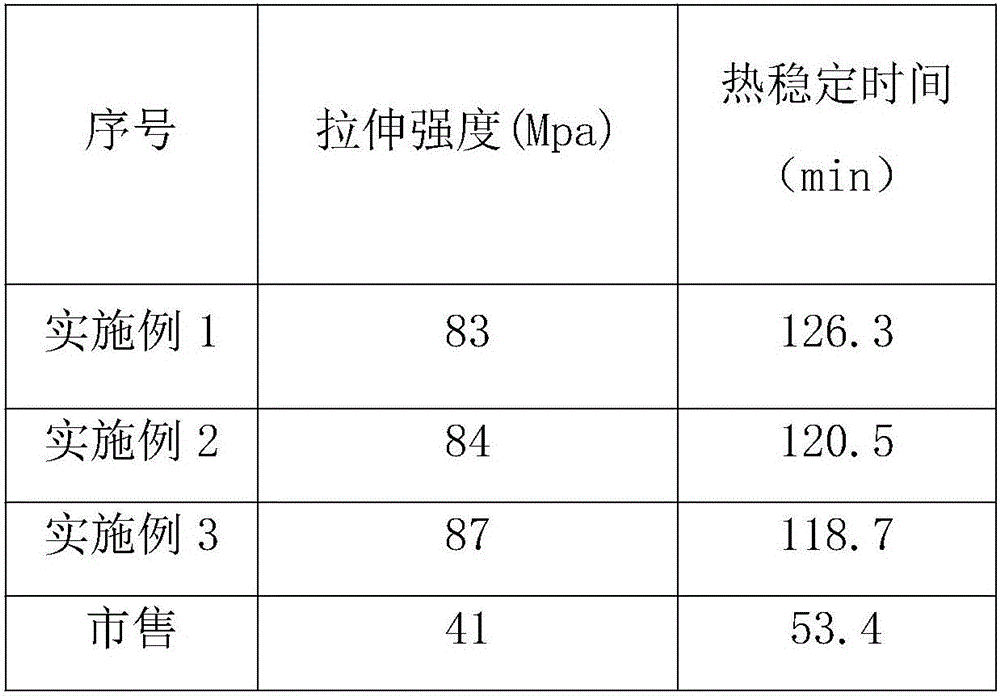

Non-toxic environment-friendly stabilizer auxiliary agent and preparation method thereof

The invention relates to a stabilizer auxiliary agent, in particular to a non-toxic environment-friendly stabilizer auxiliary agent and a preparation method thereof. The stabilizer auxiliary agent is prepared from, by weight, 45-65 parts of calcium acetylacetonate, 30-40 parts of modified molecular sieves, 5-10 parts of a chelating agent and 5-10 parts of a coupling agent. A preparation method of the modified molecular sieves comprises the steps of conducting drying and dehydration treatment on molecular sieves, then mixing the molecular sieves with pentaerythritol ester and diisooctyl phenyl phosphite, and grinding the mixture, so that the modified molecular sieves are obtained. When the non-toxic environment-friendly stabilizer auxiliary agent is used, such constituents as beta-diketone, bisphenol A and pentaerythrite in a traditional calcium-zinc stabilizer formula can be substituted, the consumption of hard calcium and hard zinc is reduced, the excellent synergistic effect and lubricating effect are achieved, heat stability time of a PVC product can be prolonged, the precipitation and blooming phenomena are prevented, later-period weatherability is improved, and production cost is lowered. The invention further provides the preparation method of the non-toxic environment-friendly stabilizer auxiliary agent.

Owner:山东和隆新材料科技有限公司

Method for producing ultra-white polyvinyl chloride resin after suspension polymerization of vinyl chloride

ActiveCN107033374BImprove initial whitenessGood whitening effectDownstream processingPolyvinyl chloride

The invention relates to a production method of ultra-white polyvinyl chloride paste resin, in particular to a method for producing ultra-white polyvinyl chloride resin after suspension polymerization of vinyl chloride. Proceed as follows: 12 to 18 parts of ethanol, 1 to 3 parts of liquid carbolic acid, 4 to 8 parts of blue pigments, and 400 to 600 parts of deionized water are used to prepare whitening aids according to the mass ratio; The auxiliary agent is dispersed and diluted with deionized water, then added to the polyvinyl chloride slurry, stirred evenly, centrifuged, and dried to obtain a high whiteness polyvinyl chloride resin product. Compared with the existing technology, it has the following advantages: good whitening effect: 2), high whitening efficiency: because the whitening agent is a water-soluble high-dispersion solution, the blue pigment molecules are adsorbed by the folds of the resin particles, and in blue light- The phenomenon of yellowing of the resin is eliminated under the complementary effect of yellow light. Since the pigment molecules are fully dispersed in the slurry, the coloring efficiency is greatly improved; and the downstream processing cost of the later resin is reduced.

Owner:TANGSHAN SANYOU CHLOR ALKALI

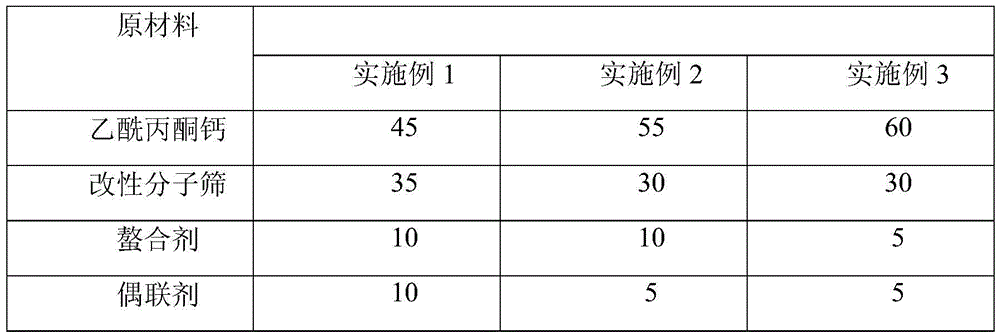

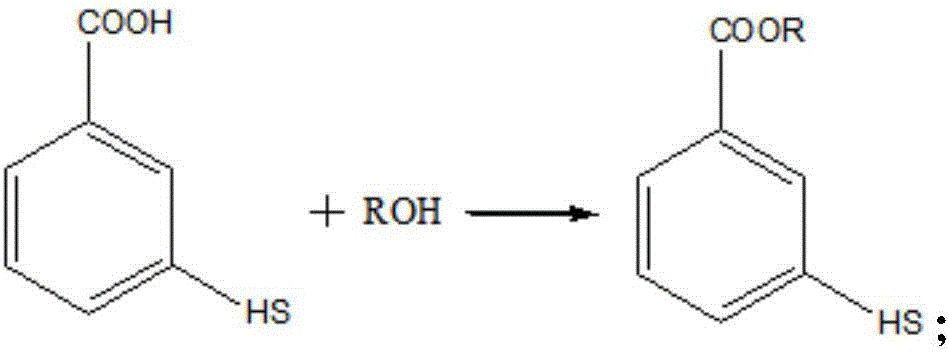

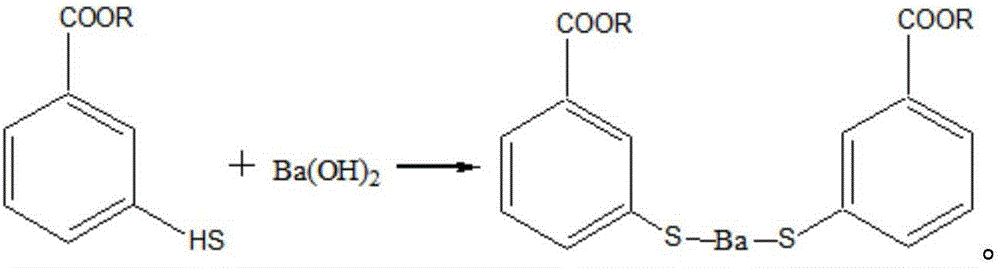

Thiosalicylic acid fatty alcohol ester barium and preparation method, composition and application thereof

The invention relates to thiosalicylic acid fatty alcohol ester barium and a preparation method, composition and application thereof. Thiosalicylic acid fatty alcohol ester barium is synthesized according to the following process routes of 1 an esterification reaction, wherein reacting is continuously conducted for 2.5-3.5 h at the temperature of 105 DEG C to 115 DEG C and the vacuum degree of 0.06 MPa to 0.09 MPa by taking 2-thiosalicylic acid and C8-C22 fatty alcohol as raw materials and taking concentrated sulfuric acid as a catalyst, generated water is removed, then washing is conducted to remove concentrated sulfuric acid, and dewatering is conducted to obtain thiosalicylic acid fatty alcohol ester; 2 a metal saponification reaction, wherein an appropriate amount of solvent-butanediol methyl ether and barium hydroxide is added into the product obtained in the step 1, reacting is conducted for 2.5-3.5 h at the temperature of 105 DEG C to 115 DEG C, and after reacting is finished, dewatering and filtering are conducted. Thiosalicylic acid fatty alcohol ester barium can combine hydrogen chloride separated from PVC to terminate the automatic catalysis effect of hydrogen chloride and generate stable ester by substituting unstable chloride atoms on PVC chains by thiosalicylic acid fatty alcohol ester to prevent thermal decomposition of hydrogen chloride; thiosalicylic acid fatty alcohol ester barium belongs to thiolate and has the effects of an antioxidant, and the system stability is improved.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

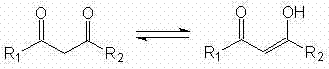

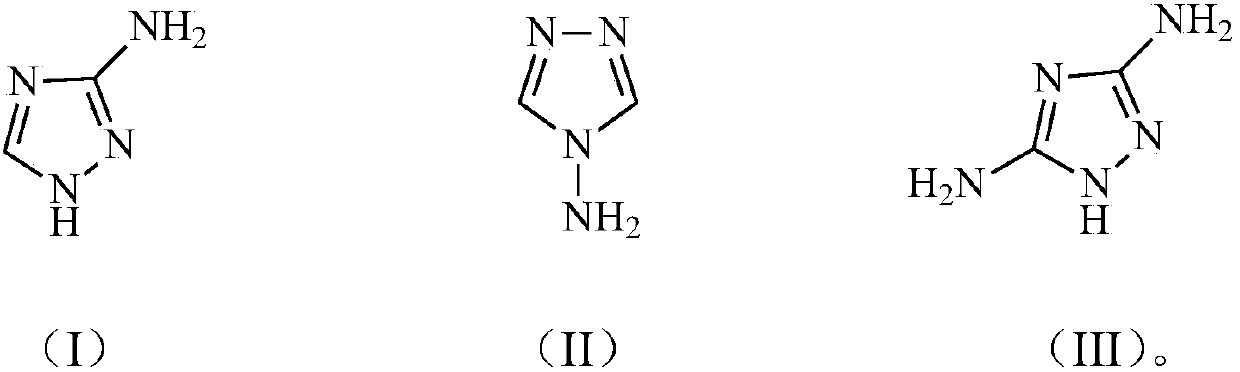

A kind of triazole-based composite heat stabilizer for pvc

The invention discloses a triazolyl / zinc composite thermal stabilizer for PVC (Polyvinyl Chloride). The triazolyl / zinc composite thermal stabilizer for PVC is characterized by consisting of a main stabilizer and an auxiliary thermal stabilizer, wherein the main stabilizer is a triazolyl compound and zinc stearate; the auxiliary thermal stabilizer is one or a mixture of polyhydric alcohols, beta-diketone, epoxy compounds and long-chain fatty acid; the main stabilizer accounts for 40.0-80% by mass; the auxiliary thermal stabilizer accounts for 20-60% by mass; the main stabilizer comprises the following components in parts by mass: 10.0-70.0 parts of the triazolyl compound, and 30.0-90.0 parts of the zinc stearate; the auxiliary thermal stabilizer comprises the following components in parts by mass: 20.0-40.0 parts of the polyhydric alcohols, 20.0-40.0 parts of the beta-diketone, 30.0-50.0 parts of the epoxy compounds and 10.0-20.0 parts of the long-chain fatty acid. The triazolyl / zinc composite thermal stabilizer disclosed by the invention is capable of effectively inhibiting zinc burning, improving the thermal stability of PVC and can be widely applied to the field of PVC processing.

Owner:ZHEJIANG UNIV OF TECH

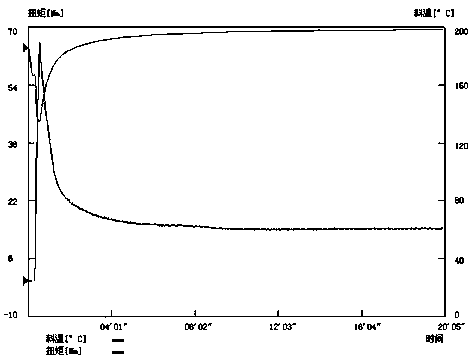

Magnesium-aluminum-zinc modified non-toxic compound stabilizing agent for PVC (Polyvinyl Chloride) pipe fitting injection molding

The invention relates to a magnesium-aluminum-zinc modified non-toxic compound stabilizing agent for PVC (Polyvinyl Chloride) pipe fitting injection molding. The stabilizing agent disclosed by the invention is formed by the following raw materials in a weight ratio: a fatty acid calcium zinc composition, calcium stearate, an antioxidant 1076, acetylacetone calcium or acetylacetone magnesium, hydrotalcite, dehydroacetic acid or sodium dehydroacetate, stearoylbenzoylmethane, macromolecular ester-group calcium, calcium carbonate or talcum powder. The stabilizing agent disclosed by the invention is used for injection molding of a pipe fitting, has good whiteness, excellent stabilizing effect, smooth machining and good plastifying performance, and can realize continuous machining; inner and outer surfaces of the machined pipe fitting are smooth and the mechanical property meets various international requirements; the stabilizing agent is non-toxic and environment-friendly; and the fatty acid calcium zinc composition and the macromolecular ester-group calcium are added into a formula to improve the product compatibility, the machining stability, long-period stability and the like, so that the product has the good comprehensive performance.

Owner:广东森德利环保新材料科技有限公司

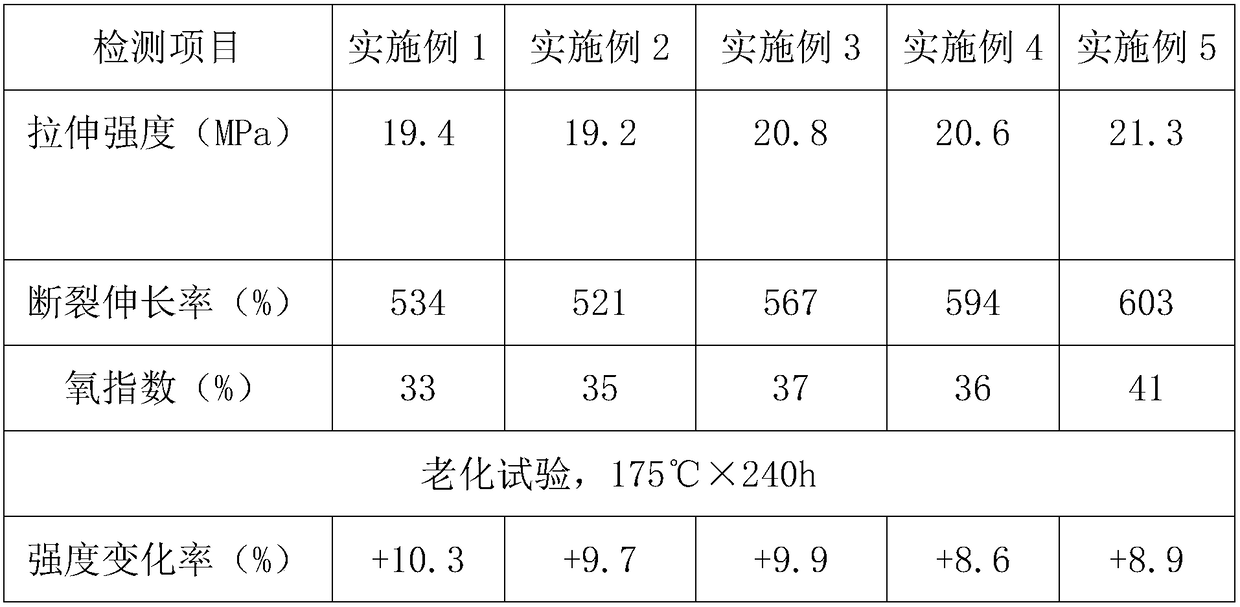

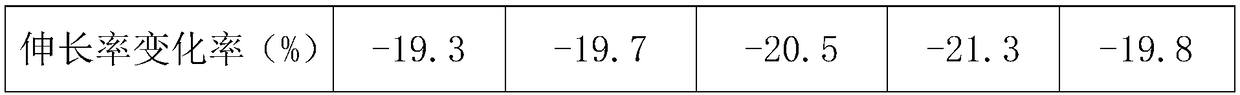

Heatproof flame-retardant locomotive cable

InactiveCN108690280AImprove heat resistanceHigh tensile strengthPlastic/resin/waxes insulatorsPolyesterPolyvinyl chloride

The invention discloses a heatproof flame-retardant locomotive cable, which comprises a core and a sheath that wraps the core. The sheath comprises following components in parts by weight: 100 to 150parts of polyvinyl chloride, 30 to 60 parts of nitrile rubber, 5 to 25 parts of polyester type thermoplastic polyurethane elastomer, 3 to 15 parts of polyamide acid, 3 to 7 parts of zinc oxide, 0.3 to1.2 parts of stearic acid, 0.9 to 2 parts of sulfur, 6 to 15 parts of pentaerythritol, 5 to 15 parts of ammonium polyphosphate, 10 to 15 parts of melamine, 5 to 20 parts of titanium dioxide, 2 to 10parts of zinc hydroxyl stannate coated magnesium hydroxide, 3 to 12 parts of nano silicon dioxide, 3 to 15 parts of nano calcium carbonate, 1 to 5 parts of ammonium octamolybdate, 2 to 5 parts of zincnaphthenate, 1 to 4 parts of calcium stearate, 2 to 5 parts of 1-phenyl-3-methyl-5-pyrazolone, and 2 to 7 parts of sorbitol. The provided heatproof flame-retardant locomotive cable has the advantagesof excellent heatproof and flame-retardant properties, and high strength.

Owner:ANHUI ELECTRIC GRP SHARES

Method for producing super-white polyvinyl chloride resin through vinyl chloride suspension polymerization after-treatment

The invention relates to a production method of super-white polyvinyl chloride resin, and particularly relates to a method for producing super-white polyvinyl chloride resin through vinyl chloride suspension polymerization after-treatment. The method comprises the following steps of preparing a whitening assistant from the following raw materials in parts by weight: 12-18 parts of ethanol, 1-3 parts of liquid carbolic acid, 4-8 parts of a blue pigment substance and 400-600 parts of deionized water; dispersing and diluting the whitening assistant by using the deionized water; and adding the product to slurry polymerized by polyvinyl chloride, stirring evenly, centrifuging and drying to prepare a super-white polyvinyl chloride resin product. Compared with the prior art, the method has the advantages that the whitening effect is good; the whitening efficiency is high; the whitening assistant is a water-soluble high-dispersion solution and a blue pigment molecule is adsorbed by resin particle fold, so that the yellowing phenomenon is eliminated under the blue light-yellow light complementary action; the pigment molecule is fully dispersed in the slurry, so that the coloring efficiency is greatly improved; and the later resin downstream processing cost is reduced.

Owner:TANGSHAN SANYOU CHLOR ALKALI

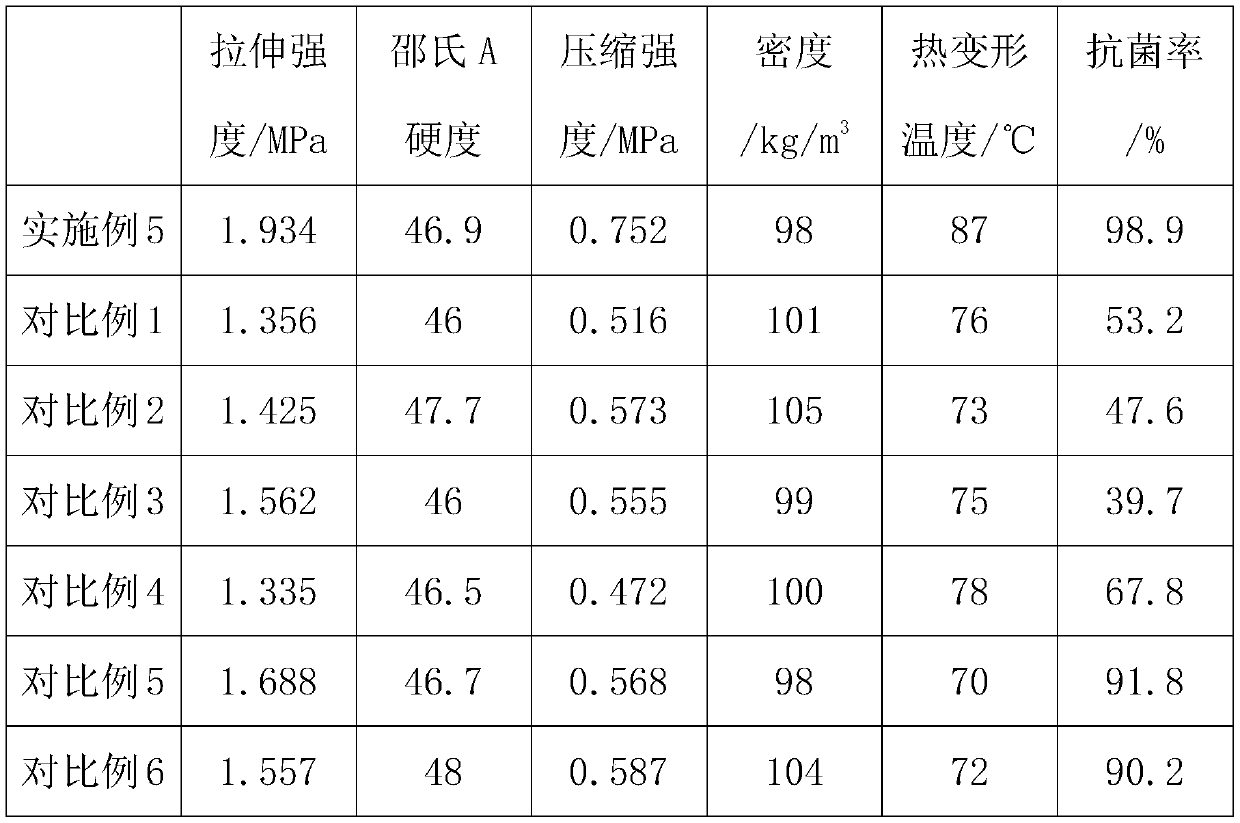

Antibacterial heat-resistant polyvinyl chloride wall-protecting plate

The invention discloses an antibacterial heat-resistant polyvinyl chloride wall-protecting plate. The wall protecting plate comprises the following raw materials, in parts by weight: 55-80 parts of polyvinyl chloride, 11-23 parts of a vinyl chloride-vinyl acetate copolymer, 5-13 parts of polypropylene, 3-8 parts of chlorinated polyethylene, 3-6 parts of a nano titanium dioxide complex, 0.3-1.5 parts of activated clay, 1-2 parts of hydrotalcite, 0.5-2 parts of nano montmorillonite, 2-3 parts of a composite foaming agent, 0.2-1.1 parts of 1-phenyl-3-methyl-5-pyrazolone, 1-2 parts of zinc stearate, 1-2 parts of calcium adipate, 0.1-0.25 part of sorbitol, 0.53-2.7 parts of cinnamaldehyde barbituric acid, 0.1-0.3 part of a lubricant, 0.1-0.32 part of methyl silicone oil, and 1-3 parts of dibutyl phthalate. The antibacterial heat-resistant polyvinyl chloride wall-protecting plate provided by the invention has good heat resistance and excellent antibacterial properties.

Owner:安徽优丽普科技有限公司

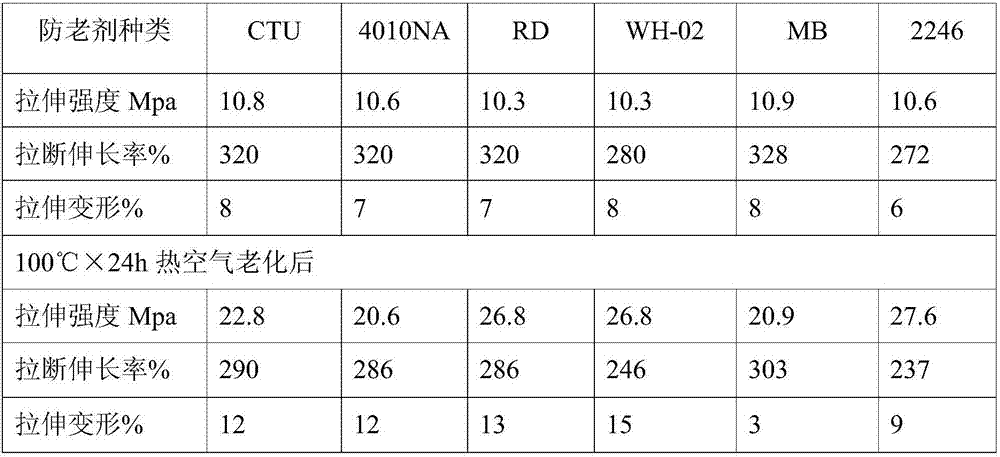

Environment-friendly and oil-resistant rubber for sealing

InactiveCN107353454AImprove performanceMeet environmental health requirementsOther chemical processesAcrylic resinPolystyrene

The invention discloses environment-friendly and oil-resistant rubber for sealing. The rubber is prepared from raw materials in parts by mass as follows: 50-70 parts of nitrile rubber, 8-15 parts of a stabilizer, 20-50 parts of modified chloroprene rubber, 20-30 parts of carbon black, 8-12 parts of polystyrene, 1-1.5 parts of a vulcanizing agent, 15-20 parts of an additive, 3-4 parts of stearic acid, 5-10 parts of zinc oxide, 12-18 parts of magnesium oxide, 10-14 parts of an anti-ageing agent, 20-30 parts of paraffin and 4-5 parts of an aid. In combination with the characteristics of nitrile rubber and modified chloroprene rubber, the rubber not only has the characteristics of good oil resistance, higher wear resistance and better heat resistance, but also has high initial adhesive force and bonding strength, flexible adhesive layer, good elasticity, impact resistance and vibration resistance; the proportion of the vulcanizing agent is reduced, so that environmental protection and no pollution are realized; the additive prepared from cyanate ester resin, acrylic resin, sodium tripolyphosphate and kaolin in a specific ratio is added, and accordingly, the air tightness of the rubber is improved.

Owner:四川省蓝扬科技有限公司

Toughened heat resistant type environmentally-friendly efficient compound stabilizer and preparation technology

The invention discloses a toughened heat resistant type environmentally-friendly efficient compound stabilizer and a preparation technology, and relates to the field of the compound stabilizer. The toughened heat resistant type environmentally-friendly efficient compound stabilizer is prepared from the following components in percentage by weight: 30-40% of zinc stearate, 5-15% of calcium stearate, 1-3% of diphenyl formyl methane, 2-8% of polyhydric alcohols, 2-8% of hydrotalcite, 2-8% of phosphite ester, 4-18% of zeolite, 1-3% of antioxidant, 2-8% of methyl methacrylate, 2-8% of butadiene-acrylonitrile glue and 10-20% of Fischer Tropsch wax. The toughened heat resistant type environmentally-friendly efficient compound stabilizer has the beneficial effects that the stability and anti-impact tensile strength of PVC (polyvinyl chloride) are improved by utilizing the synergistic effect and complementary effect of multiple organic matters, and meanwhile the two large problems of poor temperature tolerance and low modified efficiency of the PVC product are solved; the additive amount of the compound stabilizer is one half of the additive amount of similar products, but the effect of the compound stabilizer exceeds the effect of the similar products by 20%, so that the two problems are solved by one kind of product; the comprehensive cost of the product is reduced; the preparation technology is simple and easy to operate; and the production efficiency is improved.

Owner:李宝兴

Environment-friendly stabilizer with low processing temperature and simplicity in plasticization for wires and cables

The invention discloses an environment-friendly stabilizer with low processing temperature and simplicity in plasticization for wires and cables. The stabilizer is prepared from the following components by weight: 45-220kg of a fatty acid calcium-zinc composition, 10-100kg of calcium stearate, 1-10kg of an antioxidant 1076, 3-21kg of stearoylbenzoylmethane, 30-100kg of hydrotalcite, 5-120kg of 2-oxazolidinone and 20-200kg of inorganic hydroxides. The stabilizer disclosed by the invention is used for manufacturing wire and cable colloidal particles, the processing temperature of the stabilizer is 20-30 DEG C lower than that of a compound lead stabilizer, the temperature of each section can be controlled to be 120-130 DEG C for a conical twin-screw extruder, and the energy can be saved; the colloidal particles are good in plasticization, and the wire surface is bright; and moreover, the produced colloidal particle Congo red time is longer than or equal to 60 minutes, and the product is excellent in humidity resistance, particularly is not separated out on a black wire, is good in flowing property and suitable for highly filling wires and also can be applied to medium / low-temperature wires specified in GB8815.

Owner:广东森德利环保新材料科技有限公司

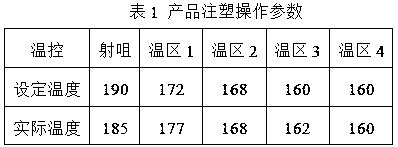

Magnesium-aluminum-zinc modified non-toxic composite environment-friendly stabilizer for U-PVC transparent injection molded part product

The invention relates to a magnesium-aluminum-zinc modified non-toxic composite environment-friendly stabilizer for a U-PVC transparent injection molded part product. The stabilizer is composed of 169-420 kg of fatty acid calcium-zinc composition, 150-280 kg of magnesium-aluminum-zinc composition, 20-87 kg of antioxidant 1076, 0-150 kg of hydrotalcite, 28-40 kg of dehydroacetic acid or sodium dehydroacetate, 24-49 kg of stearoyl benzoyl methane and 261-445 kg of high-molecular ester base calcium. The stabilizer is used for injection molding of the U-PVC transparent injection molded part, and is good in plasticizing effect, good in stabilizing effect, smooth in processing and capable of achieving continuous processing; the inner surface and the outer surface of a processed pipe are smooth,the transparency is high, the mechanical property meets various requirements of the national standard, and the stabilizer is free of toxins and environment-friendly; the magnesium-aluminum-zinc composition and the fatty acid calcium-zinc composition are simultaneously used in the formula, so that the product compatibility, the processing stability and the long-term stability are coordinated and unified, and the product has good comprehensive performance.

Owner:广东森德利环保新材料科技有限公司

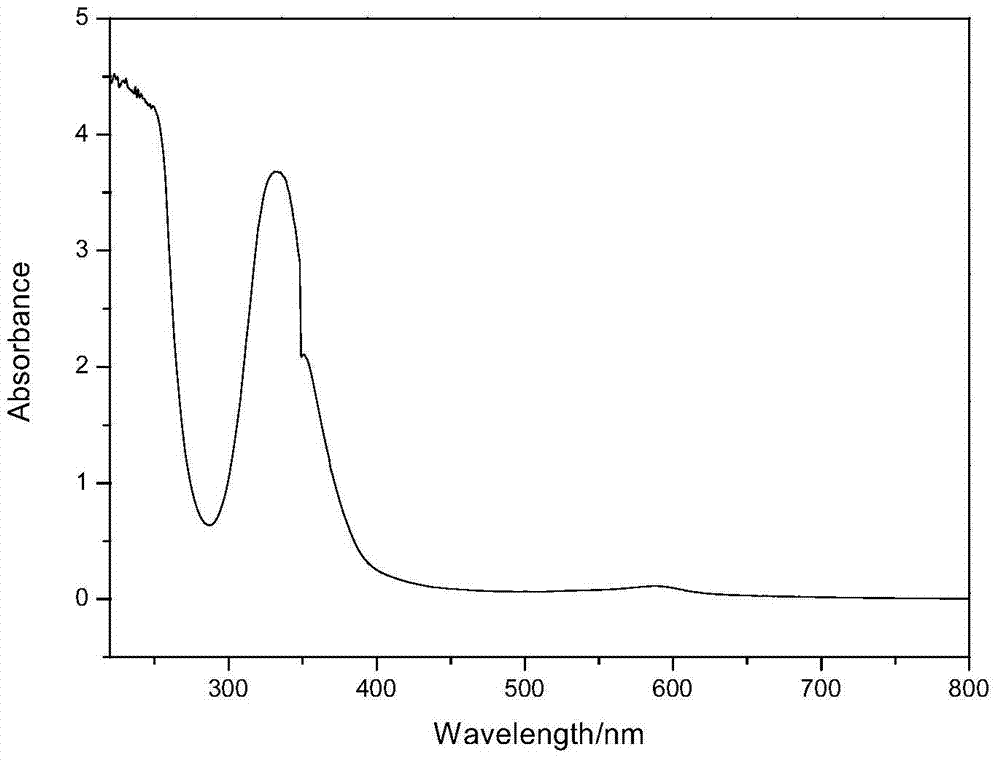

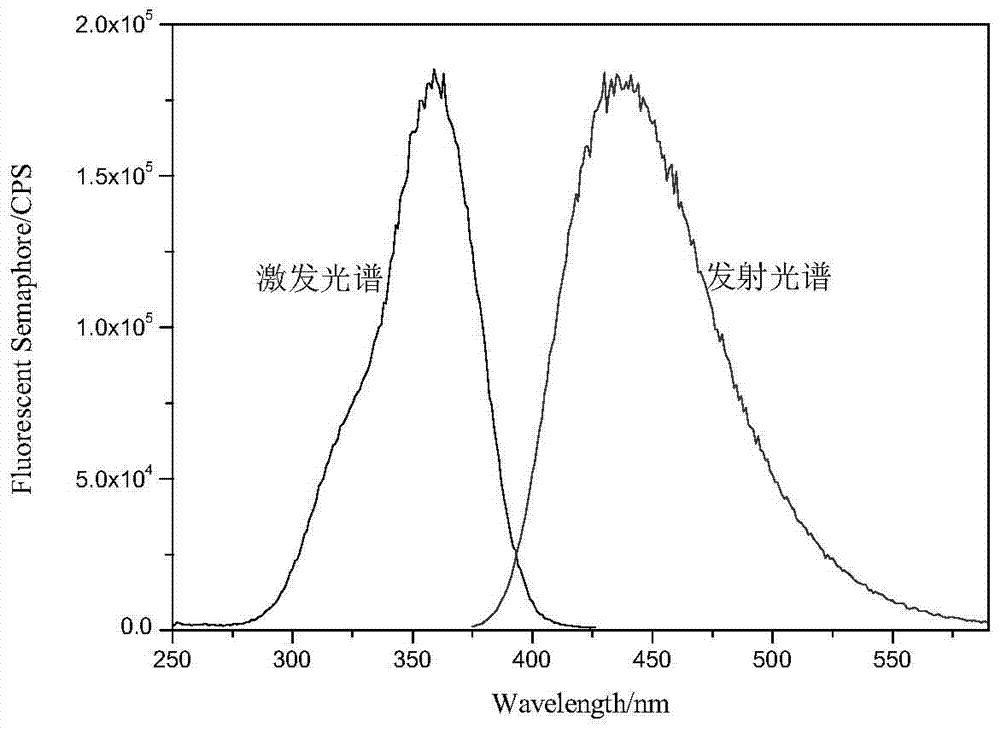

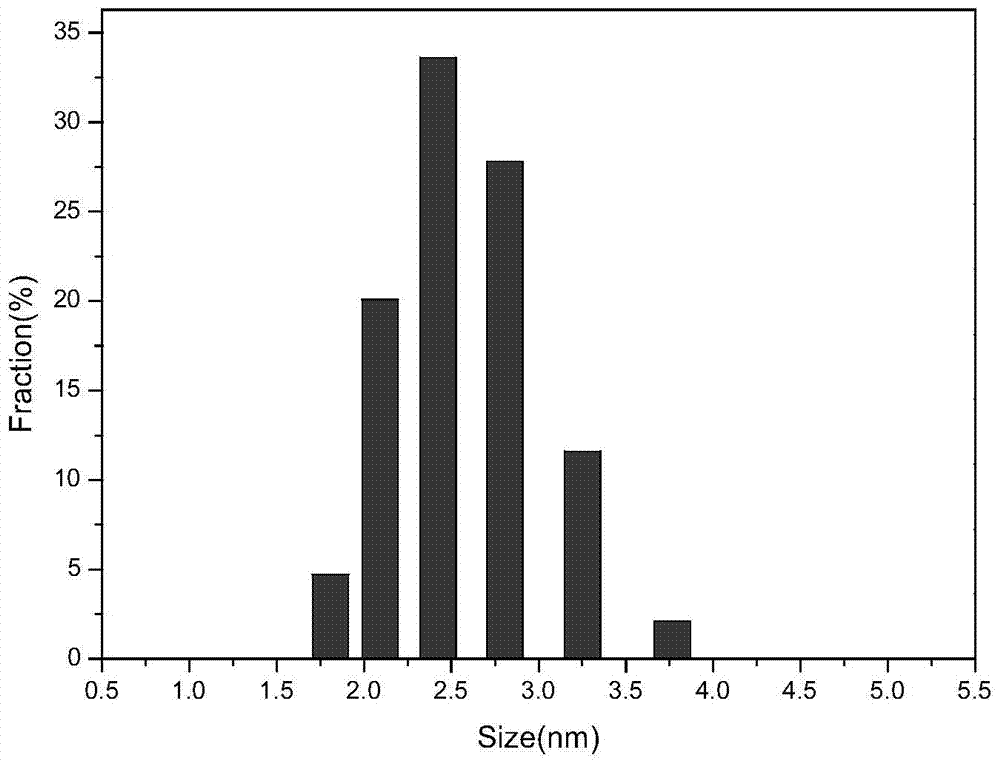

A kind of preparation method and application of carbon quantum dot light stabilizer

ActiveCN105568762BImprove initial whitenessLight colorLuminescent/fluorescent substance additionSolubilityScavenger

The invention discloses a preparation method and application of a carbon quantum dot light stabilizer. Cheap organic carboxylic acid is adopted as a carbon source, piperylhydrazine is adopted as a modifier, and a carbon quantum dot is synthesized and modified to obtain a nitrogen-doped carbon quantum dot containing a radical scavenger fragment by hydrothermal reaction. The prepared carbon quantum dot light stabilizer is light in color and high in water solubility and light fastness, and has broad application prospect, and when the carbon quantum dot light stabilizer is applied to paper pattern coating as a high-yield pulp paper light stabilizer, a result shows that the carbon quantum dot light stabilizer has a certain inhibition effect on light-induced color reversion of paper and the initial whiteness of the paper can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

Efficient anti-precipitation liquid composite heat stabilizer and preparation method thereof

ActiveCN107540875BSolve the problem of short storage timeImprove component compatibilityCarbon numberZinc compounds

The invention relates to a high efficiency anti-precipitation liquid composite heat stabilizer and a preparation method thereof. The composite heat stabilizer is composed of the following raw materials by weight: 40-60 parts of barium carboxylate, 10-18 parts of mercapto zinc, 2-12 parts of an anti-settling agent, 10-35 parts of phosphate ester, 1-10 parts of an antioxidant, and 15-45 parts of a solvent. According to the invention, by adding of the anti-settling agent into the liquid composite heat stabilizer and solvent collocation of different carbon number distributions, the compatibility of all the components in the liquid composite stabilizer system is effectively improved, the storage stability is significantly improved, and the problem of short storage time in existing liquid composite stabilizers is solved. In addition, the mercapto zinc compound is added, the zinc salt contains a thiol structure and has good antioxidant effect, and the activity of mercapto zinc is greater thanthat of ordinary zinc carboxylate, can absorb allyl chloride more rapidly, and significantly improve the early whiteness of the product.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com