Preparation method for high-brightness calcium acetylacetonate for PVC (Polyvinyl Chloride) heat stabilizer

A heat stabilizer and whiteness acetylation technology, which is applied in the field of preparation of high whiteness calcium acetylacetonate, can solve the problems of bubbles in PVC products, and the production of high whiteness calcium acetylacetonate has not been seen, and achieves low cost and high cost performance , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

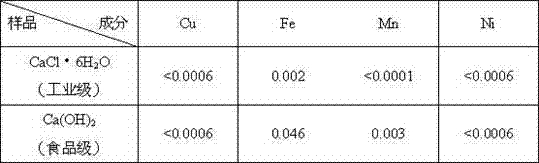

[0045] 220g CaCl 2 ·6H 2 O was placed in a 500ml beaker and dissolved in 150ml deionized water. Filter the solution with qualitative filter paper, transfer the clear liquid into a 500ml flask, and adjust the pH value to 2.0 with 1M hydrochloric acid. Slowly add 10ml of commercially available chlorine bleach (bleach water) while stirring within 10 minutes, and then slowly heat up to 80°C , continue to insulate and stir for 1h. Add a small amount of milk of lime to adjust the pH of the solution to 7.0. Filter to obtain a colorless and transparent calcium chloride solution.

Embodiment 2

[0047] 220g CaCl 2 ·6H 2 O was placed in a 500ml beaker and dissolved in 150ml deionized water. The solution was filtered with qualitative filter paper, the clear liquid was transferred to a 500ml flask, and the pH value was adjusted to 5.0 with 1M hydrochloric acid. Raise the temperature to 80°C, add the calculated amount of dilute potassium permanganate solution dropwise while stirring, the solution will first turn reddish and then disappear within a short time at the end of the dropwise addition. Add a small amount of milk of lime to adjust the pH of the solution to 7.0. Filter to obtain a colorless and transparent calcium chloride solution.

Embodiment 3

[0049] 220g CaCl 2 ·6H 2 O was placed in a 500ml beaker and dissolved in 150ml deionized water. Filter the solution with qualitative filter paper, transfer the clear liquid into a 500ml flask, and adjust the pH value to 3.0 with 1M hydrochloric acid. Slowly add 10ml of 30% hydrogen peroxide dropwise while stirring within 10 minutes, then slowly raise the temperature to 80°C, and continue to keep warm Stir for 1h. Add a small amount of milk of lime to adjust the pH of the solution to 7.0. Add 3g magnesium hexasilicate (2MgO 6SiO 2 ·xH 2 O), and stirred for 1 h. Filter through qualitative filter paper to obtain a colorless and transparent calcium chloride solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com