Patents

Literature

109 results about "Methylmethacrylates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

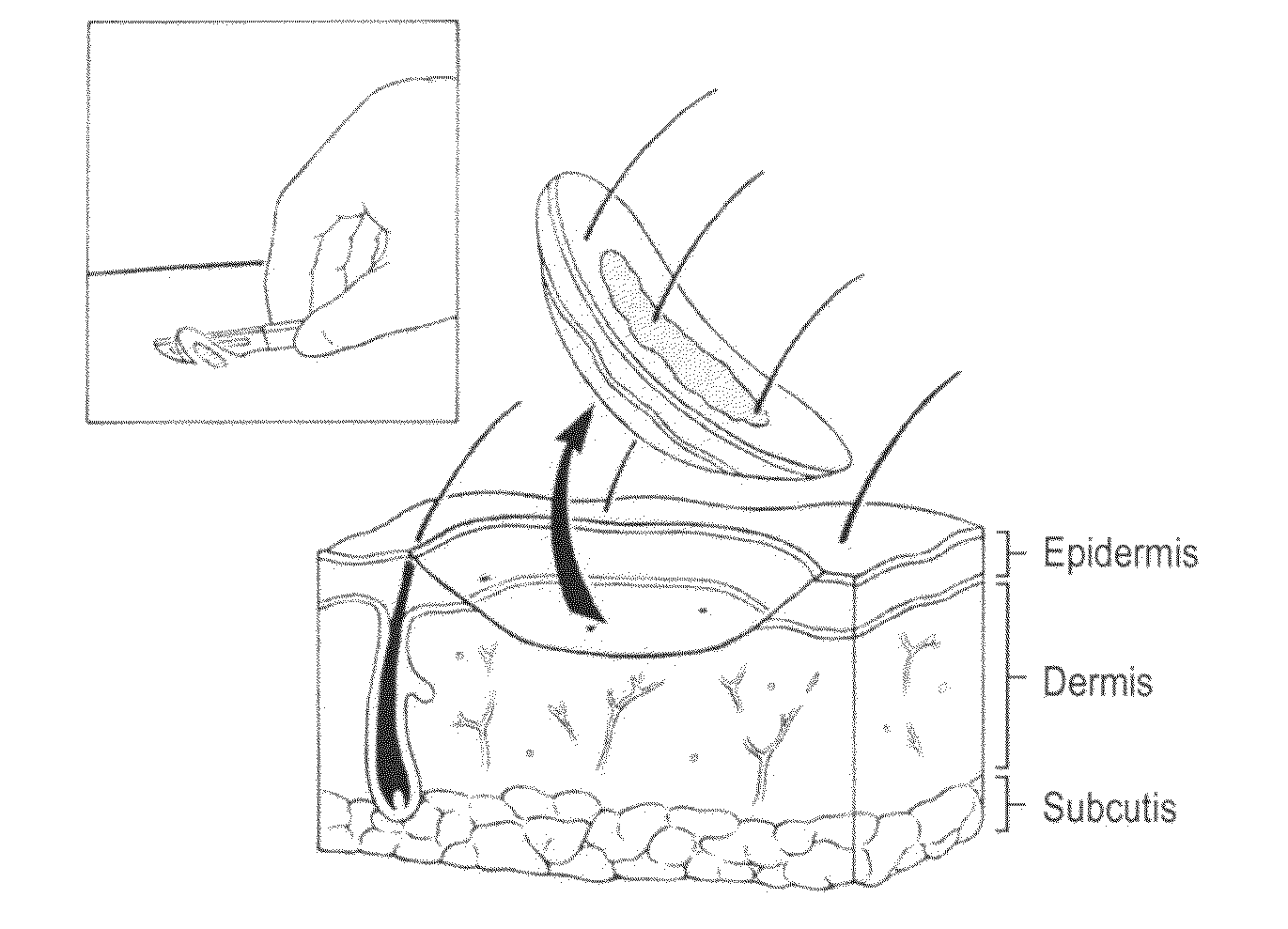

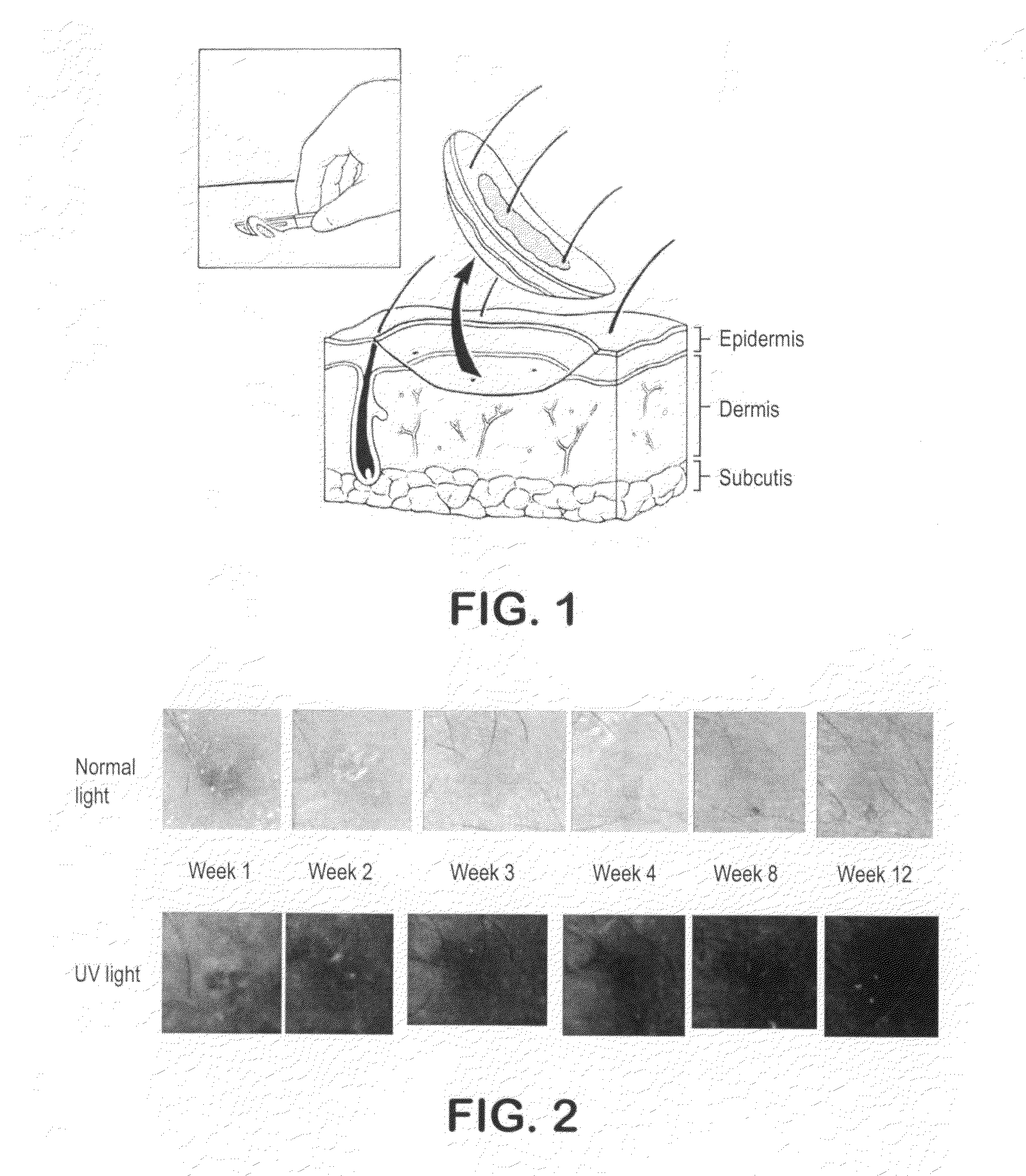

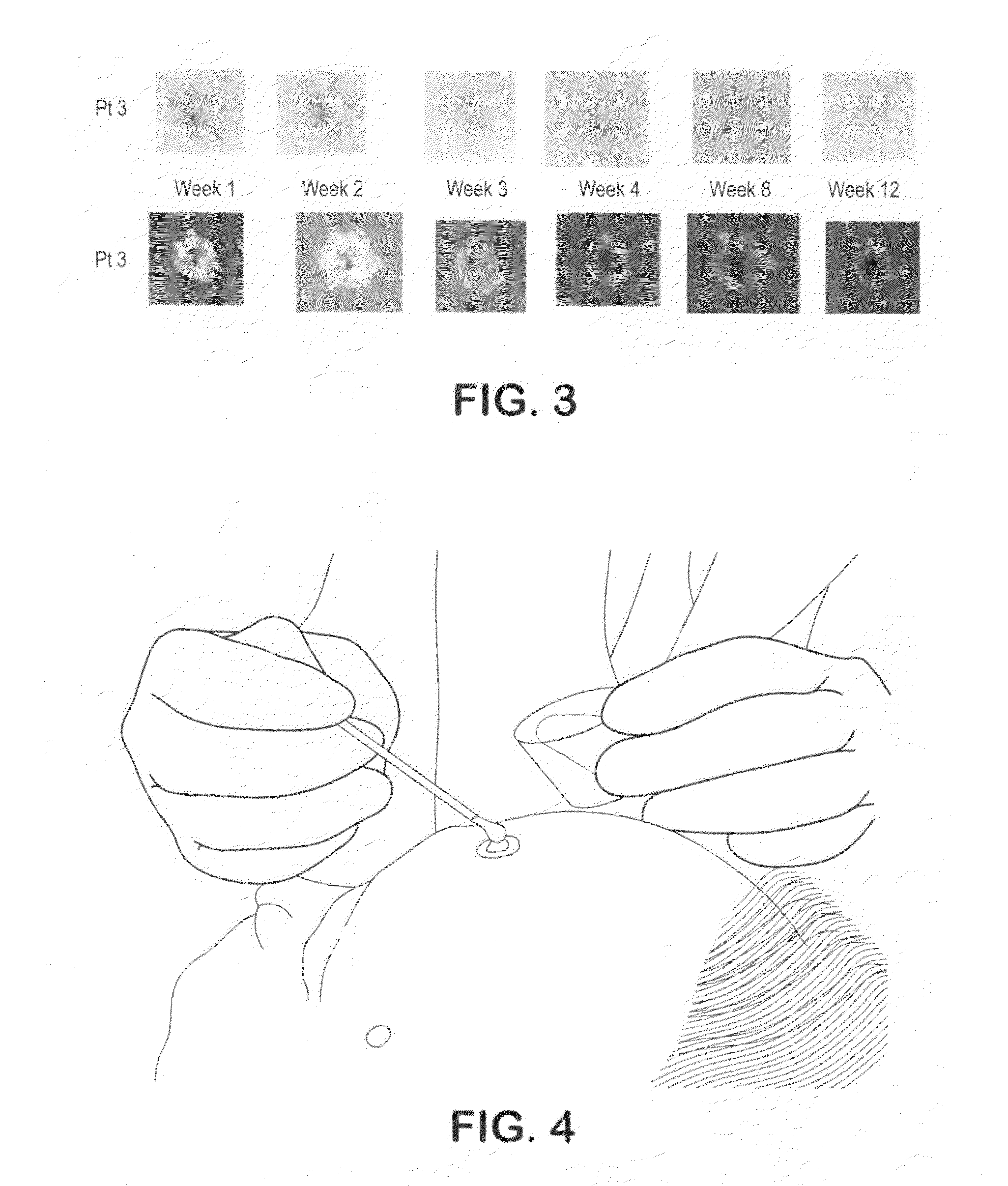

Biopsy marker composition and method of use

InactiveUS20110077512A1Improve efficiencyUltrasonic/sonic/infrasonic diagnosticsDispersion deliveryFluorescenceMedicine

An aqueous suspension of titanium dioxide, polymethylmethacrylate and Vitamin E oil is used to mark a location wherein a skin biopsy has been taken to enable subsequent identification of the biopsy location under ultraviolet light. The location is advantageously treated with Vitamin E oil on a daily basis subsequently extend the fluorescing life of the applied titanium dioxide.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

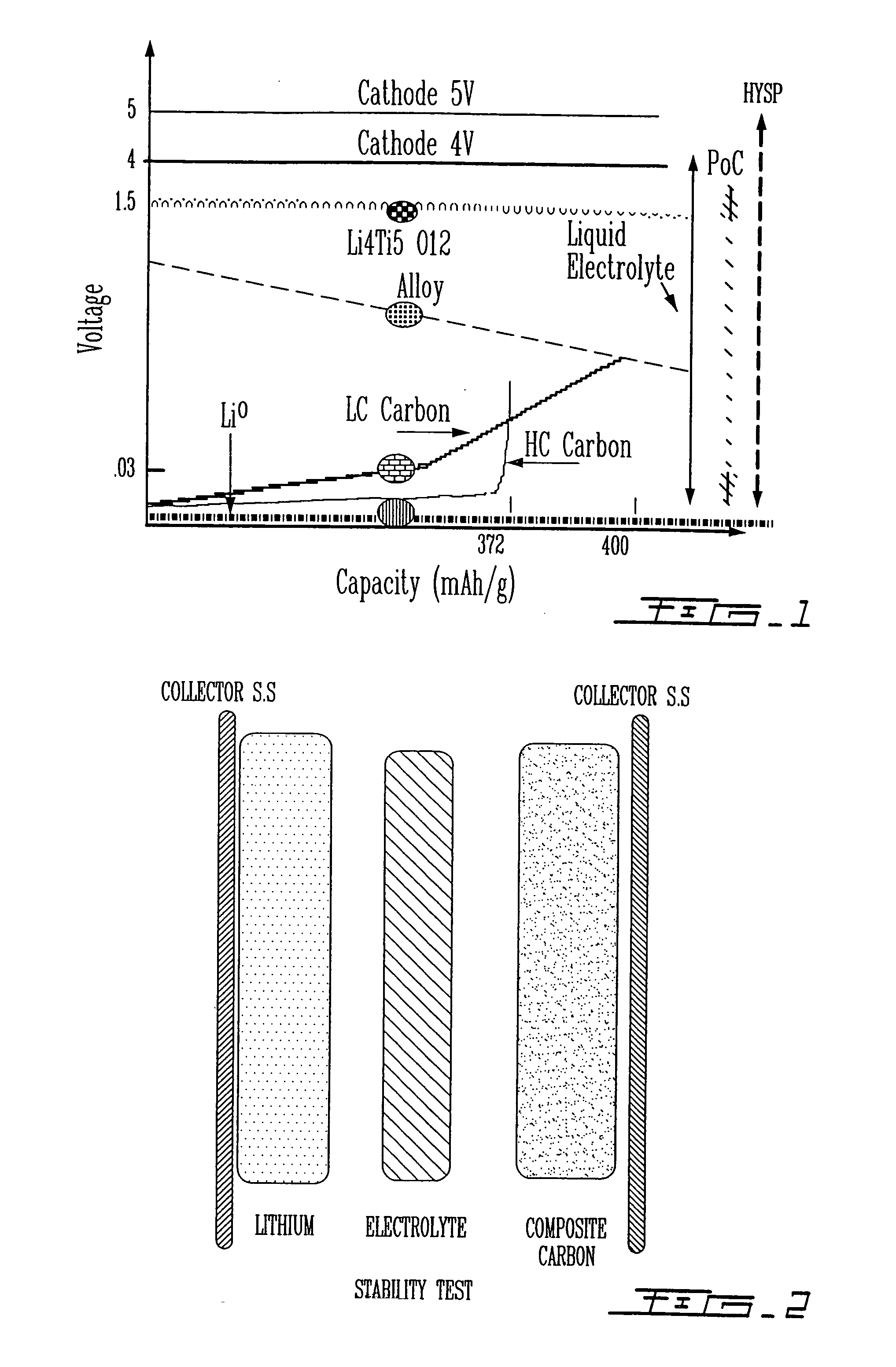

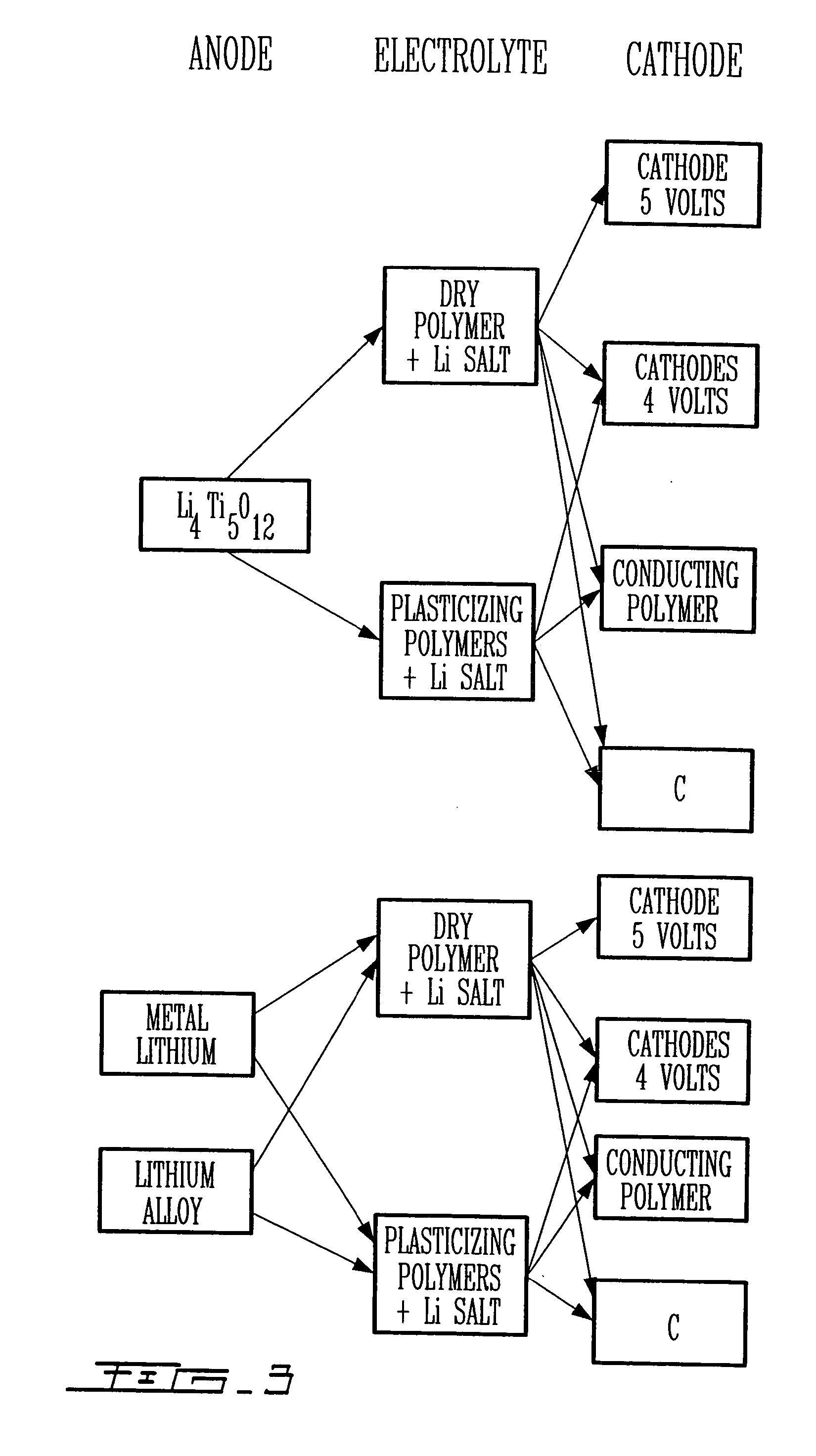

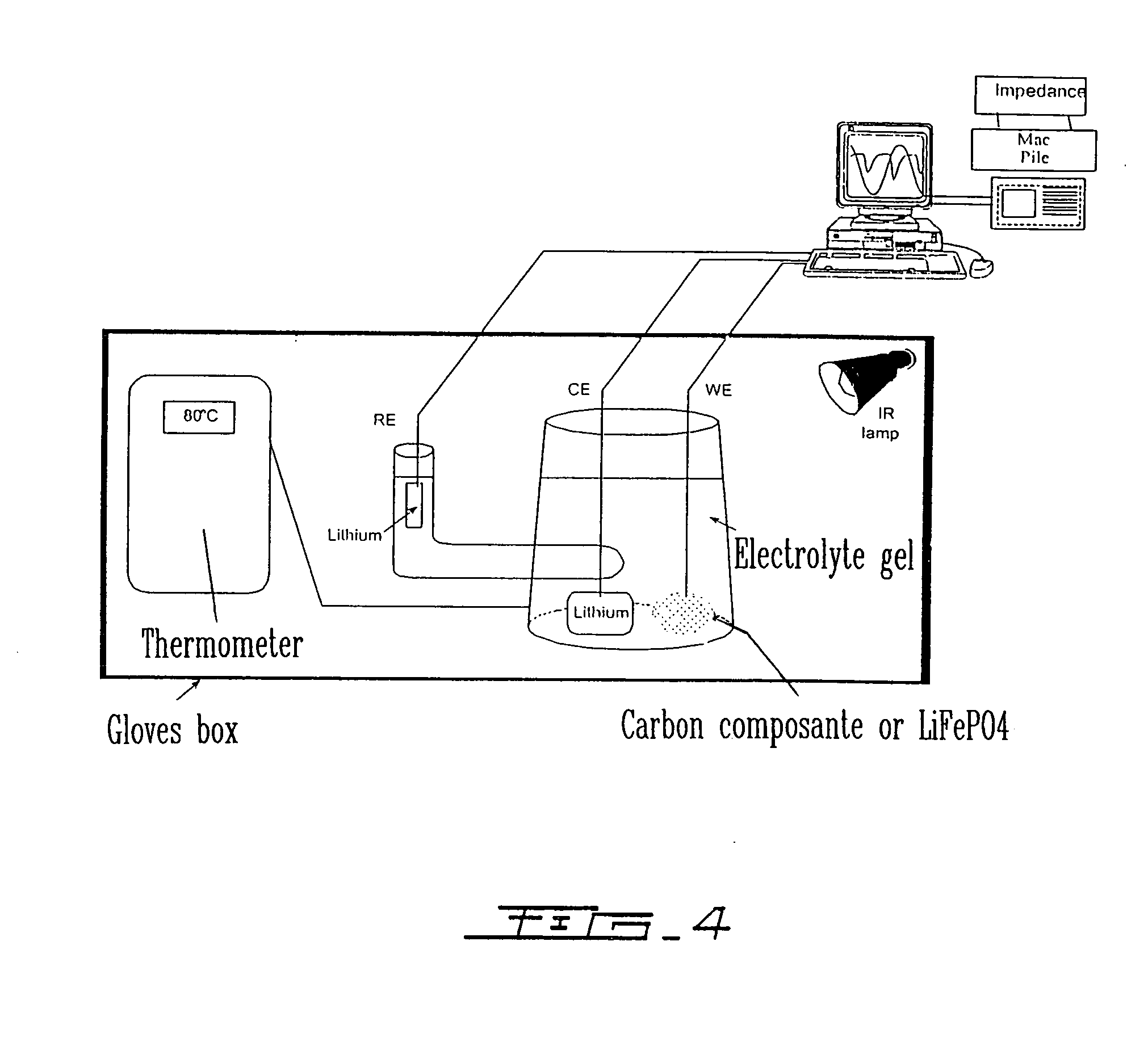

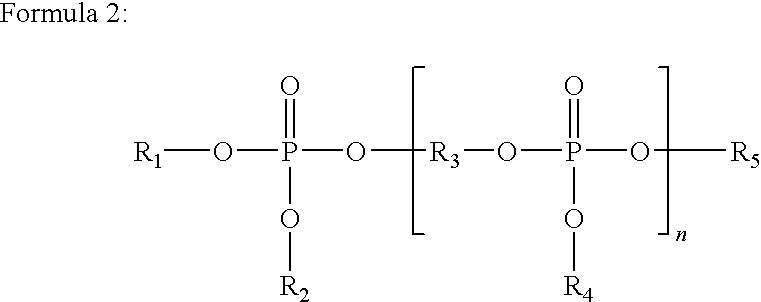

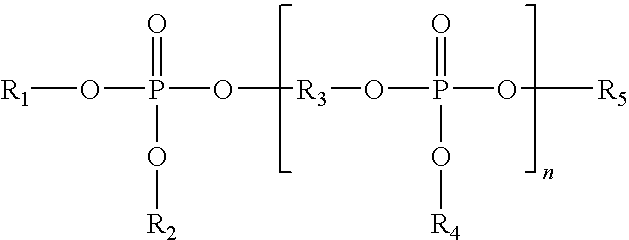

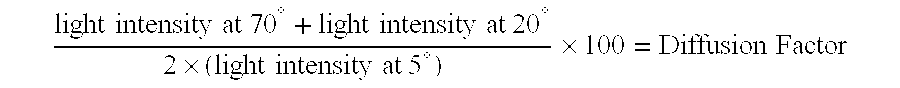

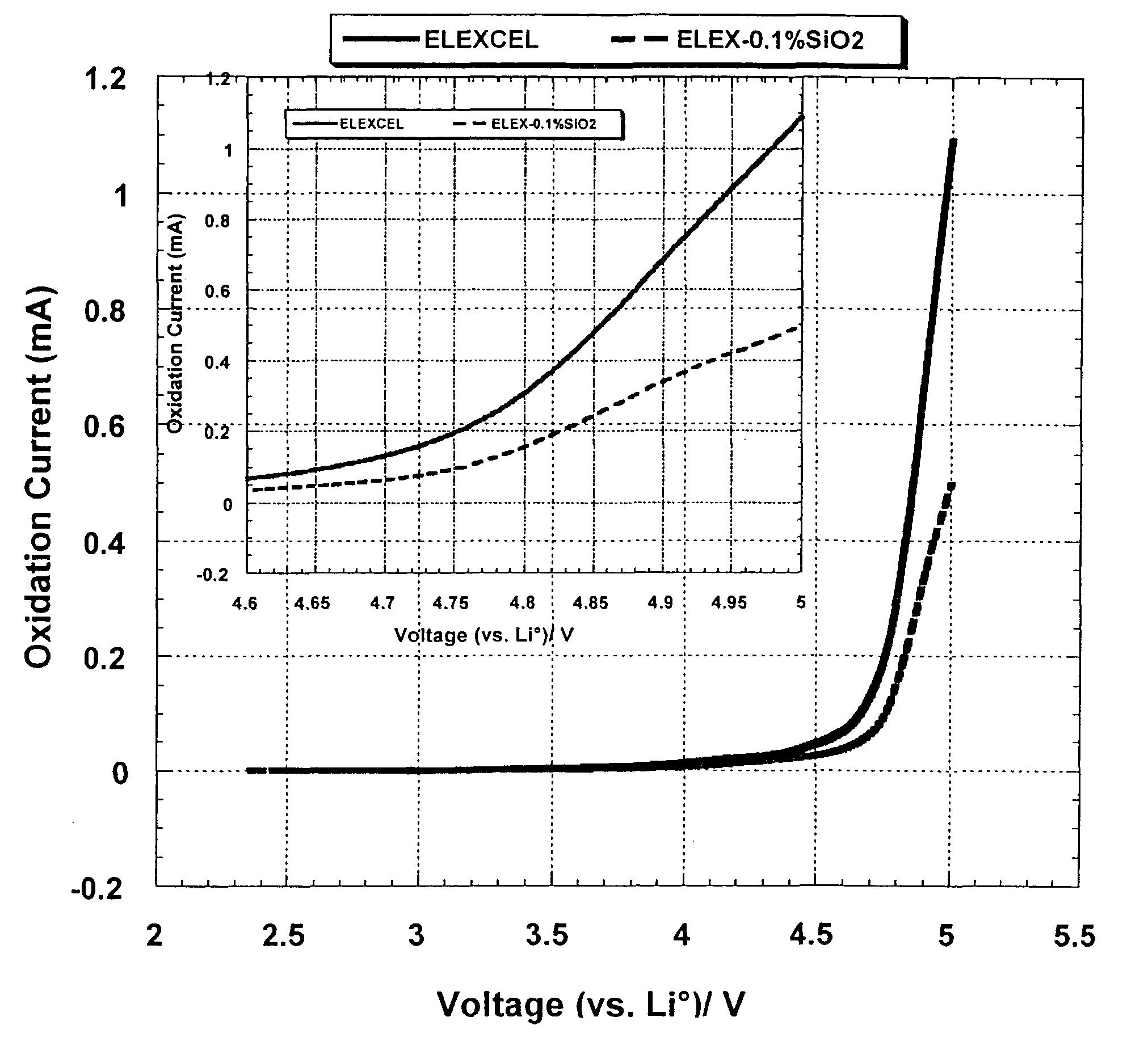

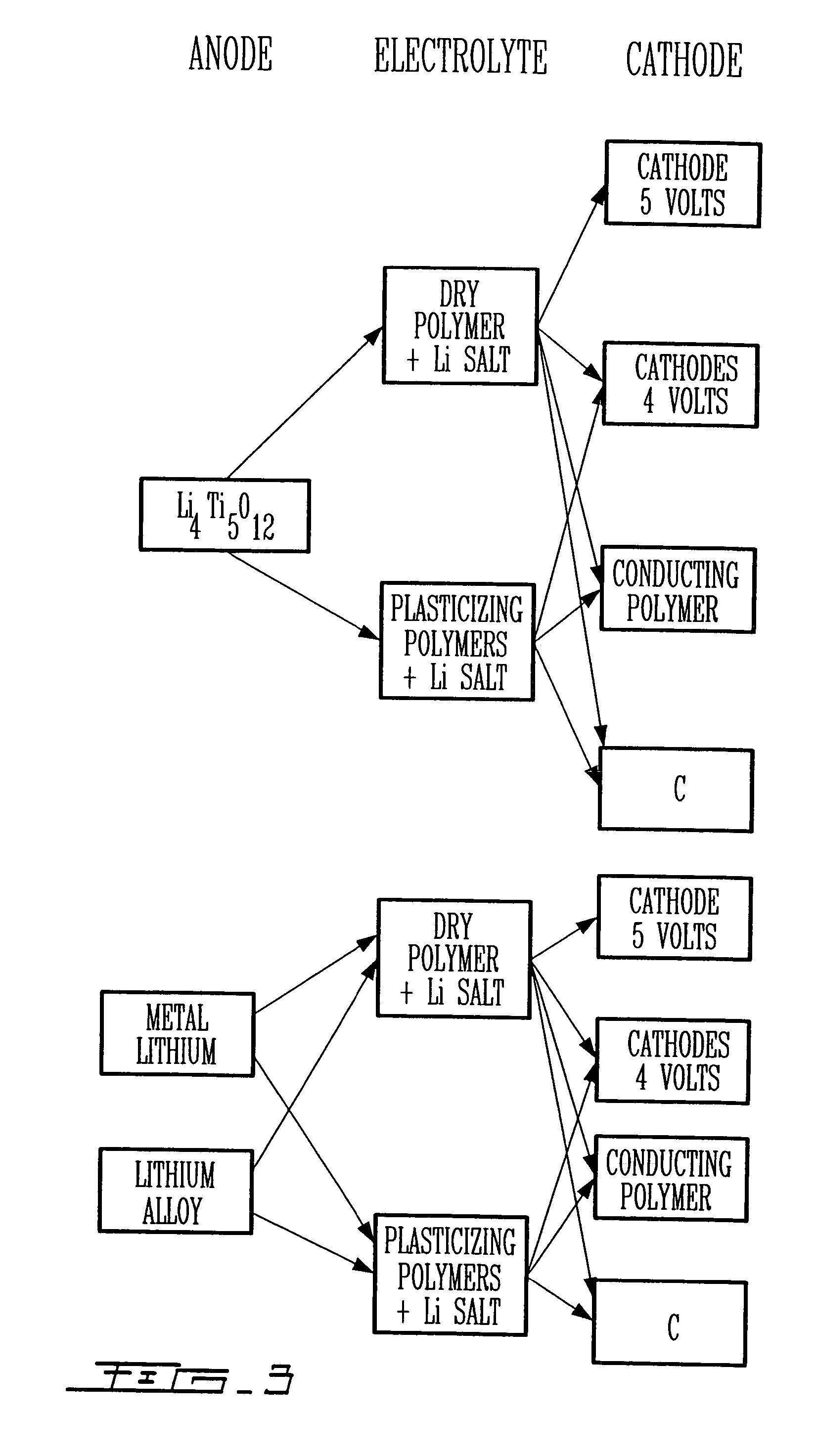

Highly-stable polymeric electrolyte and use thereof in electrochemical systems

ActiveUS20050234177A1Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesElectrolysis

Polymer electrolyte for an electrochemical generator based on at least a four branched polymer, at least a poly(vinylyldienefluoride), a poly(vinyldiene fluoro-co-hexafluoropropene copolymer), a poly(tetrafluoroethylene), a poly(ethylene-co-propylene-co-5-methylene-2-norbornene) or an ethylene propylene-diene copolymer, a polyol, a poly(methylmethacrylate, a poly(acrylonitrile), SiO2Al2O3, or nano TiO2 non coated or coated with an organic material. This electrolyte allows to prepare electrolytic compositions that can be used in high performance electrochemical devices.

Owner:HYDRO QUEBEC CORP

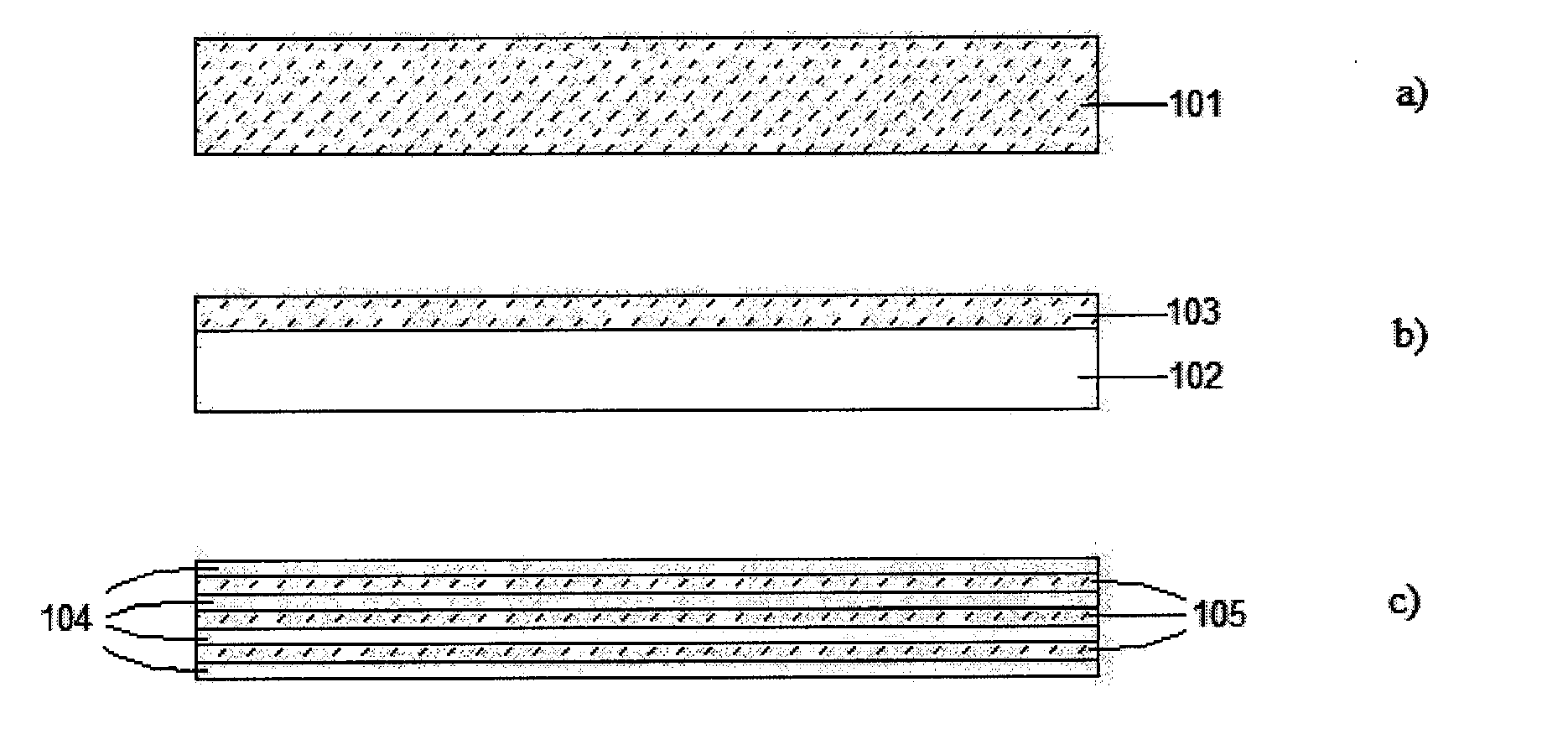

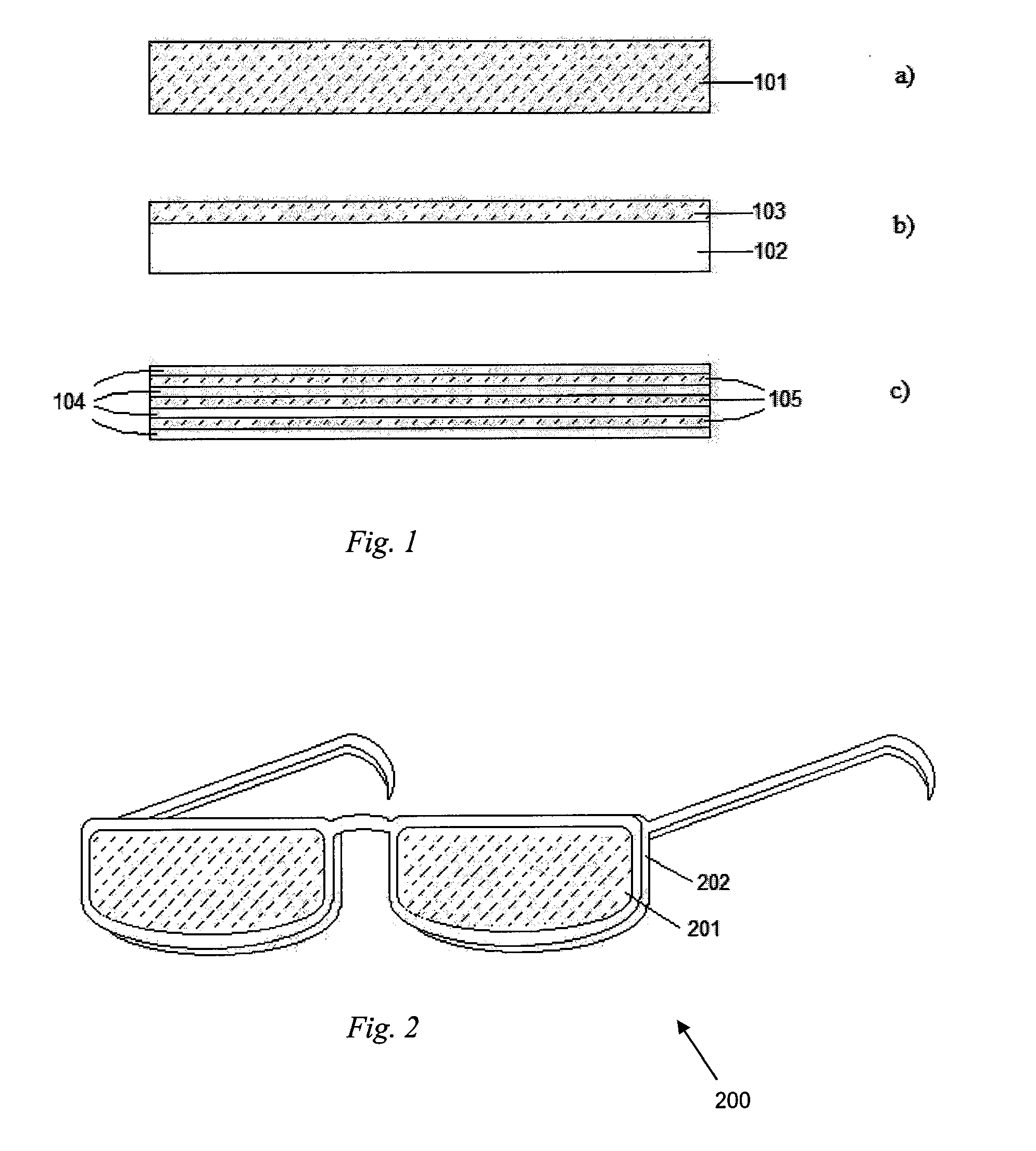

Lenses having dispersed metal nanoparticles for optical filtering including sunglasses

InactiveUS20070298242A1Evenly dispersedSpectales/gogglesSynthetic resin layered productsMethylmethacrylatesPoly(methyl methacrylate)

Lenses appropriate for use as sunglasses and other optical filtering devices include one or more composite layers including metal nanoparticles dispensed in a polymer matrix. The entire lens can be a single layer of the composite or the composite can be a coating on one or both faces of the lens. Gold nanoparticles can be dispersed in a poly(methylmethacrylate) or polycarbonate polymer at 0.01 to 1 weight percent.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

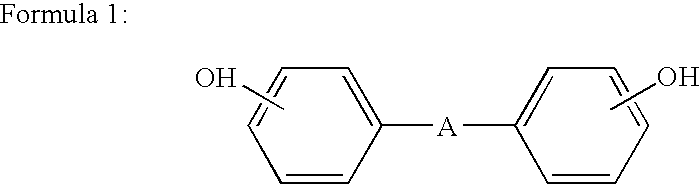

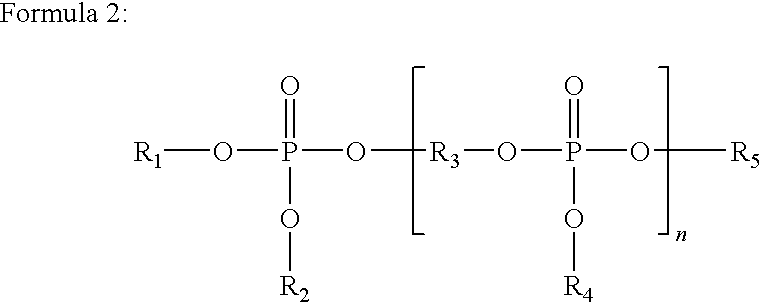

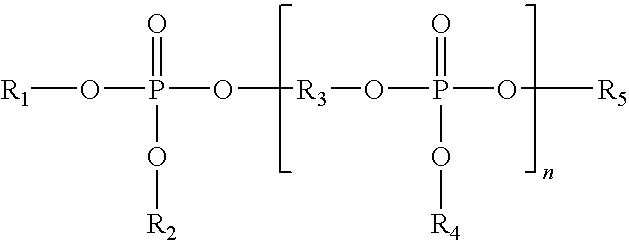

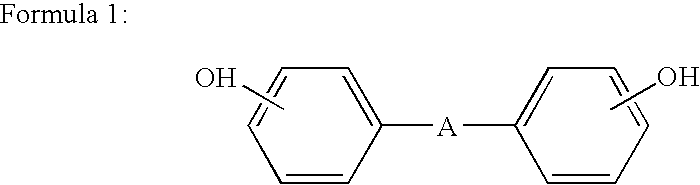

Scratch-Resistant Flameproof Thermoplastic Resin Composition

ActiveUS20090118402A1Improve scratch resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsDyeing processPolyethylene terephthalate glycolPolyethylene terephthalate

Disclosed herein is a flame retardant thermoplastic resin composition that has superior scratch resistance and mechanical properties, satisfying requirements for the appearance of housing materials resulting from a recent increase in volume of electrical and electronic products, and that contains a phosphorus-based flame-retarding agent, satisfying requirements for fire safety and prevention of environmental problems. The resin composition with scratch resistance comprises a base resin comprising (A) about 30 to about 90 parts by weight of a polycarbonate resin, (B) about 15 to about 50 parts by weight of a polymethylmethacrylate resin and (C) about 5 to about 50 parts by weight of a polyethylene terephthalate-based resin, and (D) about 5 to about 30 parts by weight of a phosphorus-based flame-retarding agent based on 100 parts by weight of the base resin. The composition may further comprise about 1 to about 30 parts by weight of an impact modifier based on 100 parts by weight of the base resin.

Owner:LOTTE ADVANCED MATERIALS CO LTD

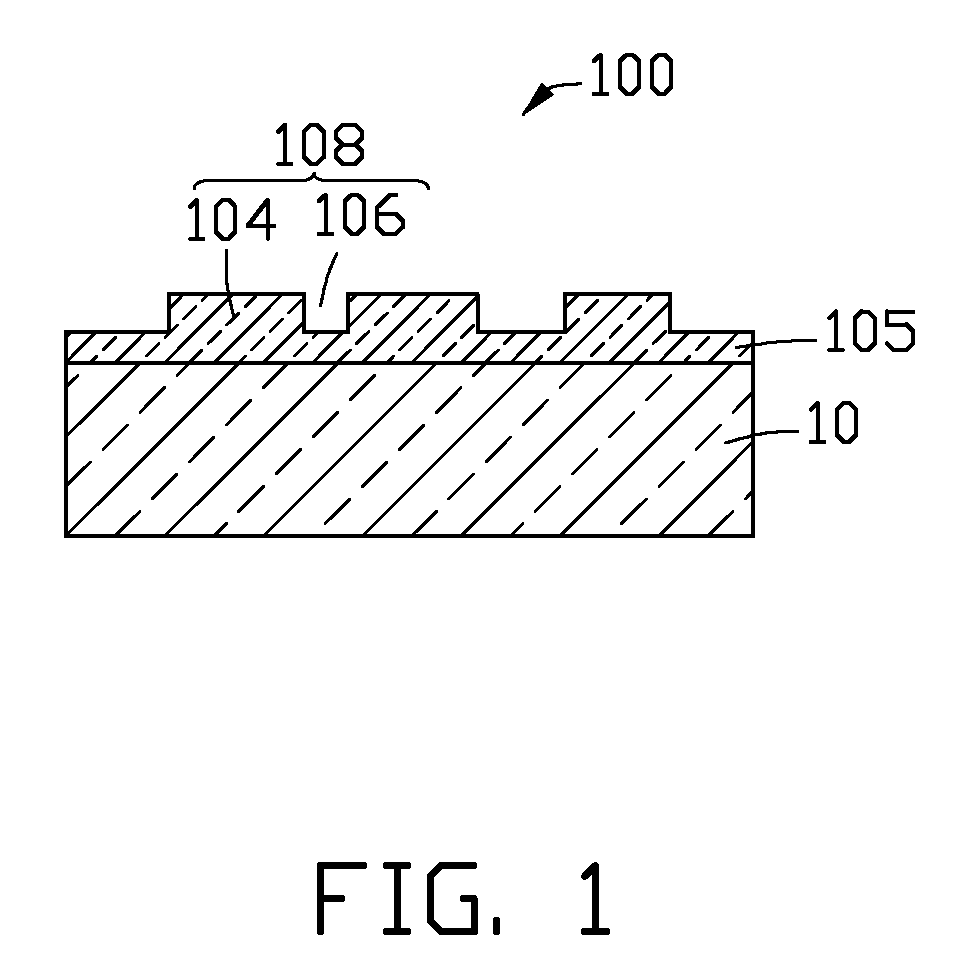

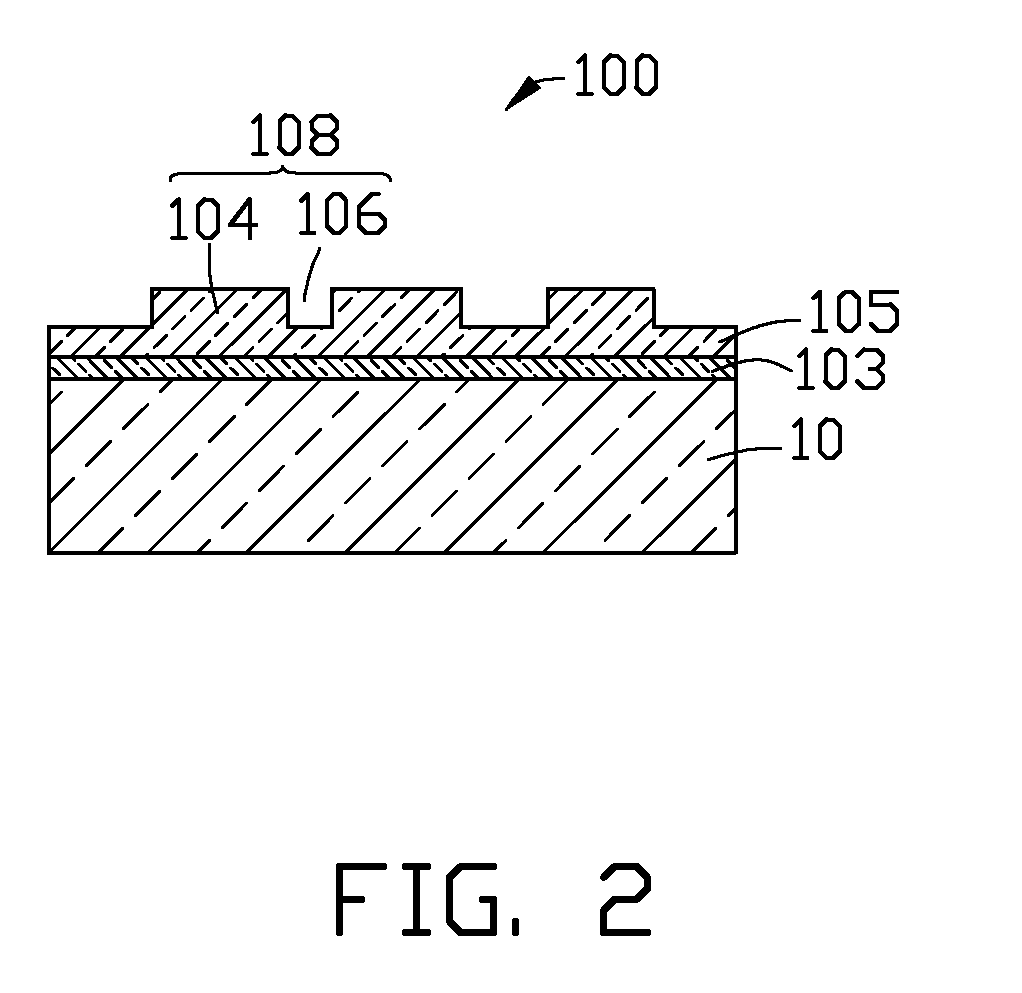

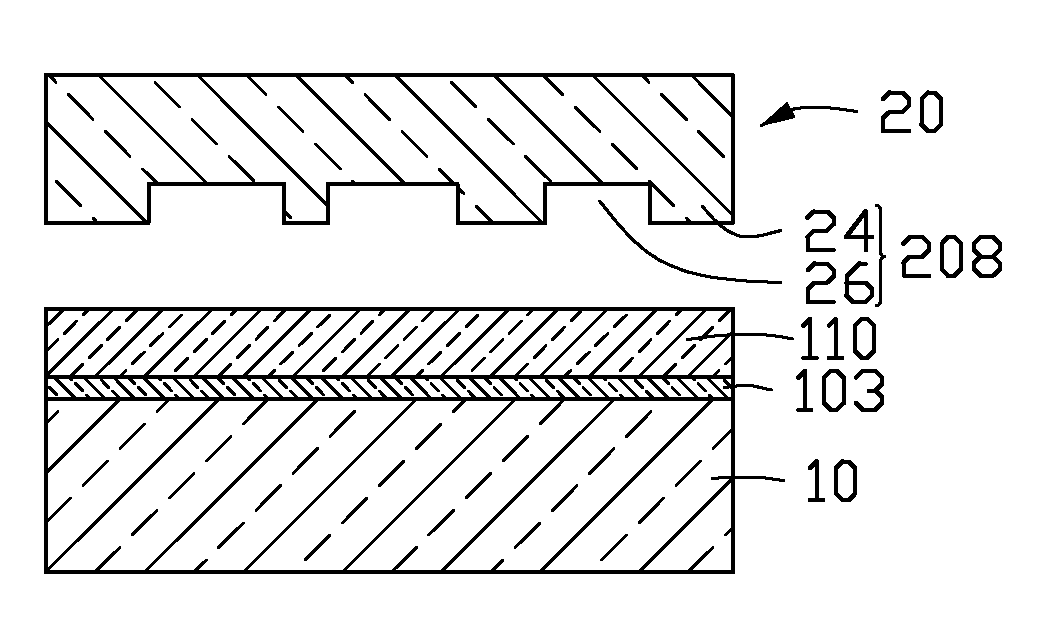

Nanoimprint resist, nanoimprint mold and nanoimprint lithography

ActiveUS20100308008A1Low modulusEasy to crushDecorative surface effectsNanoinformaticsResistOligomer

A nanoimprint resist includes a hyperbranched polyurethane oligomer (HP), a perfluoropolyether (PFPE), a methylmethacrylate (MMA), and a diluent solvent. A method of a nanoimprint lithography is also provided.

Owner:TSINGHUA UNIV +1

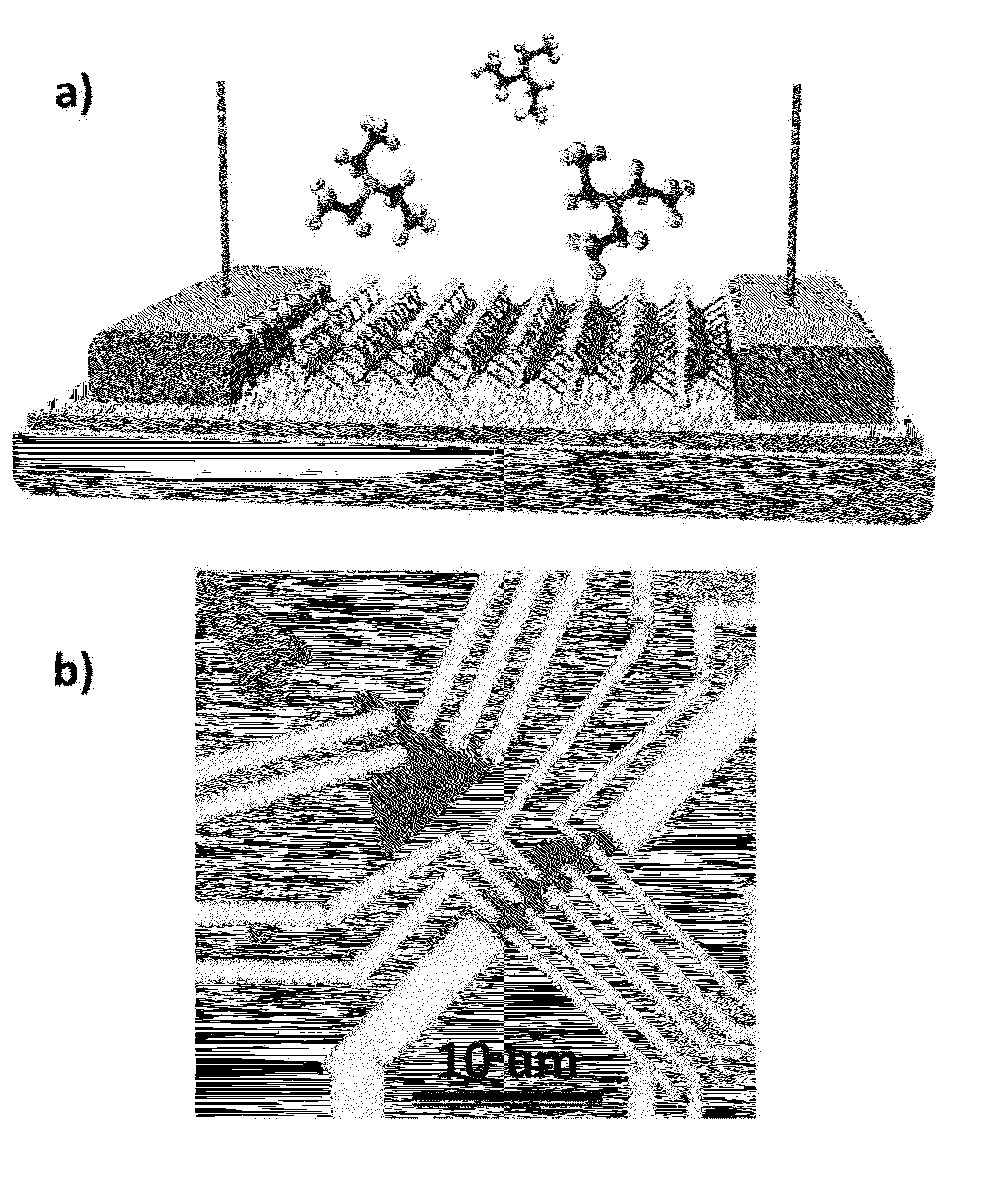

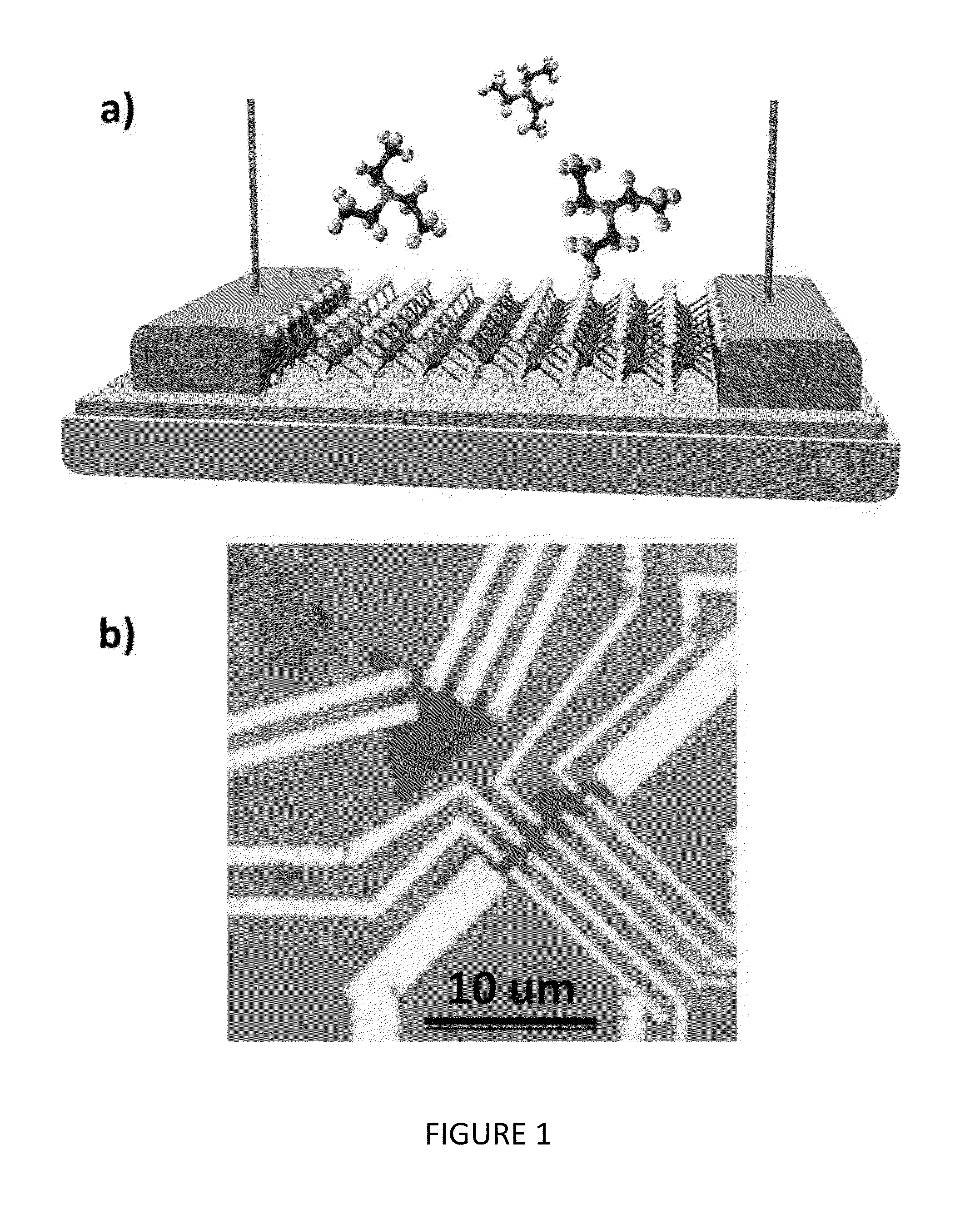

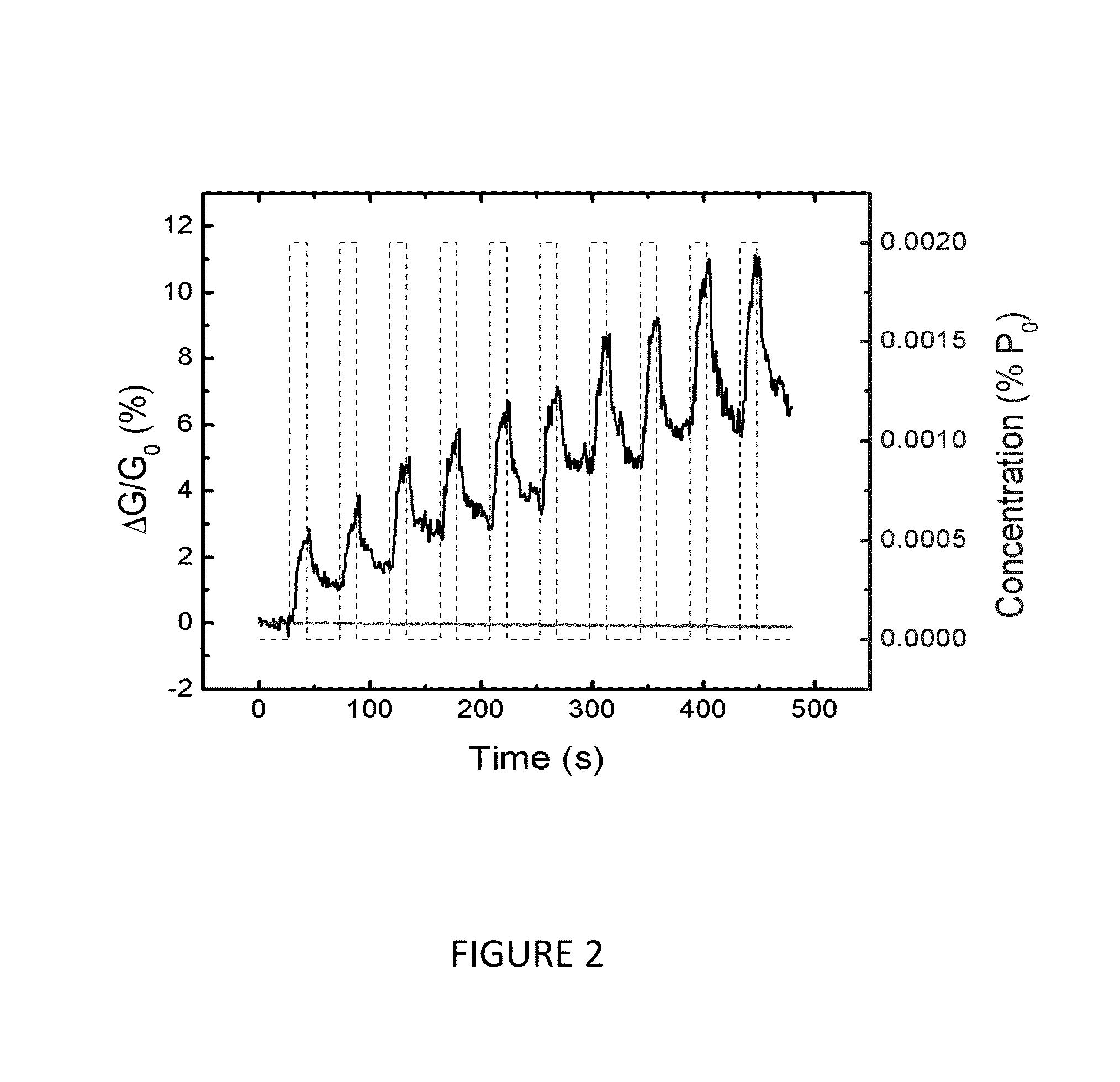

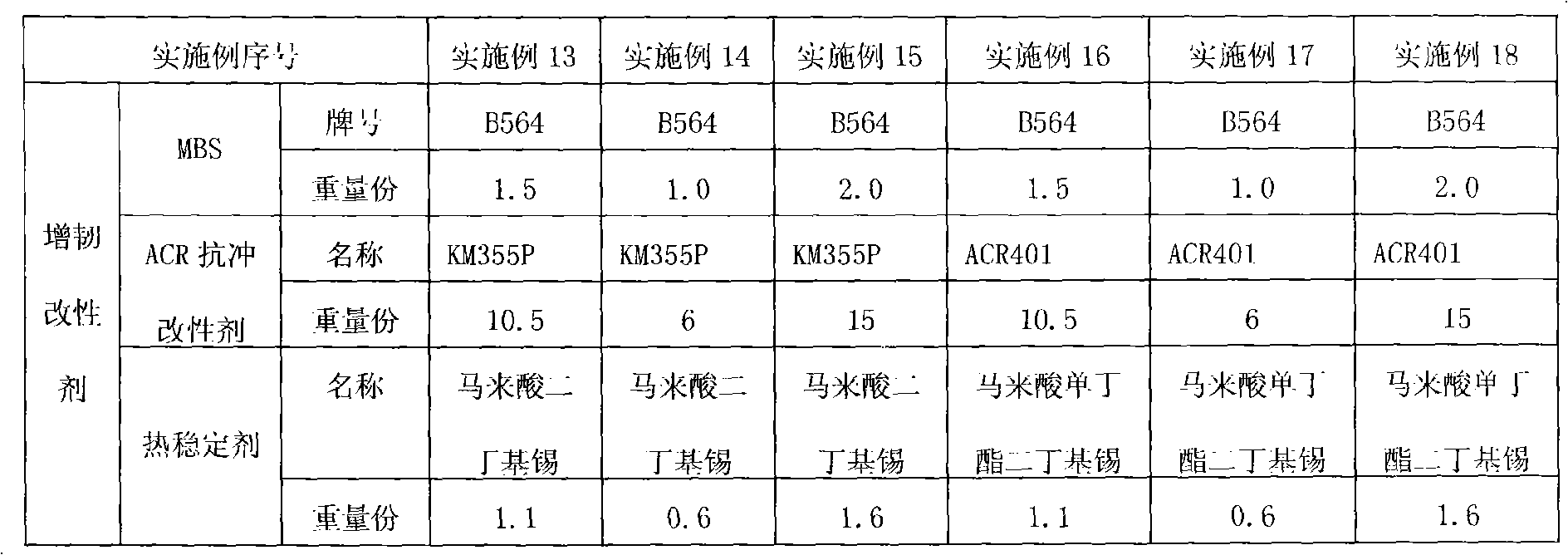

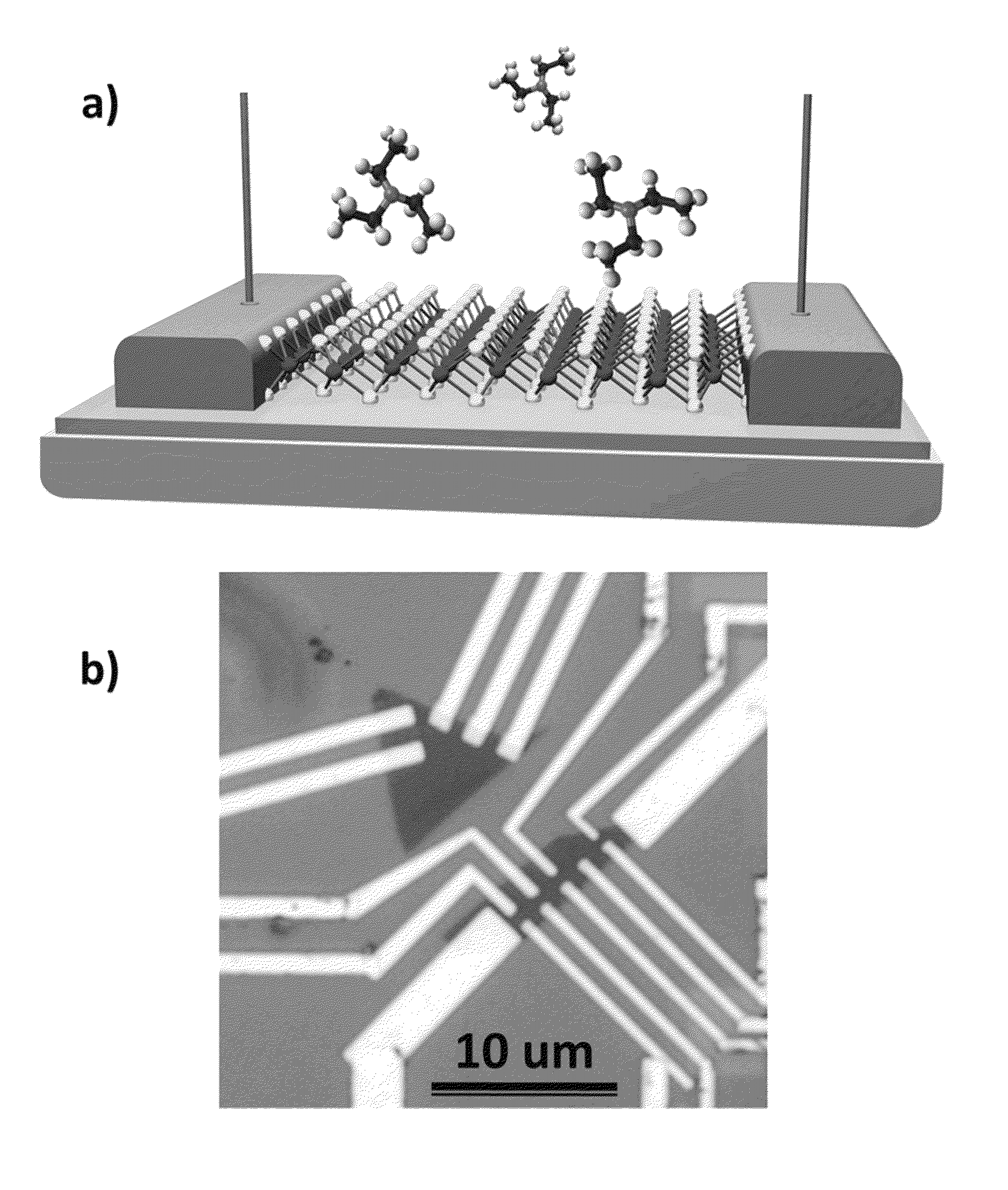

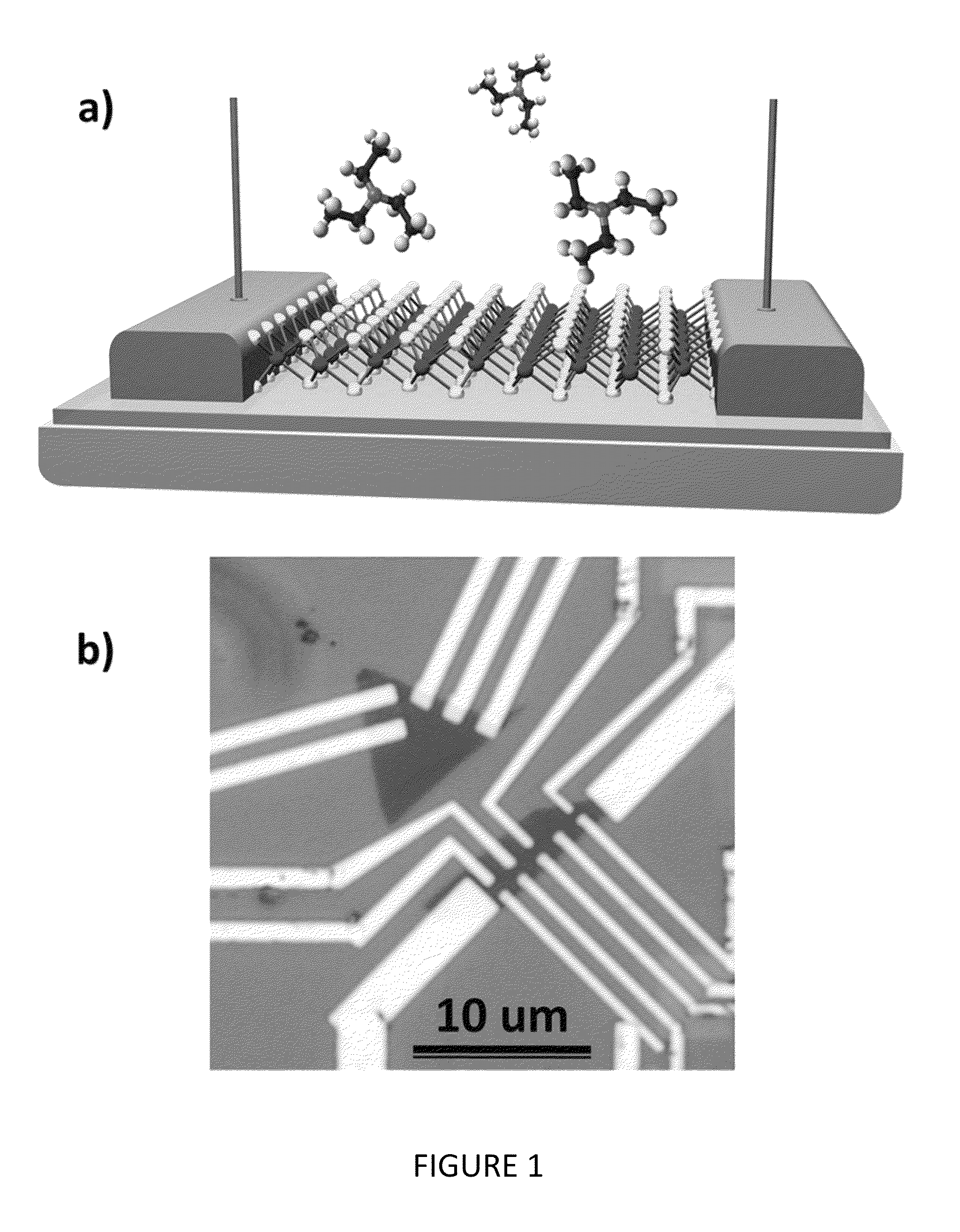

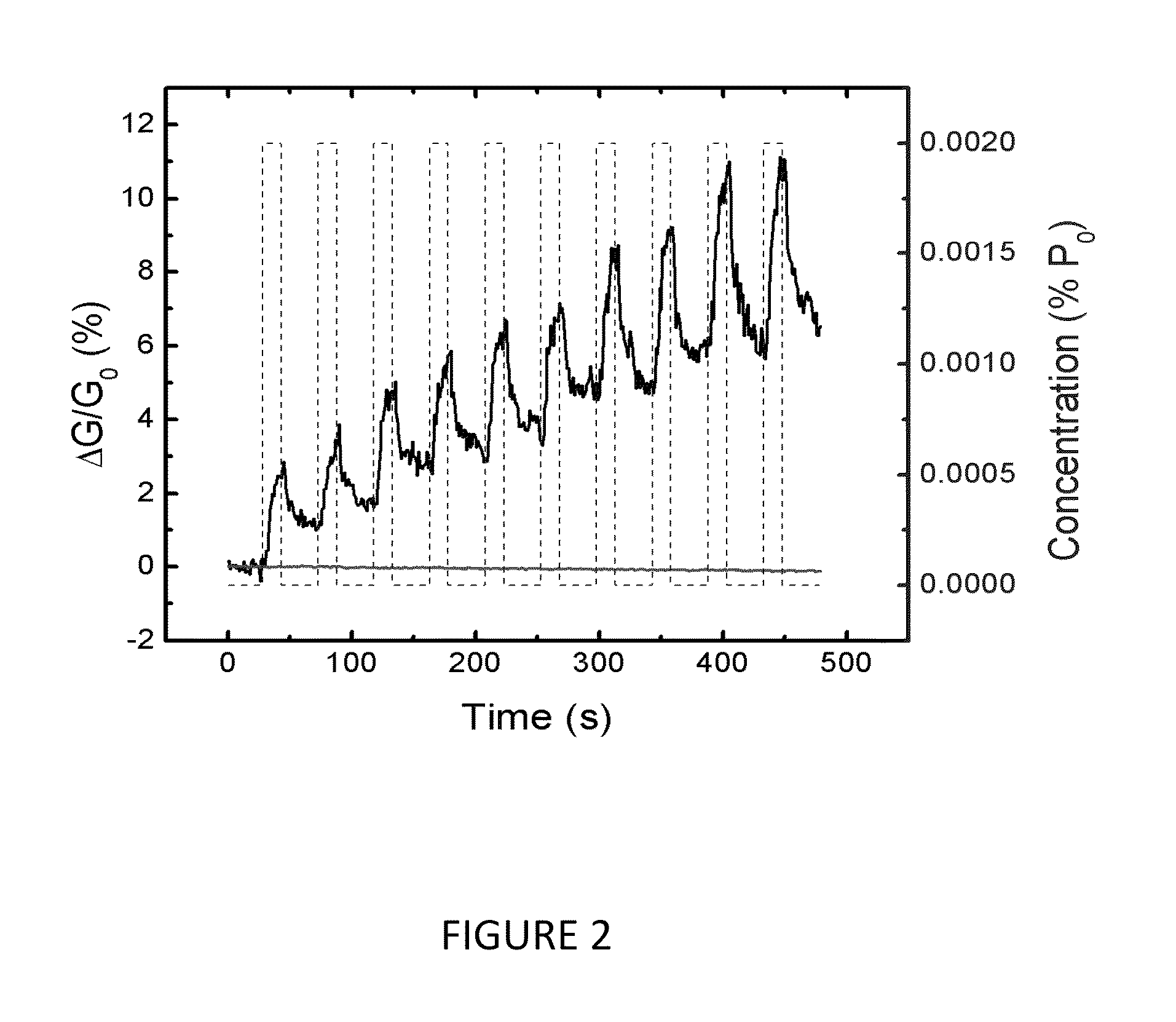

Low-Dimensional Material Chemical Vapor Sensors

InactiveUS20140273259A1Line/current collector detailsLamination ancillary operationsAnalyteCarbon nanotube

A method of making a low-dimensional material chemical vapor sensor comprising exfoliating MoS2, applying the monolayer flakes of MoS2 onto a SiO2 / Si wafer, applying a methylmethacrylate (MMA) / polymethylmethacrylate (PMMA) film, defining trenches for the deposition of metal contacts, and depositing one of Ti / Au, Au, and Pt in the trench and resulting in a MoS2 sensor. A low-dimensional material chemical vapor sensor comprising monolayer flakes of MoS2, trenches in the SiO2 / Si wafer, metal contacts in the trenches, and thereby resulting in a MoS2 sensor. A full spectrum sensing suite comprising similarly fabricated parallel sensors made from a variety of low-dimensional materials including graphene, carbon nanotubes, MoS2, BN, and the family of transition metal dichalcogenides. The sensing suites are small, robust, sensitive, low-power, inexpensive, and fast in their response to chemical vapor analytes.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Scratch-resistant flameproof thermoplastic resin composition

ActiveUS7732515B2Maintain good propertiesIncrease resistancePlastic/resin/waxes insulatorsDyeing processThermoplasticPolymer science

Owner:LOTTE ADVANCED MATERIALS CO LTD

Water-based room temperature crosslinking acrylic acid emulsion and preparation method thereof

InactiveCN101597355AImprove performanceThe application process is convenient and easy to useInksCoatingsSodium bicarbonateWater based

The invention provides a water-based room temperature crosslinking acrylic acid emulsion and a preparation method thereof, wherein, the water-based room temperature crosslinking acrylic acid emulsion comprises the following components by weight percent: 10-40% of methylmethacrylate, 0-40% of styrene, 0-3% of methacrylic acid, 0.5-1.5% of acrylic acid, 0.5-2% of N-hydroxylacrylamide, 1-3% of ethylmethacrylate, 1-23% of butyl methacrylate, 1-3% of emulsifier, 0.3-1% of initiator, 0.1-0.5% of sodium bicarbonate, 3-9% of neutralizer, 30-60% of water, 0.1-1% of inhibition stabilizer and 0.05-2% of crosslinking agent. In the process of polymerization, the crosslinking monomers (modified monomers) like acrylic acid, methacrylic acid and N-hydroxylacrylamide are introduced to perform carboxyl crosslinking, hydroxyl crosslinking and amido crosslinking with copolymer so that the cohesive strength, heat resistance and ageing resistance of emulsion are obviously increased and the stability of emulsion is increased; the inhibition stabilizer is used so as to prolong the service life.

Owner:彭文表

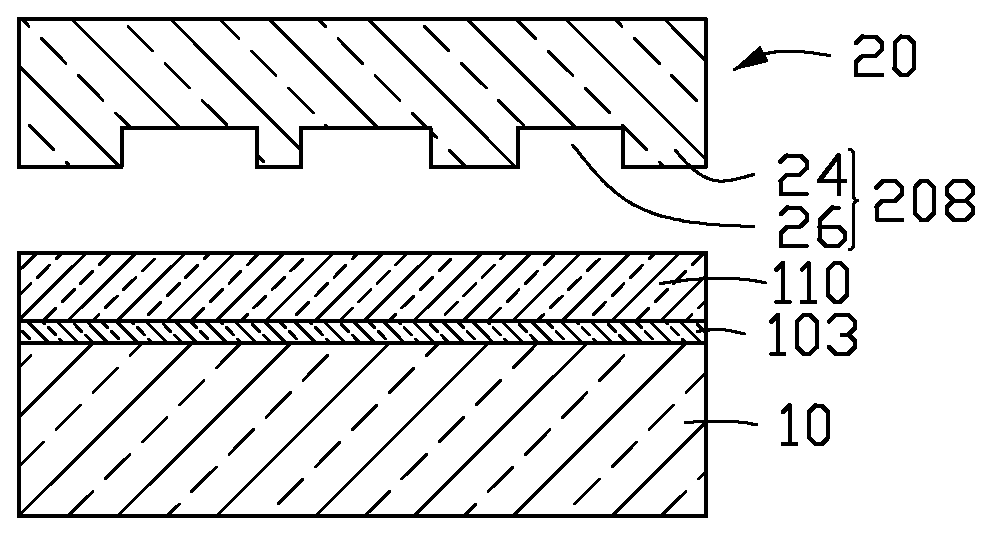

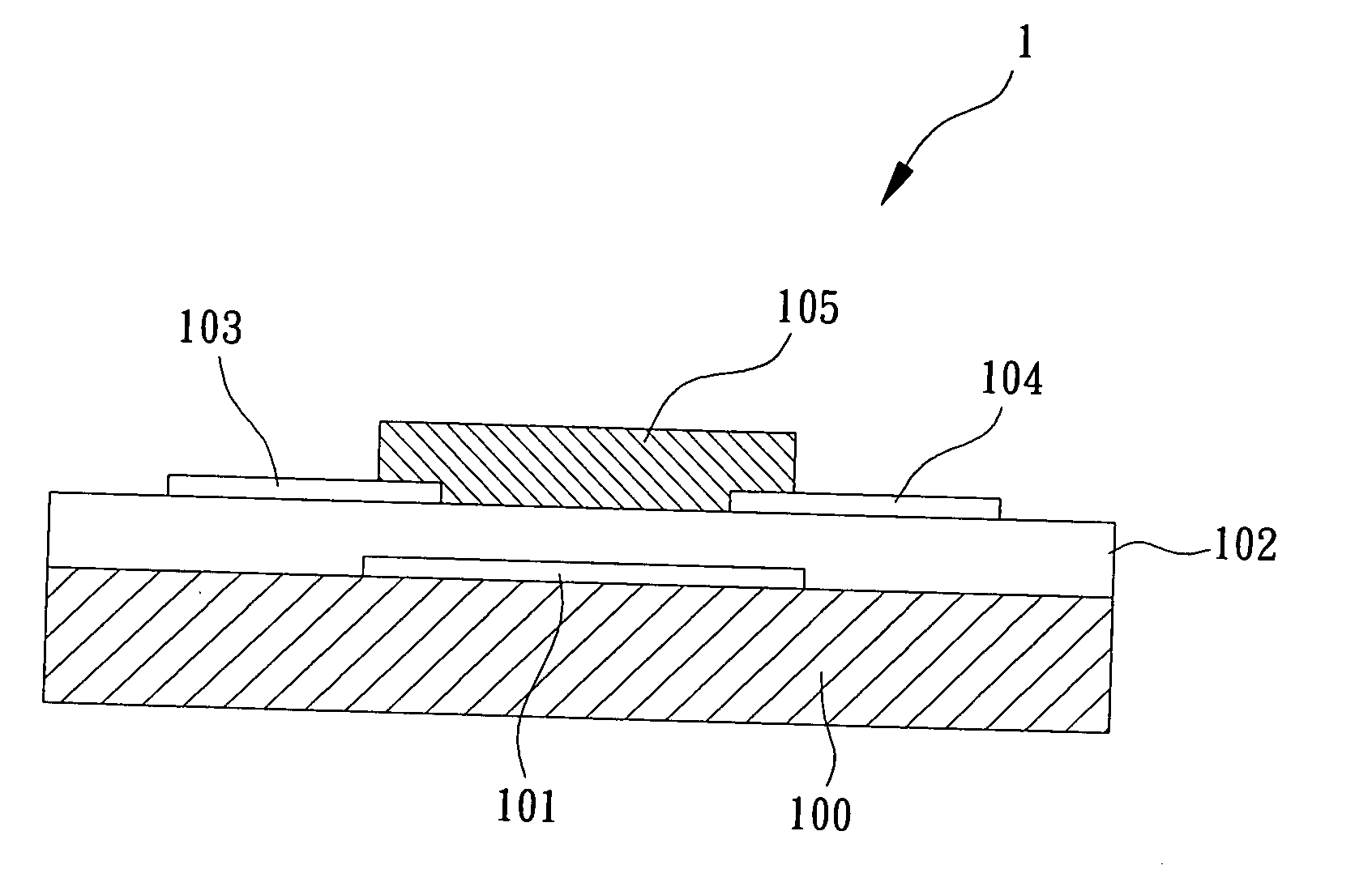

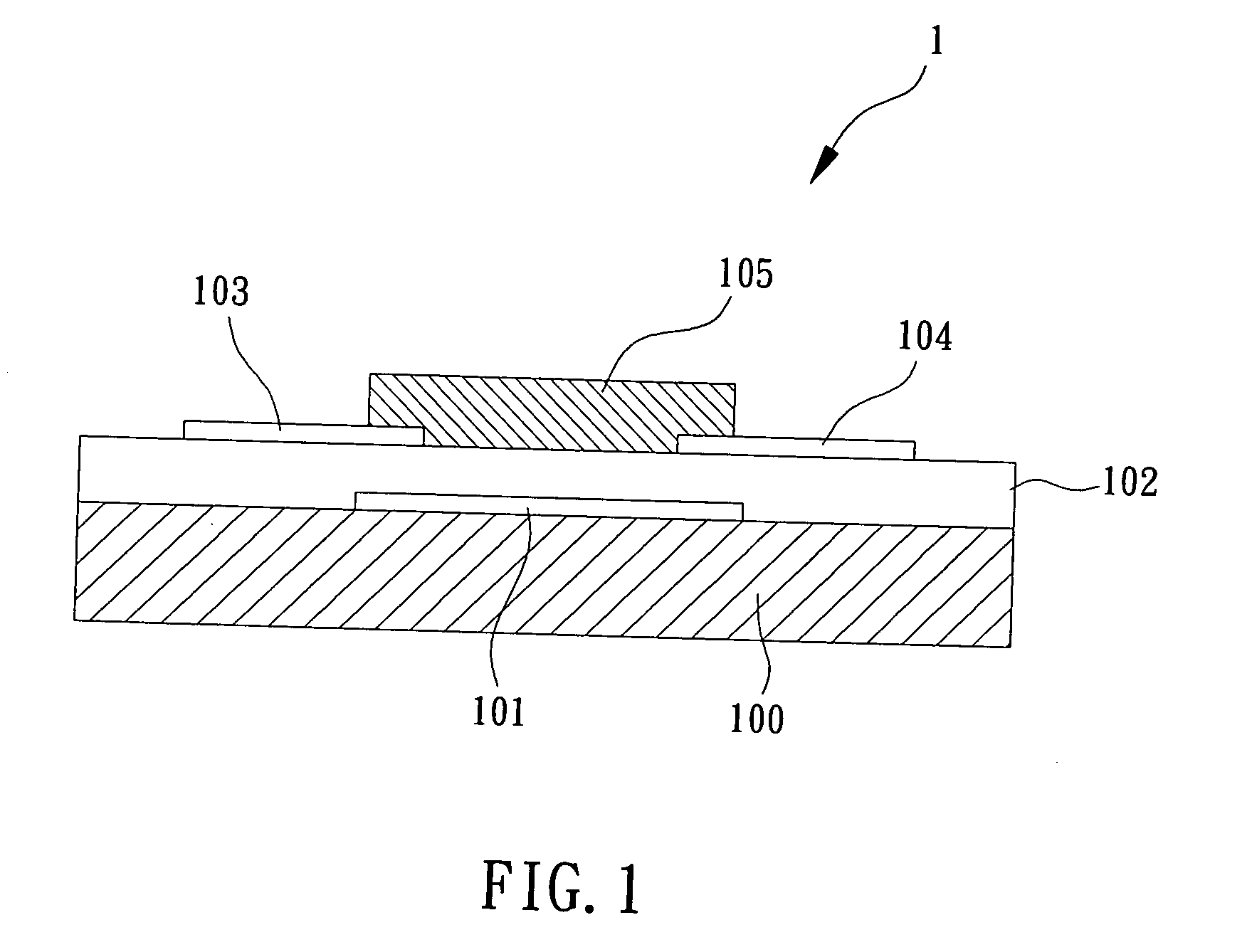

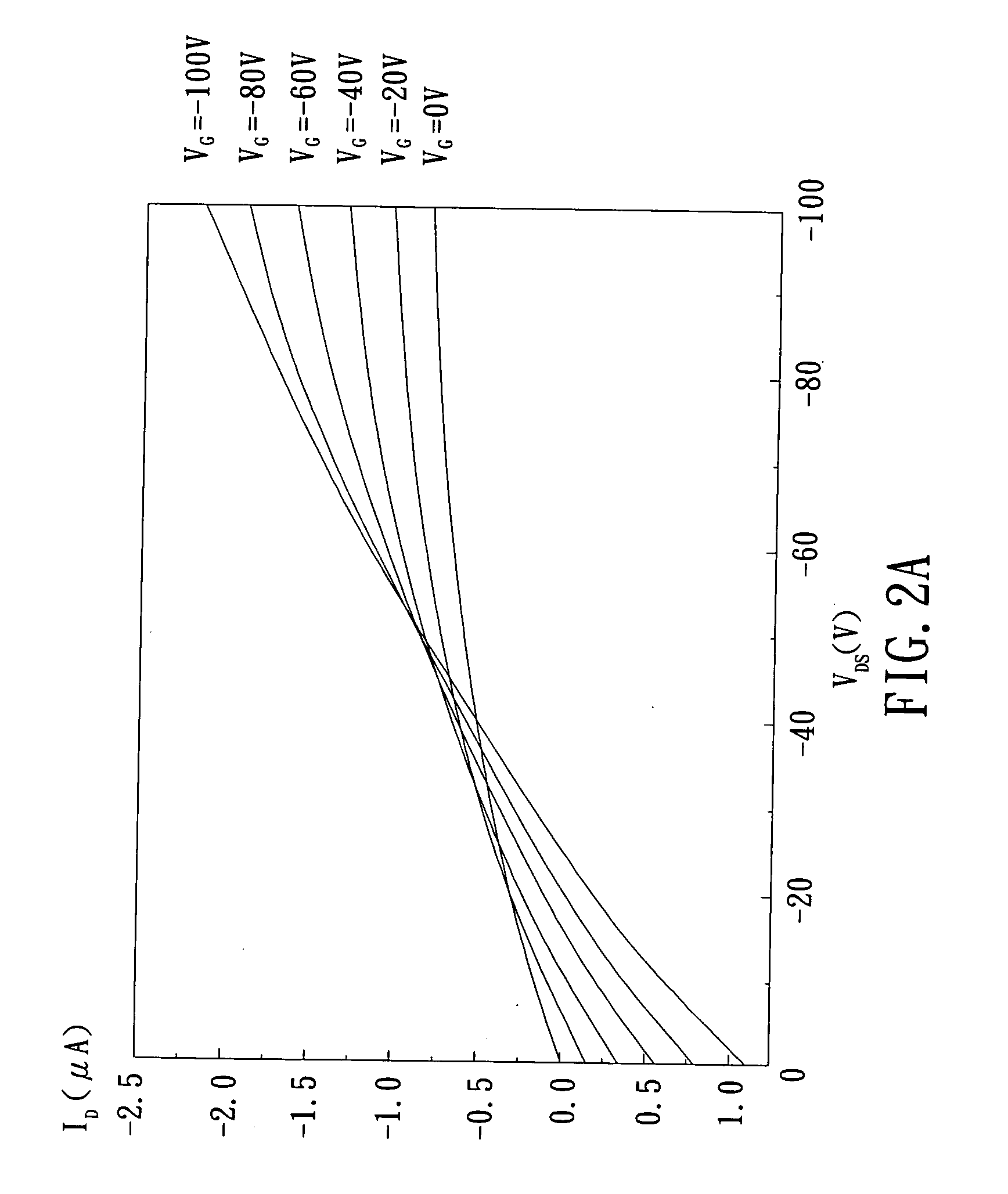

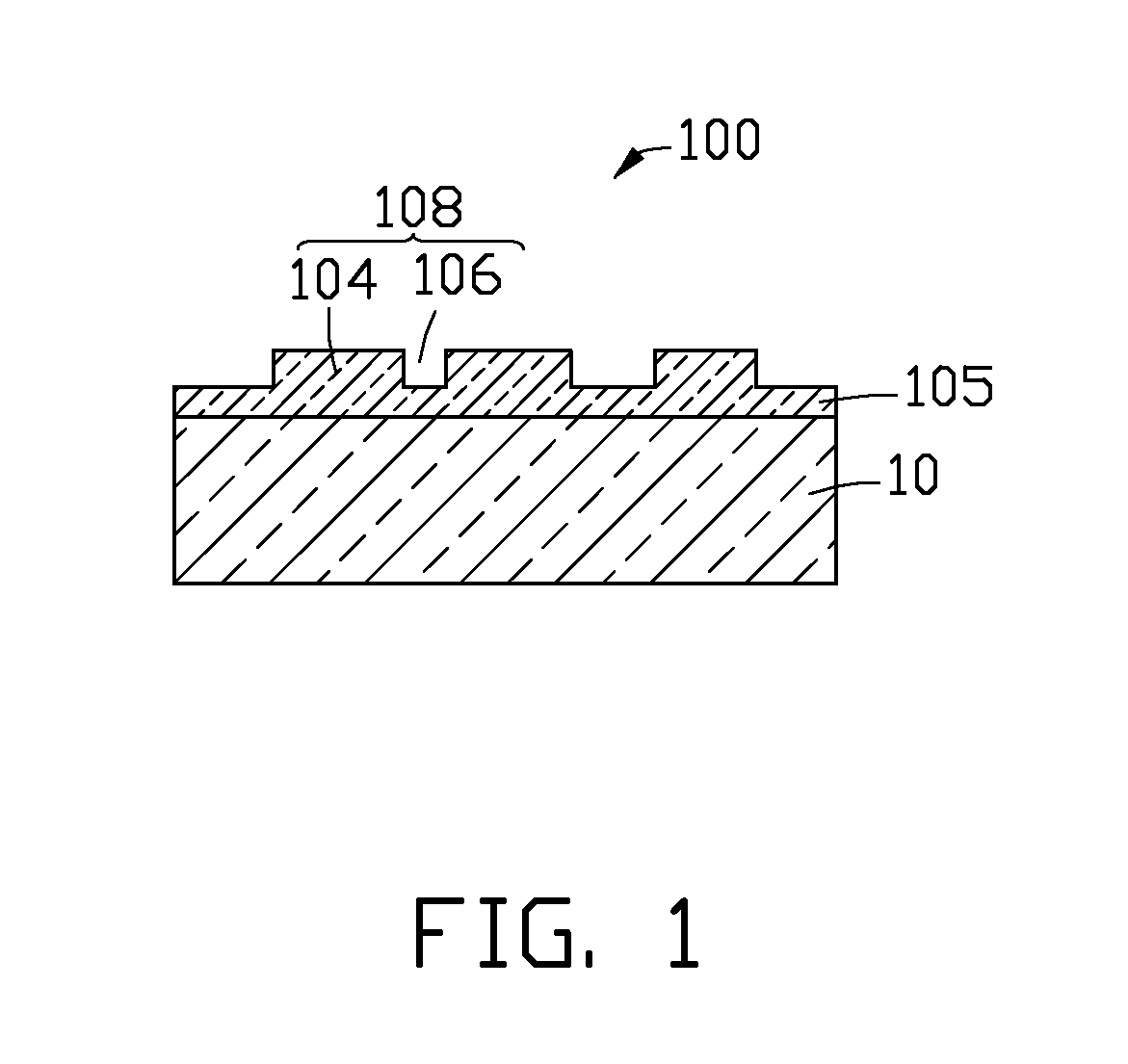

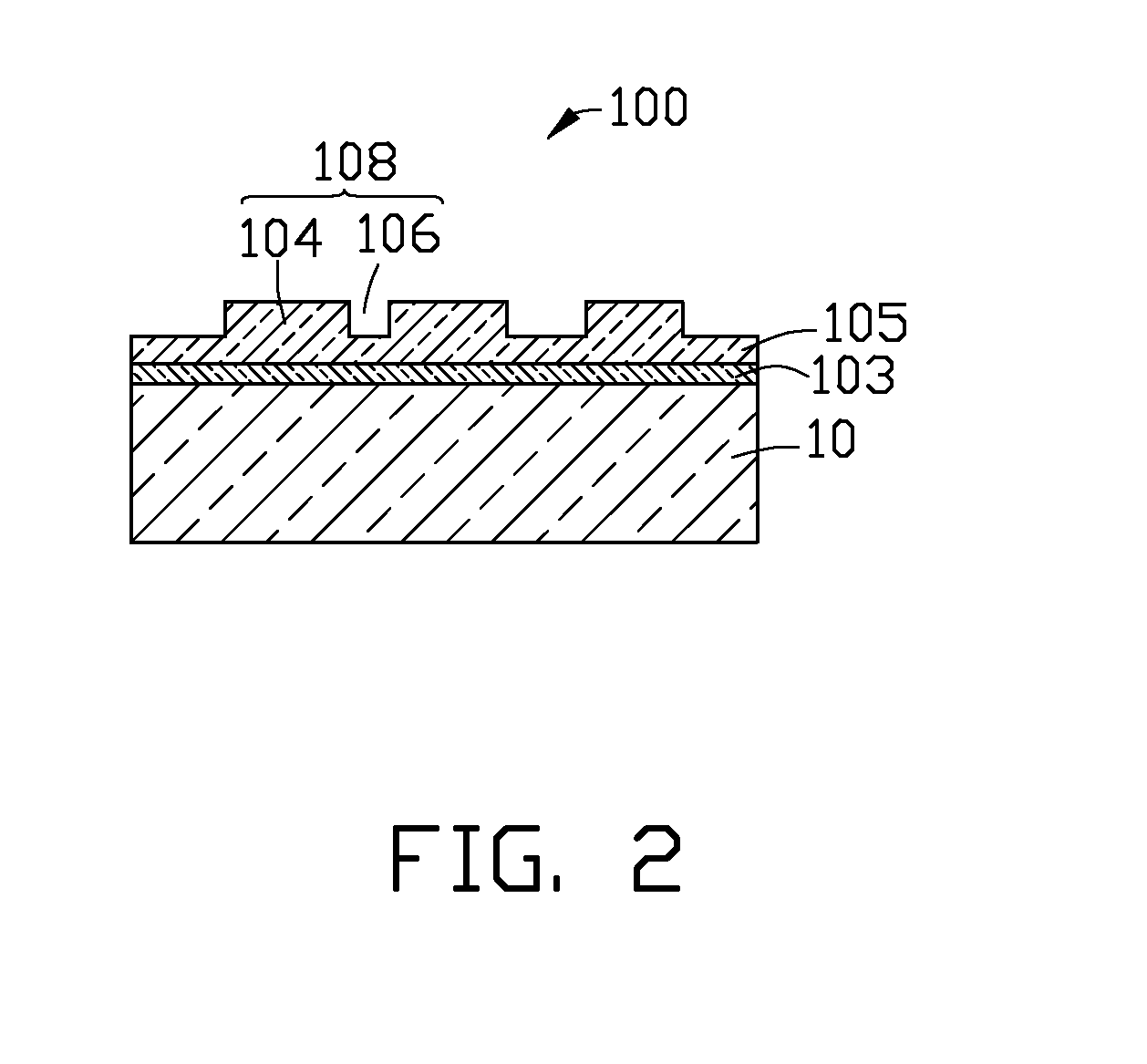

Method for enhancing electrical characteristics of organic electronic devices

InactiveUS20050221530A1Improve electrical characteristicsThe process is simple and fastTransistorMaterial nanotechnologyPolytetramethylene terephthalateCarbon nanotube

The present invention provides a method for enhancing electrical characteristics of organic electronic devices, especially for an organic thin-film transistors, comprising the steps of: providing a substrate with a gate and an insulator layer formed thereon; preparing an organic solution by mixing materials of an organic semiconductor polymer, an organic insulator polymer, a conducting particle and a solvent; forming an organic semiconductor layer on top of the insulator layer between the source and the drain using the organic solvent. Wherein, the organic semiconductor polymer can be a polymer selected from the group consisting of poly(3-alkylthiophene) (P3AT) with different alkyl side groups of 2, 4, 6, 8, 10, 12, and 18, as the P3HT is a P3AT with alkyl side group of 6, and the organic insulator polymer can be a polymer selected from the group consisting of poly(methylmethacrylate) (PMMA), and polybutylene terephthalate (PBT), etc. and the conducting particle can be a kind of particle selected from the group consisting of carbon nanotubes (CNTs), C60, and nano silver particle, and so on, and the solvent can be a solvent selected from the group consisting of xylene, toluene, and THF, and so forth.

Owner:IND TECH RES INST

Heat activated epoxy adhesive and use in a structural foam insert

ActiveUS7084210B2Good chemical bondIncreased durabilityInorganic adhesivesAdhesive processes using foamed adhesivesYoung's modulusViscosity

An expandable adhesive for a structural foam insert useful for vehicular reinforcement is described. The adhesive is characterized by containing a viscosity enhancing agent such as a polymethylmethacrylate, which results in a cured adhesive having unusually small voids and unusually high Young's modulus.

Owner:DOW GLOBAL TECH LLC

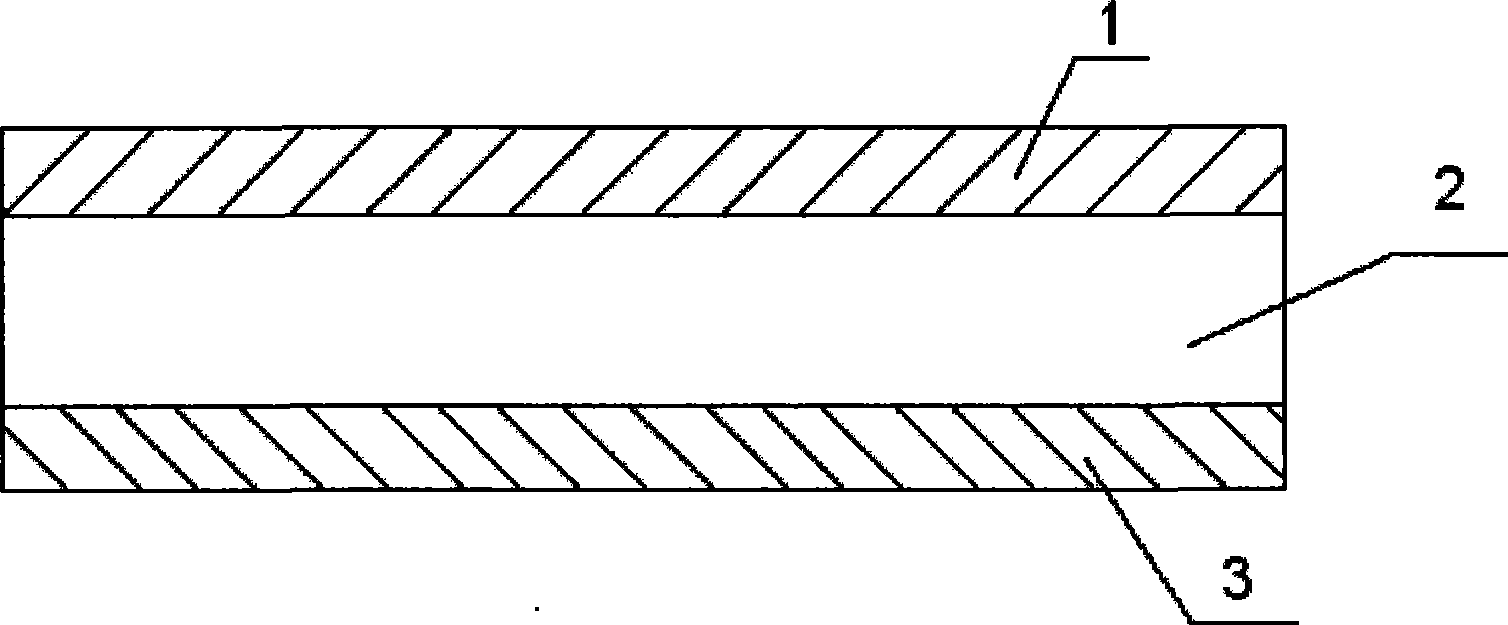

Plastic sheet product offering matte appearance and method of preparation

InactiveUS20060019113A1Cheap preparationImprove propertiesLayered product treatmentSynthetic resin layered productsMethacrylatePolymer science

A plastic sheet product having a matte finish comprises a core layer of a thermoplastic polymer and at least one layer of a capstock composition which overlies, and is bonded to, at least one face of the core layer. The capstock composition comprises the same or different thermoplastic polymer and contains a plurality of discrete particles immiscible with and dispersed in the thermoplastic polymer of the capstock composition. The sheet product may be prepared by the co-extrusion of the thermoplastic polymer and the capstock composition, and in a particular embodiment, such co-extrusion may be conducted by means of a feedblock. In a particular embodiment, the thermoplastic polymer of the core layer and that of the capstock composition may be the same, such as in the instance of a methylmethacrylate-methylacrylate copolymer. Sheet products prepared in accordance with the invention exhibit improved post-processability and ease of surface maintenance, and may be fabricated into a variety of products including light diffusers, projection screens, and the like.

Owner:EVONIK CYRO

Polymer electrolyte with high stability, its use in electrochemical systems

ActiveUS7897674B2Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesTetrafluoroethylene

Polymer electrolyte for an electrochemical generator based on at least a four branched polymer, at least a poly(vinylyldienefluoride), a poly(vinyldiene fluoro-co-hexafluoropropene copolymer), a poly(tetrafluoroethylene), a poly(ethylene-co-propylene-co-5-methylene-2-norbornene) or an ethylene propylene-diene copolymer, a polyol, a poly(methylmethacrylate, a poly(acrylonitrile), SiO2Al2O3, or nano TiO2 non coated or coated with an organic material. This electrolyte allows to prepare electrolytic compositions that can be used in high performance electrochemical devices.

Owner:HYDRO QUEBEC CORP

Film coating

InactiveUS20040058001A1Improve propertiesNegates needOrganic active ingredientsDigestive systemControlled releaseMethylmethacrylates

A film coating composition suitable for use in coating pharmaceutical formulations comprising a) an acrylic polymer dispersion, e.g. an ethylacrylate / methylmethacrylate copolymer such as Eudragit NE30D, b) a surfactant, c) sodium stearyl fumarate, and d) a water-containing liquid useful for the achievement of controlled release from pharmaceutical formulations such as tablets, pellets, etc.

Owner:ASTRAZENECA AB

Aluminized non-stretching polypropylene film with enhanced aluminium layer peeling strength and preparation method thereof

InactiveCN101380837AImprove adsorption capacityHigh Peel Strength PropertiesSynthetic resin layered productsPolypropyleneMethylmethacrylates

The invention discloses an aluminum plating non-stretching polypropylene film with aluminum layer peeling intensity enhancement type, which is composited by a heat sealing layer, a sandwich layer and a corona layer; wherein, the heat sealing layer uses ternary polymerization polypropylene; the sandwich layer uses HOPP; the corona layer uses the blended materials of the ternary polymerization polypropylene and ethylene / methylmethacrylate. The invention also discloses a preparation method of the aluminum plating non-stretching polypropylene film with the aluminum layer peeling intensity enhancement type. The aluminum plating non-stretching polypropylene film of aluminum layer peeling intensity enhancement type draws into a surface active material ethylene / methylmethacrylate in the corona layer, thus increasing the adsorption capability of the corona layer on the aluminum layer and having high aluminum layer peeling intensity performance which can not be exceeded by the common aluminum plating non-stretching polypropylene film.

Owner:南京金中达新材料有限公司

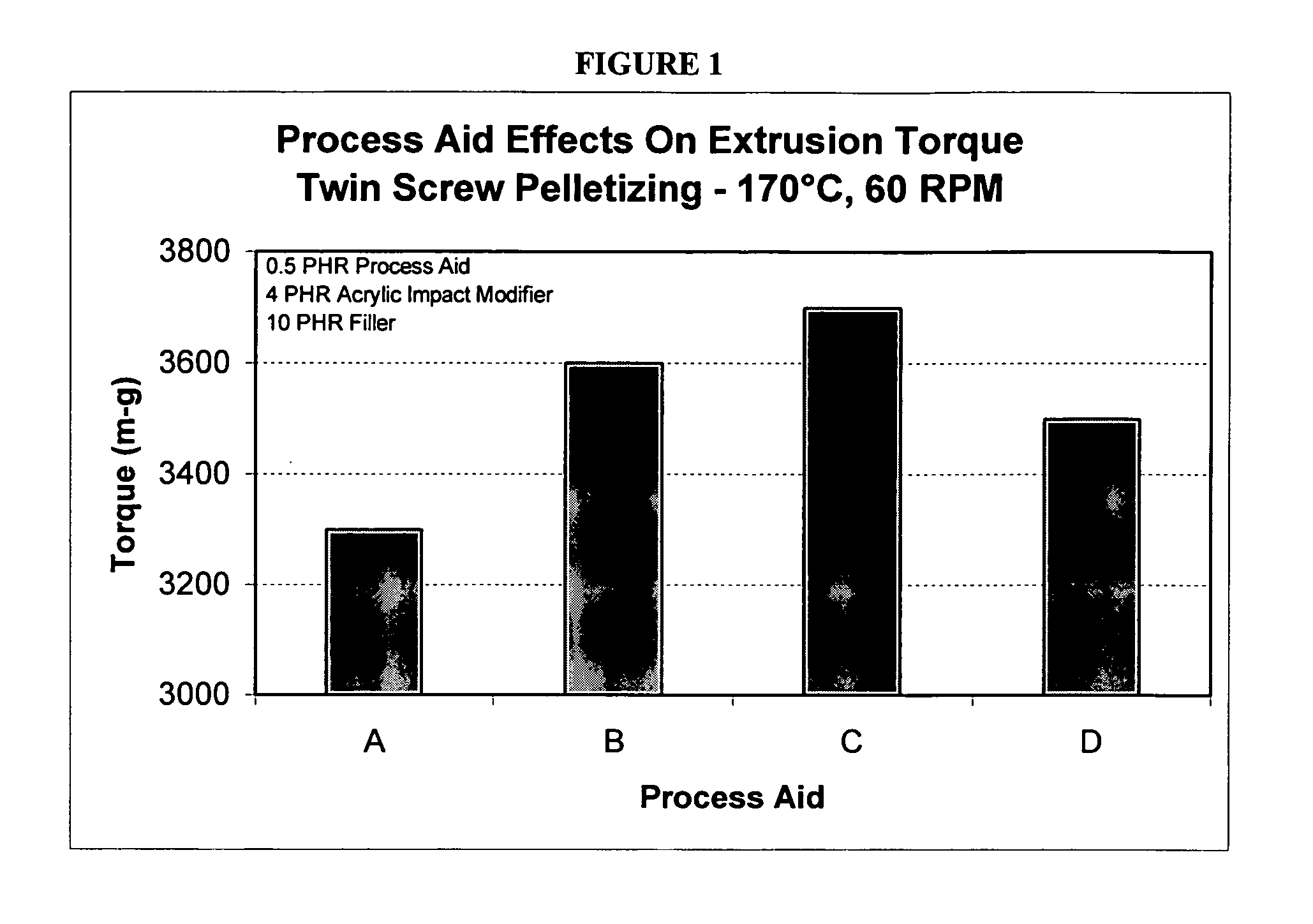

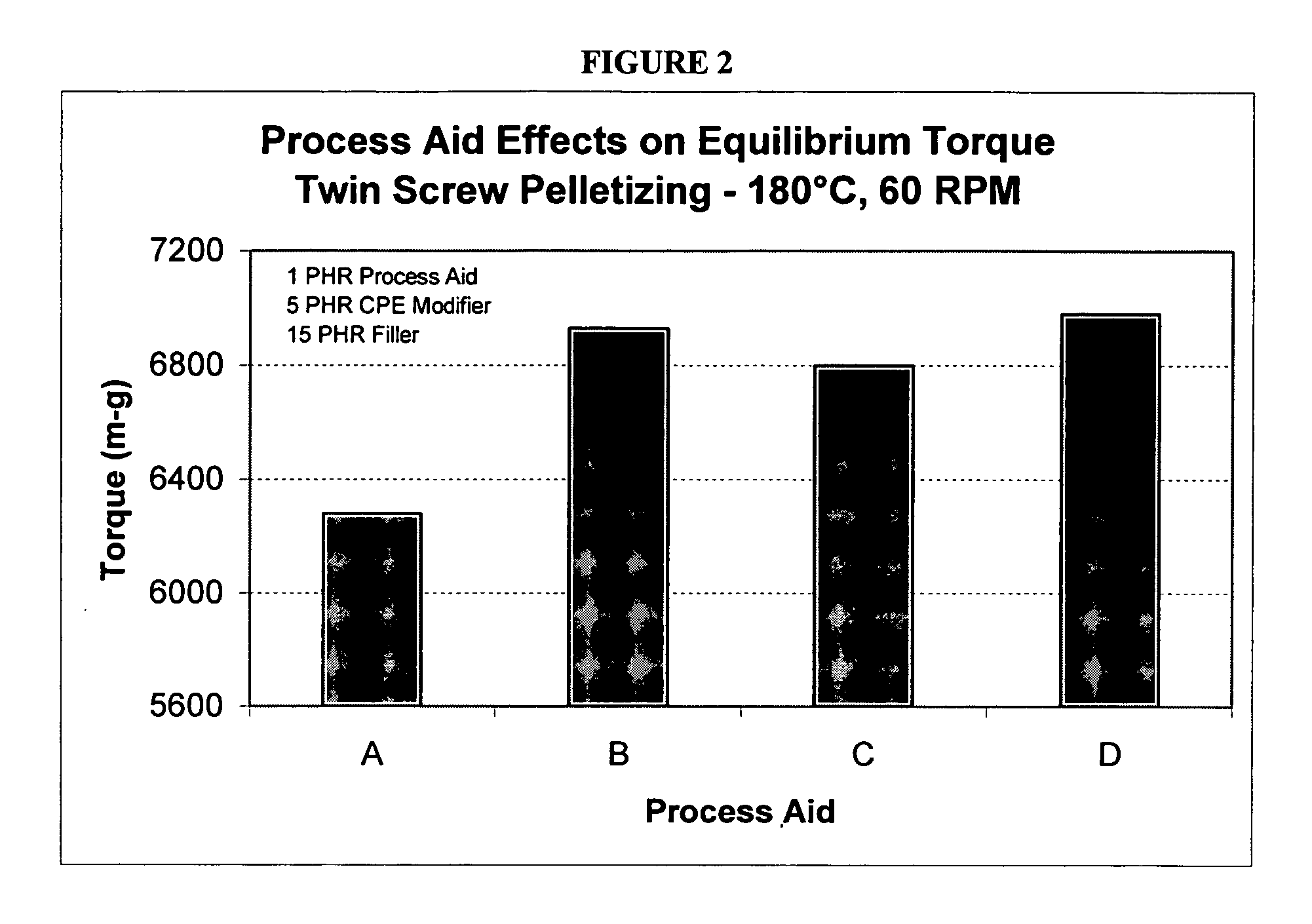

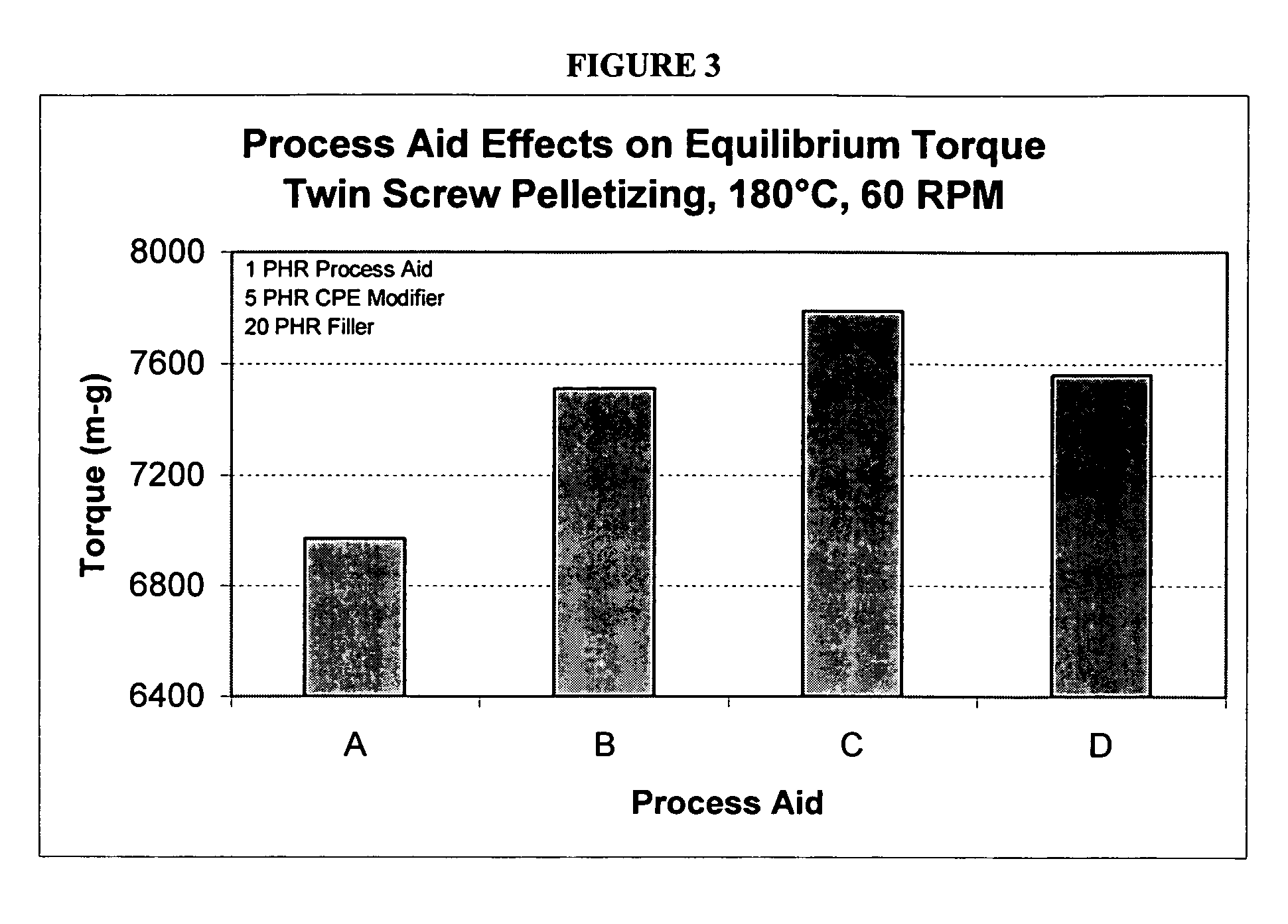

Reduced melt viscosity rigid polyvinylchloride (PVC) composition

ActiveUS20060175728A1Reduce meltingImprove throughputCeramic shaping apparatusProduction rateProcedure Agents

The invention relates to a process aid for use in rigid thermoplastic compositions, and especially in rigid polyvinylchloride (PVC) compositions. The process aid is an acrylic terpolymer of methylmethacrylate, butyl acrylate and styrene at an optimal ratio to produce a significant reduction in melt process viscosity. The resulting reduction in extrusion melt torques enables manufacturers of rigid PVC products to have higher throughput production rates.

Owner:ARKEMA INC

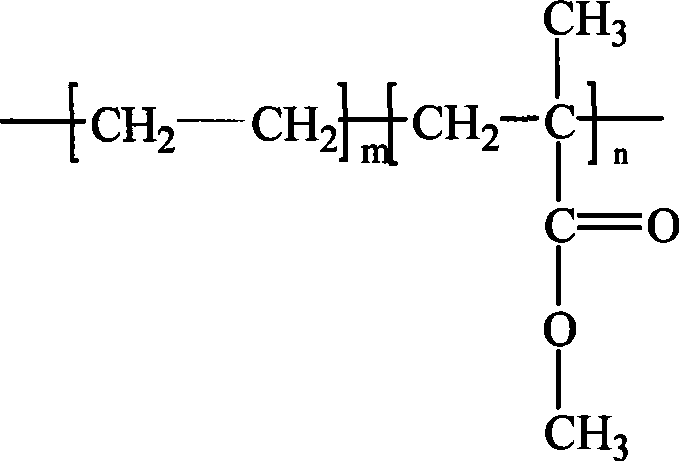

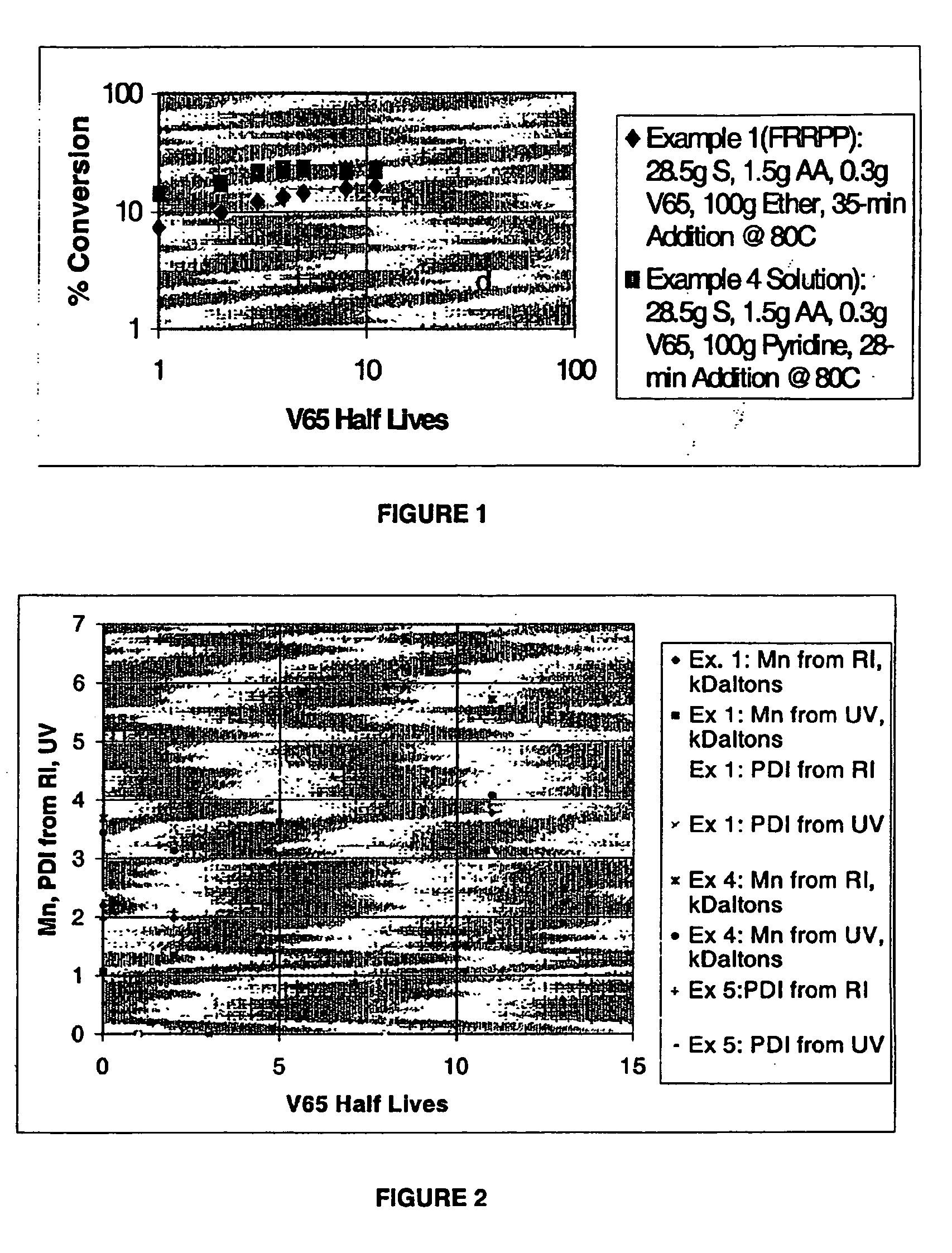

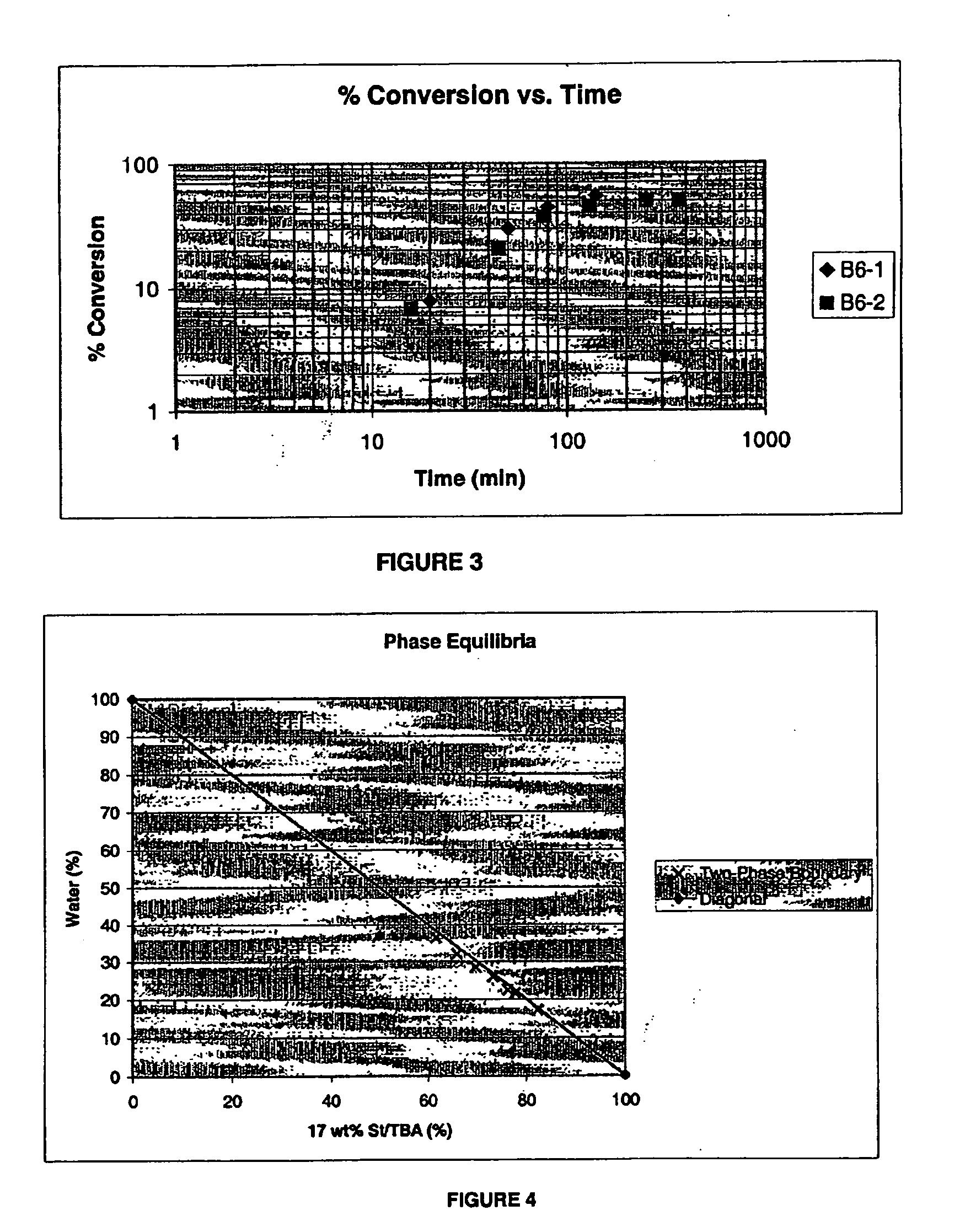

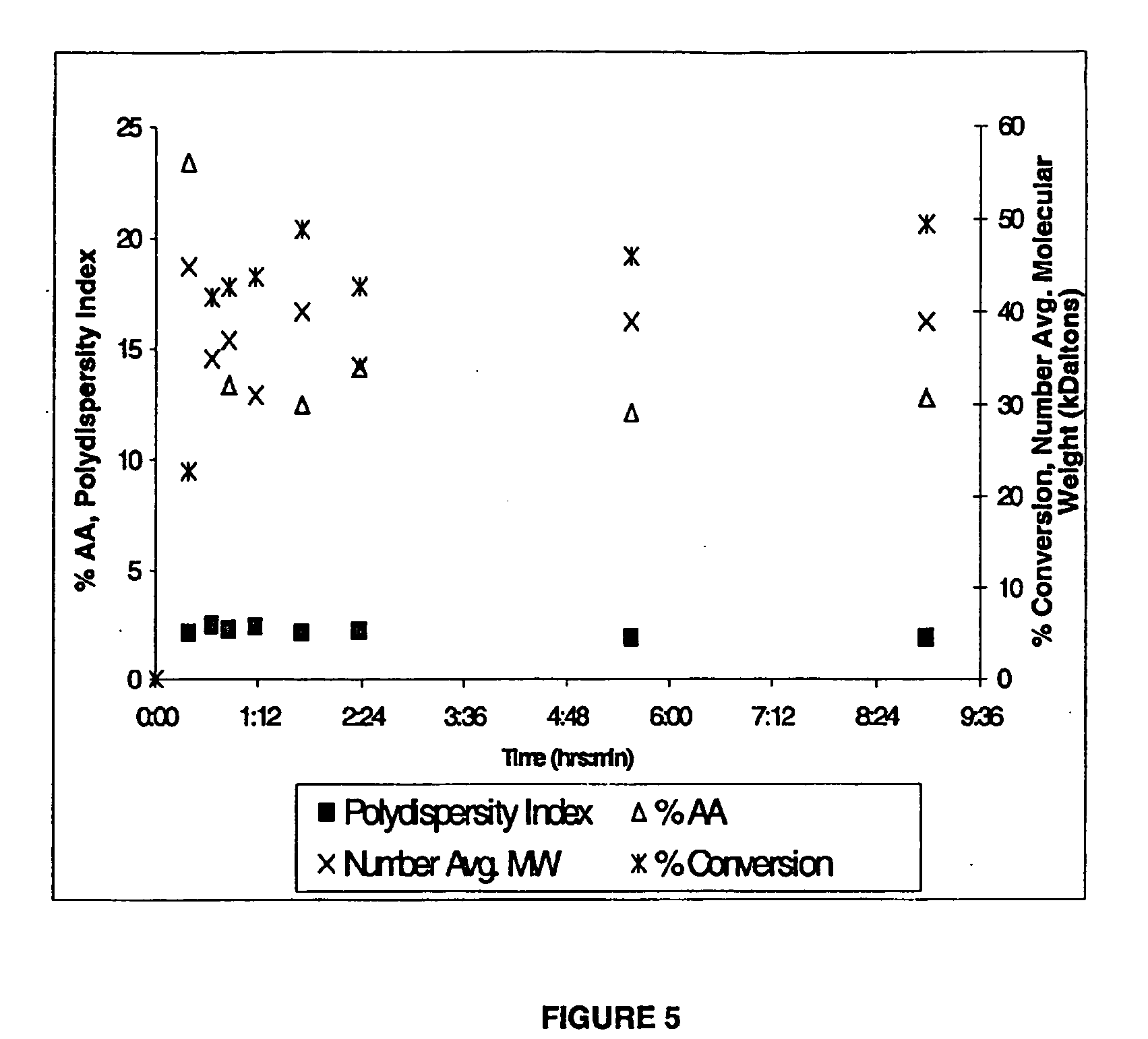

Free radical retrograde precipitation copolymers and process for making same

The present invention is directed to a single stage free radical precipitation polymerization process for producing a copolymer involving admixing a solvent, a free-radical-forming agent, (meth)acrylic acid, and at least one monomer selected from the group consisting of styrene, vinyl acetate, methylmethacrylate, butyl acrylate, methyl acrylate, acrylonitrile, and isopropylacrylamide; initiating a free-radical precipitation polymerization to form a plurality of polymer radicals; precipitating a polymer from said polymer radicals; maintaining the admixture of reactants at a temperature above the lower critical solution temperature of said admixture; and controlling the temperature of said admixture to control the rate of propagation of the polymer. The process is useful for producing random copolymers of vinyl acetate or styrene with more than 4 percent and up to greater than 20 percent by weight of (meth)acrylic acid.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

Structural antibacterial acrylic emulsion, and preparation method and application thereof

InactiveCN107383283AMildew-resistantImprove water resistanceAntifouling/underwater paintsPaints with biocidesSodium bicarbonateEmulsion

The invention provides a structural antibacterial acrylic emulsion, and a preparation method and an application thereof. The structural antibacterial acrylic emulsion is prepared from an emulsifier, an initiator, sodium bicarbonate and a polymerizable antibacterial monomer polyhexamethylene guanidine hydrochloride modified with butyl acrylate, methylmethacrylate and allyl glycidyl ether in a semi-continuous seed emulsion polymerization manner. The preparation method is simple and environmentally-friendly, and is suitable for industrial production; the polyhexamethylene guanidine hydrochloride used as an antibacterial functional group makes the prepared emulsion reserve the self antibacterial capability of the polyhexamethylene guanidine hydrochloride, makes the emulsion and a film formed by the emulsion have excellent antibacterial properties, has no influences on the other performances of the emulsion, and is very safe to human bodies.

Owner:南京邦鼎生物科技有限公司

Film coating

A film coating composition suitable for use in coating pharmaceutical formulations comprising a) an acrylic polymer dispersion, e.g. an ethylacrylate / methylmethacrylate copolymer such as Eudragit NE30D, b) a surfactant, c) sodium stearyl fumarate, and d) a water-containing liquid useful for the achievement of controlled release from pharmaceutical formulations such as tablets, pellets, etc.

Owner:ASTRAZENECA AB

Polymethylmethacrylate composite material for 3D printing and preparation method thereof

The invention discloses a polymethylmethacrylate composite material for 3D printing and a preparation method thereof. The preparation method comprises the following steps: dissolving acrylic acid in ethyl acetate, adding zaodiisobutyronitrile, placing at room temperature, then sequentially adding paranitrobenzoic acid and isobutyl cyanacetate, stirring at room temperature, subsequently adding polymethylmethacrylate particles and continuously stirring at room temperature to obtain the polymethylmethacrylate composite material for 3D printing. The polymethylmethacrylate composite material comprises 30-60 percent of polymethylmethacrylate, 10-30 percent of isobutyl cyanoacetate, 1-10 percent of crylic acid, 20-40 percent of ethyl acetate, 1-2 percent of zaodiisobutyronitrile, and 1-10 percent of paranitrobenzoic acid. The composite material prepared according to the preparation method can be used for 3D printing within the temperature range of 10-35 DEG C, and the polymethylmethacrylate composite material for 3D printing and the preparation method thereof are easily popularized and applied due to simple preparation process, easy availability of the raw materials and low production cost.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

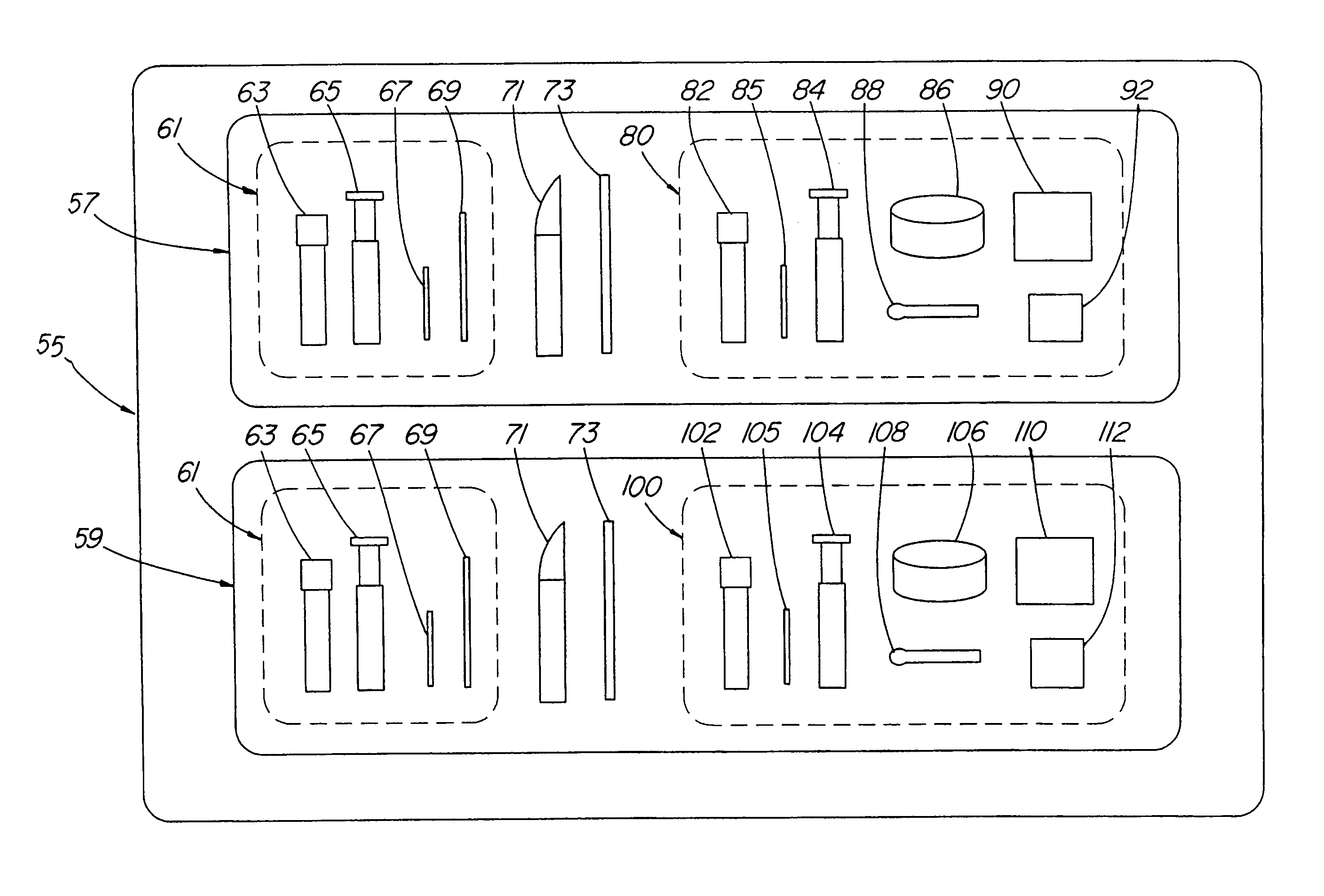

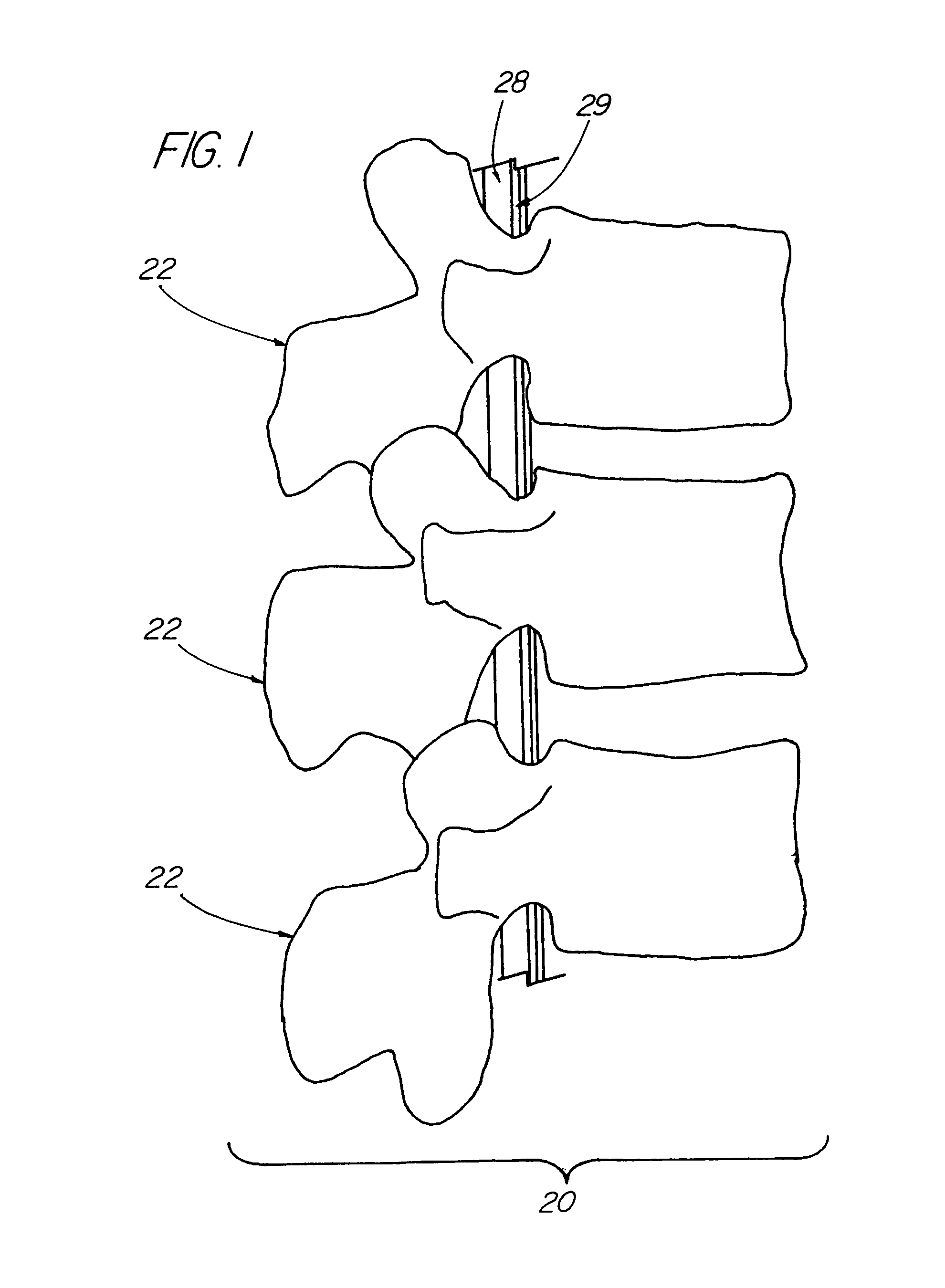

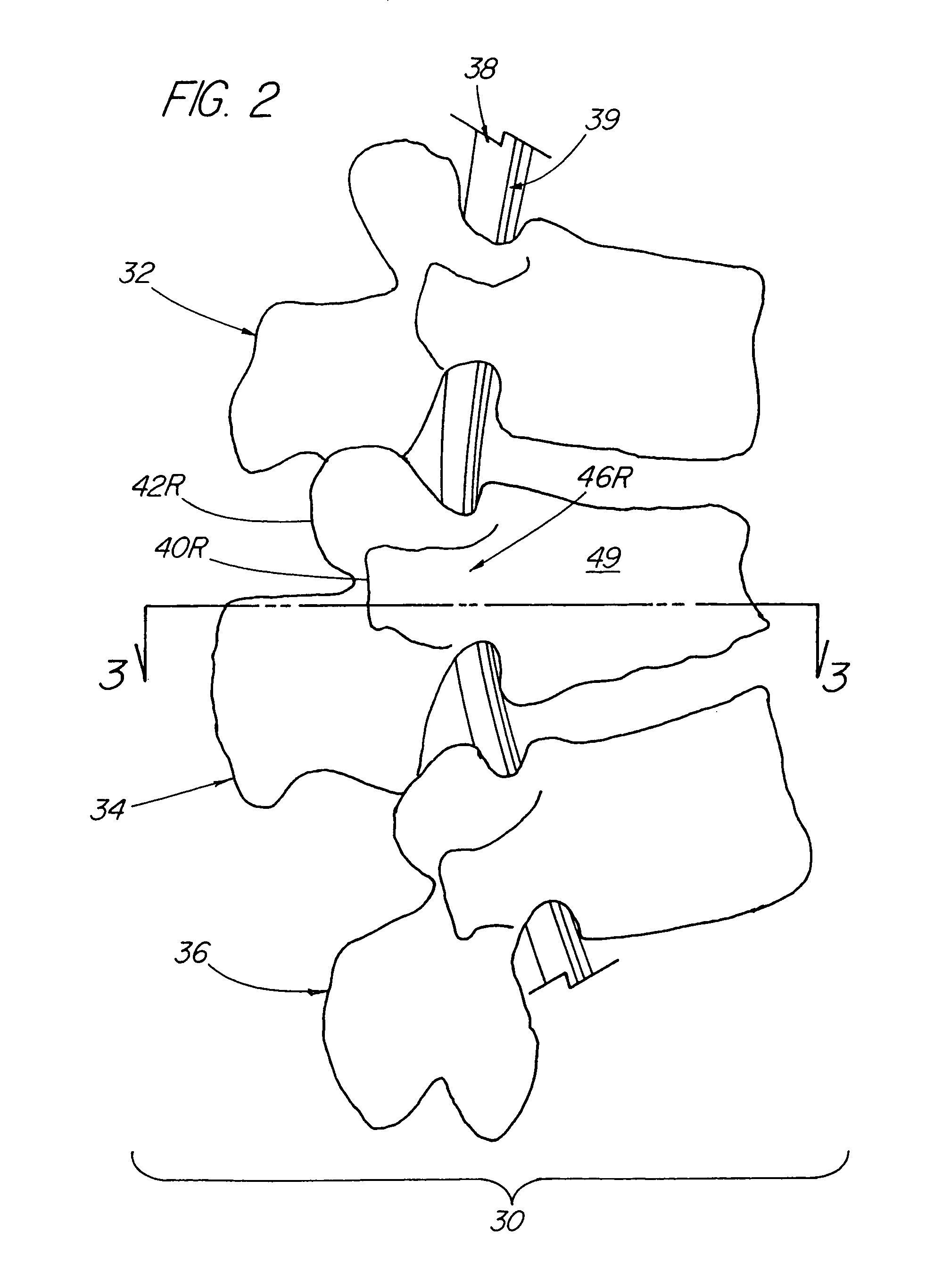

Apparatus for strengthening vertebral bodies

An apparatus and method for performing vertebroplasty are provided. In one embodiment of the invention, there is provided a kit for performing vertebroplasty having two trays, each tray having the necessary components for performing vertebroplasty via each pedicle of the damaged vertebrae. Each tray is sterilized, so that if the vertebroplasty performed via one pedicle is sufficient, then the second tray can be saved for later use. In another embodiment, each tray within the kit has two cements, each cement having different imaging properties, such that each cement will appear different when viewed with an imaging device in the lateral plane and / or will be viewable when overlapping. A presently preferred embodiment involves two trays having methylmethacrylate powder but each tray has a different amount of opacifier, either as supplied or added by the vertebroplasty professional, such that when each cement is mixed and injected, each cement is visible when exposed to X-ray lateral fluoroscopy. A method is also provided that utilizes the kit, and which allows a medical professional to monitor a second injection of cement via the second pedicle and thus reduce the risk of spinal cord compression or venous filling due to unwanted flow of cement into the spinal canal.

Owner:IZI MEDICAL PROD

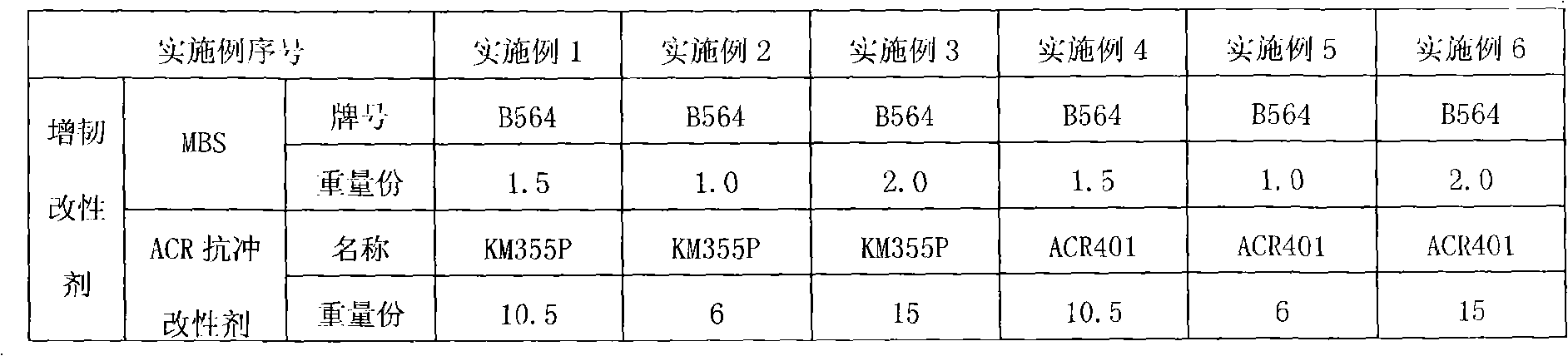

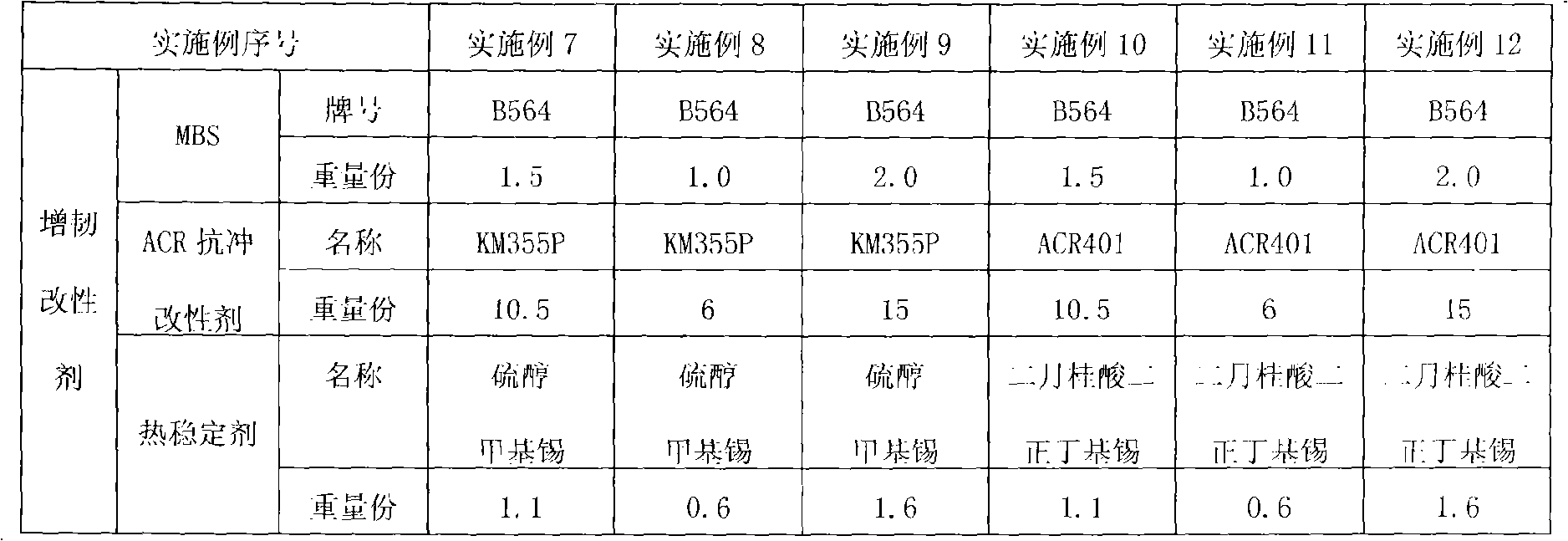

Polyvinyl chloride toughening modifier

InactiveCN101565530AImprove impact resistanceHigh surface glossRigid pipesMethylmethacrylatesPolyvinyl chloride

The invention discloses a polyvinyl chloride toughening modifier, which comprises 1.0 to 2.0 portions of methylmethacrylate butadine stryrene copolymer which is also called MBS, and 6 to 15 portions of acrylates impact modifier which is also called ACR impact modifier; and the portion of the compositions is weight portion. The polyvinyl chloride toughening modifier has good toughening and modification effects on polyvinyl chloride.

Owner:干方明

Foamable polyvinyl halogenated resin mass, use of polymerizates thereof as processing aids and objects formed therefrom

InactiveUS6043293ALow foam densitySurface quality is not negativelyProcedure AgentsPolymer chemistry

There are provided foamable, foamable polyvinyl halide resin masses containing: A) 1 to 25 parts relative to 100 parts of polyvinyl halide, of a polymerizate obtainable through the emulsion polymerization of i) up to 20 to not more than 75 parts of methylmethacrylate, ii) 25 to 80 parts of one or more C2-C18 alkylmethacrylates, iii) 0 to 5 parts of one or more vinyl unsaturated monomers copolymerizable with (i) and / or (ii, wherein the components (i)-(iii) together yield 100 parts and are polymerized with up to a further 100 parts of usual additives for emulsion polymerization, wherein the emulsion polymerizate is single stepped and has a viscosity number of >700 cm3 / g and wherein copolymers are excluded which contain iv) MMA per se, or less than 20 or more than 75 parts of MMA together with either v) one or more acrylic acid esters, and / or vi) ethyl methacrylate, n-butyl-methacrylate, or ethylhexyl methacrylate. The resin mass further includes: B) 0.1-10 parts based on 100 parts of the polyvinyl halide of one or more foaming materials, C) 0-100 parts based on 100 parts polyvinyl halide of the usual additives. This polyvinyl halide resin mass, after foaming, yields a resin mass which, as well as of good surface properties, has a foam density of <0.7 g / cm3.

Owner:KANEKA BELGIUM

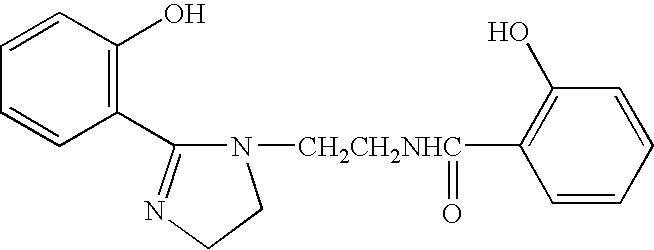

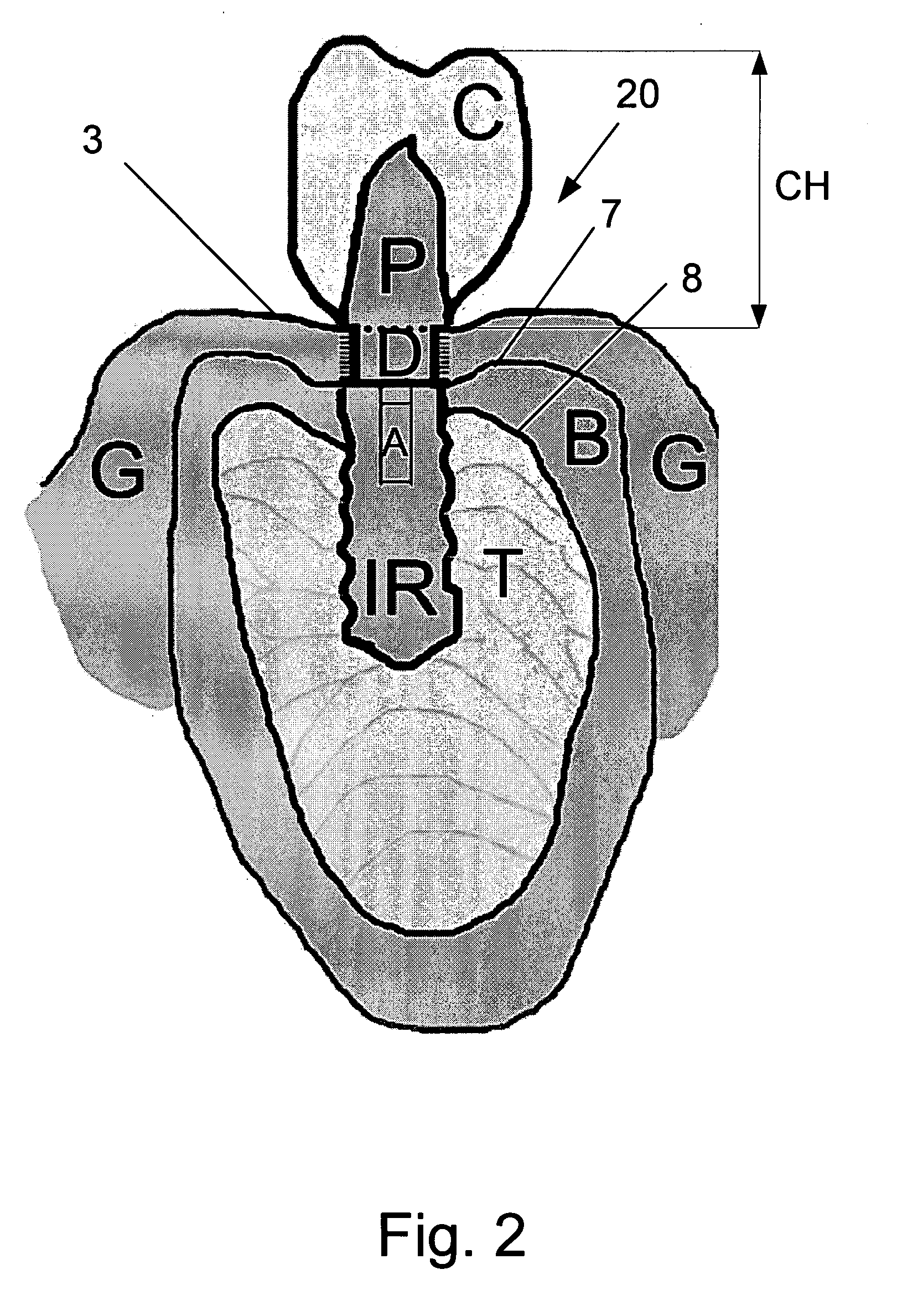

Device and Method for Gingival Attachment Associated with Endosseous Implants

A gingival attachment device associated with an endosseous implant, which comprises a cervically located component of a dental implant coated on a gingival facing surface thereof with a biocompatible and non-degradable polymeric scaffold, to which epithelial and connective tissue cells of the gingiva are attachable. The polymeric scaffold may be polyvinylpyrronidole mixed with butyl-methylmethacrylate, silk fibroin fibrous protein polymer mixed with chitosan or with derivatives of chitosan, and polyHEMA and may be coated on all gingival facing surfaces of the cervically located component.

Owner:MEDINTAL

Method for enhancing polymethylmethacrylate through cellulose

The invention discloses a method for enhancing polymethylmethacrylate (PMMA) through cellulose and belongs to the technical field of cellulose enhanced materials. The method comprises the following steps: S01, smashing wood blocks into wood grains; S02, preparing a lignin removing solution; putting the wood grains into the lignin removing solution and continuously boiling for 4h or more; then washing with distilled water to remove impurities, so as to obtain wood grains I; S03, putting the wood grains I into H2O2 with the mass percent of 30 percent and heating and boiling, wherein the mass ofthe wood grains I is not higher than 30 percent of the mass of the H2O2. The invention aims at improving the mechanical strength of the polymethylmethacrylate; modified wood fibers and a pre-polymerized MMA (Methylmethacrylate) solution are prepared into a PMMA transparent composite material with any size and high light transmittance rate; and raw materials of the wood fibers have a wide source and wood dust processing waste materials (such as sawdust and branches) can be adopted, so that the cost is low, resources are saved and the preparation efficiency is high.

Owner:NANJING FORESTRY UNIV

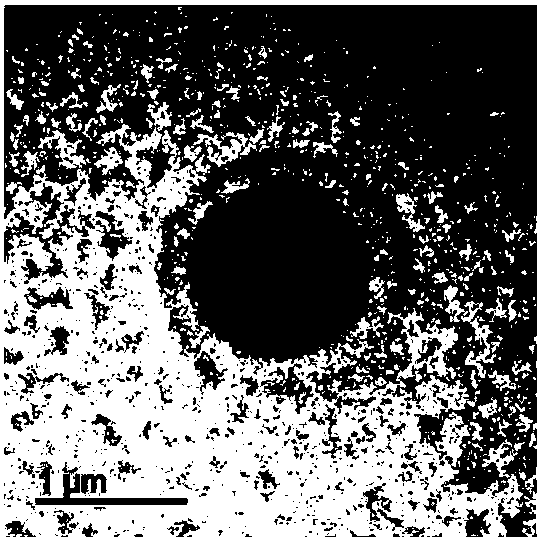

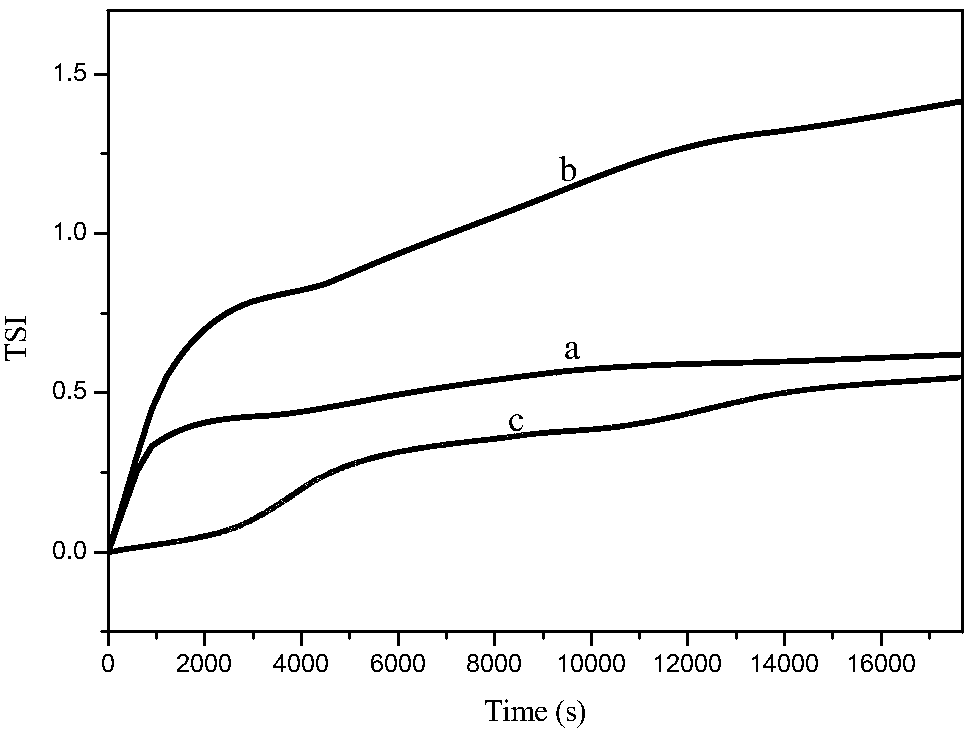

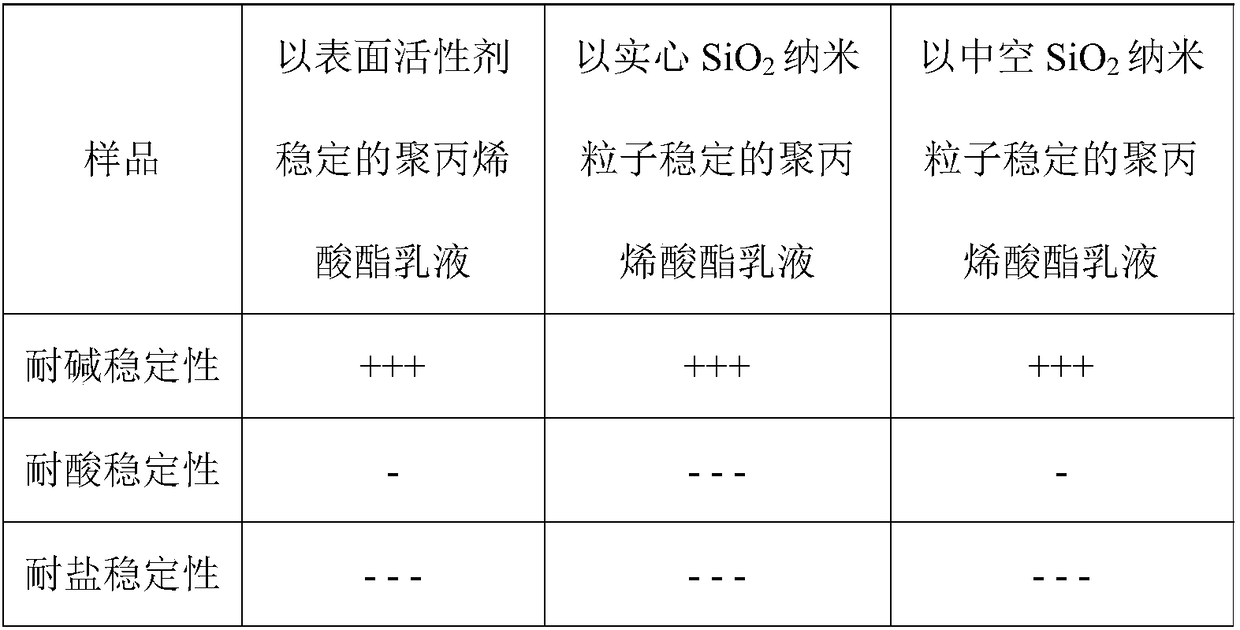

Method for preparing polyacrylate Pickering emulsion

Provided is a method for preparing polyacrylate Pickering emulsion. The method comprises the steps of: adding ammonium persulfate and modified hollow SiO2 nanoparticles into water, then adding methylmethacrylate, butyl acrylate and acrylic acid, raising the temperature to 50-70 DEG C, maintaining the temperature for a reaction for 0.5-1.0 h, raising the temperature to 70-80 DEG C, adding a mixedsolution of core-layer mixed monomer, the modified hollow SiO2 nanoparticles and ammonium persulfate which is dissolved in water dropwise, maintaining the temperature for a reaction for 1-3 hours after adding is completed dropwise, raising the temperature to 80-85 DEG C, adding the mixed solution of the core-layer mixed monomer, modified hollow SiO2 nanoparticles and ammonium persulfate which is dissolved in water dropwise, and maintaining the temperature for a reaction for 1-3 hours after adding is completed dropwise so as to obtain the polyacrylate Pickering emulsion. A membrane which is obtained by using the hollow SiO2 nanoparticle-stabilized polyacrylate emulsion still has good mechanical properties and water resistance under the condition of basically unchanged hygienic performance.

Owner:SHAANXI UNIV OF SCI & TECH

Nanoimprint resist, nanoimprint mold and nanoimprint lithography

ActiveUS20100308009A1Low modulusEasy to crushDecorative surface effectsNanoinformaticsResistOligomer

A nanoimprint resist that includes a hyperbranched polyurethane oligomer (HP), a perfluoropolyether (PFPE), a methylmethacrylate (MMA), a diluent solvent and a photo initiator. A method of a nanoimprint lithography is also provided.

Owner:TSINGHUA UNIV +1

Solvent type gold-mixed oil for gravure and flexible print

The present invention relates to one special mixture comprising resin, organic solvent, platicizer and pigment for mixing with gold powder in printing. Specially, it consists of thermoplastic methylmethacrylate / butyl methacrylate copolymer resin 10-50 wt%, ethyl acetate 30-80 wt%, propylene glycol methyl ether acetate 1-25 wt%, dioctyl o-phthalate 1-15 wt% and pigment 1-10 wt%. It may be used in compounding gold ink with high adhesivity to base material, and this can reduce the consumption of gold powder, lower cost and makes it possible to realize large-area printing, gold stamping, etc.

Owner:山西精华科工贸有限公司

Low-dimensional material chemical vapor sensors

A method of making a low-dimensional material chemical vapor sensor comprising exfoliating MoS2, applying the monolayer flakes of MoS2 onto a SiO2 / Si wafer, applying a methylmethacrylate (MMA) / polymethylmethacrylate (PMMA) film, defining trenches for the deposition of metal contacts, and depositing one of Ti / Au, Au, and Pt in the trench and resulting in a MoS2 sensor. A low-dimensional material chemical vapor sensor comprising monolayer flakes of MoS2, trenches in the SiO2 / Si wafer, metal contacts in the trenches, and thereby resulting in a MoS2 sensor. A full spectrum sensing suite comprising similarly fabricated parallel sensors made from a variety of low-dimensional materials including graphene, carbon nanotubes, MoS2, BN, and the family of transition metal dichalcogenides. The sensing suites are small, robust, sensitive, low-power, inexpensive, and fast in their response to chemical vapor analytes.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

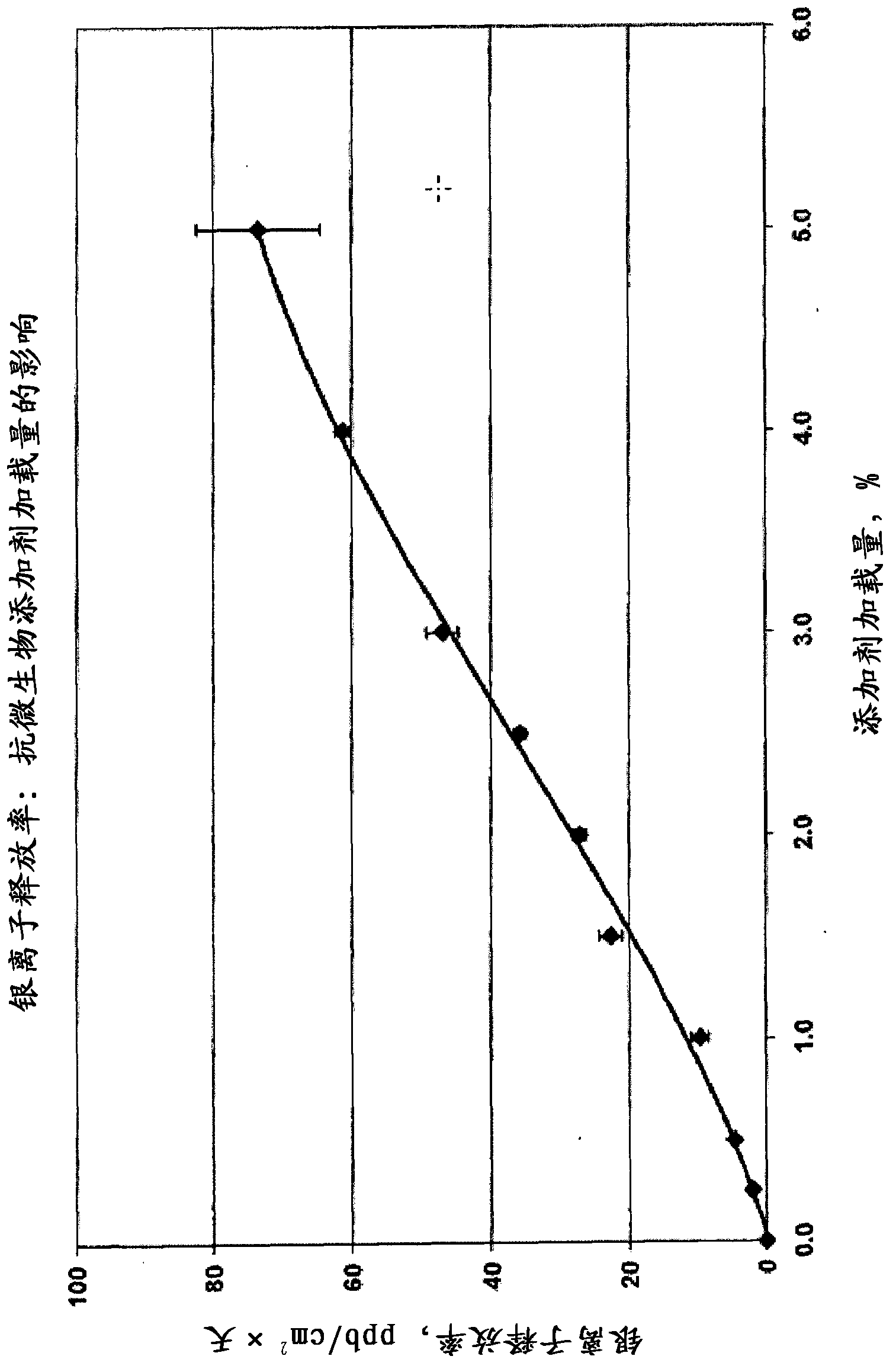

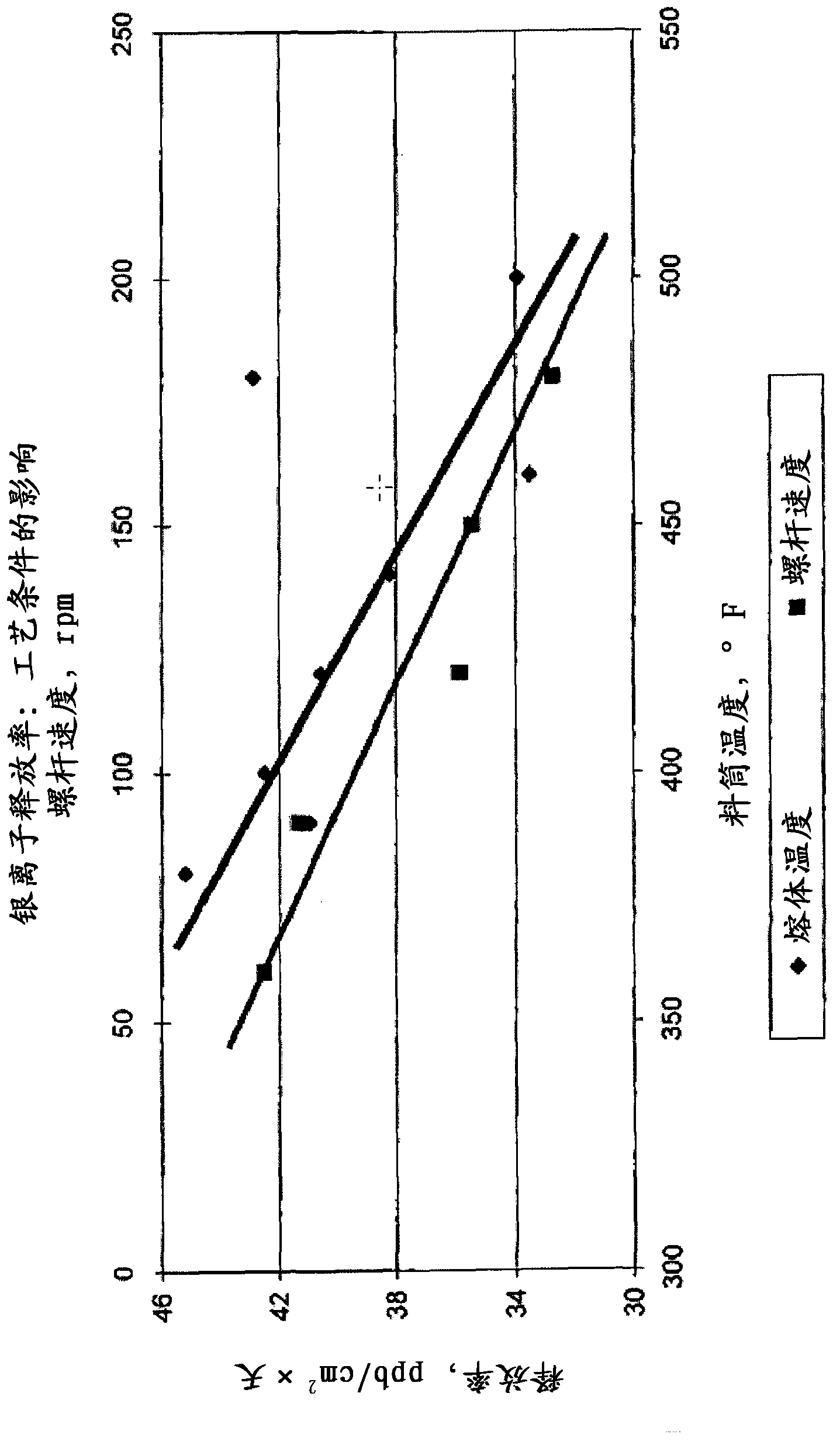

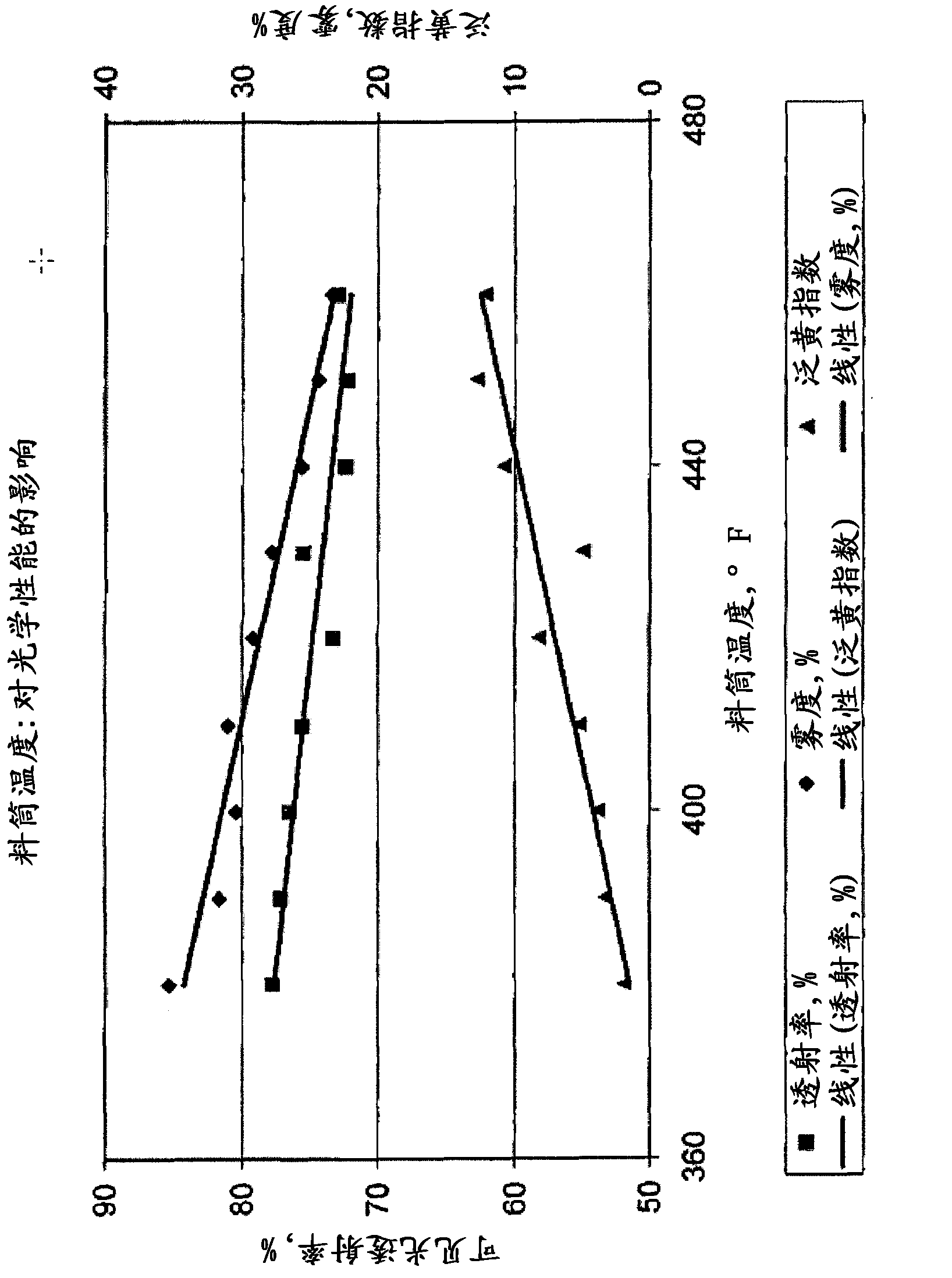

Method for manufacturing antimicrobial acrylic materials

Acrylic materials with antimicrobial activity are tumble blended, melted and extruded through an extruder. The resulting polymer compounds include an acrylic resin, such as methylmethacrylate polymers, copolymers and multipolymers, and blends thereof, silver-containing antimicrobial additives; and optional additives such as impact modifiers, flow promoters, stabilizers and coloring agents. The properties of the acrylic materials, especially the antimicrobial performance, are strongly dependent on the manufacturing process conditions, including feed resins pre-drying, residual moisture content, screw speed and melt temperature. The materials composition and manufacturing procedures are equally significant.

Owner:EVONIK ROEHM GMBH

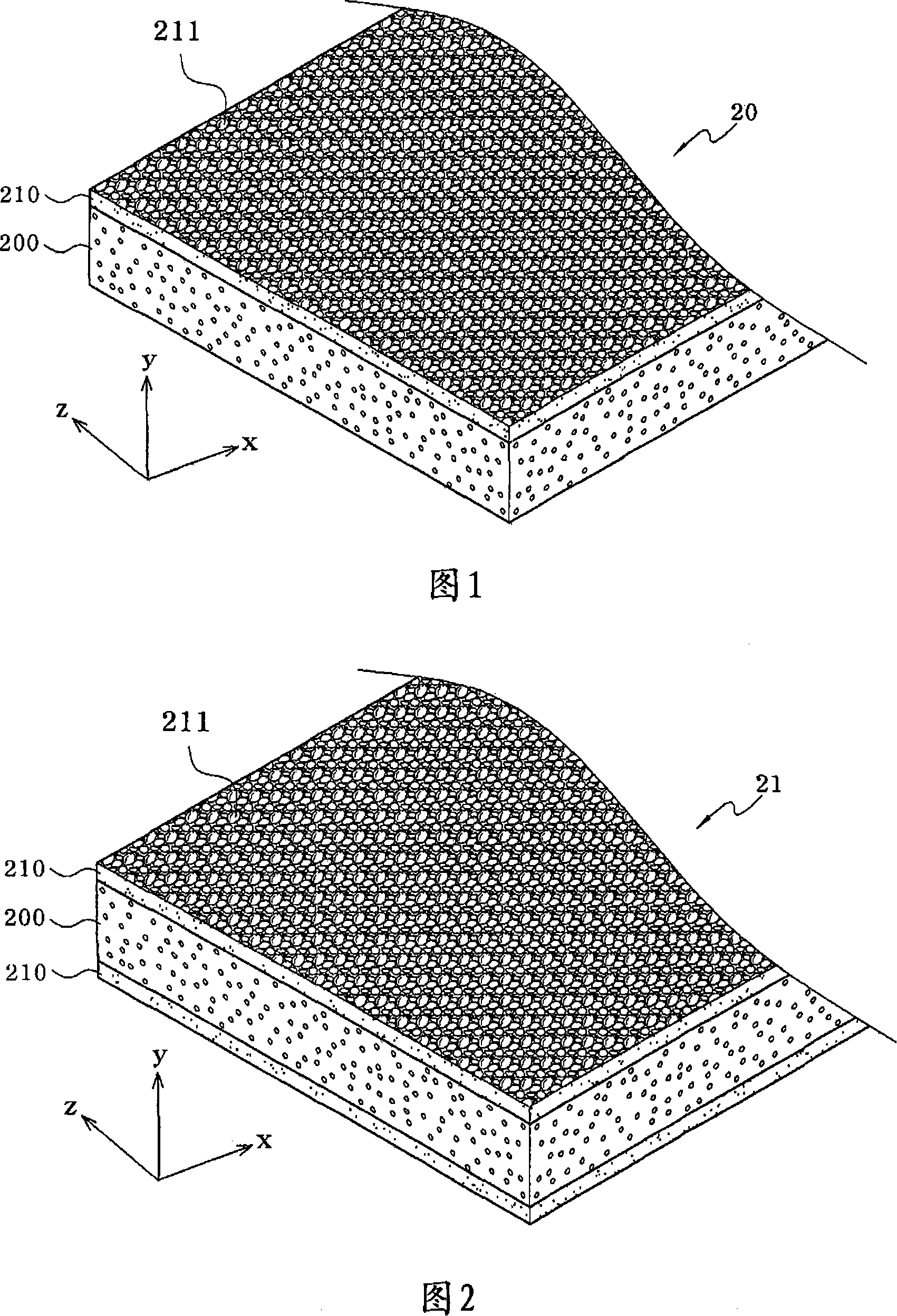

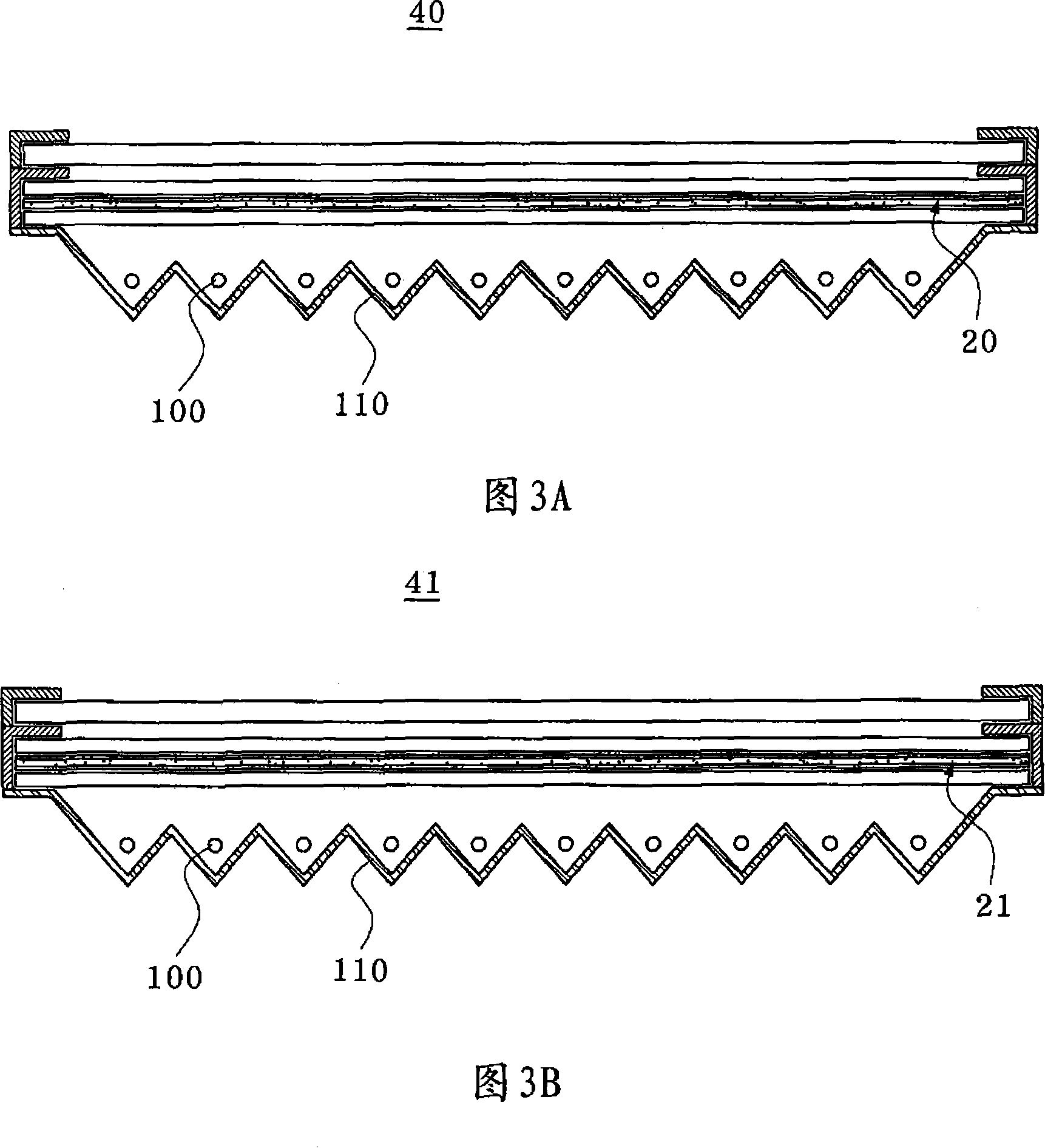

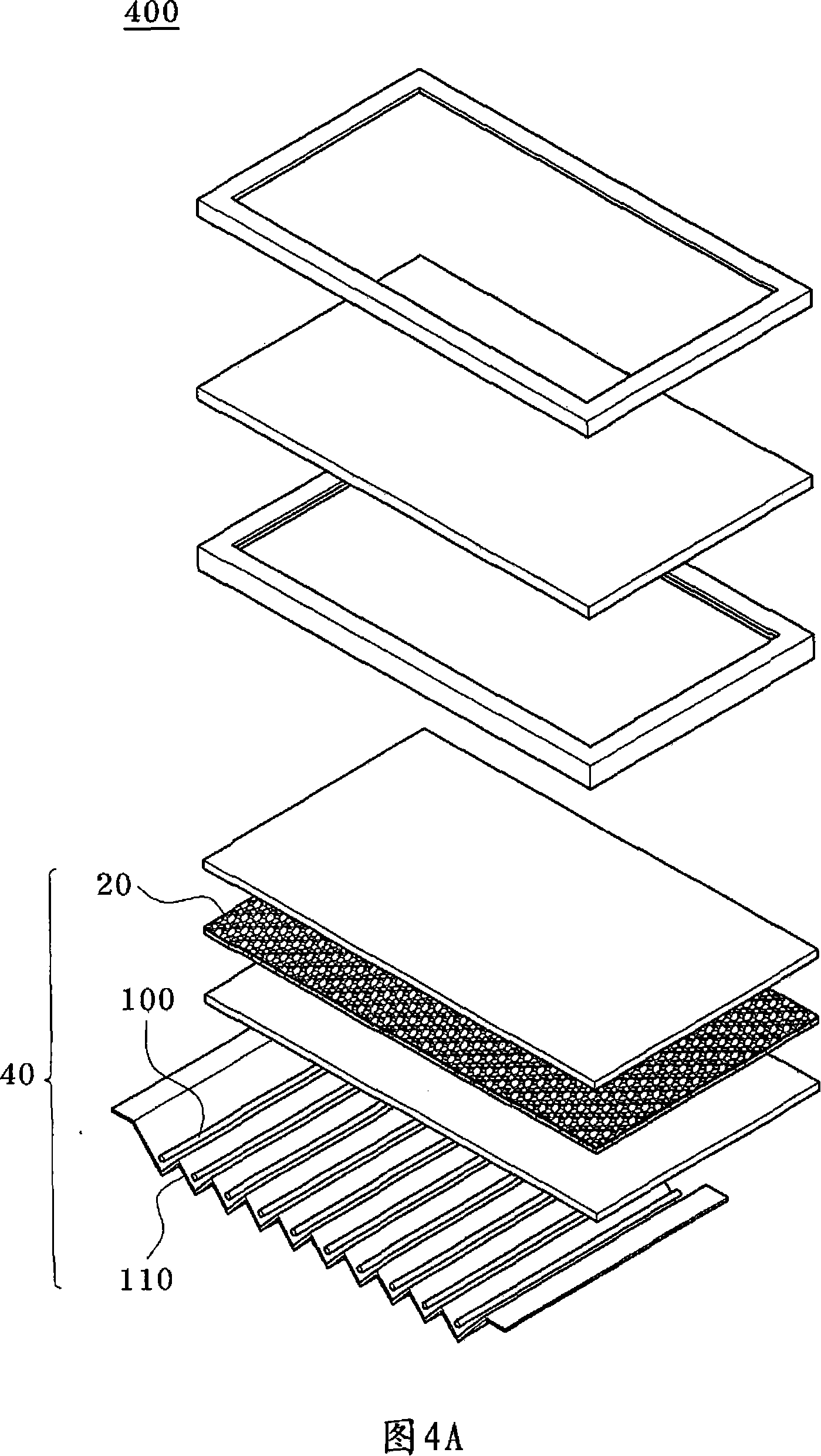

Light diffusion sheet for a display device

A light diffusion sheet for a display device includes a base layer having a base resin mixture of a methacrylate-styrene copolymer and a methylmethacrylate-styrene copolymer and about 0.2 to 20 ppwb of a first light diffuser, and at least one coating layer on the base layer, the coating layer including a methylmethacrylate-styrene copolymer base coating resin, about 0.1 to 30 ppwb of a second light diffuser, about 0.01 to 2 ppwb of an UV absorber, and about 0.001 to 10 ppwb of an antistatic agent.

Owner:HB TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com