Preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis

A technology of particle size distribution and continuous method, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc. It can solve the problems of simultaneous production of multiple products, lack of adjustability of production lines, and wide particle size distribution of products. and other problems, to achieve the effect of being conducive to centralized recycling, good product appearance, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

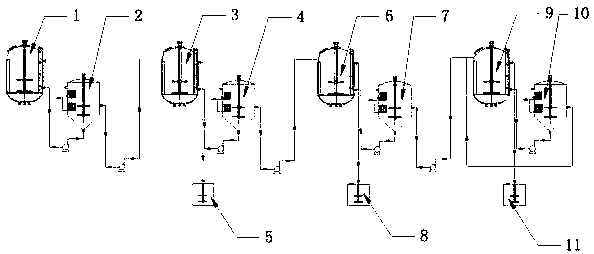

[0041] Such as figure 1 As shown, inject 0.5 mol / l metal salt mixed solution, 15 mol / l lye, and 5 mol / l ammonia solution into the reaction kettle 1 through their corresponding feeding pipes, start stirring, and feed nitrogen to control the pH of the reaction kettle 1. The value is 11.5, the reaction temperature is 65° C., the stirring speed is 300 rpm, and the nitrogen flow rate is 50 L / h. After the reactor one 1 reaches the full kettle state, open the overflow pipe that the reactor one 1 is connected with the thickener one 2, the slurry is concentrated in the thickener one 2, and the thickener one 2 controls the solid content value to be 300g / l Inject the thick slurry into the reaction kettle two 3; after the reaction kettle two 3 is filled, start stirring, feed nitrogen, inject the aforementioned metal salt mixed solution, lye, and ammonia solution for continuous reaction, and control the pH value of the reaction kettle two 3 to 11.3, The reaction temperature was 45° C., t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com