Automatic box packing machine

An automatic cartoning machine and carton technology, applied in the field of packaging, can solve the problems of small adjustment range and complicated adjustment process, and achieve the effects of large adjustment range, simple operation and convenient comparison.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

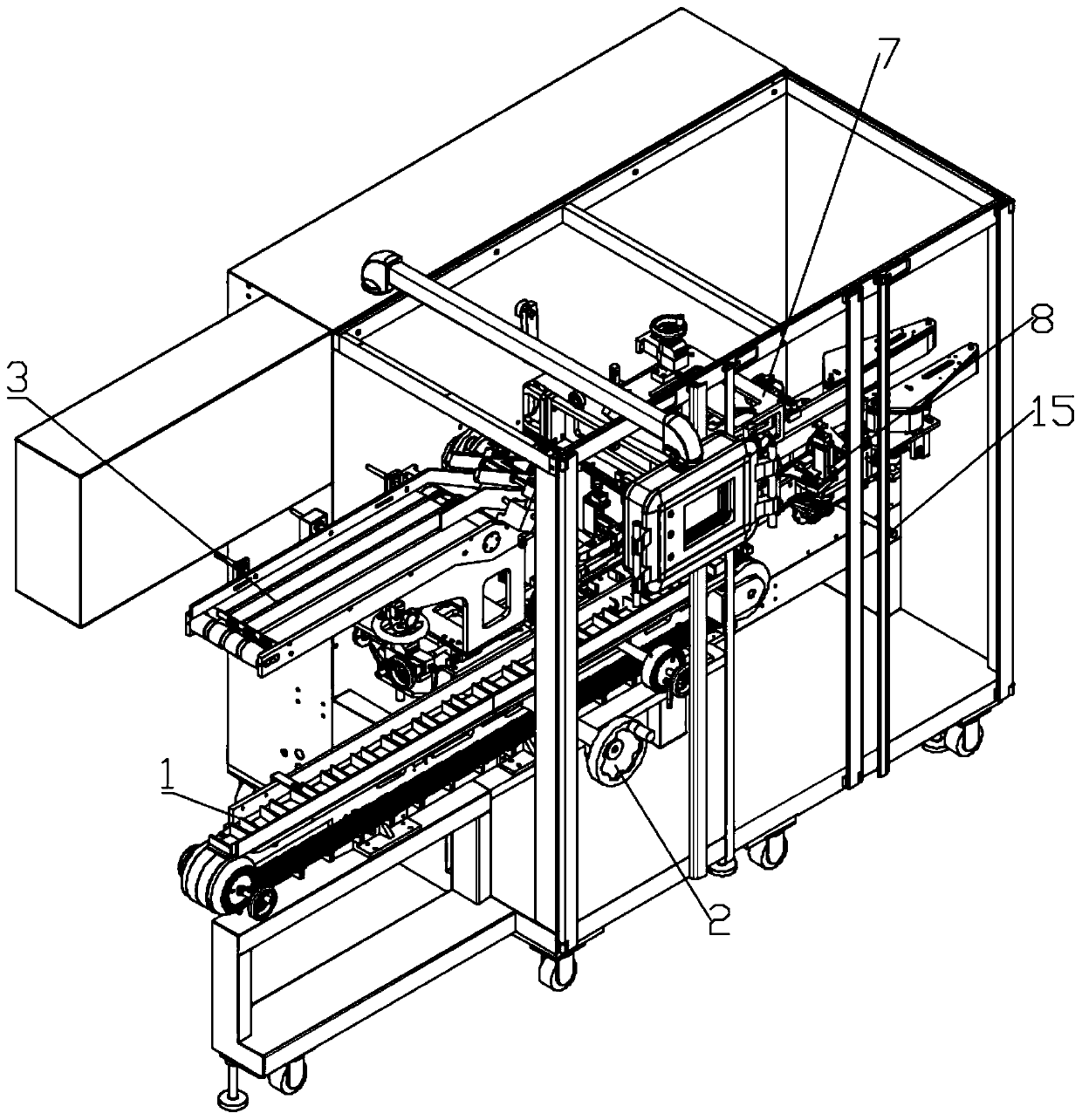

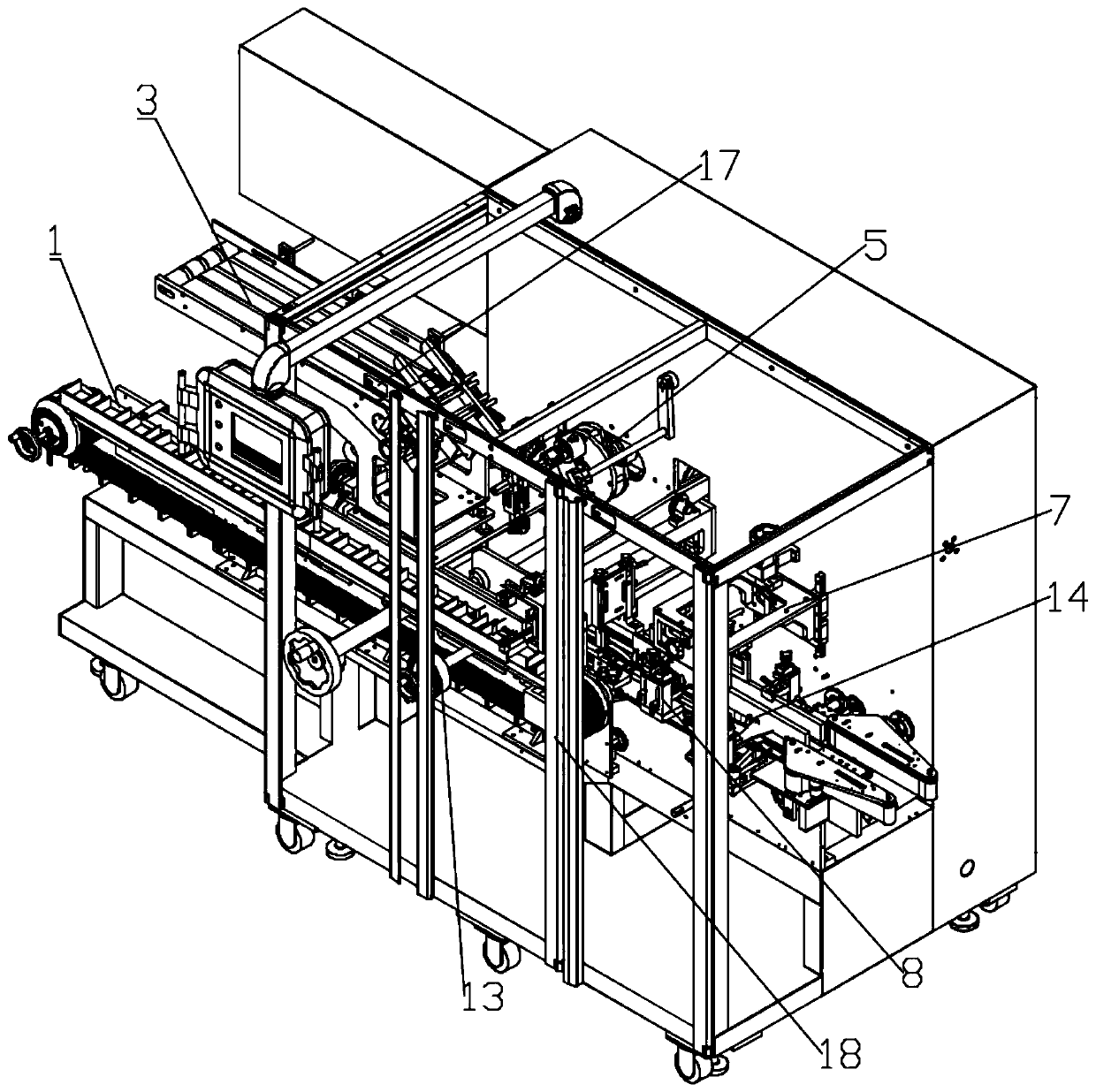

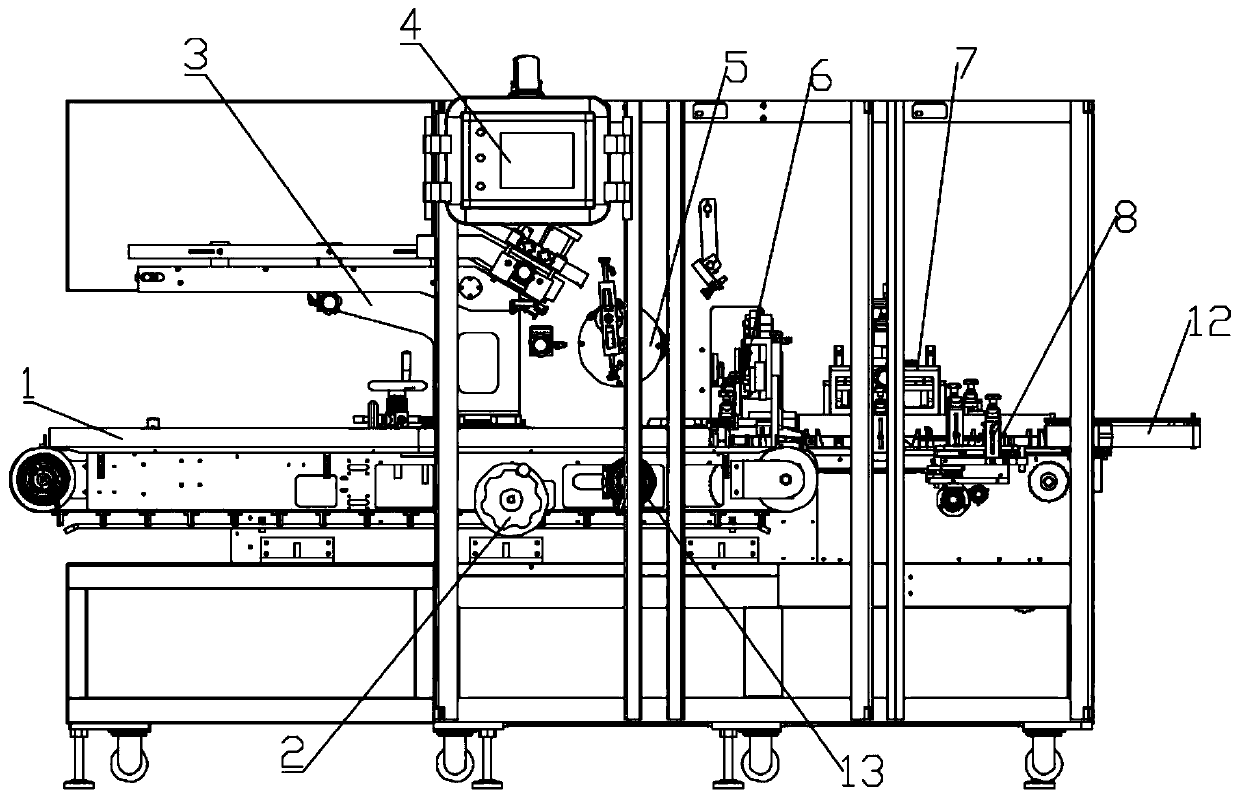

[0026] An automatic cartoning machine, comprising a frame and a control panel 4, on which a motor 11, a carton storehouse 3, a feeding conveying device 1, a carton conveying device 14, a discharging conveying device 12, and a pushing device 6 are installed With the suction cup device 5, the feeding conveying device 1 and the carton storehouse 3 are positioned at the same end of the frame, the discharge conveying device 12 is positioned at the other end of the frame, and the sucker device 5 is positioned at the junction of the carton storehouse 3 and the carton conveying device 14, The pusher device 6 is located at the connection between the feeding conveying device 1 and the carton conveying device 14, the motor 11 is respectively connected with the feeding conveying device 1 and the carton conveying device 14 through the transmission shaft 9 and the transmission shaft 9 cooperates with the intermittent divider 10 In use, both sides of the carton conveying device 14 are provide...

Embodiment 2

[0032] An automatic cartoning machine, comprising a frame and a control panel 4, on which a motor 11, a carton storehouse 3, a feeding conveying device 1, a carton conveying device 14, a discharging conveying device 12, and a pushing device 6 are installed With the suction cup device 5, the feeding conveying device 1 and the carton storehouse 3 are positioned at the same end of the frame, the discharge conveying device 12 is positioned at the other end of the frame, and the sucker device 5 is positioned at the junction of the carton storehouse 3 and the carton conveying device 14, The pusher device 6 is located at the connection between the feeding conveying device 1 and the carton conveying device 14, the motor 11 is respectively connected with the feeding conveying device 1 and the carton conveying device 14 through the transmission shaft 9 and the transmission shaft 9 cooperates with the intermittent divider 10 In use, both sides of the carton conveying device 14 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com