Pre-stress constraint concrete structure and manufacture method thereof

A technology for constraining concrete and concrete structures, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of unsatisfactory use effect of concrete structures, poor overall bearing capacity, overall rigidity and overall seismic capacity of concrete structures, etc. Achieve the effect of improving lateral stiffness and integrity, improving bearing capacity and seismic performance, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

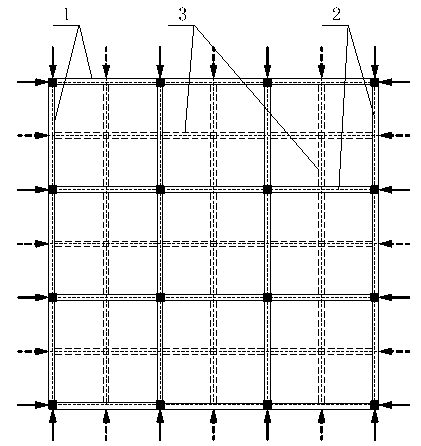

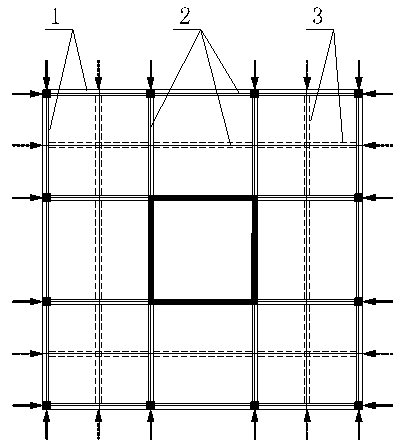

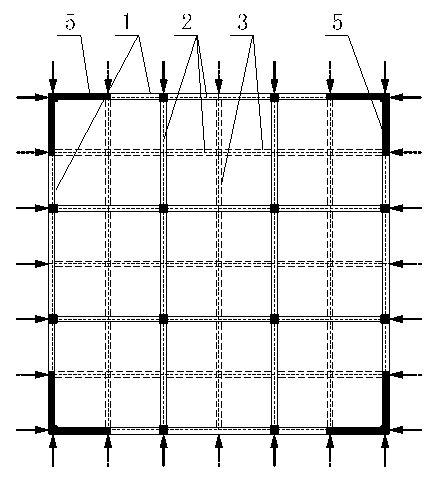

[0023] Embodiments of the present invention: when making a concrete structure, make it according to the technical scheme of a kind of prestressed restrained concrete structure and its manufacturing method of the present invention, that is, when making a concrete frame structure, a concrete frame tube structure, a concrete frame shear structure or When the concrete truss tube structure is used for these four types of concrete structures, except for the main beam 1 structural part in the concrete structure, other structural parts in the concrete structure can be manufactured according to the existing reinforced concrete structure; When the main beam 1 is used, all the main beams 1 are provided with prestressed tendons 2 parallel to the central axis of the main beam 1, preferably the prestressed tendons 2 are arranged along the central axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com