Patents

Literature

339results about How to "Promote plasticization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

High cold resistance polyvinyl chloride cable material and preparation method thereof

InactiveCN101260214AEasy to useExpand the usable rangeInsulated cablesInsulated conductorsPolyvinyl chlorideEngineering

The invention provides a polyvinyl chloride (PVC) cable material used in gelid state (minus 50 DEG C to minus 70 DEG C) and a preparation method of the cable material. During use, the cable material does not split and can be bent normally, thereby greatly increasing the application range of products. Moreover, the cable material is made from the following raw materials in portions by weight: PVC of 80 to 100 portions, dioctyl phthalate of 20 to 40 portions, dioctyl sebacate of 60 to 80 portions, dioctyl butane dicarboxylic acid of 4 to 8 portions, light activated calcium carbonate of 20 to 40 portions, lubricant of 1 to 3 portions , Ca-Zn composite stabilizer of 4 to 8 portions, antioxidant 1010 of 1 to 4 portions, frost resisting agent K175C of 0.5 to 5 portions and nitrile butadiene rubber of 20 to 50 portions.

Owner:WUXI DONGTIAN CABLE

Wet process refractory mortar

The invention relates to wet process refractory mortar which comprises the following raw materials by weight: 25-50 parts of white fused alumina powder with the granularity of not more than 180 meshes, 40-65 parts of the white fused alumina powder with the granularity of not more than 320 meshes, 1-5 parts of phosphate binder, 1-4 parts of plasticizer, 1-3 parts of water retention agent, 0.1-1 part of resin type preservative, 0.05-0.5 part of preservative agent and 0-10 parts of Cr2O3 powder with the granularity of not more than 320 meshes, the wet process refractory mortar is prepared by uniformly stirring the raw materials, adding 12-18 parts of water, continuously uniformly stirring, and then loading into a plastic bag for sealing and preserving, and the preservation period is a year and a half to two years.

Owner:PUYANG REFRACTORIES GRP CO LTD

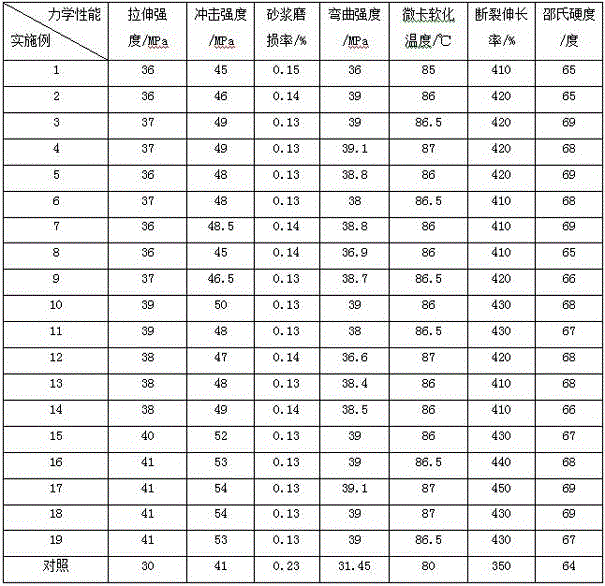

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

Plasticized Biodegradable Polyester Film and Preparation Method Thereof

A plasticized biodegradable polyester film formed from a biodegradable polyester in approximately 100 parts by weight, a plasticizer in from approximately 5-25 parts by weight, an inorganic filler in from approximately 0-150 parts by weight; and an antioxidant in from approximately 0.1-1 parts by weight. A method for preparing the plasticized biodegradable polyester film including drying the biodegradable polyester, drying the inorganic filler, mixing the biodegradable polyester, the plasticizer, the inorganic filler and the antioxidant, adding the mixed biodegradable polyester, plasticizer, inorganic filler and antioxidant into an extruder forming extruded plasticized biodegradable polyester material, drying the extruded plasticized biodegradable polyester material, and blowing the dried plasticized biodegradable polyester material as a master batch into film through a extruder to obtain the plasticized biodegradable polyester film.

Owner:GUANGZHOU HAIRMA CHEM GZ

Vegetable gum based on modified starch, preparation method thereof and application of vegetable gum

The invention discloses vegetable gum based on modified starch. The vegetable gum is prepared from the following raw materials in parts by weight, 40-90 parts of modified starch, 3-30 parts of gelatinizing agents, 2-20 parts of plasticizers, 2-20 parts of polymer, 2-20 parts of plant fibers, 10-50 parts of deionized water and 1-15 parts of cross-linking agents. The raw materials are mixed and subjected to reaction at the temperature ranging from 20 DEG C to 120 DEG C for 10-200 minutes, and the vegetable gum is prepared by kneading, extruding and cutting procedures. The starch and the polymer or macro-molecules are compounded and mixed or grafted and copolymerized, the vegetable gum overcomes the shortcomings of poor plasticity, low tensile strength and frangibility of original starch and difficulty in degradation and non-renewable performance of the macro-molecules, the vegetable gum is degradable, renewable, low in cost, good in plasticity, stable on heat and resistant to aging, and a preparation method of the vegetable gum controls extrusion temperature, screw rotation speed, cutter rotation speed and granule cooling, so that granules cannot be adhered and are uniform in size and good in plasticity. The vegetable gum is applied to related products such as degradable plastics, capsules and food and drug packing materials.

Owner:安顺济世科技有限公司

Process for preparating medical polyvinyl chioride resin with high polymerization

InactiveCN1657545ARegular particle shapeConcentrated resin particle size distributionCatheterSingle useDisperser

A process for preparing the medical polyvinyl chloride resin with high polymerization degree includes such steps as adding vinyl chloride, trigger, disperser, assistant and water to reactor, polymerizing reaction, adding reaction-stopping agent, removing excessive vinyl chloride, centrifugal dewatering and drying.

Owner:上海天原集团天原化工有限公司

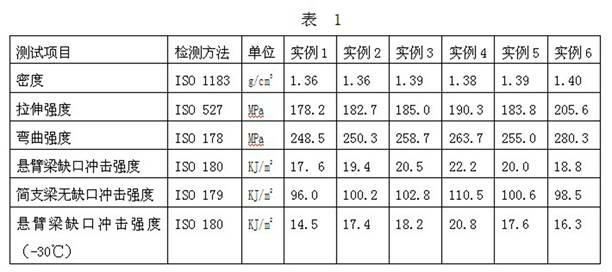

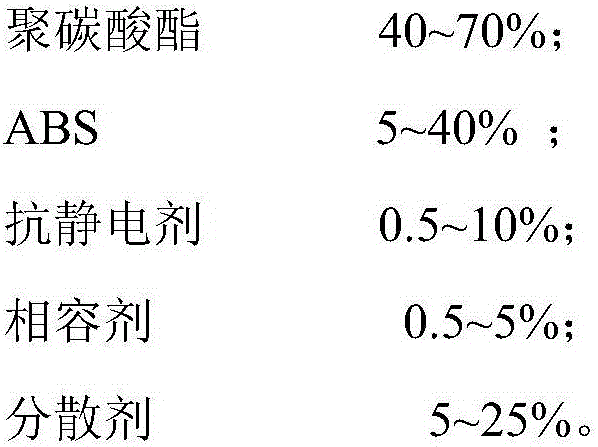

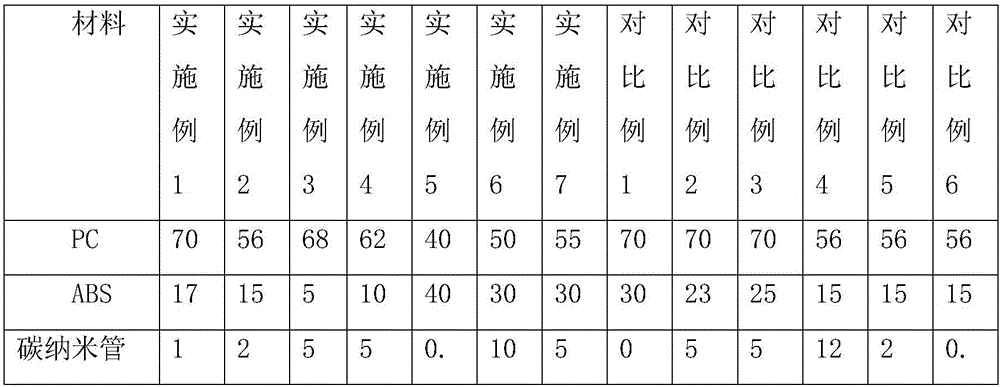

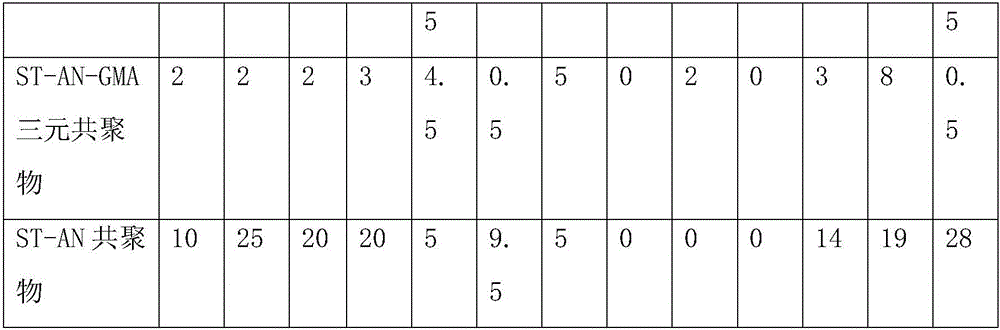

Efficient anti-static PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

The invention provides an efficiency anti-static PC / ABS (Polycarbonate / Acrylonitrile Butadiene Styrene) composite material and a preparation method thereof. The composite material is prepared from the following components in percentage by weight: 40-70 percent of polycarbonate, 5-40 percent of ABS, 0.5-10 percent of antistatic agent, 0.5-5 percent of compatilizer and 5-25 percent of dispersing agent. The preparation method comprises the following steps: firstly, mixing the antistatic agent, the compatilizer and the dispersing agent in the raw materials according to a certain proportion at the room temperature; performing melt extrusion through double screws to obtain antistatic master batch; extruding the composite material according to a certain proportion, extruding through the double screws, and granulating to obtain the efficient anti-static PC / ABS composite material. The composite material prepared by the method has superior antistatic performance, high chemical performance and attractive appearance.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

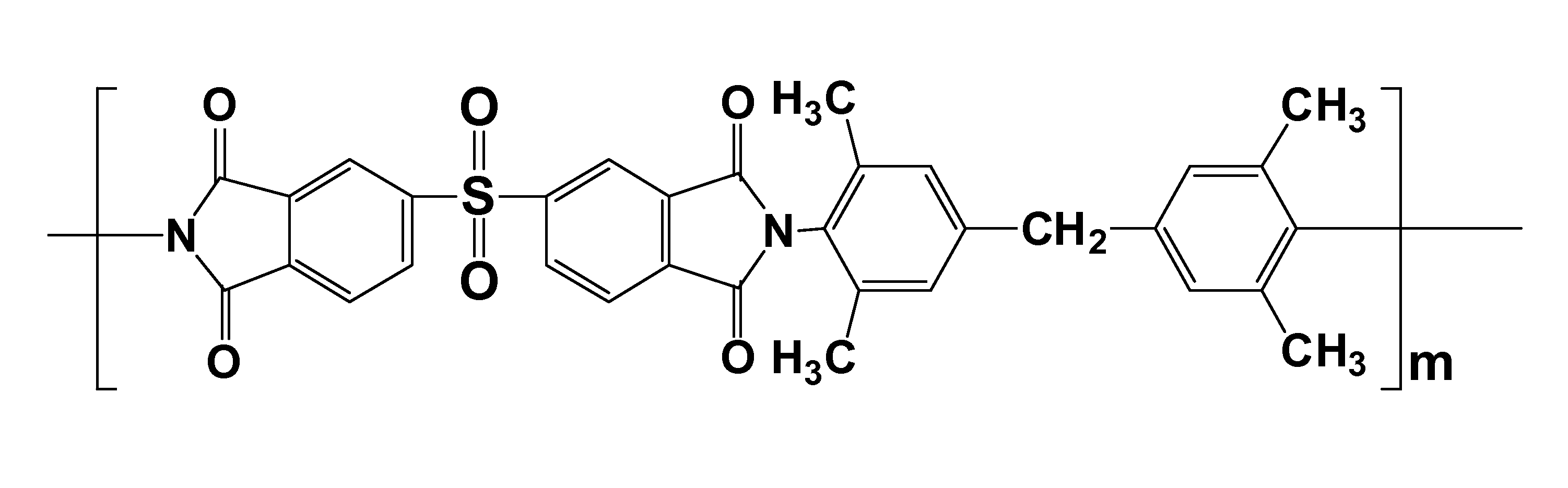

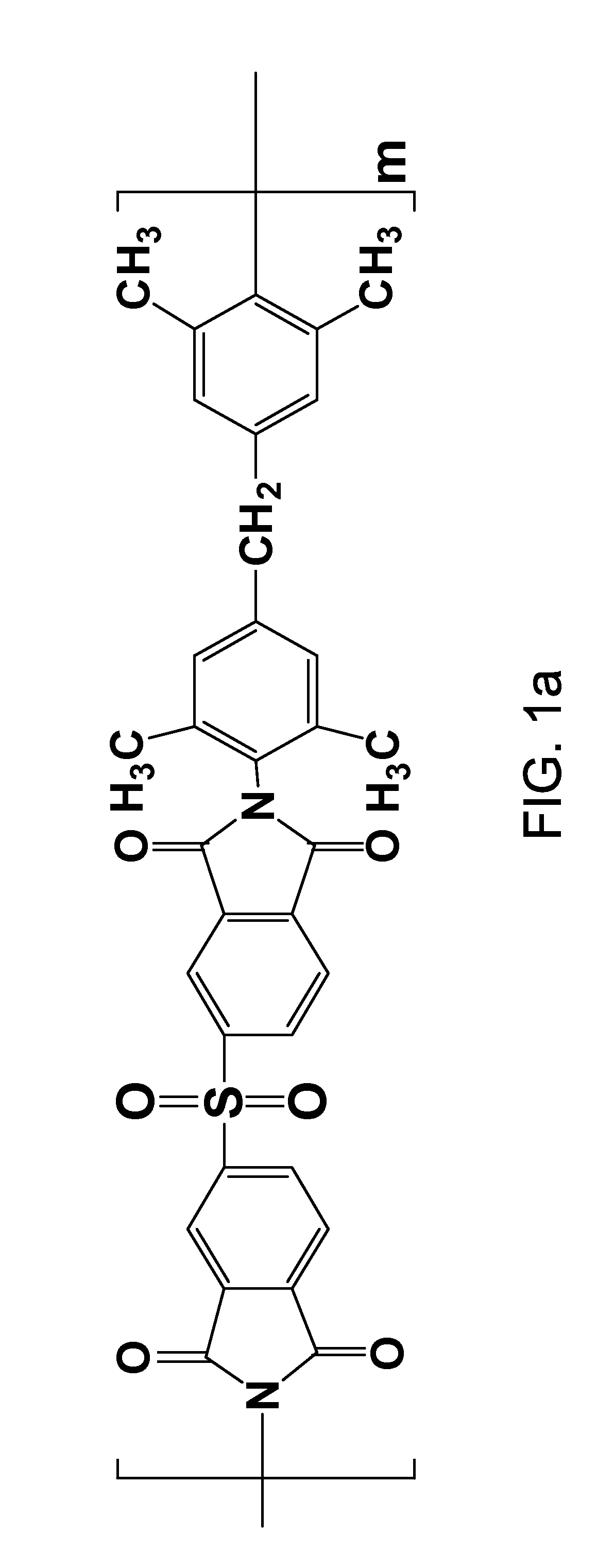

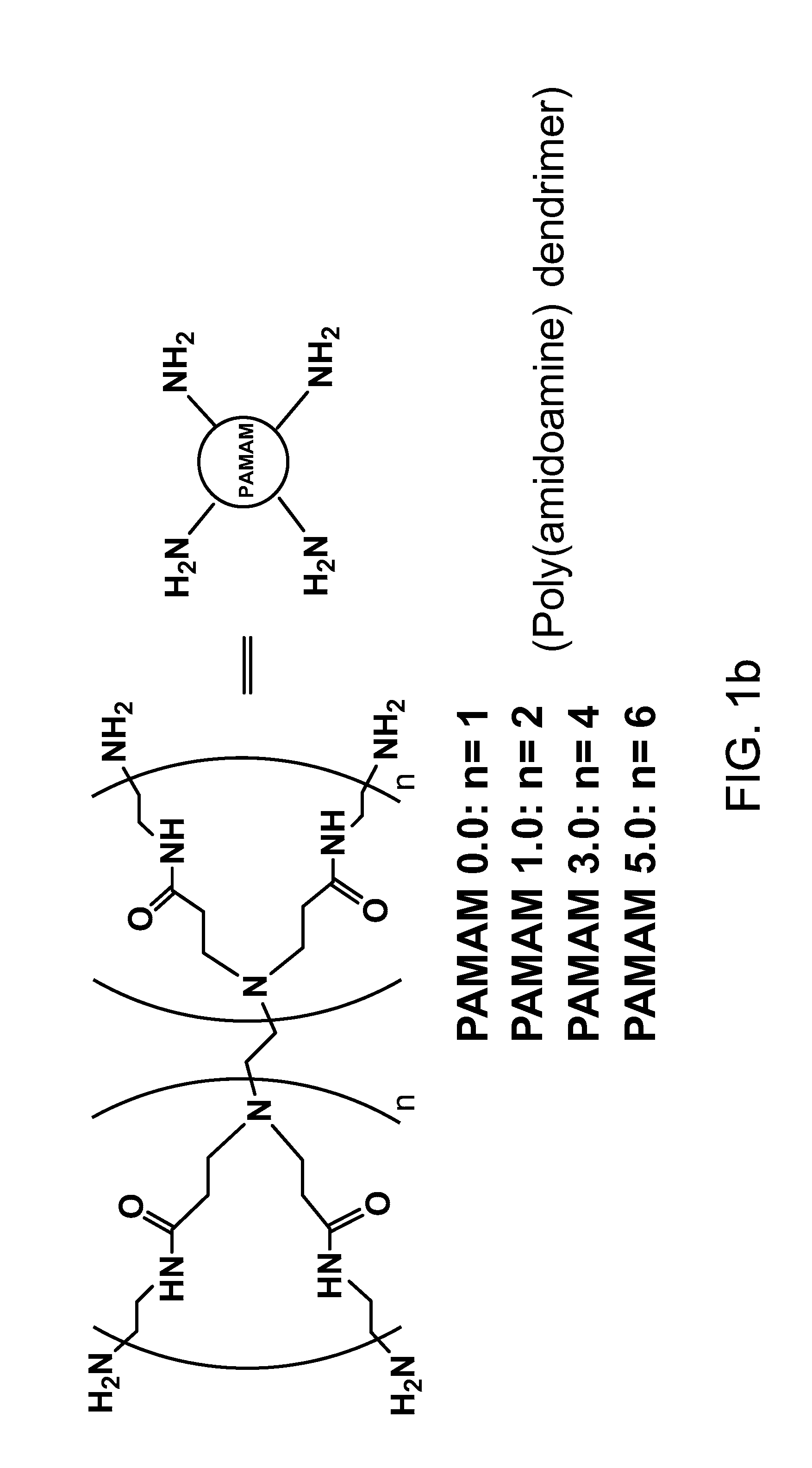

Cross-linked polyimide membranes for separations

InactiveUS20140137734A1Reduces polyimide polymer chain flexibilityEasy to distinguishSemi-permeable membranesGas treatmentCross-linkPAMAM dendrimer

The present invention discloses new types of poly(amidoamine) (PAMAM) dendrimer-cross-linked polyimide membranes and methods for making and using these membranes. The membranes are prepared by cross-linking of asymmetric aromatic polyimide membranes using a PAMAM dendrimer as the cross-linking agent. The PAMAM-cross-linked polyimide membranes showed significantly improved selectivities for CO2 / CH4 compared to a comparable uncrosslinked polyimide membrane. For example, PAMAM 0.0 dendrimer-cross-linked asymmetric flat sheet poly(3,3′,4,4′-diphenylsulfone tetracarboxylic dianhydride-3,3′,5,5′-tetramethyl-4,4′-methylene dianiline) (DSDA-TMMDA) polyimide membrane showed CO2 permeance of 135.2 A.U. and CO2 / CH4 selectivity of 20.3. However, the un-cross-linked DSDA-TMMDA asymmetric flat sheet membrane showed much lower CO2 / CH4 selectivity (16.5) and higher CO2 permeance (230.8 GPU).

Owner:UOP LLC

Coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material and preparation method thereof

The invention discloses a coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material and a preparation method thereof. The coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material is prepared from the following raw materials: by weight, ultra high molecular weight polyethylene, a flow modifier, a compatibilizer, a lubricant, an antistatic agent, a flame retardant, pretreated calcium sulfate whisker, a nucleating agent and a coupling agent. Firstly, all the raw materials are mixed in a high speed, then the mixed materials are added into an extruder for extrusion forming, and then the coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material is obtained by sizing, cooling and final cutting of the formed material. The coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material prepared by the preparation method is well plasticized and is smooth in the inner wall, the wall thickness of the continuously produced coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material can reach 40mm, flame-retardant and antistatic functions can be improved, the cost is reduced, and the production efficiency and safety coefficient are improved. Products prepared by the preparation method can completely meet the safety technology requirements of coal mine-use pipe materials.

Owner:LUOHE KELAIBAO TECH CO LTD

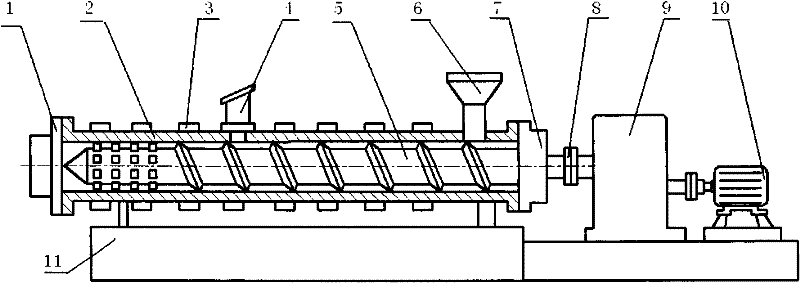

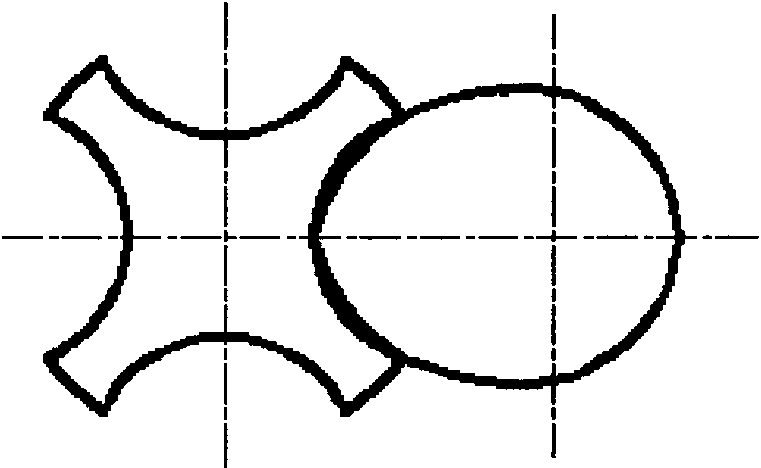

Exhaust-type differential double-screw extruder

The invention relates to an exhaust-type differential double-screw extruder, mainly comprising a feeder, a cylinder, screws, a machine head, a heating and cooling device, an exhaust outlet, a motor and a driving device, wherein one screw is a male rotor, and the other screw is a female rotor; at least one screw thread engaging region is arranged when the screws are combined, the screw socket number of the female rotor in the region is integral multiples of that of the male rotor, the rotating speeds of the female rotor and the male rotor are in inverse proportion to the screw socket number, and differential rotation and no interference during movement can be realized for the female rotor and the male rotor. At least one exhaust outlet is arranged on a material cylinder so as to remove moisture and other volatile components, and the screw configuration distribution meets the exhausting requirement. According to material processing requirements, screw thread sections or other forms with different leads and section shaped lines can be arranged on different sections of a charging section, a fusion section, an exhausting section and a metering section of the screws; when the screws are installed, besides at least one screw thread engaging region with differential rotation is ensured, the screws in different sections can be engaged and can be also unengaged so as to reinforce mixing or other functions. The extruder has favorable mixing, plasticizing and conveying capabilities and is suitable for processing and forming various granules, powder materials or even block materials, such as plastics, rubbers, food, explosives and the like.

Owner:BEIJING UNIV OF CHEM TECH

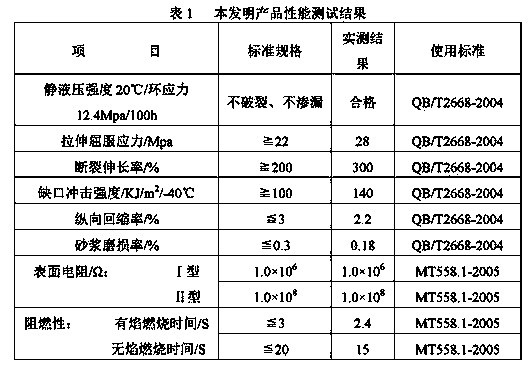

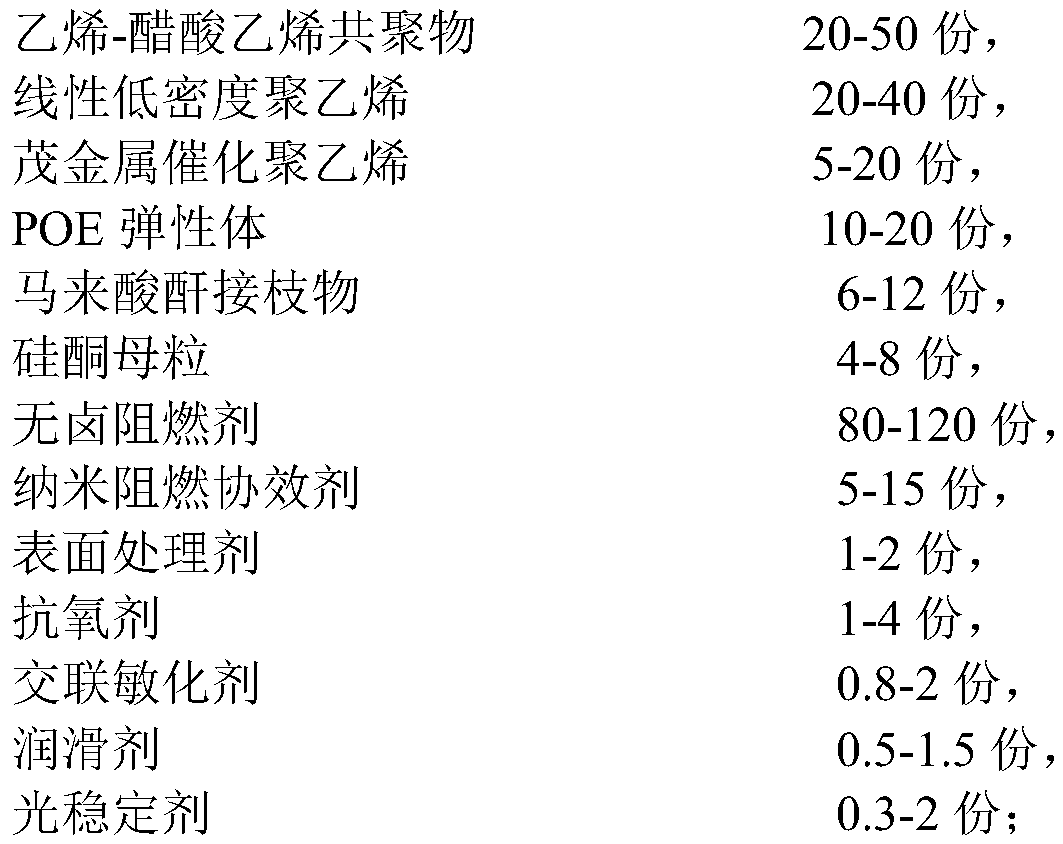

125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for photovoltaic cable and preparation method thereof

PendingCN111234358AGood mechanical propertiesEasy to operatePlastic/resin/waxes insulatorsMaleic anhydrideWeather resistance

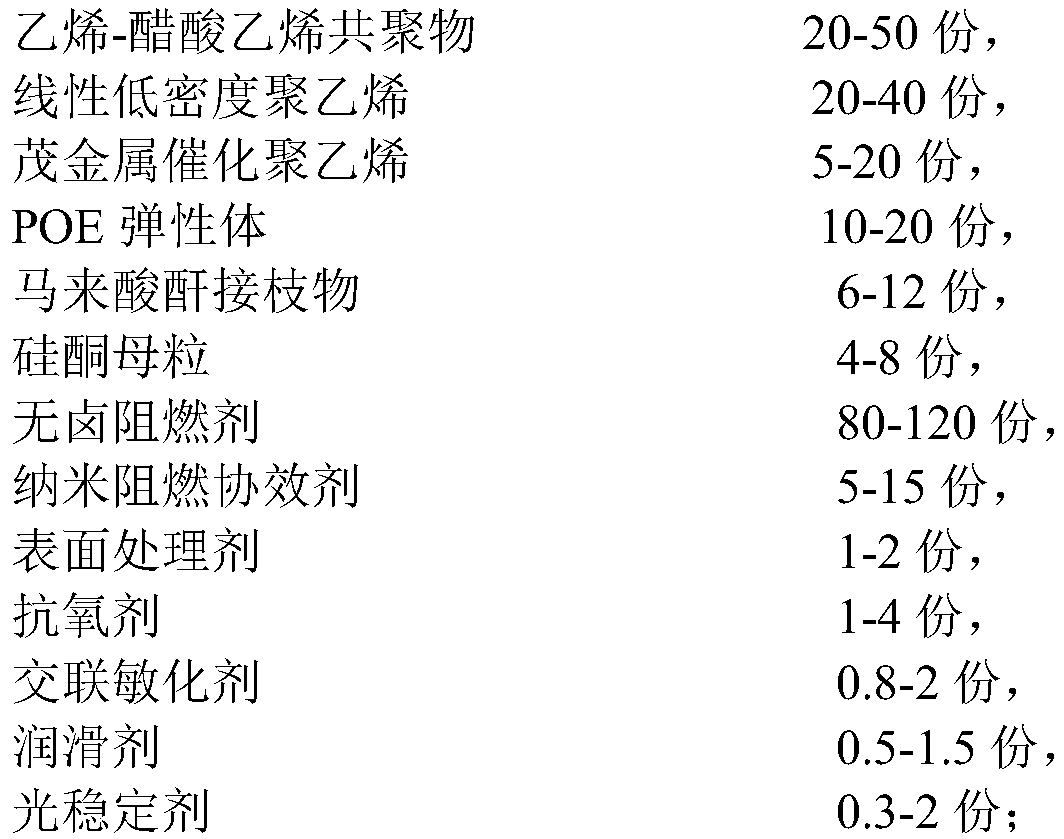

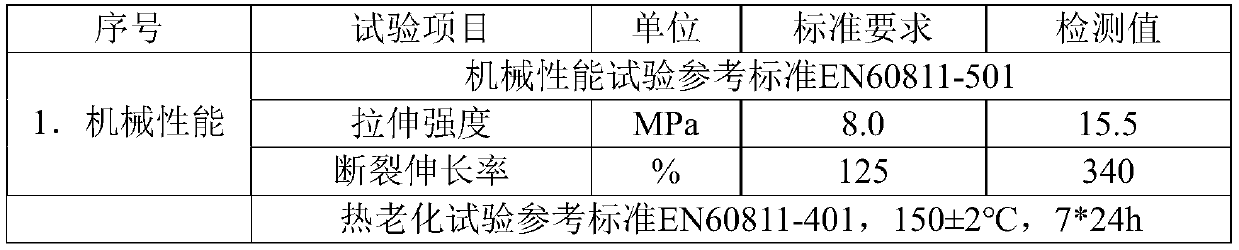

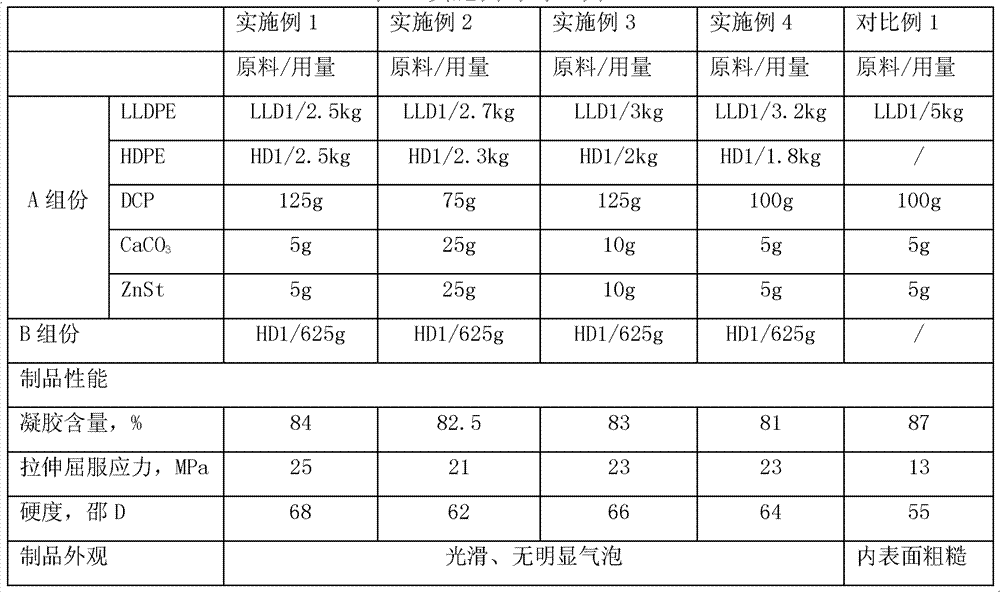

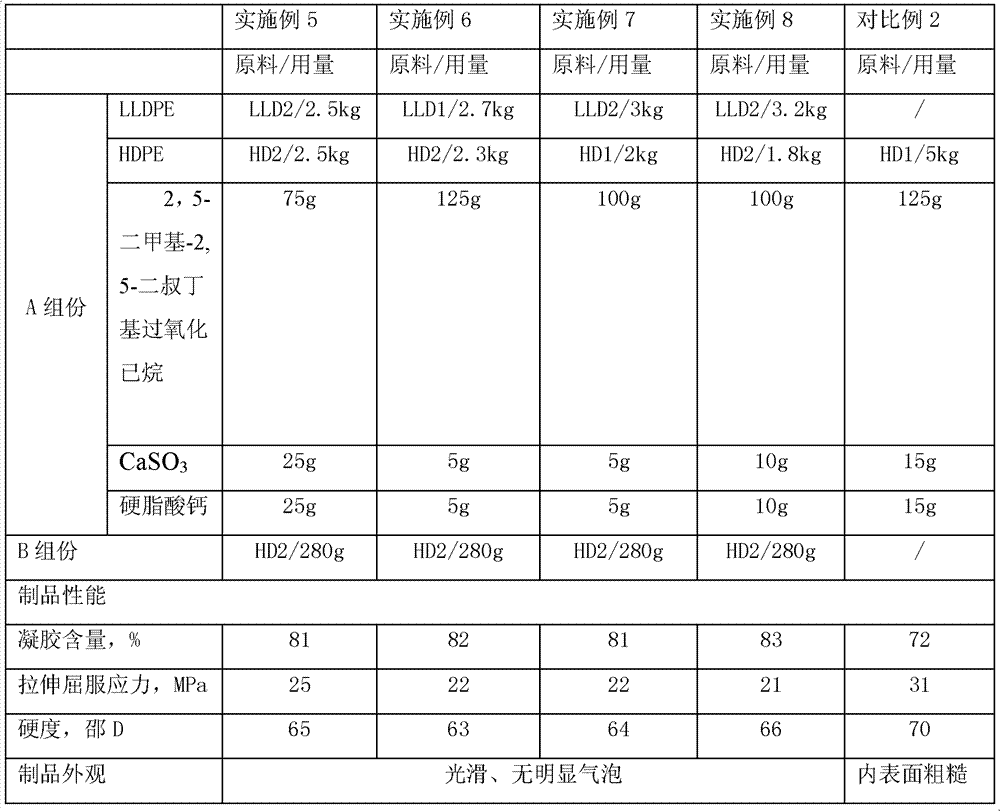

The invention discloses a 125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for a photovoltaic cable and a preparation method of the cable material. The cable material is prepared from, by mass 20 to 50 parts of an ethylene-vinyl acetate copolymer, 20 to 40 parts of linear low density polyethylene, 5 to 20 parts of metallocene catalyzed polyethylene, 10-20 parts of a POE elastomer, 6-12 parts of maleic anhydride graft, 4-8 parts of silicone masterbatch, 80-120 parts of a halogen-free flame retardant, 5-15 parts of a nano flame retardant synergist, 1-2 parts of a surface treating agent, 1-4 parts of an antioxidant, 0.8-2 parts of a cross-linking sensitizer, 0.5-1.5 parts of a lubricant and 0.3-2 parts of a light stabilizer. The cable material hasgood mechanical property, electrical insulation property, flame retardant property, weather resistance, aging resistance, scratch resistance, acid and alkali resistance and processability, and a photovoltaic cable prepared from the cable material can meet the requirements of German 2Pfg1169 and European EN50618 standards after being subjected to irradiation processing; the preparation method hasthe advantages of simple operation, high production efficiency and high process automation, and is beneficial to plasticization and dispersion of each raw material component.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD

Cross-linked polyolefin composition for rotational molding and preparation method thereof

The invention relates to a cross-linked polyolefin composition for rotational molding and a preparation method thereof, belonging to the field of cross-linked polyolefin composition for rotational molding. The cross-linked polyolefin composition comprises a component A and a component B, wherein the component A comprises 100 weight parts of linear low density polyethylene (LLDPE), 50-100 weight parts of high density polyethylene (HDPE), 2-5 weight parts of cross-linking agent, 0.2-1.0 weight parts of nucleating agent, and 0.2-1.0 weight parts of lubricant; and the component B is high density polyethylene, and the ratio of the component A to the component B is 90:10-95:5. According to the invention, optimum crosslinking degree is achieved and high hardness and difficulty in warpage are guaranteed by selecting the basic resin, and the addition of the nucleating agent is beneficial for reducing product bubbles; products produced by using the composition of the invention has smooth internal and external surface, easiness in mold stripping, high crosslinking degree, and good comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP

High-impact high-flowability PVC (polyvinyl chloride) formula and preparation method thereof

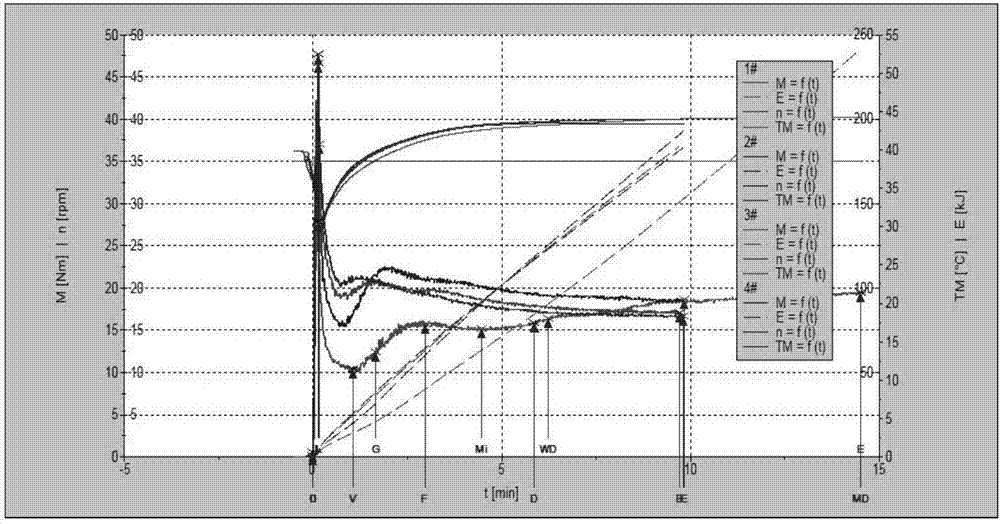

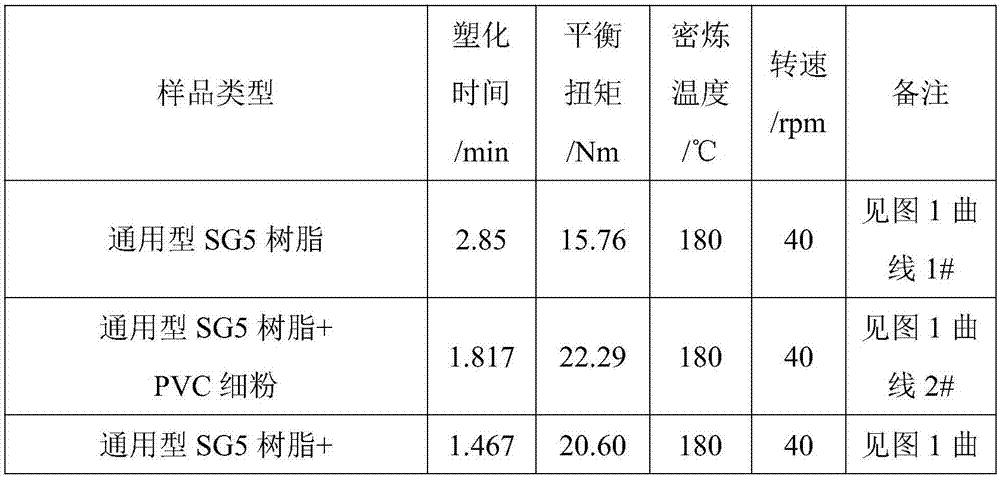

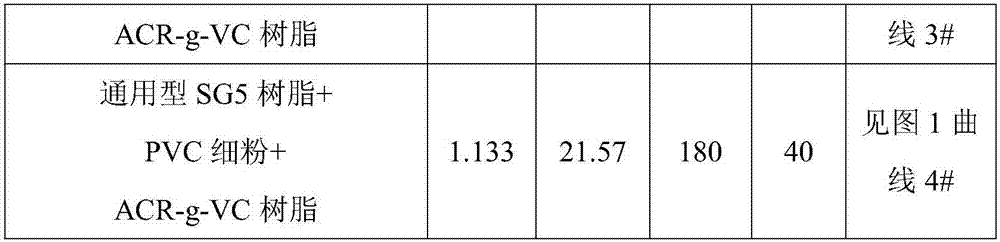

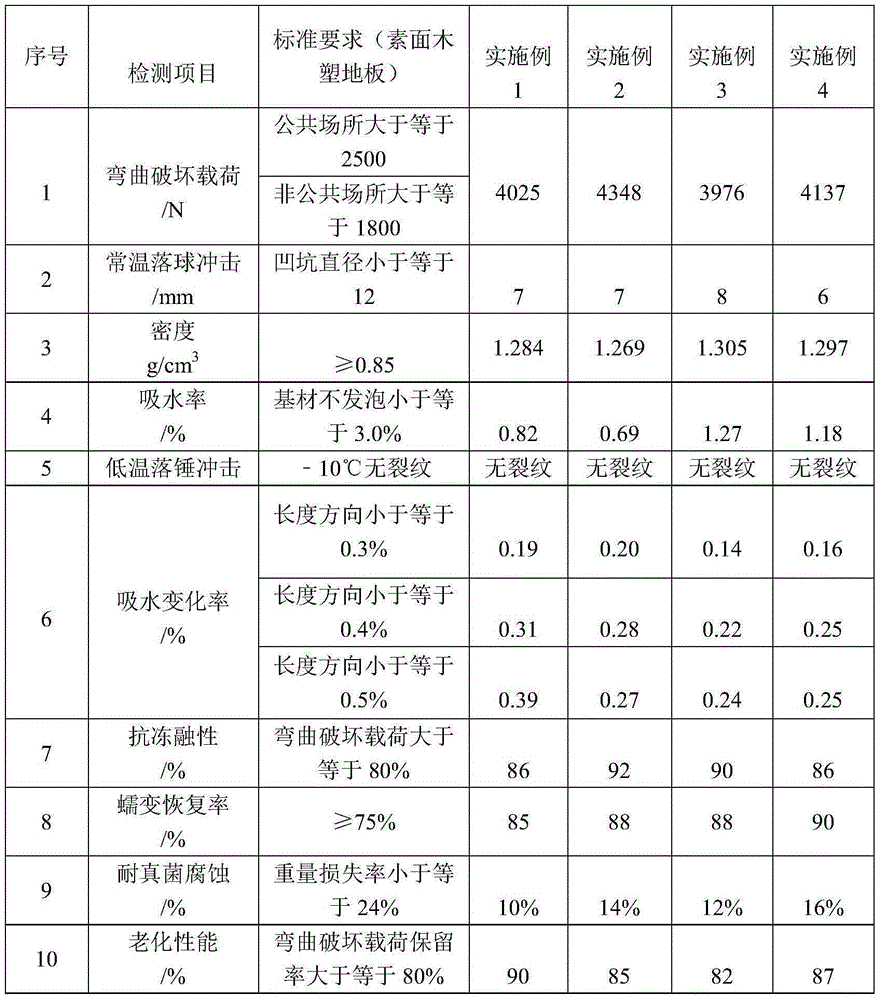

The invention discloses a high-impact high-flowability PVC (polyvinyl chloride) formula and a preparation method thereof. The high-impact high-flowability PVC formula is prepared from the following ingredients in parts by weight: 60 to 95 parts of PVC resin, 3 to 50 parts of ACR-g-VC resin, 3 to 15 parts of PVC fine powder, 2 to 5 parts of composite stabilizing agents, 0.5 to 2 parts of inner lubricating agents, 0.5 to 1 part of outer lubricating agents and 20 to 50 parts of calcium carbonate. A conventional extrusion process is used; low-polymerization-degree PVC fine powder and ACR-g-VC resin (chloroethylene-n-butyl acrylate graft copolymers) are added; the inner plasticization effects of low-polymerization-degree PVC resin and the chloroethylene-n-butyl acrylate graft copolymers is mainly utilized; the plasticization performance is improved in a cooperated way; the plasticization time is shortened; meanwhile, the anti-impact performance of the plastic product is obviously improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

Chinese medicine residue reinforced reprocessed plastic composite material, and preparation method thereof

InactiveCN105400052AImprove physical performanceImprove mechanical propertiesWeather resistanceNational standard

The invention relates to a Chinese medicine residue reinforced reprocessed plastic composite material, and a preparation method thereof, and belongs to the field of composite material. The Chinese medicine residue reinforced reprocessed plastic composite material comprises, by mass, 50 to 70% of Chinese medicine residue, 20 to 40% of modified reprocessed plastic, 2 to 10% of a mineral filling material, 2 to 5% of a compatilizer, 1 to 5% of a lubricant, 1 to 3% of a colouring agent, 1 to 3% of an anti-oxidant, and 1 to 3% of a light stabilizer. The preparation method comprises following steps: Chinese medicine residue pretreatment; reprocessed plastic modification; material mixing; pelletizing; extrusion moulding, and surface post-processing. The physical properties, mechanical properties, and weathering resistance of the Chinese medicine residue reinforced reprocessed plastic composite material are equal to or better than that disclosed in national standard GB / T 24508-2009 <wood-plastic flooring>; and the Chinese medicine residue reinforced reprocessed plastic composite material is capable of satisfying market requirements, and possesses insect expelling effect and mould resistance.

Owner:南京聚锋新材料有限公司 +1

Chlorinated polyvinyl chloride resin and preparation method and application

InactiveCN104231130AEasy to plasticizeImprove processing fluidityChlorinated polyvinyl chlorideOxygen

The invention discloses a chlorinated polyvinyl chloride resin and its preparation method and application. The preparation method comprises the following steps: in an oxygen-free atmosphere, chlorine is introduced, at the speed of 20-40m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1>, into a mixed system of polyvinyl chloride resin, an initiator and a dispersant and water or hydrochloric acid; the speed of introducing chlorine is adjusted to 20-32m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1>, 30-50 m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1> and 20-32 m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1> respectively; and introduction of chlorine is stopped, and a reaction continues. The total amount of introduced chlorine during the above steps meets the following requirement: chlorine content of the chlorinated polyvinyl chloride resin reaches 63.5-65.5 wt%. The chlorinated polyvinyl chloride resin provided by the invention is easy to plastify and has good processing fluidity and heat-resistant stability.

Owner:SHANGHAI CHLOR ALKALI CHEM

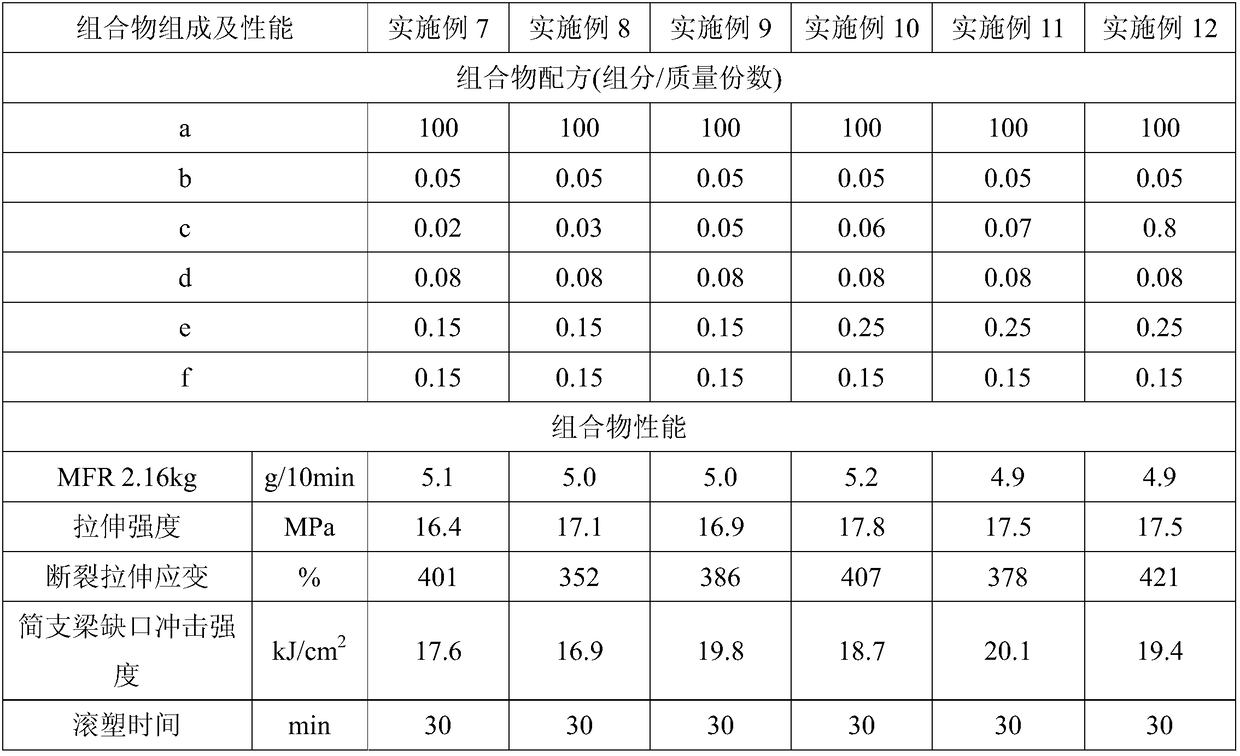

Rotomolded polyolefin composition and preparation method thereof

The invention relates to a polyolefin composition, in particular to a rotomolded polyolefin composition and a preparation method thereof. The rotomolded polyolefin composition comprises polyethylene,hyperbranched polyethylene, a nucleating agent, an acid absorbent, an ultraviolet absorbent, and an antioxidant, wherein the hyperbranched polyethylene, the nucleating agent, the antioxidant and the acid absorbent are pretreated; to be specific, the hyperbranched polyethylene, the nucleating agent, the antioxidant and the acid absorbent are mixed, n-hexane is added, a solvent is removed after heating and reflowing, and drying is performed. The rotomolded polyolefin composition and the preparation method thereof have the advantages that mechanical properties of rotomolding materials can be significantly improved, melt viscosity (low zero-cut viscosity) is reduced, the produced rotomolded product has smooth inner and outer surfaces and good plasticity, the section of the product has no evident bubbles, heating time is short, demolding is facilitated, and the product has long-term ultraviolet ageing resistance. The invention also provides the preparation method of the rotomolded polyolefin composition.

Owner:CHINA PETROLEUM & CHEM CORP

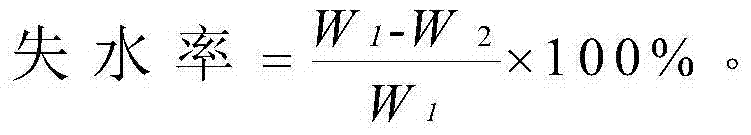

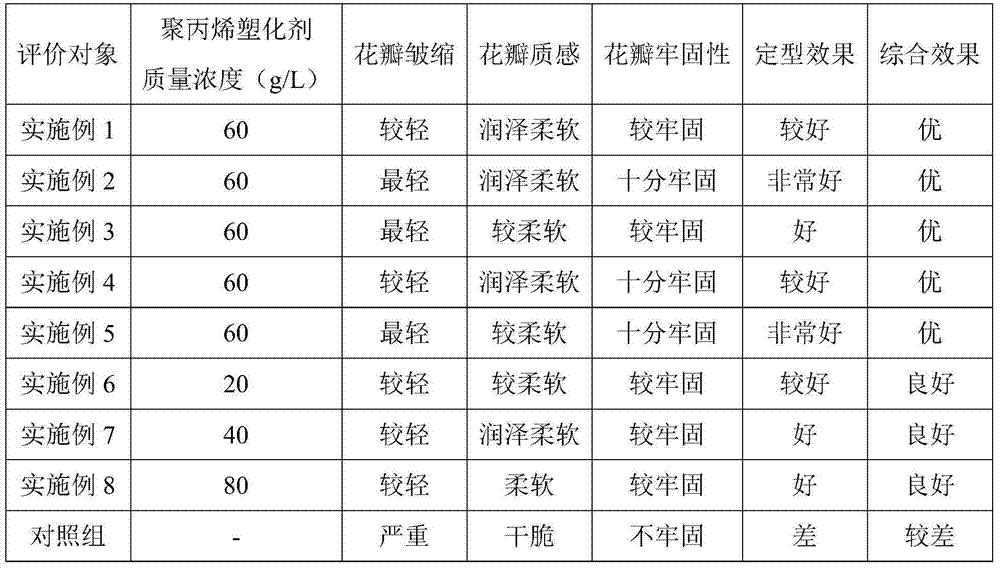

Preparation method of three-dimensional dried flower

InactiveCN104210311ARealistic appearanceStrong ornamentalDead plant preservationSpecial ornamental structuresPolypropyleneChemistry

The invention discloses a preparation method of three-dimensional dried flower. The preparation method comprises the following steps of 1, putting fresh flower to be treated into a dehydrant and carrying out dehydration treatment to obtain dried flower, 2, by a polypropylene plasticizer, carrying out vacuum dipping treatment on the dried flower obtained by the step 1 to obtain plasticized flower, and 3, carrying out hardening treatment on the plasticized flower obtained by the step 2. The preparation method of the three-dimensional dried flower adopts a plastination technology. Through dehydration, vacuum dipping and hardening treatment, the three-dimensional dried flower retains the original texture, color and components of the fresh flower, also retains the original graceful shape of the fresh flower, has lifelike appearance and a good ornamental value, has a certain toughness and elasticity, has no smell and no deformation, has stable quality, can be stored for a long time and is conducive to package, transport and exhibition. The preparation method can realize shaping treatment and plasticizing treatment on whole flowers and large flowers, provides a novel method for high-quality flower processing and has high applicability and a wide application scope.

Owner:HENAN UNIV OF SCI & TECH

Smelting method capable of reducing inclusions of spring steel

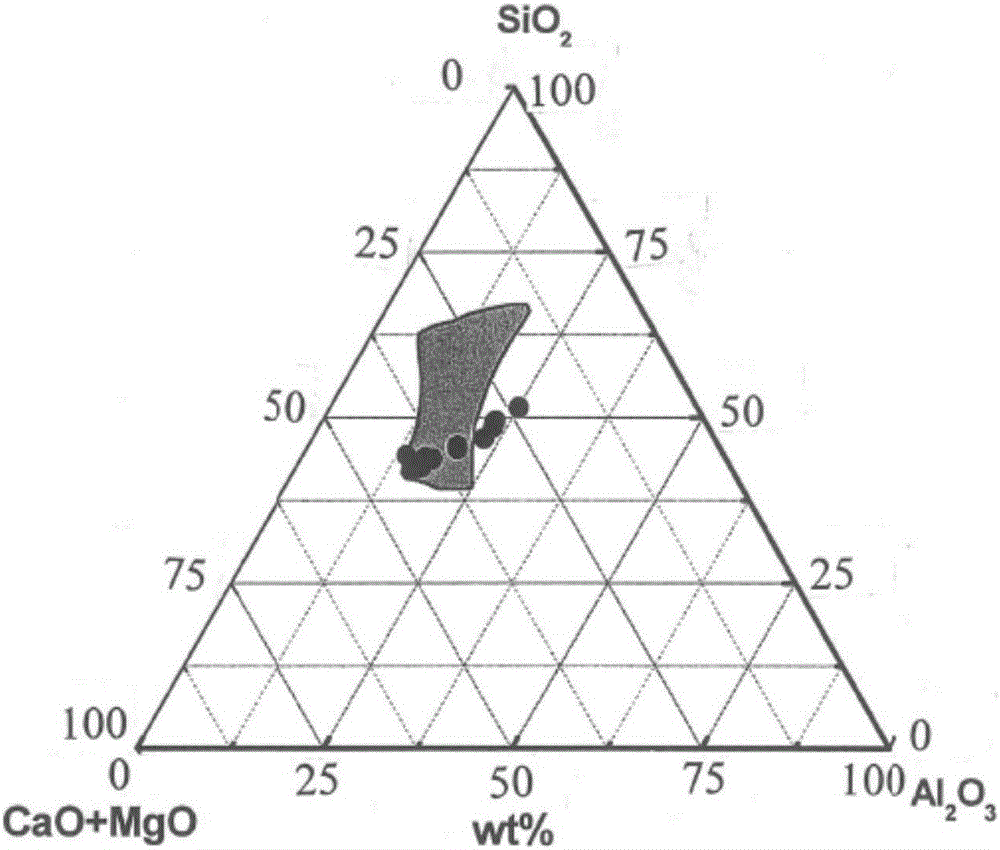

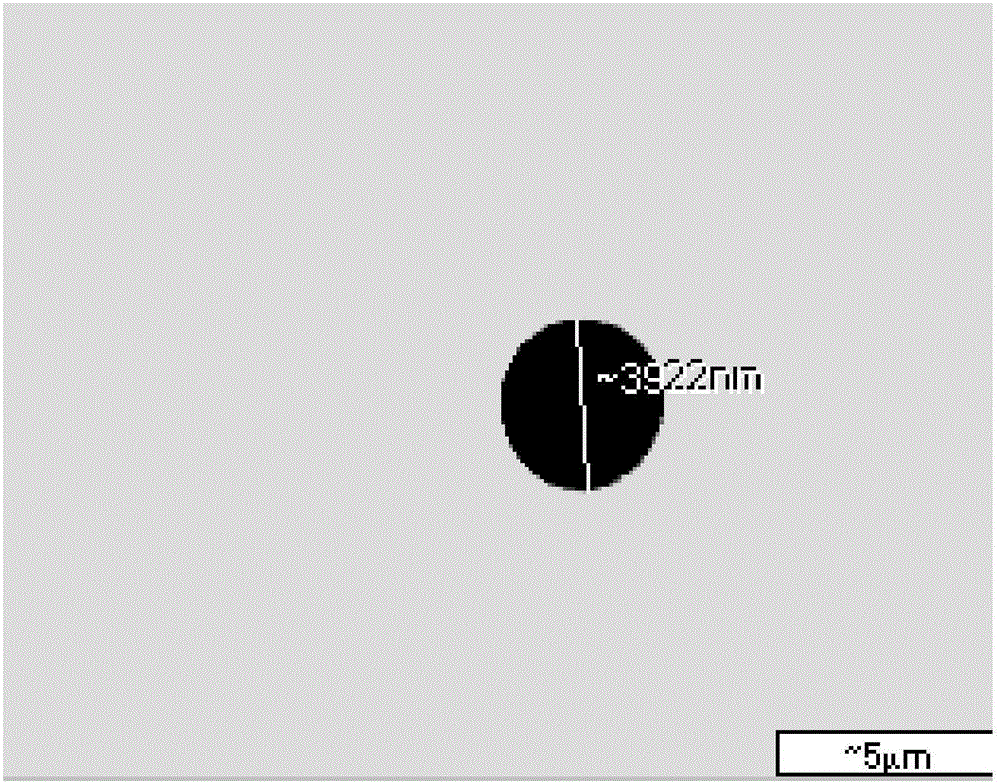

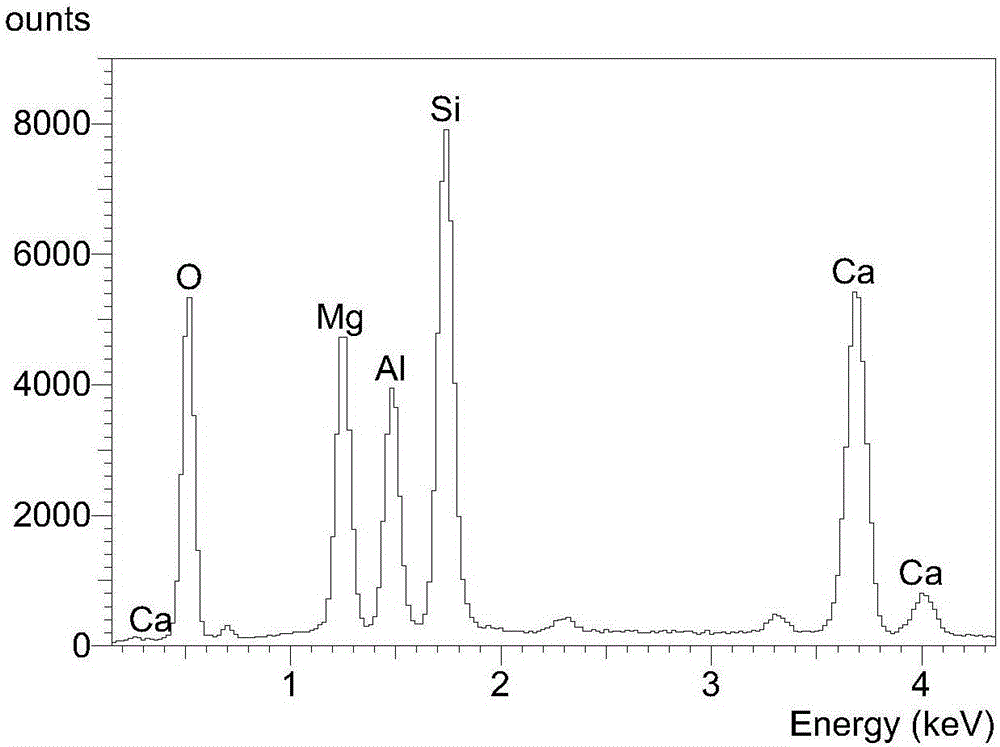

The invention discloses a smelting method capable of reducing inclusions of spring steel. The smelting method includes the following steps of (1) smelting through a high carbon withdrawing process; (2) argon blowing; (3) refining in an LF furnace; (4) vacuum treatment; (5) LF soft blowing; and (6) spring steel rolling. Especially, aluminum-free deoxidation is adopted during smelting through the high carbon withdrawing process, and a low-alkalinity slag process is adopted during refining in the LF furnace. According to the smelting method capable of reducing inclusions of spring steel, on the basis of researching thermodynamics and kinetics for separation out of inclusions, the content of oxides is lowered by controlling the deoxidation depth during smelting, the low-alkalinity slag process facilitates plasticization of inclusions, the plasticized inclusions can easily aggregate and grow up, flotation removal is facilitated during soft blowing in secondary refining, and therefore the purpose of controlling the level of nonmetal inclusions of spring steel is achieved; and the problem of judgment amending caused by exceeding of inclusions is completely solved, and the production cost is greatly lowered.

Owner:武汉钢铁有限公司

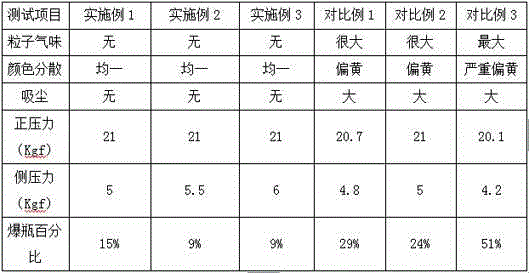

Ultrafine talcum powder and polypropylene filling color masterbatch and preparation method thereof

The invention relates to ultrafine talcum powder and polypropylene filling color masterbatch and a preparation method thereof. The ultrafine talcum powder and polypropylene filling color masterbatch comprises the following raw materials by weight percent: 0.05-5% of pigment, 50-80% of ultrafine talcum powder, 10-40% of polypropylene, 2-10% of fatty glyceride and 0.5-2% of porous inorganic silicon. The production efficiency and the dispersion performance of the ultrafine talcum powder and polypropylene filling color masterbatch are improved, and the ultrafine talcum powder and polypropylene filling color masterbatch is applied to a polypropylene product to endow the product with high luster degree, good heat resistance and characteristics of no smell and dust absorption prevention.

Owner:广东波斯科技股份有限公司

Polyvinyl chloride function modifier and its prepn process

The present invention discloses one kind of polyvinyl chloride function modifier and its preparation process. The modifier is prepared with polyhydric alcohol borate ester, polyhydric alcohol salicylate ester and acrylate as processing assistant, and oxide homopolymer or oxidized polyethylene wax. The modifier has the functions of coupling agent, dispersant, internal and external lubricant, processing assistant, etc. and has unique PVC / CaCO3 stuffing system modifying effects, including promoting plasticization, raising dispersivity, improving antiageing and machining performance, realizing high stuffing, etc.

Owner:NANJING CONCORD FERTILIZER CHEM

Application method of carbon black in master batch of conductive fiber and master batch of garment conductive fiber

InactiveCN101845163AImprove conductivityPromote plasticizationElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentSurface modificationElectrically conductive

The invention discloses an application method of carbon black in the master batch of a conductive fiber, which comprises the following steps: carrying out surface modification on the carbon black, kneading the carbon black with other raw materials for preparing the master batch and granulating to obtain the master batch, and the method for surface modification of the carbon black comprises the steps of atomizing the coupling agent for superconductive carbon black and spraying on the surface of the carbon black for modifying. The master batch of the garment conductive fiber prepared from the modified superconductive carbon black of the invention comprises the following components in mass percent: 44.5% of carrier resin, 12% of composite modified resin, 35% of modified superconductive nano carbon black, 3.5% of lubricant, 1.0% of antioxidant and 4.0% of dispersant. By modifying the superconductive carbon black, compared with the traditional carbon black, the conductivity is improved by more than one time, and the prepared conductive master batch has the advantage of preparing various conductive fibers.

Owner:SHANDONG TIANYE PLASTICIZATION +1

Multifunctional plastic additive and preparation method thereof

The invention relates to the field of plastic processing and in particular relates to a multifunctional plastic additive and a preparation method thereof. The multifunctional plastic additive comprises the following components in parts by weight: 70-89 parts of light calcium carbonate powder, 10-15 parts of stearate, 1.0-1.8 parts of mica powder, 3-5 parts of light magnesium oxide powder, 1-2 parts of organic tin, 2-3 parts of glass fiber powder, 1-2 parts of methacrylate, 1.0-1.5 parts of a coupler and 2-4 parts of a lubricant. The preparation method comprises the following steps: pre-modifying the light calcium carbonate powder by stearate, mixing the pre-modified light calcium carbonate powder, the mica powder, the light magnesium oxide powder and the glass fiber powder at a low speed, adding other formulation components, producing a high-temperature and low-speed stirring reaction, and discharging to obtain the multifunctional plastic additive. The preparation process is simple, and the prepared plastic additive can be used for improving the tensile strength, the strength, the pressure resistance and the like of a PVC (polyvinyl chloride) wood plastic composite material and a PVC engineering plastic.

Owner:汕头市亨德利塑胶有限公司

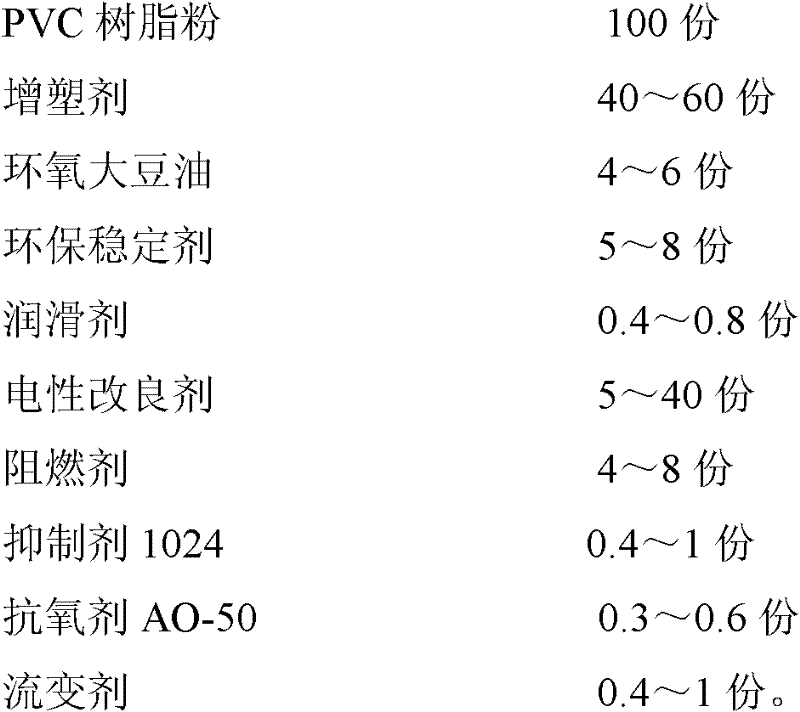

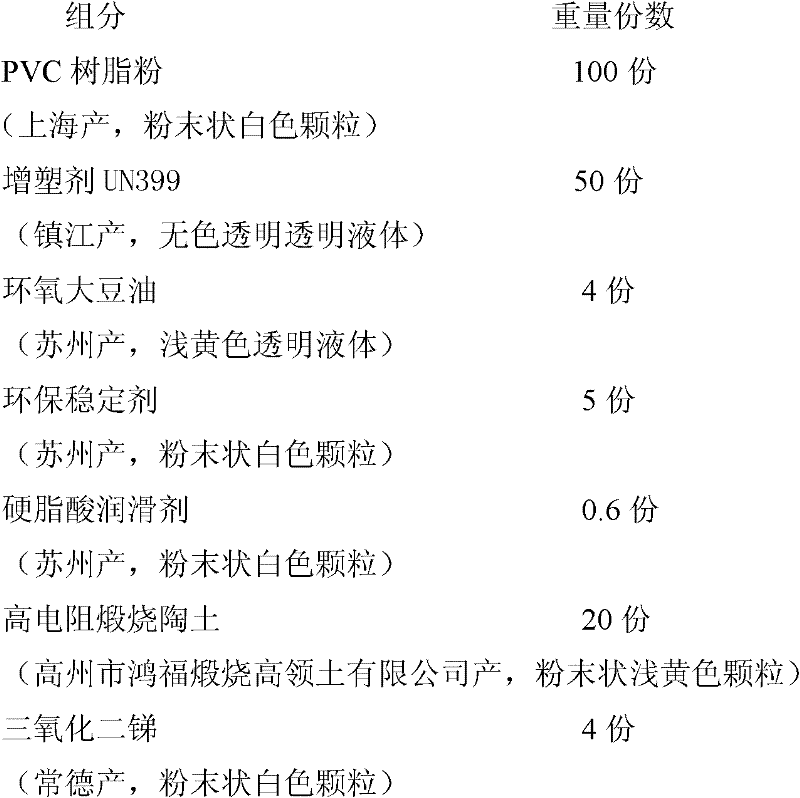

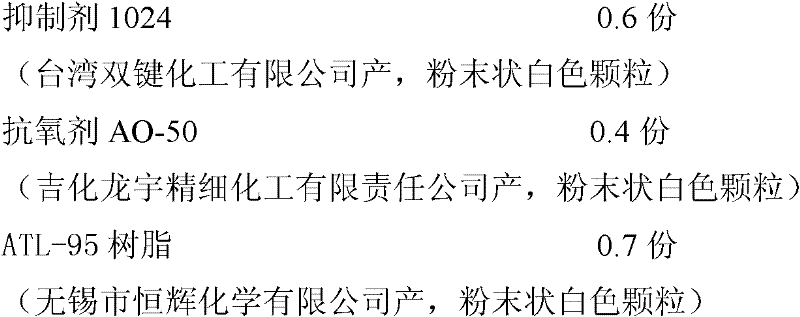

High humidity tolerance, high electric performance and environment-friendly polyvinyl chloride insulation material for electric wires and cables

InactiveCN102336987AExcellent high electrical propertiesPrevent agingPlastic/resin/waxes insulatorsPolyvinyl chlorideFire retardant

The invention discloses a high humidity tolerance, high electric performance and environment-friendly polyvinyl chloride (PVC) insulation material for electric wires and cables. The PVC insulation material is prepared by the following components by weight: 100 parts of PVC resin powder, 40 to 60 parts of a plasticizer, 4 to 6 parts of epoxy soybean oil, 5 to 8 parts of an environment-friendly stabilizing agent, 0.4 to 0.8 part of a lubricant, 5 to 40 parts of an electric performance modifier, 4 to 8 parts of a fire retardant, 0.4 to 1 part of inhibitor 1024, 0.3 to 0.6 part of the anti-oxidant AO-50 and 0.4 to 1 part of a rheological agent. The PVC insulation material for electric wires and cables in the invention, prepared by adopting a special raw material ratio, not only has excellent high humidity tolerance and high electric performance, but also enables a wire drawing speed of the material to be improved and environmental protection to be obtained. The PVC insulation material is applicable to wires used in temperature transmission devices for air-conditioners or to power lines, data lines or the like used in other high humidity environments.

Owner:SUZHOU HUAYING PLASTICS

Bentonite/ starch composite degrading material produced by melt intercalation and preparation method

The invention discloses a bentonite / starch composite degrading material produced by melt intercalation and a preparation method. The bentonite / starch composite degrading material is prepared from the following raw materials in parts by weight: 10 to 90 parts of biodegradable polymer material, 10 to 90 parts of starch, 5 to 30 parts of plasticizer, 1 to 5 parts of internal / external lubricant, 1 to 5 parts of heat stabilizer, 0.5 to 2.5 parts of antioxidant, and 1 to 30 parts of bentonite. The preparation method comprises the steps of blending the compound materials; plasticizing; extruding; granulating to obtain the final product. The bentonite / starch composite degrading material produced by melt intercalation and the preparation method has the beneficial effects that (1) the bentonite added can improve the heat resistance and processing fluidity of starch and can be greatly intercalated or filled, so that the production cost is decreased; (2) the starch is easily plasticized through the plasticizer; (3) the starch strength is greatly improved after the plasticizing; (4) the biodegradation is completely done; the characteristics of being small in investment, fast to develop and simple in production method are achieved.

Owner:WEIFANG HUAWEI MATERIALS TECH CO LTD

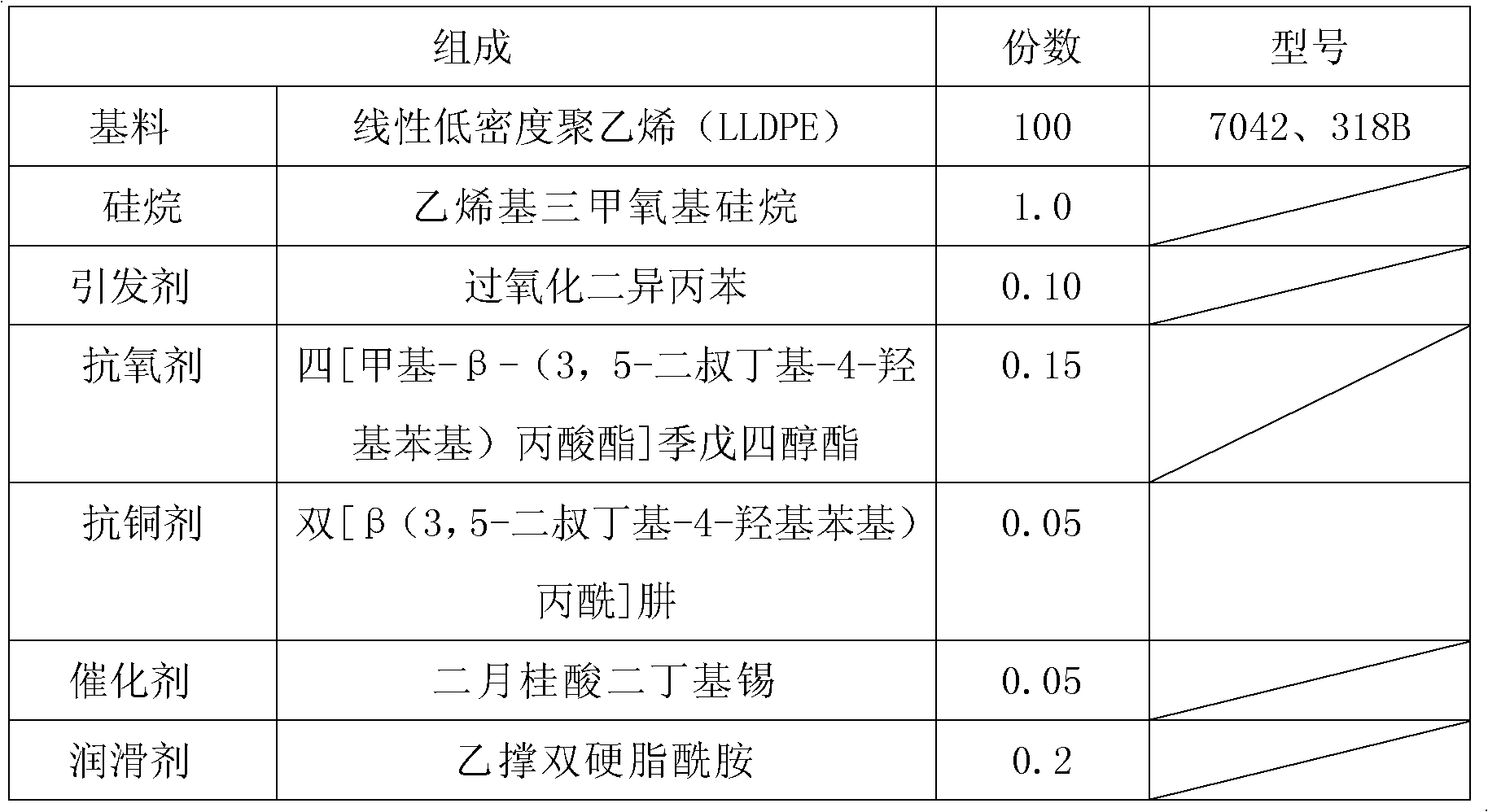

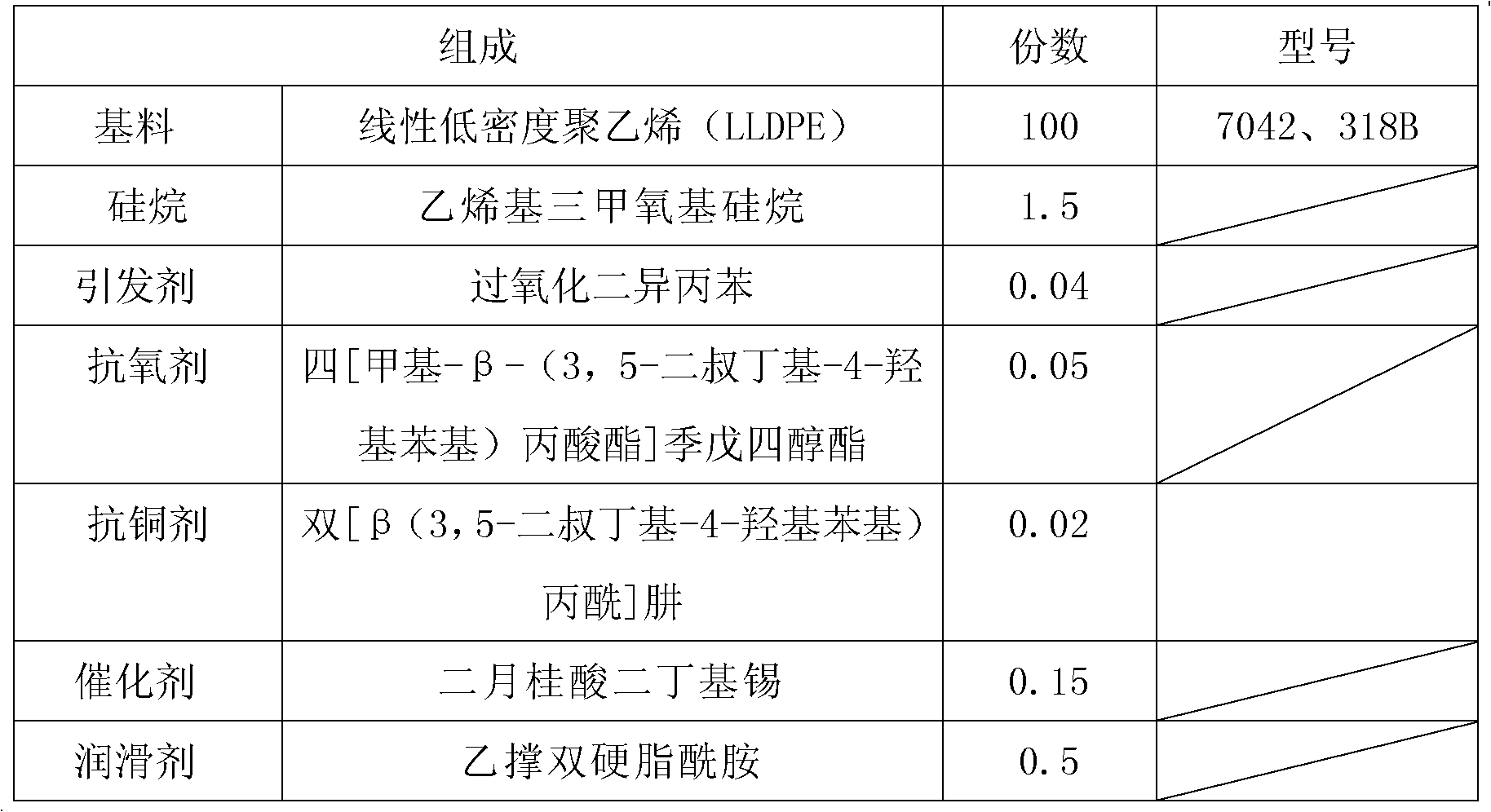

Low-retraction silicane XLPE (Cross Linked Polyethylene) insulating material of 10 KV and below applicable to extrusion one-step method

ActiveCN102838827ALow shrinkageControlled Insulation Shrinkage Test PerformancePlastic/resin/waxes insulatorsLinear low-density polyethyleneTest performance

The invention relates to a low-retraction silicane XLPE (Cross Linked Polyethylene) insulating material of 10 KV and below applicable to an extrusion one-step method. The low-retraction silicane XLPEinsulating material comprises the following components in parts by weight: 100 parts of linear low-density polyethylene, 1-1.5 parts of silicane, 0.04-0.10 part of initiator, 0.05-0.15 part of antioxidant, 0.01-0.05 part of anti-copper agent, 0.02-0.15 part of catalyst and 0.10-0.50 part of lubricant. The insulating material produced according to the invention is applicable to the process that the silicane, the initiator, the catalyst and the like are directly added into a same extruder for granulation by the one-step method, so that the insulating shrinkage test performance of a silicane XLPE insulating cable of 10 KV and below is improved, and meanwhile, insulating shrinkage test of the silicane XLPE insulating cable of 10 KV and below produced by using an extrusion mold can extremely easily reach index requirements.

Owner:FAR EAST CABLE +2

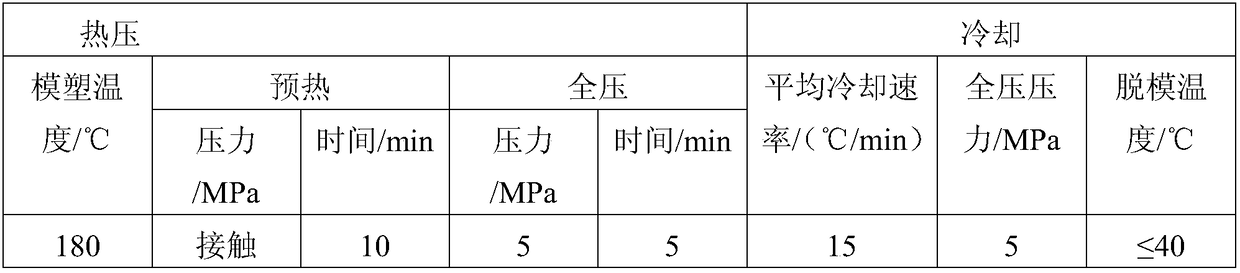

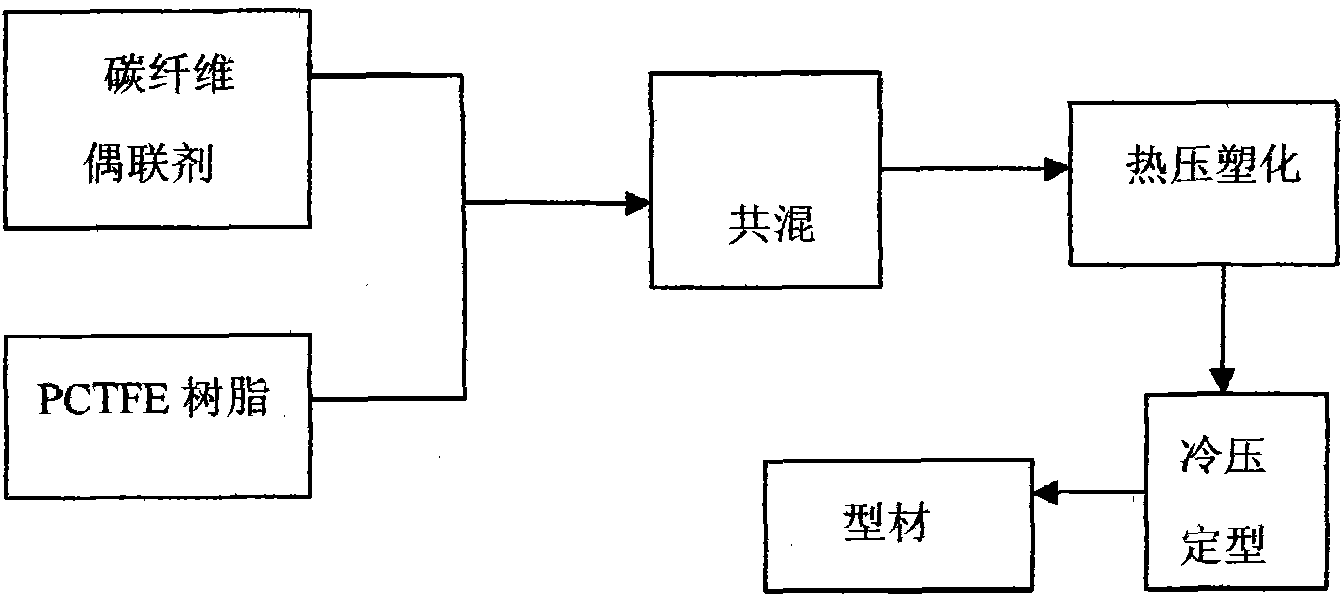

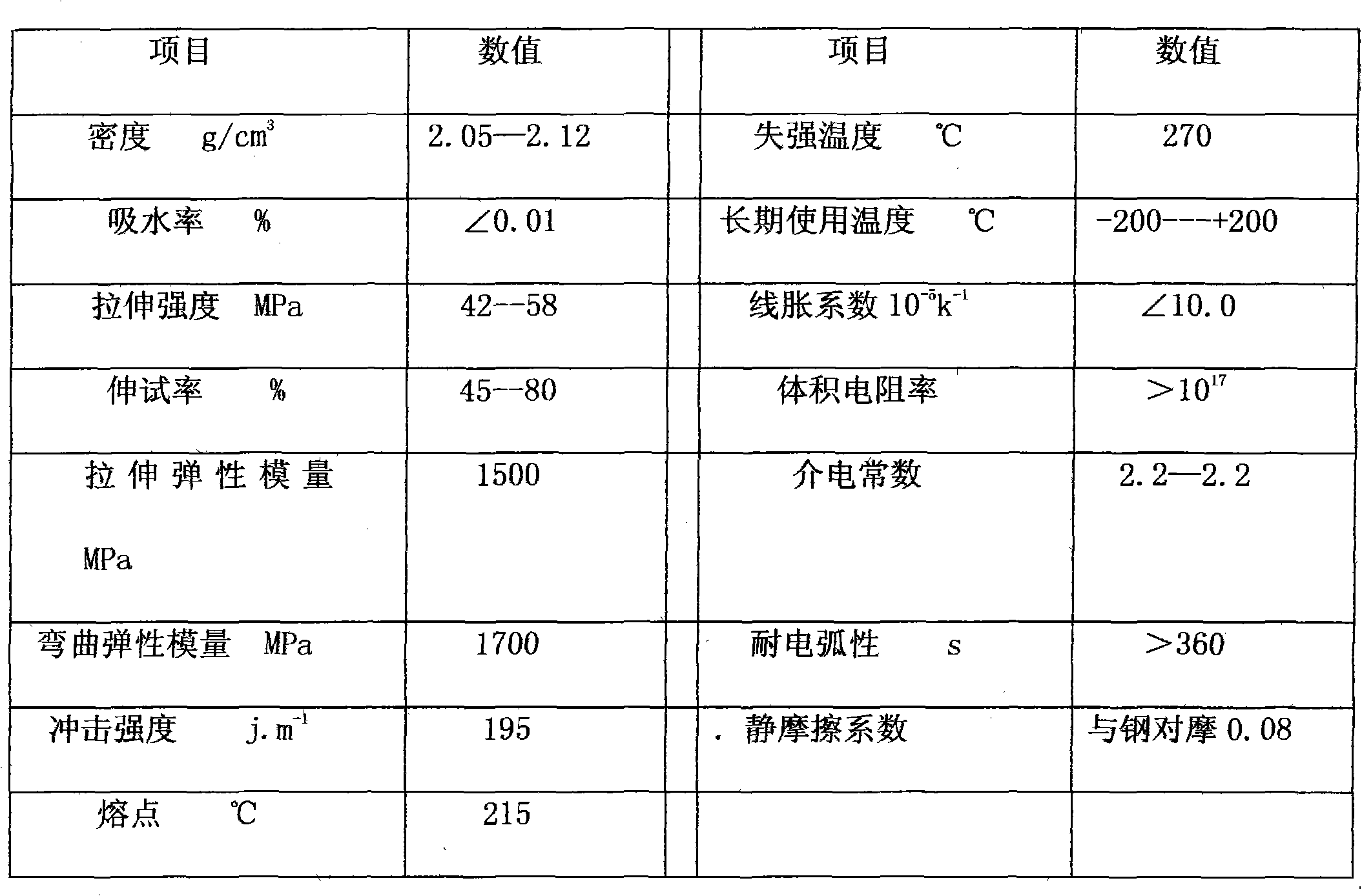

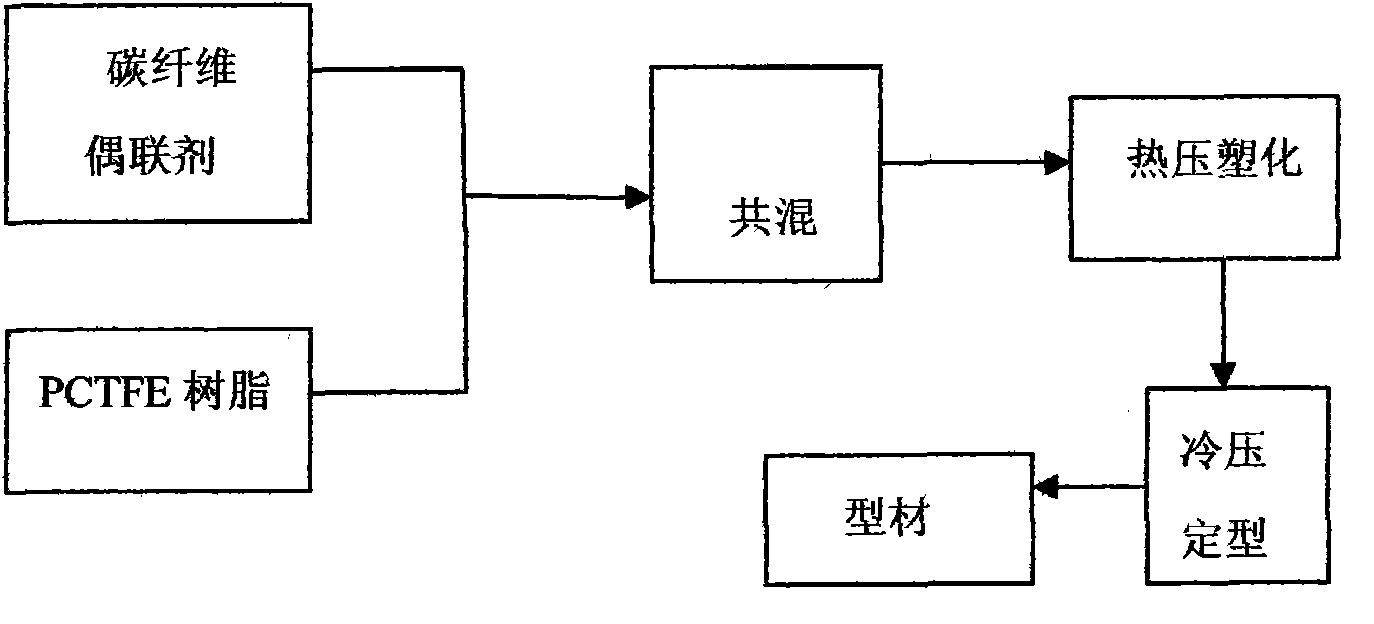

PCTFE modified filling composite material and production method thereof

The invention relates to a PCTFE modified filling composite material which comprises the following components in percentage by weight: 75-95% of PCTFE polymer, 4.2-24.2% of carbon fiber and 0.3-0.8% of coupling agent. The production method comprises the following steps: (1) material mixing; (2) extruding and blending; (3) plastifying by heating; and (4) setting by cold pressing. The PCTFE modified filling composite material has the advantages of low melt viscosity, favorable flowability, favorable thermal conductivity, wide forming temperature range, low requirements for processing temperature and soaking time, and favorable product plastication, and can be formed by multiple methods.

Owner:深圳市明鑫高分子技术有限公司

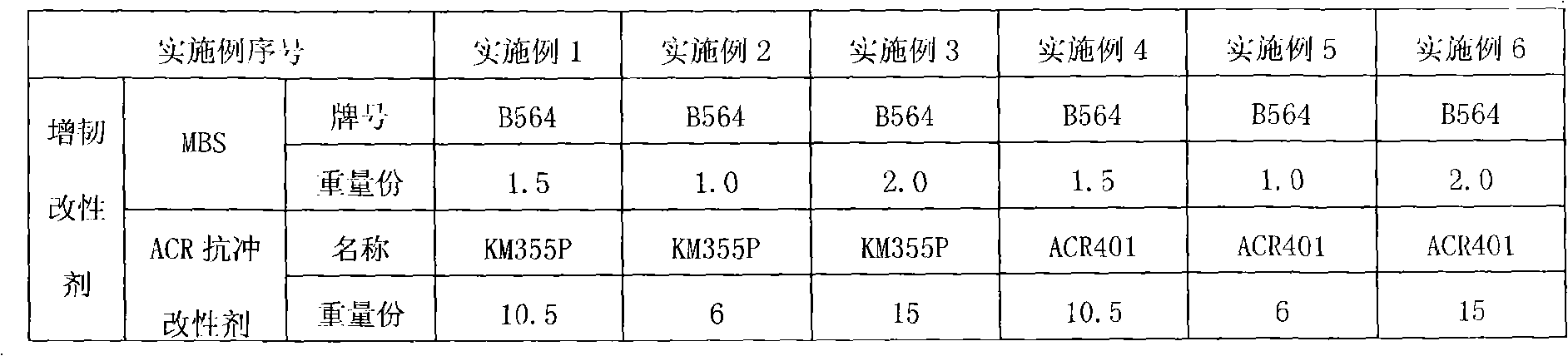

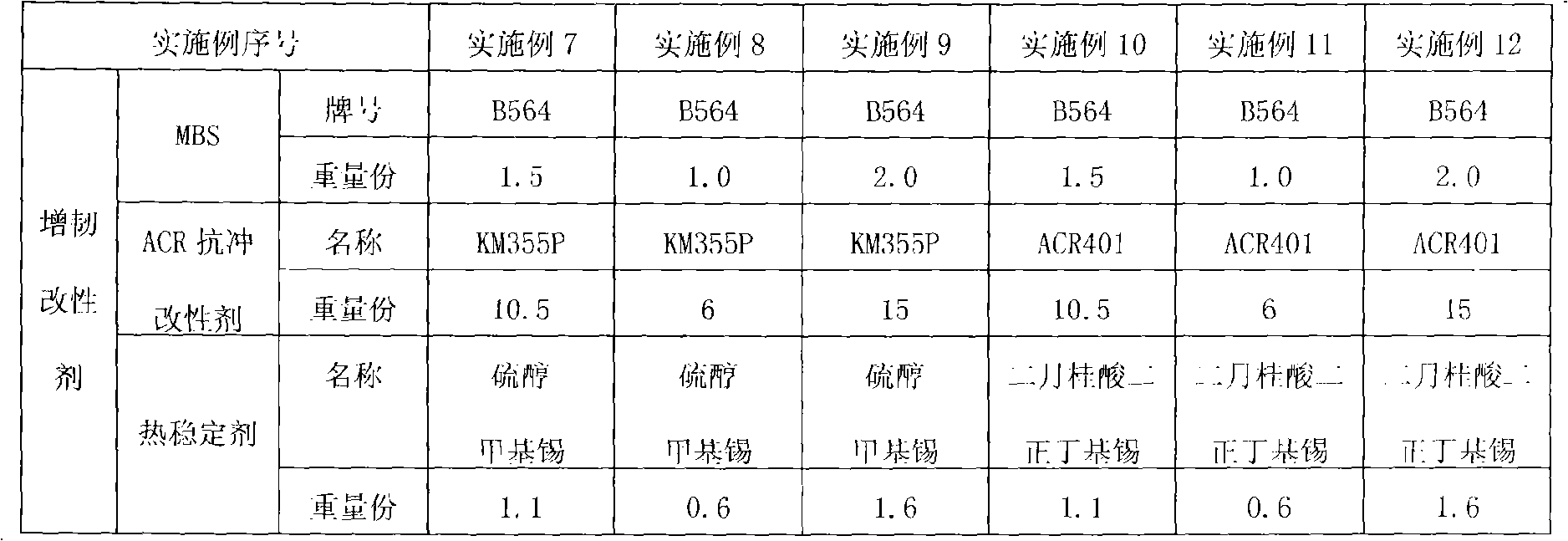

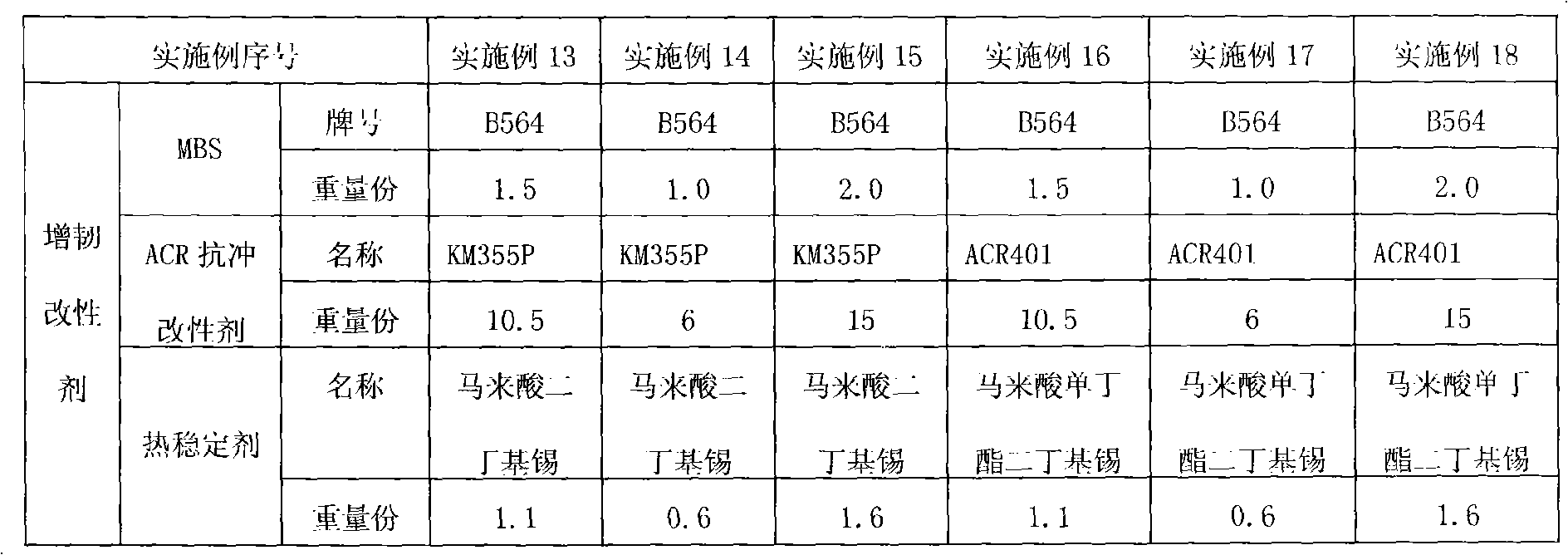

Polyvinyl chloride toughening modifier

InactiveCN101565530AImprove impact resistanceHigh surface glossRigid pipesMethylmethacrylatesPolyvinyl chloride

The invention discloses a polyvinyl chloride toughening modifier, which comprises 1.0 to 2.0 portions of methylmethacrylate butadine stryrene copolymer which is also called MBS, and 6 to 15 portions of acrylates impact modifier which is also called ACR impact modifier; and the portion of the compositions is weight portion. The polyvinyl chloride toughening modifier has good toughening and modification effects on polyvinyl chloride.

Owner:干方明

High-toughness matte modified polylactic acid material for 3D printing and preparation method of high-toughness matte modified polylactic acid material

ActiveCN109575539AImprove poor toughnessImprove anti-agingAdditive manufacturing apparatusElastomerAntioxidant

The invention relates to a high-toughness matte modified polylactic acid material for 3D printing and a preparation method of the high-toughness matte modified polylactic acid material. The modified polylactic acid material is prepared from, by weight, 100 parts of polylactic acid, 10-15 parts of a main toughening agent, 5-8 parts of an auxiliary toughening agent, 20-40 parts of filler, 3-6 partsof silicon dioxide matting powder, 0.1-0.5 part of a titanate coupling agent, 0.1-0.6 part of an antioxidant, 0.1-0.6 part of a light stabilizer and 0.2-0.5 part of a lubricant, wherein the main toughening agent is a soft-core hard-shell type core-shell copolymer with methyl methacrylate as a shell, the auxiliary toughening agent refers to an elastomer toughening agent containing anhydride or epoxy group, and the filler refers to barium sulfate powder or calcium carbonate powder. The high-toughness matte modified polylactic acid material for 3D printing is excellent in toughness, remarkable inaging resistance and great in matte surface effect.

Owner:诺思贝瑞新材料科技(苏州)有限公司

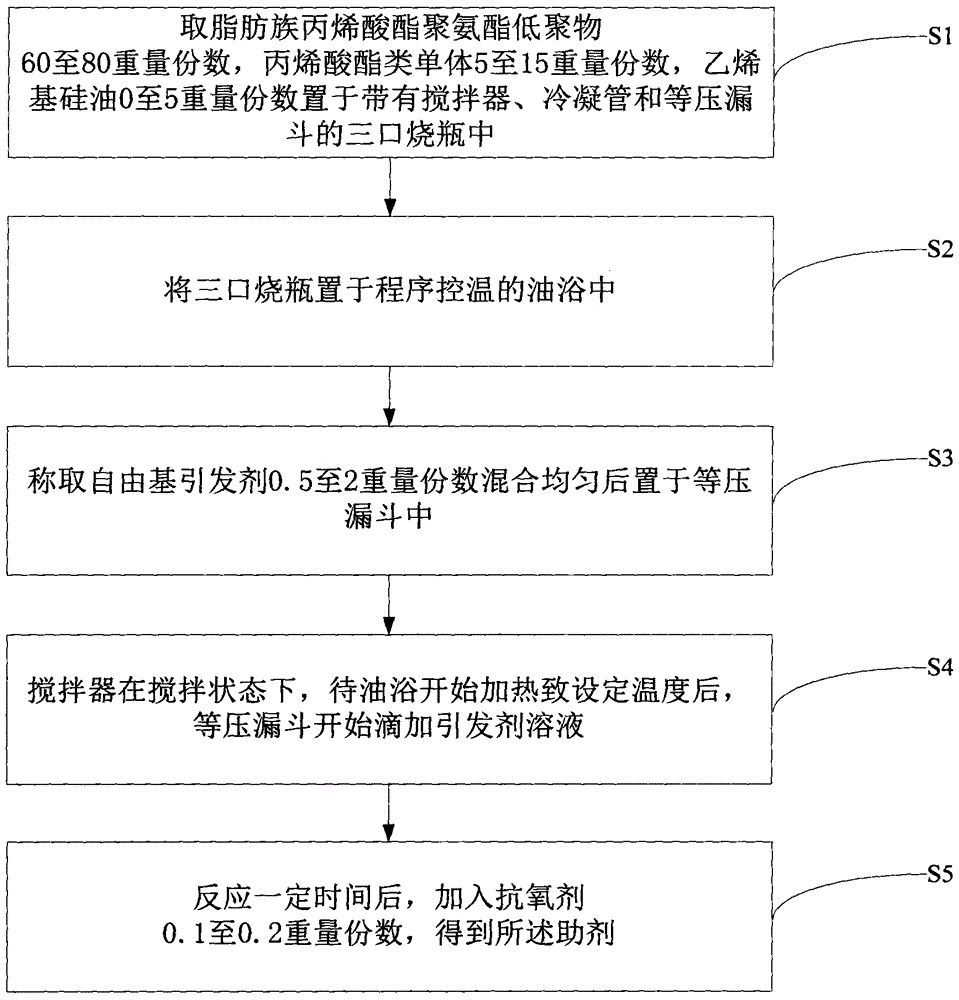

Preparation method for multifunctional plastic additive

A preparation method for a multifunctional plastic additive including following steps: filling a three-necked flask with 60-80 parts by weight of an aliphatic acrylate polyurethane oligomer, 5-15 parts by weight of an acrylate monomer and 0-5 parts by weight of vinyl silicone oil, wherein the three-necked flask is provided with a stirring apparatus, a condensing pipe and a constant-pressure funnel; placing the three-necked flask into an oil bath which is temperature-controlled by program; weighing 0.5-2 parts by weight of a radical initiator with mixing uniformly; feeding the radical initiator into the constant-pressure funnel; when the oil bath heats the three-necked flask to a preset temperature, dropwisely adding the initiator solution from the constant-pressure funnel with the stirring apparatus being in a stirring status; adding 0.1-0.2 parts by weight of an antioxidant after a reaction being carried out for a certain time to obtain the additive. Functions such as coupling, compatibility, dispersion, lubrication and the like are integrated in the multifunctional plastic additive. The multifunctional plastic additive can be used for processing polymer composites, can improve compatibilities of each components in a system well, can promote plastification, can reduce viscosity of a melt, can improve processing fluidity, can reduce a torque of an processing device and processing energy consumption and can improve efficiency.

Owner:广州源泰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com