Patents

Literature

50results about How to "Low storage stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonaqueous dispersion containing fluorine-based resin, polyimide precursor solution composition containing fluorine-based resin, polyimide, polyimide film and adhesive composition for circuit boards, each using said polyimide precursor solution composition containing fluorine-based resin; and production methods thereof

ActiveCN107429028ALow viscosityLow storage stabilityMacromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceDielectric loss

In order to provide a dispersion wherein the dispersed state of a fluorine-based resin is uniformly controlled, a polyimide precursor solution composition using this dispersion, an adhesive composition, a polyimide and polyimide film obtained from this polyimide precursor solution composition and having excellent heat resistance, excellent mechanical characteristics, excellent electrical characteristics such as lower dielectric constant and lower dielectric loss tangent, and excellent processability, a method for producing the polyimide, a method for producing the polyimide film, and a circuit board and coverlay film using the polyimide film, the present invention provides: a polyimide precursor solution composition containing a fluorine-based resin, which is characterized by containing a polyimide precursor solution and a nonaqueous dispersion of a fluorine-based resin containing a micropowder of a fluorine-based resin and a butyral resin or a fluorine-based additive containing at least a fluorine-containing group and a lipophilic group; and an adhesive composition.

Owner:MITSUBISHI PENCIL CO LTD

Starch adhesive for environment-friendly timbers and preparation method thereof

InactiveCN103788905ALow costLow storage stabilityNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesCross-linkPolymer science

The invention discloses a starch adhesive for environment-friendly timbers and a preparation method thereof. The preparation method comprises the following steps of oxidizing a starch emulsion under the effect of sodium hypochlorite and obtaining oxidized starch through first-step reaction; adding a cross-linking agent into the oxidized starch, enabling the oxidized starch to perform graft copolymerization modification reaction with acrylamide and comonomer of acrylic ester under the effect of the cross-linking agent and obtaining cross-linked oxidized adhesive liquid through second-step reaction; reducing the temperature to be room temperature, then adding a packing and a preservative into the cross-linked oxidized adhesive liquid and finally obtaining the starch adhesive for the environment-friendly timbers. The starch adhesive for the environment-friendly timbers is low in cost and environment-friendly, has the advantages of being good in storage stability and water resisting property, high in bonding strength and the like, can be widely used for timber decoration and bonding of multiple-layer plywoods, shaving boards, artificial boards and other timber adhering products.

Owner:GUIZHOU LANTU NEW MATERIALS

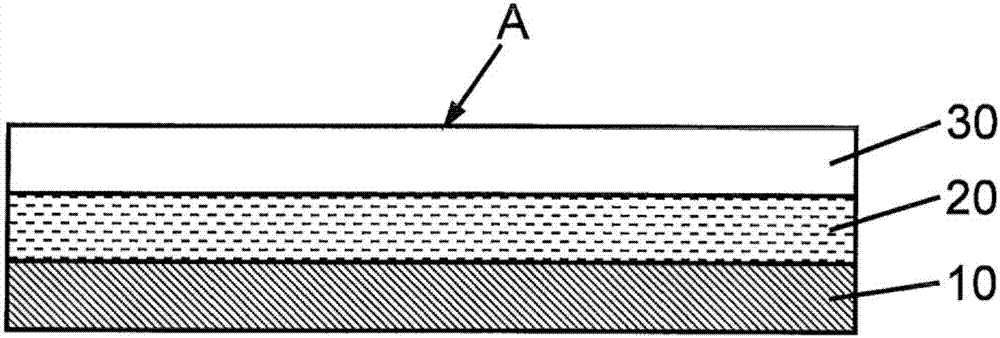

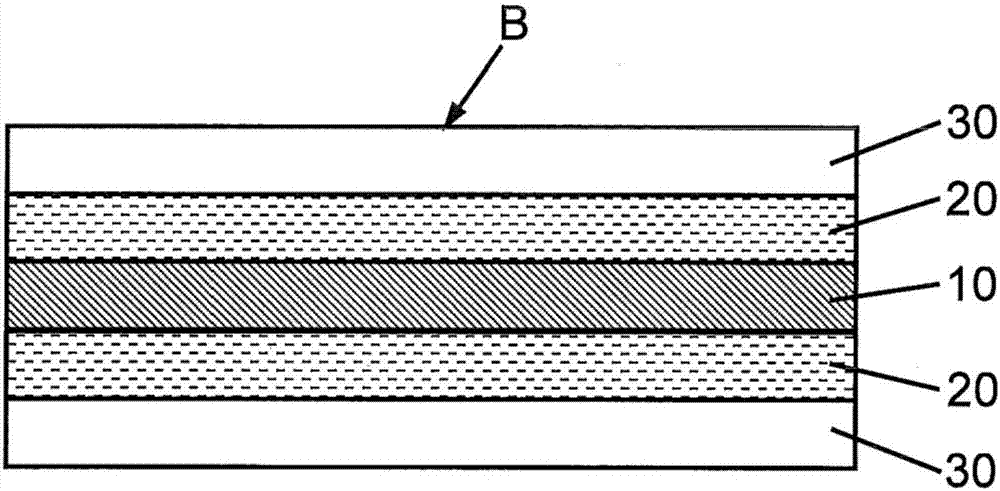

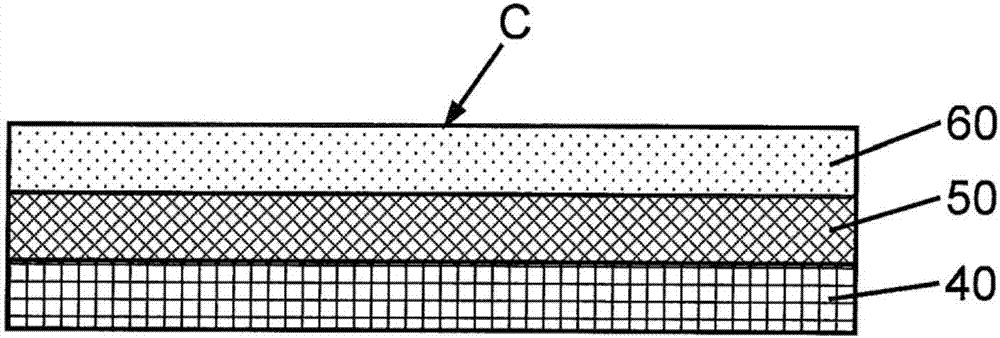

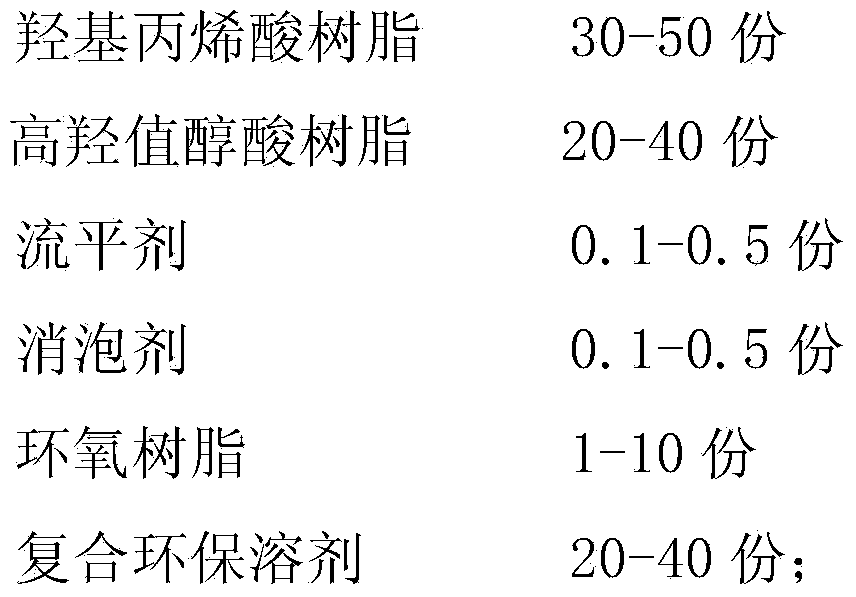

Scratch resistant PU (Poly Urethane) floor varnish and preparation method thereof

ActiveCN103450794AImprove scratch resistanceLow storage stabilityPolyurea/polyurethane coatingsChemistryVarnish

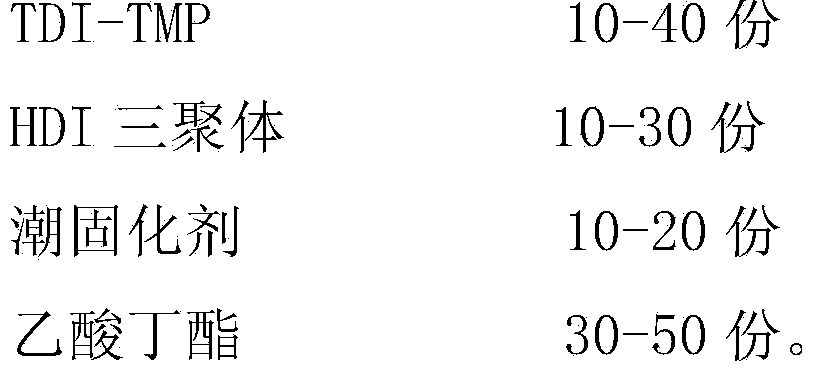

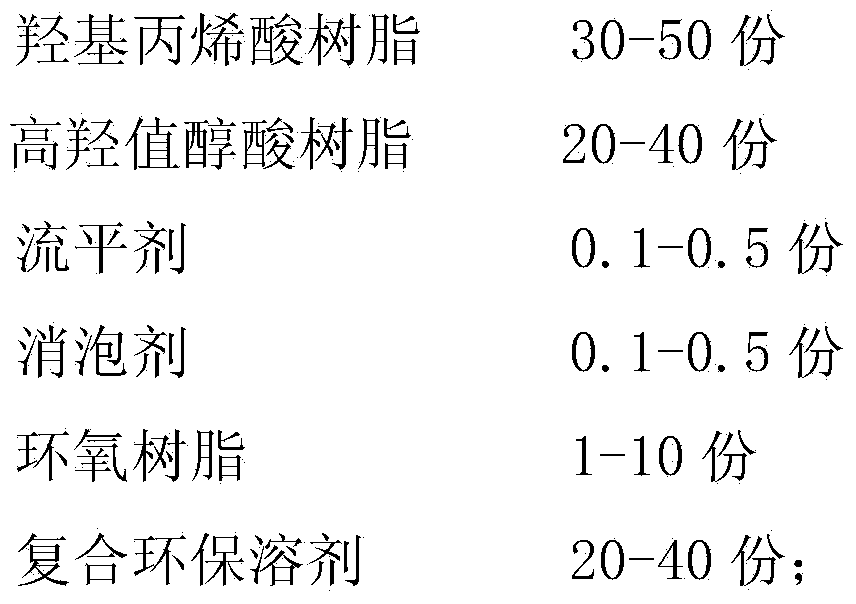

The invention relates to a scratch resistant PU (Poly Urethane) floor varnish and a preparation method thereof. The scratch resistant PU floor varnish is prepared from a first ingredient and a second ingredient at weight ratio of (0.8-1.2):(0.8-1.2), wherein the first ingredient is prepared from the following raw materials in parts by weight: 30-50 parts of hydroxy acrylic resin, 20-40 parts of high-hydroxyl number alkyd resin, 0.1-0.5 part of leveling agent, 0.1-0.5 part of antifoaming agent, 1-10 parts of epoxy resin, and 20-40 parts of composite environment-friendly solvent, and the second ingredient is prepared from the following raw materials in parts by weight: 10-40 parts of TDI-TMP, 10-30 parts of HDI (Hexamethylene Diisocyanate) tripolymer, 10-20 parts of moisture curing agent, and 30-50 parts of butyl acetate. By adopting the scratch resistant PU floor varnish disclosed by the invention, the scratch resistance of the varnish surface on the floor is obviously improved, while the other performances of transparency, storage stability and the like are rarely influenced; simultaneously the varnish film is uniform, smooth, and good in adhesion force; the number of the varnish coating layers can be reduced, therefore the cost is reduced; in addition, fracture is unlikely to form to influence the beautiful appearance of the floor.

Owner:SKSHU PAINT

Flour having low glycemic index and making method thereof

InactiveCN105360891AImprove microenvironmentSlow down digestionInorganic compound food ingredientsFood ingredient functionsFiberBlood sugar

The invention discloses flour having low glycemic index and a making method thereof. The flour is made from, by weight, wheat flour 35%-45%, soybean flour 35%-45%, buckwheat powder 1%-1.5%, oat powder1%-1.5%, isolated soy protein powder 4%-4.5%, dietary fibers 4%-4.5%, vitamins 0.5%-1.5% and mineral substance 0.5%-1.5%. The flour is based on the low-GI-value (a GI value is below 55) coarse cereal powder, uses the added protein, dietary fibers, vitamins, mineral substance and the like as nutritional materials, has good eating taste and is a high-fiber-content and low-fat healthy food. The flour can delay postprandial blood sugar rise to some degree and is suitable for high-glucose people, patients with diabetes and populations needing low-glycemic-index foods.

Owner:ANHUI TONGFU FOOD

Special wood modifier and preparation method thereof

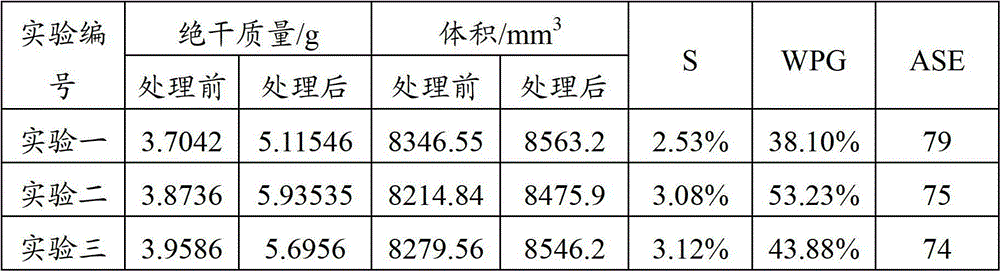

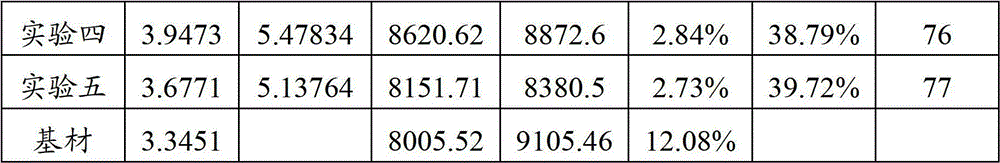

The present invention discloses a special wood modifier and a preparation method thereof. The special wood modifier comprises the following components, by weight, 500-800 parts of formaldehyde, 20 parts of urea, 200-400 parts of a phenol compound, 150-300 parts of organosilicon, 5-30 parts of an alkali catalyst, and 10-50 parts of an additive, wherein the formaldehyde is an aqueous solution with a mass concentration of 35-37%. According to the present invention, the special wood modifier mainly comprises a low molecular weight modified phenol formaldehyde resin, has characteristics of low viscosity, good water solubility, good storage stability, simple synthesis process, and low formaldehyde emission, and is applicable for modifications of various tree species, especially for modifications of fast-growing wood so as to provide high economic values; and density, size stability, hardness, water resistance and corrosion resistance of a base material can be substantially improved after the wood is treated by the special wood modifier.

Owner:EVERFIRST WISEFUND TECH BEIJING

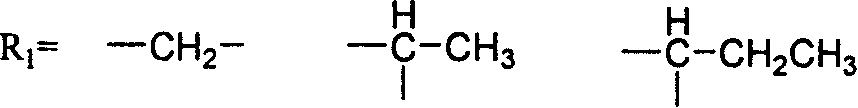

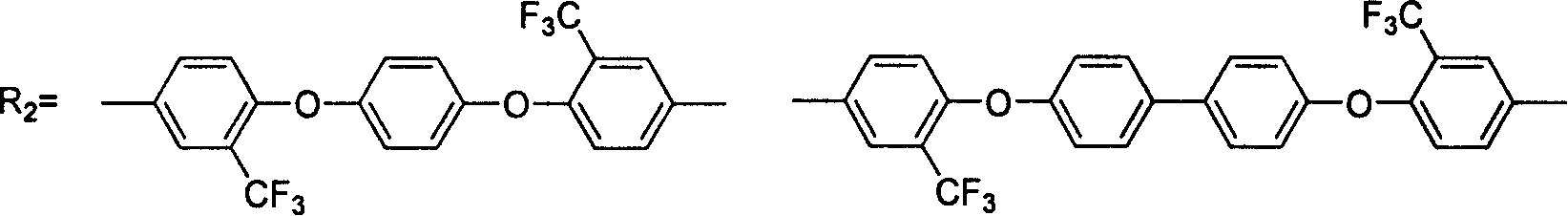

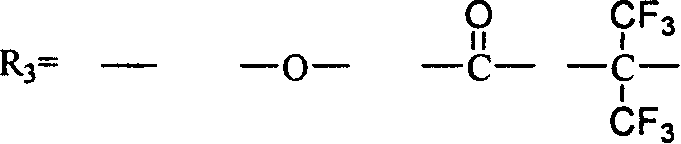

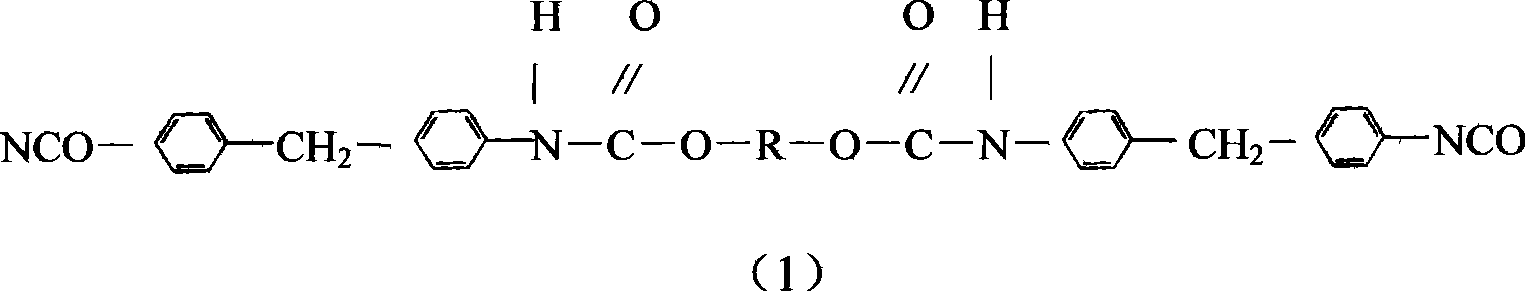

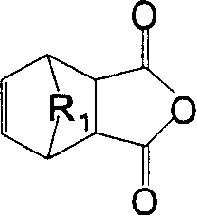

Fluorine-containing polyimide basal body resin and preparation method thereof

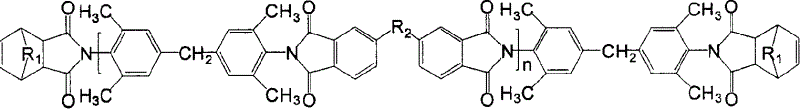

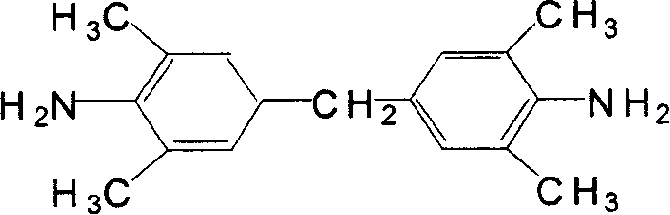

The invention discloses a fluorine polyimide base resin and making method, which is characterized by the following: adopting aromatic dianhydride, substituted organic fluorine diamine and reacted terminated agent as raw material to produce thermostable product as formula I through PMR method; leading fluorine group in the main chain molecular structure of resin; improving the manufacturing property and long-time oxidizing stability; possessing potential applying value in the high and new technological domain.

Owner:INST OF CHEM CHINESE ACAD OF SCI

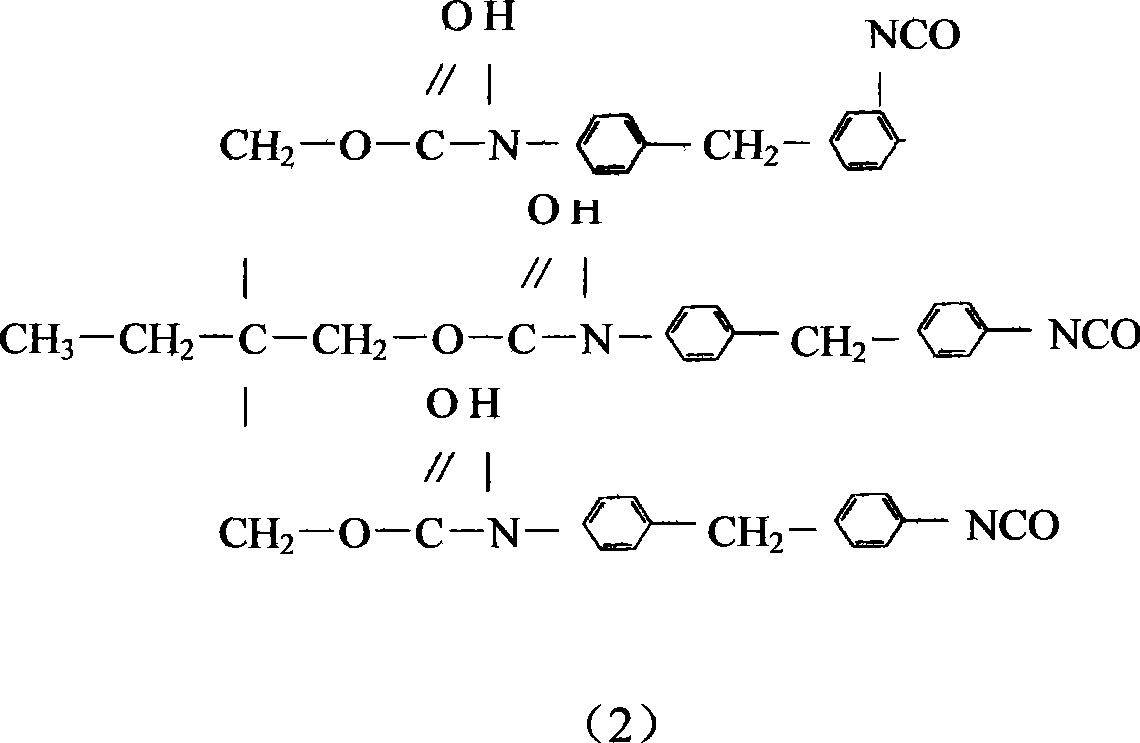

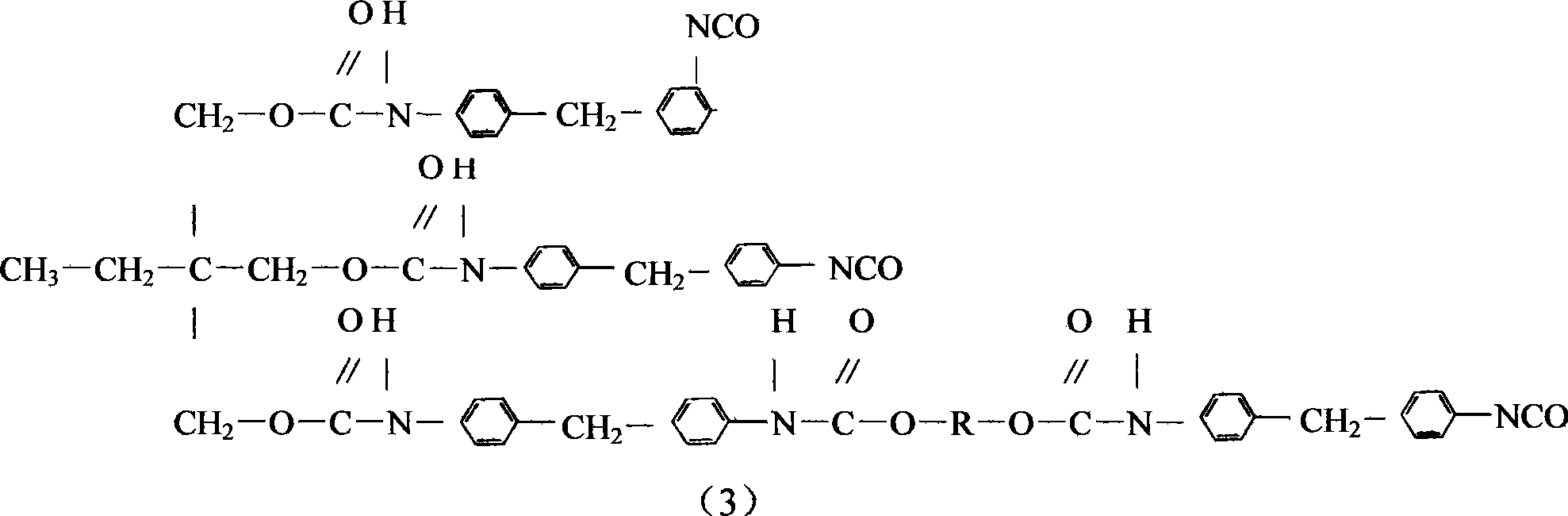

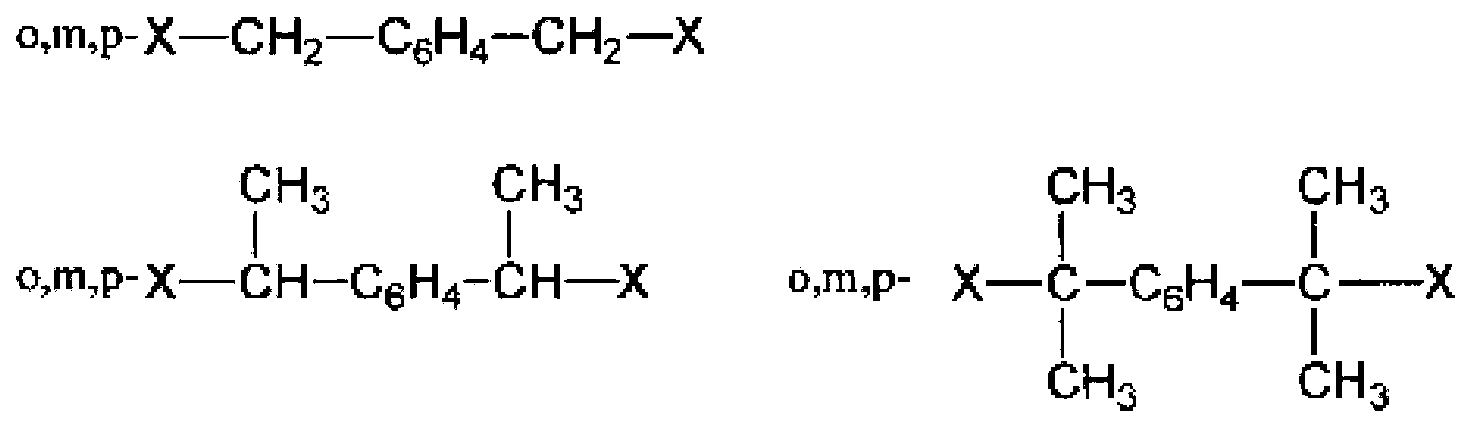

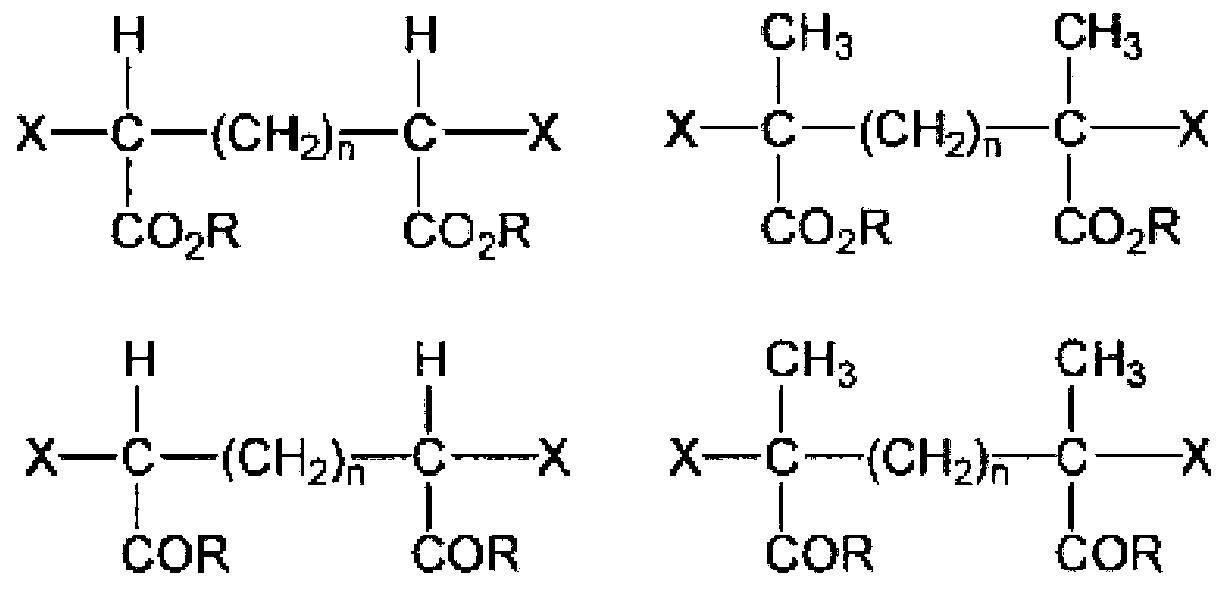

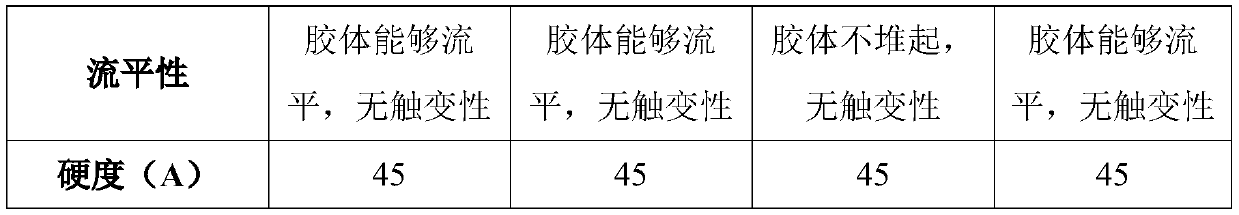

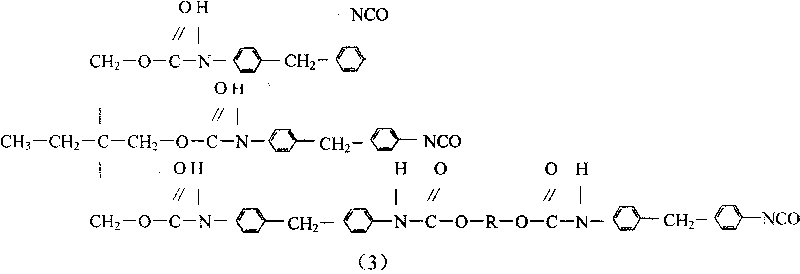

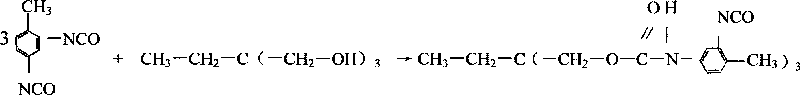

Curing agent 4,2'- and 4,4'-methyl diphenylene diisocyanate prepolymer and preparation thereof

The invention provides a prepolymer of 4,2'-methyl diphenylene diisocyanate (MDI) and 4,4'- methyl diphenylene diisocyanate (MDI) as a curing agent, and a preparation method thereof. The method comprises the following steps: 4,4-MDI and organic solvent are added to a reaction kettle, heated to between 50 an d 90 DEG C and added with dehydrated polyol, and then react for 2 to 4 hours so as to prepare 4,4-MDI modifier; a mixture of 4,2'-MDI and 4,4'MDI is added and then cooled; and trimethylolpropane and the organic solvent are dripped and thermally insulated, and react for 1 to 6 hours, so as to obtain a product. The method modifies the 4,4-MDI and then blends the 4,4-MDI with the mixture of 4,2'-MDI and 4,4'-MDI and TMP for pre-polymerization, thereby solving the problem of manufacturing the prepolymer with two isomers of MDI in an arbitrary proportioning form. A series of produced prepolymers can meet different requirements of coatings and adhesives in the polyurethane industry on the curing agent, and have the advantages of wide application range, high strength, low toxicity, adjustable room-temperature curing speed, good storage stability, capability of obtaining the products with high solid content, and the like.

Owner:周建明

Active energy ray-curable composition for optical material, cured product, and production methods for active energy ray-curable composition and cured product

InactiveCN103237827AExcellent curability with active energy raysLow viscosity propertiesCoatingsOptical elementsCrack resistanceLow temperature curing

Provided are an active energy ray-curable composition for an optical material that has excellent low viscosity, shelf life, low foamability, low-temperature curability, low-warping performance, deep curability, heat-resistant and light-resistant transparency, rubber properties, cracking resistance, moisture permeation resistance and designability; a cured product; and production methods for obtaining the active energy ray-curable composition and the cured product. The active energy ray-curable composition for the optical material comprises (A) a vinyl polymer which has, per molecule, at least one methacryloyl group represented by the general formula (1) -OC(O)C(Ra)=CH2(1) (where Ra is a hydrogen atom or C1-C20 organic group) is produced by living radical polymerization, and has a color difference delta E* of 10 or less; (B) a light-induced radical polymerization initiator; and (C) at least one antioxidant selected from the group consisting of hindered phenol antioxidants, hindered amine antioxidants, and phosphorus antioxidants.

Owner:KANEKA CORP

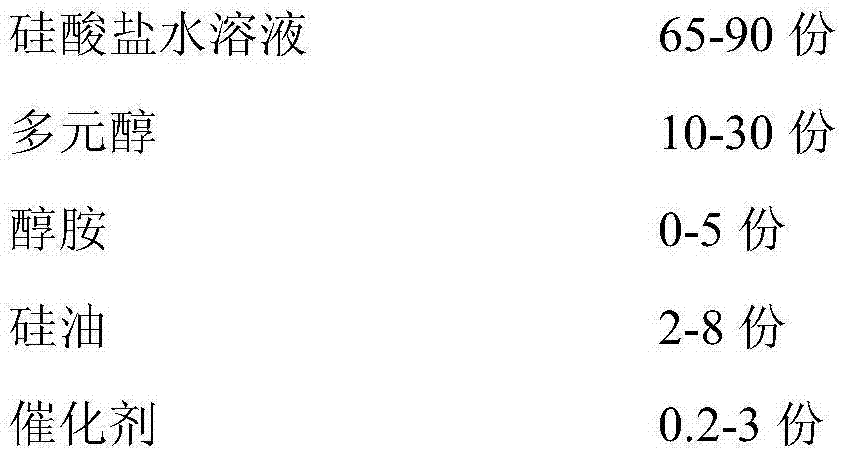

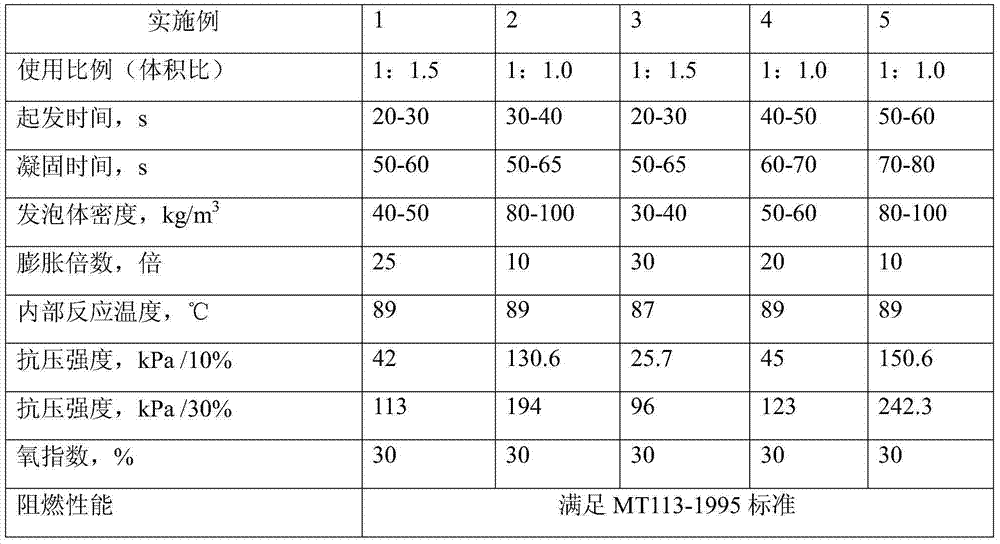

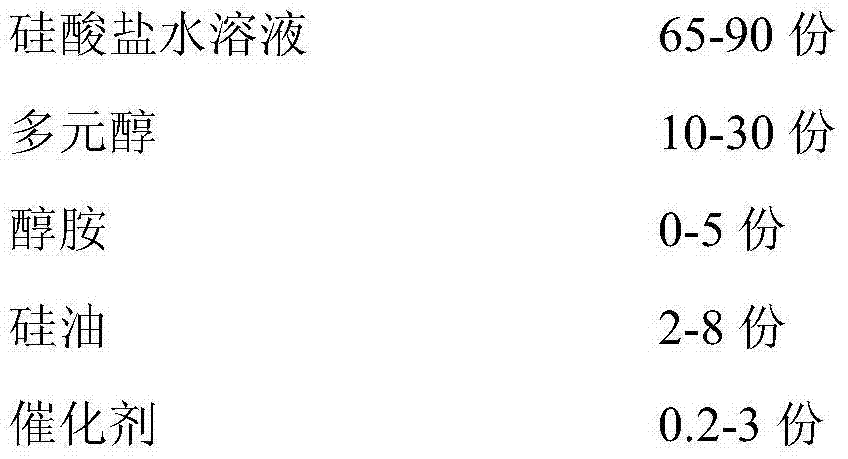

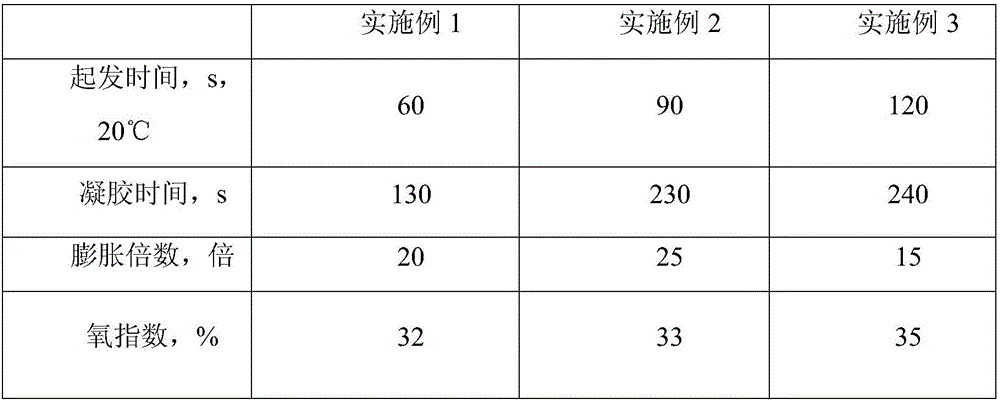

High-flame-retardance low-temperature bicomponent filling material for coal mines and preparation method thereof

The invention belongs to the field of chemical synthesis and in particular relates to a high-flame-retardance low-temperature bicomponent filling material for coal mines and a preparation method thereof. The filling material comprises a component A and a component B, wherein when the filling material is used, the component A and the component B are mixed according to the volume ratio of 1:(1.0-1.5) and are foamed; the component A is a composition with a silicate aqueous solution as the main body; and the component B is a composition with polyisocyanate as the main body. The filling material and the preparation method have the beneficial effects that the filling material is convenient to transport and has low viscosity, fluidity and storage stability; the raw materials are free from pollution and corrosion and the filling material does not contain irritating volatile solvents; the filling material has high foaming ratio and has low internal temperature during foaming; a foaming body has good flame retardance and certain toughness; the preparation method is simple and practicable, has low requirements on production and construction personnel, is short in production cycle, is free from equipment corrosion, is free from three wastes in the whole process and does not affect the environment.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

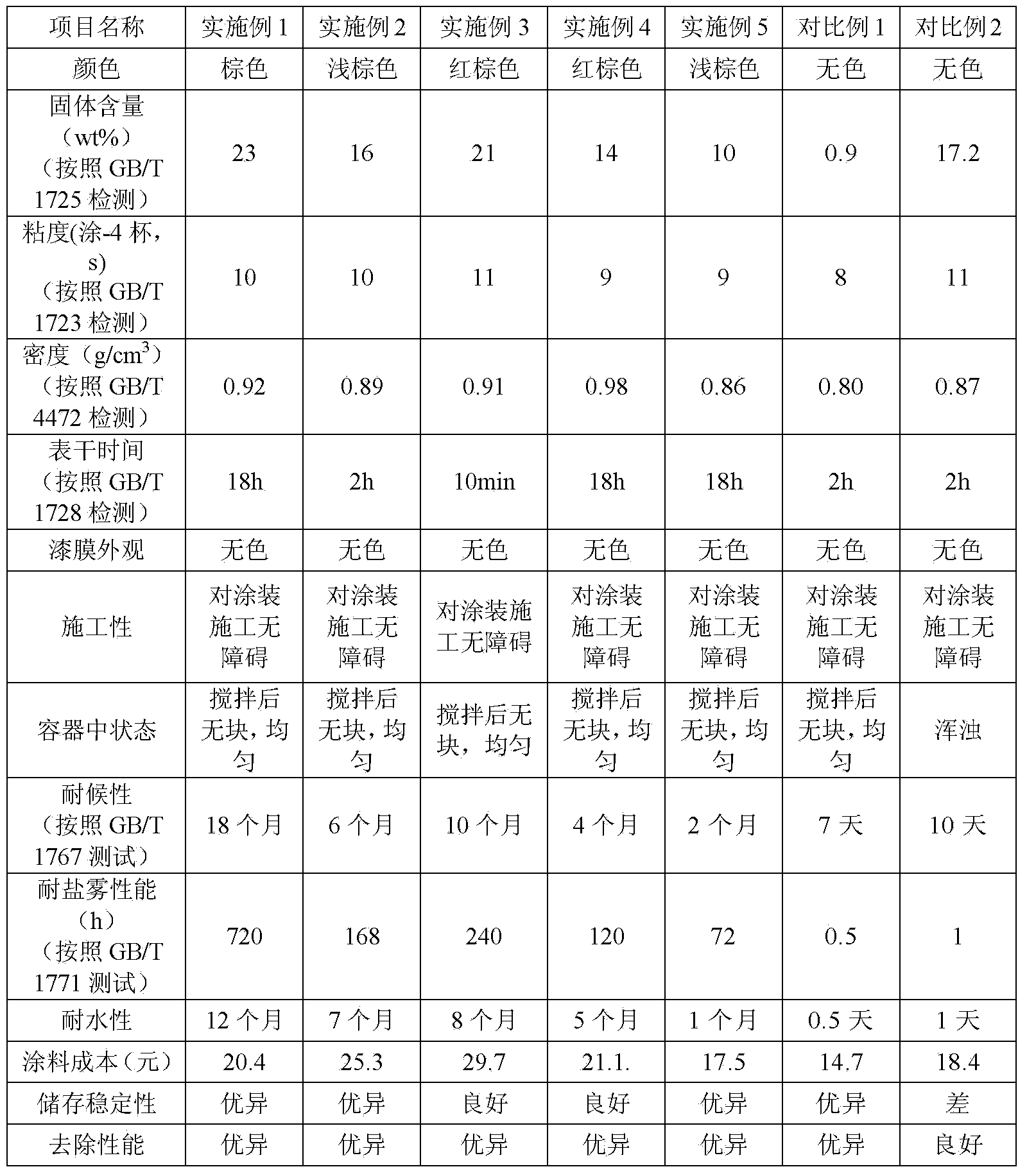

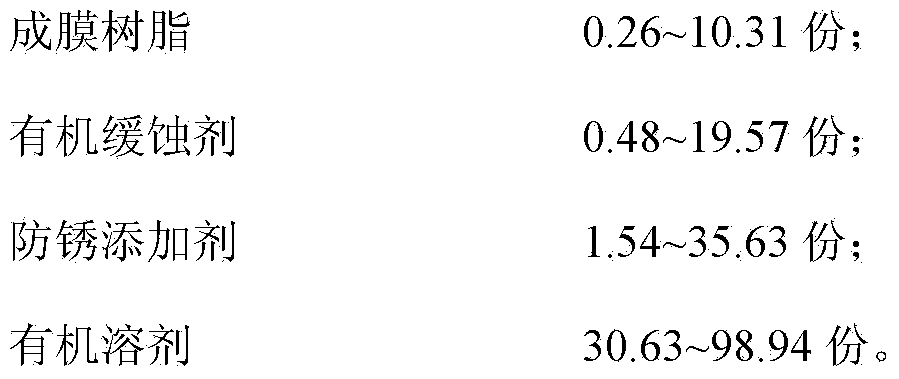

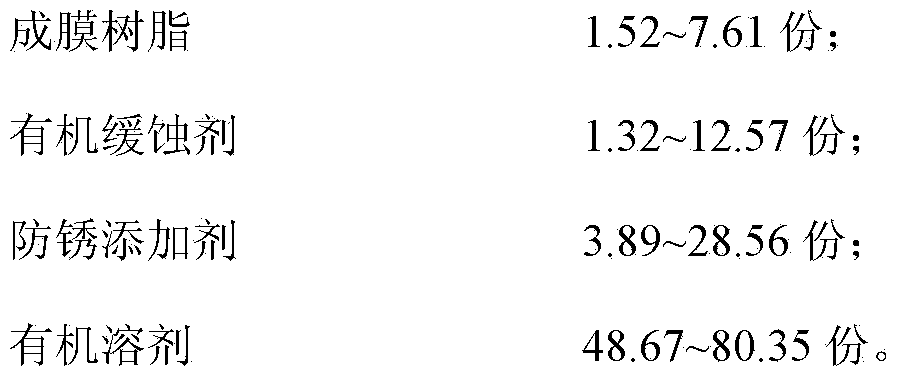

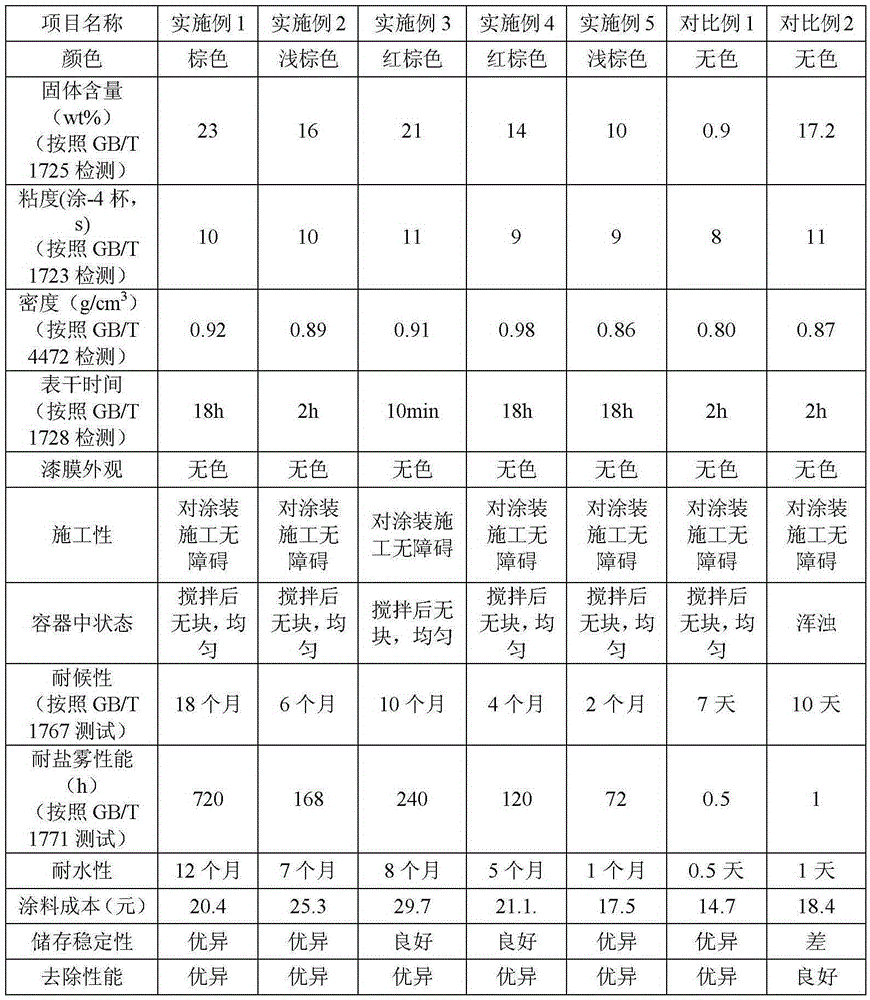

Anticorrosive paint, preparation method of anticorrosive paint and oil tube coated with anticorrosive paint

ActiveCN103820012ANot easy to layerGood construction performanceGeneral water supply conservationAnti-corrosive paintsOrganic solventOrganic chemistry

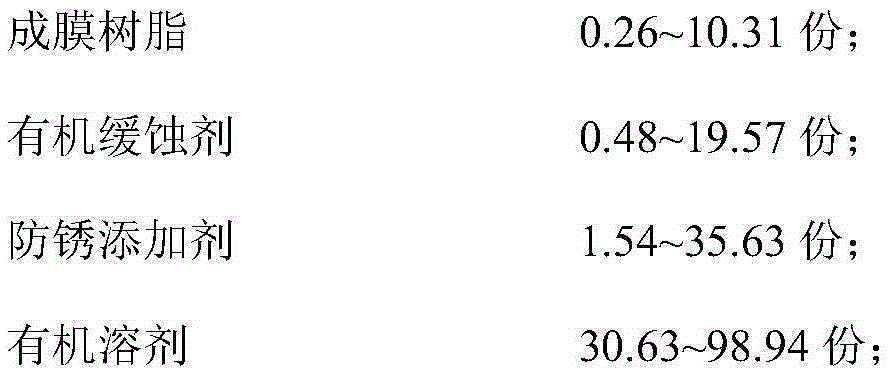

The invention discloses anticorrosive paint, a preparation method of the anticorrosive paint and an oil tube coated with the anticorrosive paint. The anticorrosive paint comprises raw materials in parts by mass as follows: 0.26-10.31 parts of film-forming resin, 0.48-19.57 parts of an organic corrosion inhibitor, 1.54-35.63 parts of an antirust additive and 30.63-98.94 parts of an organic solvent. The antirust and anticorrosive paint which is low in cost and good in storage stability and has low possibility of sedimentation or layering is obtained through selection of raw materials of the anticorrosive paint for temporary protection and content of the raw materials; the application property of the anticorrosive paint is good, the anticorrosive paint cannot block a pipeline after used, the removal property is good, and the anticorrosive paint is novel waterproof, weather-proof, non-toxic and environment-friendly protective paint; and besides, the cost performance of the raw materials of the anticorrosive paint is high, and the market competitiveness is high.

Owner:北京碧海云智新材料技术有限公司

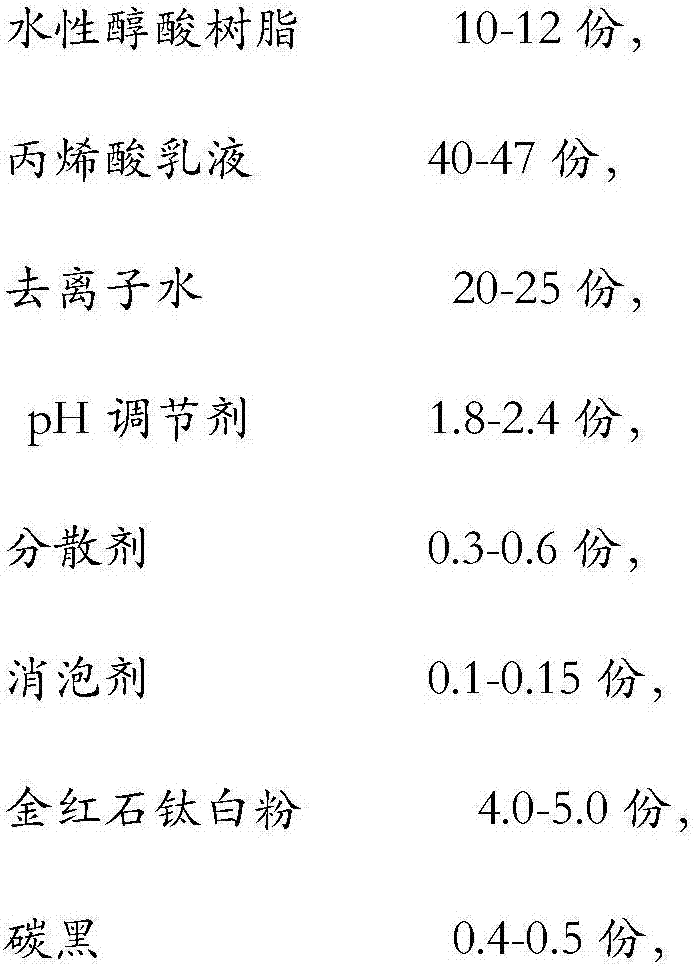

Environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and preparation method of protective paint

InactiveCN106928791AValid setLow VOC contentAnti-corrosive paintsPolyester coatingsWater basedMechanical equipment

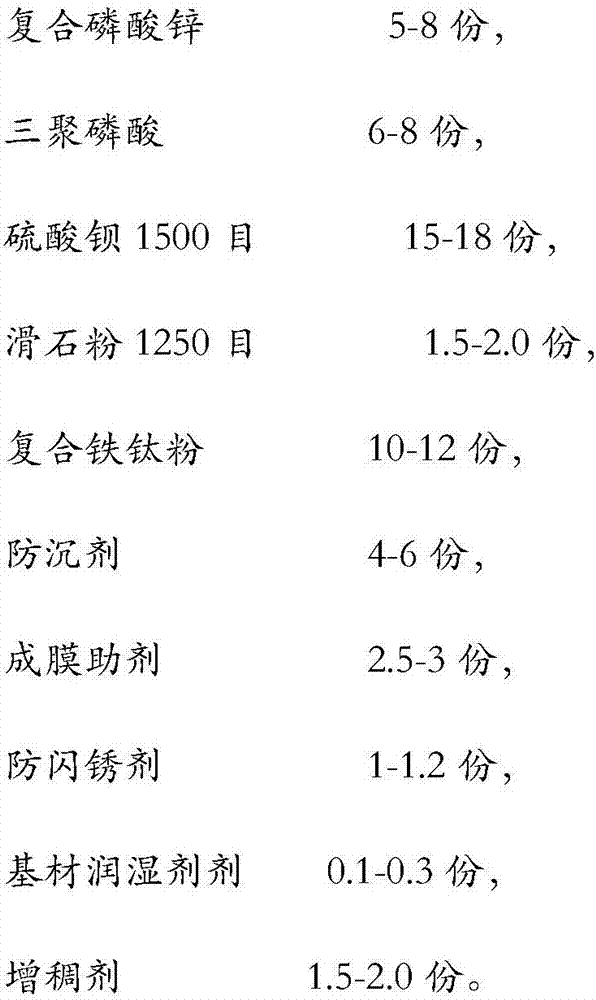

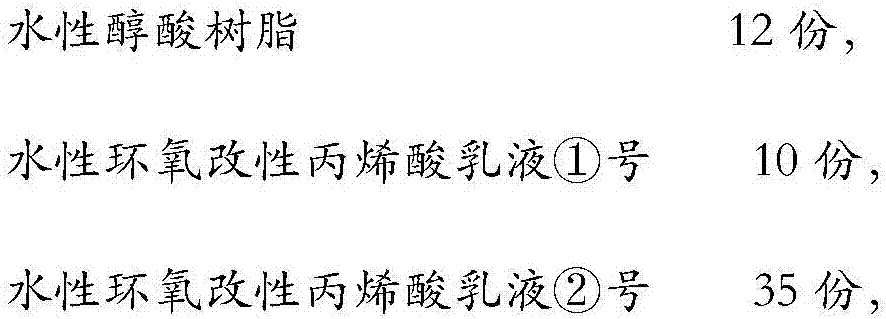

The invention discloses environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and a preparation method of the protective paint. The environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying the mechanical equipment comprises the following components in parts by weight: 10-12 parts of water-based alkyd resin, 40-47 parts of acrylic emulsion,20-25 parts of water, 1.8-2.4 parts of a pH (potential of hydrogen) regulator, 0.3-0.6 parts of a dispersant, 0.1-0.15 parts of a defoaming agent, 4.0-5.0 parts of rutile titanium dioxide, 0.4-0.5 parts of carbon black, 5-8 parts of compound zinc phosphate, triphosphoric acid, barium sulfate, talcum powder, iron-titanium compound powder, an anti-settling agent, a film forming assistant, a flash-rust preventive, a base material wetting agent and a thickening agent. The protective paint has excellent chemical properties such as corrosion resistance and water resistance, and is high in drying rate, excellent in low-temperature film forming effect, high in plumpness and good in weather resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Thermosetting polyimide matrix resin, preparation and use thereof

The invention opened a process to make the polyimide resin plate which can resist the high temperature using the aromatic dianhydride, polyalkyl-diamine and capped agent as the material. The process is first to get the resin liquor from the above materials, then the liquor is moulded to the resin forming. The product can be used to make the resin moulding material and the resin compound material which can be used for the aviation, cosmonautics, precision machinery and petrochemical engineering.

Owner:INST OF CHEM CHINESE ACAD OF SCI

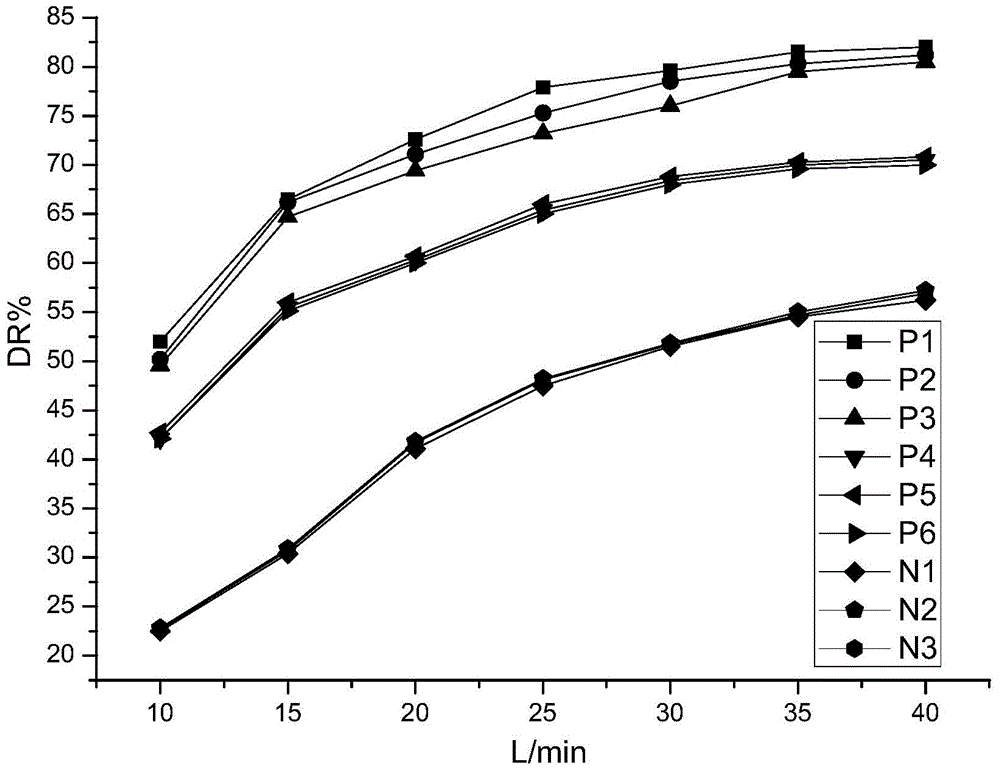

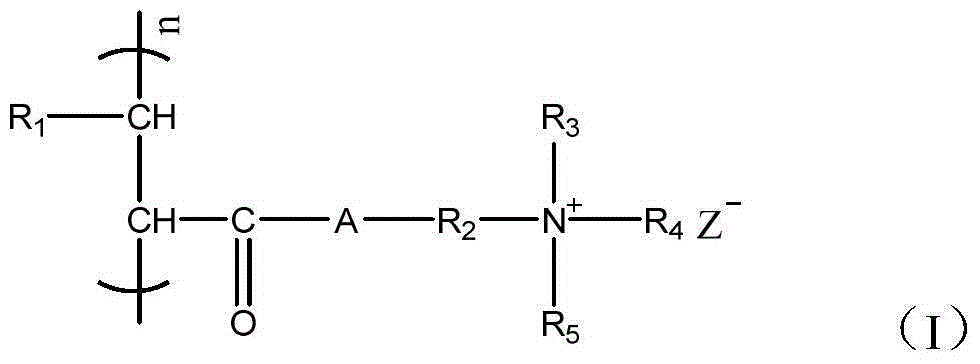

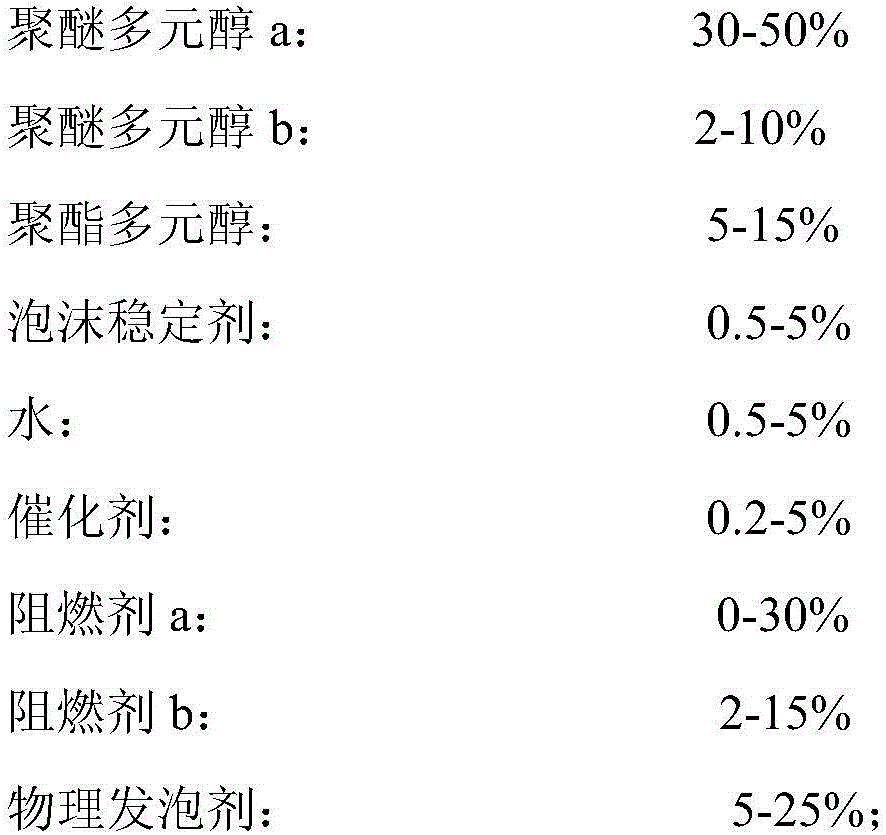

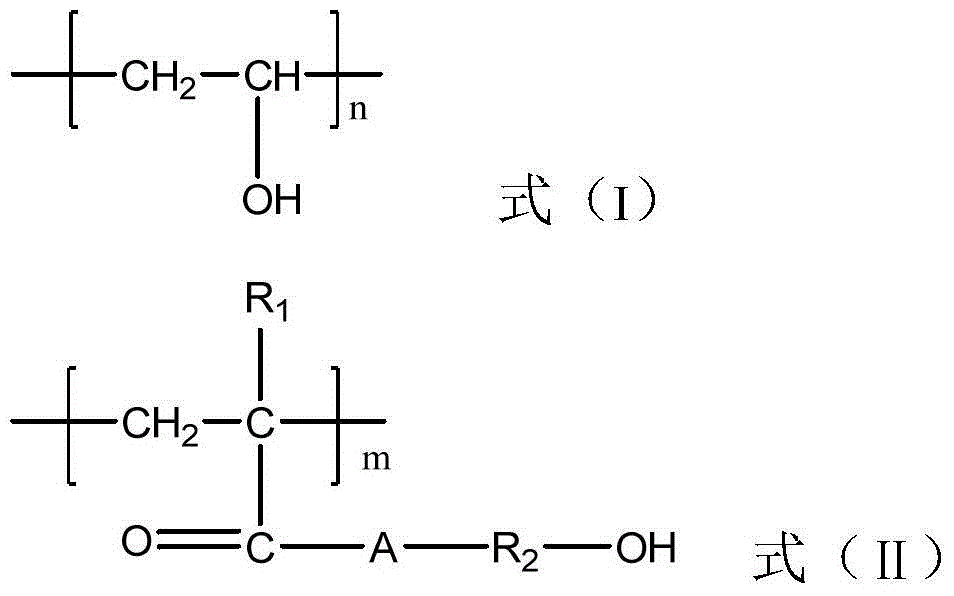

Resistance reducing agent for fracture and preparation method thereof

ActiveCN104974298AChange spatial configurationChange the spatial structureDrilling compositionSolubilityInorganic salts

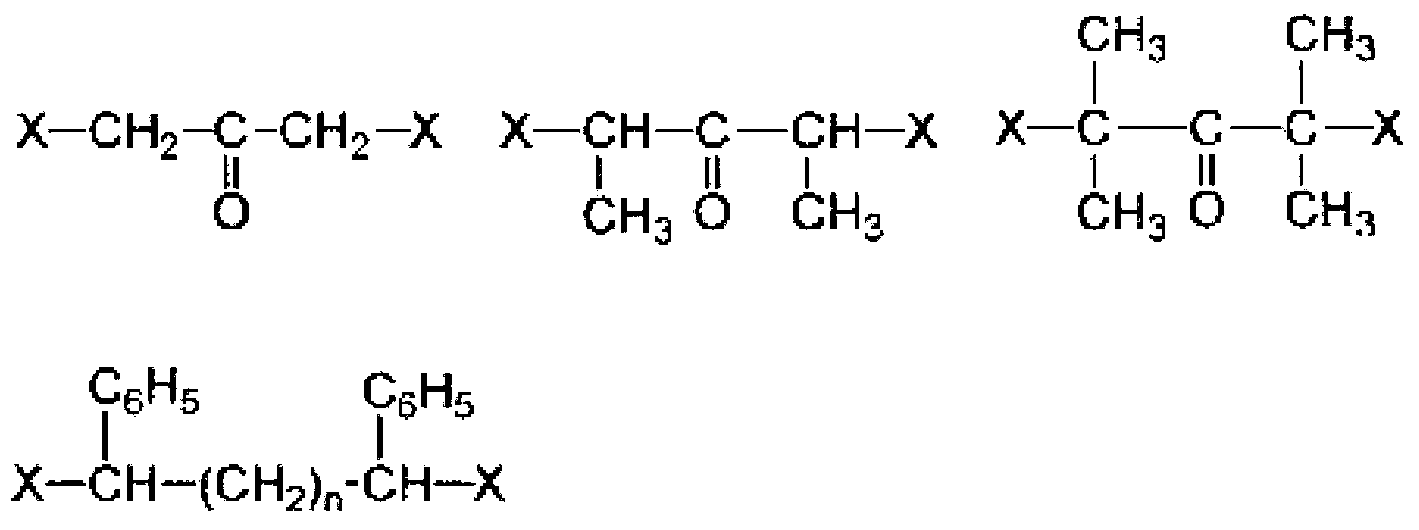

The invention relates to a preparation method of a resistance reducing agent for fracture. The preparation method includes the steps of: (1) mixing an acrylamide-series monomer, an anionic monomer containing a double bond, a cationic polymer template, a dispersing agent, a molecular weight regulating agent and inorganic salts with water with pH value being regulated to obtain a water solution of which the pH value is 4-7; and (2) under an inert atmosphere, contacting the water solution with an initiator in batches and performing a polymerization reaction. The molecular weight of the cationic polymer template is less than 1000000, and the structure formula of the cationic polymer template is represented as the formula (I). The invention also relates to the resistance reducing agent for fracture prepared through the method. The resistance reducing agent for fracture is high in resistance reducing rate, is low in formation damage property, is high in inhibition on clay expansion, is good in water solubility and is green and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

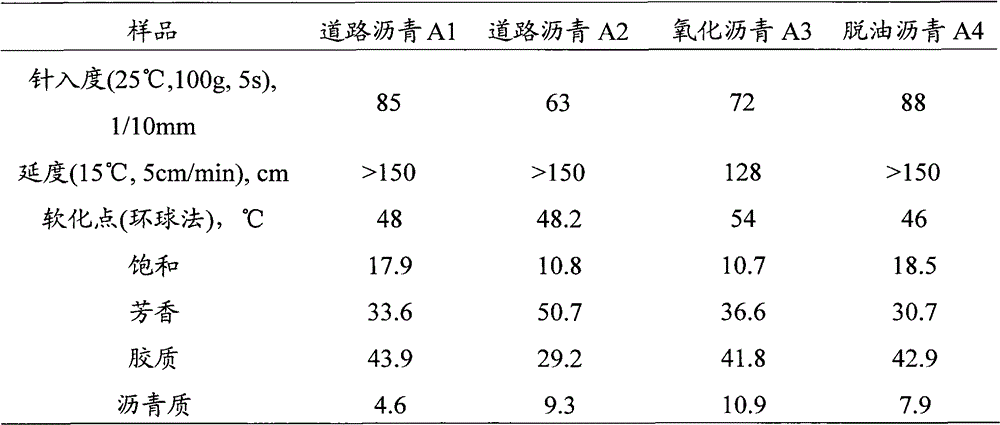

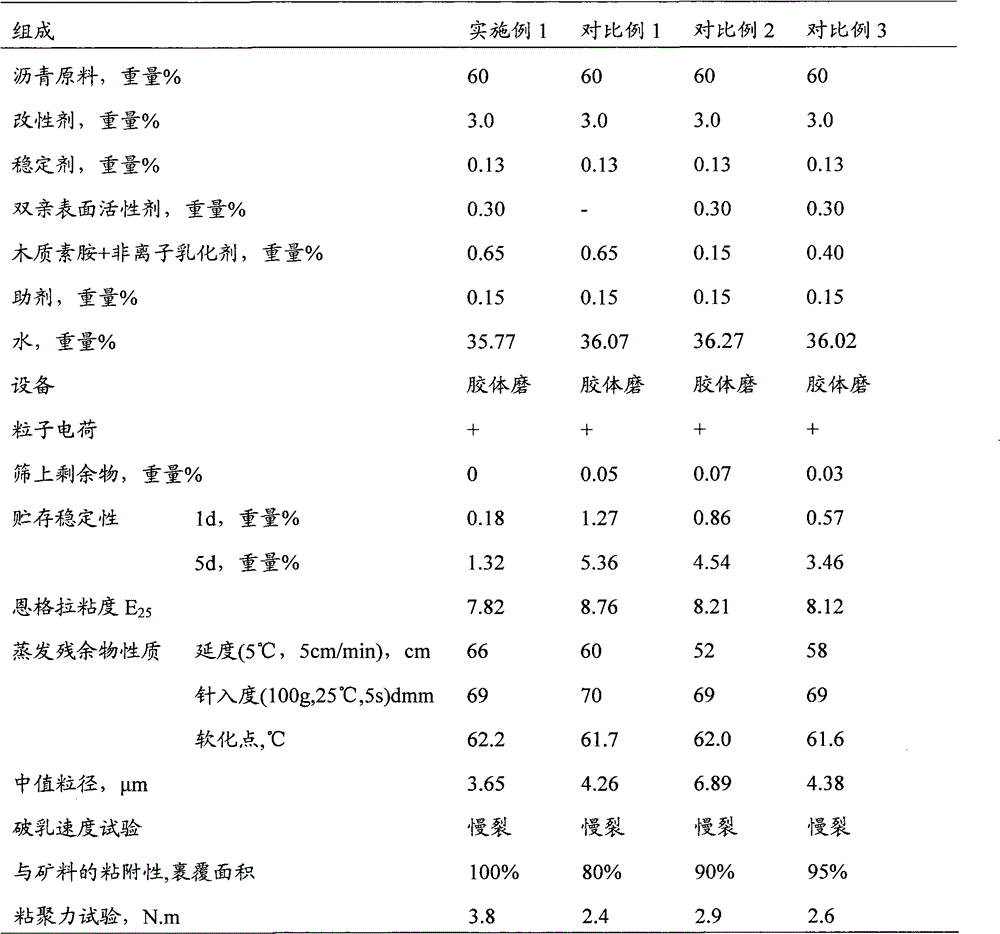

Modified asphalt emulsion and preparation method thereof

ActiveCN103059585ASimple production processLow production costBuilding insulationsNeedle penetrationEmulsion

A modified asphalt emulsion and a preparation method thereof. The modified asphalt emulsion comprises 50-72 wt% of modified asphalt, 0.05-5 wt% of an emulsifier compound, 0.02-2 wt% of a cosurfactant and 25-45 wt% of water. The emulsifier compound is composed of a lignin emulsifier, an amphiphilic surfactant and a non-ionic surfactant. The preparation method of the modified asphalt emulsion comprises steps of: preparing the modified asphalt; and mixing the modified asphalt with an emulsifier aqueous solution containing the lignin emulsifier, the amphiphilic surfactant, the non-ionic surfactant, the cosurfactant and water, and dispersing and cooling. The modified asphalt emulsion provided by the invention has advantages of simple preparation method, low cost, JTG F40-2004 modified asphalt emulsion technology requirements reached, low sieve residue, good storage stability, high ductility of evaporation residue, high needle penetration, good high and low temperature performance; and a mixture prepared from the modified asphalt emulsion has good demulsification cohesion and improved road performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

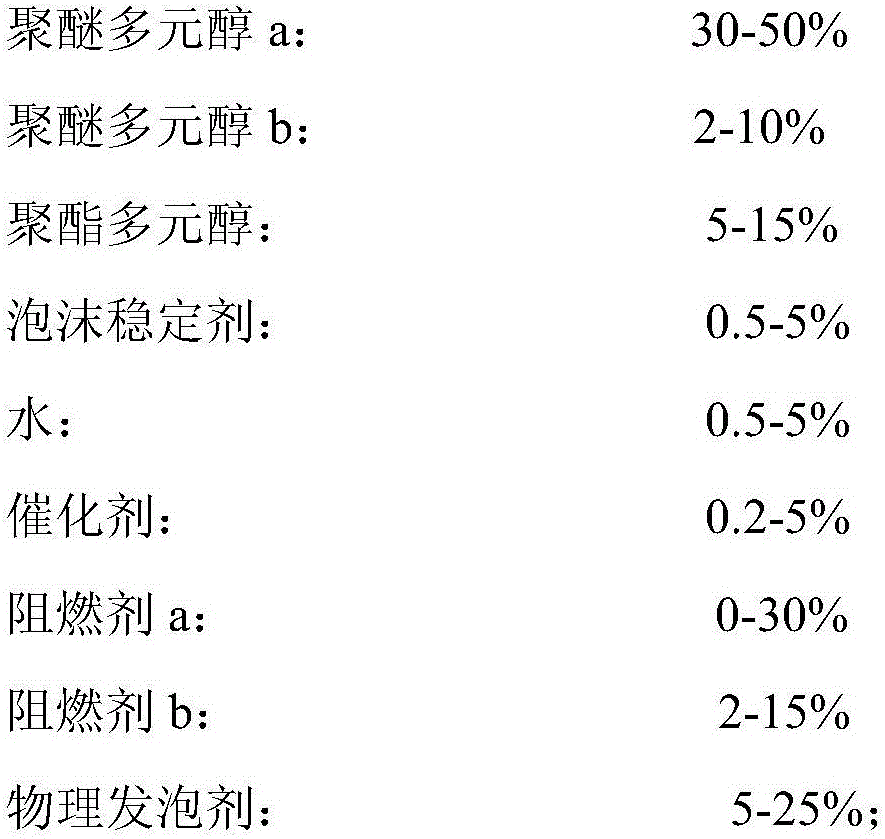

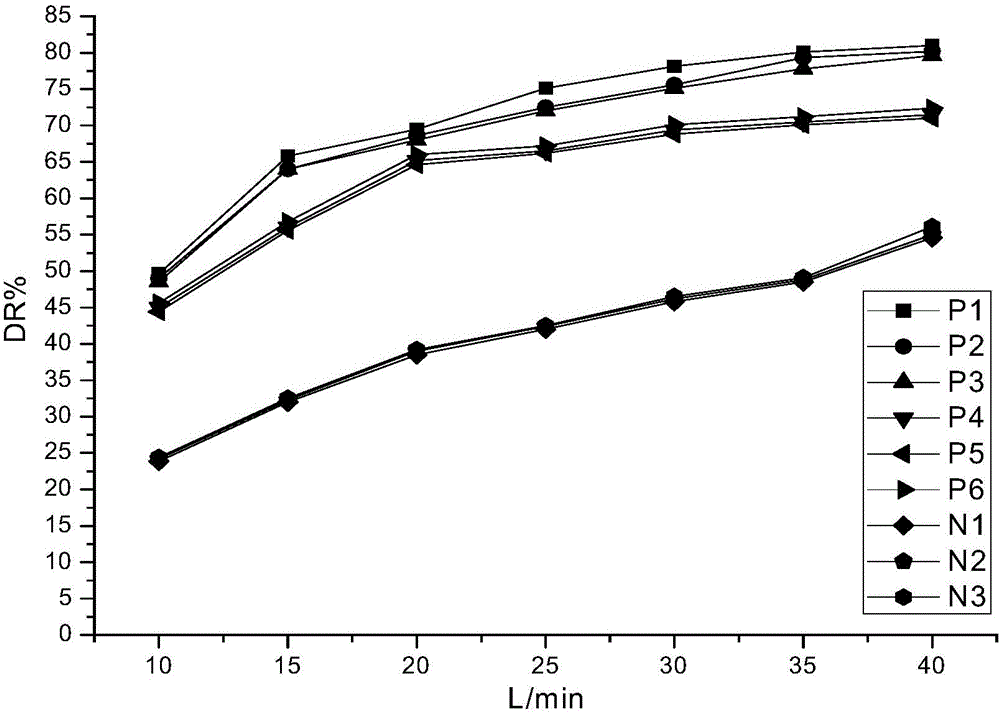

High-flame-retardancy polyurethane gas hole sealing material for coal mine and preparation method of high-flame-retardancy polyurethane gas hole sealing material

InactiveCN106832208AImprove flame retardant performanceImprove adhesionDrilling compositionFire retardantCoal

The invention relates to the technical field of polyurethane, in particular to a high-flame-retardancy polyurethane gas hole sealing material for a coal mine and a preparation method of the high-flame-retardancy polyurethane gas hole sealing material. The hole sealing material is prepared from a component A and a component B, wherein the component A comprises polyhydric alcohol, water, an adjuvant, a flame retardant and a physical foaming agent; the component B is polymethylene polyphenyl isocyanate. Due to the formula design, a high-flame-retardancy polyurethane material which is high in flame retardancy, stable in effect and applied to gas hole sealing is obtained by compounding the polyhydric alcohol, the adjuvant and the flame retardant, and has the advantages of normal temperature reaction, adjustable reaction speed, adjustable foaming rate and high flame retardancy; foam produced by the high-flame-retardancy polyurethane material is high in flame retardancy, high in bonding strength to a coal and rock mass, high in shear strength and toughness after being bonded and impact-resistant; relevant raw materials are low in odor and cannot generate any toxic gas, and the use and environmental protection requirements of the gas hole sealing material can be completely met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

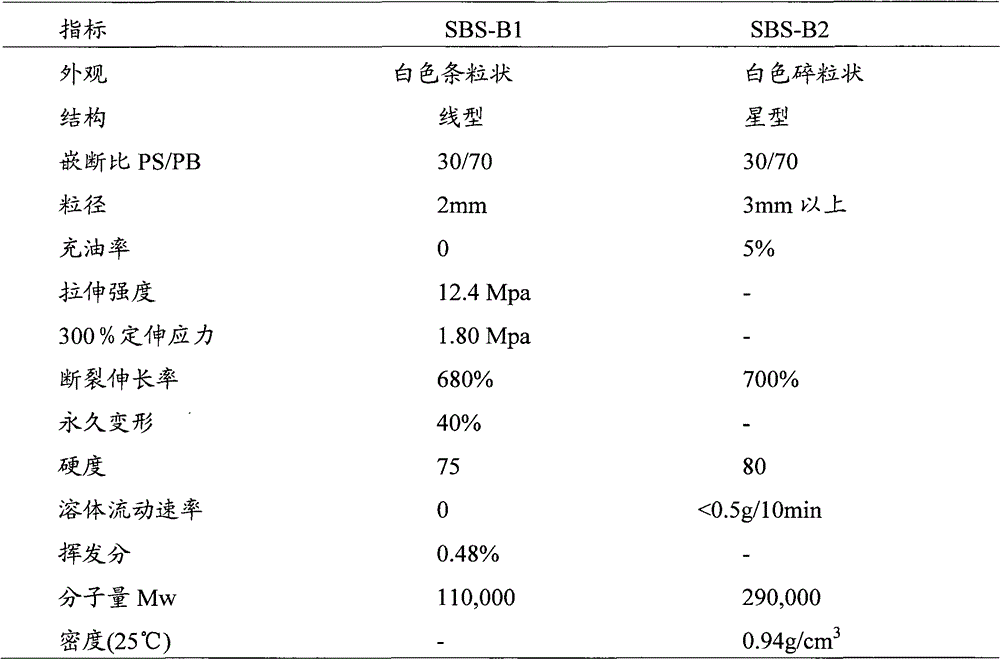

High-performance SBS modified emulsified asphalt and SBS latex, and preparation methods thereof

ActiveCN111019366AHigh solid contentGood storage stabilityBuilding insulationsPolymer scienceBitumen emulsion

The invention provides a high-performance SBS modified emulsified asphalt and an SBS latex, and preparation methods thereof. The high-performance SBS modified emulsified asphalt is prepared from matrix asphalt, a modifier, the SBS latex, an emulsifier, a stabilizer, hydrochloric acid and water; and the SBS latex is prepared from SBS with the model of T6302, SBS with the model of D1101, n-pentane,dimethylformamide, stearamidopropyl dimethylamine, dioctyldodecyl lauroyl glutamate and water. The prepared modified emulsified asphalt is high in solid content and stable in performances; the storagestability is high, and the 5d storage stability is far lower than the standard requirement index; and the high-low temperature performance of evaporation residues is excellent. The solid content of the prepared SBS latex can reach 40-50%, and the storage stability of the SBS latex can reach one month or more, so it can be guaranteed that the modified emulsified asphalt prepared in the later period has excellent high and low temperature performances.

Owner:CHANGAN UNIV

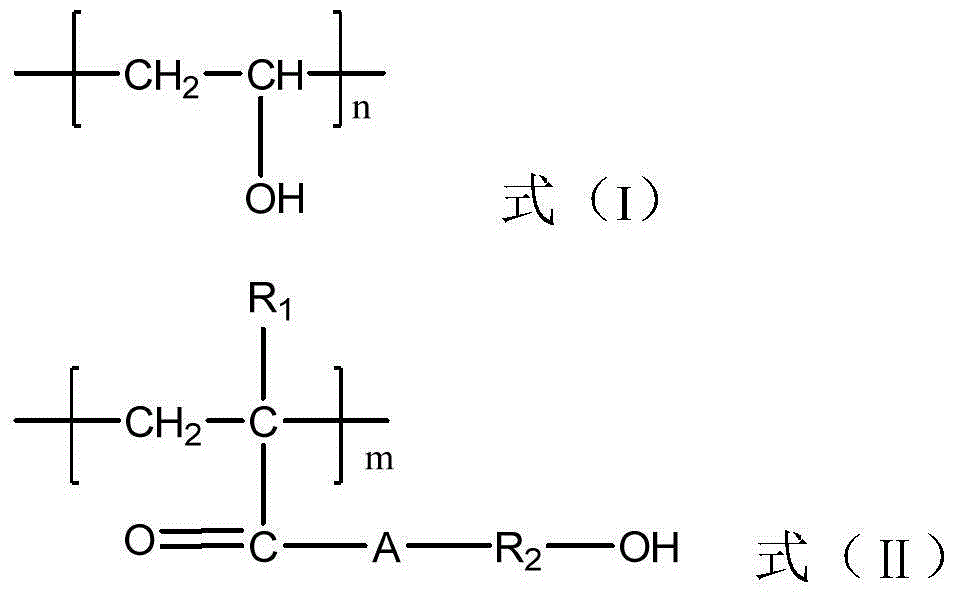

Resistance reducing agent for fracture and preparation method thereof

ActiveCN104974306AChange spatial configurationChange the spatial structureDrilling compositionSolubilityInorganic salts

The invention relates to a preparation method of a resistance reducing agent for fracture. The preparation method includes the steps of: (1) mixing an acrylamide-series monomer, a nonionic-series monomer having a hydroxyl group and containing a double bond, a polyhydroxyl nonionic polymer template, a dispersing agent, a molecular weight regulating agent and inorganic salts with water to obtain a water solution; and (2) under an inert atmosphere, contacting the water solution with an initiator in batches and performing a polymerization reaction. The molecular weight of the polyhydroxyl nonionic polymer template is less than 500000, and the structure formula of the polyhydroxyl nonionic polymer template is represented as the formula (I) or the formula (II). The invention also relates to the resistance reducing agent for fracture prepared through the method. The resistance reducing agent for fracture is high in resistance reducing rate, is low in formation damage property, is high in inhibition on clay expansion, is good in water solubility and is green and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

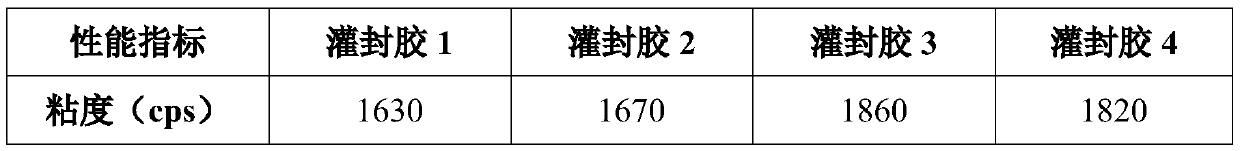

A kind of low-viscosity vinyl silicone oil and preparation method thereof

The invention discloses low-viscosity vinyl silicone oil and a preparation method thereof. The preparation method of the low-viscosity vinyl silicone oil comprises the following steps that 1, a dimethyl siloxane hybrid ring is subjected to vacuumizing devolatiligation and then pretreated by adding acid; 2, a basic catalyst and 1,3-divinyltetramethyldisiloxane are added, and full reacting is conducted; 3, a product obtained in the step 2 is subjected to medium removal to remove the basic catalyst and then subjected to vacuumizing devolatiligation, and the low-viscosity vinyl silicone oil is obtained. The low-viscosity vinyl silicone oil is colorless and transparent, the viscosity is only 80-90 cps, the product yield reaches 93% or above, the storage stability is good, and a two-component pouring sealant prepared from the low-viscosity vinyl silicone oil has the advantages of being low in viscosity, good in leveling effect, appropriate in hardness and the like. The preparation method has the advantages that operation is easy, the production cost is low, and industrialized production is easy to achieve.

Owner:新亚制程(浙江)股份有限公司

Curing agent 4,2'- and 4,4'-methyl diphenylene diisocyanate prepolymer and preparation thereof

The invention provides a prepolymer of 4,2'-methyl diphenylene diisocyanate (MDI) and 4,4'- methyl diphenylene diisocyanate (MDI) as a curing agent, and a preparation method thereof. The method comprises the following steps: 4,4-MDI and organic solvent are added to a reaction kettle, heated to between 50 an d 90 DEG C and added with dehydrated polyol, and then react for 2 to 4 hours so as to prepare 4,4-MDI modifier; a mixture of 4,2'-MDI and 4,4'MDI is added and then cooled; and trimethylolpropane and the organic solvent are dripped and thermally insulated, and react for 1 to 6 hours, so as to obtain a product. The method modifies the 4,4-MDI and then blends the 4,4-MDI with the mixture of 4,2'-MDI and 4,4'-MDI and TMP for pre-polymerization, thereby solving the problem of manufacturing the prepolymer with two isomers of MDI in an arbitrary proportioning form. A series of produced prepolymers can meet different requirements of coatings and adhesives in the polyurethane industry on the curing agent, and have the advantages of wide application range, high strength, low toxicity, adjustable room-temperature curing speed, good storage stability, capability of obtaining the products with high solid content, and the like.

Owner:周建明

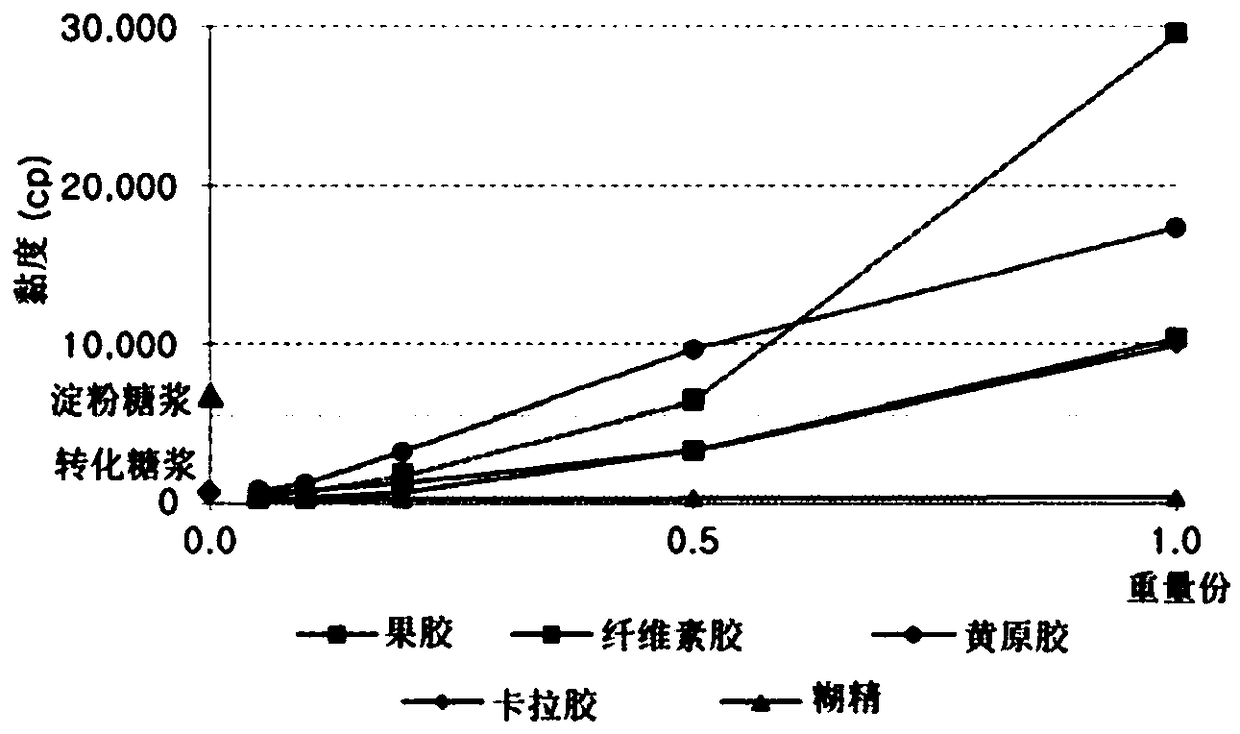

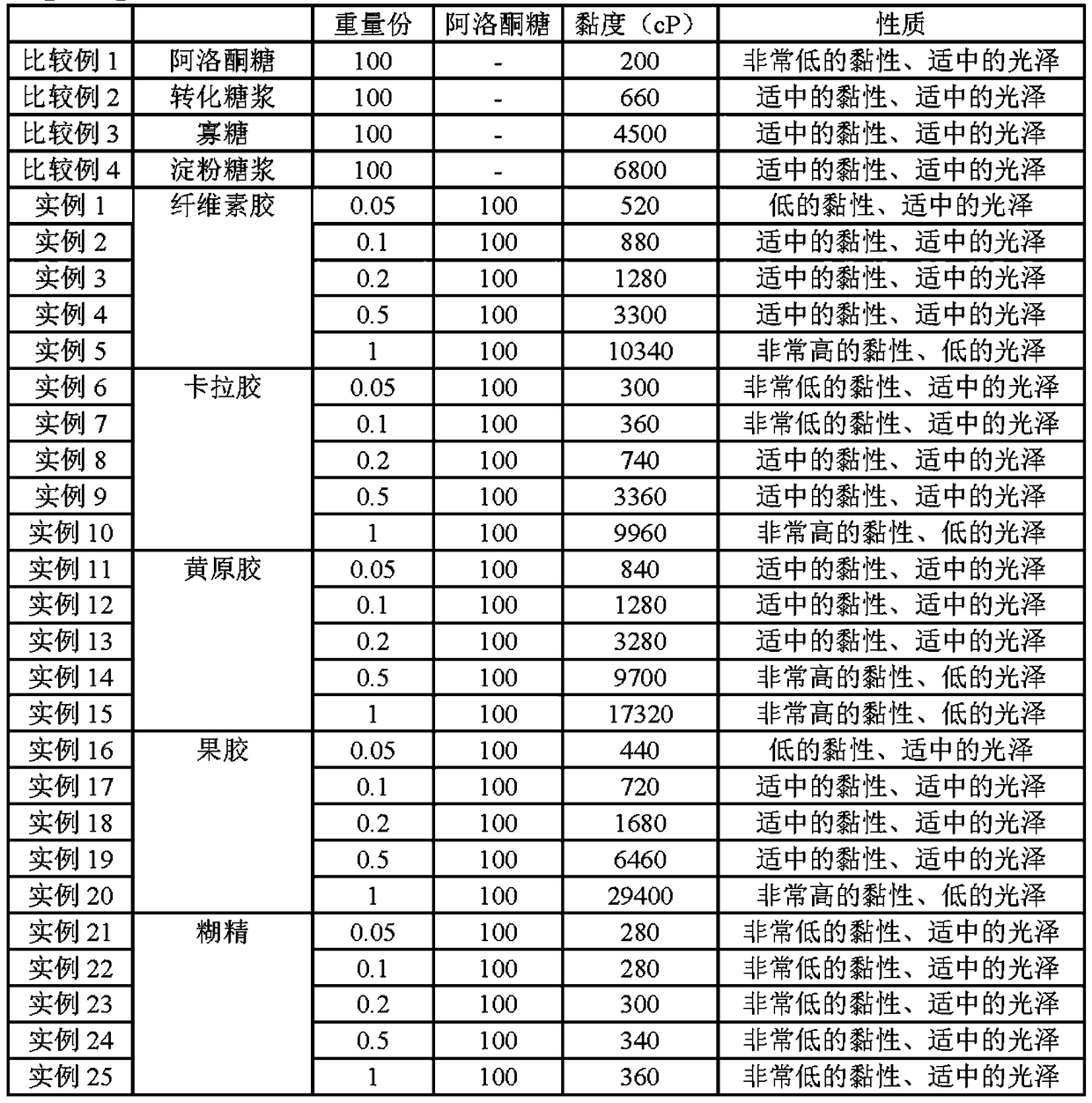

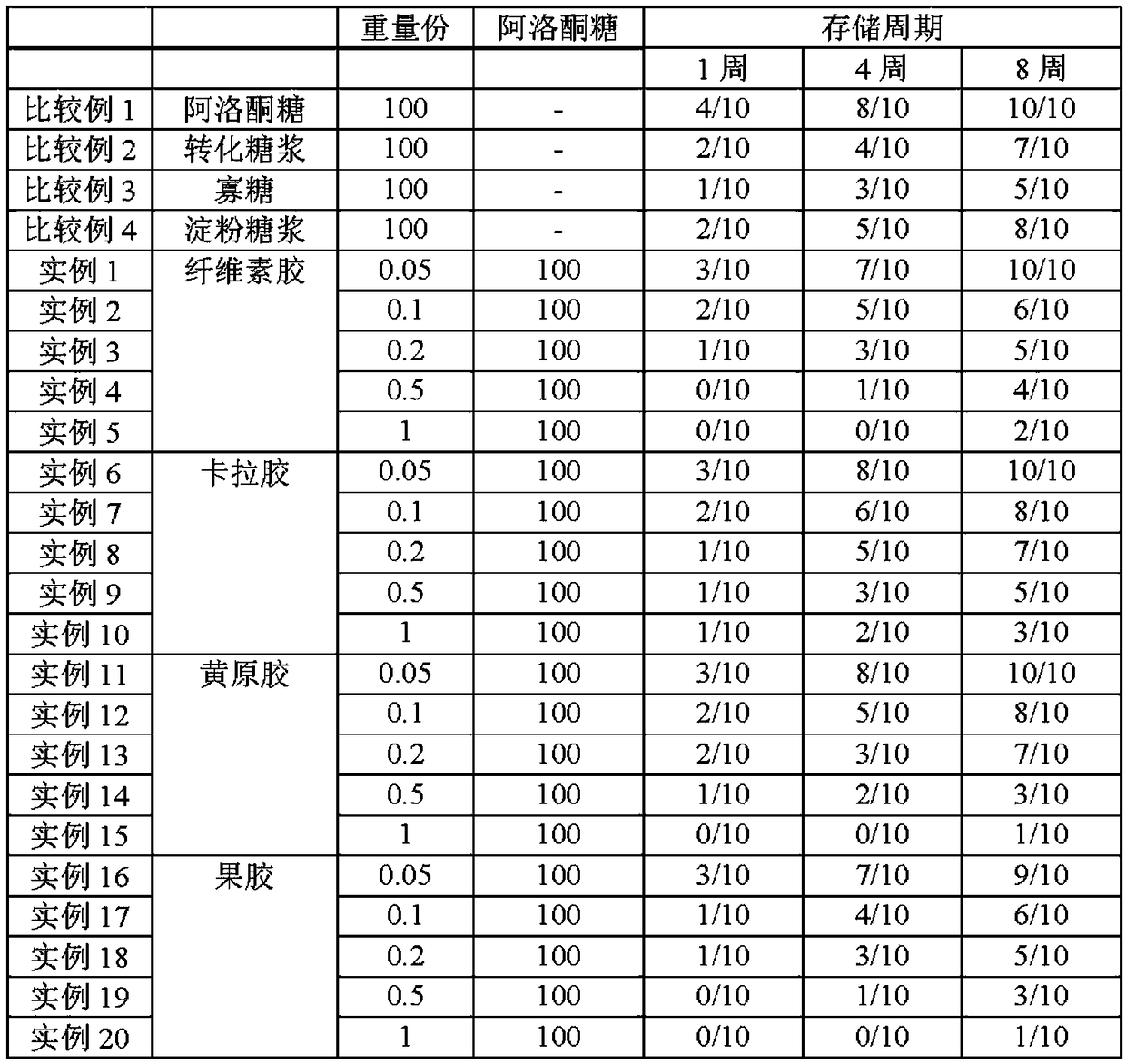

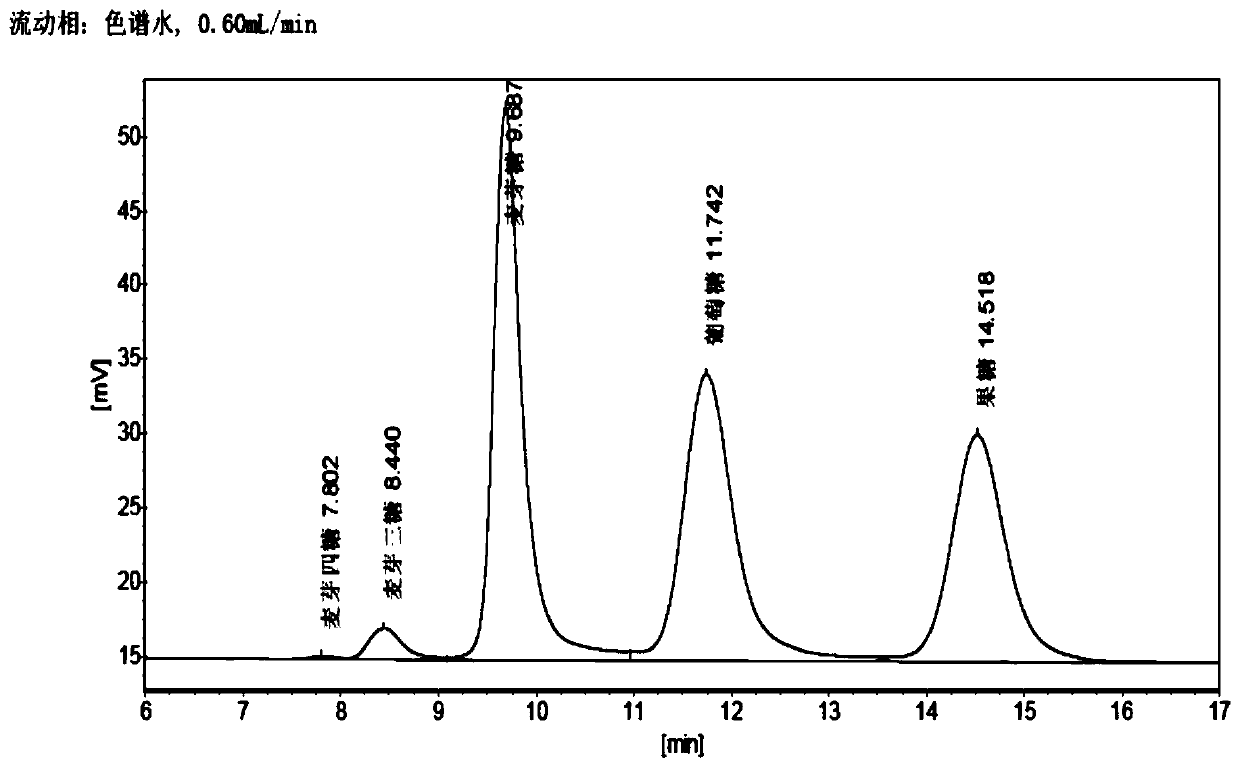

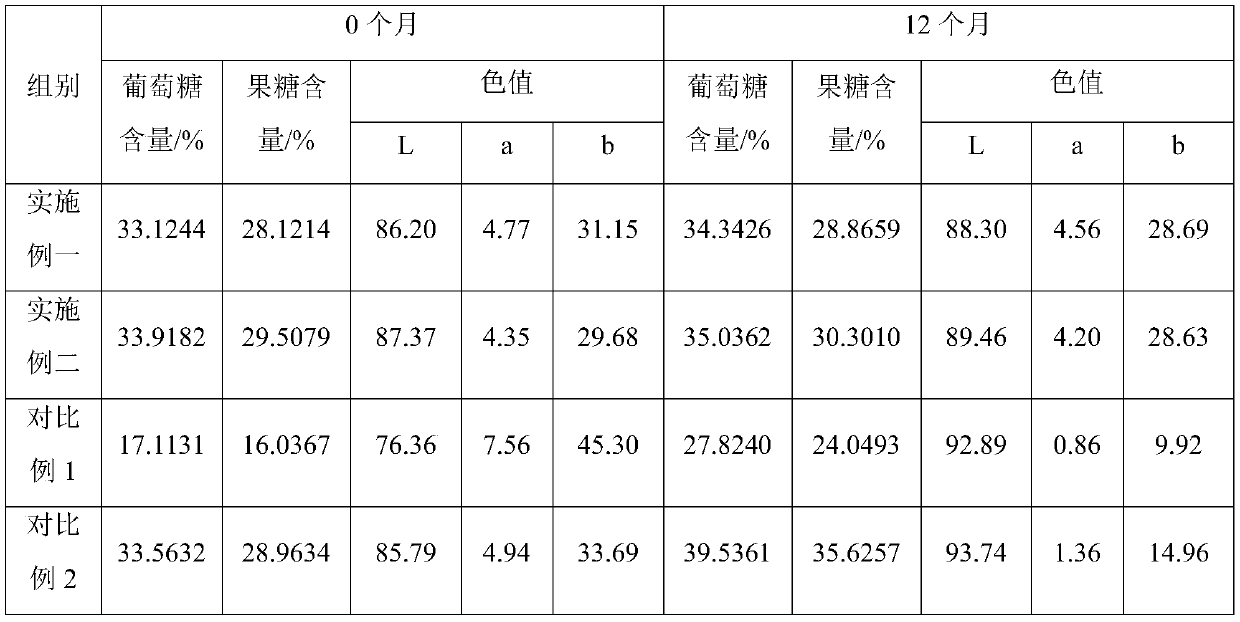

Allulose-containing syrup composition and food containing same

ActiveCN108697140ALow storage stabilityReduce viscosityFood ingredient as viscosity modification agentSugar food ingredientsBiotechnologyPsicose

The present application relates to a syrup composition comprising: gum, pectin or a combination thereof; and allulose, and food containing the composition.

Owner:CJ CHEILJEDANG CORP

Wood anti-mold modified liquid and preparation method thereof

InactiveCN107877645ALow viscosityLow water solubilityWood treatment detailsWood impregnation detailsSolubilityAmino-Levulinic Acid

The invention discloses a wood anti-mold modified liquid and a preparation method thereof and belongs to the technical field of wood anti-mold modified liquid. The wood anti-mold modified liquid is made of the raw materials, by mass, 20-40 parts of formaldehyde; 10-20 parts of phenolic compound; 5-15 parts of cupramate; 10-20 parts of nano-kaolin; 5-15 parts of zinc chloride; 5-9 parts of sodium dodecyl benzene sulfonate; 10-20 parts of 5-aminolevulinic acid; 400-600 parts of water; and 4-10 parts of emulgator. The invention further discloses a preparation method of the wood anti-mold modifiedliquid. The wood anti-mold modified liquid is low in viscosity, good in water solubility, good in storage stability, low in formaldehyde emission, good in the antimould effect, and is suitable for modification of various tree species, and is high in the economic value.

Owner:GUILIN AONISITE ENERGY SAVING & ENVIRONMENT PROTECTION TECH

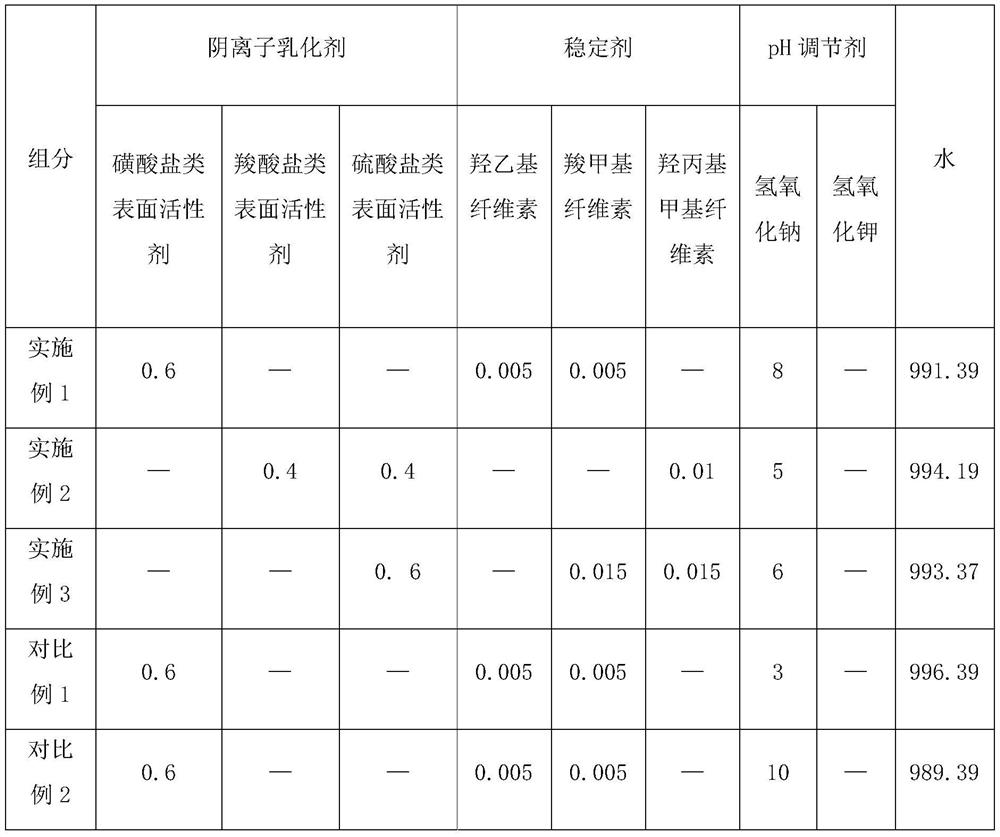

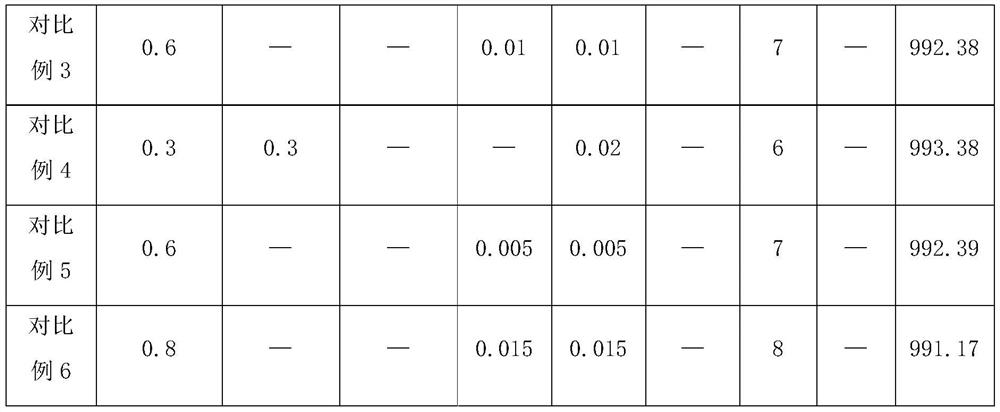

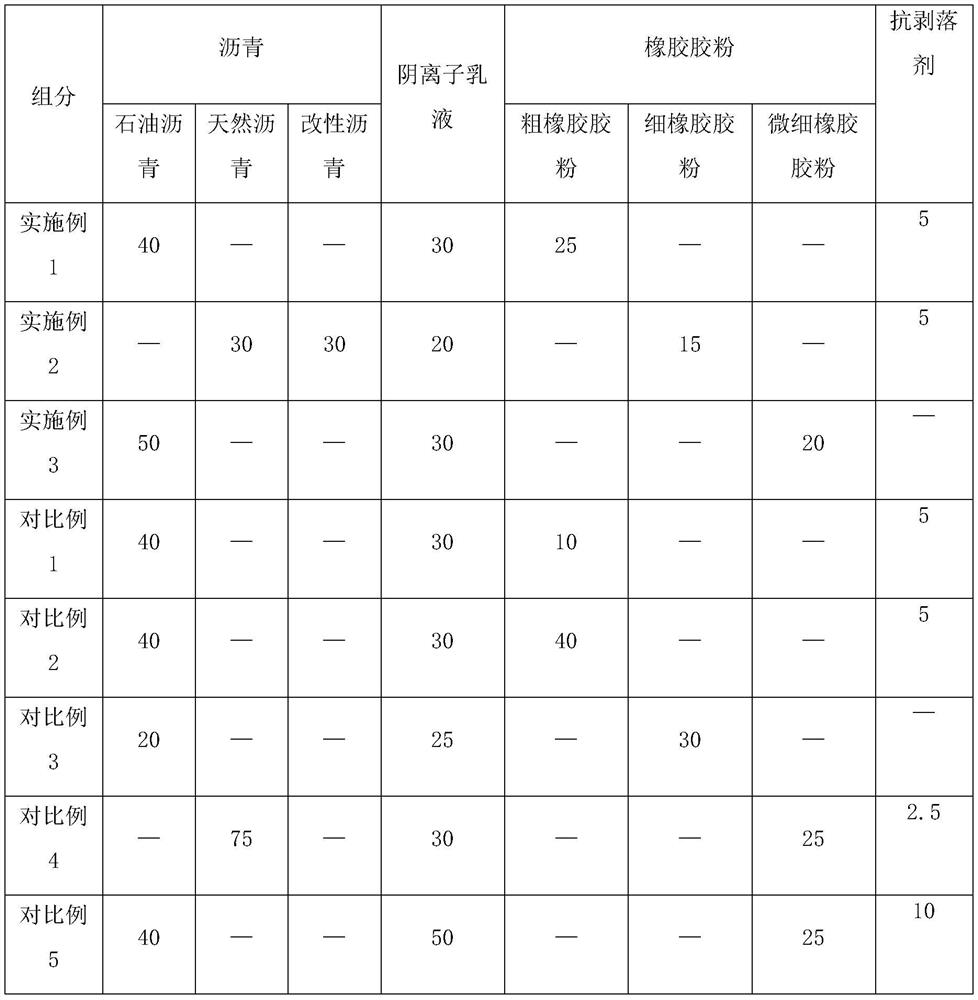

Permeable emulsified asphalt concrete and preparation method thereof

PendingCN113121170AImprove low intensityImprove the ability to resist bending deformationBitumen emulsionAsphalt concrete

The invention discloses permeable emulsified asphalt concrete and a preparation method thereof. The permeable emulsified asphalt concrete is prepared from the following components in parts by mass: 50-70 parts of coarse aggregate, 20-25 parts of cement, 5-10 parts of modified emulsified asphalt, 0-5 parts of a cementing agent and 5-10 parts of water, wherein the modified emulsified asphalt is prepared from the following components in parts by mass: 40-60 parts of asphalt, 20-30 parts of anionic emulsion, 20-25 parts of rubber powder and 0-5 parts of an anti-stripping agent. The prepared modified emulsified asphalt is suitable for low-temperature storage, and the prepared permeable emulsified asphalt concrete has the advantages of high concrete strength, high-temperature rutting resistance and wear resistance.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

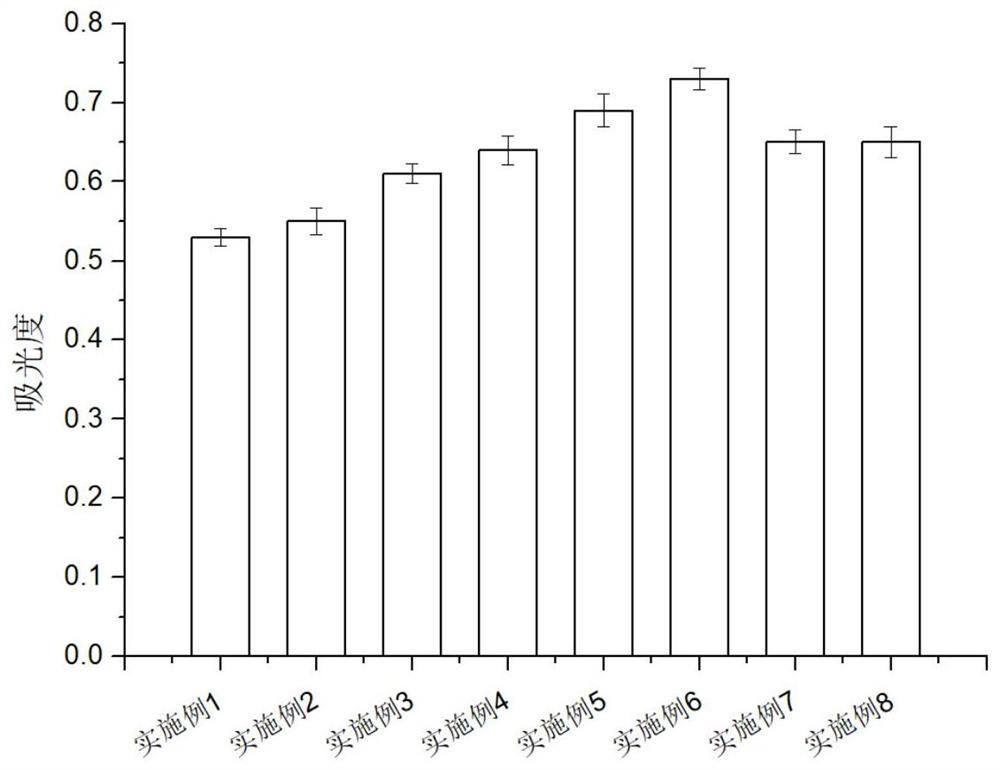

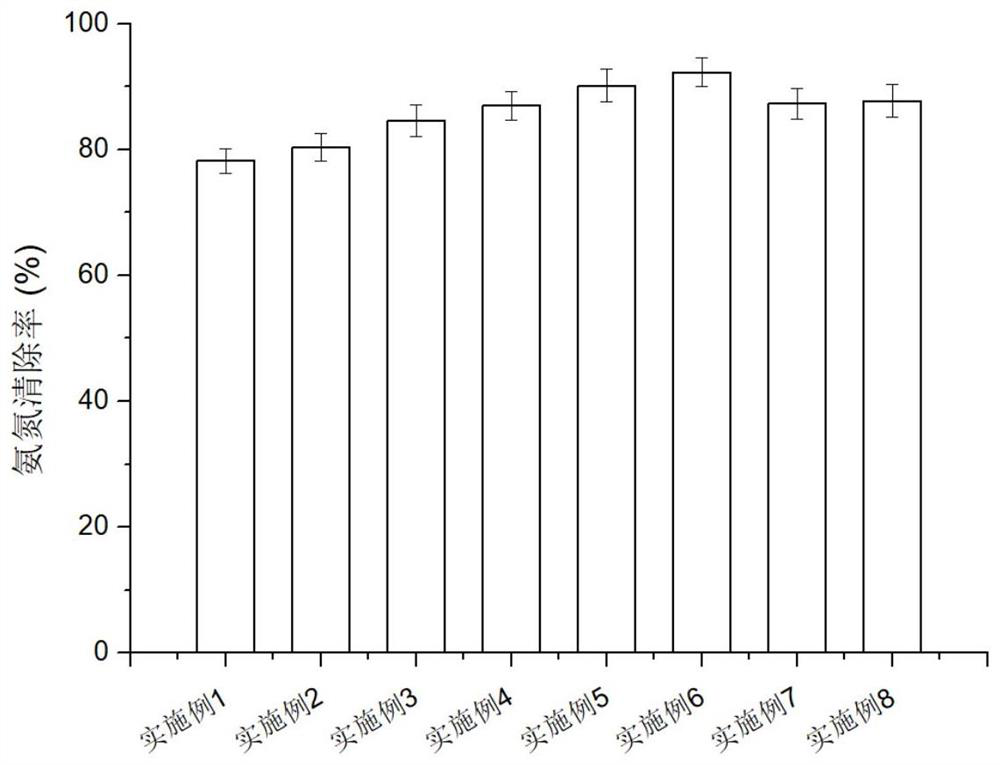

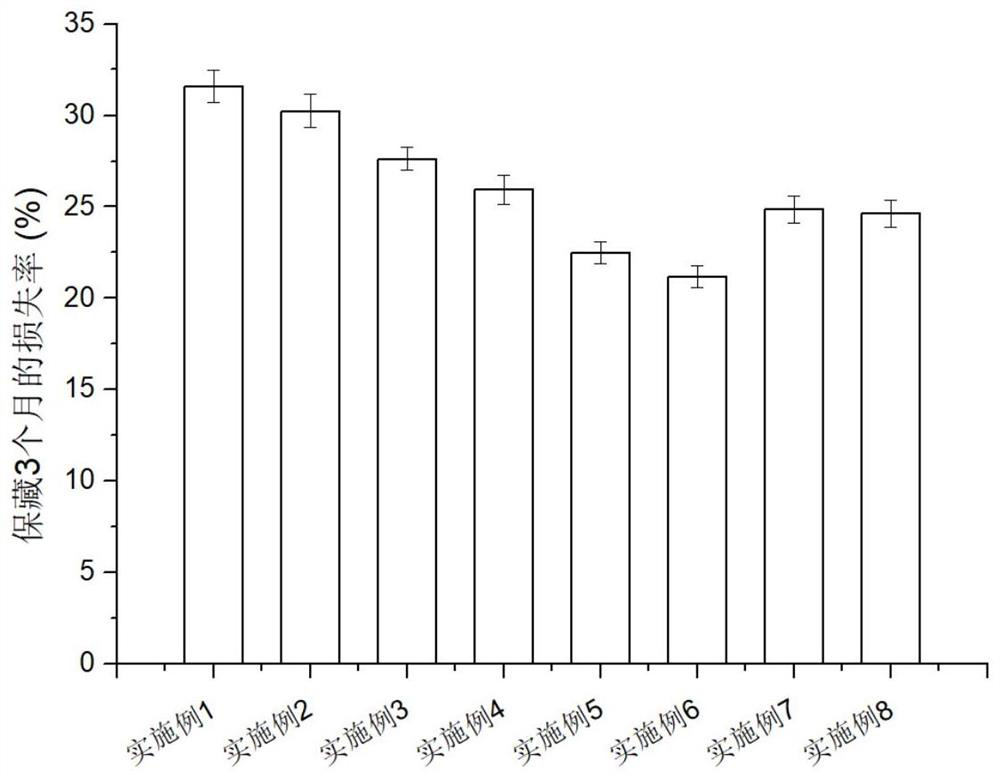

Immobilization method of microbial agent

ActiveCN112813059ALow storage stabilityEasy clearanceOn/in organic carrierBiotechnologyMicroorganism

The invention discloses an immobilization method of a microbial agent, and belongs to the field of microbial agent preparation. The immobilization method of the microbial agent comprises the following steps: treating a biological carrier through a modification process to obtain a modified biological carrier; and treating microbial liquid, the modified biological carrier and a functional agent through an immobilization process to obtain the immobilized microbial agent, wherein the modification process comprises oxidation treatment. The microbial agent is good in activity, high in ammonia nitrogen removal rate, high in immobilization efficiency and good in preservation stability, the bacterial activity loss rate of the microbial agent reaches 32% or below after the microbial agent is preserved for 3 months, the thermal stability is improved, and the bacterial activity loss rate is 60% or below after the microbial agent is preserved at the temperature of 50 DEG C for 1 h.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

Anti-corrosion coating, its preparation method and oil pipe with anti-corrosion coating on its surface

ActiveCN103820012BNot easy to layerGood construction performanceGeneral water supply conservationAnti-corrosive paintsEnvironmental resistanceOrganic solvent

Owner:北京碧海云智新材料技术有限公司

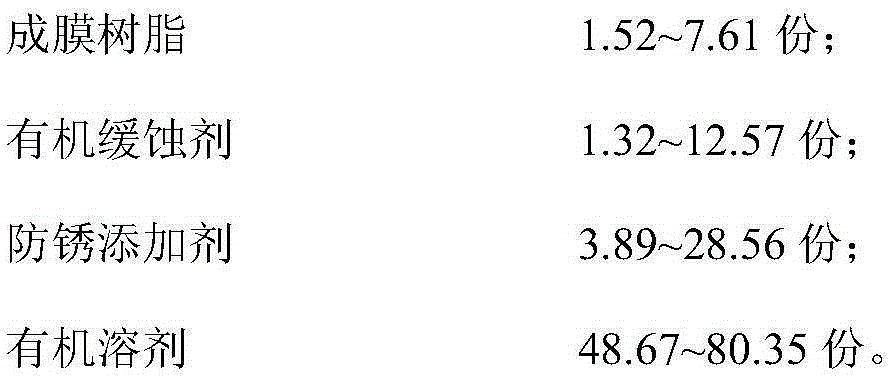

A kind of preparation method of sucrose inversion syrup and sucrose inversion syrup

ActiveCN106834551BIncrease the sugar contentNot easy to crystallizeSugar productsFermentationMaillard reactionFructose

The invention provides a preparation method of sucrose invert syrup. The preparation method comprises the following steps: S1, preparation of a sugar solution; S2, preparation of invertase liquid; S3, enzymatic hydrolysis; S4, enzyme deactivation; S5, Maillard reaction; and S6, sugar supplementation and colour modulation and blending of flavor. The invention belongs to the field of syrup production technology. The prepared sucrose invert syrup has bright caramel colour and soft caramel fragrance, is viscous syrup, has high sugar degree, is not easy to crystallize, has mellow mouthfeel, and has good storage stability. Ratio of maltose to glucose to fructose is close to 1:1:1.

Owner:苏州鲜活饮品股份有限公司

Wood modifying agent and preparation method thereof

InactiveCN107825550ALow viscosityLow water solubilityWood impregnation detailsSolubilityGallic acid ester

The invention discloses a wood modifying agent and a preparation method thereof, and belongs to the technical field of wood modifying agents. The wood modifying agent is prepared by the following rawmaterials in parts by weight: 5-15 parts of formaldehyde, 10-20 parts of methyl acrylate, 4-8 parts of alkyl polyglucoside, 8-12 parts of gallic acid, 2-6 parts of zinc chloride, 2-4 parts of sodium dodecyl benzene sulfonate, 20-40 parts of urea, 300-400 parts of water, and 1-5 parts of emulsifying agent. The invention further discloses the preparation method of the wood modifying agent. The woodmodifying agent is low in viscosity, excellent in water solubility, excellent in storage stability, low in formaldehyde release quantity, suitable for modification of various tree types and higher ineconomical value.

Owner:GUILIN AONISITE ENERGY SAVING & ENVIRONMENT PROTECTION TECH

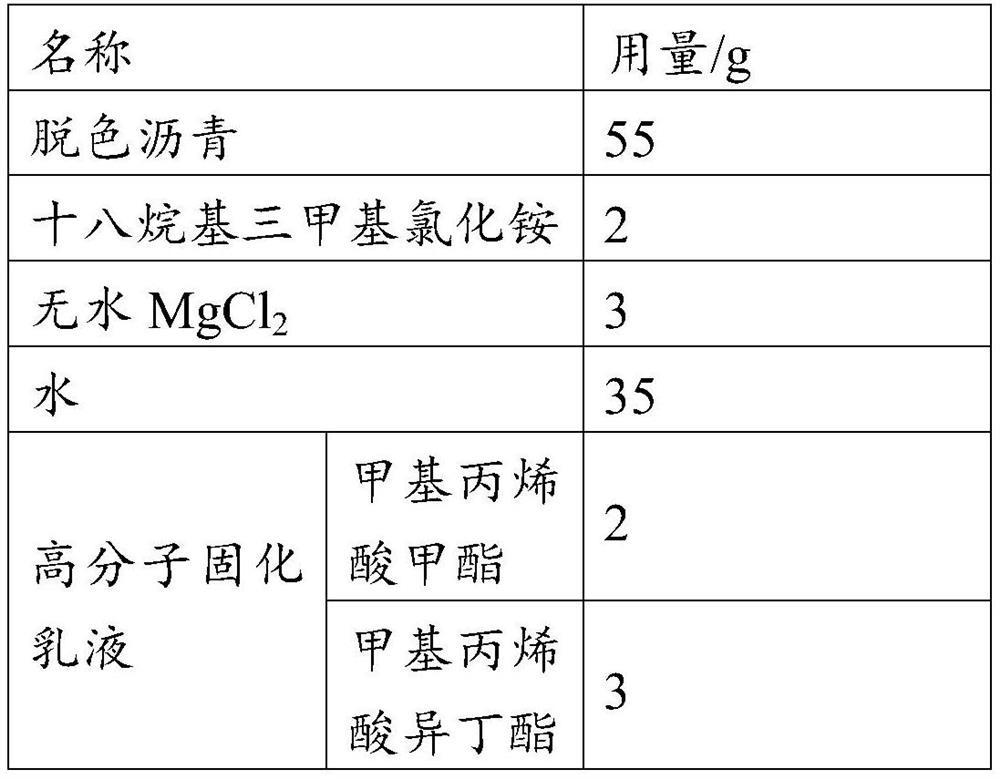

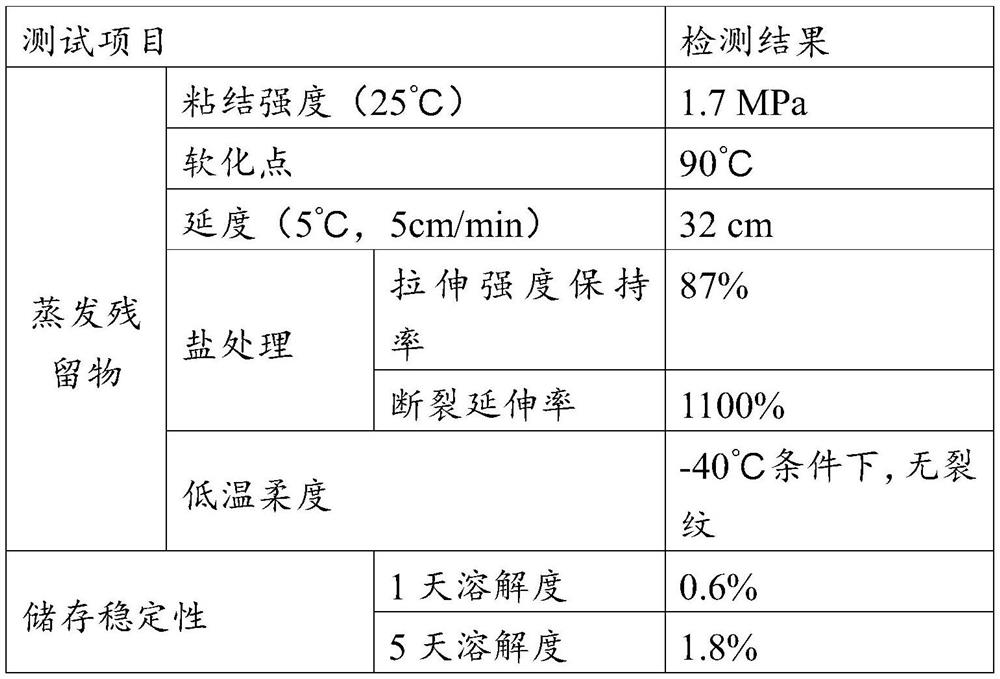

Asphalt-based material decolorizing high-viscosity curing emulsion and preparation method thereof

ActiveCN112961605AImprove high temperature stabilityNot flowingSolid waste managementAnti-corrosive paintsPolymer scienceActive agent

The invention relates to an asphalt-based material decolorizing high-viscosity curing emulsion and a preparation method thereof, and the decolorizing and high-viscosity curing emulsion comprises the following components in parts by weight: 40-60 parts of decolorized asphalt, 1-10 parts of a surfactant, 1-10 parts of a first stabilizer, 30-40 parts of water and 1-10 parts of a polymer curing emulsion. The decoloring high-viscosity curing emulsion has the main function of stabilizing a lower rubble layer, the rubble layer is prevented from stripping under the action of long-term natural conditions, the performance and the service life of a whole waterproof layer structure are not affected, and the emulsion has good waterproof performance and can further protect the lower waterproof layer.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Fruit jam comprising allulose and method for manufacturing same

ActiveCN109661181AEasy to manufactureLow storage stabilitySugar food ingredientsFood thermal treatmentBiotechnologyPsicose

The present application relates to a fruit jam comprising a fruit and a sugar containing allulose, a method for manufacturing the same, and a method for reducing bubbles in the fruit jam.

Owner:CJ CHEILJEDANG CORP

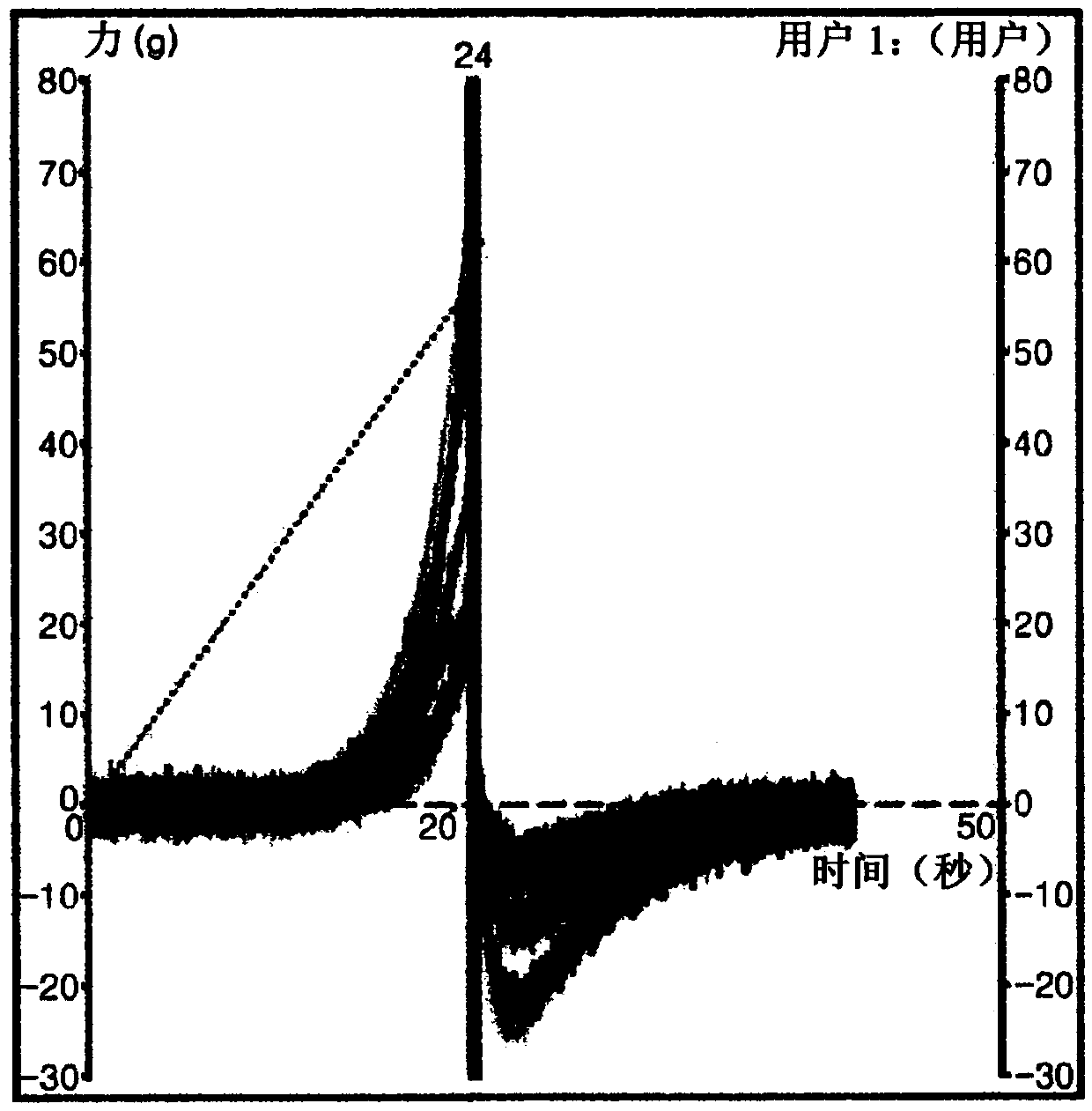

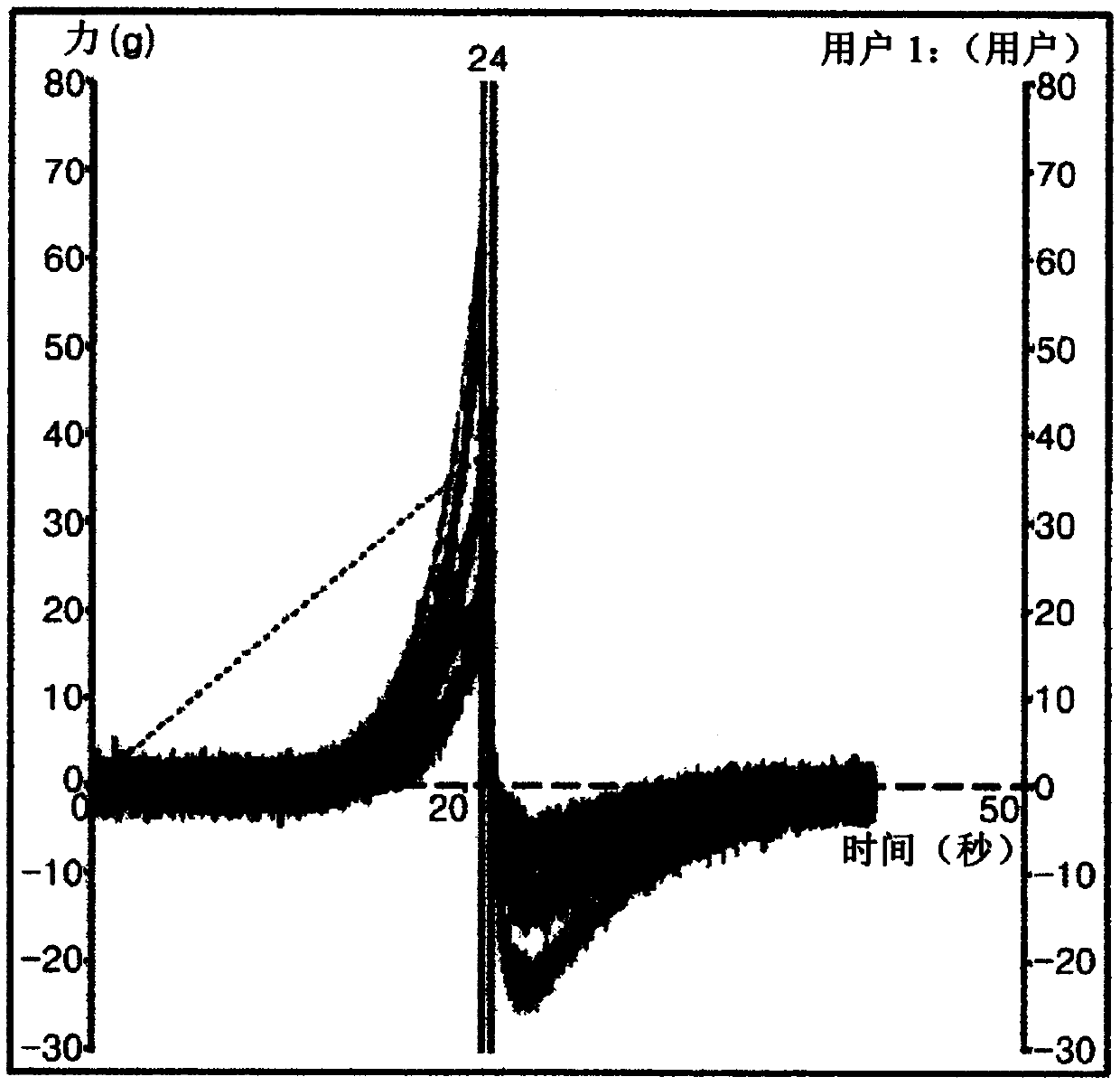

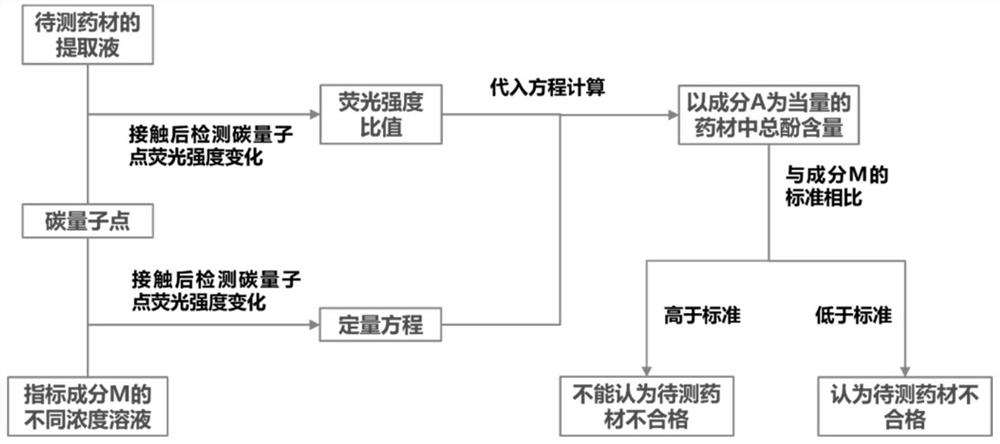

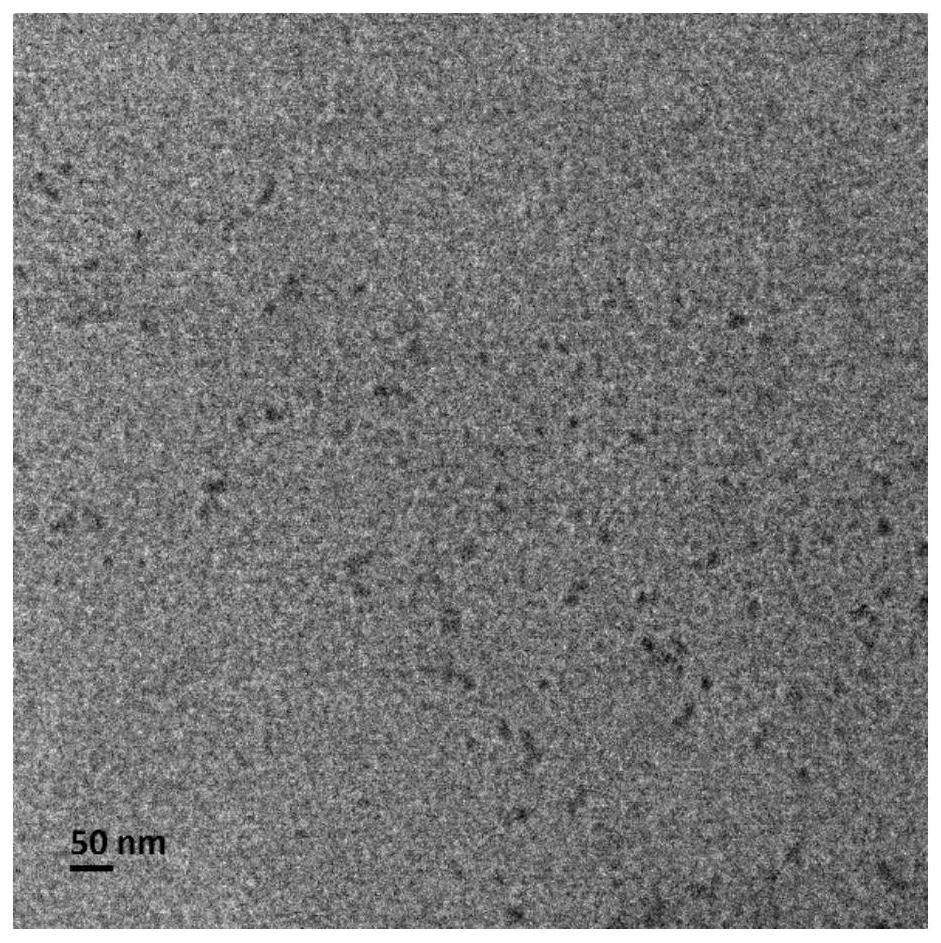

Primary screening method for medicinal material quality

InactiveCN112147122AStrong fluorescent signalReduce manufacturing costFluorescence/phosphorescenceMedicinal herbsPrimary screening

The invention discloses a primary screening method for medicinal material quality. The method comprises the following steps of 1, preparing carbon quantum dots; 2, establishing a quantitative equationof the concentration of a reference substance and the fluorescence quenching condition of the carbon quantum dots by adopting the reference substance of an index component M of a medicinal material to be detected; 3, quenching the fluorescence of the carbon quantum dots by using a medicinal material extracting solution, and calculating a total phenol value in the medicinal material according to the fluorescence quenching condition; and 4, comparing the calculated total phenol value of the medicinal material with the standard of the index component, and judging that the quality of the medicinal material is unqualified if the total phenol value does not reach the lower limit of the standard. According to the method, the carbon quantum dots are used as a detection reagent, no toxic solvent is needed during detection, the solution preparation is simple, the detection time is short, the cost of detection equipment is relatively low, and the stability of long-term storage is obviously better. The method can be used for quickly judging the quality of medicinal materials taking phenolic components as index components.

Owner:ZHEJIANG UNIV

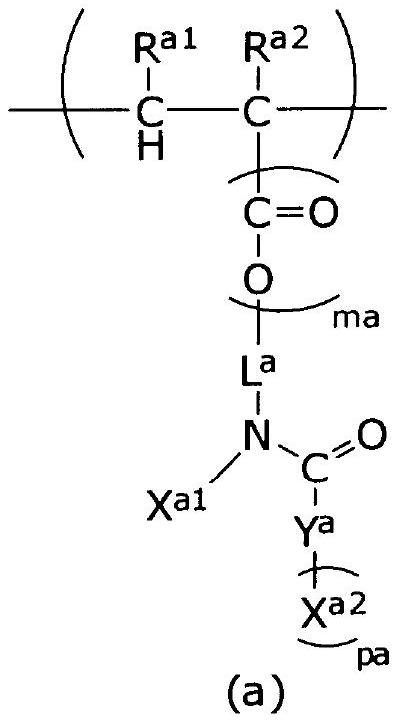

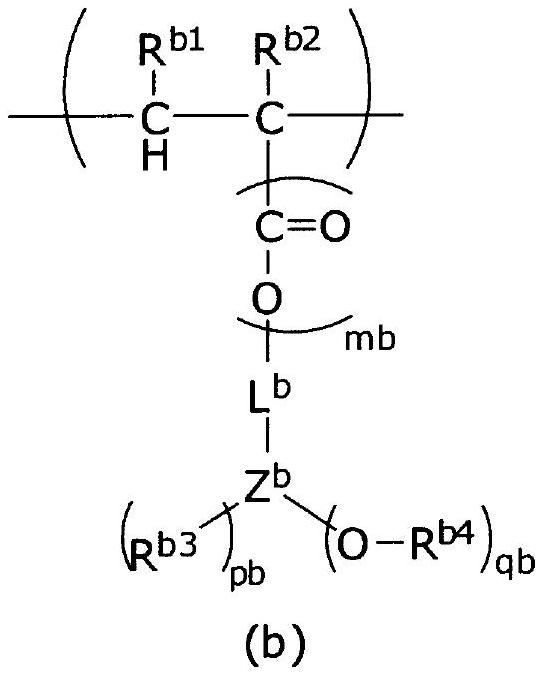

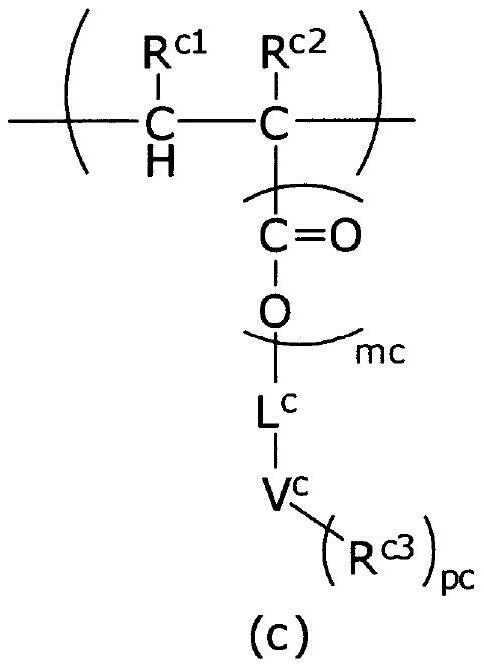

Polymer, semiconductor composition comprising polymer, and method for manufacturing film using semiconductor composition

PendingCN113454131AImprove applicabilityHigh solute solubilitySemiconductor/solid-state device manufacturingPhotosensitive material processingPolymer scienceStructural unit

Owner:MERCK PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com