Degradable thin film with waterproof and moisture permeable function

A degradable film, waterproof and moisture-permeable technology, which is applied in the field of textile fabrics, can solve the problems of easy hydrolysis, imperviousness to water washing, difficulty in anti-dermis, and resistance to acid and alkali erosion, etc., to achieve excellent resistance to ultraviolet radiation, improve moisture permeability, The effect of excellent windability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

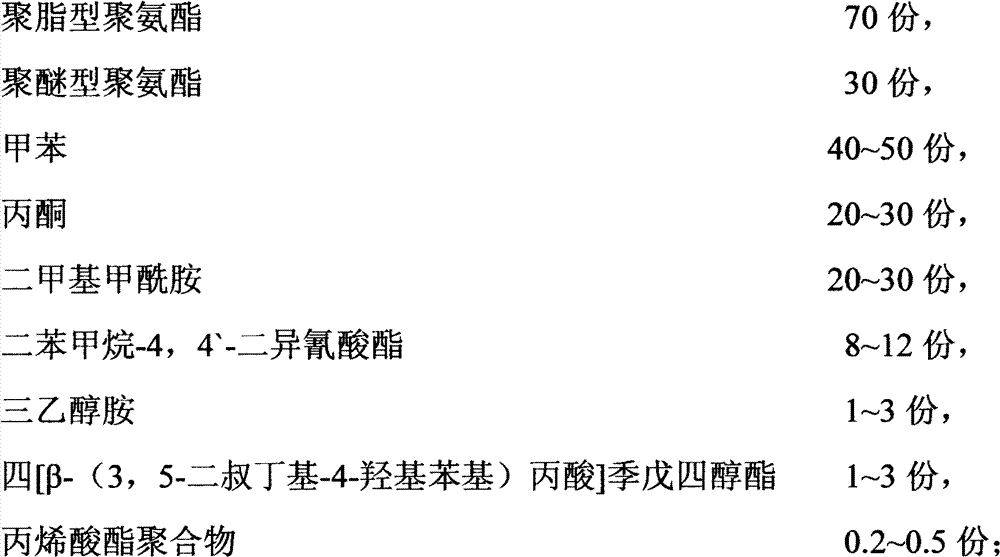

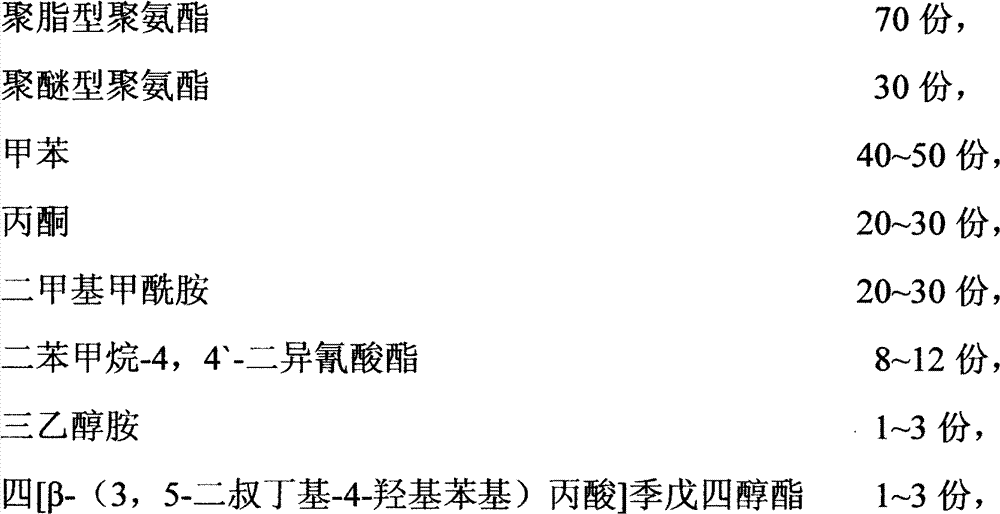

[0021] Embodiment: A degradable film with waterproof and moisture-permeable function, the degradable film is obtained by drying the slurry emulsion, and the slurry emulsion is composed of the following components by weight:

[0022]

[0023]

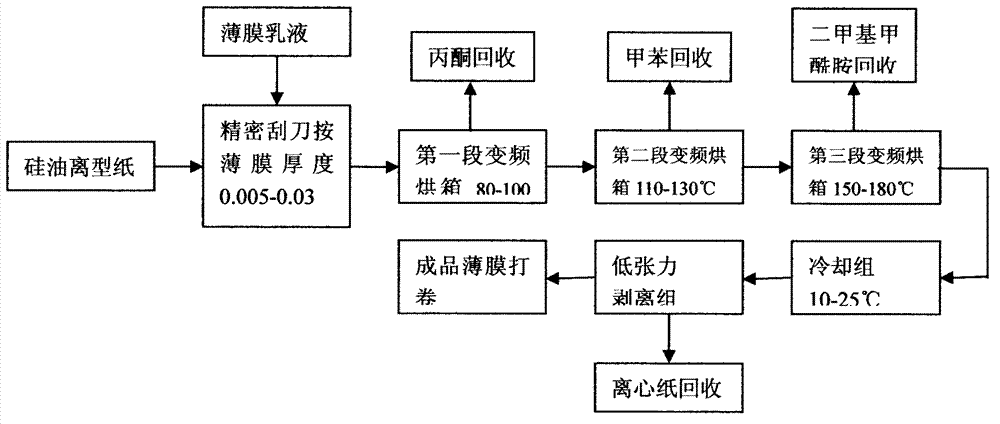

[0024] The slurry emulsion forms the degradable film through the following processes, including:

[0025] Step 1, the slurry emulsion is coated on the surface of silicone oil release paper by a scraper,

[0026] Step 2: Carry out the first-stage drying under the condition of 80-100°C and low-speed air flow,

[0027] Step 3: Carry out the second-stage drying under the condition of 110-130°C and low-speed air flow,

[0028] Step 4: Carry out the third-stage drying under the condition of 150-180°C and low-speed air flow,

[0029] Step 5, peeling off the silicone oil release paper after cooling to obtain the degradable film.

[0030] The gap of the scraper is 0.005-0.03mm.

[0031] The cooling temperature in the above step five is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com