High humidity tolerance, high electric performance and environment-friendly polyvinyl chloride insulation material for electric wires and cables

A wire and cable, polyvinyl chloride technology, applied to organic insulators, plastic/resin/wax insulators, etc., to achieve the effects of inhibiting oxidation, improving high electrical properties, and retarding aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

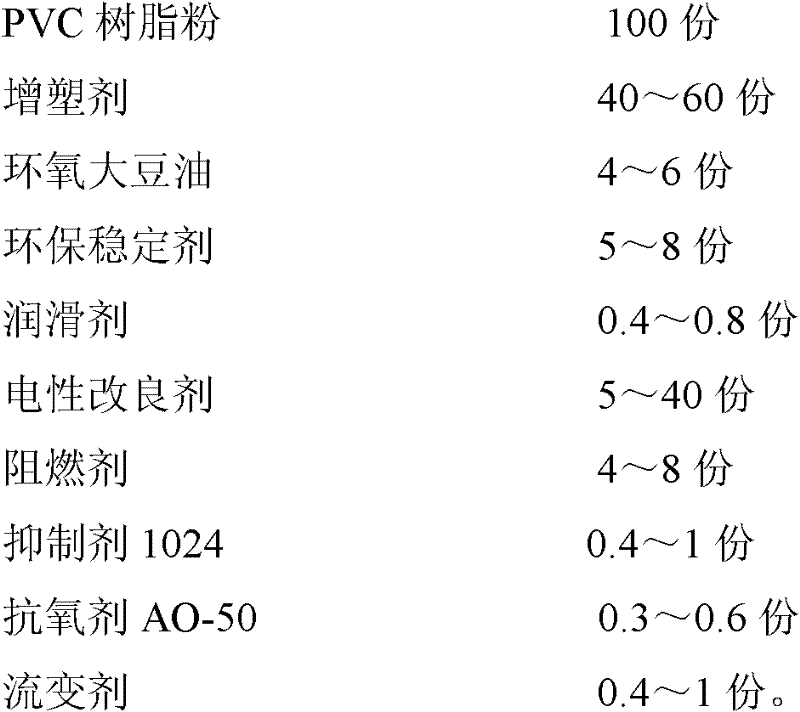

[0017] A high-humidity and high-electricity environment-friendly polyvinyl chloride insulating material for wire and cable, which includes the following components in parts by weight:

[0018]

[0019]

[0020] Put PVC resin powder, environmental stabilizer, and plasticizer UN399 into the high-speed mixer in turn according to the amount of the formula, mix at high speed for 2 to 5 minutes, then put in the rest of the auxiliary materials, mix for 10 to 15 minutes, observe that the powder is completely mixed and then discharged into the To the plastic extruder, extrude and granulate after complete plasticization.

Embodiment 2

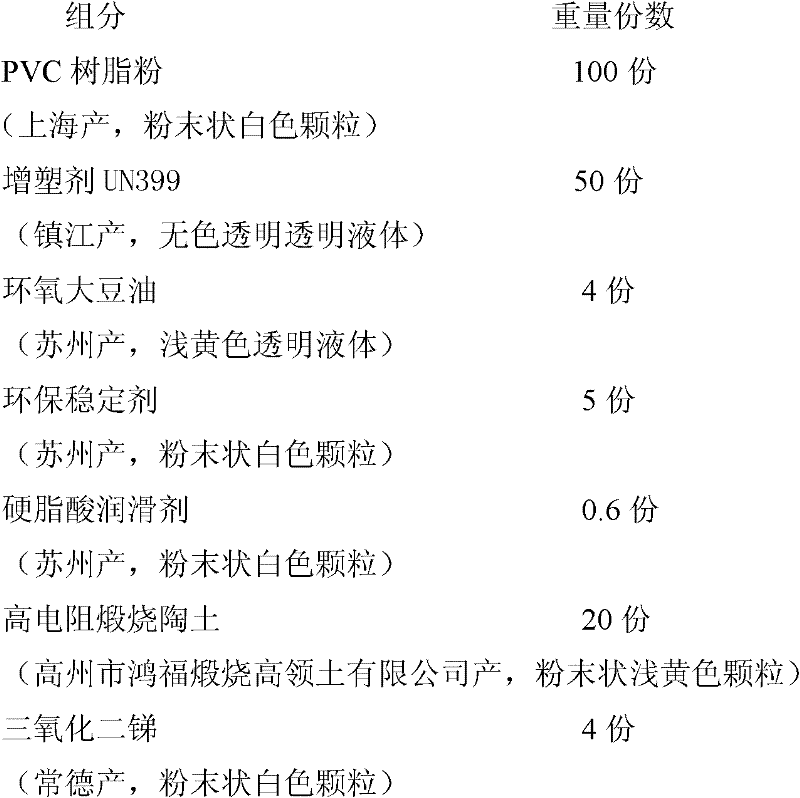

[0022] A high-humidity and high-electricity environment-friendly polyvinyl chloride insulating material for wire and cable, which includes the following components in parts by weight:

[0023]

[0024] Put PVC resin powder, environmental stabilizer, and plasticizer UN399 into the high-speed mixer in turn according to the amount of the formula, mix at high speed for 2 to 5 minutes, then put in the rest of the auxiliary materials, mix for 10 to 15 minutes, observe that the powder is completely mixed and then discharged into the To the plastic extruder, extrude and granulate after complete plasticization.

Embodiment 3

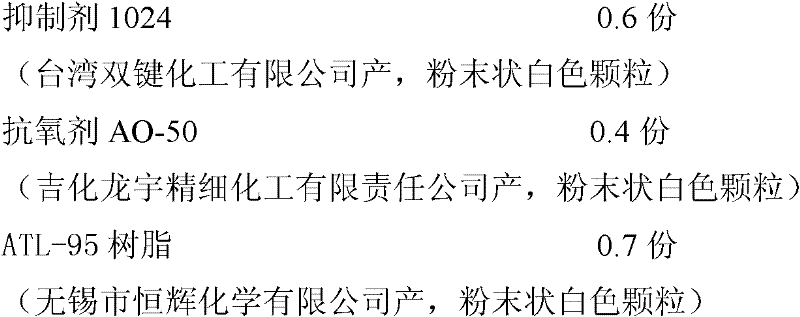

[0026] A high-humidity and high-electricity environment-friendly polyvinyl chloride insulating material for wire and cable, which includes the following components in parts by weight:

[0027]

[0028] Put PVC resin powder, environmental stabilizer, and plasticizer UN399 into the high-speed mixer in turn according to the amount of the formula, mix at high speed for 2 to 5 minutes, then put in the rest of the auxiliary materials, mix for 10 to 15 minutes, observe that the powder is completely mixed and then discharged into the To the plastic extruder, extrude and granulate after complete plasticization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com