Preparation method for multifunctional plastic additive

A plastic additive and multi-functional technology, which is applied in the chemical industry and can solve the problems of complex multi-functional additive methods, unenvironmental protection and user inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

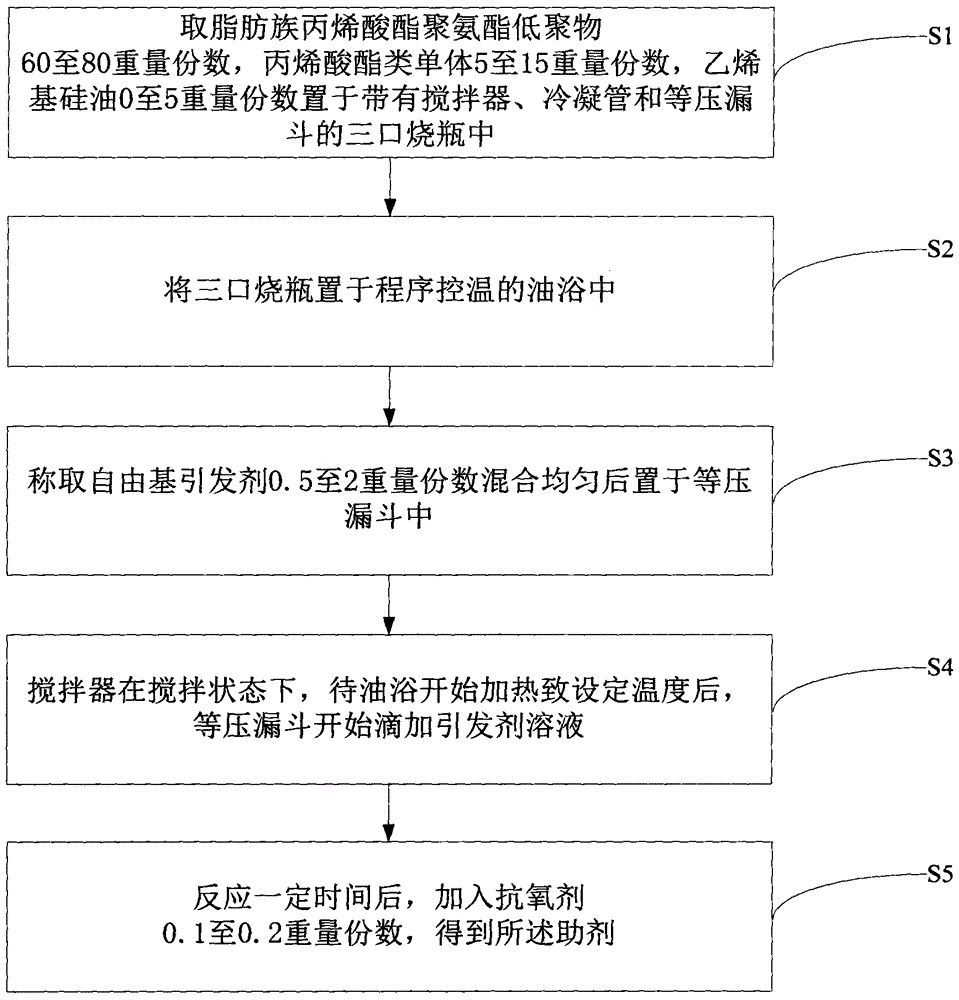

[0022] according to figure 1 As shown, a preparation method of a multifunctional plastic additive includes:

[0023] Step S1. Take 60 to 80 parts by weight of aliphatic acrylate urethane oligomer, 5 to 15 parts by weight of acrylate monomer, and 0 to 5 parts by weight of vinyl silicone oil and place it with a stirrer, condenser and In the three-necked flask of an isobaric funnel;

[0024] Step S2: Place the three-necked flask in a temperature-controlled oil bath;

[0025] Step S3: Weigh 0.5 to 2 parts by weight of the free radical initiator, mix it evenly, and place it in an equal pressure funnel;

[0026] Step S4: When the stirrer is in a stirring state, after the oil bath starts to heat to a set temperature, the isostatic funnel starts to drip the initiator solution;

[0027] Step S5: After reacting for a certain period of time, 0.1 to 0.2 parts by weight of antioxidant is added to obtain the auxiliary agent.

[0028] Wherein, the rotation speed of the stirrer during the reaction is ...

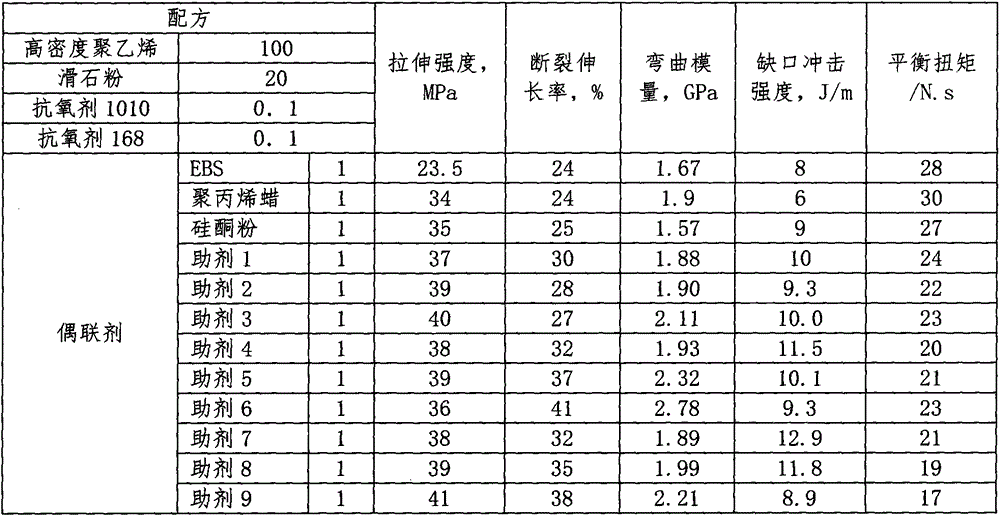

Embodiment 1

[0036] Take 60 g of aliphatic acrylate polyurethane oligomer, 10 g of methyl acrylate, and 2 g of vinyl triethoxy silane in a 100 ml three-necked flask with a stirrer, condenser and isobaric funnel. The three-necked flask is placed in the program In a temperature-controlled oil bath;

[0037] Then weigh 0.5 g of dicumyl peroxide initiator, mix it evenly, and place it in an equal pressure funnel;

[0038] When the stirrer is stirring at 200 rpm, the oil bath starts to heat to 165°C, and the isobaric funnel starts to drip the initiator solution at a rate of 30 drops / min;

[0039] After 4 hours of reaction, 168 0.2 g of antioxidant was added to obtain auxiliary agent 1.

Embodiment 2

[0041] Take 60g of aliphatic acrylate polyurethane oligomer, 10g of methyl acrylate, and 2g of vinyltrimethoxysilane in a 100ml three-necked flask with a stirrer, condenser and isobaric funnel. The three-necked flask is placed in a program control In a warm oil bath;

[0042] Then weigh 0.5 g of dicumyl peroxide initiator, mix it evenly, and place it in an equal pressure funnel;

[0043] When the stirrer is stirring at 200 rpm, the oil bath starts to heat to 165°C, and the isobaric funnel starts to drip the initiator solution at a rate of 30 drops / min;

[0044] After 4 hours of reaction, 168 0.2 g of antioxidant was added to obtain auxiliary agent 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com