Zinc-based heat stabilizer, preparation method thereof and heat stabilizer compound

A heat stabilizer and auxiliary heat stabilizer technology, applied in the field of zinc-based heat stabilizer, its preparation method and heat stabilizer compound, can solve the problem of good initial whiteness, achieve low cost, synthesis and compounding process The effect of simplicity, excellent initial thermal stability and long-term thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

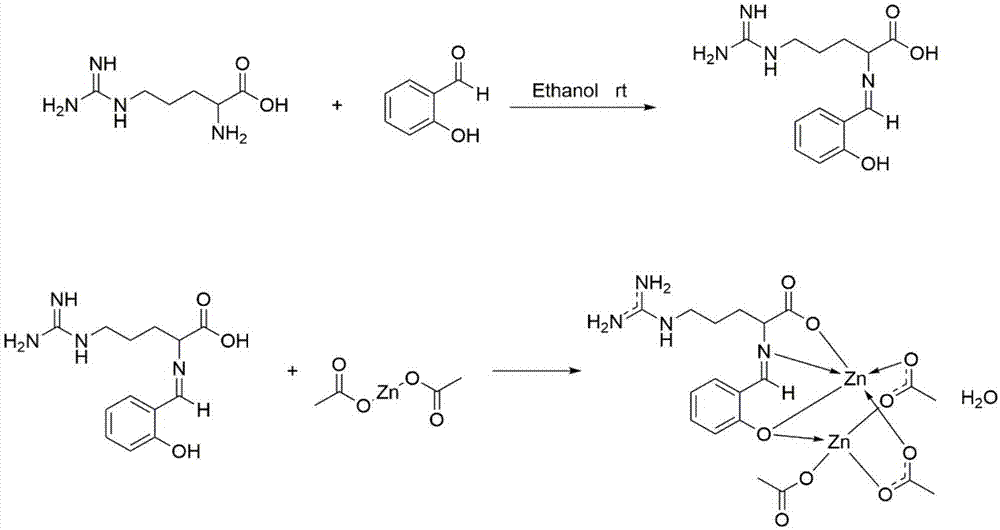

[0035] In a preferred embodiment, the preparation method of the zinc-based heat stabilizer comprises:

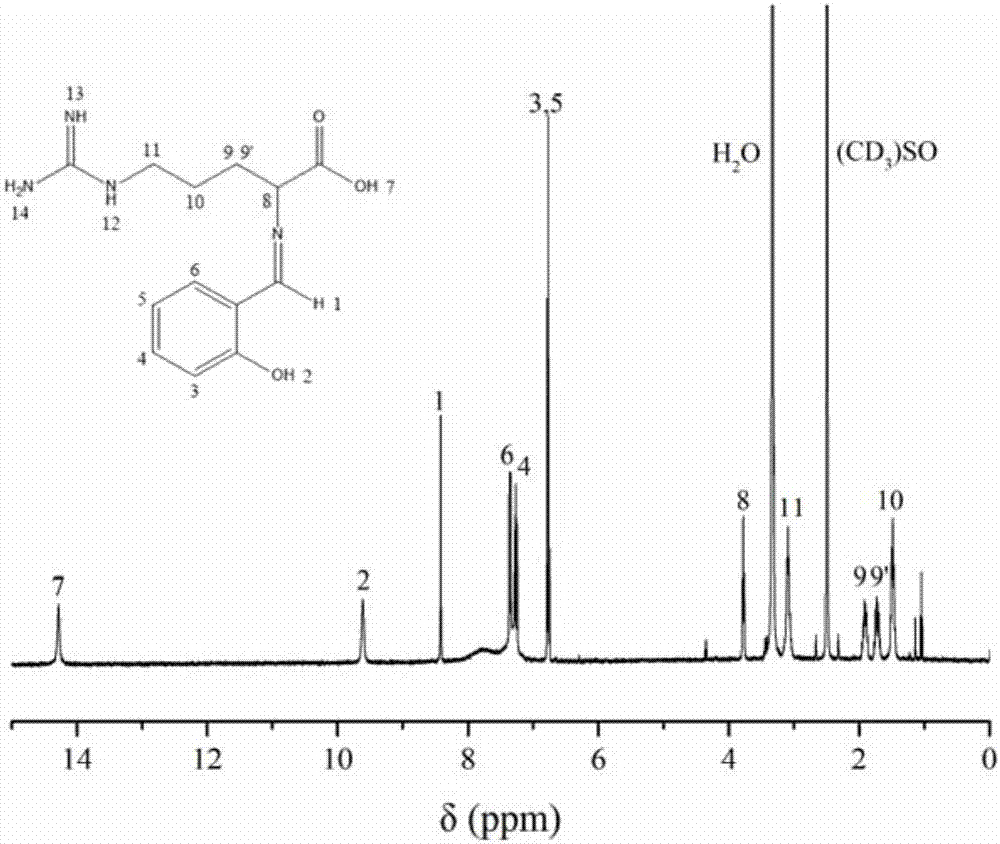

[0036] Step 1: Add the dehydrated ethanol solution dissolved with salicylaldehyde into the dehydrated ethanol solution dissolved with arginine, react to obtain a yellow solution, and filter to obtain a yellow powder solid H 2 L;

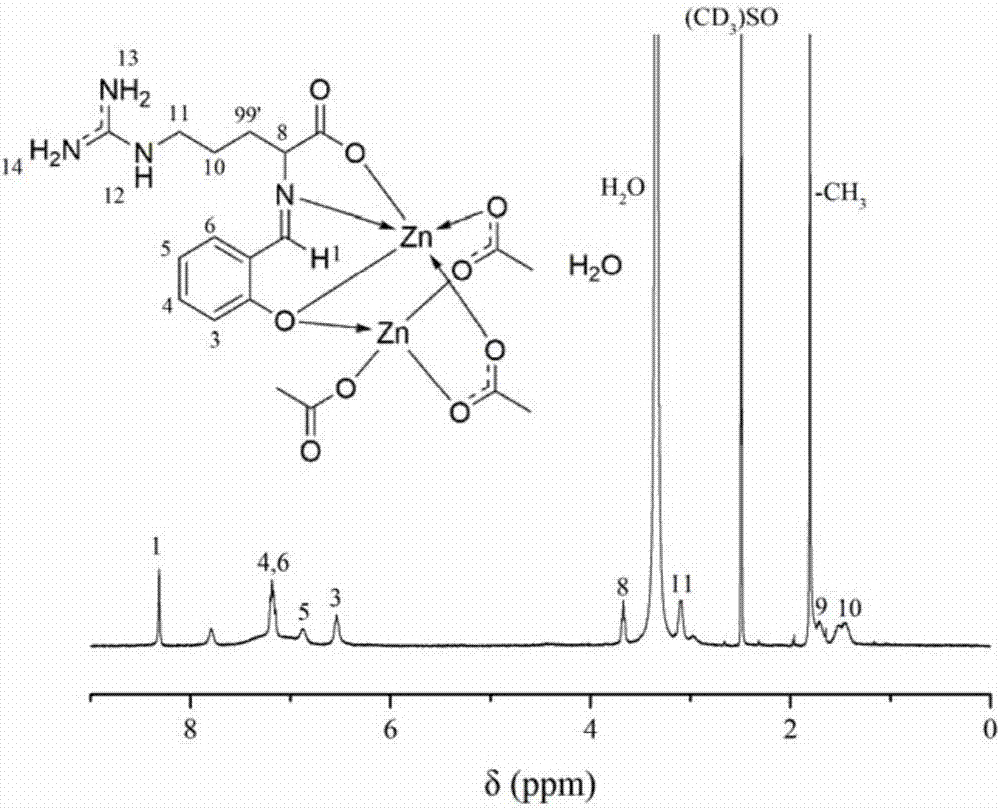

[0037] Step 2: Put H 2 L was dissolved in anhydrous methanol, anhydrous zinc acetate was added, stirred and reacted, filtered and dried to obtain Zn 2 (HL)(CH 3 COO) 3 ·xH 2 O(x=0~1.0).

[0038] In a more preferred specific embodiment, the preparation method of the zinc-based heat stabilizer may comprise the following steps:

[0039] Step 1. Dissolve 1.22g of salicylaldehyde in 25.00ml of absolute ethanol in a constant pressure funnel, drop it into 125.00ml of arginine-dissolved absolute ethanol solution at room temperature at a rate of 50.00ml / h, and then React at room temperature for 4-5h to obtain a yellow solution, and filter at room tempe...

example 1

[0060] 100.00g PVC resin, 10.00g tributyl citrate (TBC) and 3.00g Zn 2 (HL)(CH 3 COO) 3 ·xH 2 The mixture of O(x=0) prepared PVC samples according to the above PVC sample preparation method, and tested the thermal stability and anti-ultraviolet aging performance according to the above test standards. The specific results are shown in Table 1.

example 2

[0062] Mixing formula: 100.00g PVC resin, 10.00g tributyl citrate (TBC) and 3.00g compound heat stabilizer (ie heat stabilizer compound). Prepare PVC sample, test method and data list with example 1. Among them, the composite heat stabilizer contains: 1.20g Zn 2 (HL)(CH 3 COO) 3 ·xH 2 O(x=0), 1.20g ZnSt 2 , 0.60g PER.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com