Environment-friendly stabilizer with low processing temperature and simplicity in plasticization for wires and cables

A technology of environmental protection stabilizer and processing temperature, which is applied in the field of PVC production stabilizer, can solve the problems of cost increase and environmental protection stabilizer difficult to meet the requirements, and achieve energy saving, good stabilization effect and bright wire surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

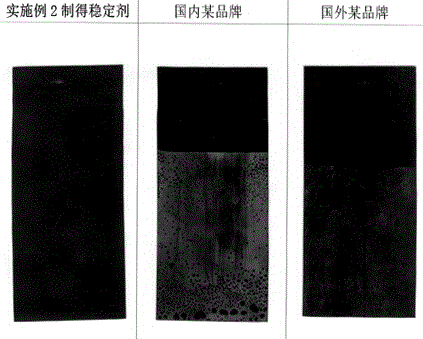

Image

Examples

Embodiment 1

[0026] Embodiment 1 adopts following formula to prepare a kind of environment-friendly stabilizer for wire and cable with low processing temperature and easy plasticization: fatty acid calcium zinc composition 50kg, calcium stearate 20kg, antioxidant 1076 2kg, stearyl benzoylmethane 4kg , hydrotalcite 37.5kg, 2-oxazolidinone 61.5kg, calcium hydroxide 46.5kg; Adopt the following steps to prepare:

[0027] (1) Put each component into a high-speed mixer after weighing, and raise the temperature of the material to 65°C under high-speed stirring.

[0028] (2) Stir and cool in a cooling cylinder. When the temperature drops below 40°C, pack into bags to obtain a finished stabilizer.

[0029] Among them, the fatty acid calcium zinc composition is prepared according to the patent ZL201210258546.8:

[0030] (1) Put 1500kg of lauric acid and 350kg of 12-hydroxystearic acid into the reactor and heat;

[0031] (2) When heated to 120°C, add 18kg of adipic acid into the reactor, and slowly...

Embodiment 2

[0034] Embodiment 2 adopts following formula to prepare a kind of environment-friendly stabilizer for wire and cable with low processing temperature and easy plasticization: fatty acid calcium zinc composition 55kg, calcium stearate 12.5kg, antioxidant 1076 2kg, stearyl benzoylmethane 5.5kg, hydrotalcite 48kg, 2-oxazolidinone 9.8kg, magnesium hydroxide 21kg; adopt the following steps to prepare:

[0035] (1) Weigh each component and put it into a high-speed mixer, and raise the temperature of the material to 65°C under high-speed stirring;

[0036] (2) Put the material into the cold cylinder to stir and cool it, and when the temperature drops below 40°C, transport it to the horizontal mixer;

[0037] (3) Repeat step (1) and step (2) for 5 times, continue mixing the final mixed material in a horizontal mixer for 30 minutes, pack it into a bag, and obtain a finished stabilizer.

[0038] Among them, the fatty acid calcium zinc composition is prepared according to the patent ZL20...

Embodiment 3

[0043] Embodiment 3 adopts following formula to prepare a kind of environmental protection stabilizer for electric wire and cable that low processing temperature is easy to plasticize: embodiment 1 makes fatty acid calcium zinc composition 120kg, calcium stearate 70kg, antioxidant 1076 5kg, stearyl Benzoylmethane 15kg, hydrotalcite 80kg, 2-oxazolidinone 67kg, calcium hydroxide and magnesium hydroxide are prepared according to the mass ratio of 1:1 mixture 200kg; adopt the following steps to prepare:

[0044] (1) Weigh each component and put it into a high-speed mixer, and raise the temperature of the material to 65°C under high-speed stirring;

[0045] (2) Put the material into the cold cylinder to stir and cool it, and when the temperature drops below 40°C, transport it to the horizontal mixer;

[0046](3) Repeat step (1) and step (2) for 3 times, continue mixing the final mixed material in a horizontal mixer for 30 minutes, pack it into a bag, and obtain a finished stabilize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com