High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

A technology with ultra-high molecular weight and high molecular weight, which is applied in the field of polymer processing, can solve problems such as poor compatibility, and achieve the effects of good compatibility, good dispersion and improved impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

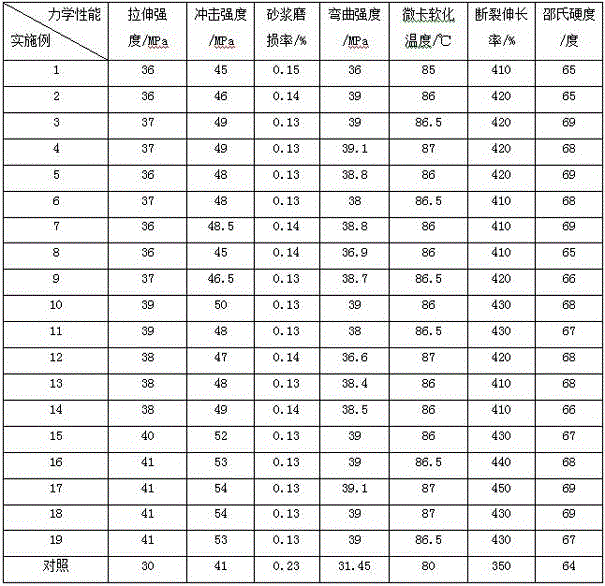

Examples

Embodiment 1

[0035]A high molecular weight polymer nucleating agent modified ultra-high molecular weight polyethylene blend material, comprising the following raw materials in parts by weight:

[0036] Ultra-high molecular weight polyethylene UHMWPE: 60.0 kg, high-density polyethylene HDPE: 5.0 kg, linear low-density polyethylene LLDPE: 6.0 kg, high molecular weight polymer nucleating agent PNA: 0.1 kg and ethylene bisoleamide: 1.5 kg .

Embodiment 2

[0038] A high molecular weight polymer nucleating agent modified ultra-high molecular weight polyethylene blend material, comprising the following raw materials in parts by weight:

[0039] UHMWPE: 62.0 kg, HDPE: 5.8 kg, LLDPE: 7.0 kg, high molecular weight polymer nucleating agent PNA: 0.23 kg and ethylene bis-lauramide: 1.56 kg.

Embodiment 3

[0041] A high molecular weight polymer nucleating agent modified ultra-high molecular weight polyethylene blend material, comprising the following raw materials in parts by weight:

[0042] UHMWPE: 70.0 kg, HDPE: 6.7 kg, LLDPE: 8.1 kg, high molecular weight polymer nucleating agent PNA: 0.45 kg, MA-PP: 1.7 kg, antioxidant 1076: 0.21 kg and ultraviolet absorber UV-329: 0.23 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com