Drawing transmission device of spinning frame

A transmission device and spinning frame technology, applied in spinning frames, drafting equipment, continuous winding spinning frames, etc., can solve the problems of twist transfer and spinning tension instability, achieve reliable technical support, and easy to change production. , The effect of improving twist transfer and stabilizing spinning tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

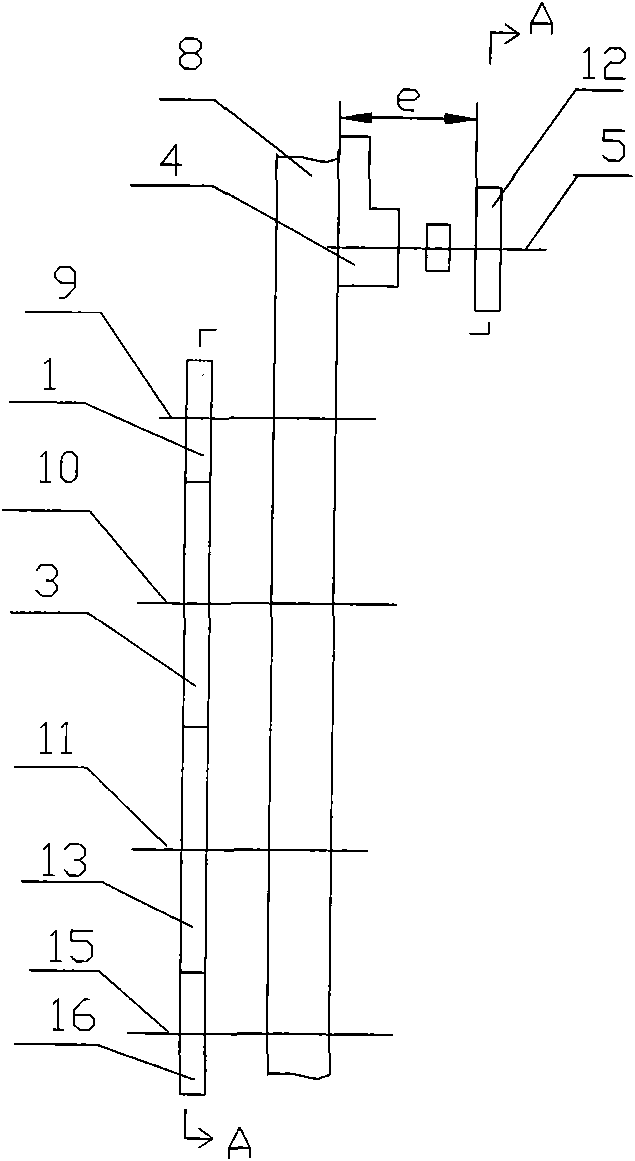

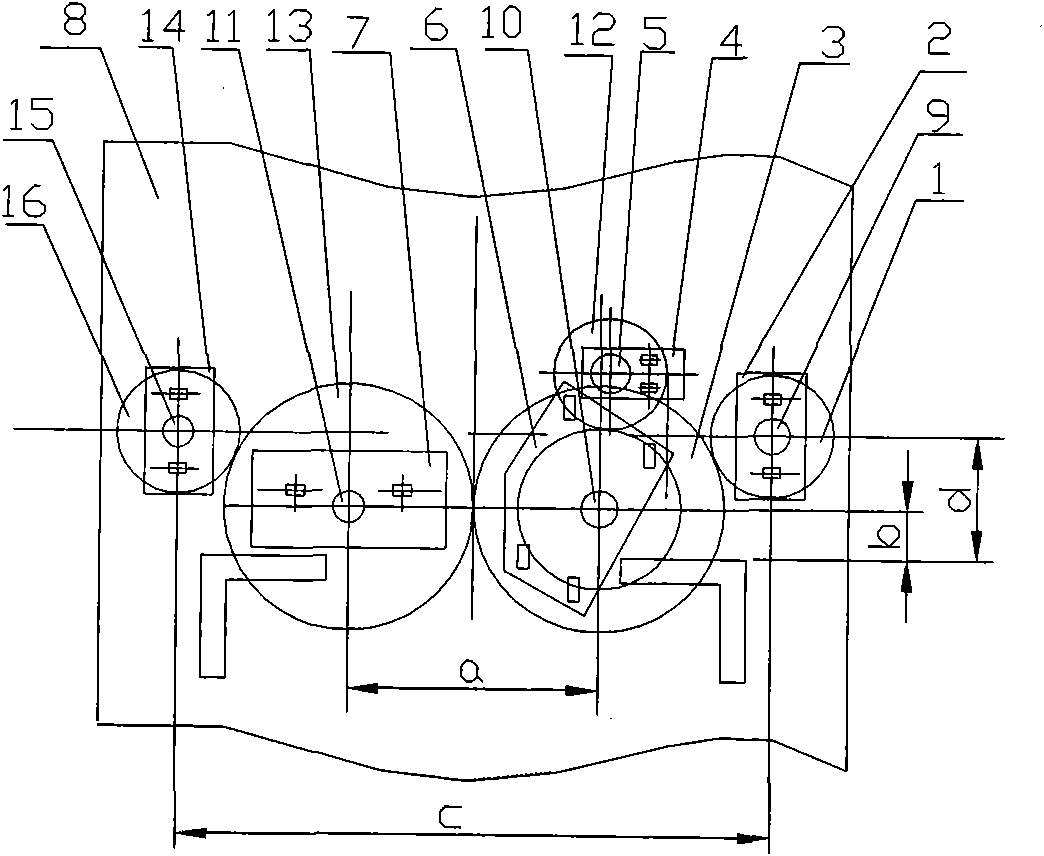

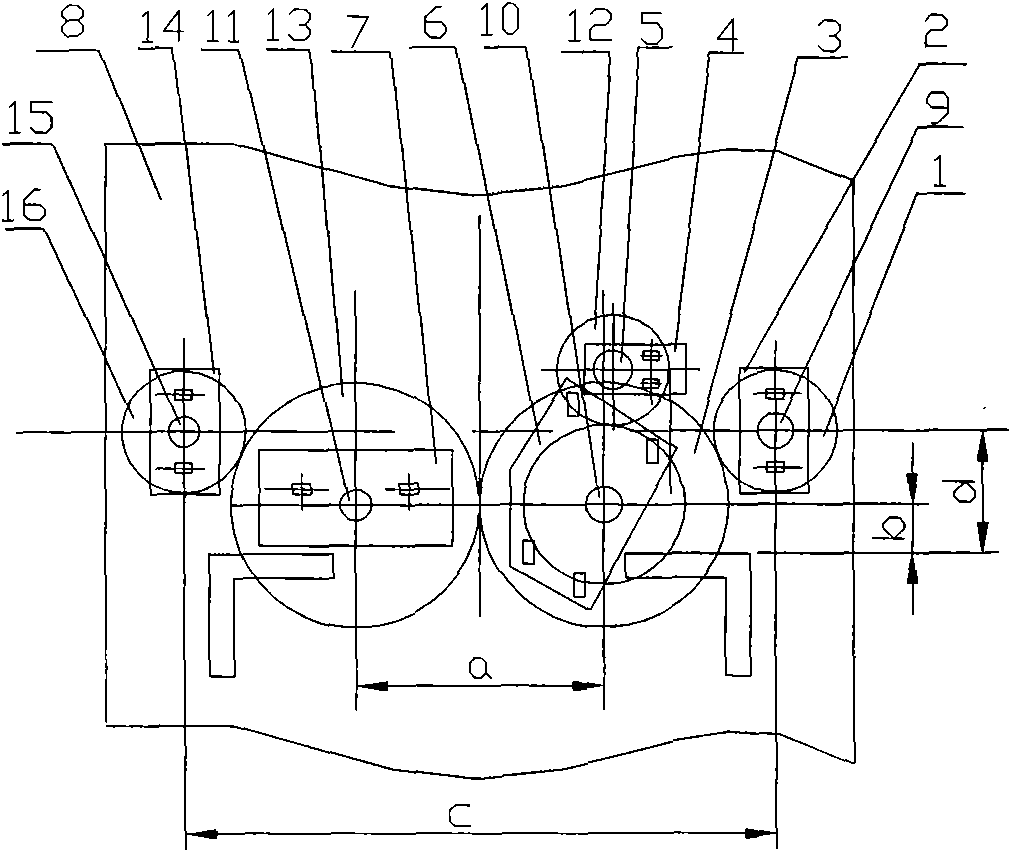

[0009] A drafting transmission device for a spinning frame, which includes a right front roller gear 1, a right front roller bearing seat 2, a right butterfly tooth 3, a roller transmission bearing seat 4, a middle rear roller transmission shaft 5, a double bearing seat 6, and a left butterfly tooth bearing seat 7. Head wall panel 8, right front roller head section shaft 9, right butterfly tooth shaft 10, left butterfly tooth shaft 11, middle and rear roller transmission gear 12, left butterfly tooth 13, left front roller bearing seat 14, left front roller head section shaft 15 , front left roller gear 16, right front roller bearing seat 2, roller transmission bearing seat 4, double bearing seat 6, left butterfly tooth bearing seat 7, left front roller bearing seat 14 are arranged on the head wall plate 8; right front roller bearing seat 2 is provided with There is a shaft 9 of the right front roller head, and a right front roller gear 1 is arranged on the shaft 9 of the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com