Non-toxic environment-friendly stabilizer auxiliary agent and preparation method thereof

A stabilizer additive, non-toxic and environmentally friendly technology, which is applied in the field of stabilizer additives, can solve the problems of poor weather resistance in addition, and achieve the effects of improving weather resistance, stability, and precipitation prevention in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0029] Preparation of modified molecular sieve:

[0030] Weigh 300g of 4A type molecular sieve and place it in a muffle furnace for high-temperature dehydration treatment. The temperature is 255±5°C, keep it for 2 hours, take out the heat-treated molecular sieve, weigh 150g, 20g of phenyldiisooctyl phosphite and 20g of pentaerythritol. , mixed in a high-speed mixer, kept for 5 minutes, taken out, ground, and sieved to obtain a white powder modified molecular sieve.

[0031] The preparation of the new molecular sieve non-toxic and environmentally friendly stabilizer auxiliary is as follows:

[0032] In the high-speed mixer, add calcium acetylacetonate and heat up to 75±5°C, continue to add modified molecular sieve at 110°C and keep stirring, add chelating agent and coupling agent, and after stirring evenly, release the material to obtain the product.

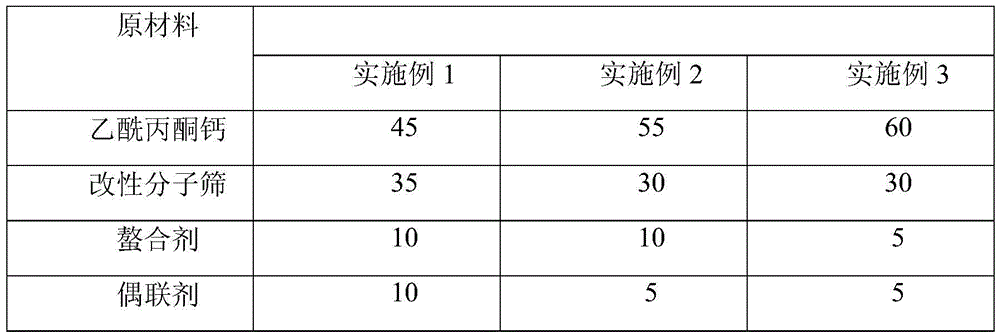

[0033] The formulations of the raw materials of Examples 1 to 3 are shown in Table 1.

[0034] The formula of each raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com