Curing agent 4,2'- and 4,4'-methyl diphenylene diisocyanate prepolymer and preparation thereof

A technology of diphenylmethane and diisocyanate, which is applied in 4 fields, can solve the problems of not being able to produce products with high solid content, the single type of prepolymer, and the high viscosity of the product, so as to avoid the problem of cementation or deterioration of the curing agent. Strong, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

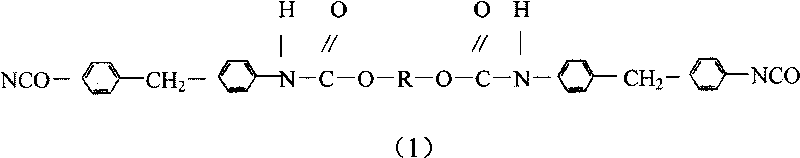

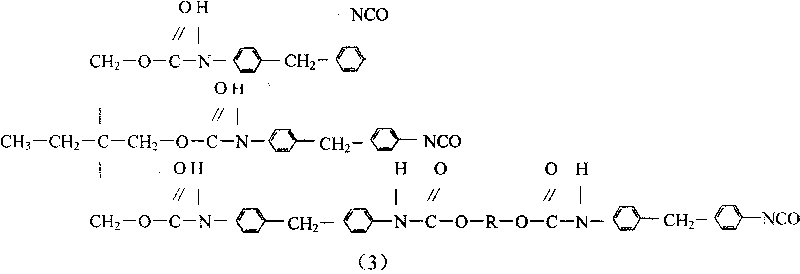

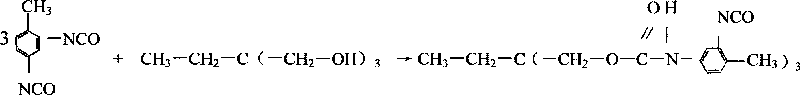

Method used

Image

Examples

Embodiment 1

[0047] a. Add 100 grams of molten 4,4'-MDI and 60 grams of ethyl acetate to the reaction kettle, stir evenly, heat up to 80°C, add 80 grams of polycarbonate-caprolactone diol dehydrated by vacuum, React at 80-90°C for 2 hours, and react at 90-100°C for 1 hour; b, add 150 grams of MDI-45 under stirring (that is, the weight of 4,2'-MDI is 45%, and the weight of 4,4'-MDI 55% mixture), after mixing evenly, lower the temperature to below 80°C, add dropwise a mixture of 37.3 grams of trimethylolpropane and 37.3 grams of ethyl acetate, drop it in 2 hours, and keep it warm at 75-85°C 3 hours, rise to 80~90 ℃ of insulation reaction for 2 hours again, lower the temperature; c, add 25 grams of propylene glycol monomethyl ether acetate solvents according to the solid content requirement of product, stir well, and the solid content of 489 grams of discharging is 75% and the viscosity is 2500mpa.s (25°C) 4,2'- and 4,4'-MDI prepolymer curing agent, the NCO content of the curing agent is 8.6%...

Embodiment 2

[0052] a. Add 300 grams of molten 4,4'-MDI and 50 grams of ethyl acetate into the reaction kettle, stir evenly, heat up to 70°C, and add 21 grams of 3-methyl-1,5-pentanedi that has been vacuum-dehydrated Alcohol, react at 70-80°C for 2 hours, and react at 90-100°C for 1 hour; b, add 43 grams of MDI-50 under stirring (that is, 4,2'-MDI weight is 50%, 4,4'- MDI weight is 50% mixture), after mixing evenly, cool down to below 80°C, add dropwise the mixed solution of 46 grams of trimethylolpropane and 56 grams of ethyl acetate, drop it in 1 hour, at 70~80°C, Heat preservation reaction for 2 hours, then rise to 80~90°C for heat preservation reaction for 2 hours, and then cool down; c, add 30 grams of xylene solvent according to the solid content of the product, stir evenly, and discharge 546 grams of 4,2 with a solid content of 75%. As for the '- and 4,4'-MDI prepolymer curing agent, the NCO content of the curing agent was detected to be 10.5% (14.1% based on total solids).

Embodiment 3

[0054] a. Add 150 grams of molten 4,4'-MDI and 180 grams of ethyl acetate in the reaction kettle, stir evenly, heat up to 75 ° C, add 200 grams of hydrogenated hydroxyl-terminated polybutadiene diol through vacuum dehydration, React at 75-85°C for 2.5 hours, and at 90-100°C for 0.5 hours; b, add 200 grams of MDI-60 under stirring (that is, 4,2'-MDI weight is 60%, 4,4'-MDI weight 40% mixture), after mixing evenly, lower the temperature to below 80°C, add dropwise a mixture of 53.6 grams of trimethylolpropane and 73.6 grams of ethyl acetate, drop it in 2.5 hours, and keep it warm at 70-80°C 1.5 hours, then rise to 80-90°C for 3 hours, then cool down; c. Add 150 grams of toluene, 180 grams of cyclohexanone, and 20 grams of N,N-dimethylformamide solvent according to the solid content requirements of the product, and stir evenly , 1207 grams of 4,2'- and 4,4'-MDI prepolymer curing agent with a solid content of 50% are obtained in the output, and the NCO content of this curing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com