Patents

Literature

87results about How to "Easy to change production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colorful transparent polished-glazed brick and production method thereof

The invention discloses a colorful transparent polished-glazed brick and a production method thereof. The production method for the colorful transparent polished-glazed brick comprises the following steps: enameling a dried ceramic blank, spreading one or more glazes in different colors and with different burning temperature and different refractive indexes on the brick blank, and performing calcining and profiling soft polishing treatment to obtain the brick. According to the colorful transparent polished-glazed brick and the production method thereof, the layering effects and transition of the surface of the colorful transparent polished-glazed brick are closer to those of a natural stone, and the grade of the product is improved to a certain extent; original color effects can be achieved without adding a coloring material, so that process complexity is reduced, the labor intensity of a worker is reduced, and the production efficiency is favorably improved, and the colorful transparent polished-glazed brick and the production method thereof are suitable for popularization and application.

Owner:GUANGDONG JIA MEI CERAMIC

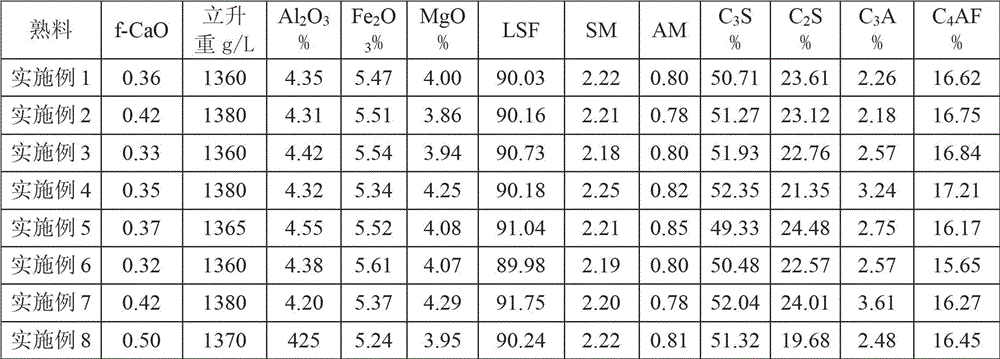

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

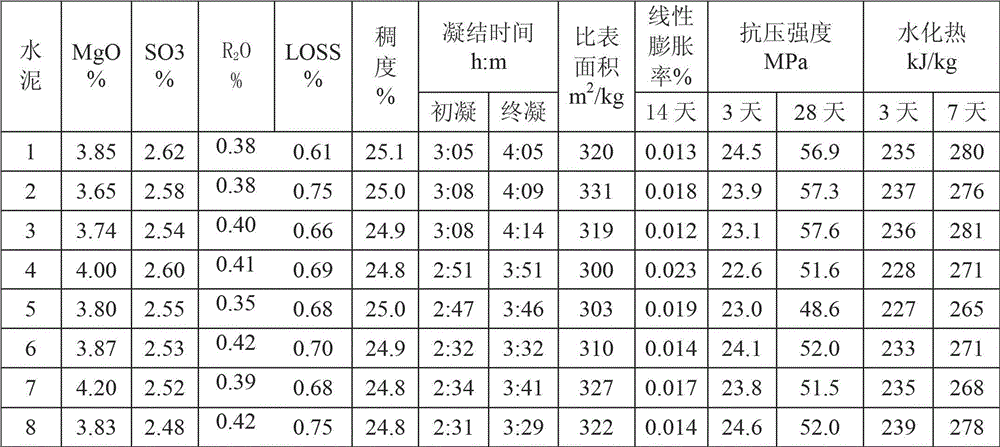

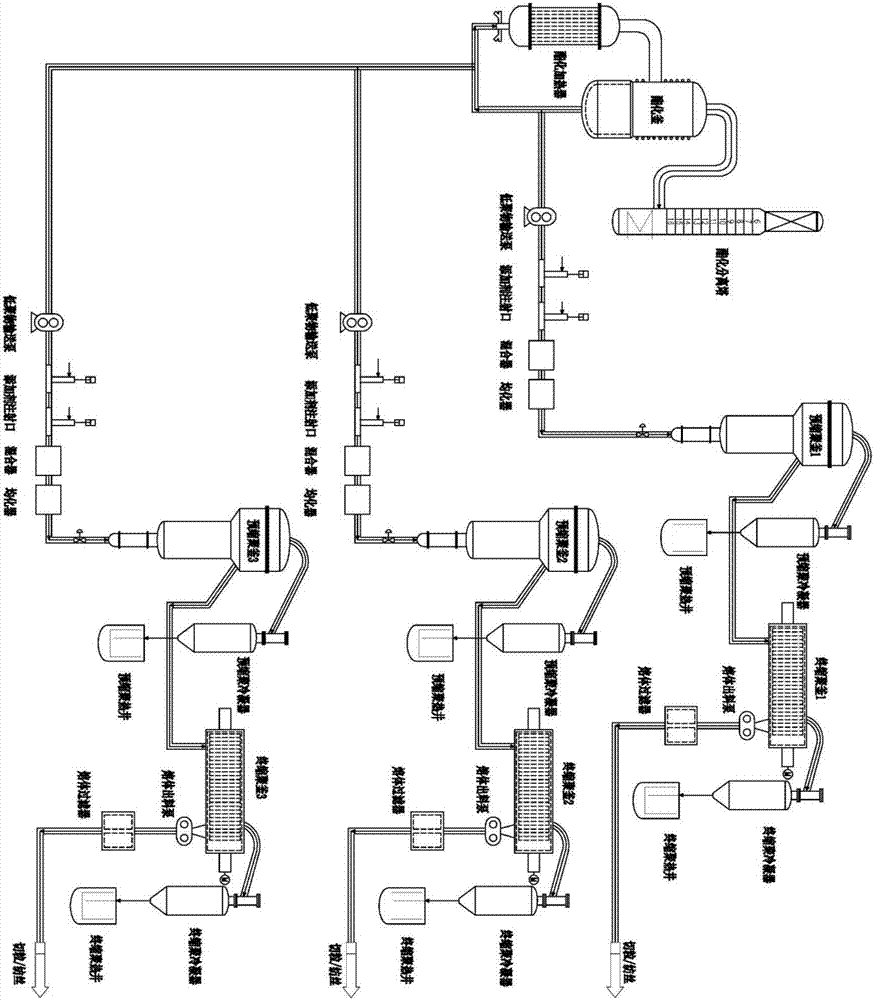

Preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis

InactiveCN108172892AImprove processing efficiencyRelieve pressureFinal product manufactureCell electrodesAmmonium hydroxideSlurry

Disclosed is a preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis. The preparation method comprises the following steps of: 1) preparing a metal salt solution, an alkali solution and an ammonium hydroxide solution; 2) enabling a reaction kettle and a solid concentration thickener to be connected in series; 3) injecting the metal salt solution, the alkali solution and the ammonium hydroxide solution into the reaction kettle 1, wherein the slurry in the reaction kettle 1 is pumped into the thickener 1 for solid-liquid separation to increase solid content when the liquid level in the reaction kettle 1 reaches the full kettle state, and the thick slurry in the thickener 1 is pumped into a reaction kettle 2; 4) performing stirring when the reaction kettle 2 is full of the slurry, and adding the metal salt solution, the alkali solution and the ammonium hydroxide solution to continue a continuous precipitation reaction, and then overflowing the product in the reaction kettle 2 into an aging tank 1; and 5) enabling the product in the aging tank 1 to be centrifuged, washed and dried. The preparation method has the advantages that the technology is simple, easily operated, energy-saving and environment-friendly. The product features good appearance, concentrated particle size distribution, high vibration density andhigh efficiency.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

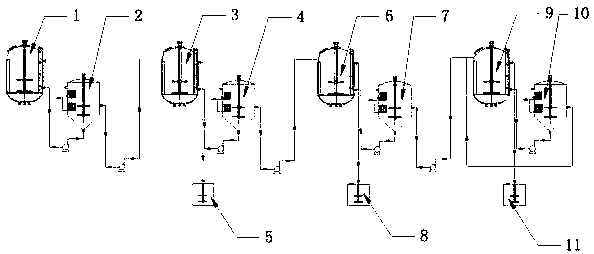

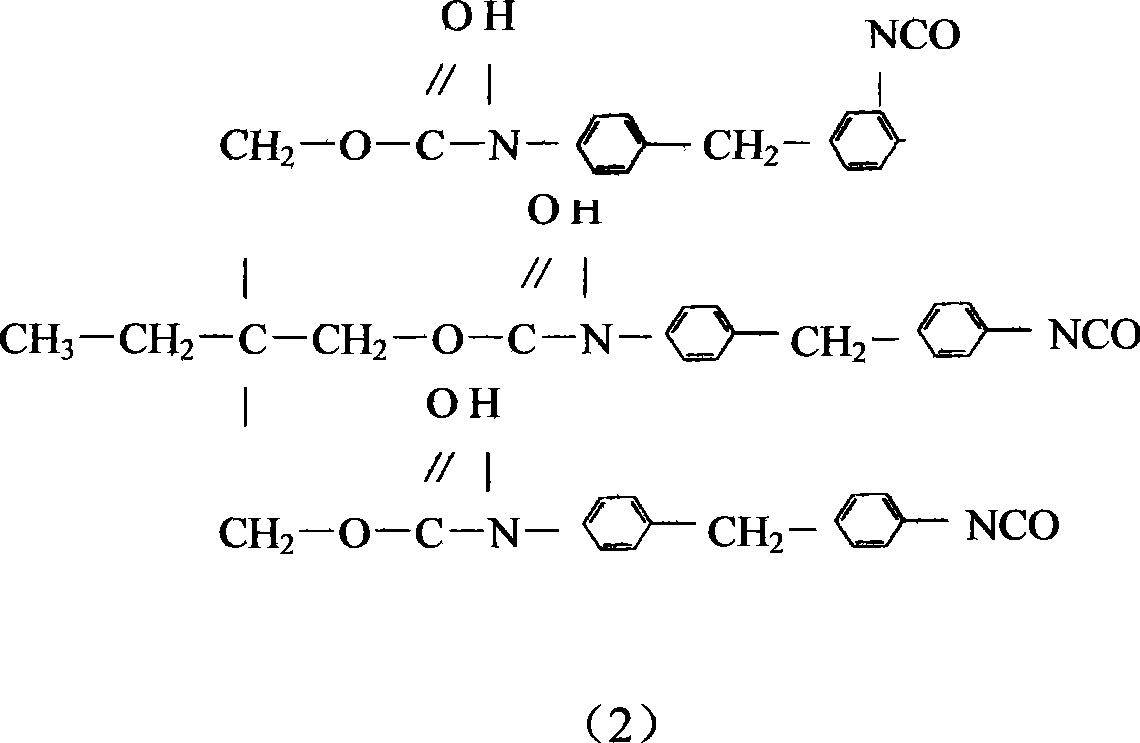

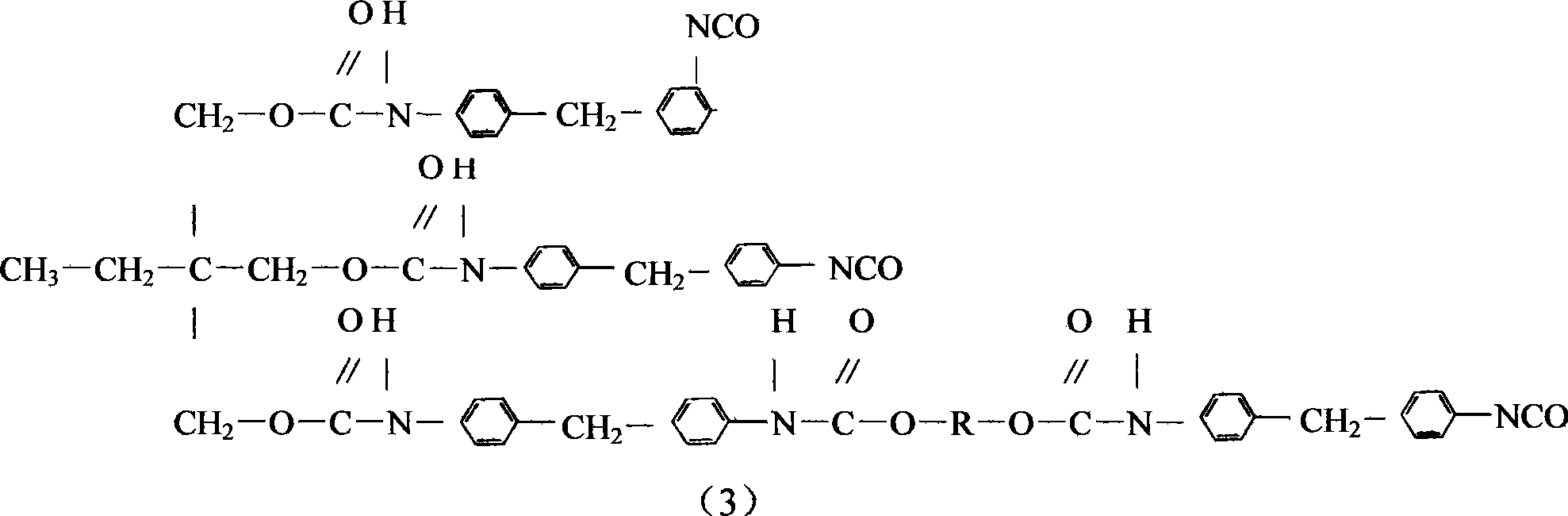

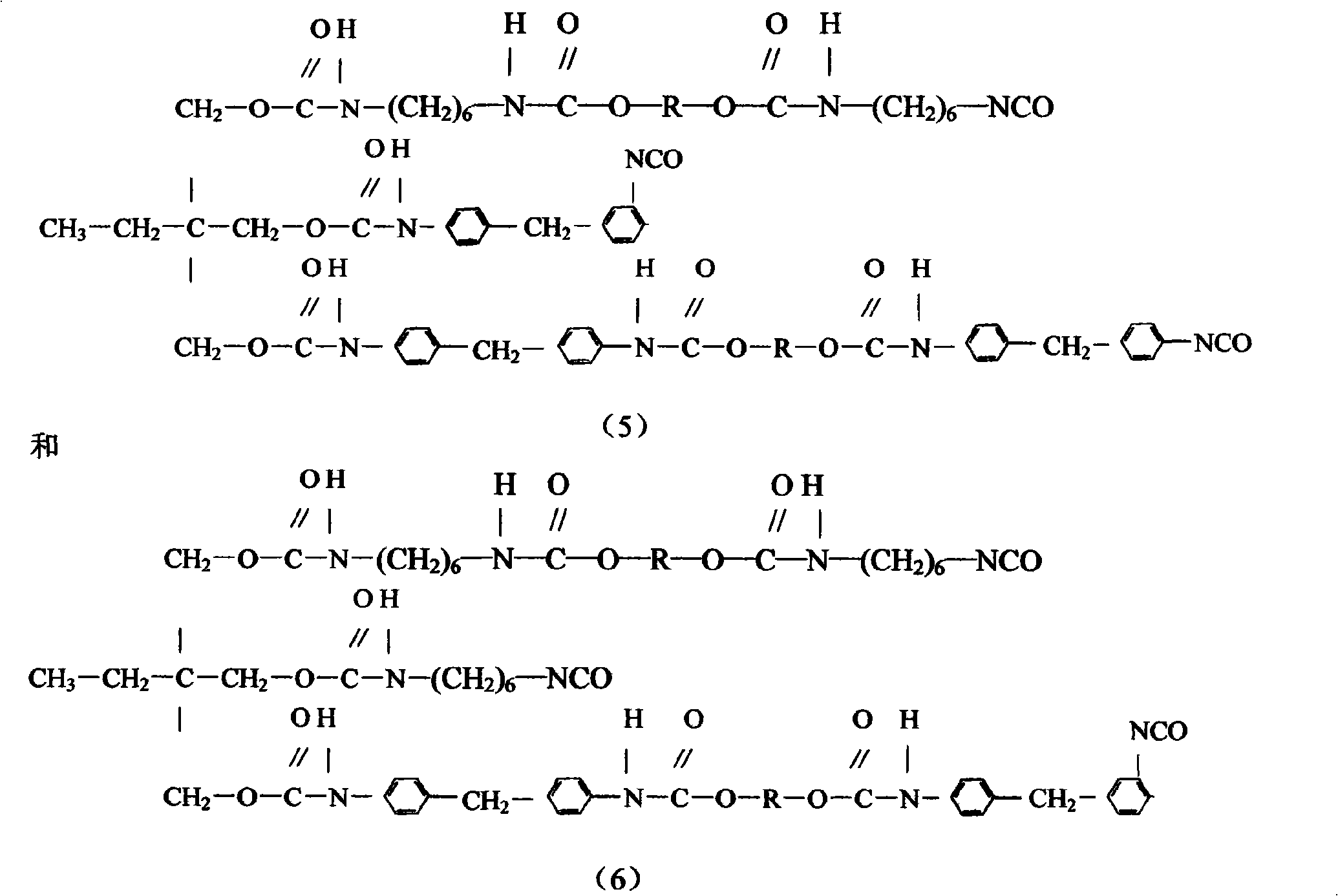

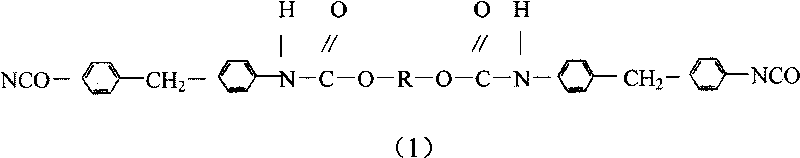

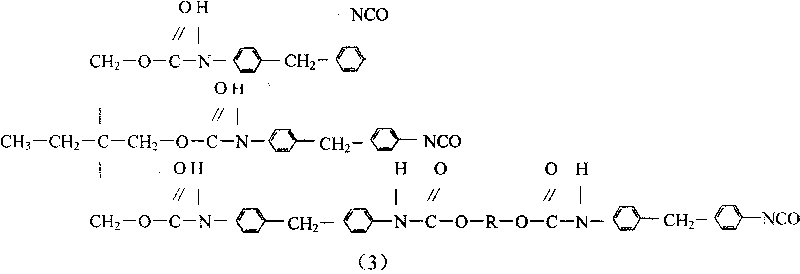

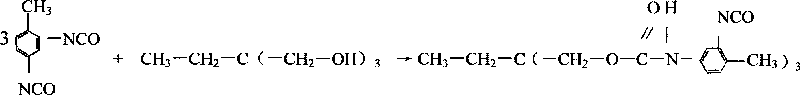

Curing agent 4,2'- and 4,4'-methyl diphenylene diisocyanate prepolymer and preparation thereof

The invention provides a prepolymer of 4,2'-methyl diphenylene diisocyanate (MDI) and 4,4'- methyl diphenylene diisocyanate (MDI) as a curing agent, and a preparation method thereof. The method comprises the following steps: 4,4-MDI and organic solvent are added to a reaction kettle, heated to between 50 an d 90 DEG C and added with dehydrated polyol, and then react for 2 to 4 hours so as to prepare 4,4-MDI modifier; a mixture of 4,2'-MDI and 4,4'MDI is added and then cooled; and trimethylolpropane and the organic solvent are dripped and thermally insulated, and react for 1 to 6 hours, so as to obtain a product. The method modifies the 4,4-MDI and then blends the 4,4-MDI with the mixture of 4,2'-MDI and 4,4'-MDI and TMP for pre-polymerization, thereby solving the problem of manufacturing the prepolymer with two isomers of MDI in an arbitrary proportioning form. A series of produced prepolymers can meet different requirements of coatings and adhesives in the polyurethane industry on the curing agent, and have the advantages of wide application range, high strength, low toxicity, adjustable room-temperature curing speed, good storage stability, capability of obtaining the products with high solid content, and the like.

Owner:周建明

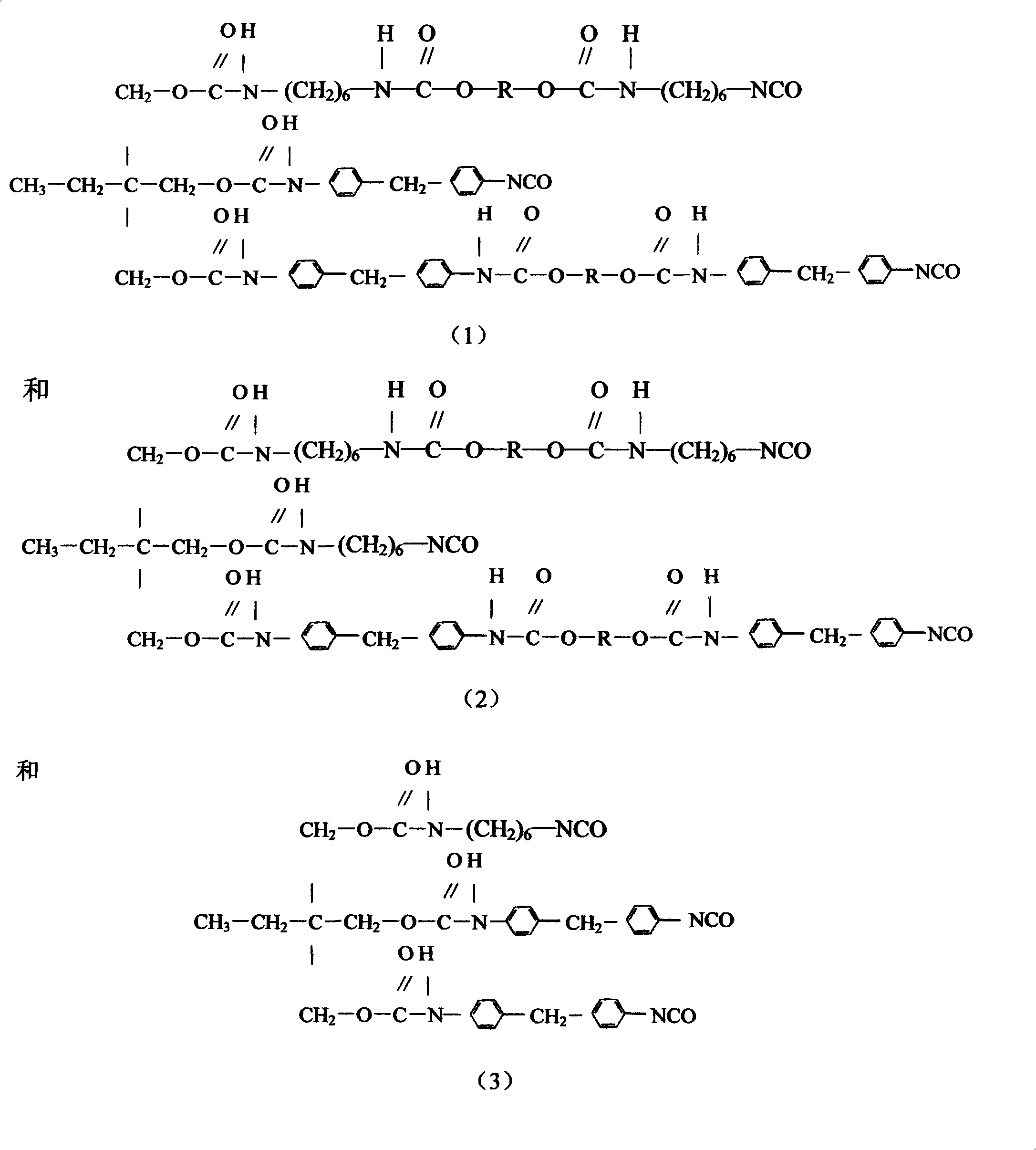

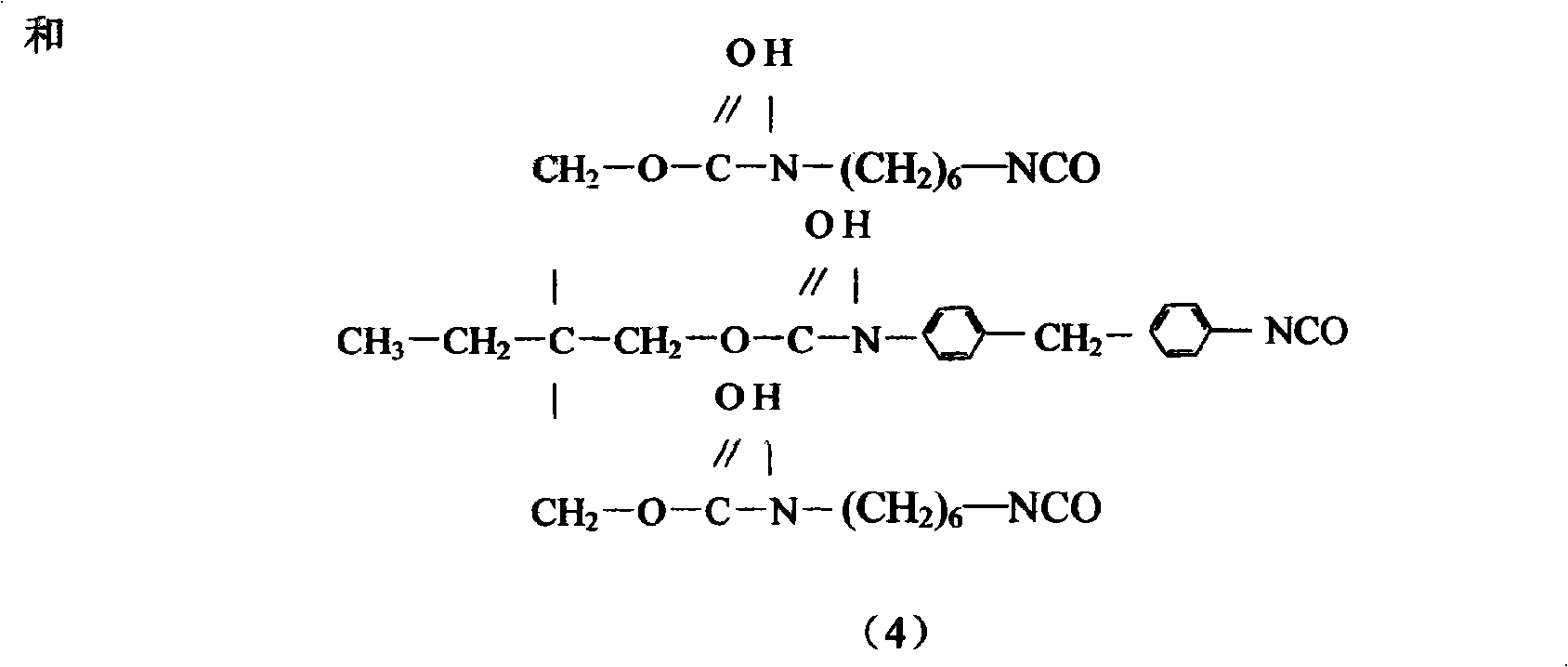

Mixed prepolymer of solidifying agent methyl diphenylene diisocyanate and 1,6-hexamethylene diisocyanate

The invention relates to a curing agent compound prepolymer composed of diphenylmenthane diisocyanate and 1, 6-hexamethylene diisocyanate and a preparation method thereof. The method comprises the following steps: MDI and an organic solvent are added and heated to 65 DEG C, polybasic alcohol is added and reacts with the mixture for 2 hours to 4 hours to obtain an MDI modifier; HID, an organic solvent and polybasic alcohol are added, heated and react for 2 hours to 5 hours, then the temperature is reduced below 70 DEG C, a TMP and organic solvent mixture is added, reaction at 70 DEG C lasts for 1 hour to 4 hours and 1 hour to 4 hours when the temperature is between 60 DEG C and 100 DEG C so as to obtain an HDI-MDI compound prepolymer curing agent. The method mixes and pre-polymerizes MDI and HDI, integrates the excellent performance of the two, produces a series of polyurethane curing agents with wide application range, high strength, good yellow-changing resistance, high curing speed, low toxicity, good storage stability and high solid content and has simple production technique.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

Bamboo-flavor lotus leaf sticky rice chicken health-care food and preparation method thereof

The invention discloses bamboo-flavor lotus leaf sticky rice chicken health-care food and a preparation method thereof. The bamboo-flavor lotus leaf sticky rice chicken health-care food is prepared from raw materials including sticky rice, chicken blocks, white spirit, bruised ginger, curry powder, light soy sauce, five-spice powder, sesame oil and the like. The color and the luster of the finished product are attractive; the texture is loose and soft; the soft, smooth, sweet and fragrant effects are achieved; the favor is tasty and refreshing but is not greasy; the nutrition is rich; the food is suitable for both young and old people. Particularly, the sticky rice and the chicken blocks are simultaneously steamed by a bamboo tube; after eating, the health-care food is soft, thoroughly cooked, fresh, fragrant, sticky and tender; the specific fragrance favor of the bamboo is also realized when the fragrance is realized; smoothness is realized while the lubricating mouthfeel is achieved. For the product production, the addition of other large-scale equipment is not needed on the basis of ordinary production; the management is easy; the production line change is easy; the economic benefits are high.

Owner:GUANGXI UNIV

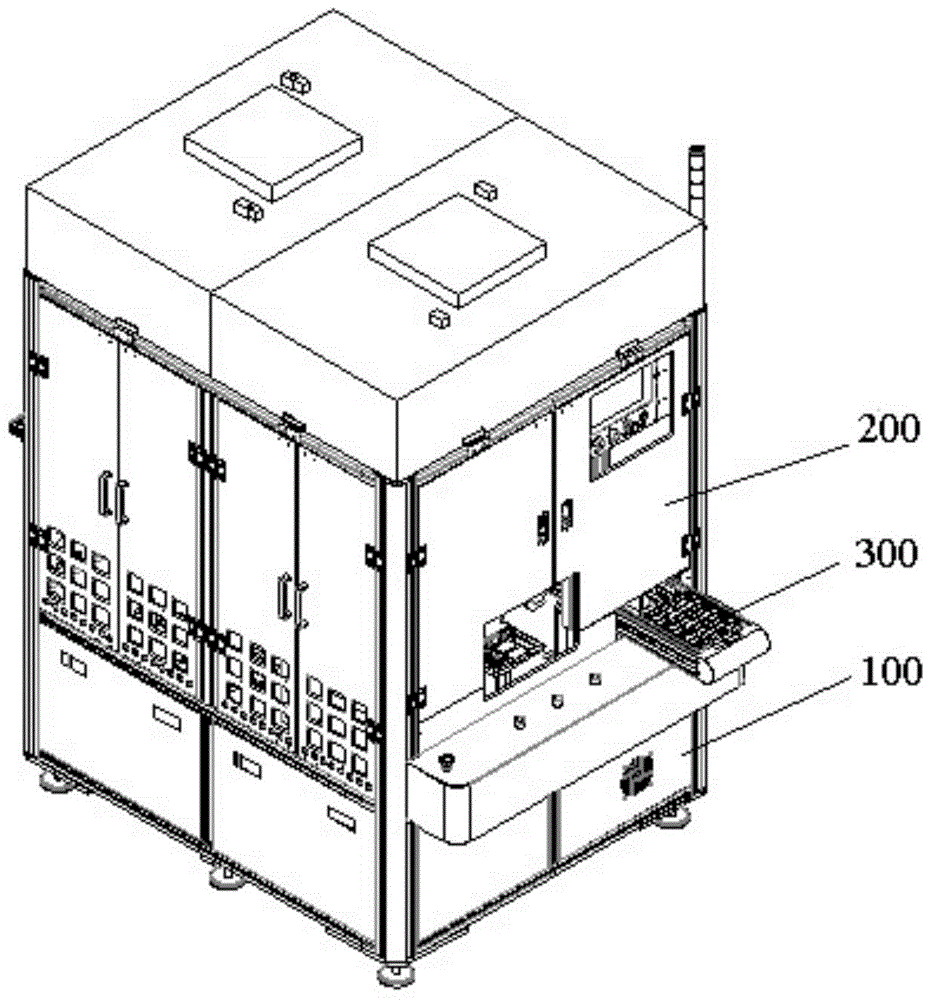

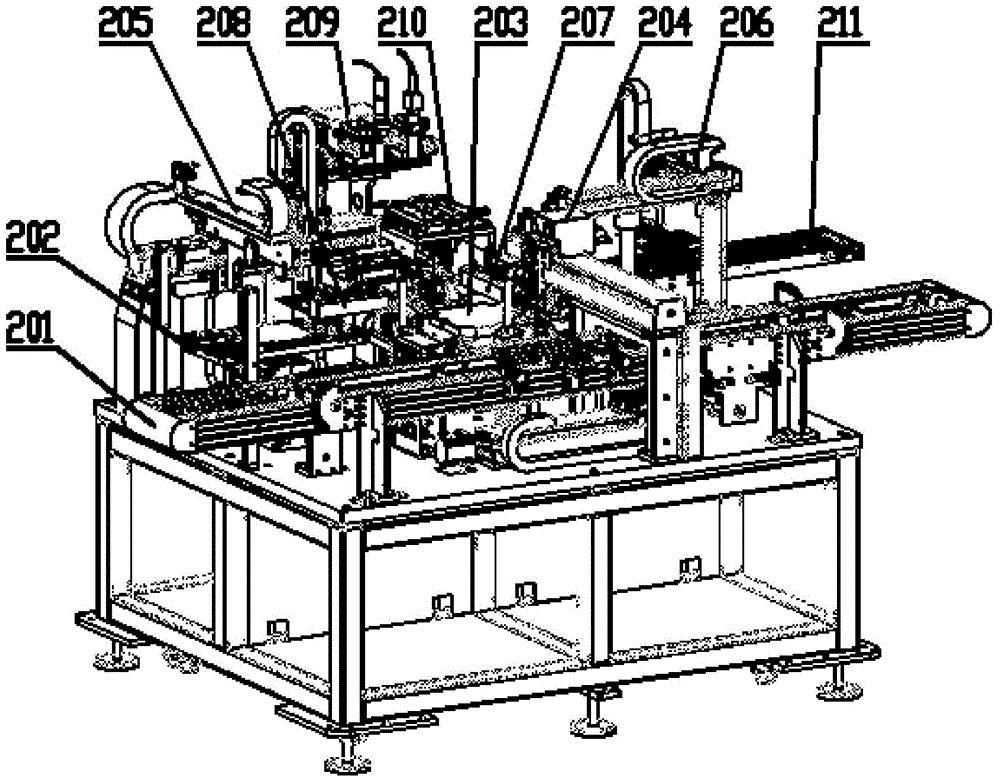

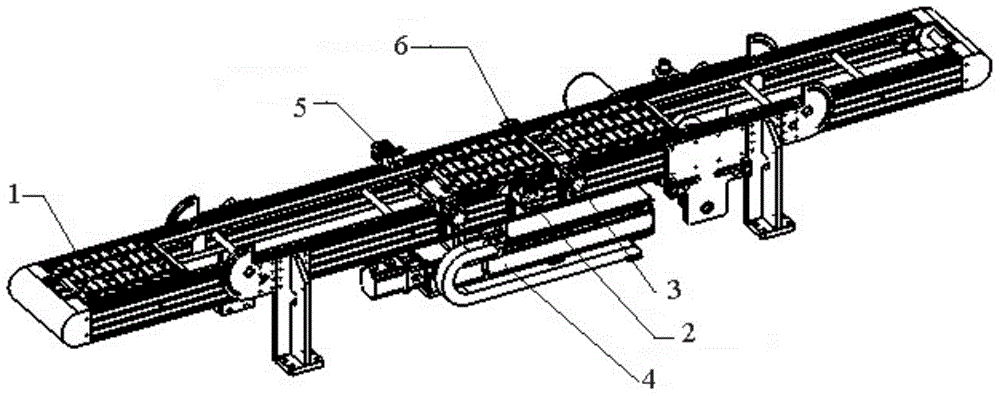

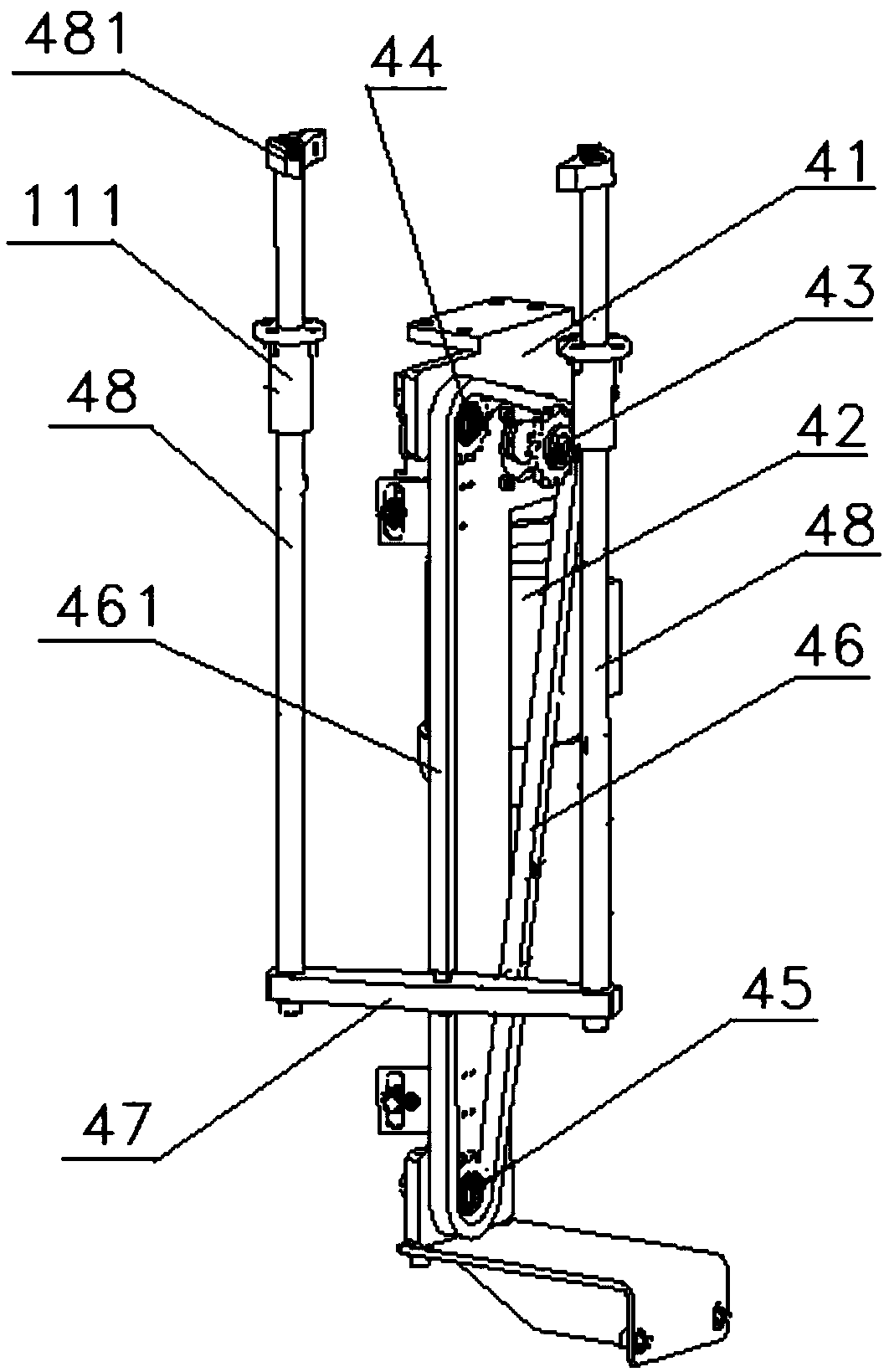

FPC light guide plate attaching machine

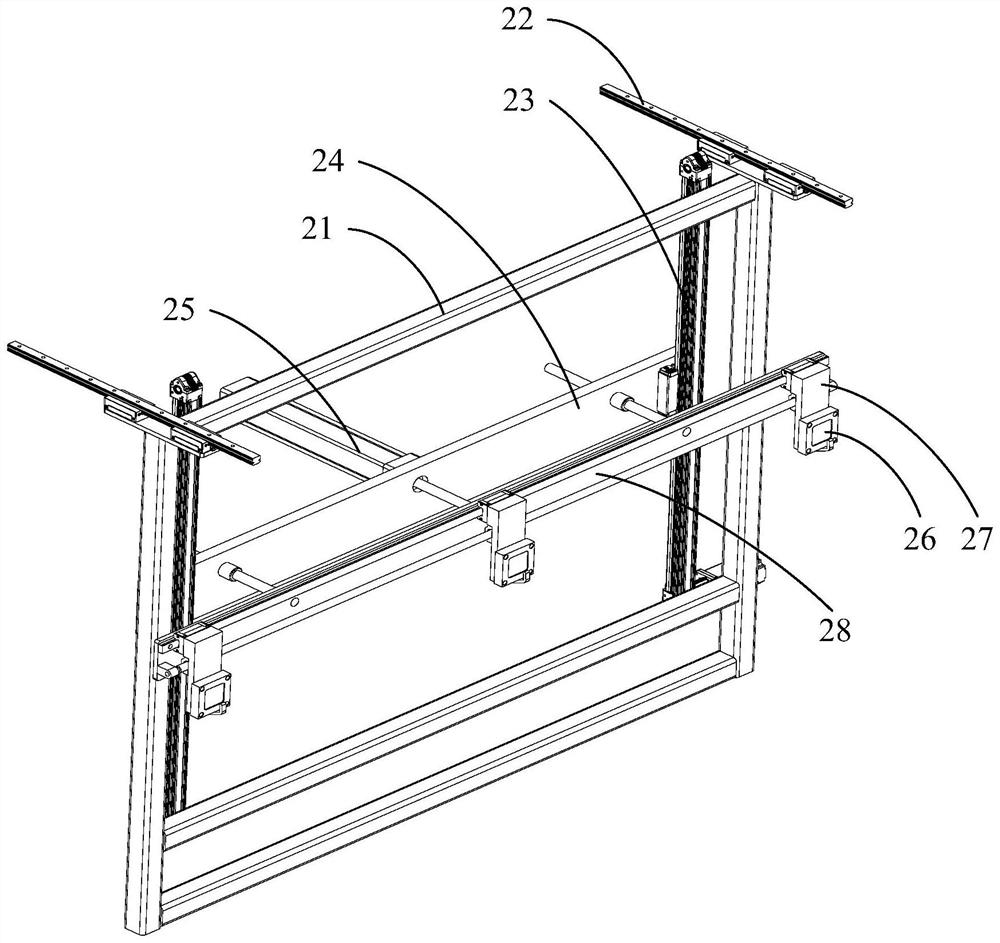

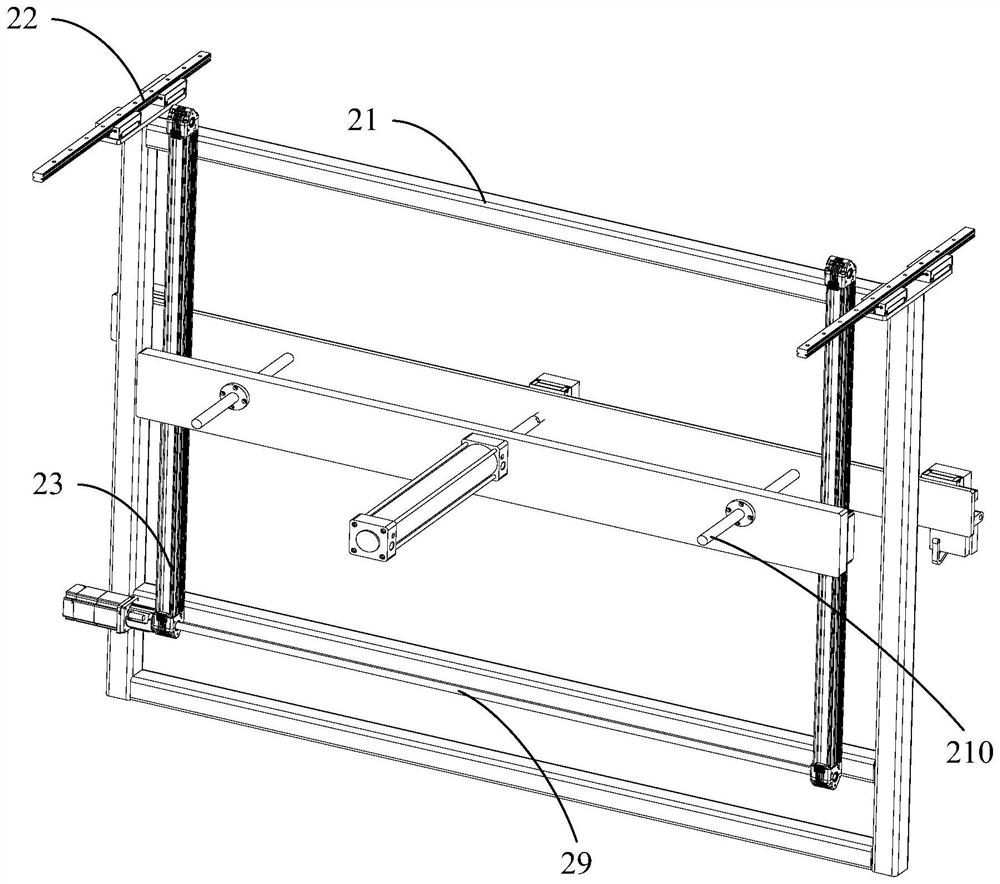

ActiveCN104816532ASolve the phenomenon of easy scratchesAdjustable pressureLaminationLamination apparatusLight guideEngineering

The present invention relates to the field of mobile phone backlight combination production equipment, particularly to an FPC light guide plate attaching machine, which comprises an upper cabinet and a lower cabinet, and comprises a first material feeding device fixedly arranged on the lower cabinet, a second material feeding device fixedly arranged on the lower cabinet, a third material feeding device fixedly arranged on the lower cabinet, a first material taking device fixedly arranged on the lower cabinet, a second material taking device fixedly arranged on the lower cabinet, a third material taking device fixedly arranged on the lower cabinet, a first destatic device fixedly arranged on the lower cabinet, a second destatic device fixedly arranged on the lower cabinet, a 2CCD image alignment device fixedly arranged on the lower cabinet, an FPC light guide plate attaching device fixedly arranged on the lower cabinet, a material discharge device fixedly arranged on the lower cabinet and an upper frame fixedly arranged on the lower cabinet, wherein the first material taking device, the second material taking device, the third material taking device, the 2CCD image alignment device, and the FPC light guide plate attaching device are positioned above the first material feeding device, the second material feeding device, and the third material feeding device. According to the FPC light guide plate attaching machine of the present invention, the technical disadvantages in the existing manual work can be overcome, and the productivity can be increased; the manual attaching is completely not required, the accurate parameters can be obtained, production switching is convenient, and the efficiency is high; and the problems of not high uniformity and low efficiency of the manual work can be solved.

Owner:SHENZHEN JIYIN TECH

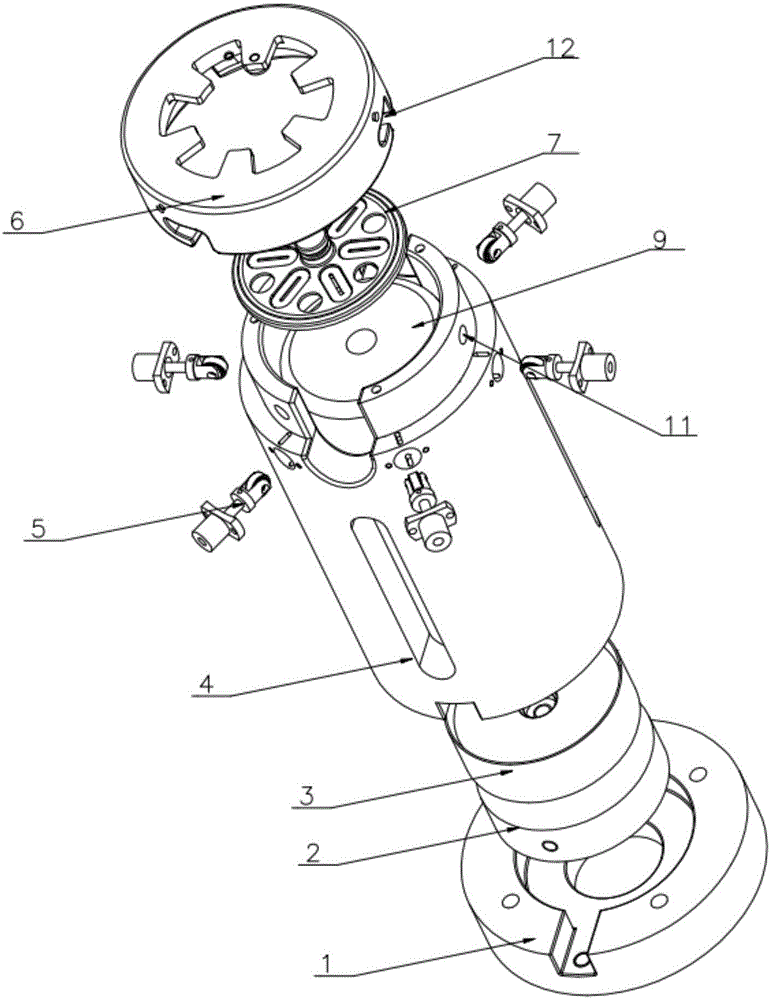

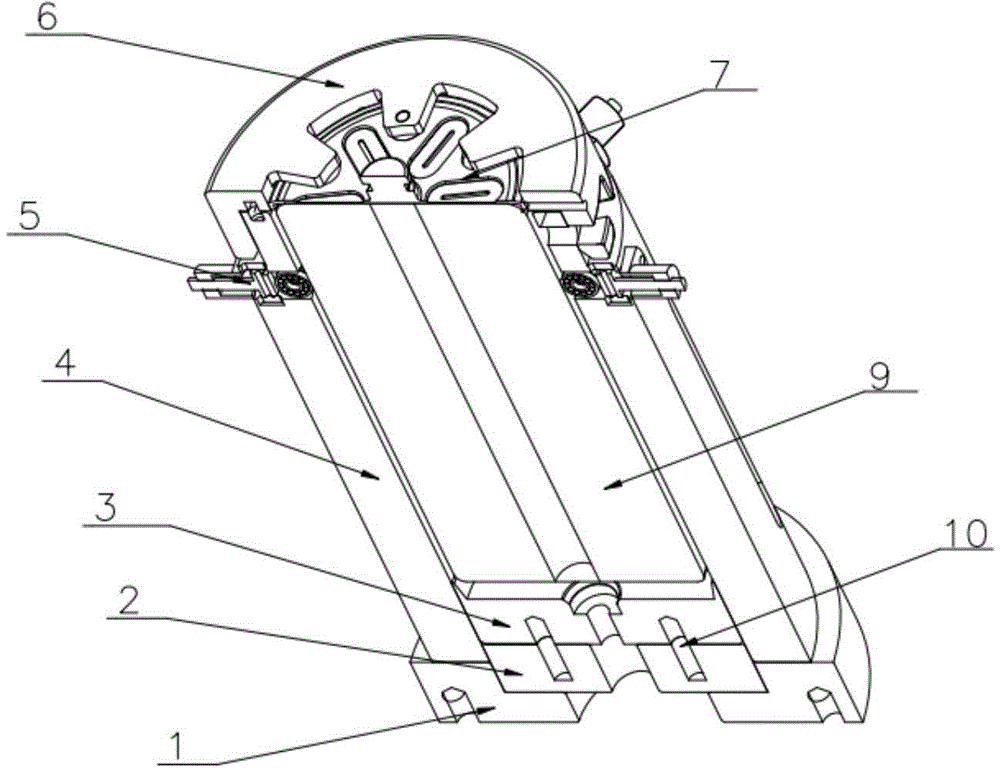

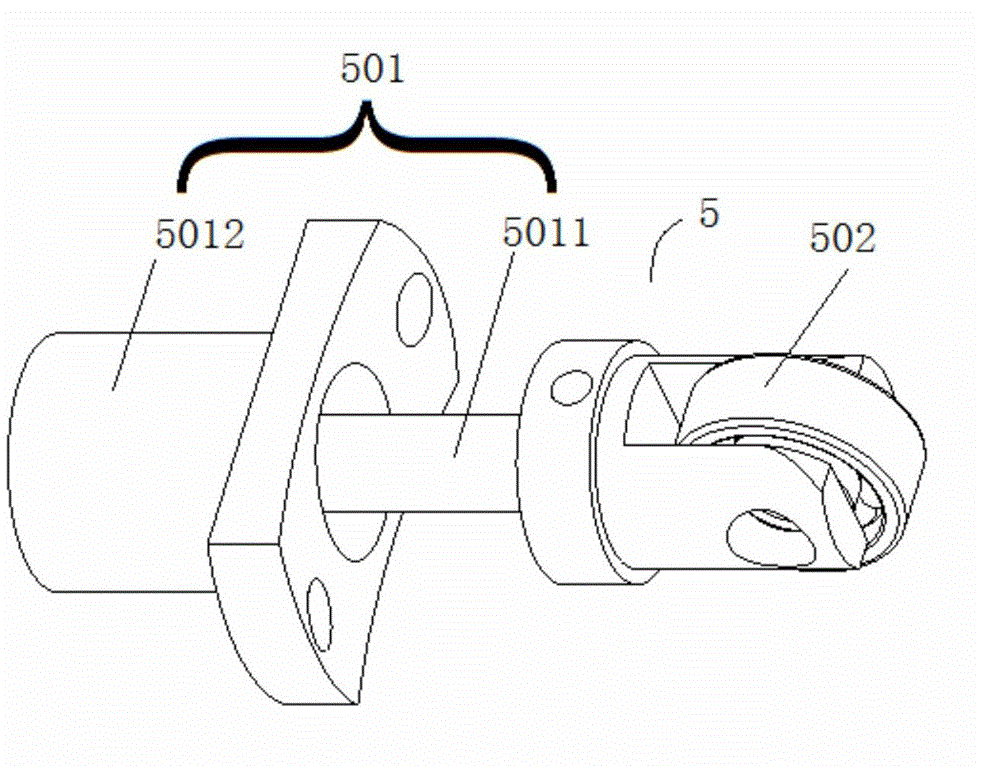

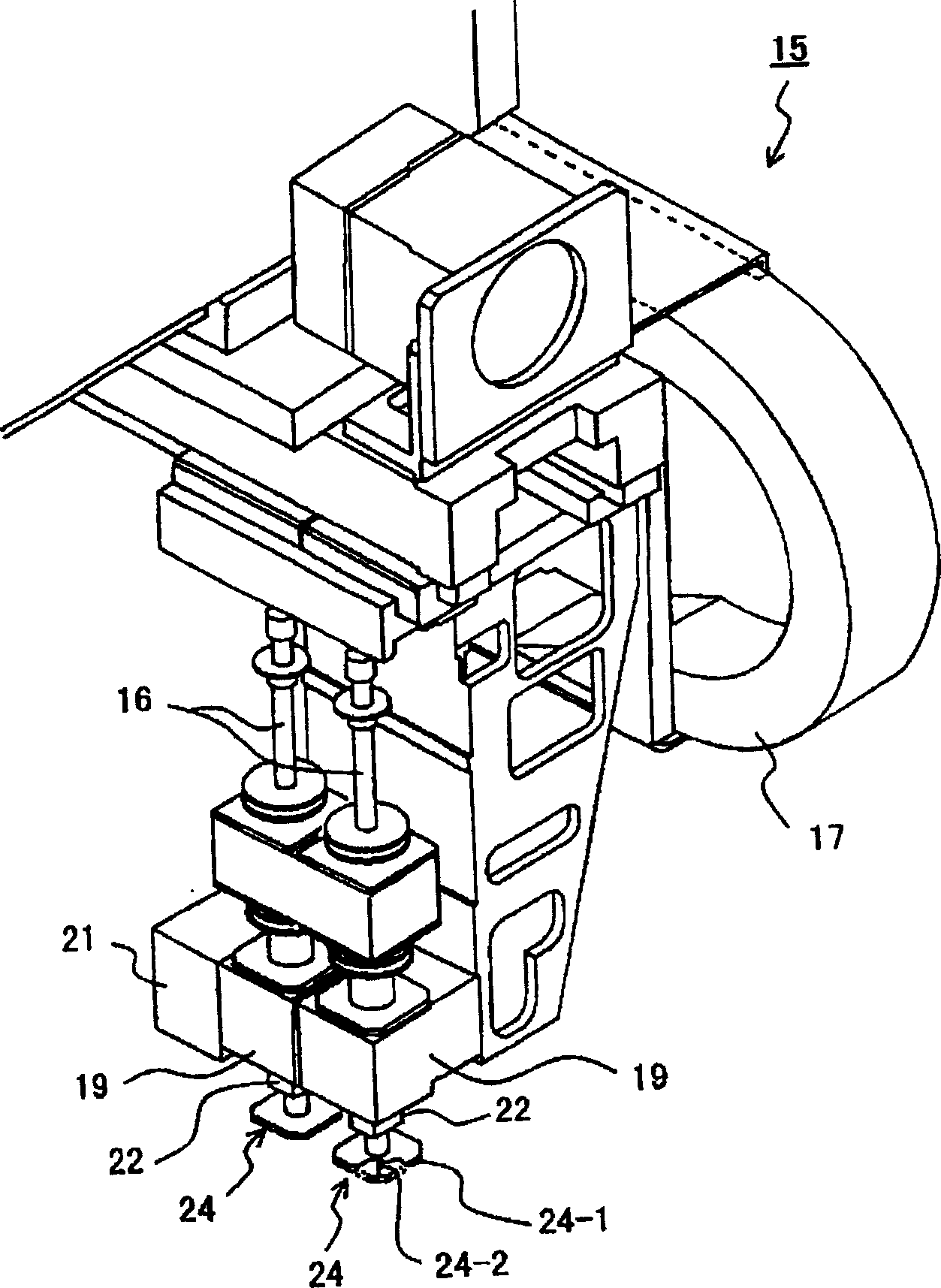

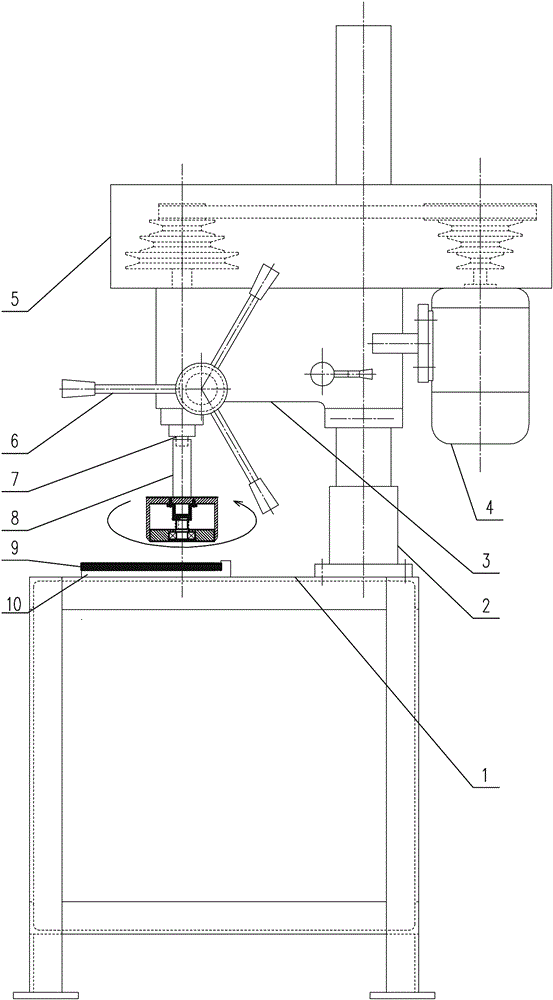

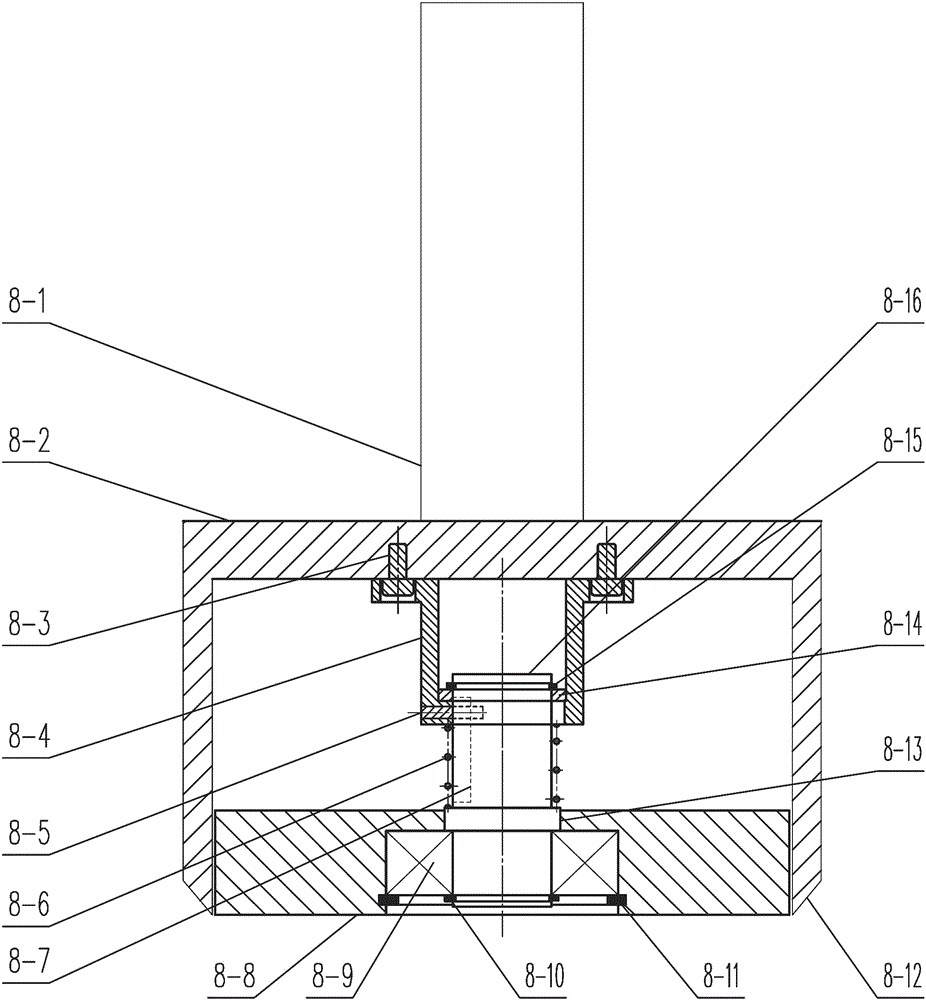

Current collecting piece welding device, lower current collecting piece welding device and fixture of lower current collecting piece welding device

ActiveCN103551774APrecise positioningEasy to change productionWelding/cutting auxillary devicesAuxillary welding devicesSupercapacitorConductor Coil

The invention provides a current collecting piece welding device, a lower current collecting piece welding device and a fixture of the lower current collecting piece welding device. The fixture comprises a base, a guide block, a winding core support block, a fixture barrel and an upper cover; a centering groove and a through hole are formed in the center of the support block; the fixture barrel is arranged outside the guide block and the winding core support block in a covering manner; the fixture barrel is provided with centering parts; a through hole needed for laser welding is formed in the bottom wall of the upper cover, and fastener grooves are formed in the side wall; bosses are arranged on the peripheral well of the fixture clamp. The fixture has the advantages that since the support block with the center provided with the centering groove and the fixture barrel provided with the centering parts are arranged at two ends of a winding core of a supercapacitor to be processed respectively, the winding core of the supercapacitor to be processed can be positioned from the upper and lower portions accurately; meanwhile, by the aid of the support block, the fixture is suitable for welding of supercapacitor winding cores and current collecting pieces with different heights and convenient for changing the line of production, and labor-hour and cost are saved.

Owner:TIG TECH CO LTD

Method for producing multifunctional differentiated polyester fiber

InactiveCN107090606AReduce lossImprove continuityMonocomponent polyesters artificial filamentFiberPolyethylene terephthalate glycol

The invention relates to a method for producing multifunctional differentiated polyester fiber. The method comprises the following steps that raw materials of purified terephthalic acid and ethylene glycol are firstly subjected to an esterification reaction in an esterification kettle to obtain a dimethyl terephthalate oligomer, then mixtures obtained after different modifiers are added into the dimethyl terephthalate oligomer on line separately through a pipeline are delivered to a first pre-polycondensation kettle, a second pre-polycondensation kettle and a third pre-polycondensation kettle separately to obtain pre-polymers of a certain viscosity, then the pre-polymers are delivered to a first final polycondensation kettle, a second final polycondensation kettle and a third final polycondensation kettle to obtain multifunctional and differentiated melt, and subsequently pelletizing or direct spinning is conducted. In the method for producing the multifunctional differentiated polyester fiber, a 'one head and three tails' technological process in a three-kettle procedure technology is adopted, the heat loss is effectively reduced, electric energy loss of electric equipment is reduced, more energy is saved, and the running cost is lower; the equipment layout is more compact, and the operation space is efficiently utilized.

Owner:TONGKUN GRP +1

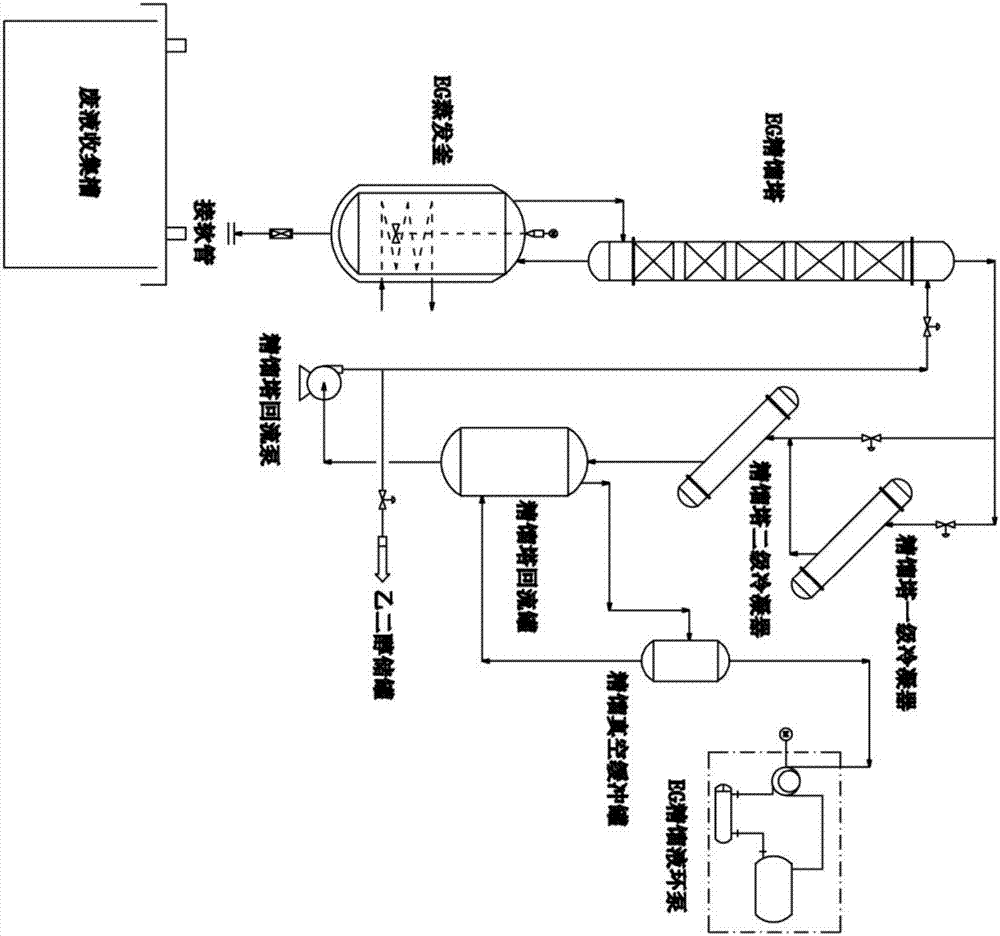

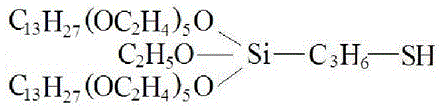

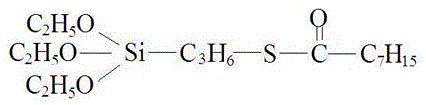

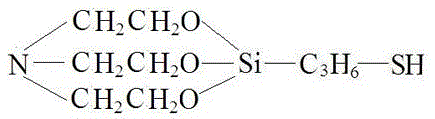

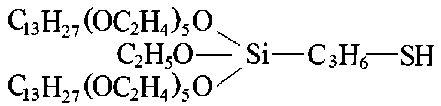

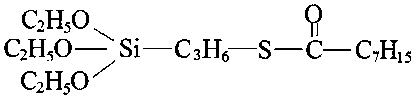

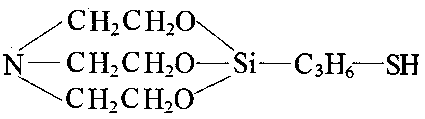

Method for preparing mercaptosilane coupling agent by using channel reactor

ActiveCN105601661AGuarantee continuous and stable operationIncrease in sizeGroup 4/14 element organic compoundsSolventImpurity

The invention provides a method for preparing a mercaptosilane coupling agent by using a channel reactor. In a solvent, a channel reactor is utilized to prepare the mercaptosilane coupling agent. The structural general formula of the mercaptosilane coupling agent is XmSiC3H6S(C=O)nY, wherein each X is independently alkyl group, alkoxy group, hydroxy group, R(OR')LO-, -ORO- or N(RO-)3, and at least one X is alkoxy group, hydroxy group or N(RO-)3; Y is hydrogen or alkyl group; R and R' are respectively independently straight-chain or branched-chain alkyl group; the average value of L is 1-30; m is 1, 2 or 3; and n is 0 or 1. The corrected diameter of the channel reactor channel is one micrometer to several centimeters; and the channel reactor is connected with an after-treatment device. The method solves the problems of long reaction period, poor stability, existence of impurity polymers and the like in the large-size reactor, and especially reduces the odor caused by the large-size reactor production.

Owner:南京曙光新材料有限公司

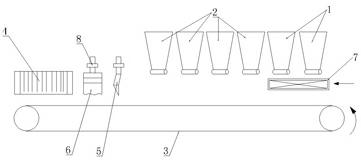

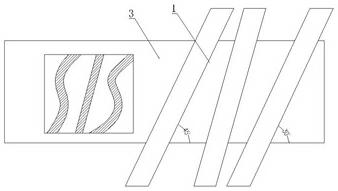

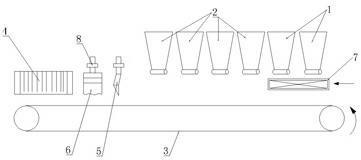

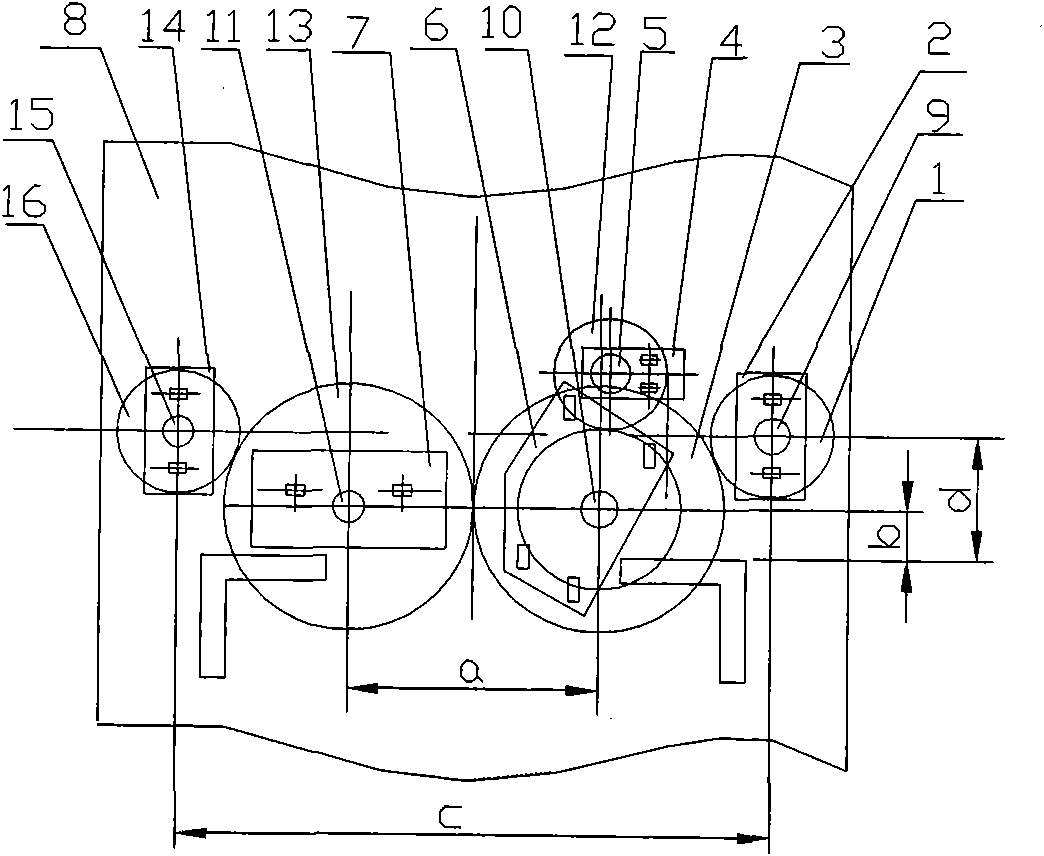

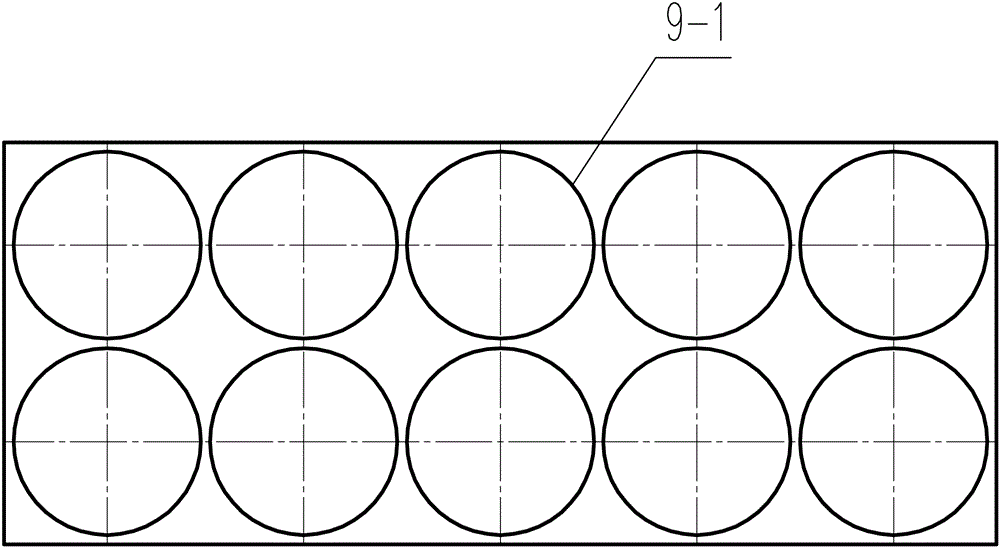

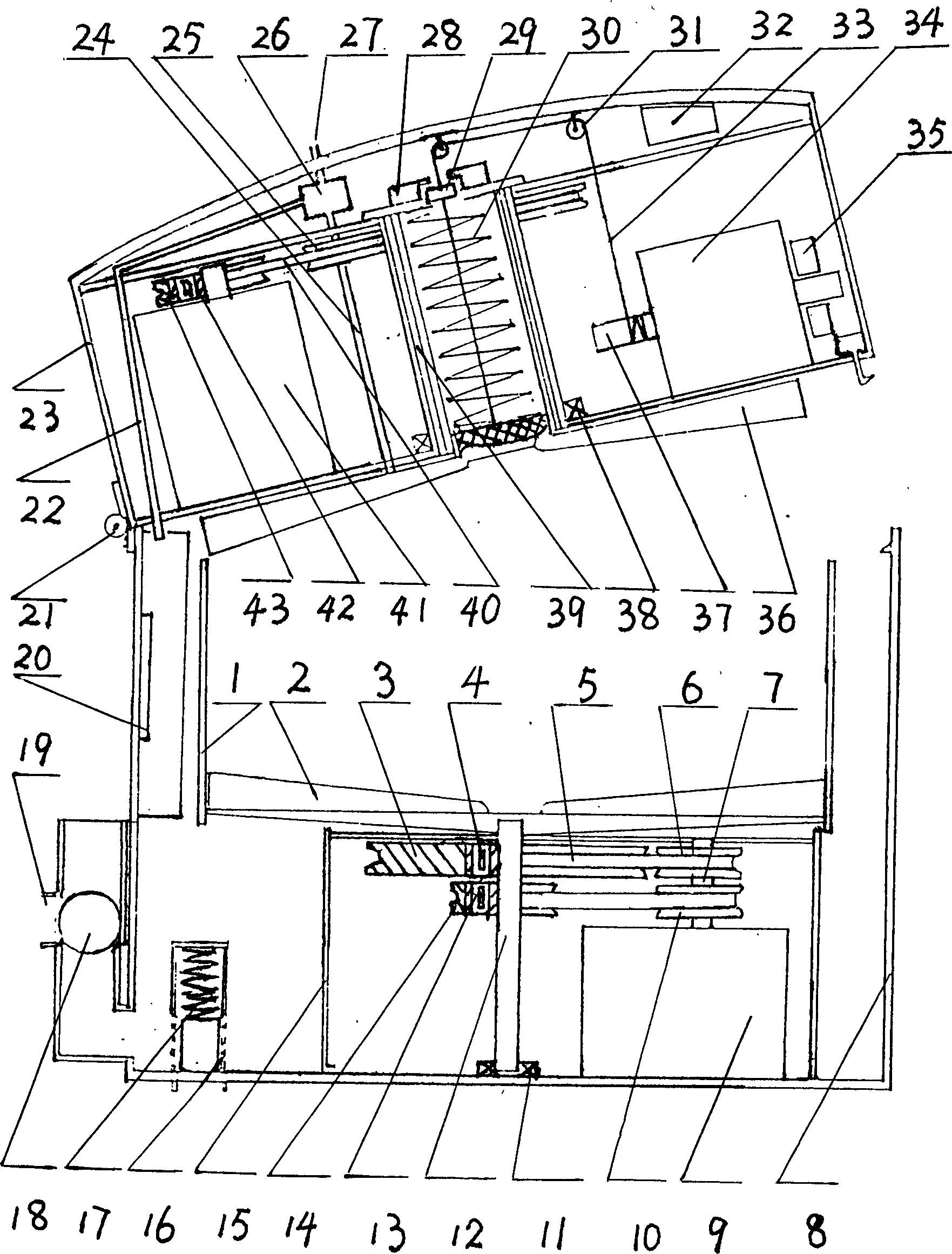

Material distributing method and equipment of polished tiles

ActiveCN102248595AEasy to replaceNatural texture decorative effectCeramic shaping apparatusBand shapeLamellar Pattern

The invention discloses a material distributing method and equipment of polished tiles. The method is characterized by comprising the following steps of: a. preparing materials: respectively distributing line materials and plus materials into a line material feeding hopper and a plus material feeding hopper which are arranged in the moving direction of a main conveyor belt; b. after the line materials are sieved by a vibration sieve, distributing the sieved line materials on the main conveyor belt to form a banded thin-layered line material, and distributing the plus materials on the main conveyor belt by virtue of the intermittent opening and closing of the plus material feeding hopper to form a banded thick-layered plus material; c. enabling the banded thick-layered plus material to be formed into linear lamellar patterns with lines by virtue of the intermittent blocking action of a linear baffle, and warping the linear material layer into a wavy material layer by virtue of the intermittent blocking action of a wavy baffle; and d. transferring the effect of the wavy material layer into a press mould by virtue of a texture fidelity feeding grate. In the invention, natural and delicate texture effects with rich layers in imitation of natural stones are formed by virtue of the combination of the formula and process provided by the invention; the equipment is easy to modify, so the equipment can be flexibly suitable for design modification requirements of products; and the product conversion cycle is shortened, and the loss and production cost are reduced.

Owner:FOSHAN DONGPENG CERAMIC +2

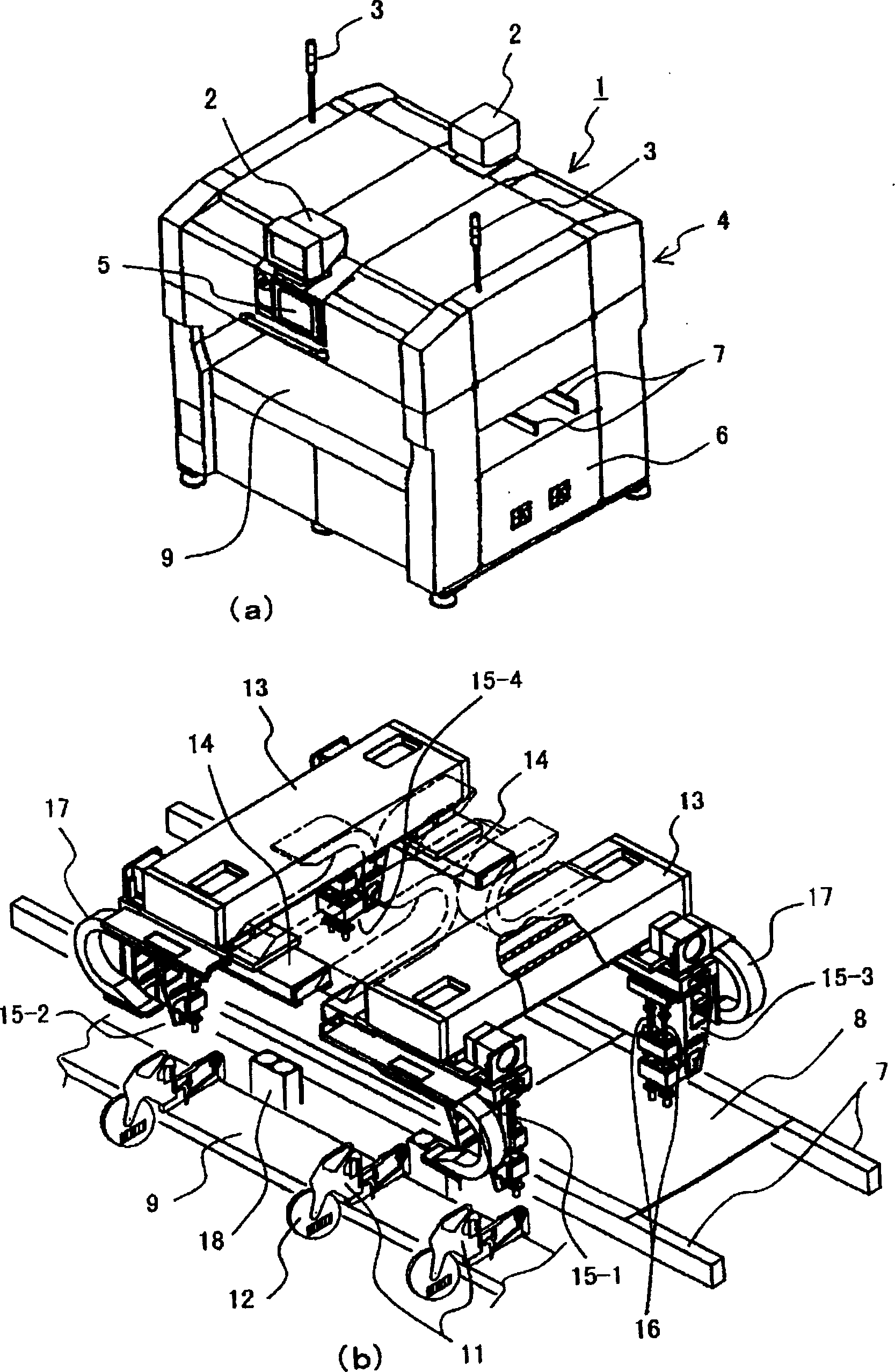

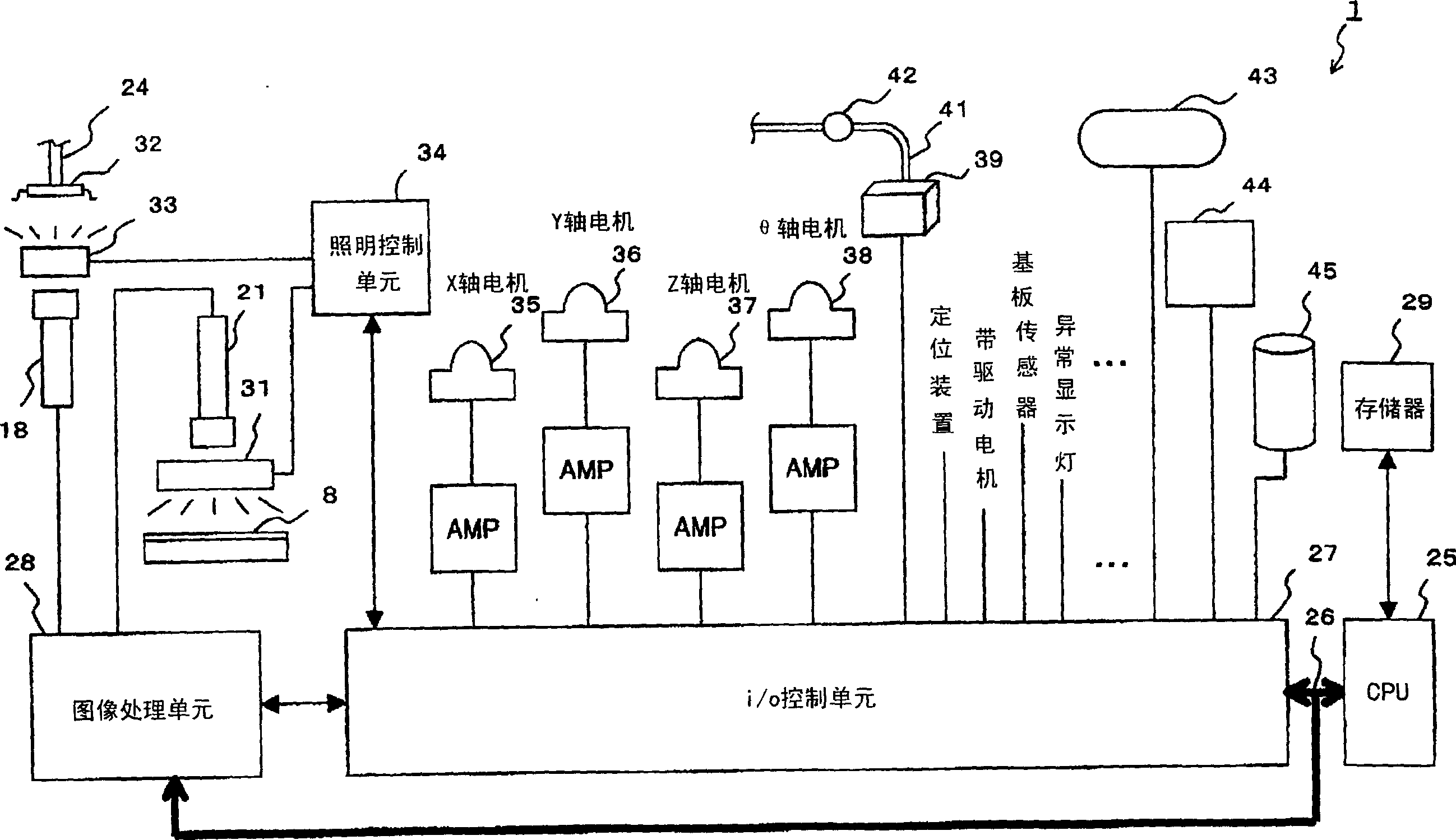

Parts loading device and demonstration method for position adjustment

InactiveCN1828462AShorten production changeover timeImprove work efficiencyProgramme controlData processing applicationsEngineeringChange positions

PROBLEM TO BE SOLVED: To provide a component mounting apparatus for shortening an arrangement work at the time of switching the kind of a substrate to be produced, and to provide a method of teaching an arrangement changing position thereof. ŽSOLUTION: In the arrangement changing work, a CPU determines whether or not comparison in arrangement data between a kind A substrate after arrangement changing with a type B substrate before the arrangement changing has been all completed (S1). If it has not completed, the CPU extracts one type of component in incompletion from the arrangement data of the kind A (S2), and determines whether or not the arrangement data of the type B includes a component coinciding with the extracted component (S3). If not included (No in S3), the processing returns to S1, and if included (Yes in S3), the CPU further determines whether or not a feeder number matches (S4), and if it coincides (Yes in S4), "no move (common)" is displayed on a display screen (S5) and the processing returns to S1. If the feeder number does not match (No in S4), the feeder number of a moving source (kind B) is displayed on the display screen (S6) and the processing returns to S1. Ž

Owner:YAMAGATA CASIO CO LTD

Colour hollow glass brick production process

InactiveCN1640831AFast productionEasy to change productionGlass reforming apparatusHollow corePropeller

The color hollow glass brick producing process is completed in an improved production apparatus with material channel coloring system separated into five areas with individual temperature regulators, including color material melting area, stirring area, cooling area, temperature regulating area and material basin. The melting area has color material throwing unit, and the stirring area has five separate detachable propeller stirrers. The production process has raised temperature of the work part and the different areas of the coloring system and regulated flame atmosphere for obtaining high quality color hollow glass brick product.

Owner:德州振华装饰玻璃有限公司

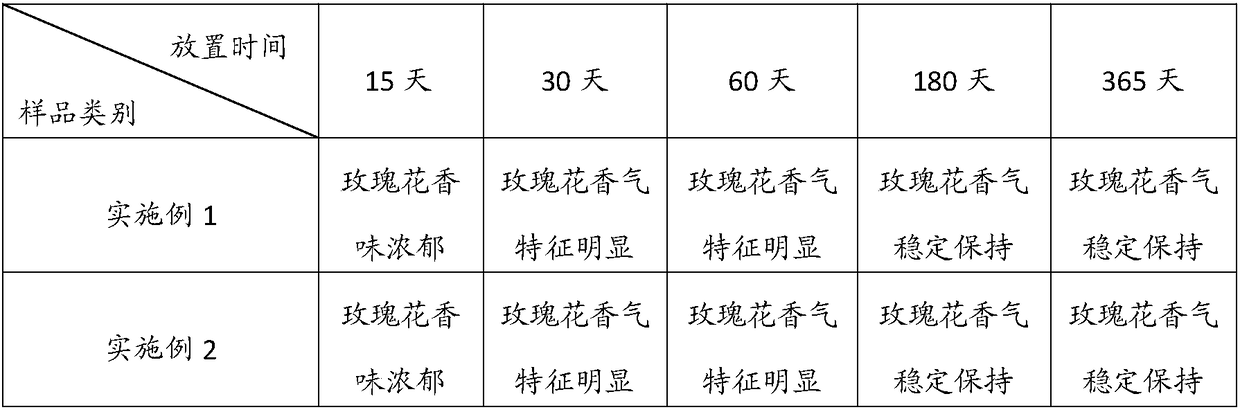

Rose scented cigarette paper and preparation method thereof

InactiveCN109247614AAvoiding Dispersion Loss ProblemsWill not polluteCigar manufacturePaper coatingFiberCombustion

The invention provides rose scented cigarette paper, comprising the following raw materials in parts by mass: 65-85 parts of fibers, 15-40 parts of filler, 0.5-8 parts of combustion improver, and 0.1-3 parts of microcapsule powder of rose essential oil, wherein the rose essential oil microcapsule powder comprises a rose essential oil capsule core and a wall material coating the surface of the capsule core, and the mass content of the rose essential oil in the rose essential oil microcapsule powder is 45% or less. According to the invention, the rose scented cigarette paper is prepared by usingthe rose essential oil microcapsule powder as a raw material, and the rose essential oil microcapsule powder is a thermal cracking microcapsule, thereby ensuring that the microcapsule containing therose essential oil is ruptured during combustion of the cigarette and releases scent. Therefore, the rose essential oil has the advantages of low volatility, low transferability and thermal stability,overcomes the shortcomings of traditional scented components, such as easy volatilization and unstable effects, and ensures a unique suction taste of a rose scented cigarette.

Owner:云南红塔蓝鹰纸业有限公司

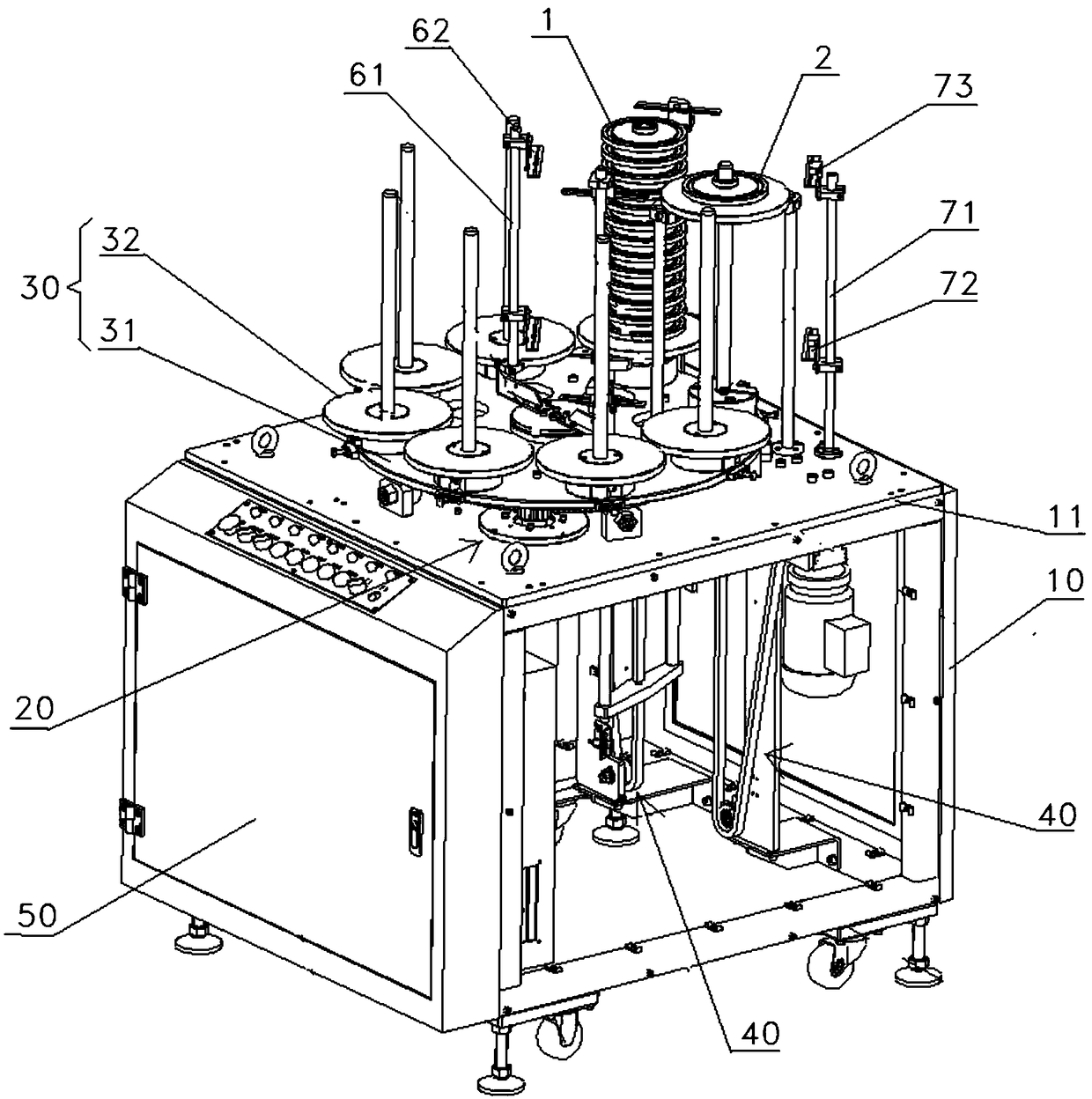

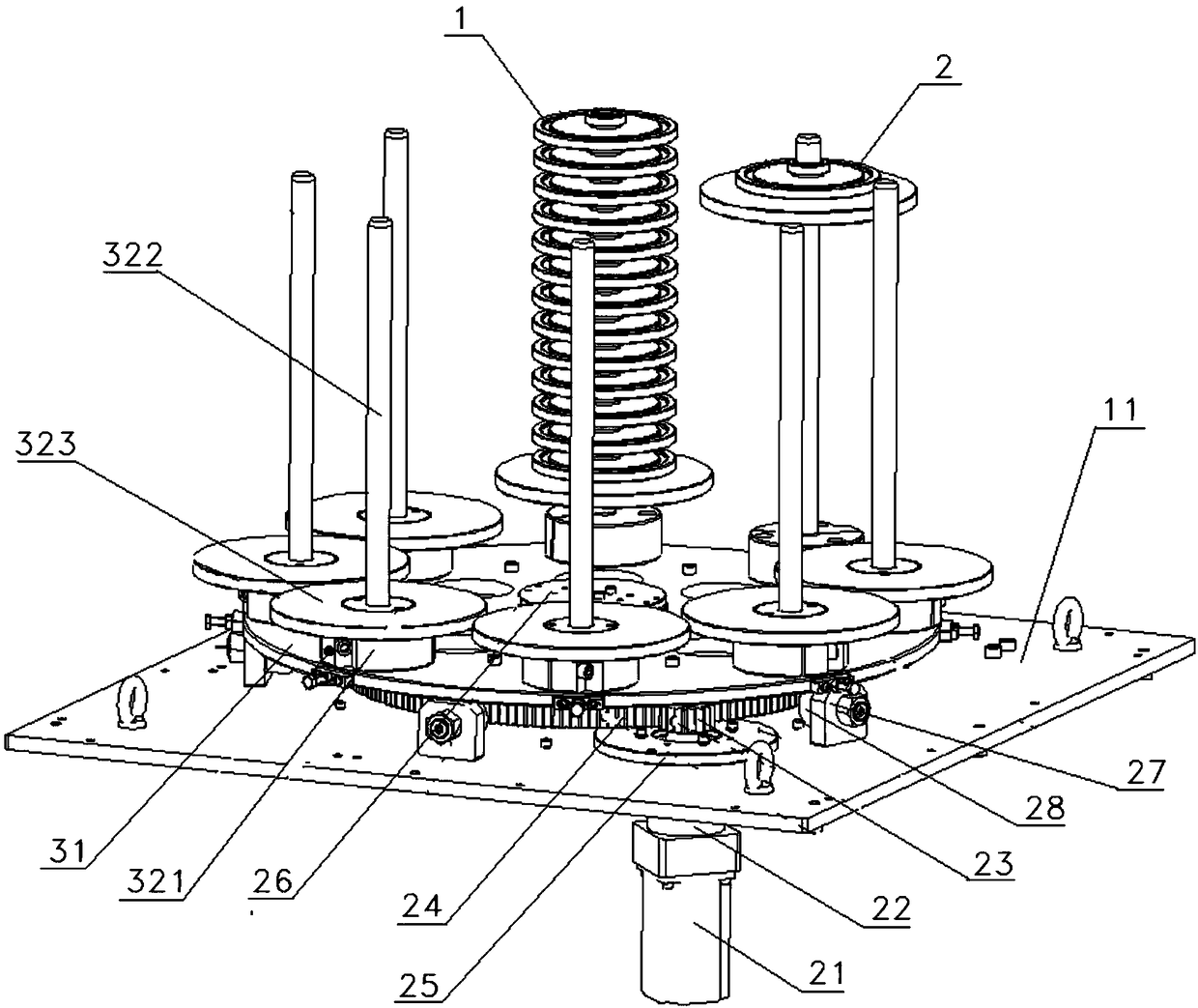

Rotating type feeding and discharging machine

PendingCN108637776AHigh degree of automationGuaranteed uptimeMetal working apparatusEngineeringRotating disc

The invention discloses a rotating type feeding and discharging machine which comprises a rack provided with a supporting table, a driving mechanism, a rotation mechanism and lifting mechanisms. The driving mechanism, the rotation mechanism and the lifting mechanism are installed on the supporting table. The rotation mechanism comprises a rotary disc installed on the supporting table, and materialsupporting assemblies evenly distributed on the rotating disc. The driving mechanism drives the rotary disc to rotate. Each material supporting assembly comprises a positioning rod connected to the rotary disc, and a tray arranged on the positioning rod in a sliding manner. One material supporting assembly is located on the feeding station, and the adjacent material supporting assembly is locatedon the discharging station. The two lifting mechanisms are arranged and are arranged corresponding to the feeding station and the discharging station correspondingly. Each lifting mechanism comprisesa driving part installed on the supporting table and a lifting rod, wherein the driving part drives the lifting rod to move, and the lifting rod can slide to the position behind the supporting tableto abut against the lower end of the corresponding tray. The rotating type feeding and discharging machine is high in automation degree, stable and reliable in running, convenient in yield changing, capable of saving labor, easy to operate and convenient to use.

Owner:浙江陀曼智能科技股份有限公司

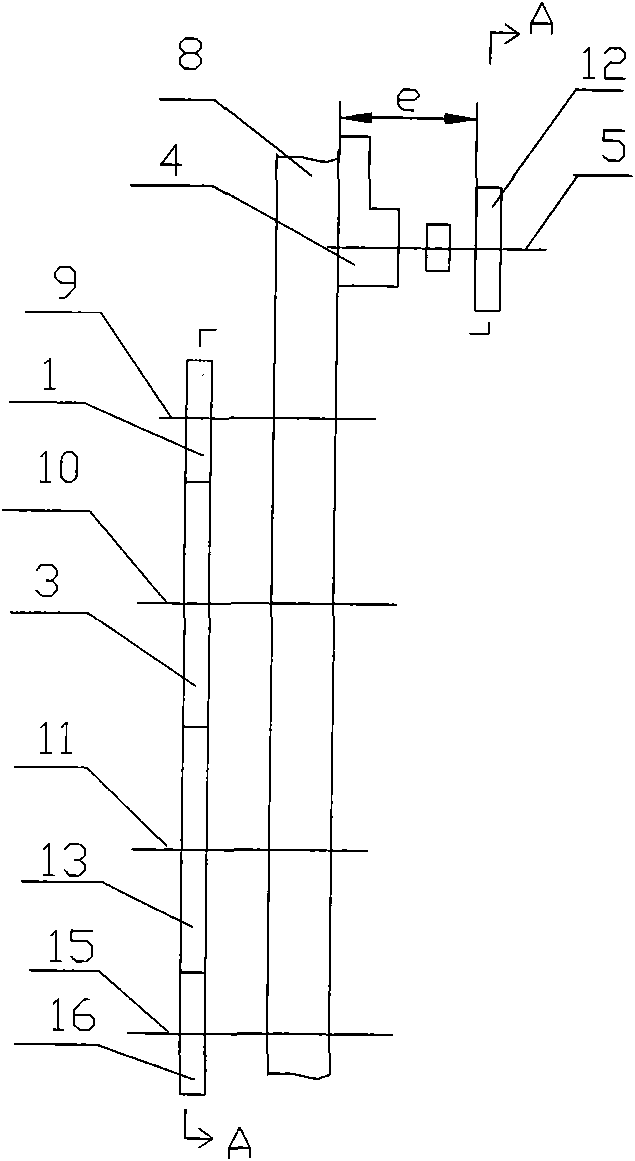

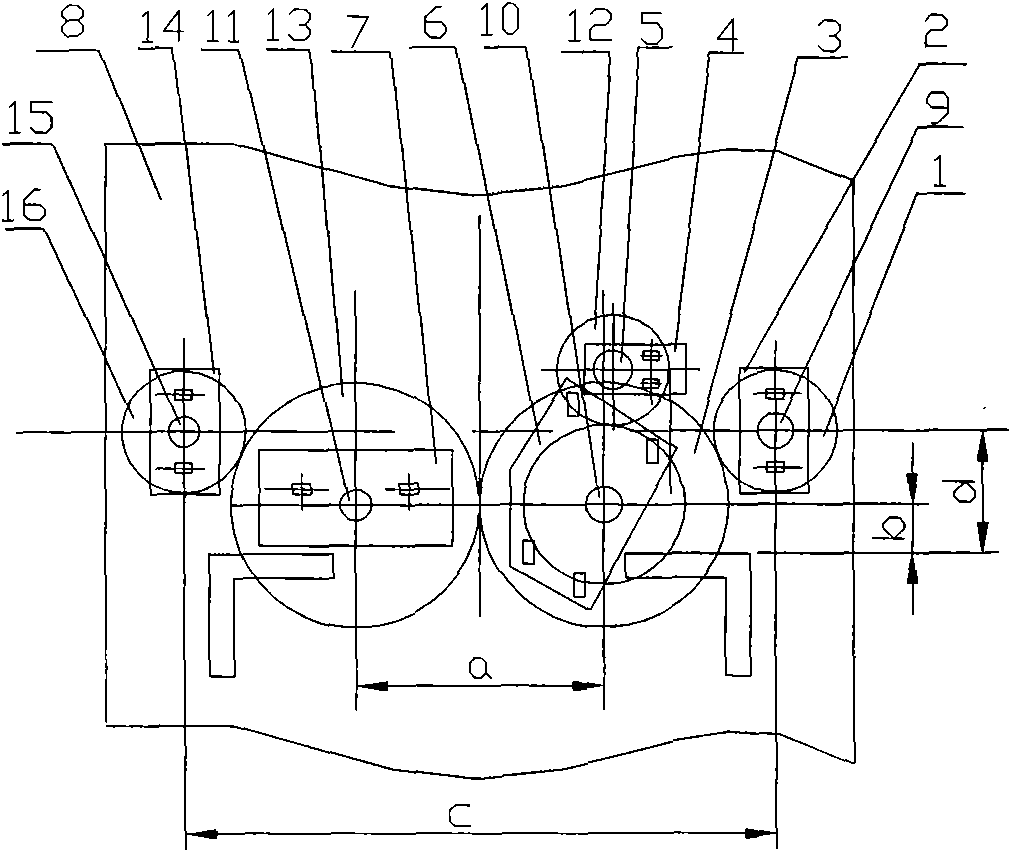

Drawing transmission device of spinning frame

InactiveCN102021684AReasonable layoutEasy to changeDrafting machinesContinuous wound-up machinesYarnDrive shaft

The invention relates to a drawing transmission device of a spinning frame. A right front roller bearing seat (2) is provided with a right front roller head one-section shaft (9); a right front roller gear (1) is arranged on the right front roller head one-section shaft (9); a right butterfly tooth shaft (10) is provided with right butterfly teeth (3); the right front roller gear (1) and the right butterfly teeth (3) are meshed; a left butterfly tooth shaft (11) is provided with left butterfly teeth (13), and the right butterfly teeth (3) are meshed with the left butterfly teeth (13); a left front roller head one-section shaft (15) is provided with a left front roller gear (16) which is meshed with the left butterfly teeth (13); and a roller transmission bearing seat (4) is provided with a middle rear roller transmission shaft (5) which is provided with a middle rear roller transmission gear (12), the right butterfly teeth (13) are connected with the middle rear roller transmission gear (12) by a gear. By utilizing the device, the problems of instable degree transfer and spinning tension are solved, yarn breaks are reduced, and spinning quality is improved.

Owner:JINGWEI TEXTILE MASCH CO LTD

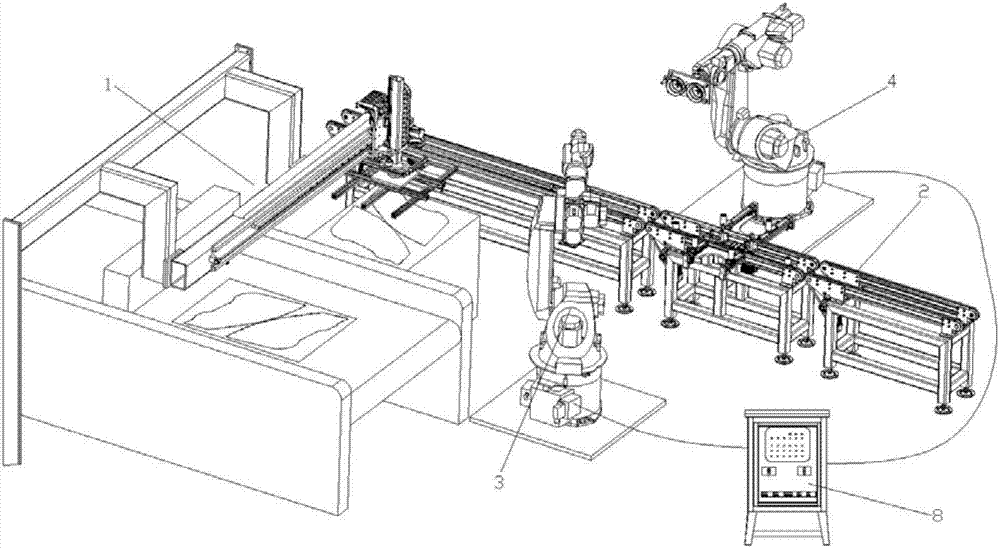

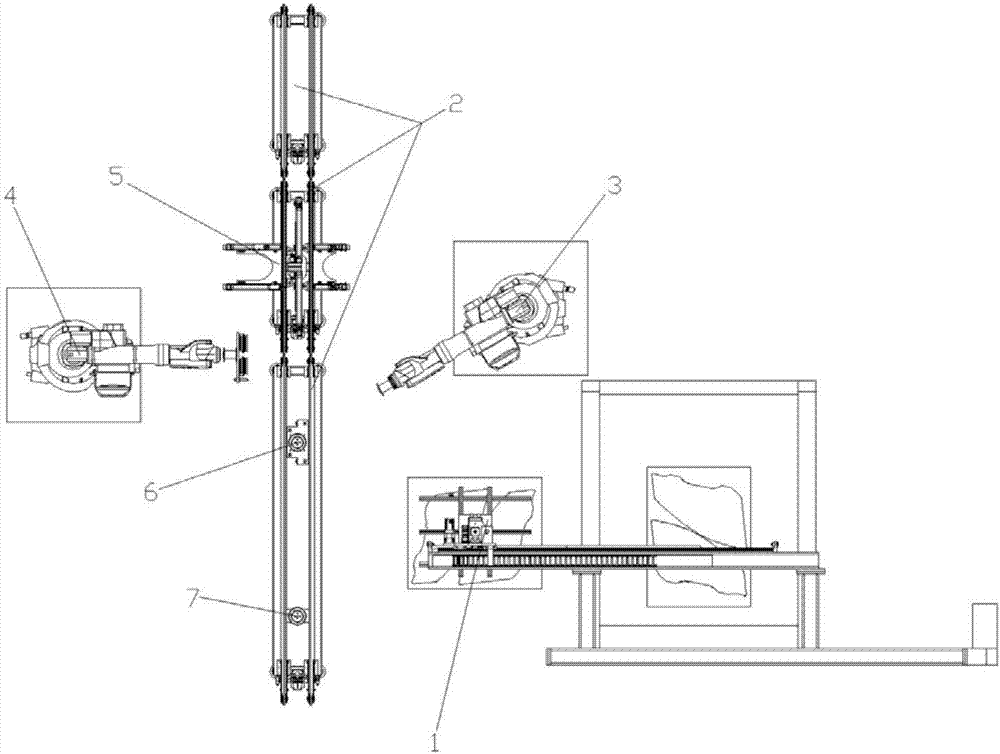

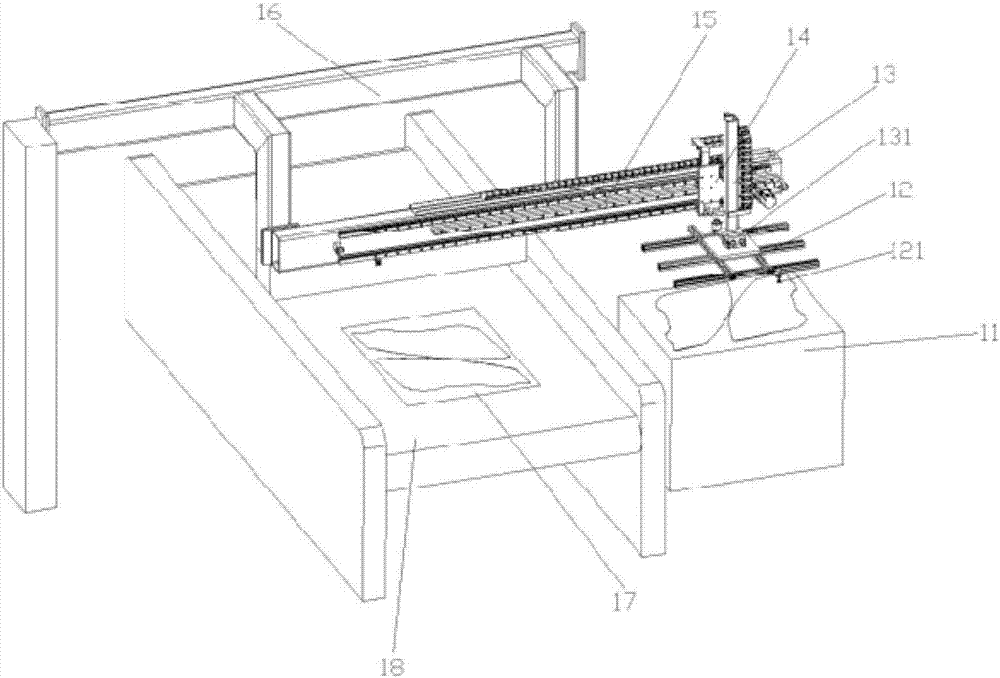

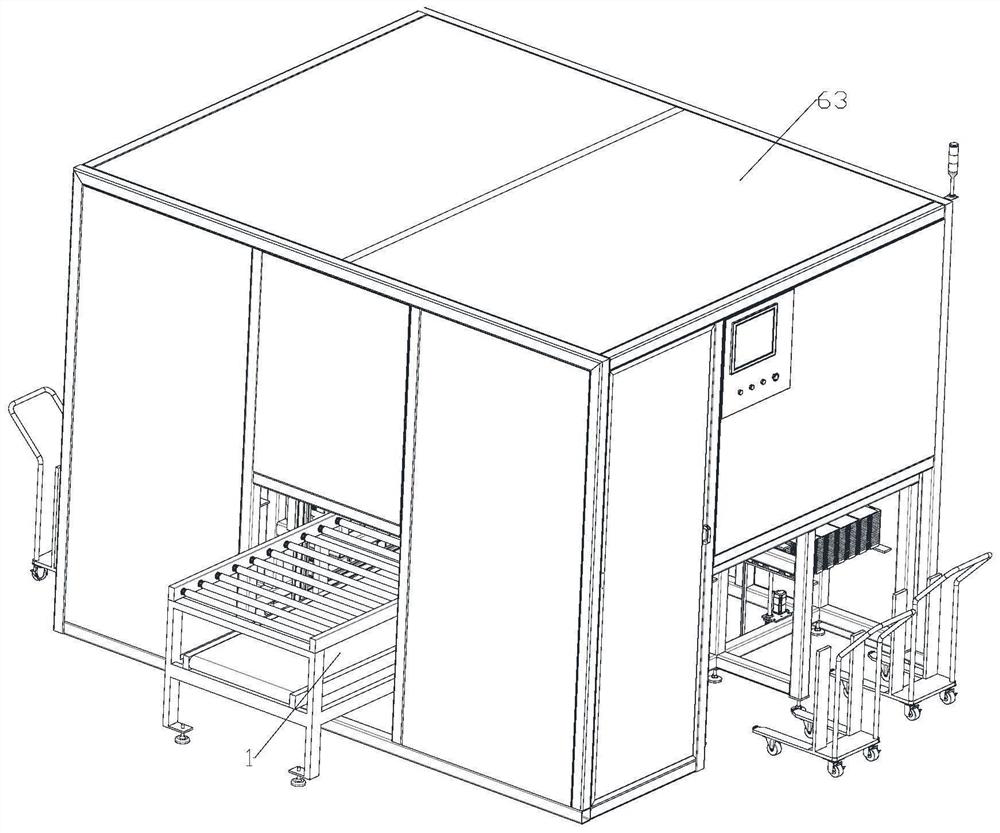

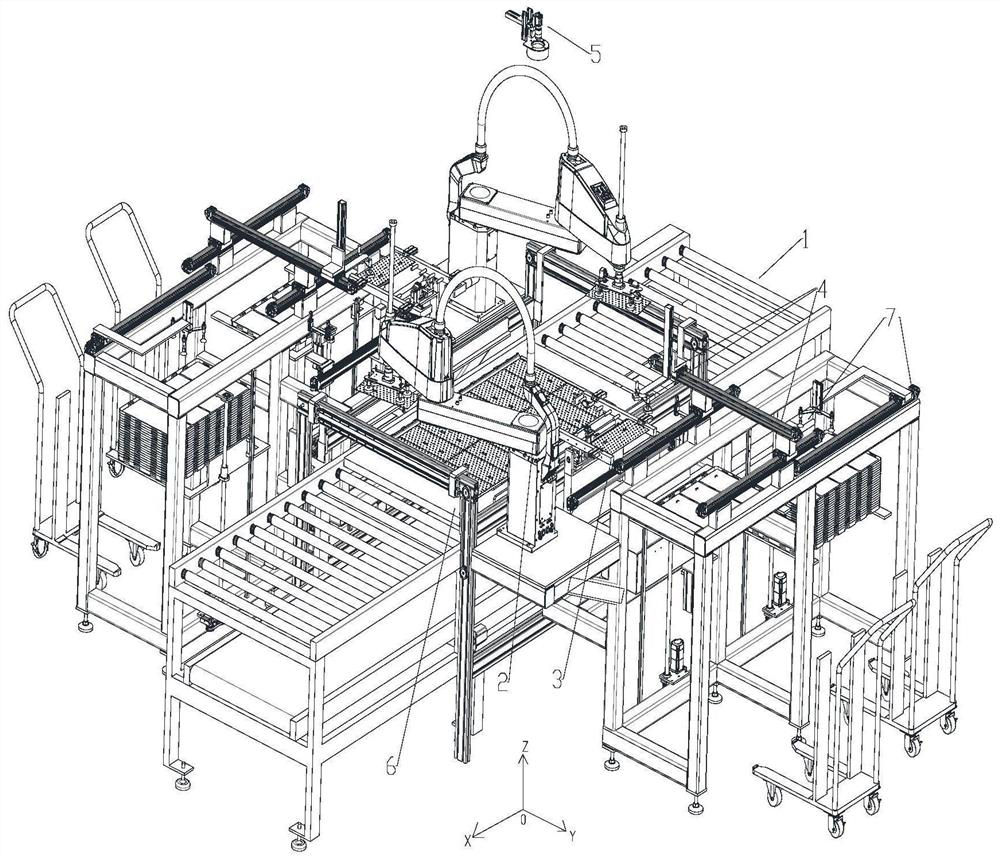

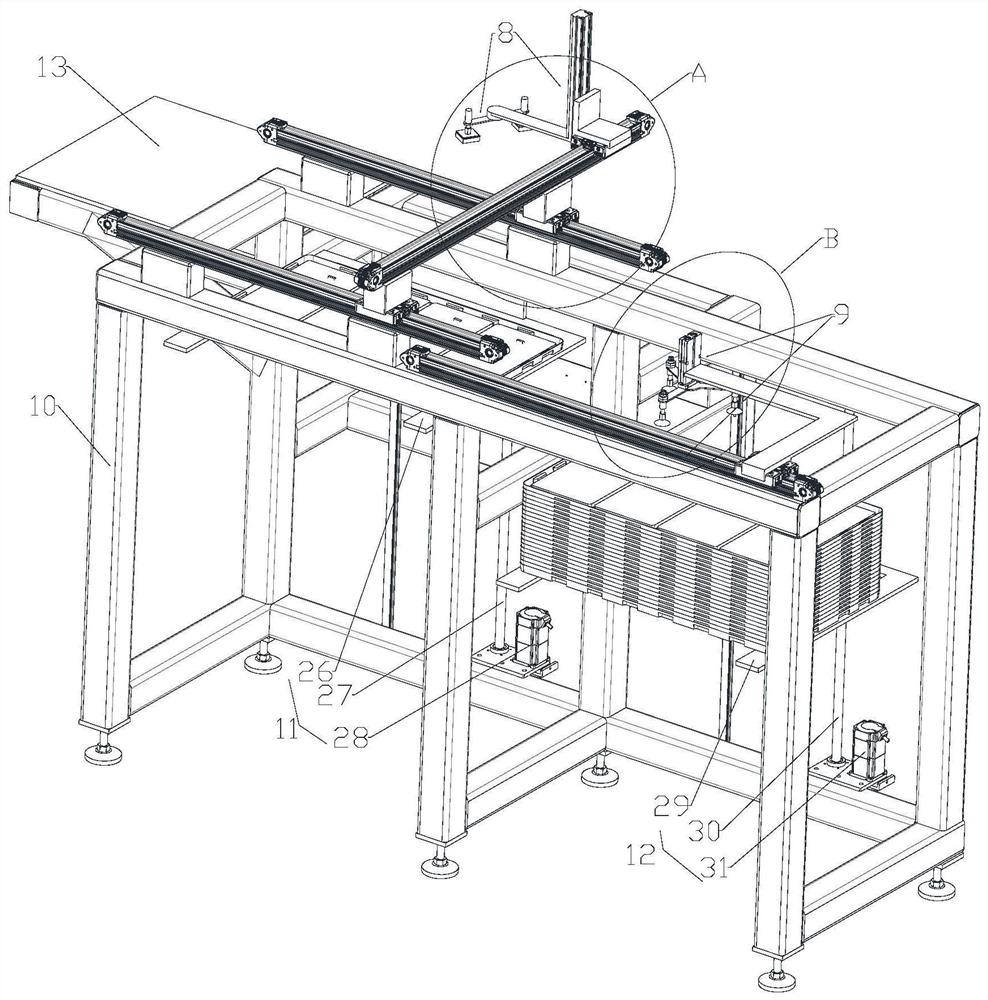

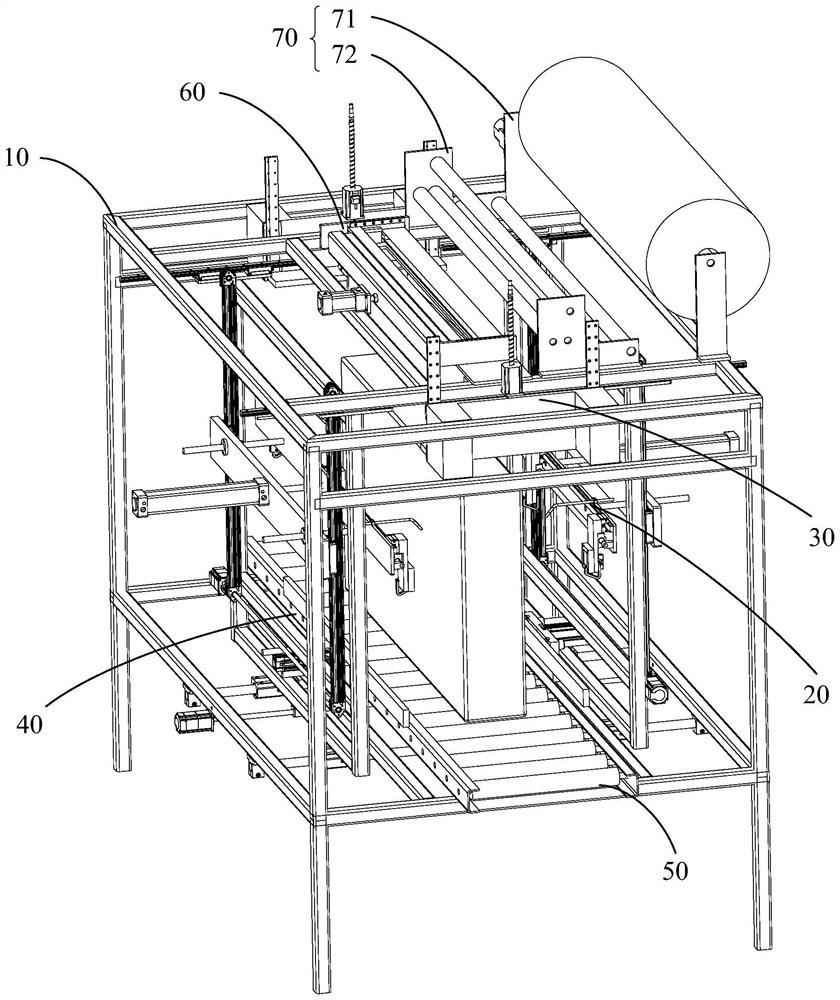

Novel automatic lamination device and method of automobile laminated glass

The invention discloses a novel automatic lamination device and method of automobile laminated glass. The novel automatic lamination device comprises a membrane cutting and transportation system, a belt conveyor, a positioning platform, a lamination mechanical arm, a membrane lamination mechanical arm, a lamination supporting mechanism, a visual positioning system and a control system, wherein the membrane cutting and transportation system comprises an automatic membrane cutting machine, a membrane transportation mechanism and a membrane placement table; a membrane raw material is cut and separated and then is transported to the membrane placement table; after outer-sheet glass and inner-sheet glass are conveyed to the positioning platform and are positioned, the outer-sheet glass and the inner-sheet glass are conveyed to a lamination working position for lamination; the positioning platform comprises a longitudinal sliding rail and a transverse sliding rail which are vertically and crossly arranged and the glass is positioned through a positioning column; the lamination mechanical arm is used for grasping the glass and putting the glass on the lamination working position; the membrane lamination mechanical arm is used for grasping a membrane and putting the membrane on the glass; the lamination supporting mechanism is located on the lamination working position; the visual positioning system comprises a first photographing device and a second photographing device; the control system is used for processing images photographed by the first photographing device and the second photographing device. Compared with the prior art, a process step of manually trimming can be cancelled, a production process is simplified and the consumption of raw materials is reduced.

Owner:FUJIAN WANDA AUTOMOBILE GLASS IND

Processing process of angel wine koji

InactiveCN108117949AReduce generationImprove production hygiene conditionsAlcoholic beverage preparationBiotechnologyDigestion

The invention discloses a processing process of angel wine koji. Sweet wine is mainly prepared from rice and sticky rice through fermentation of natural microorganism pure koji, contains nutrients including 40% or over of glucose, rich vitamins, amino acid and the like and has the efficacies of activating vital energy, nourishing blood, activating collaterals, stimulating menstrual flow, enrichingand producing blood and moistening lung. A bamboo cylinder is taken as a fermentation jar in a fermentation process, and a traditional production process is improved through an inner sleeve process measure, so that the operations are effectively standardized, meanwhile, the traditional flavor and taste are not influenced, the angel wine koji has special faint scent of bamboos besides the sweet palate, the brewed angel wine koji has fragrant, sweet and mellow taste, the nutrients are easily absorbed by a human body, the secretion of digestive glands can be promoted, and the appetite and the digestion can be promoted. The angel wine koj is good item with a vital energy benefiting and blood nourishing effects for middle aged and elderly people, pregnant and lying-in woman and poor-health people and can be drunk all the year round. The processing process is wide in applicable range and can meet the actual production of domestic processing industry, a process method is simple and practical, and the product is safe, healthy and nutritional.

Owner:GUANGXI UNIV

Method for preparing mercaptosilane coupling agent by channel reaction device

ActiveCN105601661BIncrease in sizeGreat operating flexibilityGroup 4/14 element organic compoundsSolventImpurity

The invention provides a method for preparing a mercaptosilane coupling agent by using a channel reactor. In a solvent, a channel reactor is utilized to prepare the mercaptosilane coupling agent. The structural general formula of the mercaptosilane coupling agent is XmSiC3H6S(C=O)nY, wherein each X is independently alkyl group, alkoxy group, hydroxy group, R(OR')LO-, -ORO- or N(RO-)3, and at least one X is alkoxy group, hydroxy group or N(RO-)3; Y is hydrogen or alkyl group; R and R' are respectively independently straight-chain or branched-chain alkyl group; the average value of L is 1-30; m is 1, 2 or 3; and n is 0 or 1. The corrected diameter of the channel reactor channel is one micrometer to several centimeters; and the channel reactor is connected with an after-treatment device. The method solves the problems of long reaction period, poor stability, existence of impurity polymers and the like in the large-size reactor, and especially reduces the odor caused by the large-size reactor production.

Owner:南京曙光新材料有限公司

Health-care barbecued pork bun steamed by double barrel lids and preparation method thereof

InactiveCN105495326ANice appearanceWhite and shinyYeast food ingredientsThinning skinEconomic benefits

The invention discloses a health-care barbecued pork bun steamed by double barrel lids and a preparation method of the health-care barbecued pork bun. The finished product has beautiful appearance, is crystal clear, is pure white and shiny, has snow-like and thin skin without exposing stuffing, has spongy texture, is soft, sweet and fragrant, non-sticky and nutritional, and is suitable for both the old and young. In particular, the barbecued pork bun is steamed by bamboo barrels, has smooth mouthfeel, and also has bamboo faint scent in addition to having delicious flavor. The production of barbecued pork bun requires no large equipment on the basis of common production, therefore, management is easy, production line can be changed easily and the economic benefit is high.

Owner:GUANGXI UNIV

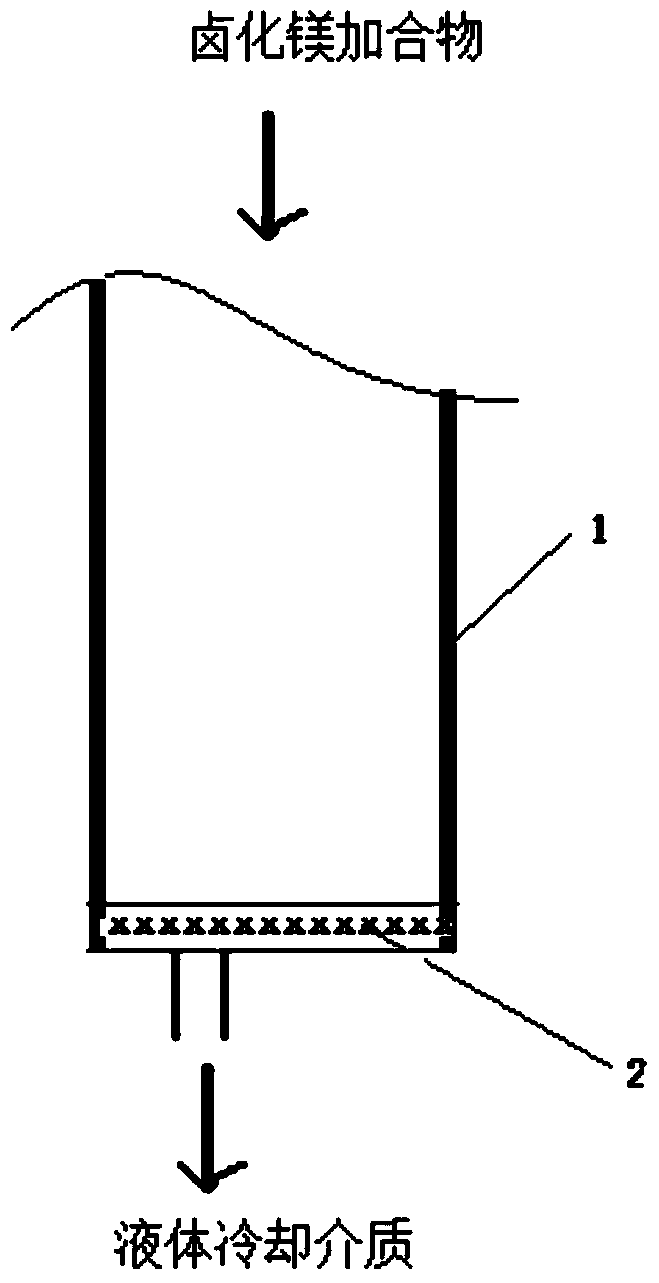

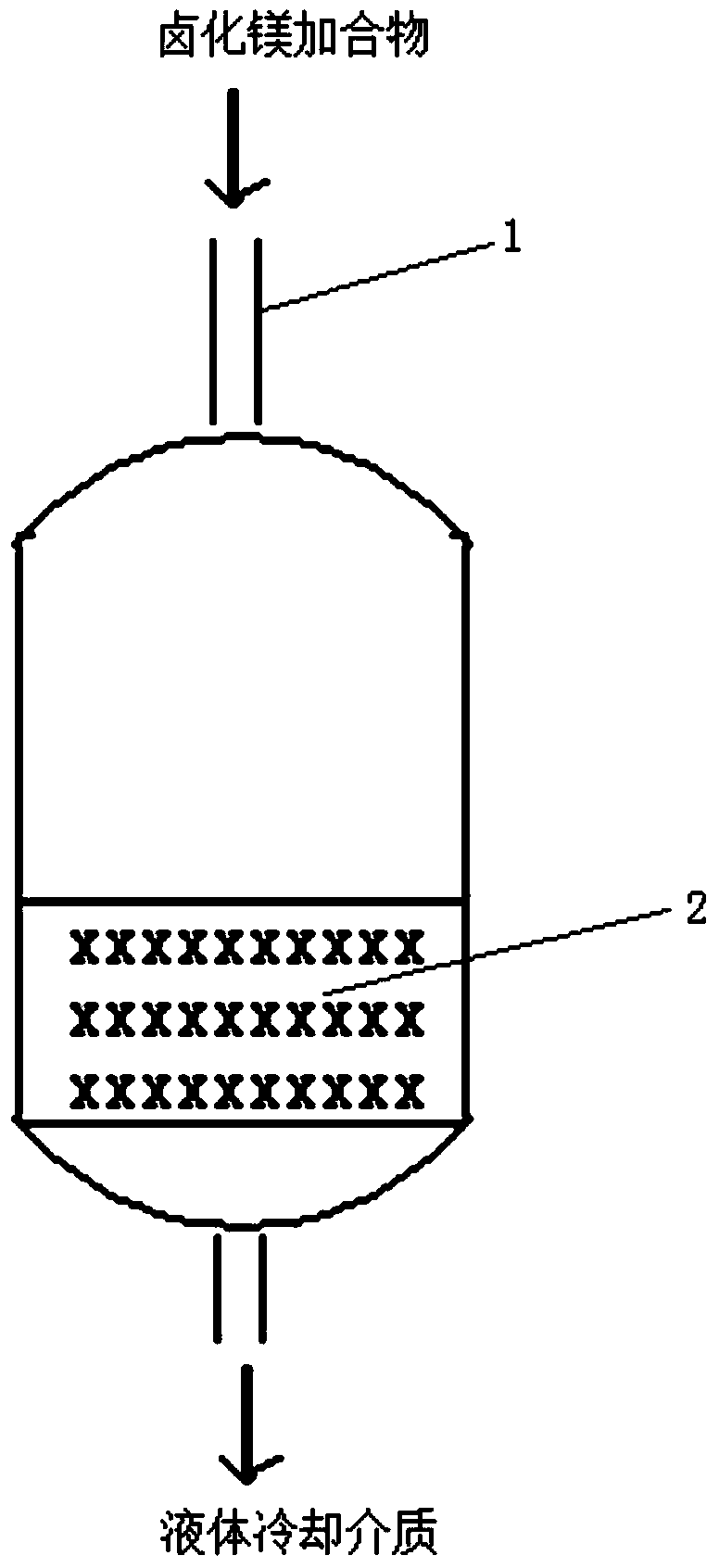

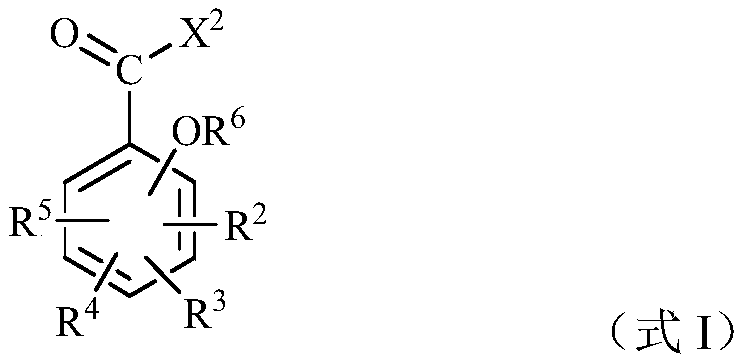

Catalyst component and its preparation method and application and catalyst system for olefin polymerization and its application and olefin polymerization method

The invention relates to the field of olefin polymerization, and specifically provides a catalyst component used for olefin polymerization and a preparation method and application thereof. The preparation method comprises a step of subjecting a magnesium halide adduct, a titanium compound and an aromatic carboxylate compound to a contact reaction. The magnesium halide adduct is prepared through the following steps: (1) mixing aquo MgX1Y, R1OH and an alkoxy benzoyl compound and heating the obtained mixture so as to obtain a liquid magnesium halide adduct, or mixing anhydrous MgX1Y, R1OH, the alkoxy benzoyl compound and water and heating the obtained mixture so as to obtain the liquid magnesium halide adduct; and (2) allowing the liquid magnesium halide adduct to penetrate through a structural unit with holes to a liquid cooling medium under the action of pressure in the presence of an inert liquid medium, and carrying out quenching formation and drying. The invention provides a catalyst system used for olefin polymerization and application thereof, and an olefin polymerization method. The catalyst component synthesized from an adduct carrier prepared by using the method has improved hydrogen sensitivity when used for olefin polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cutting device and method for cylindrical paper core for filter part

The invention discloses a cutting device and method for a cylindrical paper core of a filter part. The cutting device comprises a workbench, wherein a supporting seat is mounted on the workbench; a mechanical arm is mounted on the supporting seat; a rotary motor is mounted on the mechanical arm; the rotary motor is connected with a gearbox; the output shaft of the gearbox is connected with the rotary shaft for transmitting torque; a circular cutter is mounted on the rotary shaft; a hand wheel is mounted on the mechanical arm; and a mounting table is arranged below the circular cutter. The cutting device can be used for conveniently producing the cylindrical paper core, which is perfect and attractive in appearance, for the filter part on a large scale.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

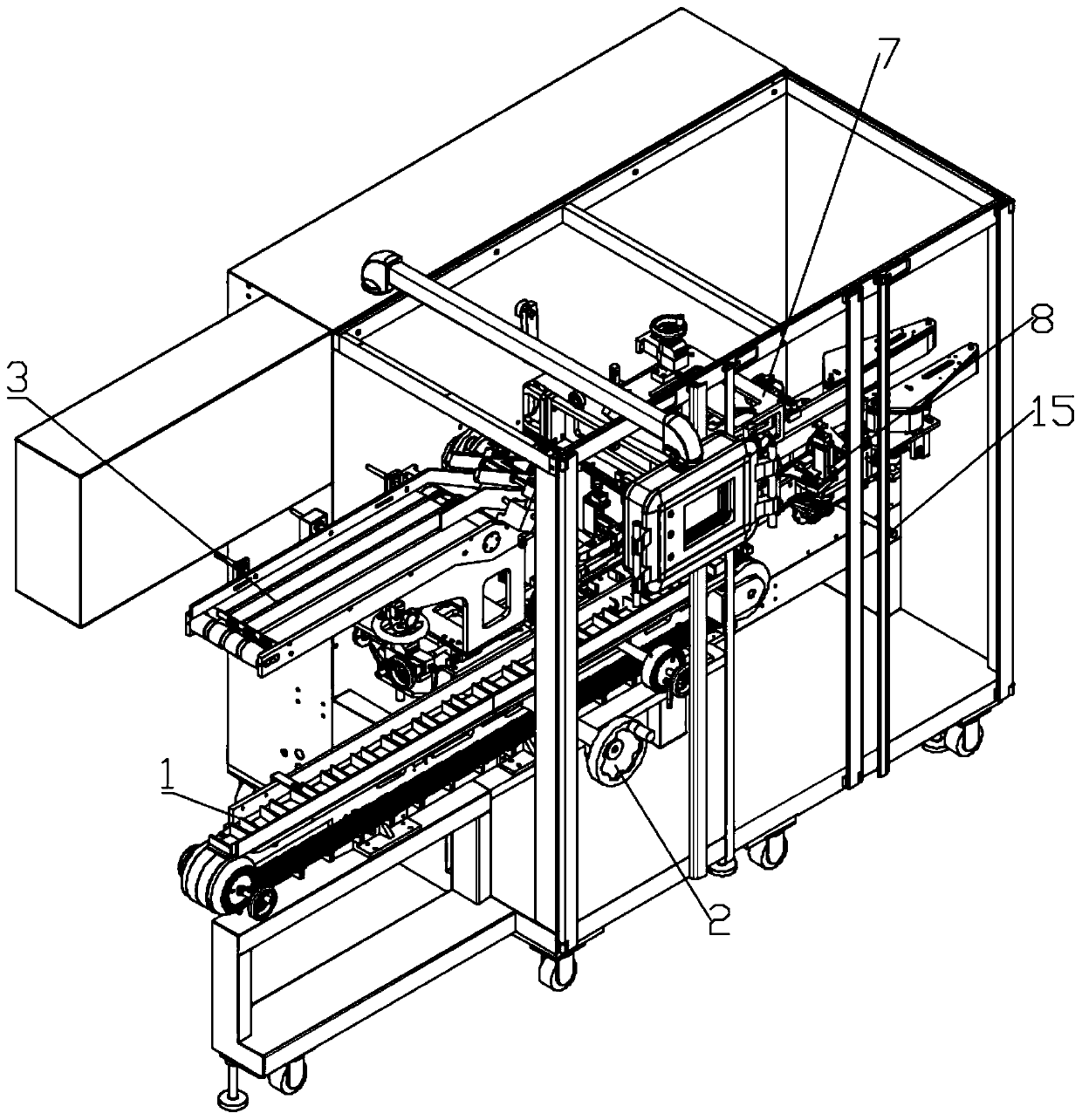

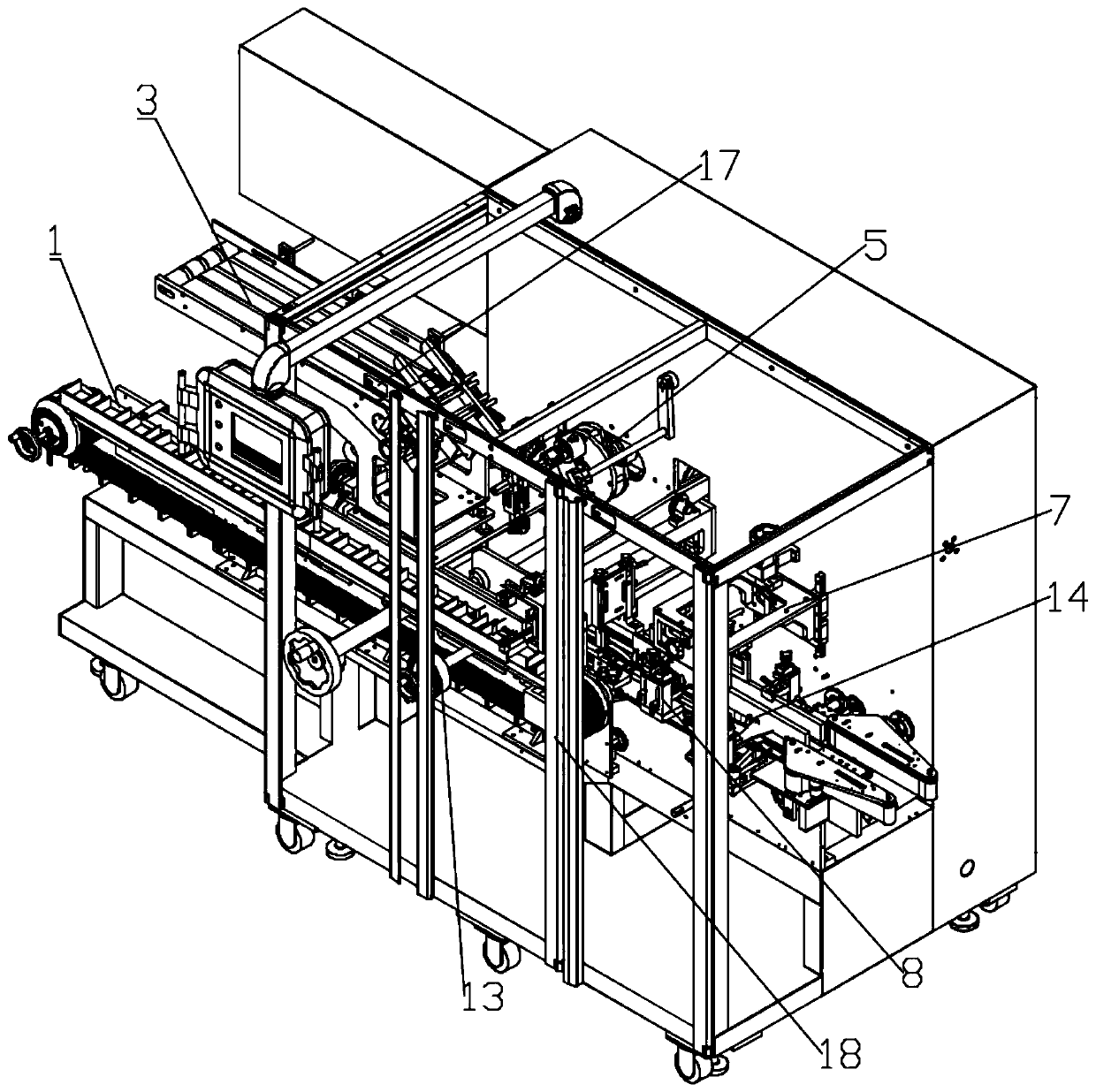

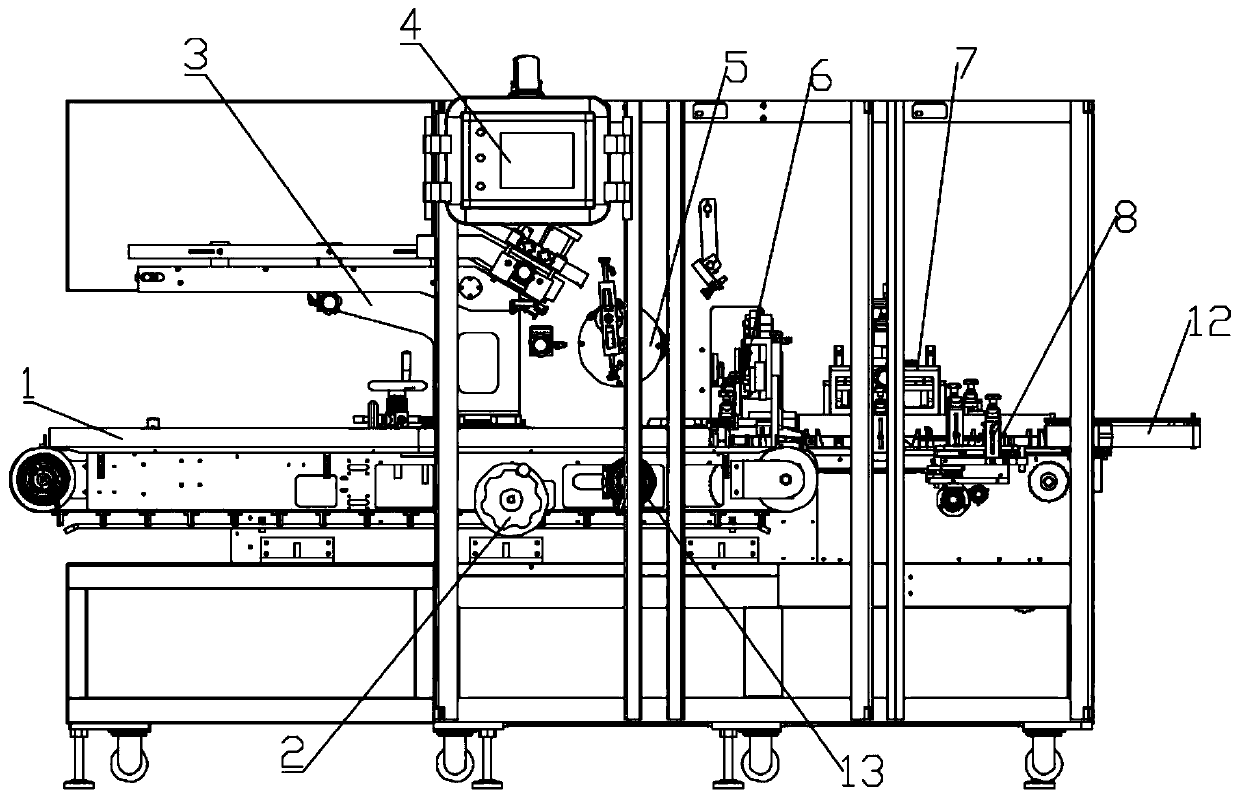

Full-automatic mounting machine

ActiveCN112707102AClear division of labor and non-interferenceImprove efficiencyMaterial gluingArticle unpackingEngineeringMechanical engineering

The invention particularly discloses a full-automatic mounting machine. The full-automatic mounting machine comprises a conveying device, a suction plate feeding mechanism, a positioning sensor, a film tearing device and a mounting mechanism, the positioning sensor is located above the conveying device, the suction plate feeding mechanism is located at one side end of the conveying device in the conveying direction, the film tearing device is located between the conveying device and the suction plate feeding mechanism, and the mounting mechanism is located at the other side end of the conveying direction of the suction plate feeding mechanism. When the positioning sensor senses a back plate conveyed by the conveying device, the suction plate feeding mechanism places a lamp plate on the conveying device, and when the lamp plate reaches the position where the film tearing device is located, the film tearing device tears off a protective film of the lamp plate, then the lamp plate is conveyed to the position where the mounting mechanism is located through the conveying device, and the mounting mechanism is used for mounting the lamp plate subjected to film tearing to the corresponding position of the back plate. The full-automatic mounting machine is independent and modular in structure, compact, coordinated and efficient in operation, and the labor cost is greatly reduced.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

Barrel-steamed fermented soybean paste health food

The invention discloses a barrel-steamed fermented soybean paste health food. Cantonese soybean paste disclosed by the invention is refined on the basis of traditional fermentation and production of soybeans through combining a modern production technology; shapes of whole soybeans are kept, and the soybean paste has a golden yellow to reddish brown color, is good in color and luster, delicious in taste, moderate in saline and sweet tastes, and is rich in aroma. Flavors and characteristics of traditional brewed soybean paste can be kept, and requirements on modern diet are also met. The soybean paste is suitable for cooking, braising, cooking and frying. The product can be produced on the basis of previous production without adding other large-size equipment; management and production line change are easy to realize and economic benefits are high.

Owner:GUANGXI UNIV

Automatic box packing machine

The invention discloses an automatic box packing machine and aims to solve the problem that an existing box packing machine is small in regulation range and complex in operation. The automatic box packing machine comprises a frame and a control panel; a motor, a paper box library, a feeding conveying device, a paper box conveying device, a discharging conveying device, a material pushing device and a suction disk device are arranged on the frame; the suction disk device is positioned at the connection position of the paper box library and the paper box conveying device; the material pushing device is positioned at the connection position of the feeding conveying device and the paper box conveying device; the motor is connected with the feeding conveying device and the paper box conveying device respectively through a transmission shaft; and a box pressing device and a box sealing device are arranged on the two sides of the paper box conveying device. The automatic box packing machine can realize automation of paper box packaging, can change the paper box of different sizes, can perform regulation and positioning without changing a mold box and only according to the size of the box,and is large in regulation range; a display is arranged at the regulation position, so the automatic box packing machine is convenient to contrast and simple to operate; and the automatic box packingmachine adopts intermittent operation, is provided with an overload protection function and can protect products to enter the box safely.

Owner:上海全驰机械有限公司

Bagging machine

InactiveCN112777044ALabor savingIncrease productivityWrapper twisting/gatheringIndividual articlesWorkbenchIndustrial engineering

The invention provides a bagging machine which comprises a rack, a workbench, an adsorption assembly, a clamping assembly and a sealing assembly. The workbench is arranged at the bottom of the rack and used for containing to-be-bagged materials. The adsorption assembly is movably arranged on the rack and used for adsorbing plastic bags and pulling the plastic bags to be arranged on the to-be-bagged materials in a sleeving mode. The clamping assembly is movably arranged on the rack and used for clamping the to-be-bagged materials sleeved with the plastic bags to move. The sealing assembly is arranged on the rack, located between the adsorption assembly and the workbench and used for sealing the plastic bags. According to the technical scheme, manual bagging is replaced, labor is saved, production efficiency is improved, and production consistency and bagging stability are ensured.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

Kneading type washing machine

InactiveCN1540058AIncrease frictionChange the washing methodOther washing machinesWashing machine with receptaclesSewageEngineering

A kneading-type washer features that an upper washing mechanism consisting of upper waving wheel able to move up and down, upper driver, upper washing motor, and upper lifting motor is additionally installed in top cover. Its advantages are high cleaning effect and less consumption of detergent, water and electric energy.

Owner:胡冬喜

Curing agent 4,2'- and 4,4'-methyl diphenylene diisocyanate prepolymer and preparation thereof

The invention provides a prepolymer of 4,2'-methyl diphenylene diisocyanate (MDI) and 4,4'- methyl diphenylene diisocyanate (MDI) as a curing agent, and a preparation method thereof. The method comprises the following steps: 4,4-MDI and organic solvent are added to a reaction kettle, heated to between 50 an d 90 DEG C and added with dehydrated polyol, and then react for 2 to 4 hours so as to prepare 4,4-MDI modifier; a mixture of 4,2'-MDI and 4,4'MDI is added and then cooled; and trimethylolpropane and the organic solvent are dripped and thermally insulated, and react for 1 to 6 hours, so as to obtain a product. The method modifies the 4,4-MDI and then blends the 4,4-MDI with the mixture of 4,2'-MDI and 4,4'-MDI and TMP for pre-polymerization, thereby solving the problem of manufacturing the prepolymer with two isomers of MDI in an arbitrary proportioning form. A series of produced prepolymers can meet different requirements of coatings and adhesives in the polyurethane industry on the curing agent, and have the advantages of wide application range, high strength, low toxicity, adjustable room-temperature curing speed, good storage stability, capability of obtaining the products with high solid content, and the like.

Owner:周建明

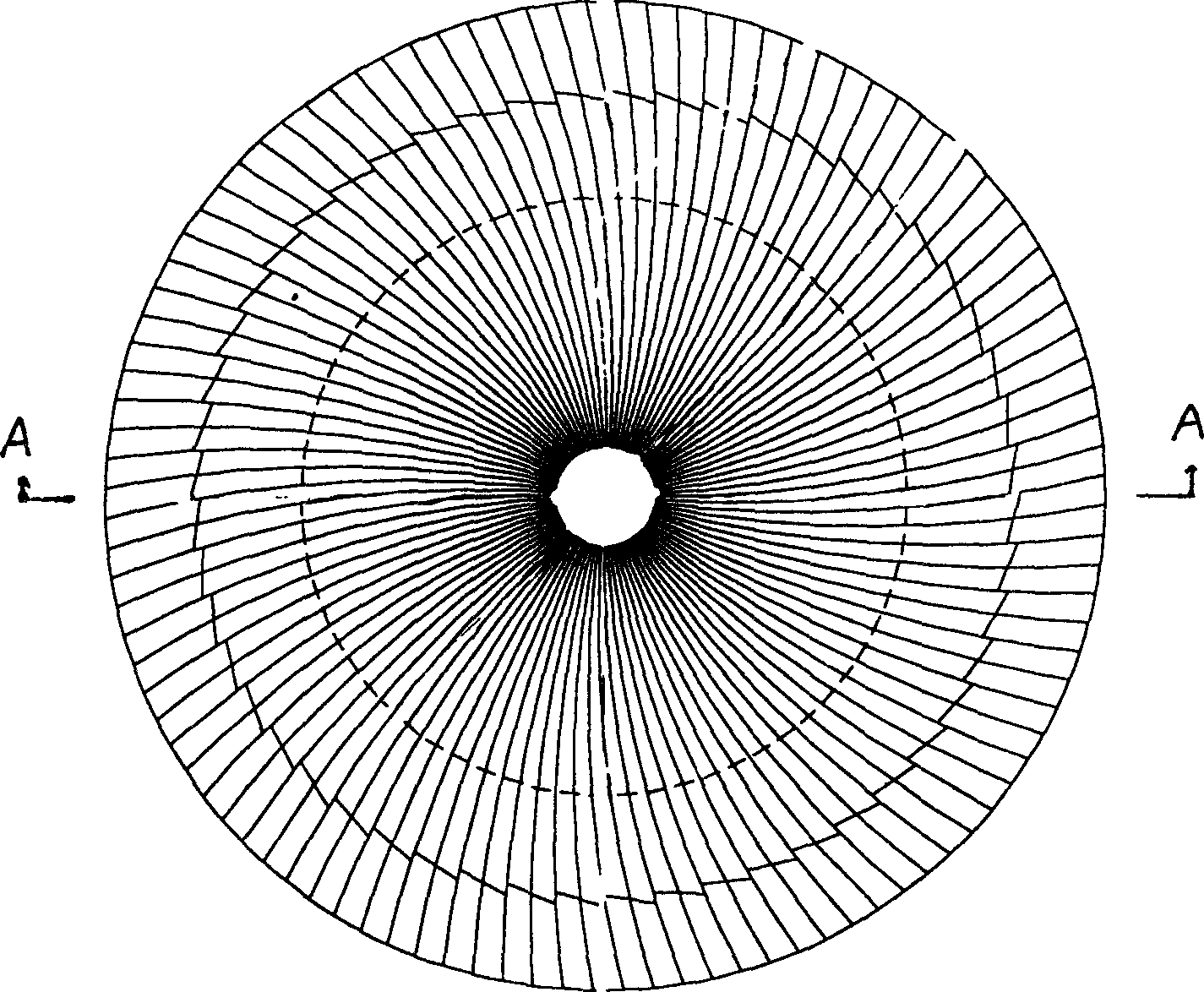

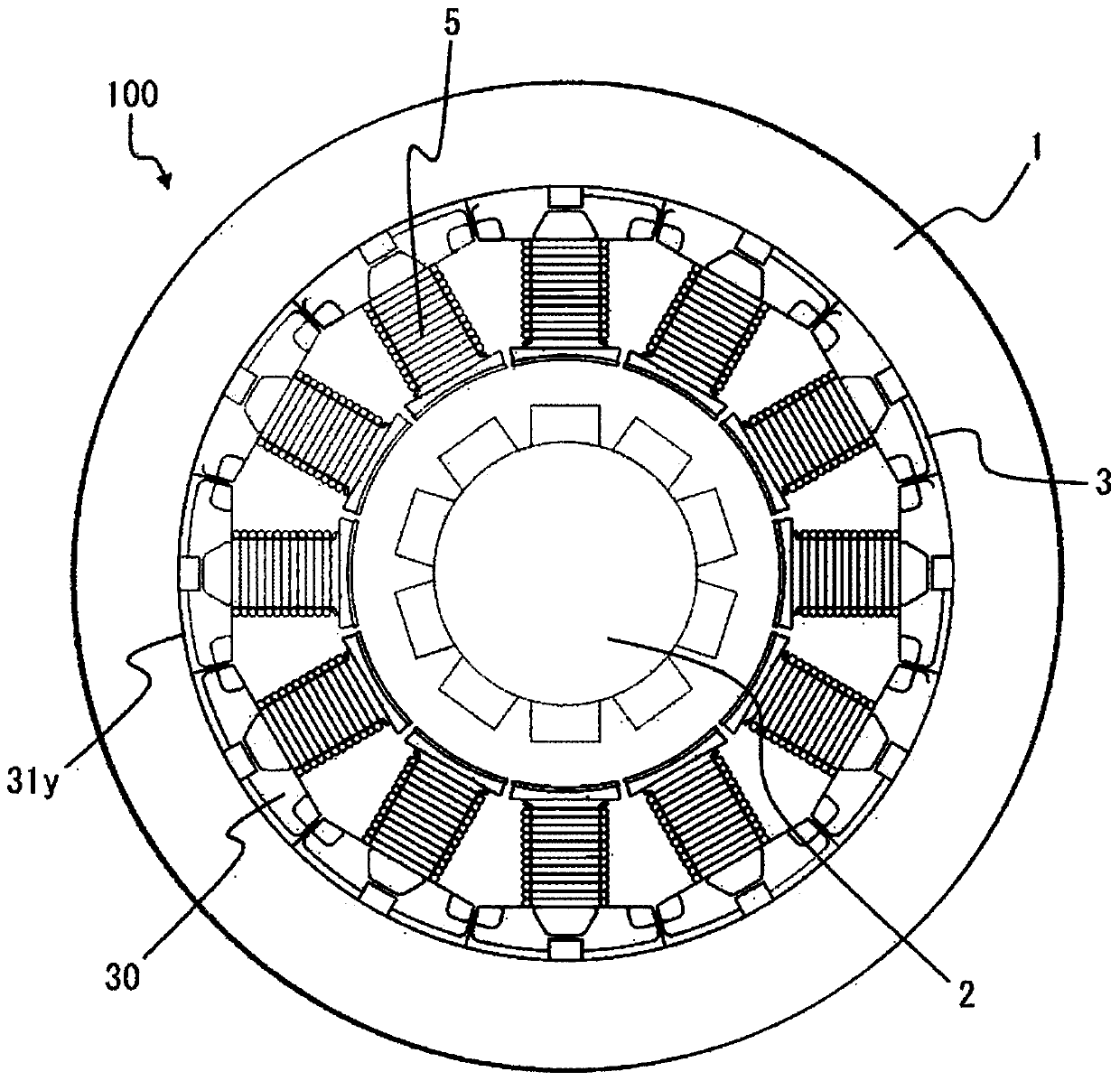

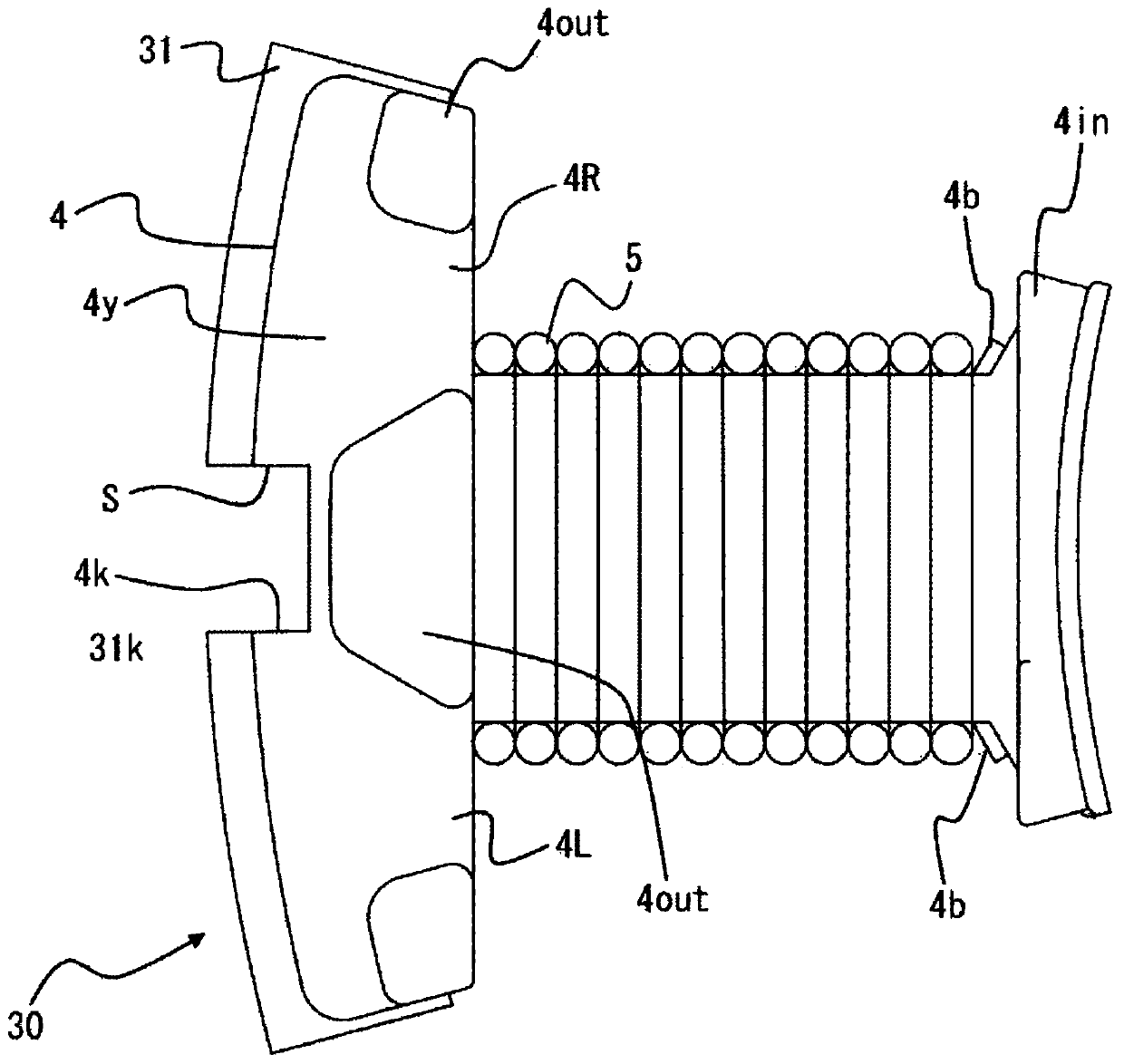

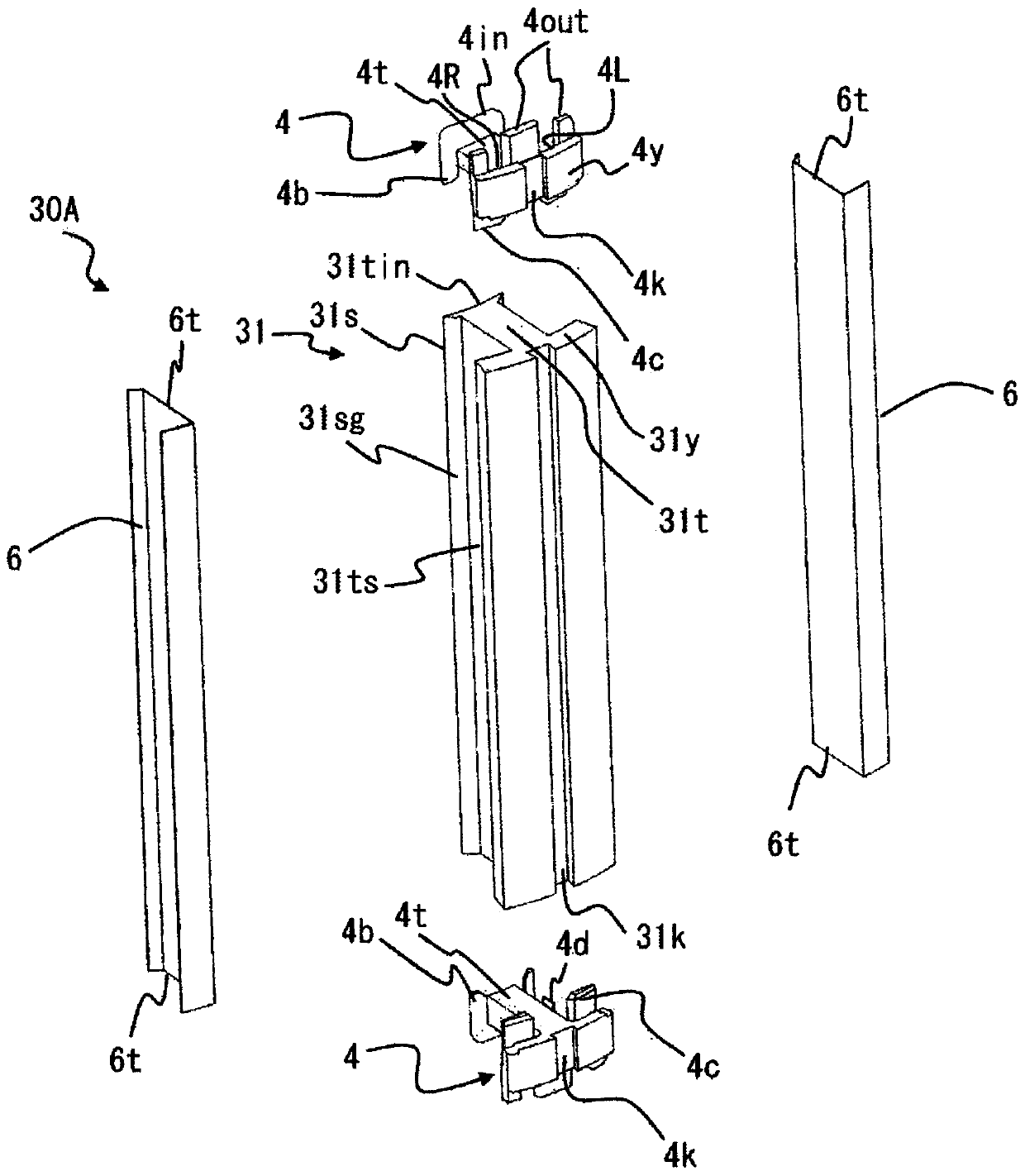

Split core unit, rotary electric machine, method for manufacturing split core unit, and method for manufacturing rotary electric machine

InactiveCN110168861AEasy to change productionWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineElectrical and Electronics engineering

The split core unit (30) has a split core (31), a coil (5), and an insulation member for insulating the split core (31) and the coil (5). The insulation member has end face insulation members (4). Each of the end face insulation members (4) has a first groove (4k) provided in a central region in the peripheral direction of an outer peripheral surface and extending in a straight line in an axial direction. A yoke part (31y) of the split core (31) has a second groove (31k) provided in a central region in the peripheral direction of an outer peripheral surface and extending in a straight line inan axial direction across the entire length of the split core (31). The first groove (4k) of each of the two end face insulation members (4) and the second groove (31k) of the split core (31) communicate with each other. The two first grooves (4k) appear overlapped with the second groove (31k) when viewed in the axial direction.

Owner:MITSUBISHI ELECTRIC CORP

Coconut cake health-care food and preparation method thereof

InactiveCN105558923ABeautiful colorRefreshing entranceFood ingredient as taste affecting agentNatural extract food ingredientsFlavorPeppermints

The invention discloses a coconut cake health-care food and a preparation method thereof. The coconut cake health-care food is mainly processed from coconuts, fresh milk, polished glutinous rice, rice dreg meal, peppermint leaves and the like. The finished products of the coconut cake health-care food are beautiful in color, smooth, clean and bright, and pleasing to both the eye and the mind, and promote appetite; when being put in mouths, the coconut cake health-care food is refreshing, sweet and smooth, and can moisten throats. The coconut cake health-care food is soft in texture, soft, moistening, sweet, fragrant, tasty, refreshing, non-greasy, rich in nutrition, and suitable for both old and young people. Specially, when the peppermint leaves are mixed in powder cakes for cooking with thick bamboo tubes, the cake health-care food is lubricant and smooth when being eaten; the coconut fragrance is mingled with special peppermint fragrance, the coconut cake health-care food is fragrant and refreshing, also has special the delicately-fragrant flavor of bamboos, and is fresh, sweet, delicious, refreshing and pleasant.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com