Low-retraction silicane XLPE (Cross Linked Polyethylene) insulating material of 10 KV and below applicable to extrusion one-step method

An extruded and insulating material technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of not disclosing the specific grade of base resin, little reference value, wide range of additive types and dosages, etc. , to achieve the effect of narrowing the dosage range, inhibiting the grafting reaction, and reducing the shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

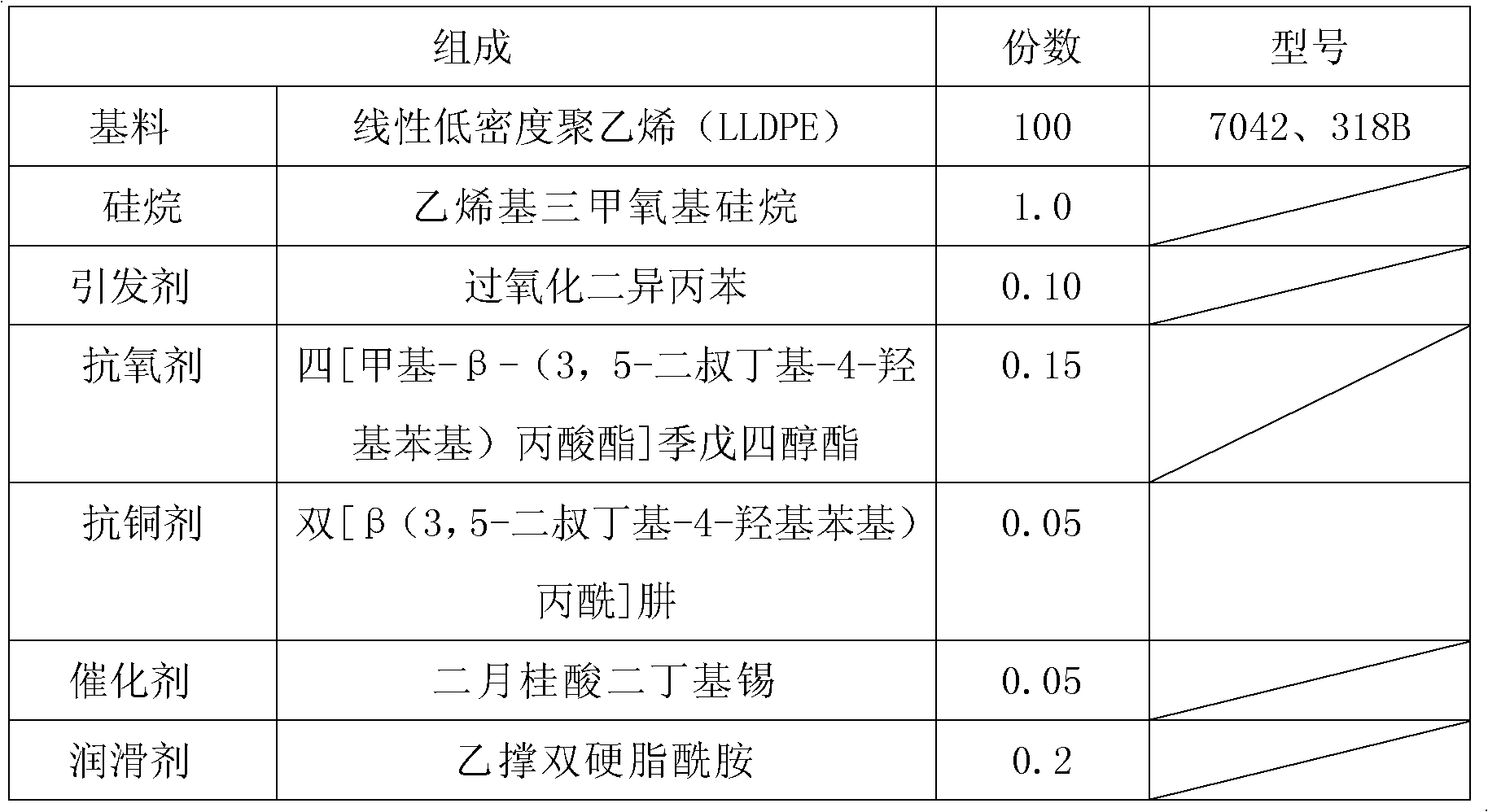

[0041] The composition, ratio and model of the 10KV and below low-retraction silane XLPE insulating material suitable for the extrusion one-step method in this embodiment are shown in Table 1:

[0042] Table I

[0043]

[0044] In the present embodiment: the mechanical property, physical property, electrical property of its insulating material are shown in Table two:

[0045] Table II

[0046] serial number

[0047] serial number

Embodiment 2

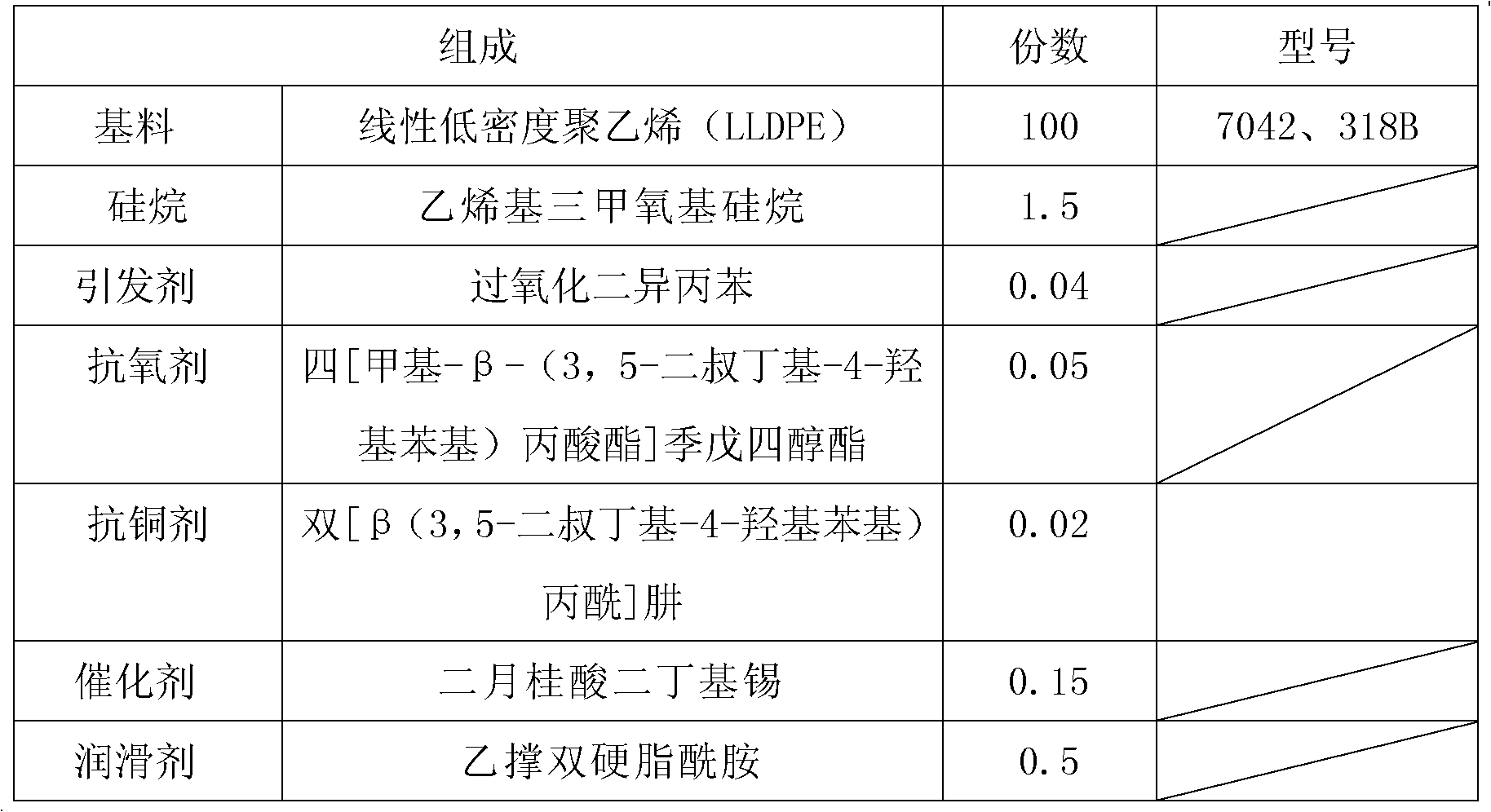

[0049] The composition, ratio and model of the 10KV and below low-retraction silane XLPE insulating material suitable for the extrusion one-step method in this embodiment are shown in Table 3:

[0050] Table three

[0051]

[0052] In the present embodiment: the mechanical performance, physical performance, electrical performance of its insulating material are shown in Table 4:

[0053] Table four

[0054] serial number

[0055] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com