Rotomolded polyolefin composition and preparation method thereof

A technology of polyolefin and composition, applied in the field of rotational molding polyolefin composition and its preparation, can solve the problems of raw material heating, slow cooling rate, increased rotational molding time, performance degradation, etc. The effect of body viscosity and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

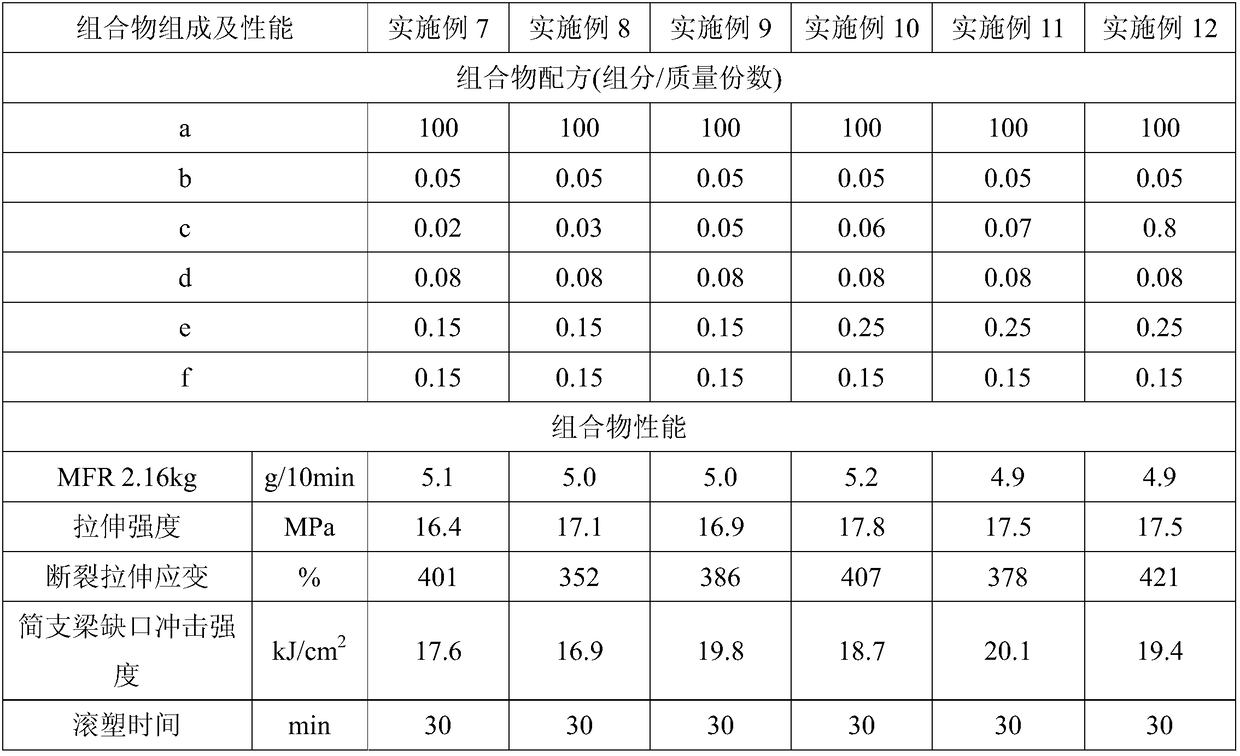

Embodiment 1-12 and comparative example 1-3

[0039] The raw materials used in embodiment 1-12 and comparative example 1-3:

[0040] a. Polyethylene: MFR4.3g / 10min, density 0.935g / cm 3 , commercially available;

[0041] b, hyperbranched polyethylene: amide hyperbranched polyethylene with ester groups, number average molecular weight 4000, commercially available;

[0042] c, nucleating agent: titanium dioxide, 800 mesh, commercially available;

[0043] d, acid absorbing agent: zinc stearate, commercially available;

[0044] e, UV absorber: 788, commercially available;

[0045] f, antioxidant: B225, commercially available.

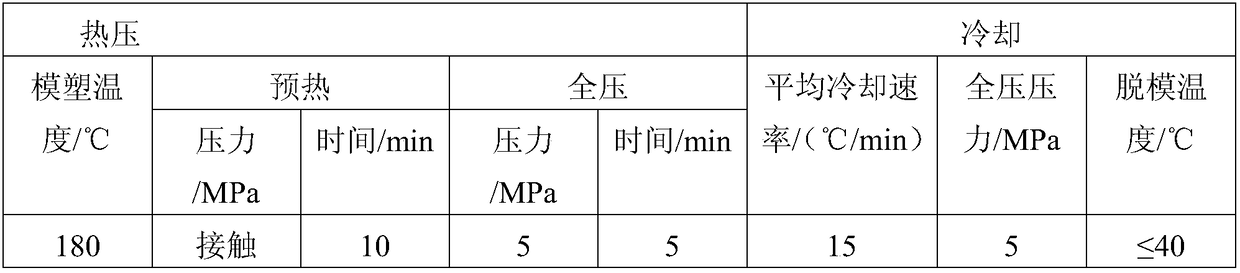

[0046] The preparation method that embodiment 1-12 and comparative example 1-3 adopt:

[0047] (1) Hyperbranched polyethylene, nucleating agent, antioxidant, acid absorbing agent are added in the reaction flask, then add n-hexane, heat to reflux and stir, remove solvent with rotary evaporator, vacuum dry;

[0048] (2) adding ultraviolet absorber and the material obtained after the treatment in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com