Method for manufacturing antimicrobial acrylic materials

An antimicrobial, acrylic technology, used in botanical equipment and methods, biocides, animal repellants, etc., to solve problems such as insufficient proof color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085]Table 2 shows the antimicrobial activity of some of the above base resins containing 1.5% by weight silver-based antimicrobial glass frit. In all examples, antimicrobial activity was measured according to JIS Z2801 and calculated as: [log(B / A)−log(C / A)]=[log(B / C)], where:

[0086] A = average number of viable bacterial cells immediately after inoculation of untreated specimens

[0087] B = mean number of viable cells of bacteria on untreated specimens after 24 hours; and

[0088] C = mean number of viable cells of bacteria on antimicrobial coupons after 24 hours.

[0089] Table 2

[0090]

Embodiment 2

[0092] Table 3 shows the loading effect of antimicrobial additives. Loadings are expressed as wt % active ingredient, based on the total weight of the composition. All samples used in G20 – Silver-based antimicrobial glass powder in HiFlo.

[0093] table 3

[0094]

[0095] *=Only for different sample groups tested by JIS Z 2801. Inoculation at 0, 24 hours, 48 hours and 72 hours. Viable count reading after 96 hours.

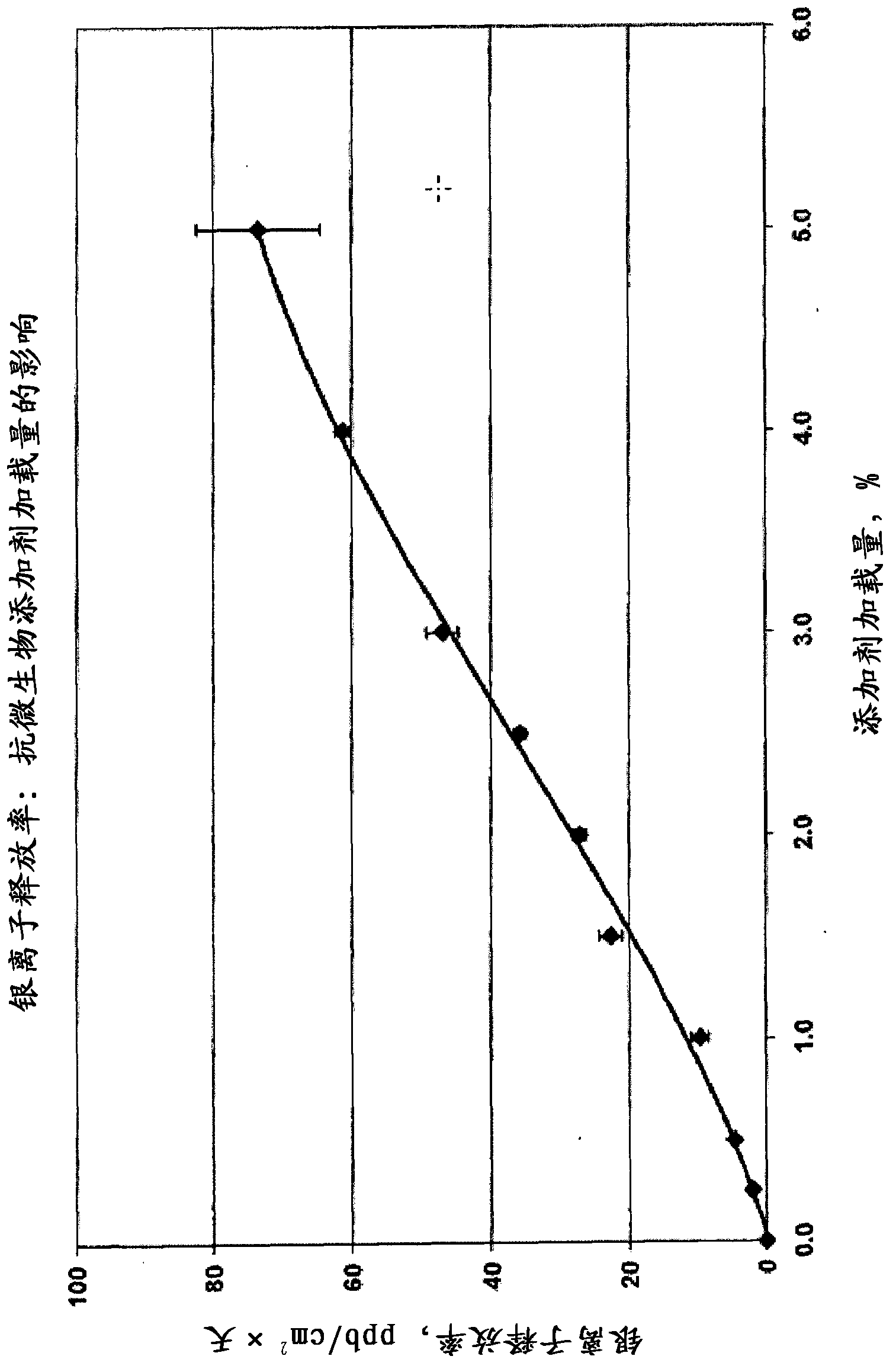

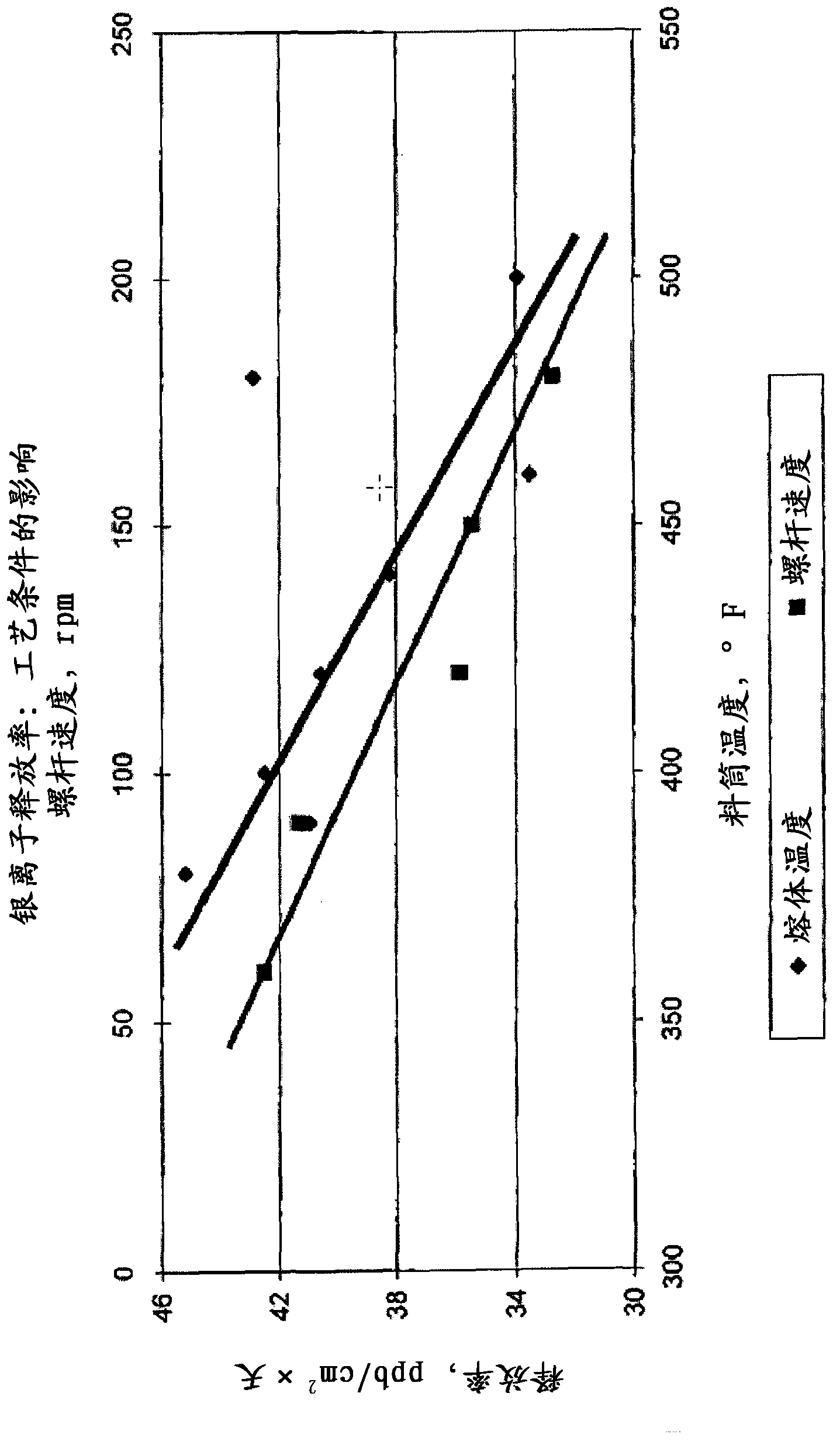

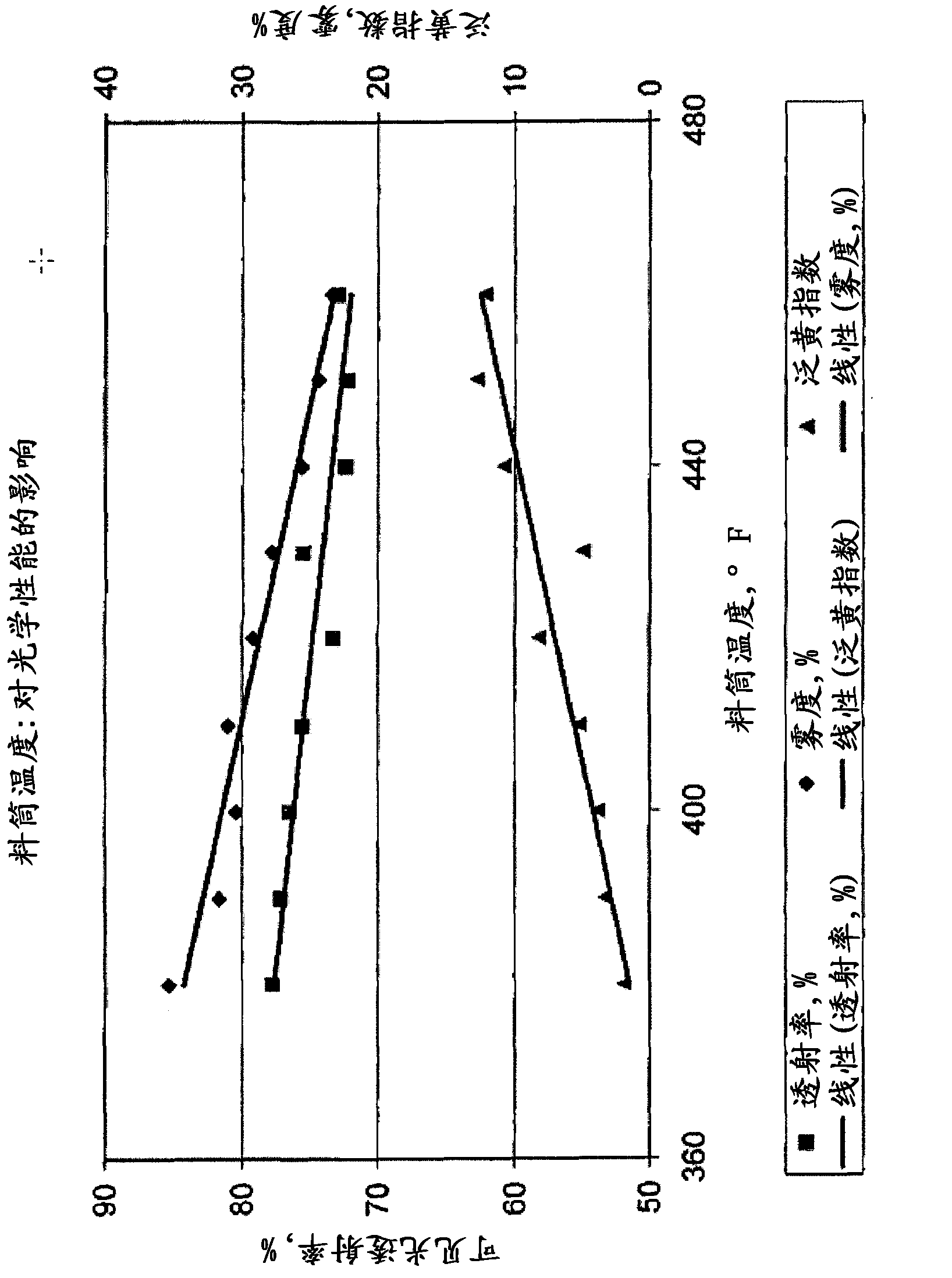

[0096] As seen, the performance depends on the loading of antimicrobial additives. Optical properties and silver ion release rates were measured on 1 / 8" thick 2" x 3" injection molded sections. Silver ion release rates and antimicrobial activity correlated well with additive loading. Most compositions showed strong antimicrobial effects, Termination rates exceeded 6 orders of magnitude (R > 6.0) for both organisms tested. figure 1 The effect of additive loading on silver release rate is shown. Sufficient silver should be present so that the rate of ...

Embodiment 3

[0098] Table 4 shows the effect of moisture. All samples were at 2.5% loading.

[0099] Table 4

[0100]

[0101] Control sample = no dilution of 0% Ionpure resin

[0102] As seen, moisture content during extrusion can significantly affect product properties. Losses in silver release rates of up to 17% have been recorded, depending on moisture content and melt pool temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com