Molecularly imprinted polymers (MIPs) for inspecting melamine and preparation method thereof

A technology of molecular imprinting and melamine, which is applied in the field of material chemistry, can solve the problems of template leakage and difficulty in obtaining molecularly imprinted polymers, and achieve the effect of improving specificity, high affinity and selectivity, and increasing specific recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Molecularly imprinted polymer for detecting melamine

[0050] The synthesis and preparation steps of the molecularly imprinted polymer in this example are as follows:

[0051] (1) Preparation of prepolymer

[0052] Weigh 0.166g (1mmol) of cyromazine simulation template in a test tube, add 5.0mL methanol / water (10 / 1, V / V), after ultrasonic dissolution, add functional monomer methacrylic acid 0.690mL (8mmol), Sonicate for 5 minutes, and stand overnight at 4°C to form a prepolymer;

[0053] (2) Photopolymerization

[0054] Add 5.00mL (25mmol) of ethylene glycol dimethacrylate and 30mg of azobisisobutyronitrile to the above prepolymer, sonicate for 5min, blow nitrogen for 5min, seal, and polymerize at 4°C under 365nm ultraviolet light for 24h;

[0055] (3) Polymerization curing

[0056] The above photopolymerization product was transferred into a water bath at 60° C. and then polymerized for 12 hours to obtain a block polymer, which is the molecularly imprinte...

Embodiment 2

[0059] Example 2 Determination of the performance of molecularly imprinted polymers for detecting melamine

[0060] In this example, the molecularly imprinted polymer (with a particle size of 38.5 μm to 75 μm) prepared in Example 1 was selected to be filled in a 3 mL solid-phase extraction empty cartridge (200 mg / column), and activated with 3 mL of methanol and 3 mL of water in sequence.

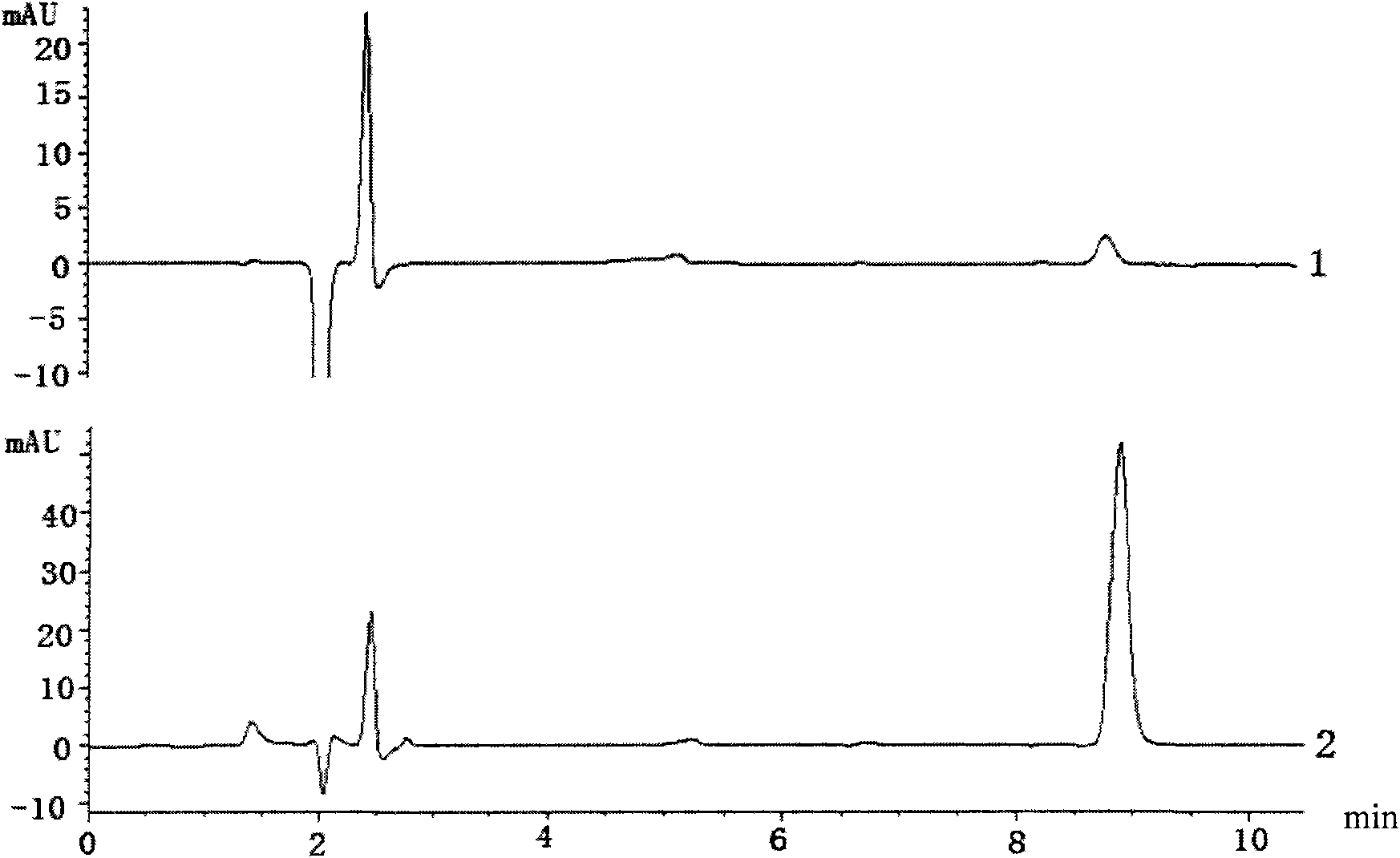

[0061] The samples in this example are melamine aqueous solutions with serial concentrations of 0.5, 2, 10 and 50 μg / mL. Take 2-5 mL of the sample and load it, wash with 3 mL of water and 3 mL of methanol, press dry, and elute with 5 mL of 5% ammoniated methanol. Blow dry carefully with nitrogen, dissolve with mobile phase, centrifuge at high speed, and detect with HPLC-UV. The detection results are as follows: figure 1 As shown, the AU on the ordinate in the figure is the absorbance unit, m=millimeters, and the abscissa represents the time in minutes (min).

[0062] figure 1 Provide two c...

Embodiment 3

[0063] Example 3 Determination of the performance of molecularly imprinted polymers used to detect melamine as a template and cyromazine as a template

[0064] In this example, the molecularly imprinted polymer (with a particle size of 38.5 μm to 75 μm) prepared in Example 1 was selected to be filled in a 3 mL solid-phase extraction empty cartridge (200 mg / column), and activated with 3 mL of methanol and 3 mL of water in sequence.

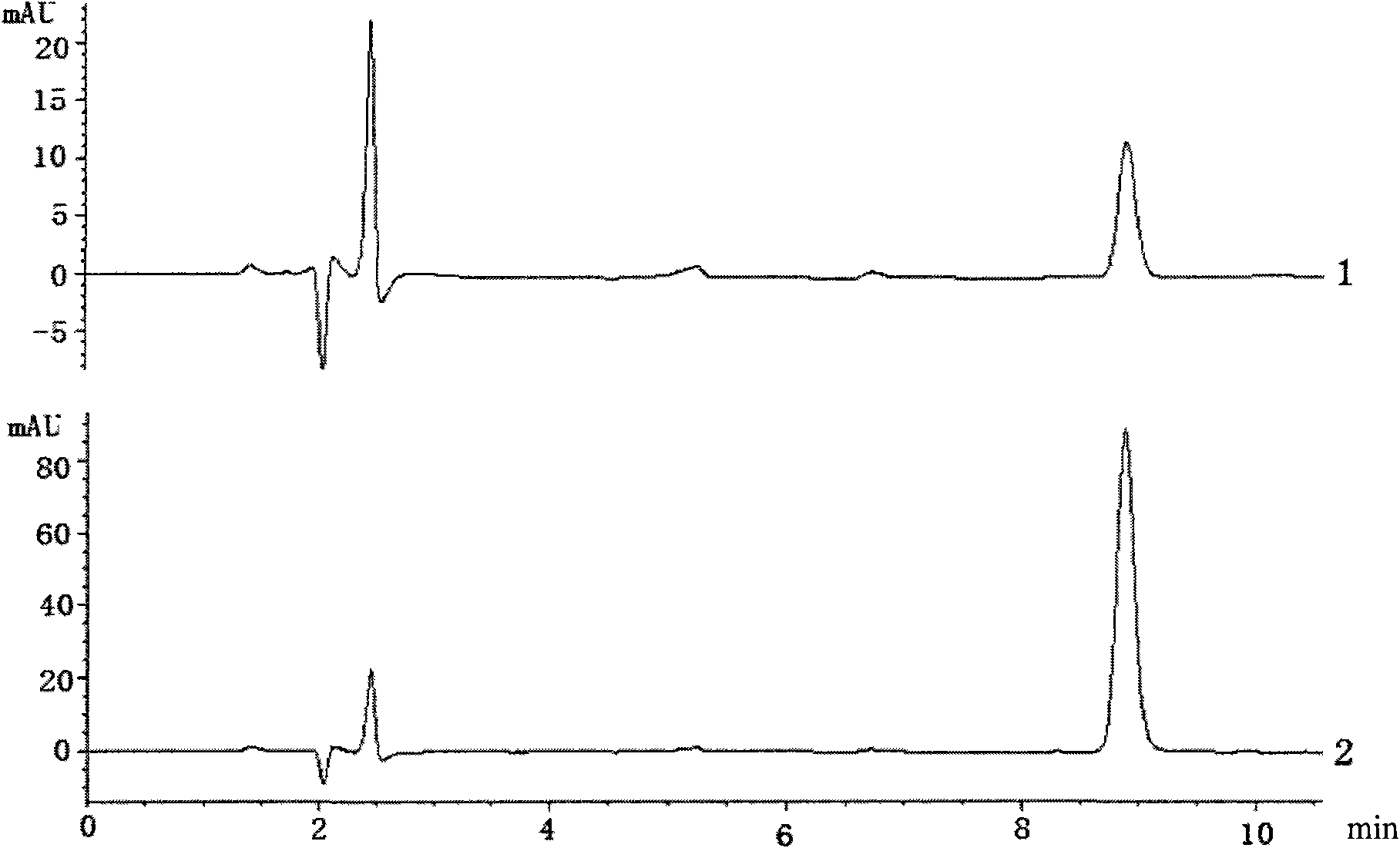

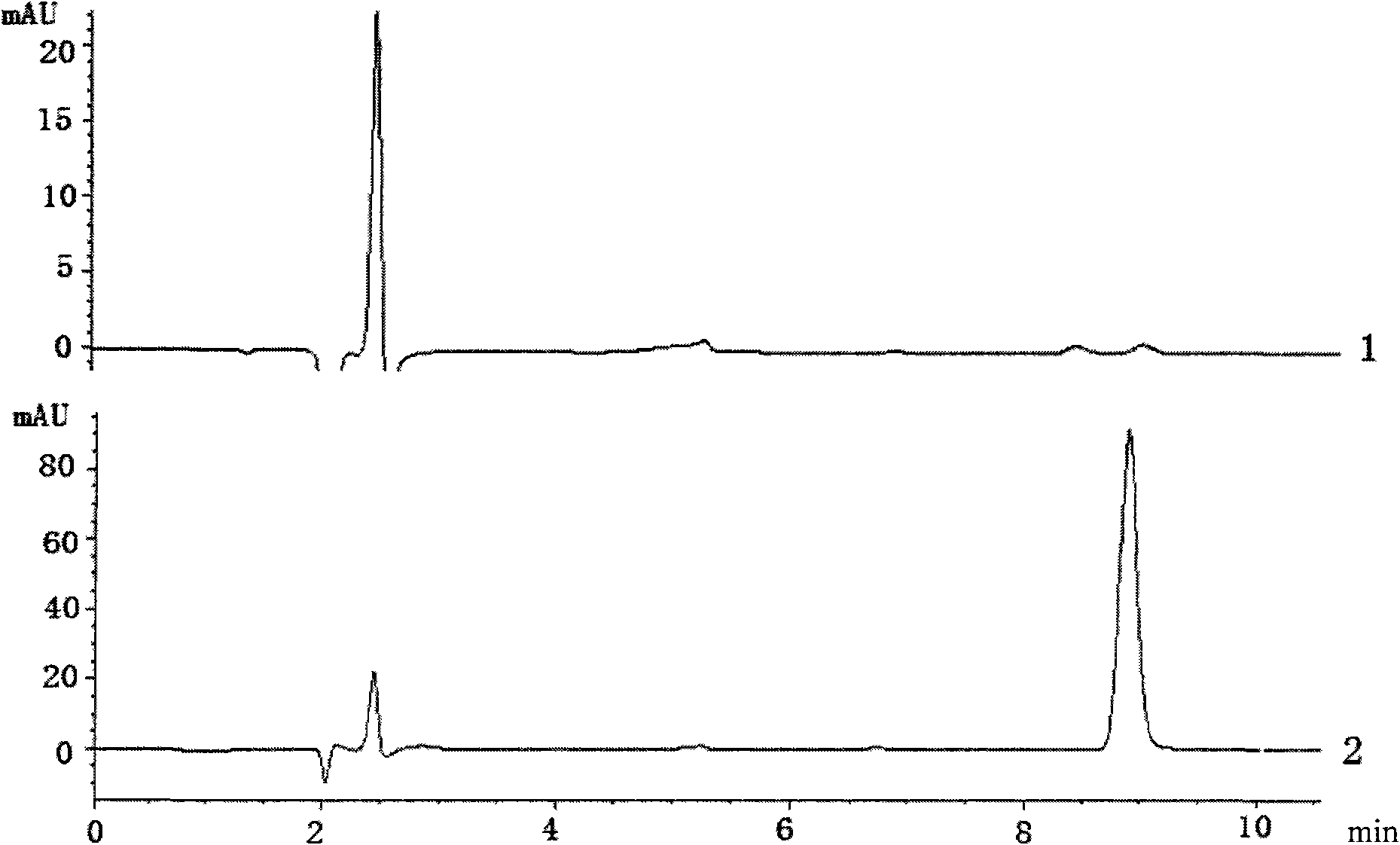

[0065] The samples in this example are 0.5 and 10 μg / mL melamine aqueous solutions. Take 2 mL of the sample for loading, wash with 3 mL of water and 3 mL of methanol, press dry, and elute with 5 mL of 5% ammoniated methanol. Blow dry carefully with nitrogen, dissolve with mobile phase, centrifuge at high speed, and detect with HPLC-UV. The detection results are as follows: figure 2 shown.

[0066] figure 2 Provide two chromatographic curves in, wherein 1 is the chromatographic curve that the MIPs solid-phase extraction small column of template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com