Structural antibacterial acrylic emulsion, and preparation method and application thereof

An acrylic emulsion and structural technology, which is applied in the field of polymers, can solve the problems of antibacterial properties to be improved, unsatisfactory copolymerization reaction efficiency, and low yield, and achieve low storage stability, human safety, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] And the preparation method of emulsion of the present invention is also comparatively easy, and concrete steps can refer to as follows:

[0060] At first, be the preparation of polymerizable antibacterial monomer, it comprises the following steps:

[0061] (a) preparation of polyhexamethyleneguanidine and / or polyhexamethyleneguanidine hydrochloride:

[0062] Under gas protection (preferably nitrogen protection or inert gas protection) conditions, guanidine and / or guanidine hydrochloride and hexamethylenediamine are heated and stirred for reaction, and the heating temperature is preferably controlled at 110-120°C; preferably, guanidine and / or hydrochloric acid The consumption of guanidine is 10~20 parts, and the consumption of hexamethylenediamine is 10~20 parts; Simultaneously, preferably, described is to carry out the reaction of above two kinds of raw materials in four-necked flask, and set corresponding tail gas absorption device, to The tail gas ammonia produced by...

Embodiment 1

[0081] Embodiment 1: the preparation of polyhexamethyleneguanidine hydrochloride (PHMG)

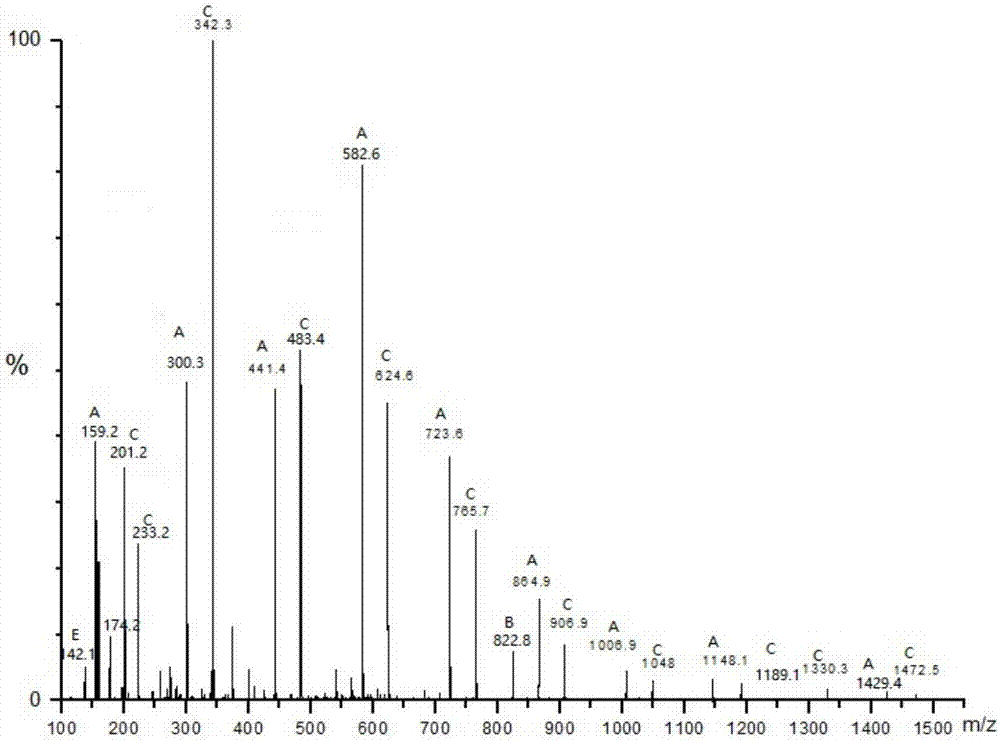

[0082] Weigh 14.5 g of guanidine hydrochloride and 17.4 g of hexamethylenediamine and put it into a four-necked flask equipped with a condenser tube and a thermometer. Simultaneously, nitrogen protection is carried out, and the temperature is raised to 120° C., and continuously stirred with a mechanical stirrer. The tail gas (ammonia) released by the reaction is Absorbed with dilute hydrochloric acid, after two hours, the reaction temperature was raised to 180°C for polycondensation reaction, after 4 hours of heat preservation, the heating was stopped, and the material was discharged while it was hot to obtain polyhexamethyleneguanidine hydrochloride (PHMG). Its molecular weight is characterized by MALDI-TOF, and the characterization results are as follows: figure 1 shown.

Embodiment 2

[0083] Embodiment 2: the preparation of polyhexamethyleneguanidine hydrochloride (PHMG)

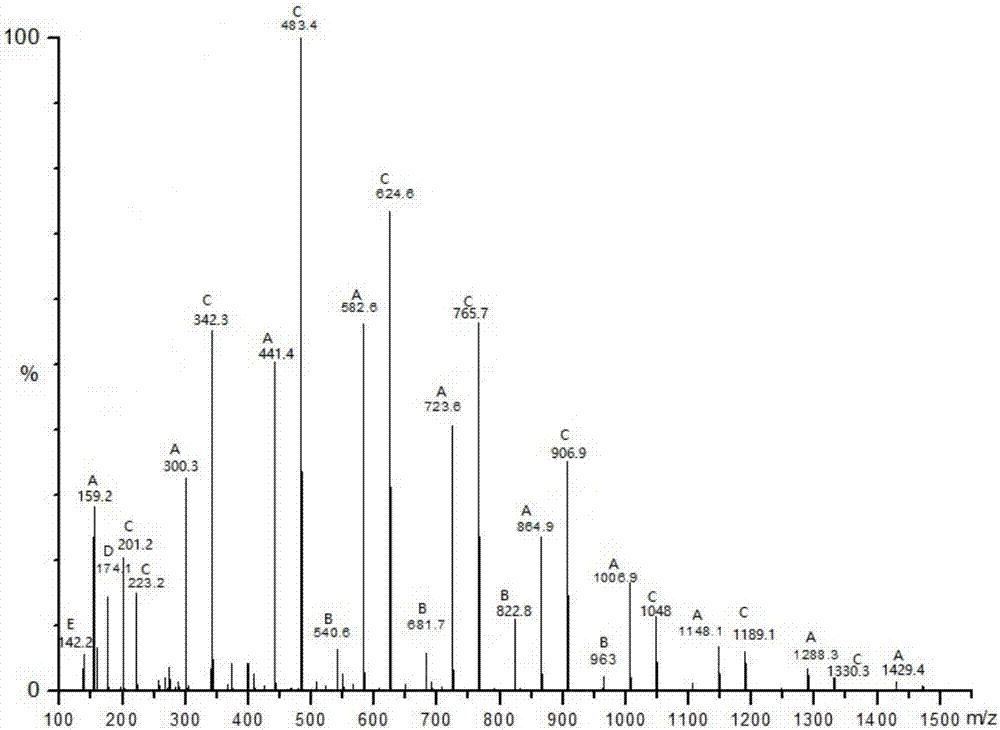

[0084] Weigh 14.5 g of guanidine hydrochloride and 17.4 g of hexamethylenediamine and put it into a four-necked flask equipped with a condenser tube and a thermometer. Simultaneously, nitrogen protection is carried out, and the temperature is raised to 120° C., and continuously stirred with a mechanical stirrer. The tail gas (ammonia) released by the reaction is Absorbed with dilute hydrochloric acid, after two hours, the reaction temperature was raised to 180°C for polycondensation reaction, after 6 hours of heat preservation, the heating was stopped, and the material was discharged while it was hot to obtain polyhexamethyleneguanidine hydrochloride (PHMG). Its molecular weight is characterized by MALDI-TOF, and the characterization results are as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com