Flame-retardant blister PC/ABS alloy material as well as preparation method and application thereof

A technology of alloy materials and phosphazene flame retardants, which is applied in the field of flame-retardant plastic-absorbing PC/ABS alloy materials and their preparation, can solve the problems of not being able to satisfy high plastic absorption and high saturation at the same time, and achieve easy processing and improved The effect of uniformity and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

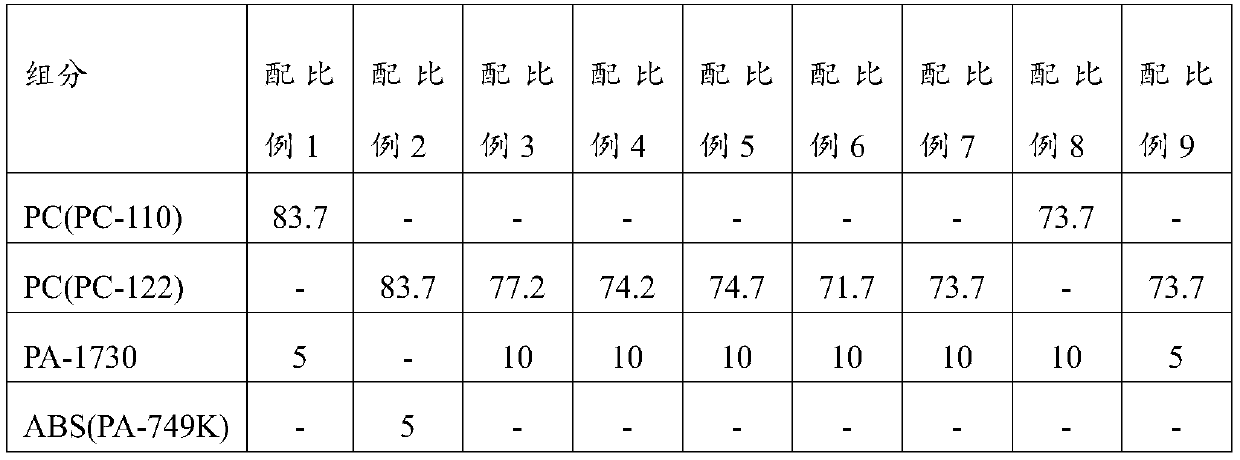

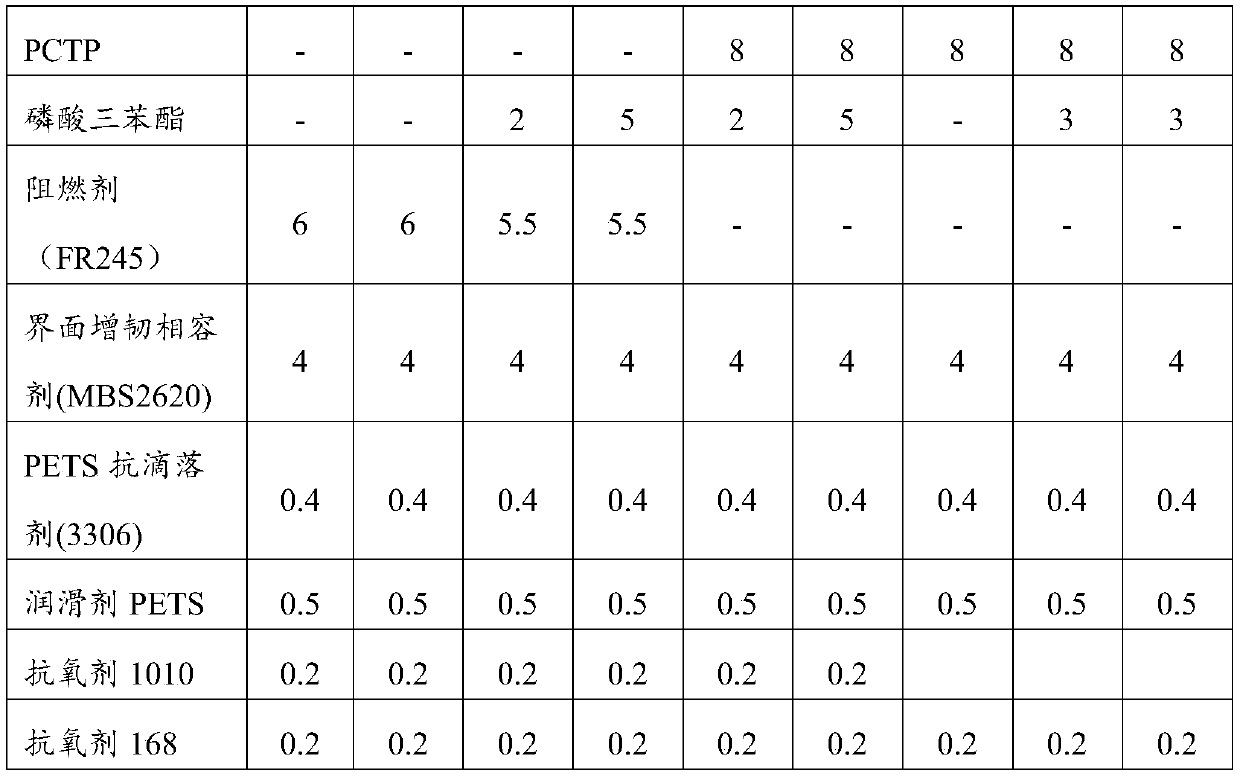

Examples

preparation example Construction

[0031] The present invention provides a method for preparing the flame-retardant plastic-absorbing PC / ABS alloy material described in the above scheme, comprising the following steps:

[0032] 1) Mix and stir PC-122 and PA-1730 to obtain the first mixture;

[0033] 2) mixing and stirring the interface toughening compatibilizer, phosphazene flame retardant, plasticizing flame retardant synergist, anti-dripping agent, lubricant and antioxidant with the first mixture to obtain the total mixture;

[0034] 3) extrude the total mixture of the step 2) into granules, and cool to obtain a flame-retardant plastic-absorbing PC / ABS alloy material.

[0035] In the present invention, PC-122 and PA-1730 are mixed and stirred to obtain the first mixture. In the present invention, the rotational speed of the mixing and stirring is preferably 400-600 r / min, more preferably 500 r / min; the mixing and stirring time is preferably 3-5 minutes, more preferably 4 minutes.

[0036]After obtaining the...

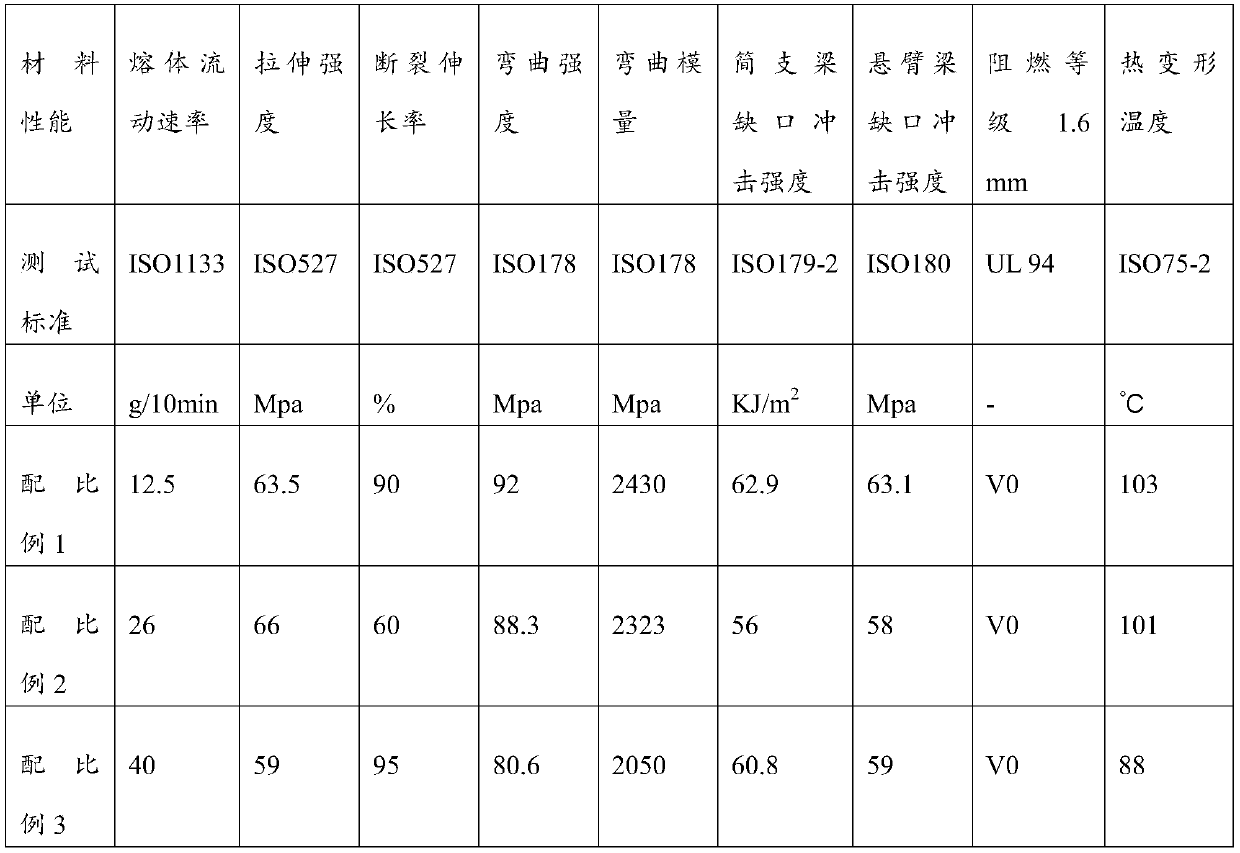

Embodiment 1

[0041] 730Kg of PC-122 and 110Kg of PA-1730 were stirred at a speed of 400r / min for 5min to obtain the first mixture.

[0042] 30Kg interface toughening compatibilizer MBS 2620, 90Kg phosphazene flame retardant (PCTP), 25Kg triphenyl phosphate, 5Kg anti-dripping agent (entropy energy 3306), 4.5Kg lubricant (Tianjin Lianlong PETS) and 2.5 Kg antioxidant (Tianjin Lianlong 168) and the first mixture were mixed and stirred for 3min at a rotating speed of 2500r / min to obtain the total mixture;

[0043] The total mixture was extruded and granulated by a co-rotating twin-screw extruder (rotating speed 300r / min, temperature 265°C), and cooled in a water tank to obtain a flame-retardant and plastic-absorbing PC / ABS alloy material.

Embodiment 2

[0045] 740Kg of PC-122 and 90Kg of PA-1730 were stirred at a speed of 600r / min for 3min to obtain the first mixture.

[0046] 50Kg interface toughening compatibilizer MBS 2620, 70Kg phosphazene flame retardant (PCTP), 35Kg triphenyl phosphate, 3Kg anti-dripping agent (entropy energy 3306), 5.5Kg lubricant (Tianjin Lianlong PETS) and 1.5 Kg antioxidant (Tianjin Lianlong 168) and the first mixture were mixed and stirred for 2min at a rotating speed of 3500r / min to obtain the total mixture;

[0047] The total mixture was extruded and granulated by a co-rotating twin-screw extruder (rotating speed 400r / min, temperature 240°C), and cooled in a water tank to obtain a flame-retardant and plastic-absorbing PC / ABS alloy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com