Fungus-resistant-treated coatings of printed wrapping paper and production method thereof

A technology of printing and packaging and anti-mildew treatment, which is applied in the direction of wrapping paper, wrapping paper, coating, etc., can solve the problems of persistent pollution of the ecological environment, inconsistent anti-mold and anti-bacterial effects of spraying, and difficult degradation, and achieve high safety and good Inhibition and killing of mold, strong anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

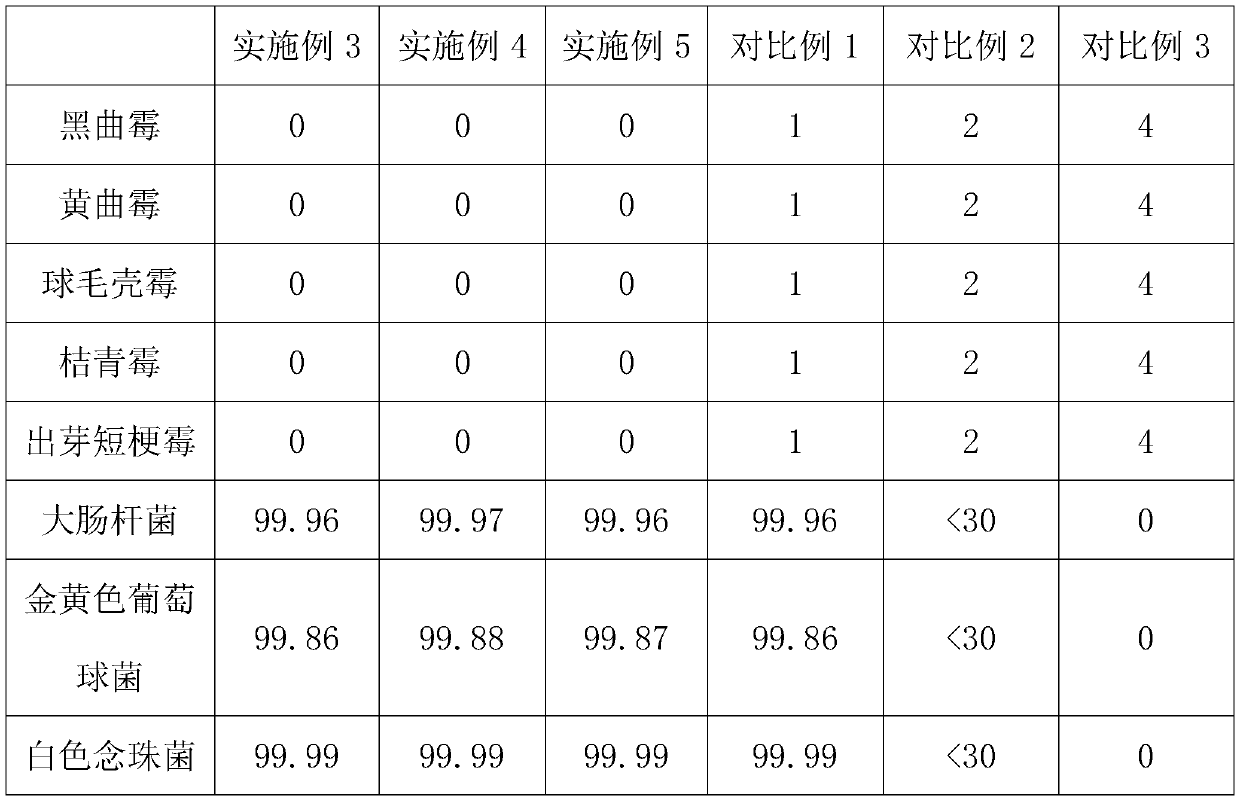

Examples

preparation example Construction

[0041] The preparation method of the anti-mildew treatment coating of the printed wrapping paper comprises the following steps:

[0042] The first step is to immerse the printed packaging paper in the treatment solution for 10-15 minutes;

[0043] The treatment liquid is prepared by the following method:

[0044] At room temperature, first measure 100mL deionized water into a three-necked round-bottomed flask, pass high-purity nitrogen gas to remove the air in the bottle, and maintain magnetic stirring at 120r / min, and add monomer N-methylol in sequence after 30min Acrylamide, acrylic acid, polyvinylpyrrolidone, cross-linking agent and activator, stir for 10 min after adding, slowly add 0.5 mL of 10% AgNO 3 solution, stirred for 60min, added 0.8mL initiator potassium persulfate, continued nitrogen reaction for 6h, then slowly added 1.2mL NaHSO reducing agent dropwise into the solution 3 solution, protected from light for 12 hours, to obtain a treatment solution, kept at room...

Embodiment 1

[0050] Preparation of treatment solution:

[0051] At room temperature, first measure 100mL deionized water into a three-necked round-bottomed flask, pass high-purity nitrogen gas to remove the air in the bottle, and maintain magnetic stirring at 120r / min, and add monomer N-methylol in sequence after 30min Acrylamide, acrylic acid, polyvinylpyrrolidone, cross-linking agent and activator, stir for 10 min after adding, slowly add 0.5 mL of 10% AgNO 3 solution, stirred for 60min, added 0.8mL initiator potassium persulfate, continued nitrogen reaction for 6h, then slowly added 1.2mL NaHSO reducing agent dropwise into the solution 3 solution, protected from light for 12 hours, to obtain a treatment solution, kept at room temperature and protected from light for subsequent use;

[0052] The amount of N-methylolacrylamide added is 0.75g, and the amounts of acrylic acid, polyvinylpyrrolidone, crosslinking agent and activator are respectively 30%, 6.5%, 3.4%, and 9.5% of the mass of N...

Embodiment 2

[0054] Preparation of antibacterial complex:

[0055] (1) Weigh 58.52mL of titanyl sulfate solution and 74.66mL of NaOH solution in a three-necked flask, raise the temperature in a water bath to 60°C, and keep the reaction for 110min under the stirring condition of 500r / min, then add 2.89mL of zirconium nitrate solution to it, Insulate and react for 2 hours, continue to react for 3 hours after heating up to 85 °C, cool naturally, wash with distilled water and absolute ethanol twice, and dry in an oven at 105 °C to obtain Zr-TiO 2 Powder;

[0056] (2) Weigh 8.1g of the above Zr-TiO 2 The powder and 1.2g of methacrylic acid were ultrasonically dispersed in 100mL of distilled water to obtain Zr-TiO 2 Dispersions;

[0057] (3) Under the conditions of water bath 72°C and stirring speed 300r / min, 80.8g of dimethyl diallyl ammonium chloride, Zr-TiO 2 Dispersion liquid, 0.52g methacrylic acid, 0.5g ammonium persulfate and 0.2g NaBH 4 Add it into a three-necked flask, react for 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com