Patents

Literature

132results about How to "Convenience for centralized recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

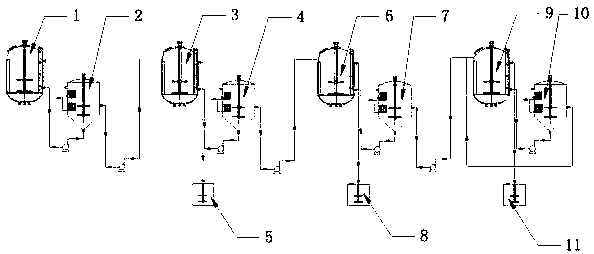

Preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis

InactiveCN108172892AImprove processing efficiencyRelieve pressureFinal product manufactureCell electrodesAmmonium hydroxideSlurry

Disclosed is a preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis. The preparation method comprises the following steps of: 1) preparing a metal salt solution, an alkali solution and an ammonium hydroxide solution; 2) enabling a reaction kettle and a solid concentration thickener to be connected in series; 3) injecting the metal salt solution, the alkali solution and the ammonium hydroxide solution into the reaction kettle 1, wherein the slurry in the reaction kettle 1 is pumped into the thickener 1 for solid-liquid separation to increase solid content when the liquid level in the reaction kettle 1 reaches the full kettle state, and the thick slurry in the thickener 1 is pumped into a reaction kettle 2; 4) performing stirring when the reaction kettle 2 is full of the slurry, and adding the metal salt solution, the alkali solution and the ammonium hydroxide solution to continue a continuous precipitation reaction, and then overflowing the product in the reaction kettle 2 into an aging tank 1; and 5) enabling the product in the aging tank 1 to be centrifuged, washed and dried. The preparation method has the advantages that the technology is simple, easily operated, energy-saving and environment-friendly. The product features good appearance, concentrated particle size distribution, high vibration density andhigh efficiency.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

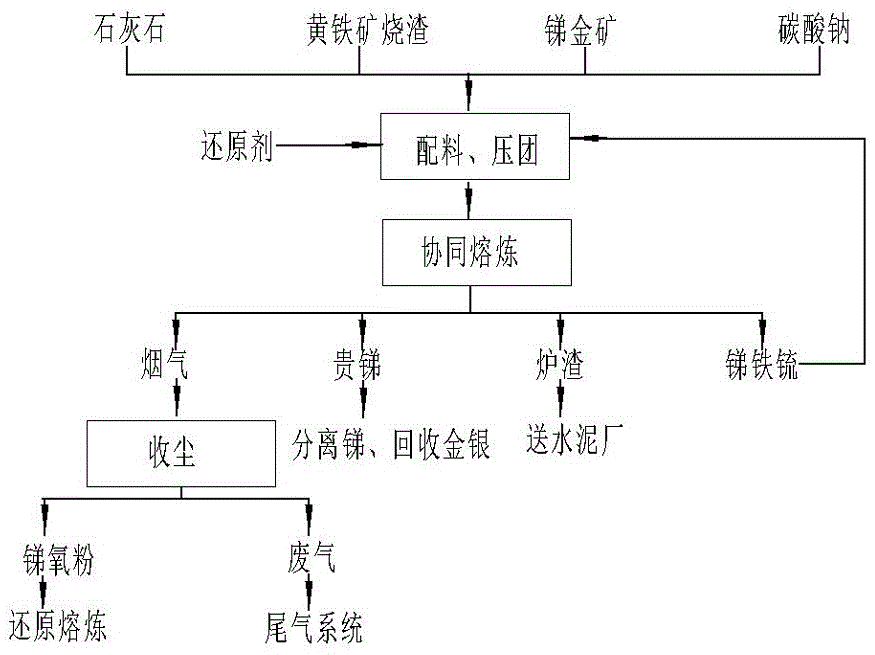

Method of enriching valuable metals through collaborative smelting of gold-antimony deposit and auriferous pyrite cinder

The invention discloses a method of enriching valuable metals through collaborative smelting of a gold-antimony deposit and auriferous pyrite cinder. According to the method, in a smelting burdening process of the gold-antimony deposit, auriferous pyrite cinder replaces the original flux iron ore concentrate, the gold-antimony deposit and the auriferous pyrite cinder are subjected to collaborative smelting together, and a given amount of sodium carbonate is added for reducing a melting point of slag and improving the flowability of a melt, so that the smelting temperature is reduced effectively, the valuable metals like gold and silver in the auriferous pyrite cinder and antimony concentrate can be enriched in crude metallic antimony more, and the probability of oxygenation volatilization of antimony is reduced. The method has the outstanding advantages as follows: firstly, one-step smelting allows antimony to generate metallic antimony more, and the scattering problem of antimony in crude metal, flue gas and iron-antimony matte in the traditional technology is solved; secondly, difficult-to-treat solid waste, namely the auriferous pyrite cinder is used comprehensively, the iron ore concentrate is replaced, the consumption of primary resources is reduced and the industrial solid waste is treated collaboratively; finally, the valuable metals, namely gold and silver in the concentrate and the auriferous pyrite cinder are enriched and recovered, the energy consumption is reduced, and the collaborative smelting effects of comprehensive recovery, low carbon cleaning and production process centralization are exerted.

Owner:合肥龙之韵医药技术有限公司

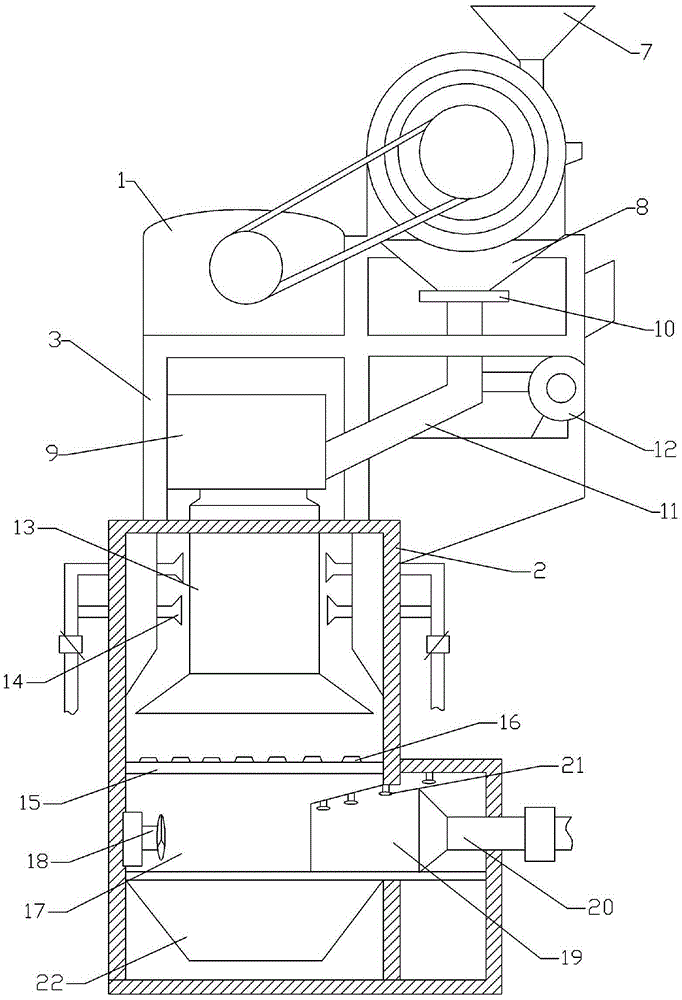

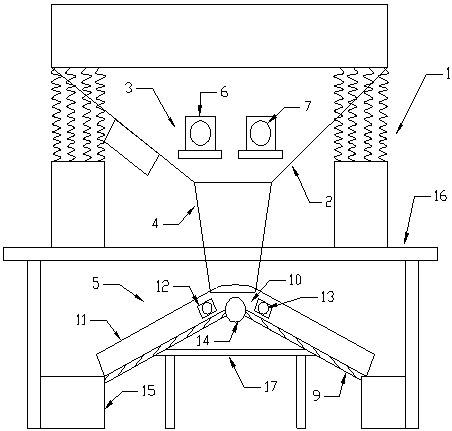

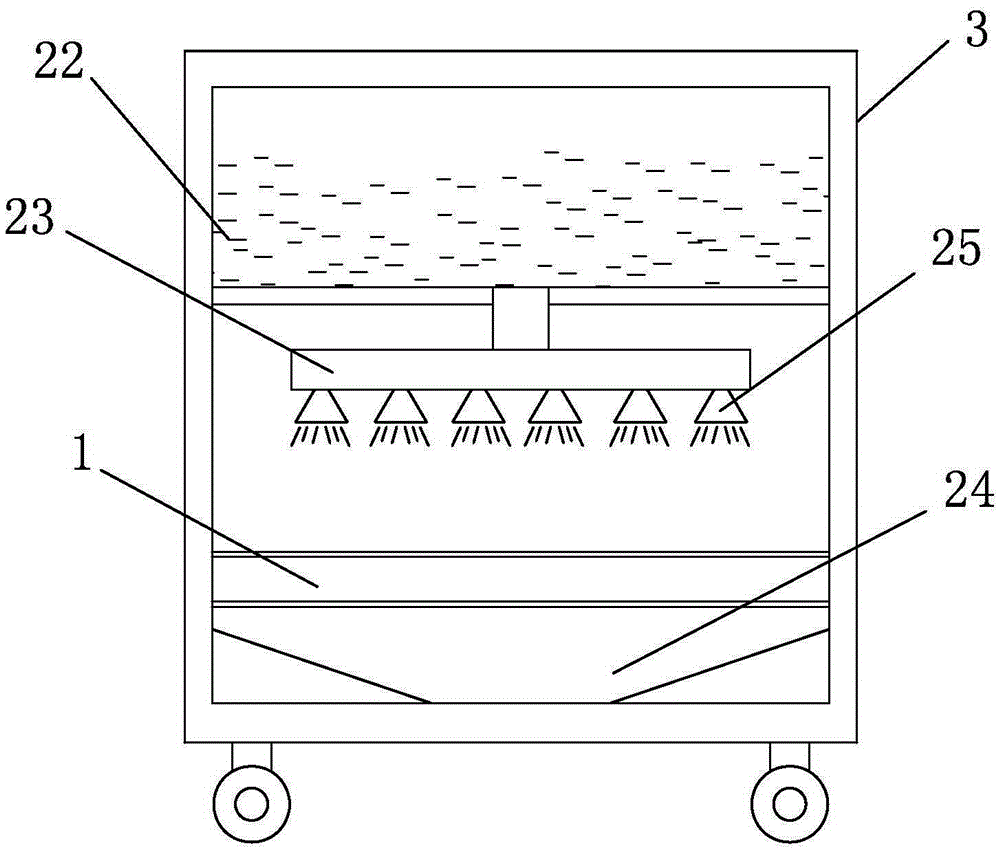

Peanut shell removing and peanut seed peeling integrated device enabling peeled peanut seed and peanut seed coat to be separated

InactiveCN105410953AImprove shelling efficiencyEfficient collectionHuskingHullingTransmission beltEngineering

The present invention discloses a peanut shell removing and peanut seed peeling integrated device enabling peeled peanut seeds and peanut seed coat to be separated. The device includes a motor, a machine base, a machine frame arranged on the machine base and a shell removing mechanism, wherein the shell removing mechanism comprises a receiving cavity and a shell removing plate installed inside the receiving cavity, convex teeth are arranged on the inner wall of the receiving cavity, the distance between the shell removing plate and the convex teeth is 1-2 cm, a material charging hopper is arranged on the top of the machine frame, a material separating trough and a material storing barrel are arranged inside the machine frame, the other end of the receiving cavity communicates with the material separating trough, a material collecting pipe is connected with a first fan through an air duct, the first fan is arranged at the other side of the material storing barrel on the machine frame, the shell removing plate is connected with the motor through a transmission belt, a cavity communicating with the material storing barrel is arranged inside the machine base, a spray chamber is arranged above the cavity, a plurality of nozzles communicating with water pipes are arranged inside the spray chamber, and a plurality of rotatable rollers are arranged below the spray chamber. The device aims to solve the problems that the existing peanut shell removing process is low in efficiency, high in shell breakage rate and difficult in collection and utilization of peanut seed coat.

Owner:重庆乐嚼食品有限公司

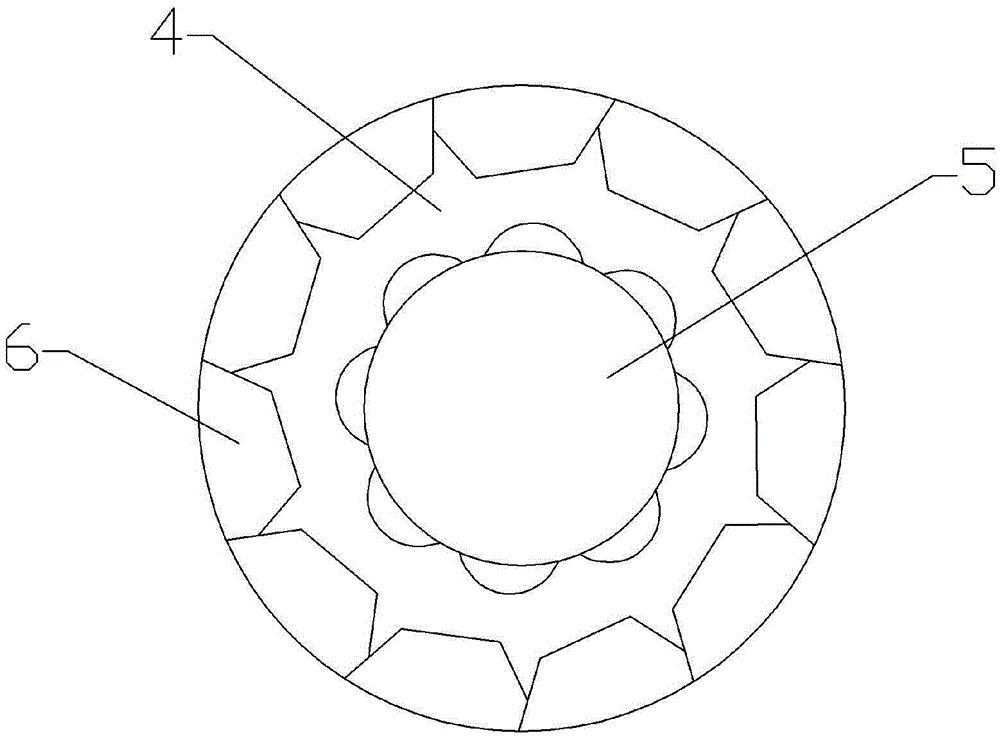

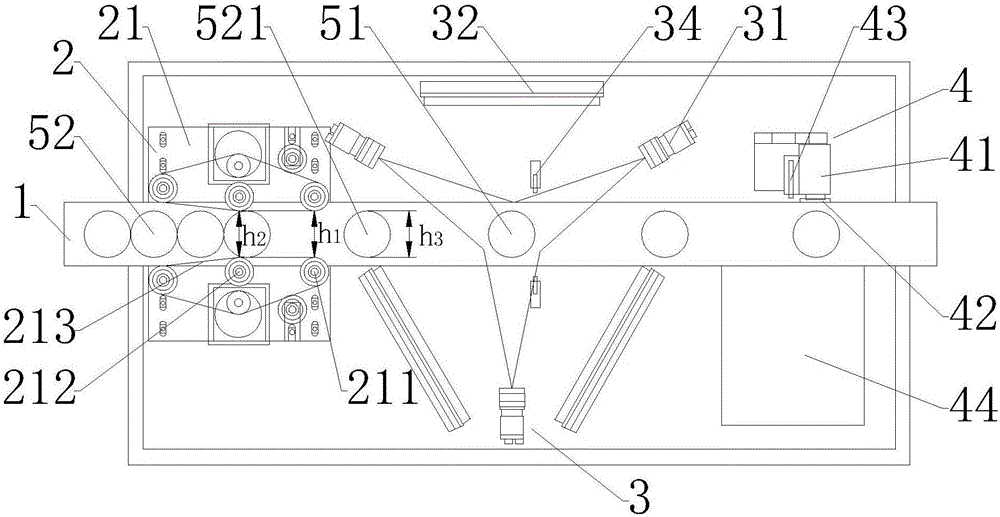

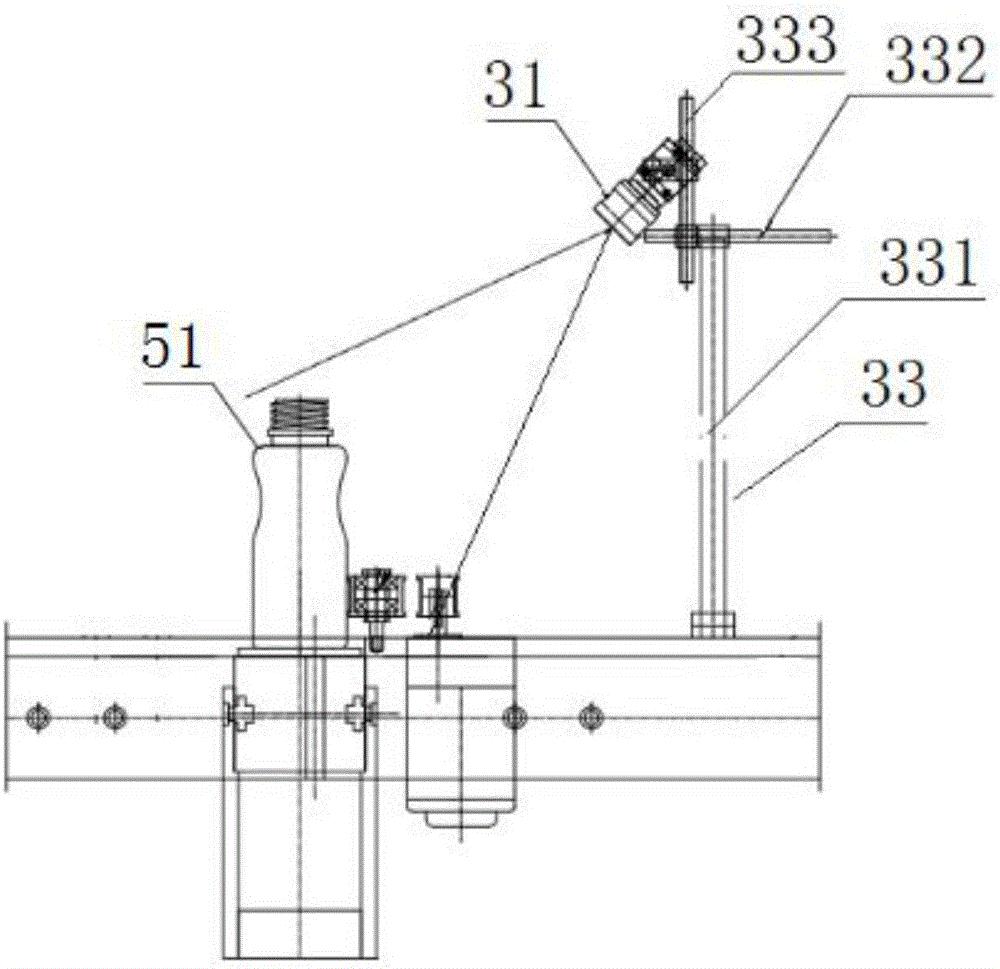

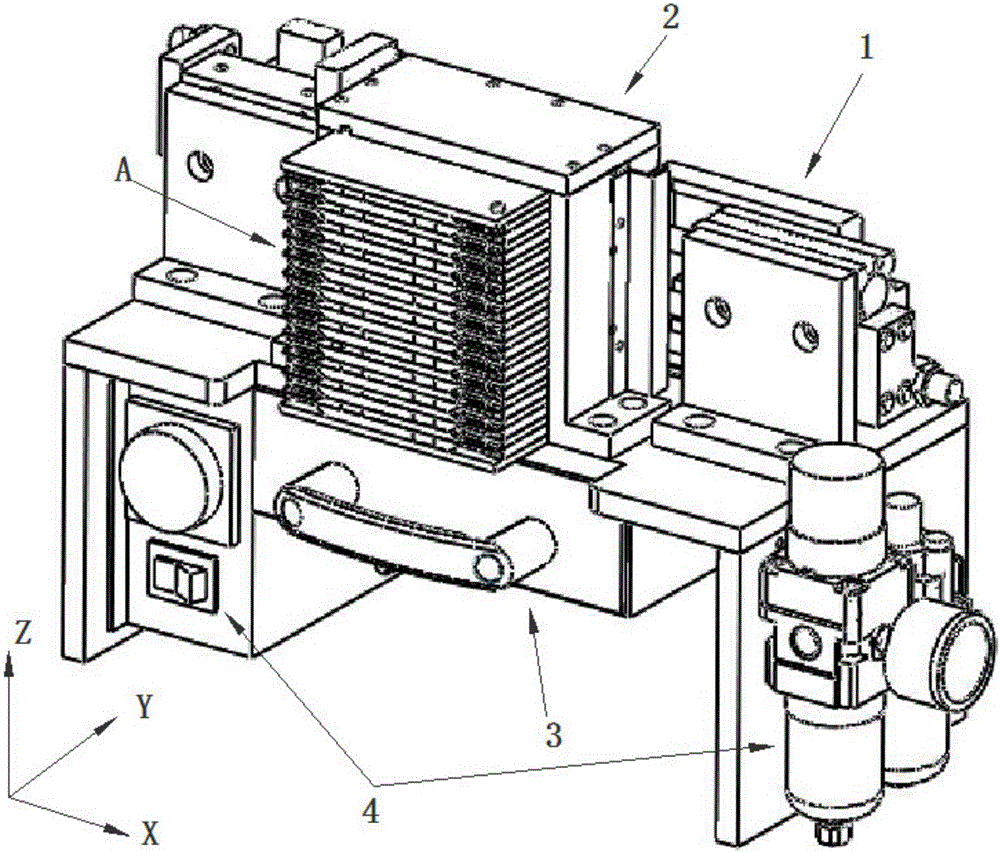

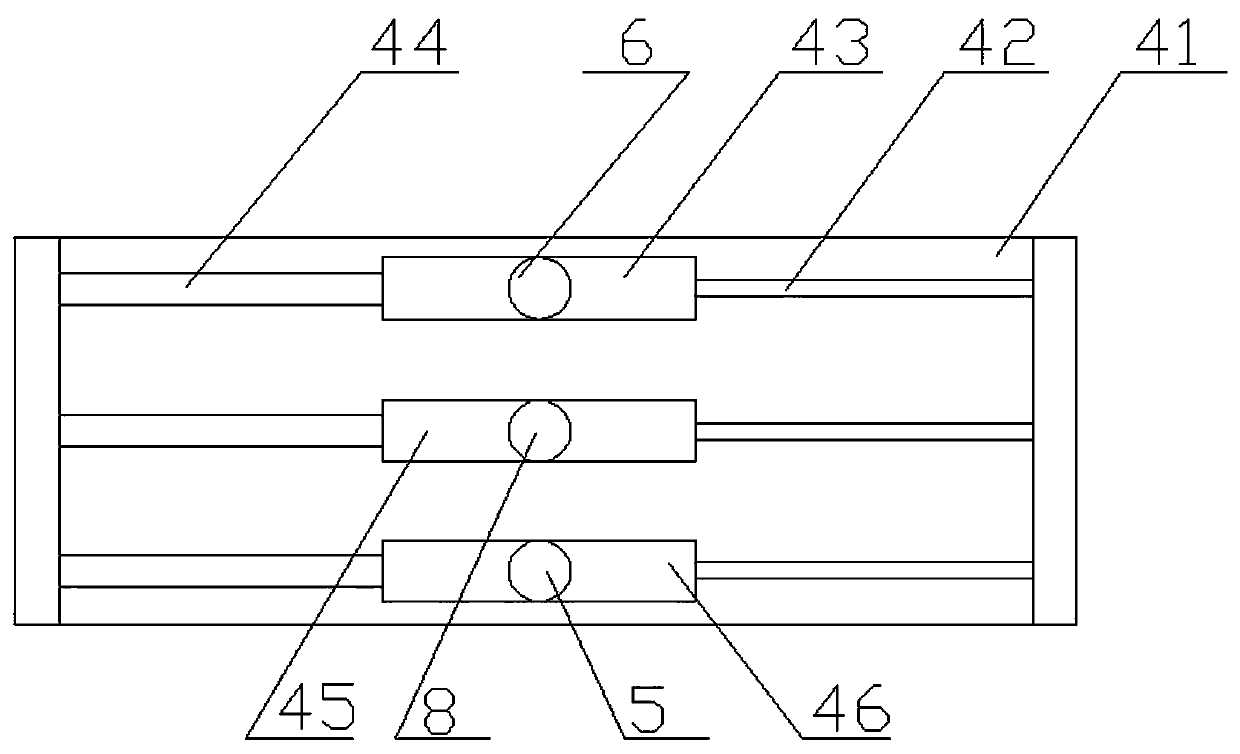

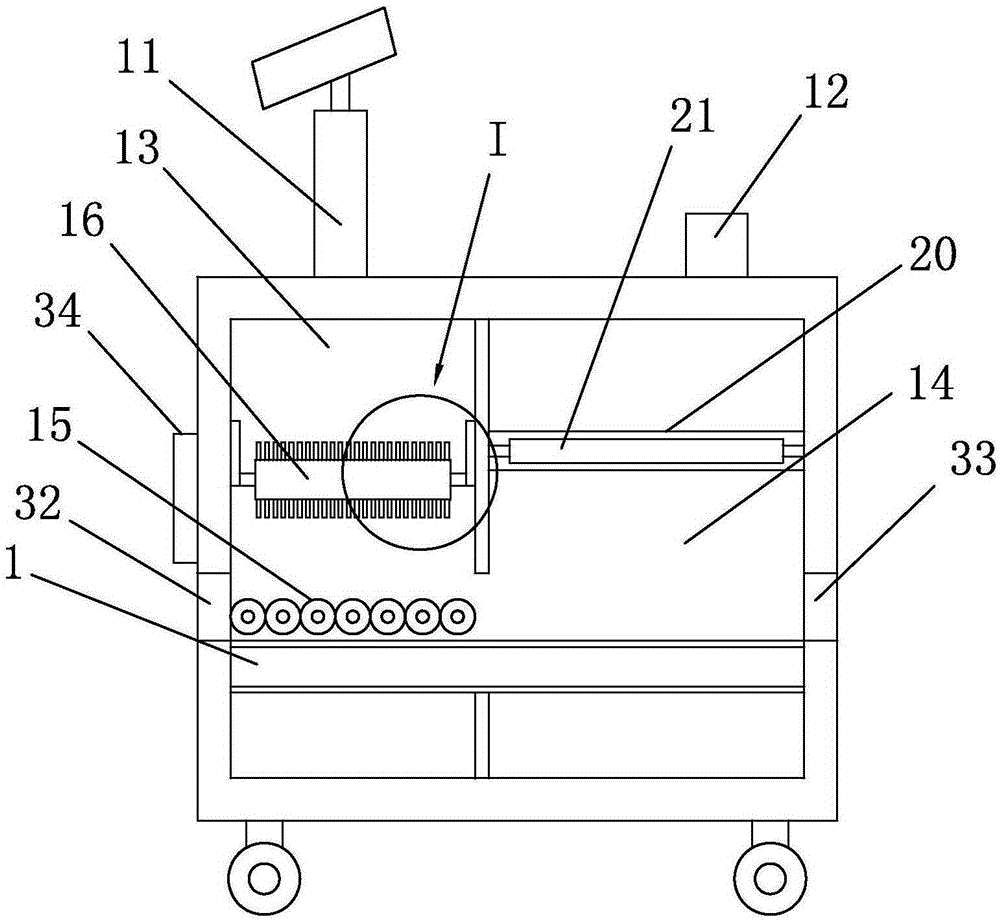

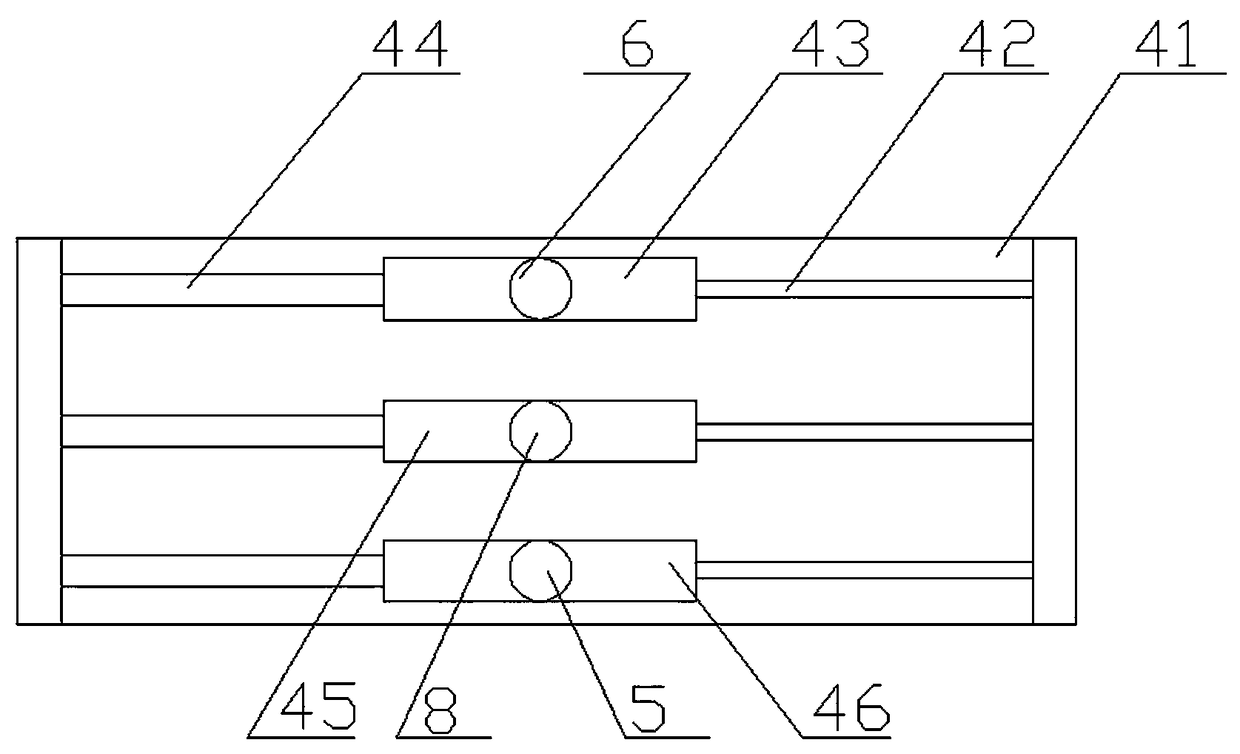

Quality visual detection system for plastic bottles

InactiveCN106706654AAchieve one-by-one separationRealize all-round image acquisitionOptically investigating flaws/contaminationEngineeringVisual perception

The invention relates to a quality visual detection system for plastic bottles. The quality visual detection system comprises a detection box and a server; a conveying guide rail, a separating mechanism and a detection mechanism are arranged in the detection box; the separating mechanism comprises two transmission parts, and the two transmission parts are used for separating the to-be-detected plastic bottles one by one to orderly enter a detection station; the detection mechanism comprises three cameras and a light source, and the three cameras are arranged on the two sides of the conveying guide rail in the shape of a regular triangle. The quality visual detection system provided by the invention has the benefits that as the separating mechanism is arranged, the next to-be-detected plastic bottle can be driven to move forwards; meanwhile, the distance between the next to-be-detected plastic bottle and the detected plastic bottle can be controlled, so that the influence on the accuracy of detection results is avoided, and the problem of slower detection speed is solved; the quality visual detection system provided by the invention can also realize the all-round image collection of the detected plastic bottles, so that the detection results are more reliable.

Owner:WUHAN EASY VIEW SCI & TECH CO LTD

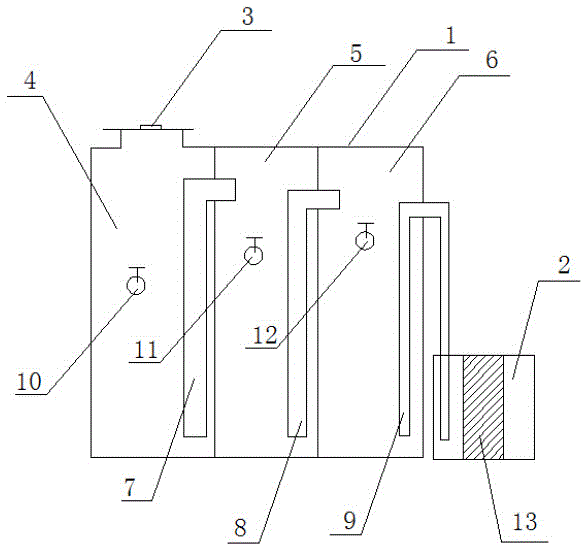

Oil-water separation device

InactiveCN104399285AEfficient separationTake up a lot of spaceSeparation devicesLiquid separationOil waterOpening height

The invention belongs to the technical field of separation equipment and relates to an oil-water separation device. The main body of the oil-water separation device comprises an enclosed first tank, the top of the first tank is provided with an oil-water mixture inlet, several separator plates are arranged in the first tank and divides the first tank into several compartments, a liquid transport pipe is arranged between each two adjacent compartments and is used for communicating the two compartments. An output pipe communicated with the external environment is arranged in the last compartment. Inlets of the liquid transport pipes and the output pipe are close to the bottoms of the compartments. Outlets of the liquid transport pipes and the output pipe are close to the top of the first tank. The first compartment communicated with the oil-water mixture inlet is provided with a first oil outlet for oil discharge. The opening height of the first oil outlet is larger than the inlet height of the liquid transport pipe in the first compartment. The oil-water separation device has a simple design, a low cost, good oil-water separation effects and high efficiency, is convenient for waste oil centralized recovery and water recovery and recycle, and can be operated conveniently and fast. The oil-water separation device realizes zero discharge of COD in water.

Owner:HENAN JINKAI CHEM INVESTMENT HLDG GRP

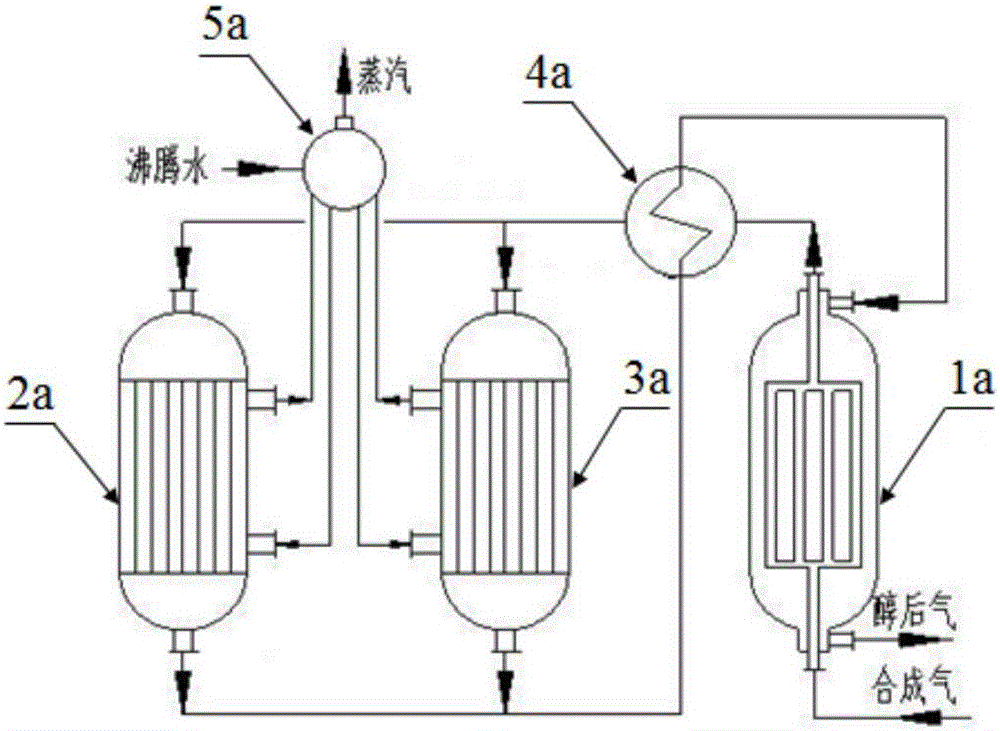

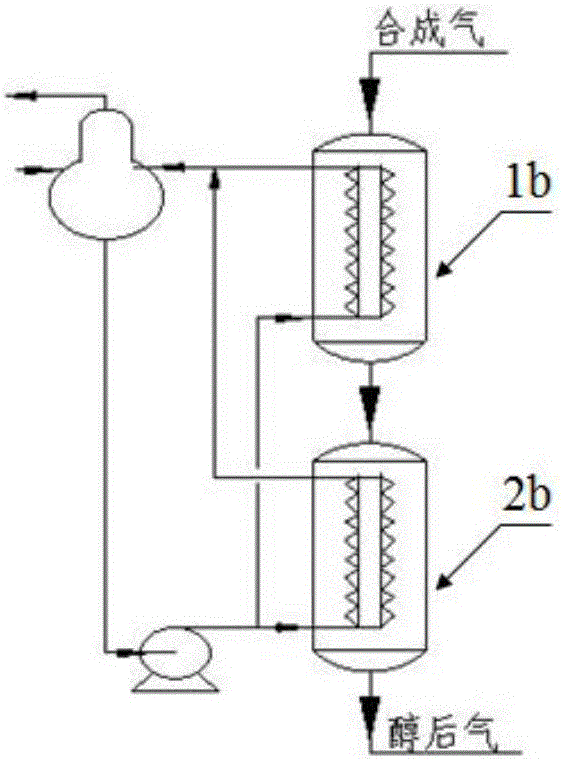

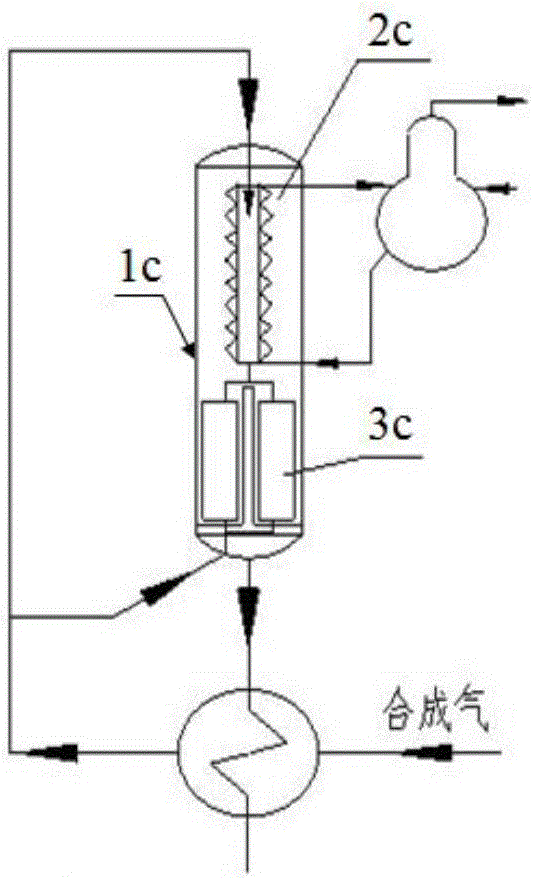

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

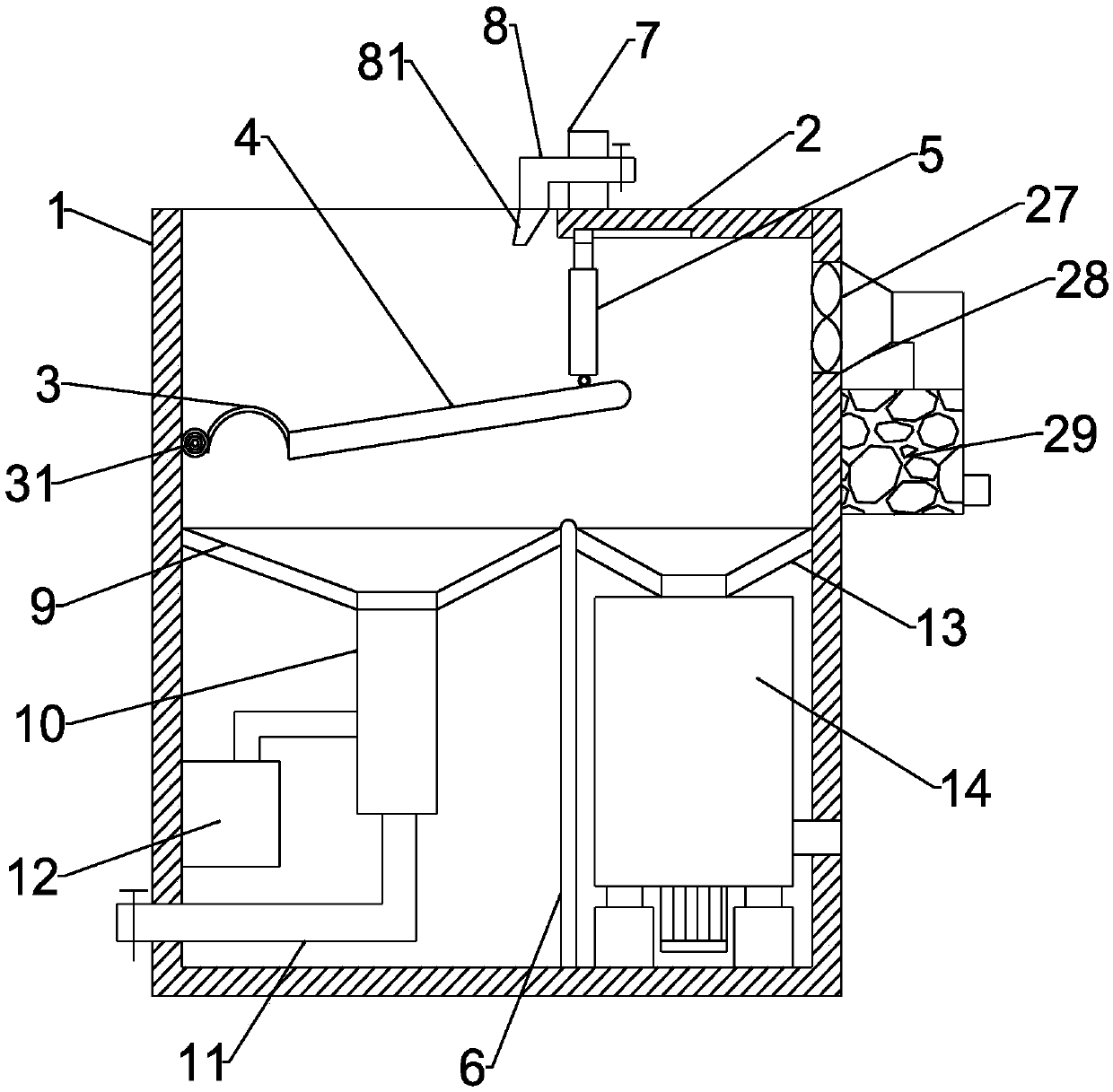

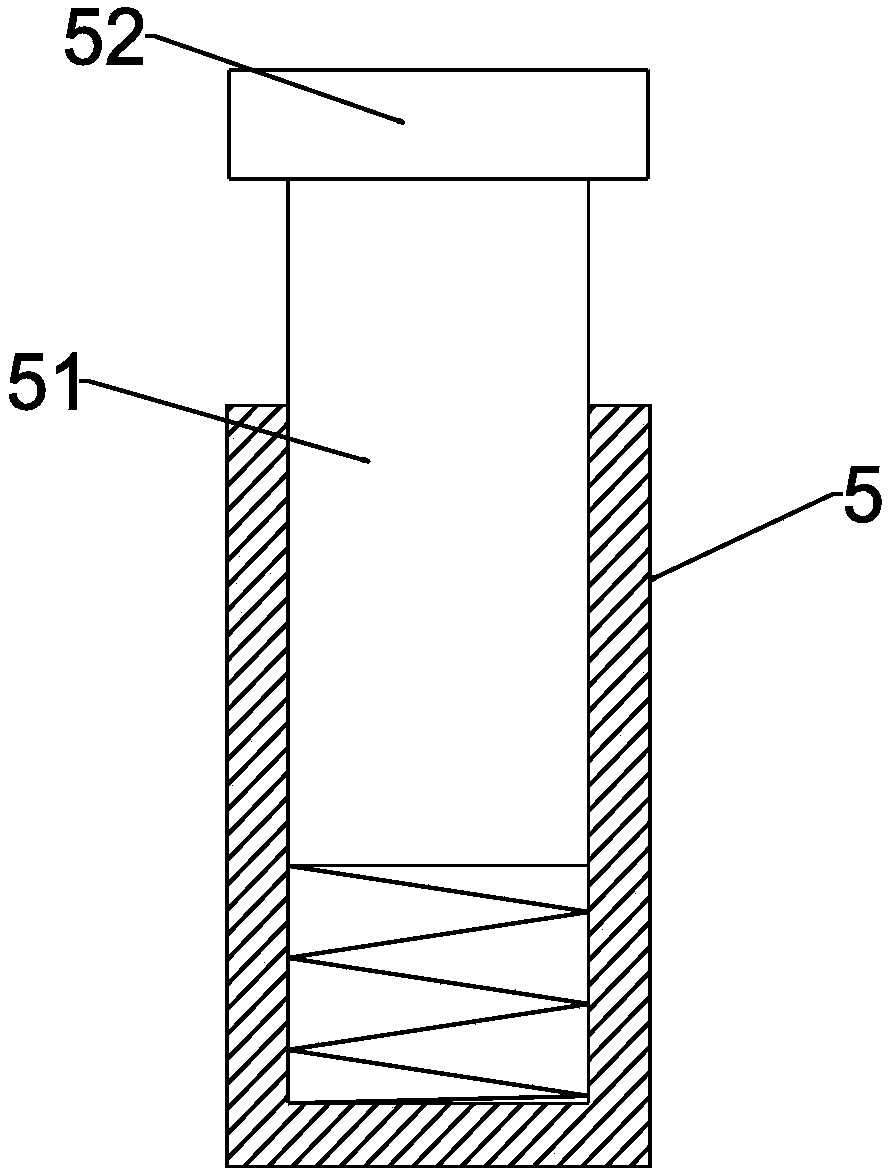

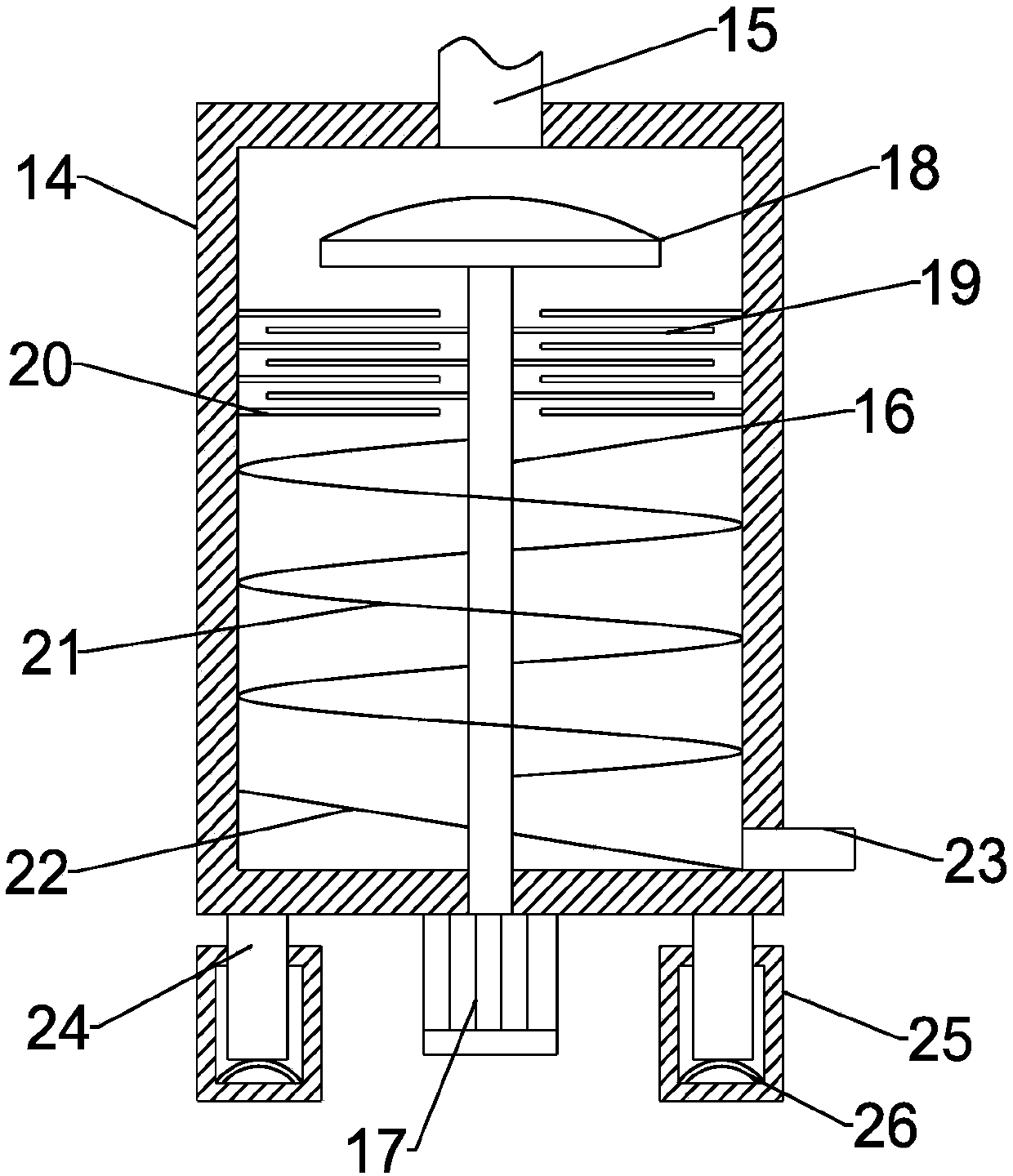

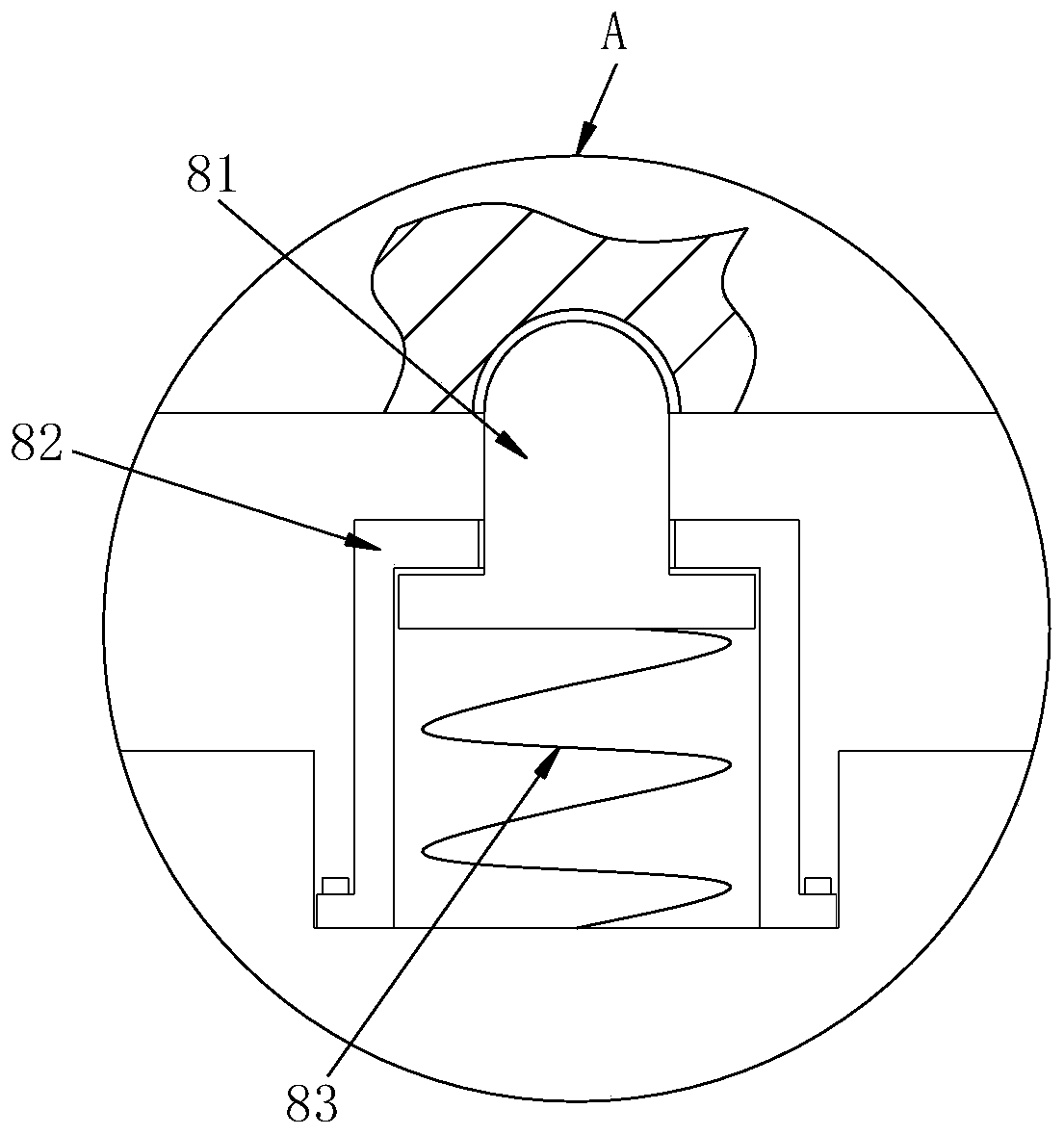

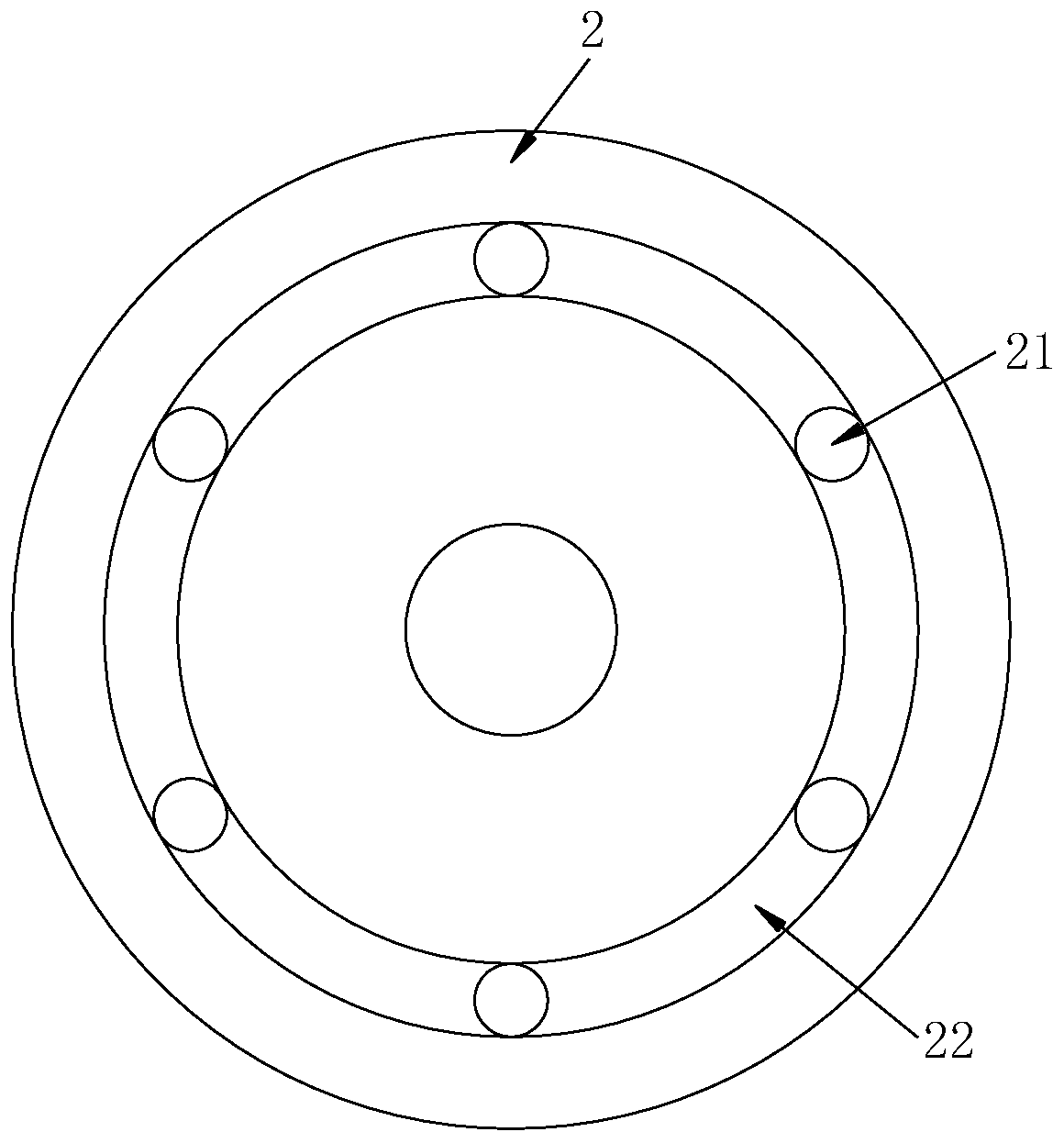

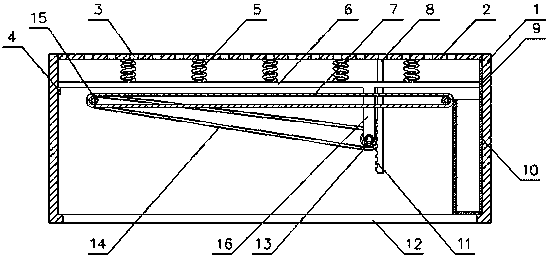

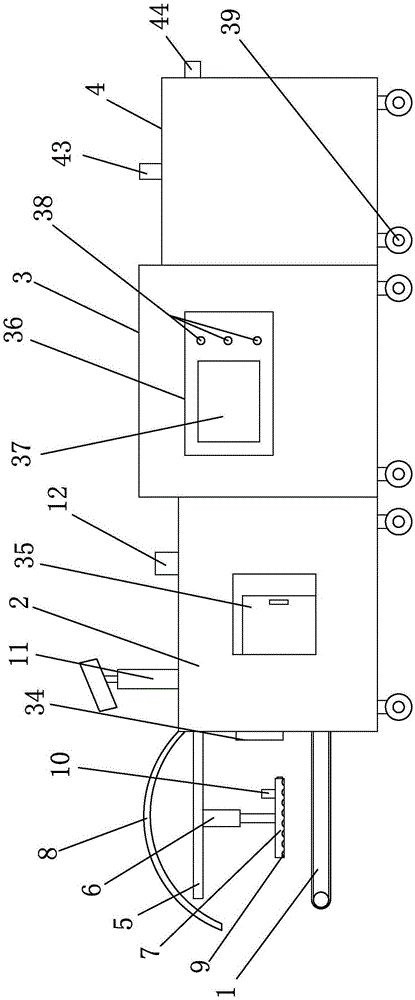

Household kitchen waste separated disposal device

InactiveCN107695079ASimple deliveryConvenience for centralized recyclingTransportation and packagingSolid waste disposalTorsion springEngineering

The invention discloses a household kitchen waste separated disposal device which comprises a shell. An upper mounting plate is arranged on the right side of the upper end of the shell. An arc filternet, a torsion spring and a guide plate are arranged on the left wall of the interior of the shell. A mounting sleeve, a movable connection rod and a movable sliding block are arranged on the right side of the upper end of the guide plate. A partition plate is arranged at the bottom of the shell. A support, a water guide pipe and a sprayer are arranged at the upper end of the upper mounting plate.A liquid material guide hopper, an oil-water separator, a drainage pipe and an oil storage tank are arranged between the inner wall of the shell and the left side of the partition plate. A waste guide hopper and a smashing cavity are arranged between the inner wall of the shell and the right wall of the partition plate. The smashing cavity is provided with a stirring shaft, a motor, a distribution plate, a rotary smashing blade, a fixed smashing blade, a spiral guide vane, a guide bottom plate, a discharging pipeline and a supporting bottom rod. A supporting sleeve and a damping leaf spring are arranged on the lower side of the supporting bottom rod. An air exchange fan, an air gathering cover and a sundry filtering cavity are arranged on the right wall of the shell. The household kitchenwaste separated disposal device can separate out kitchen solid sundries, oil and waste water, and is simple and efficient.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

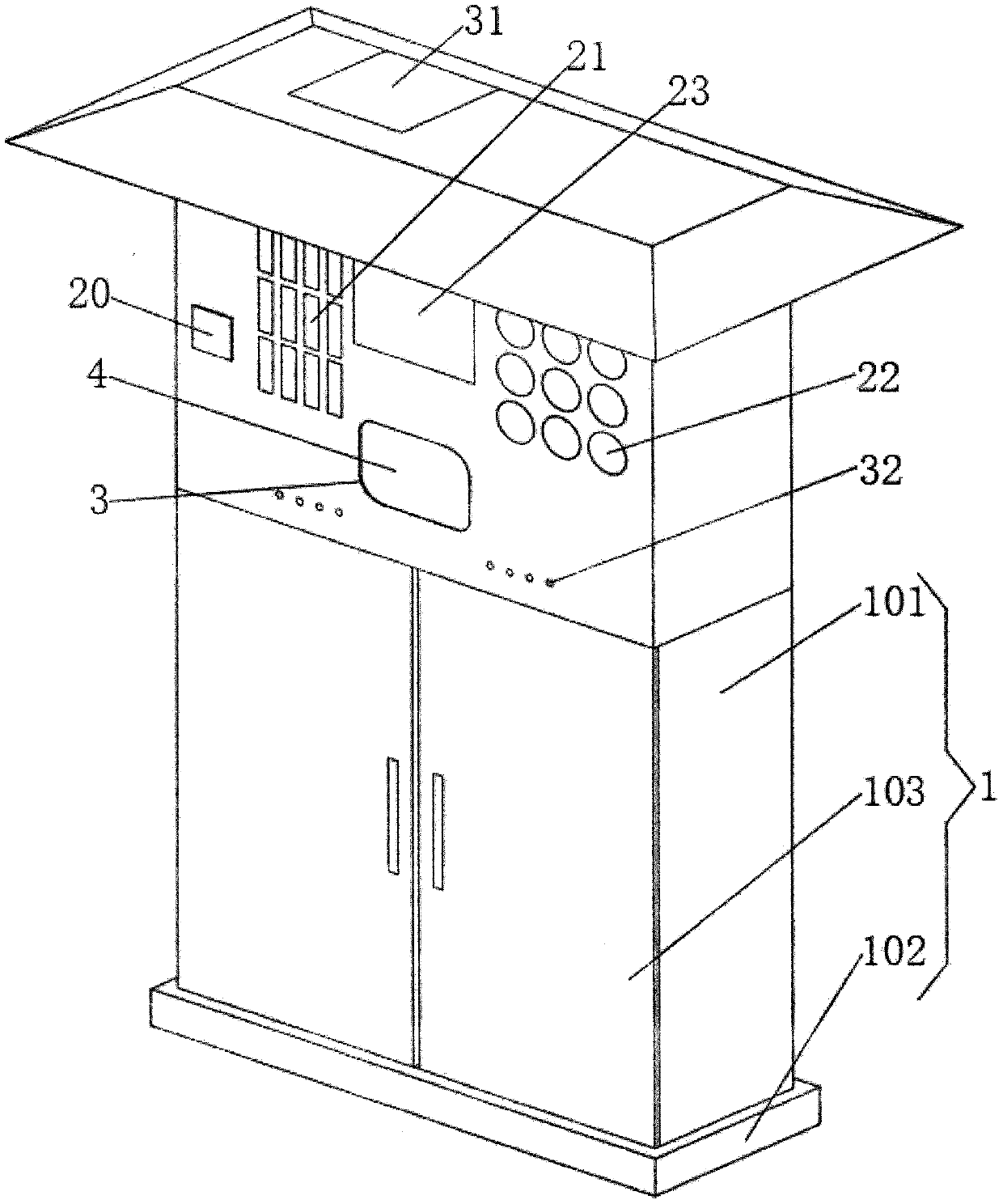

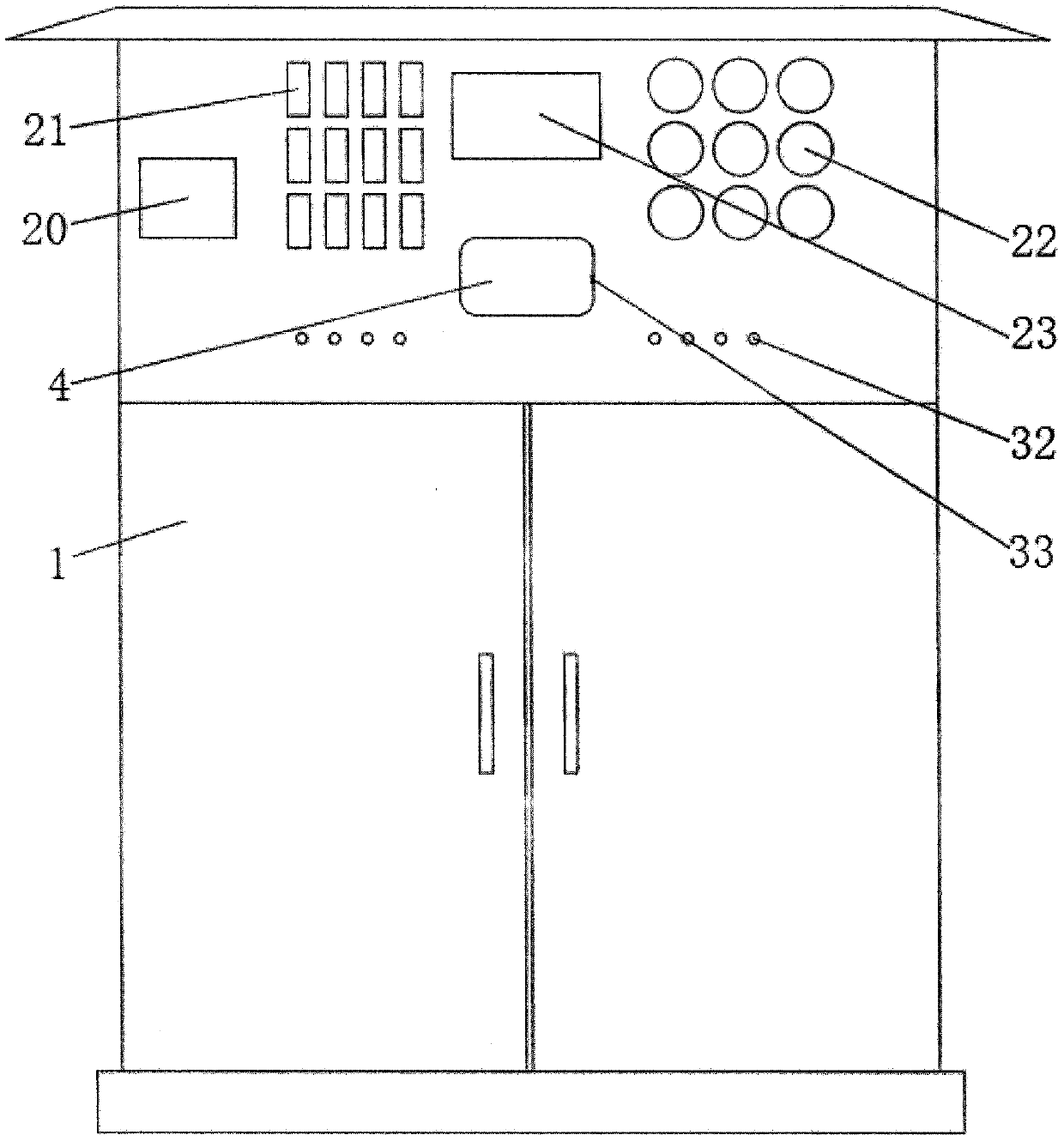

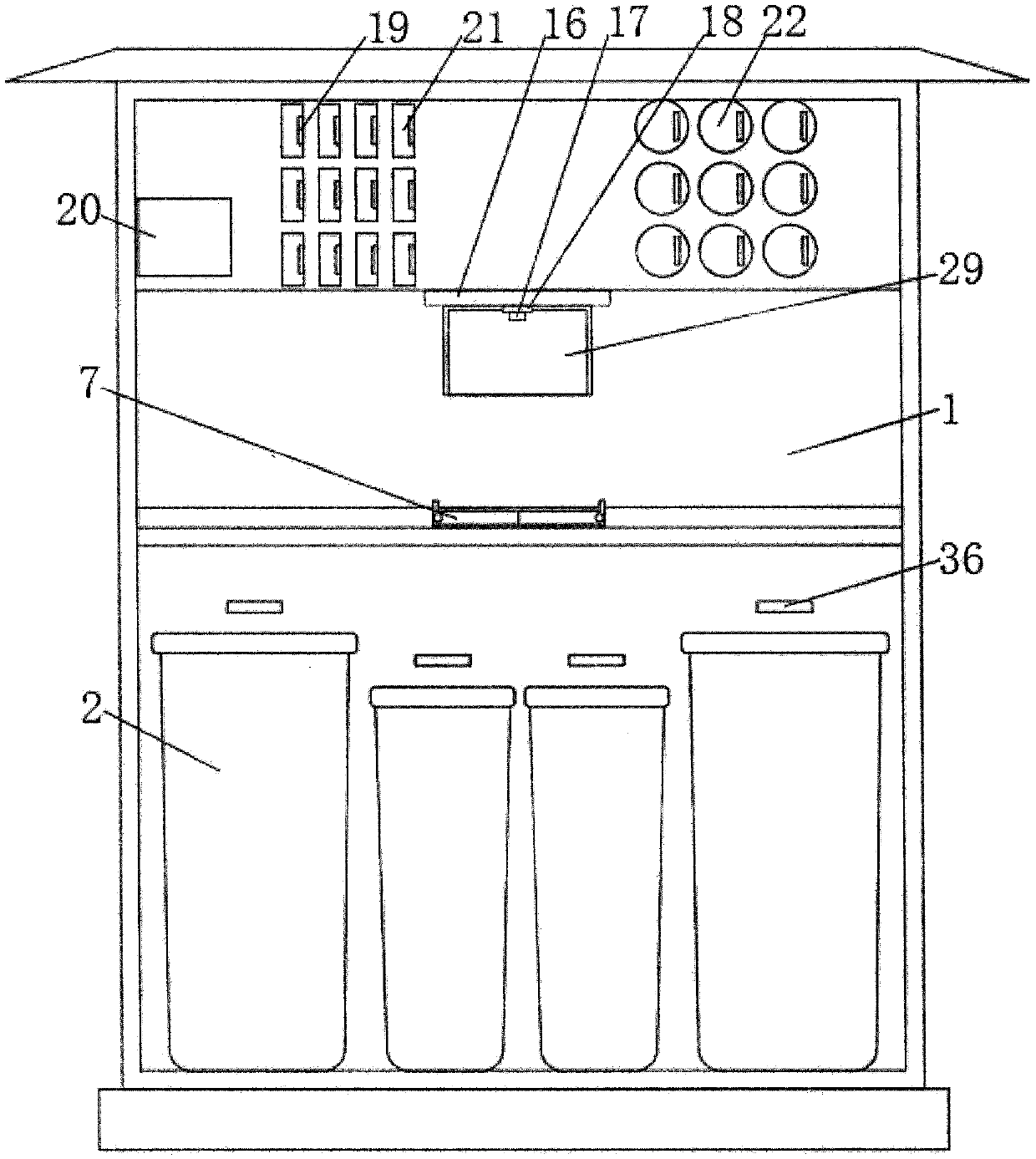

Intelligent garbage classification garbage can

ActiveCN110902188AAvoid pinchingImprove safety performanceWaste collection and transferRefuse receptaclesOperating systemComputer engineering

The invention discloses an intelligent garbage classification garbage can, and belongs to the field of garbage classification. The intelligent garbage classification garbage can comprises a garbage can body, wherein four garbage bins are placed in the garbage can body; a garbage throwing port is formed in the top part of the front surface of the garbage can body; an automatic garbage door is slidably connected to the inner side of the garbage throwing port; and a second infrared object sensor is fixedly arranged on the inner side of the garbage throwing port and is located on the front surfaceof the automatic garbage door. According to the intelligent garbage classification garbage can provided by the invention, garbage can be automatically classified, so that the garbage classification error caused by the reason that people do not know the garbage types is avoided, the garbage can be conveniently classified and recycled, and the contribution is made for environmental protection; through shared power banks and shared umbrellas, the functions of the garbage can are enriched; and due to a solar panel fixedly arranged on the top part of the garbage can body, electric appliances in the garbage can body can be powered, so that the energy loss is reduced, and the device can be used in an environmental protection and conservation way.

Owner:上海良韶智能科技有限公司

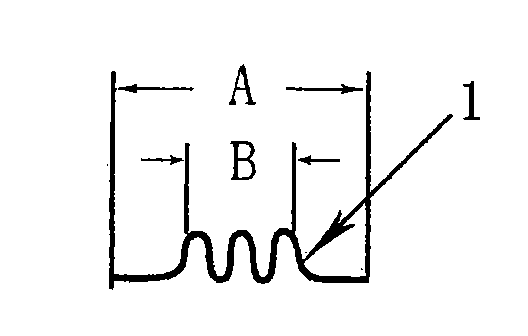

Two-faced adhesive tape and preparing process thereof

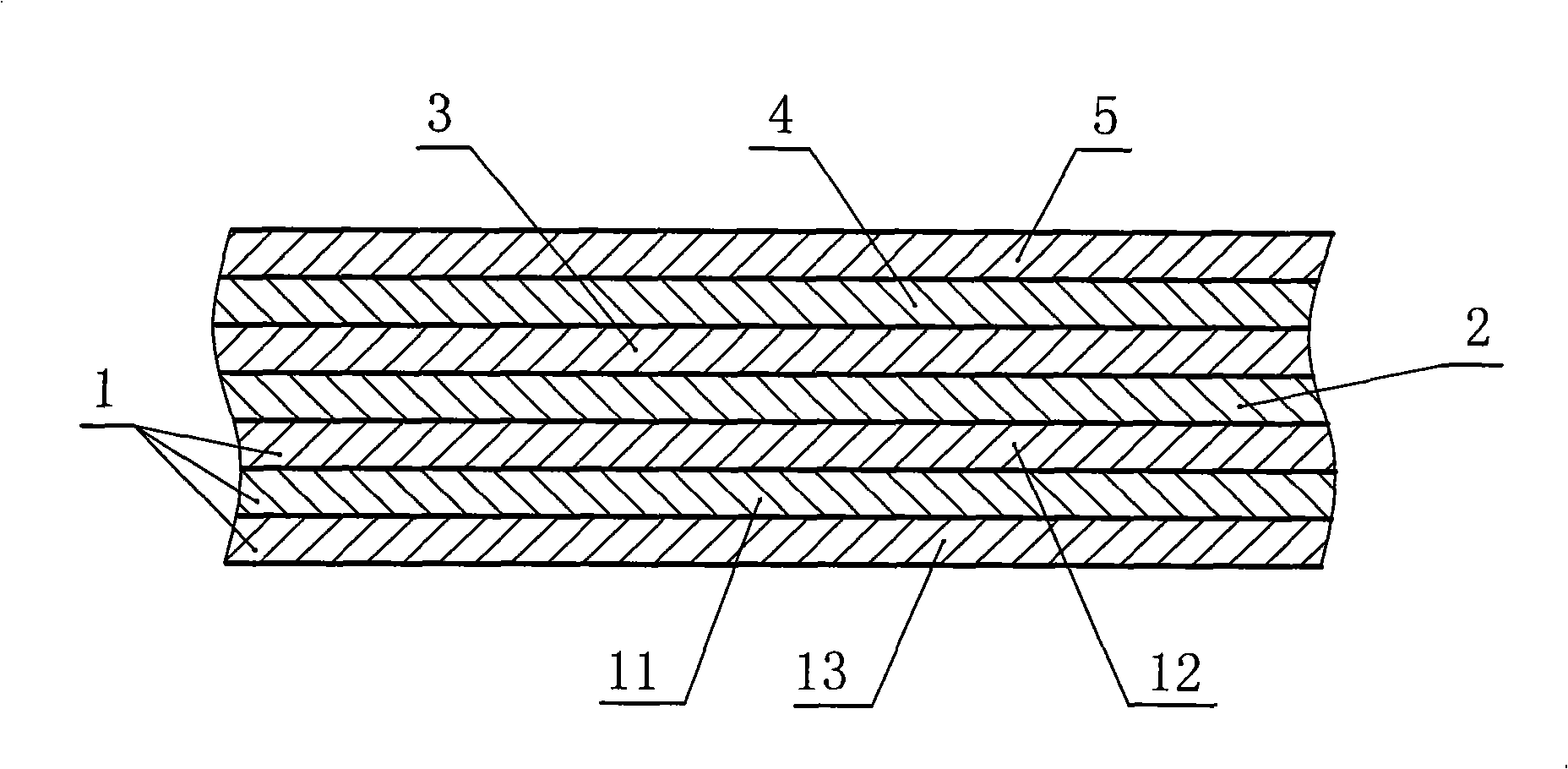

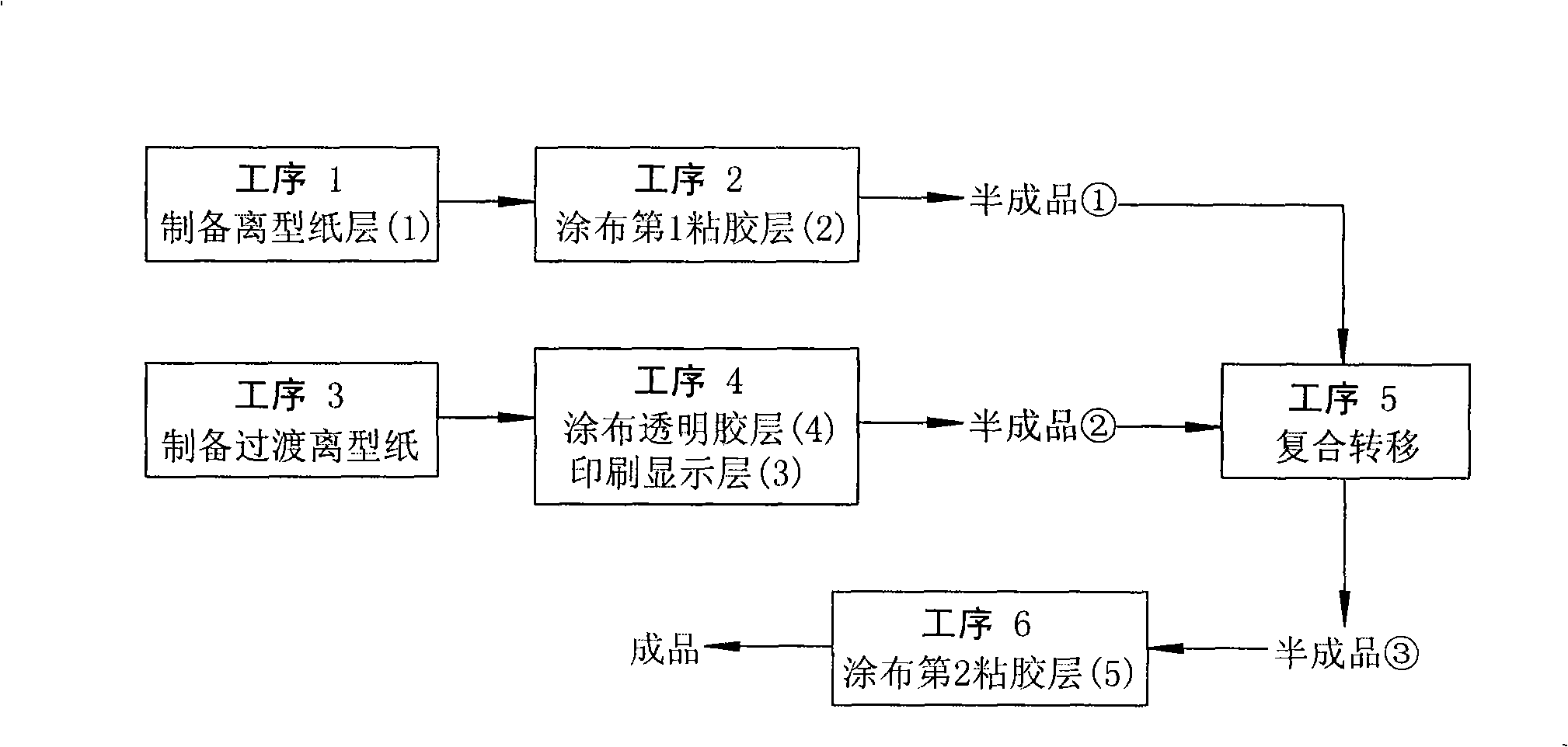

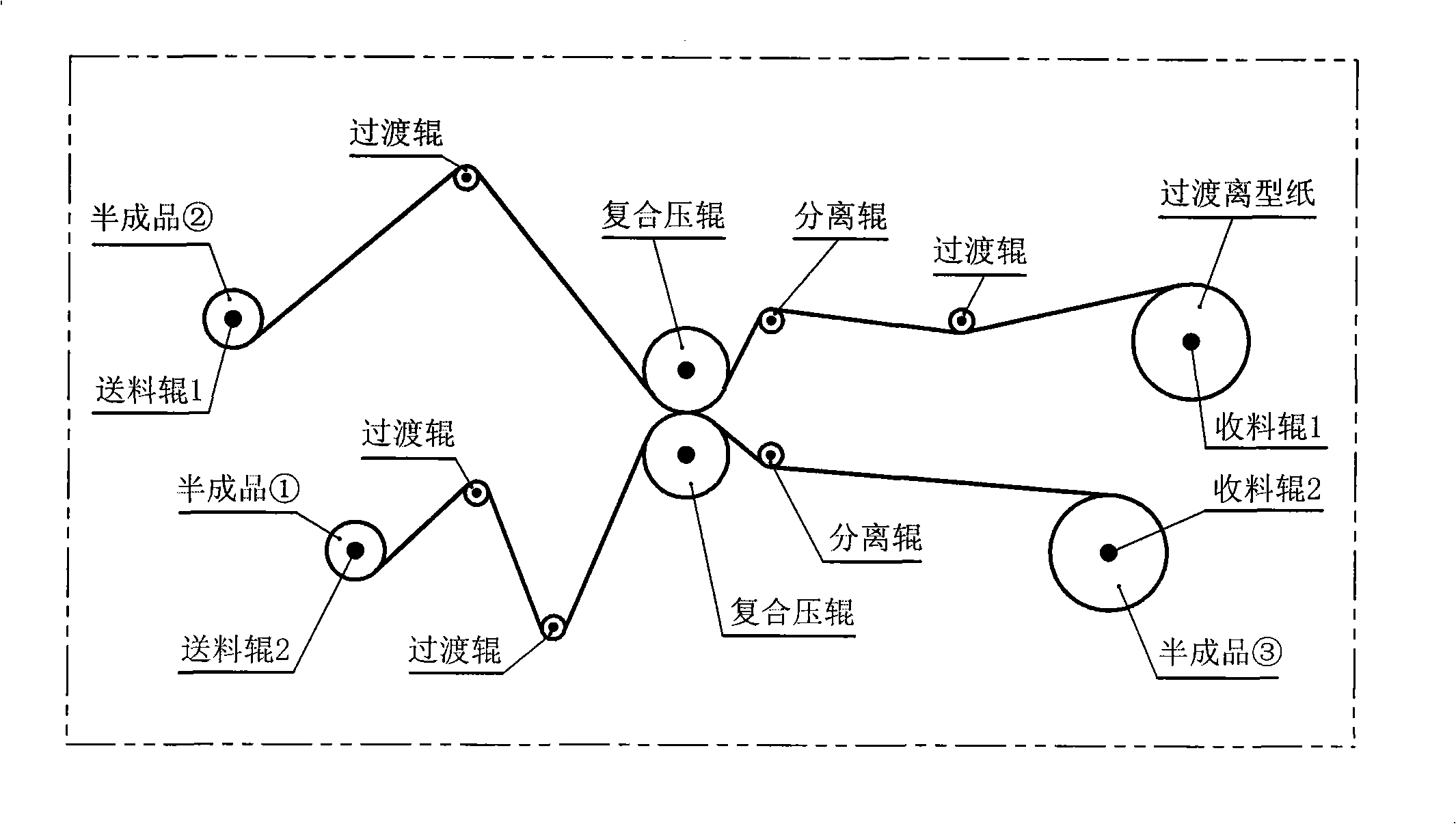

ActiveCN101314701AReduce thicknessReduce the number of layersLamination ancillary operationsFilm/foil adhesivesAdhesiveEngineering

The invention discloses a double-sided adhesive tape, which comprises a release paper layer consisting of a tape base layer and an upper and a lower anti-sticking layers applied on and connected with the upper and the lower surfaces of the tape base layer, a first adhesive layer connected with the upper surface of the release paper layer, a display layer connected with the upper surface of the first adhesive layer, a transparent adhesive layer connected with the upper surface of the display layer, and a second adhesive layer connected with the upper surface of the transparent adhesive layer, which are mutually superposed and arranged to form the layered structure of the double-sided adhesive tape. Compared with novel double-sided adhesive tapes of the prior art, the double-sided adhesive table produced by adopting a new structure design and a coating process has the advantages of less layer number, thinness, and low production cost besides the practical efficacies such as new adhesion property, advertisement and indication. The double-sided adhesive tape with the novel function can be coiled to small core shape and arranged in a double-sided adhesive applier box to provide convenience for users. Meanwhile, the used belt box and the belt core release paper can be recycled conveniently, thus being conducive to environment protection.

Owner:XIAOXUEREN STATIONERY NINGHAI COUNTY

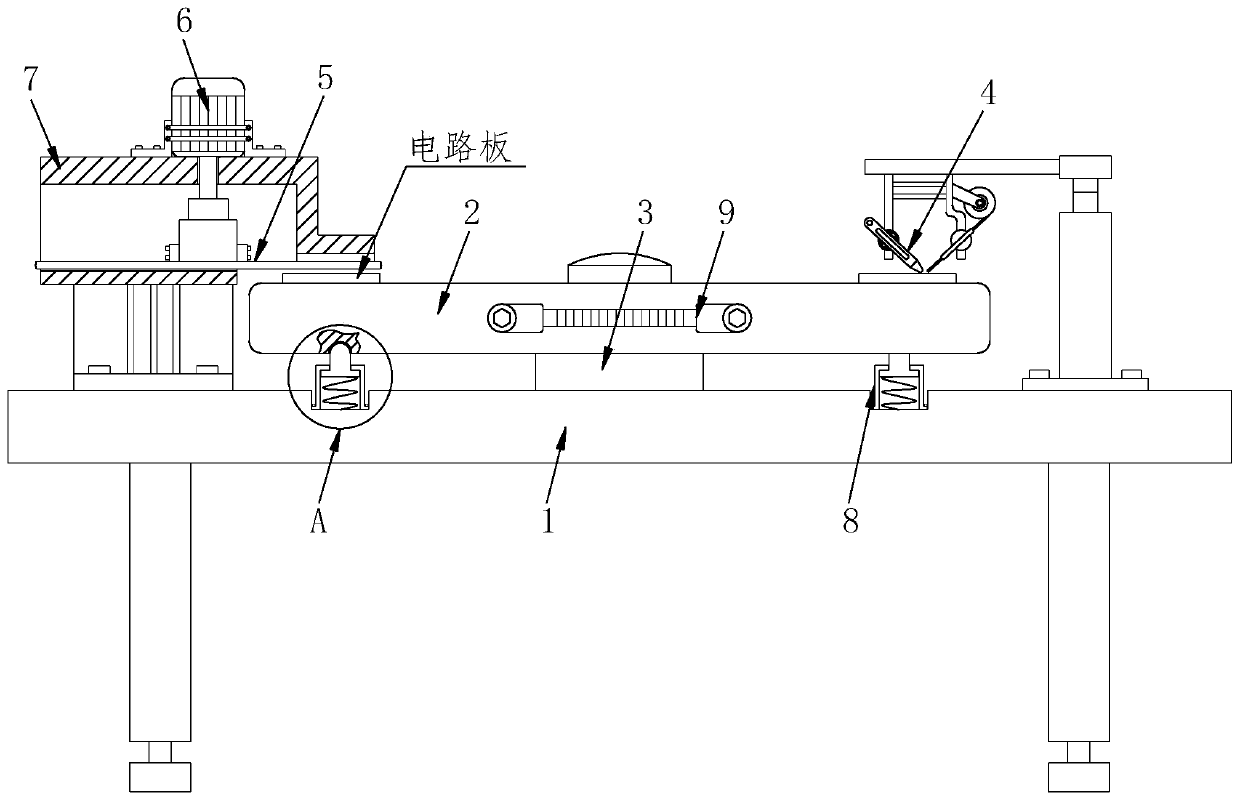

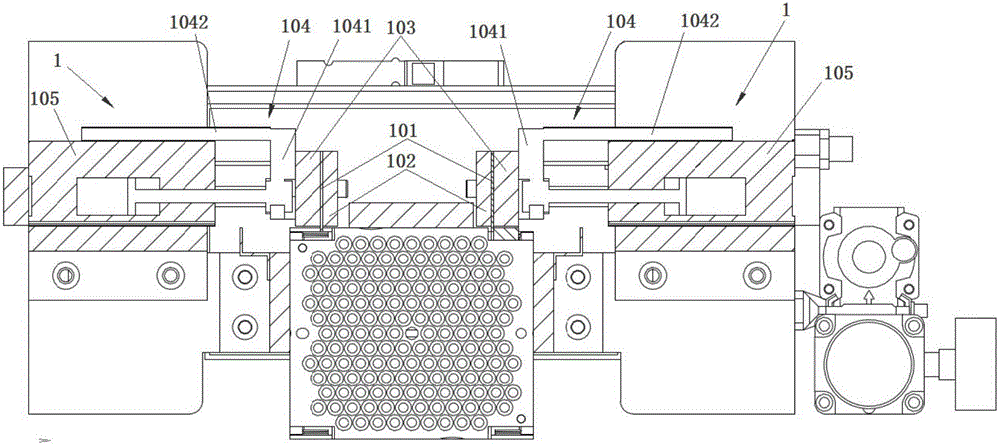

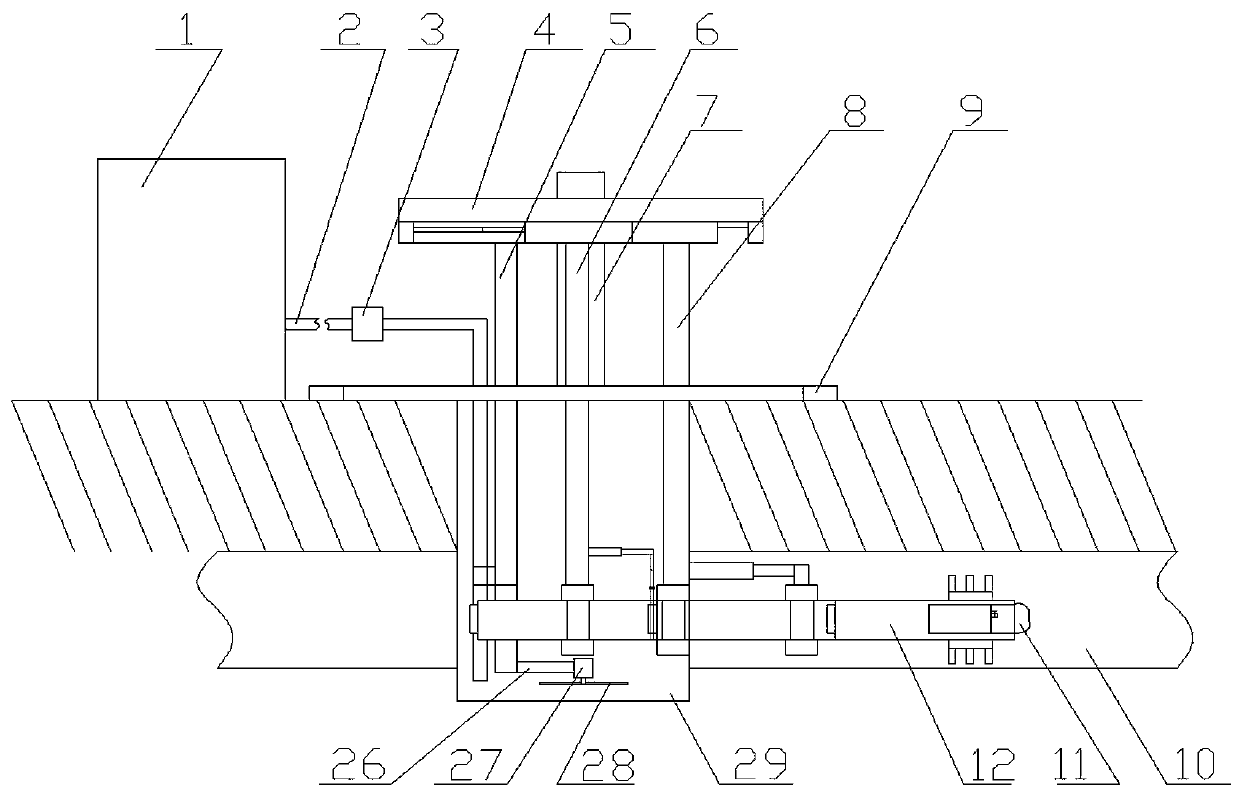

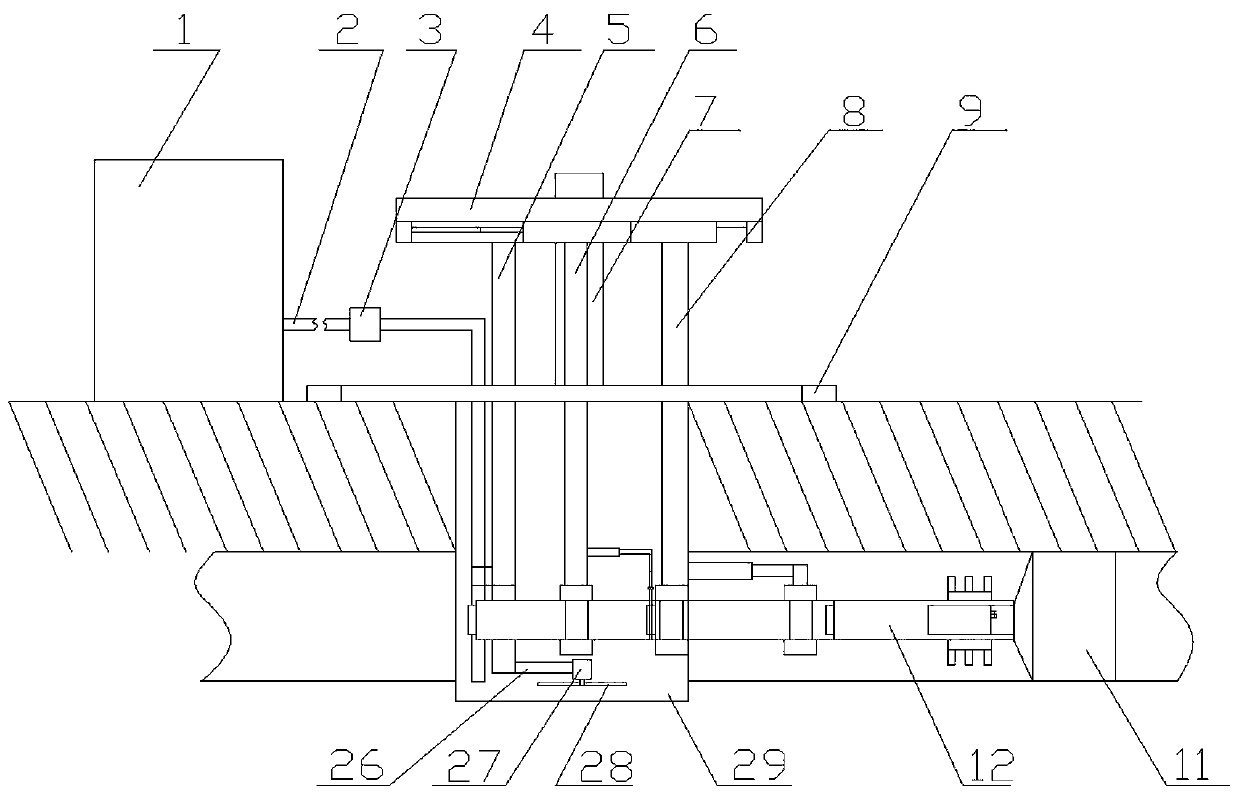

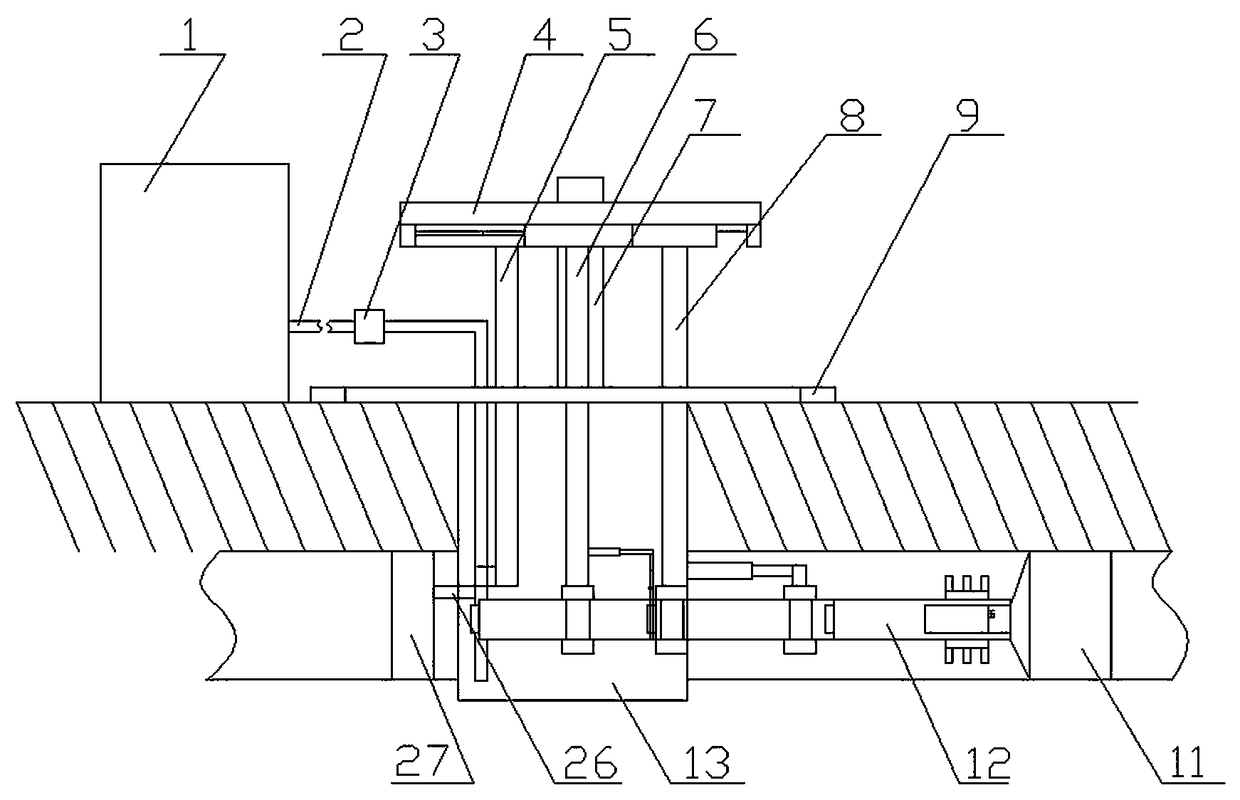

Location-welding all-in-one machine for electrical apparatus element pins of assembled circuit board

ActiveCN110899892AWon't fall intoPrevent fallingMetal working apparatusSoldering auxillary devicesElectric machineCoupling

The invention relates to a location-welding all-in-one machine for electrical apparatus element pins of an assembled circuit board. The location-welding all-in-one machine for the electrical apparatuselement pins of the assembled circuit board comprises a workbench surface, a placement rotary disc, a rotary shaft, a welding gun, a cutting assembly, a drive motor, a fixed frame, a location assembly and rotary handles, wherein the rotary shaft is installed at the central position of the top of the workbench surface; the placement rotary disc is installed at the upper end of the rotary shaft; the rotary handles are equidistantly arranged on the sidewall of the placement rotary disc; the location assembly is arranged at the top of the workbench surface and in an area on the lower end surfaceof the placement rotary disc; the welding gun is installed at one end of the placement rotary disc; the fixed frame is installed at the other end of the placement rotary disc; the drive motor is installed at the central position of the top of the fixed frame; the cutting assembly is connected to the bottom of the drive motor through a shaft coupling; and a circular rail is formed at the bottom ofthe placement rotary disc. According to the location-welding all-in-one machine for the electrical apparatus element pins of the assembled circuit board, the electrical apparatus element pins can be rapidly inserted into metal through holes; and moreover, the location-welding all-in-one machine for the electrical apparatus element pins of the assembled circuit board is appliable to different typesof circuit boards, and capable of rapidly and effectively cutting redundant pins.

Owner:东莞市硕动自动化设备有限公司

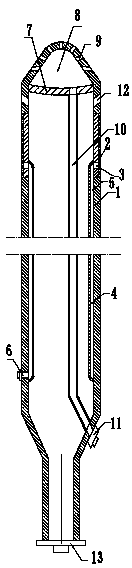

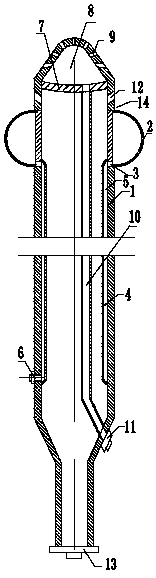

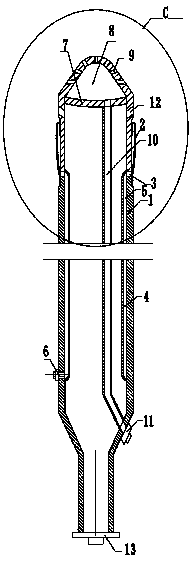

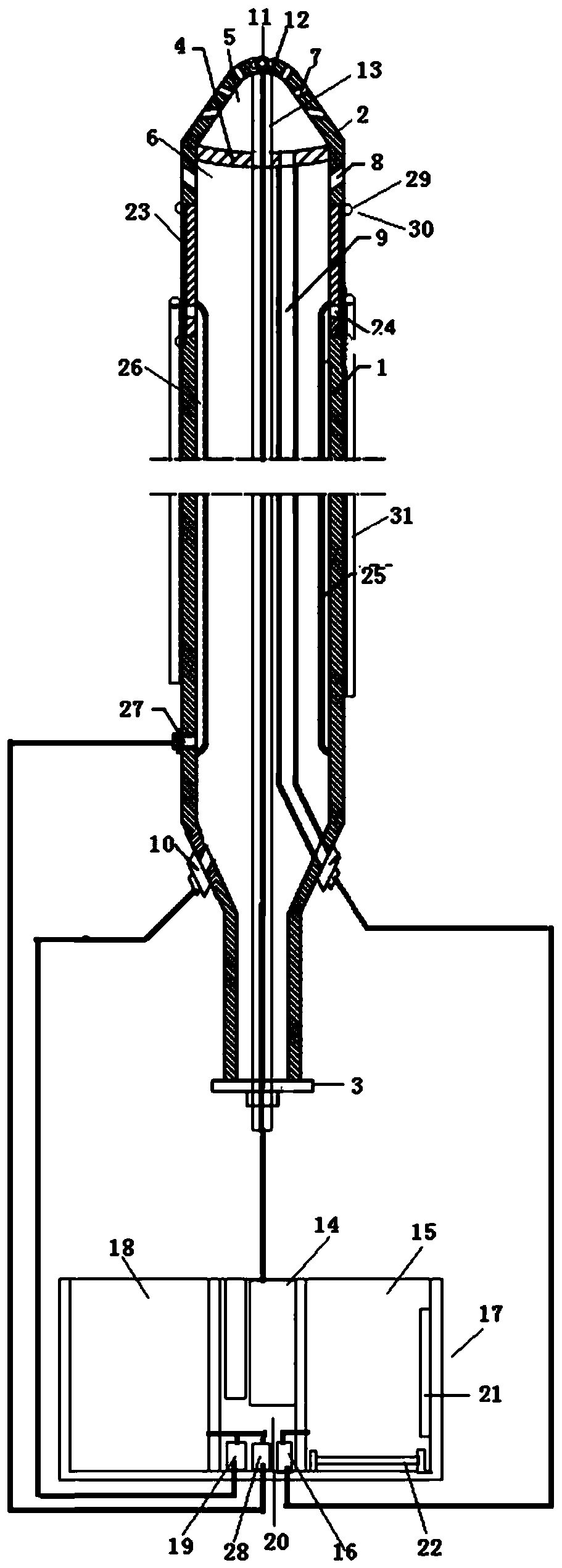

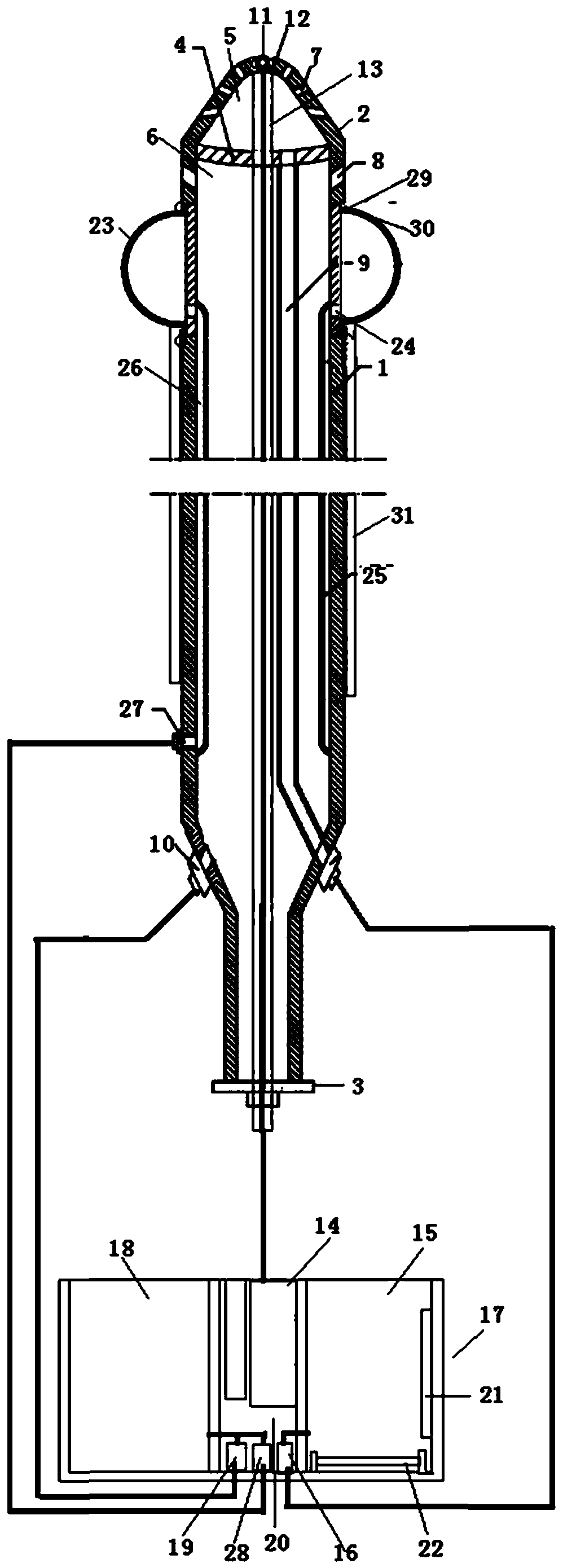

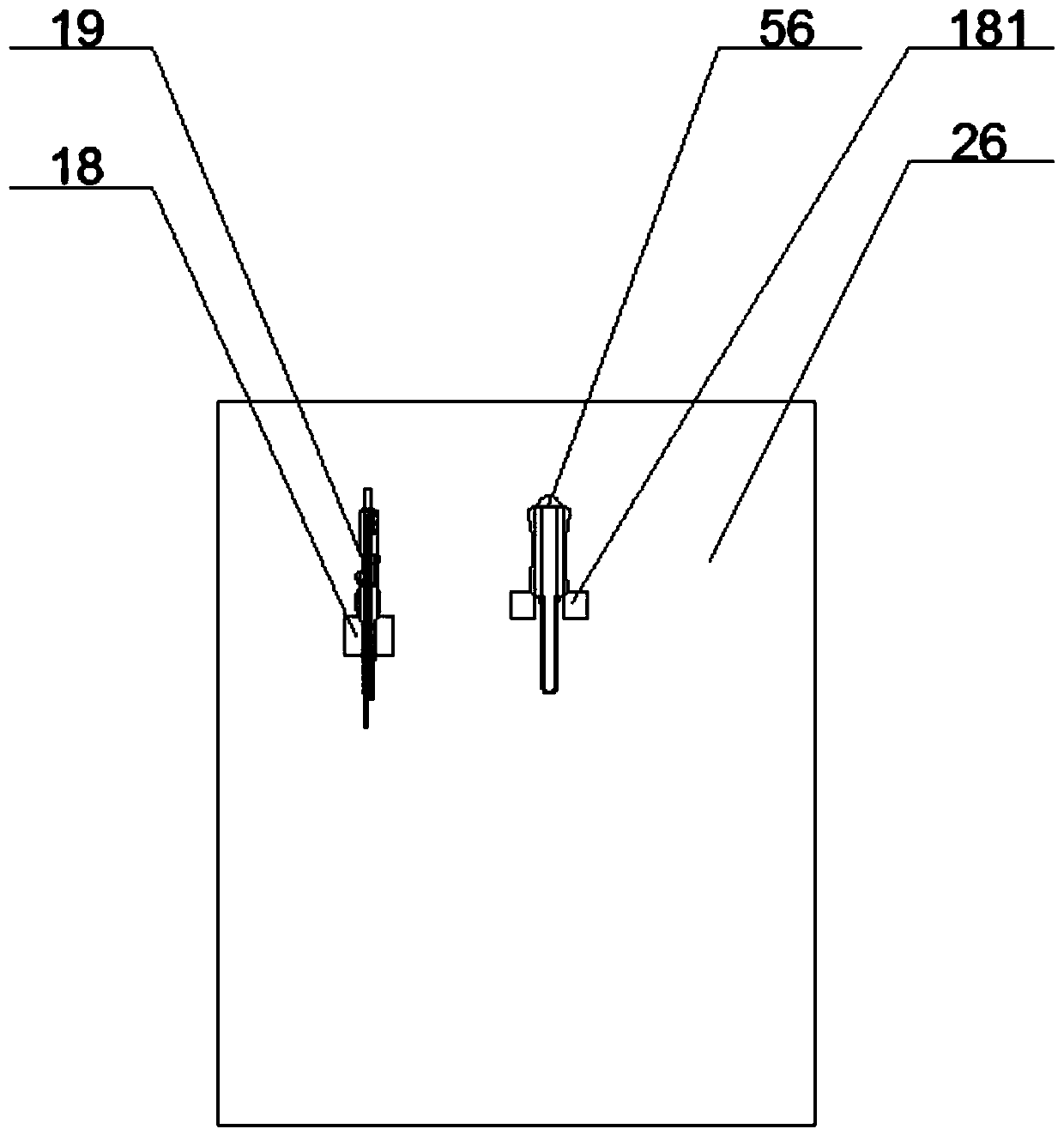

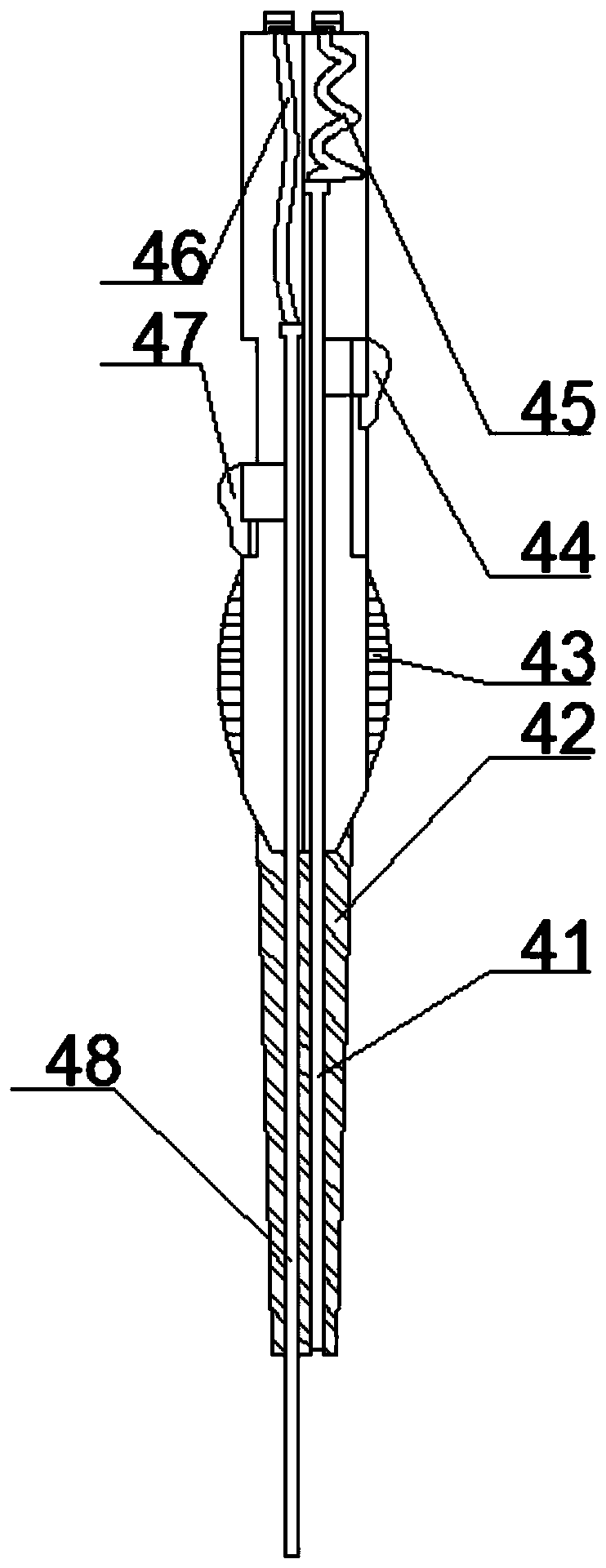

Vaginal cleaner for gynecology

InactiveCN108465140AFully cleanedEasy to operateCannulasEnemata/irrigatorsLiquid diffusionMedical equipment

The invention relates to medical equipment. In order to solve the technical problems existing in the gynecological vaginal cleaning process, the invention provides a vaginal cleaner for gynecology; the cleaner comprises a conveying tube with a hollow lumen, an outer tube wall near the front end of the conveying tube is covered with expandable film, a channel for pressurizing the film is arranged inside the conveying tube, the top end of the conveying tube is closed, a sealing plate is arranged in the lumen near the top end of the conveying tube, a closed liquid spreading cavity is formed between the sealing plate and the top end of the conveying tube, and a plurality of injection holes are formed in the end surface of the top end of the conveying tube; an injection tube is arranged insidethe conveying tube, the top end of the injection tube is communicated with the liquid spreading cavity, and the end of the injection tube is connected with a liquid injection interface on the wall ofthe conveying tube; a plurality of liquid return holes are formed in the wall of the conveying tube between the sealing plate and the film, and a recovery liquid control valve is arranged at the bottom of the conveying tube. The vaginal cleaner for the gynecology has a reasonable structure and convenient operation, and can be widely used in the gynecological treatment operation process.

Owner:姜凤霞

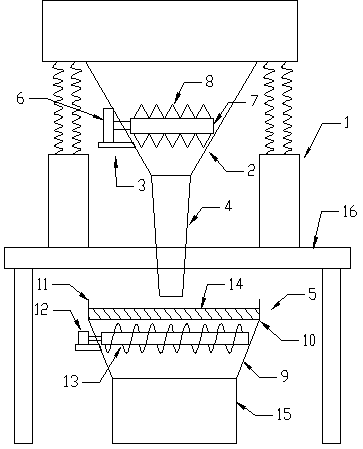

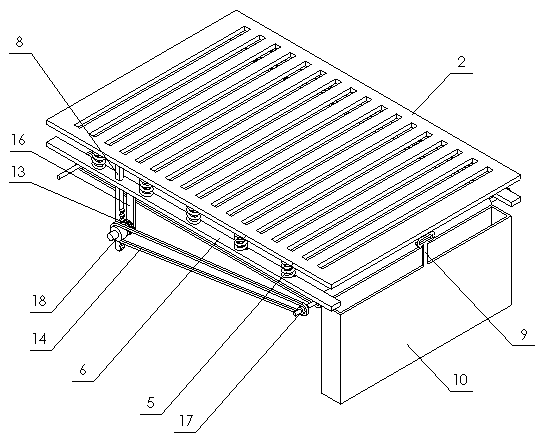

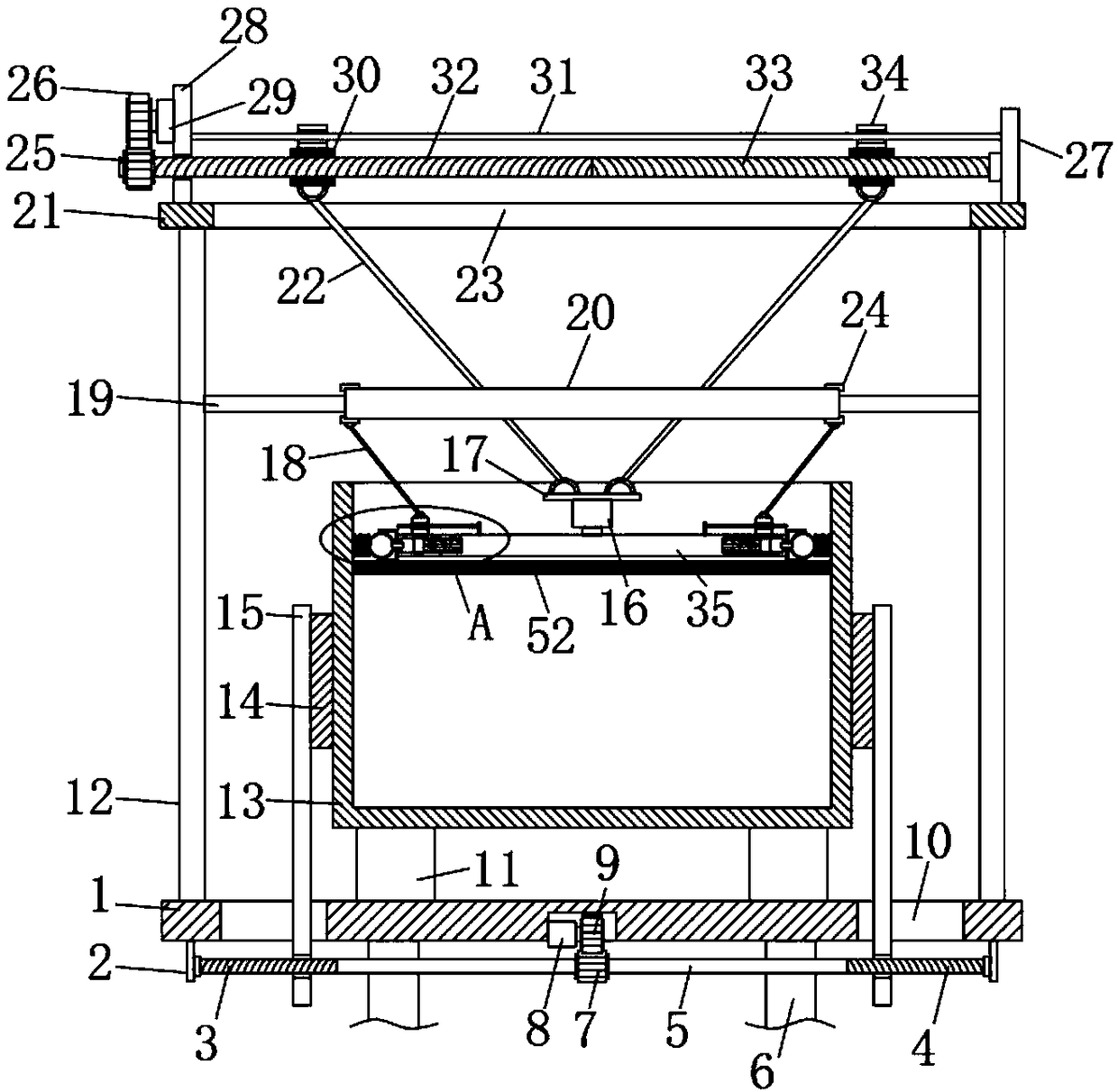

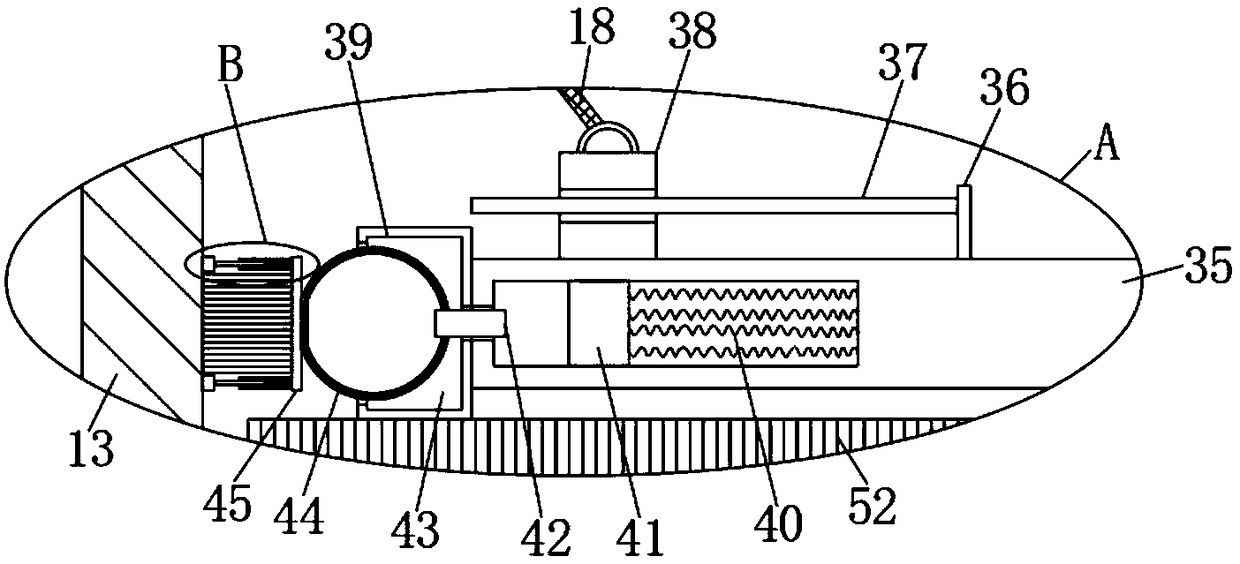

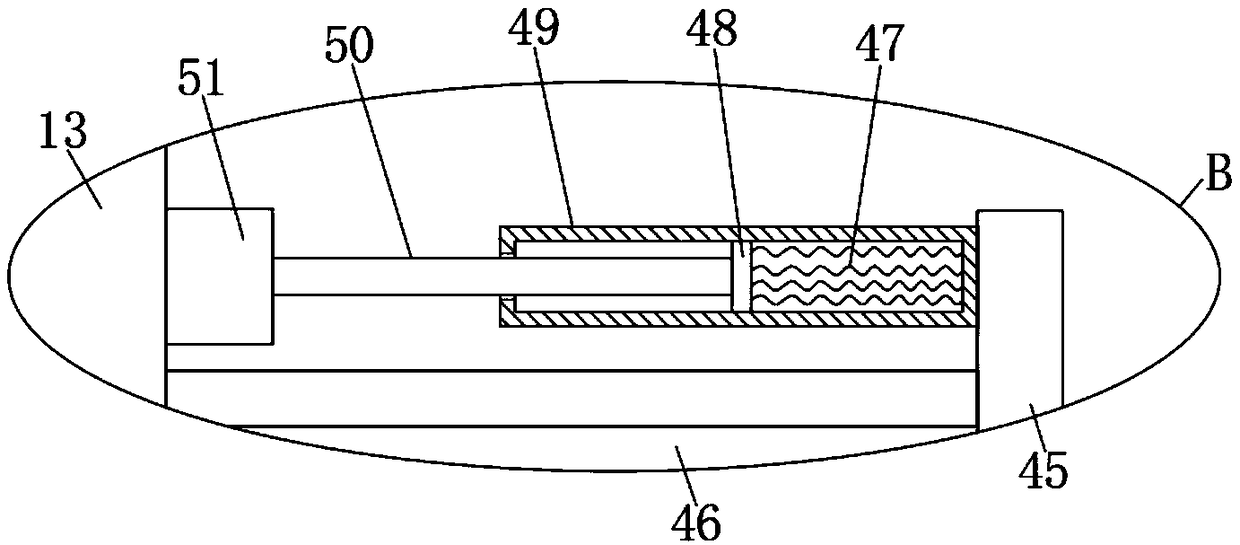

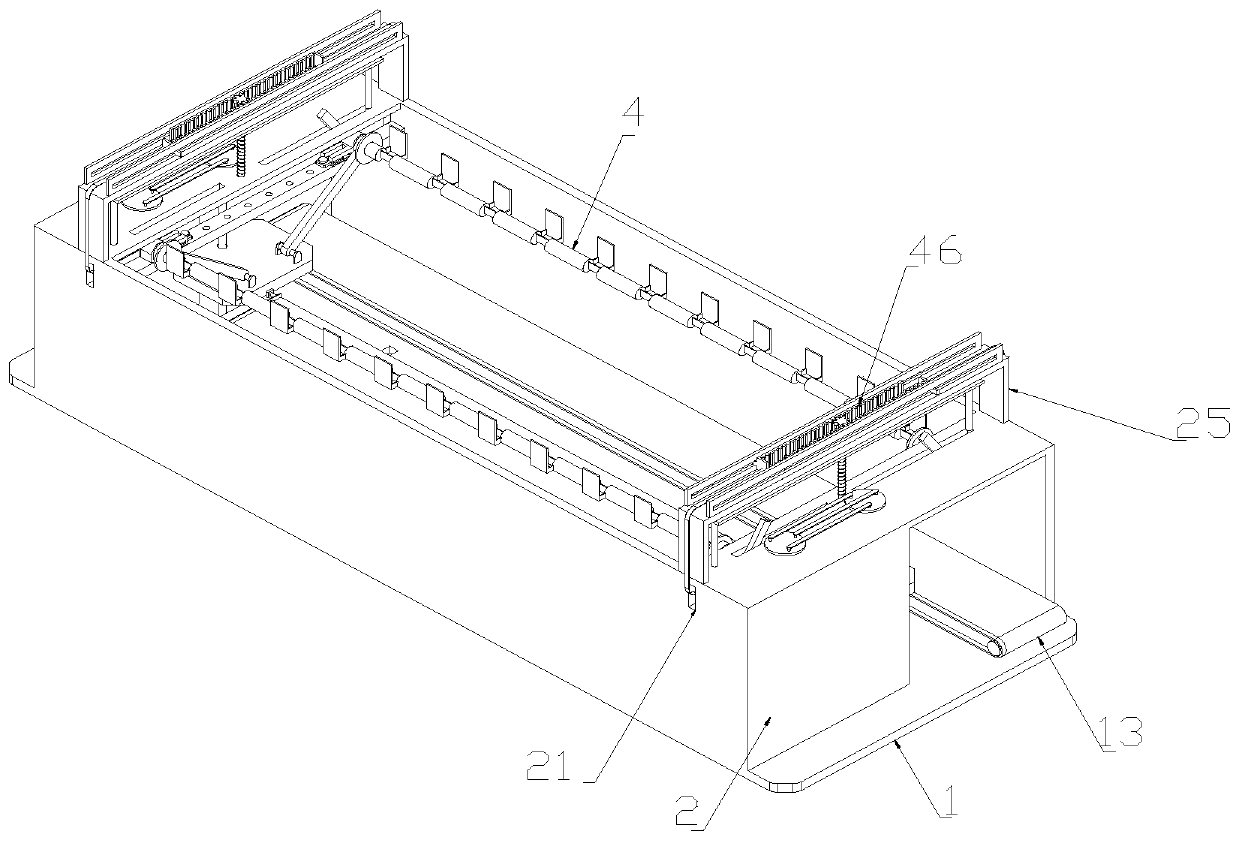

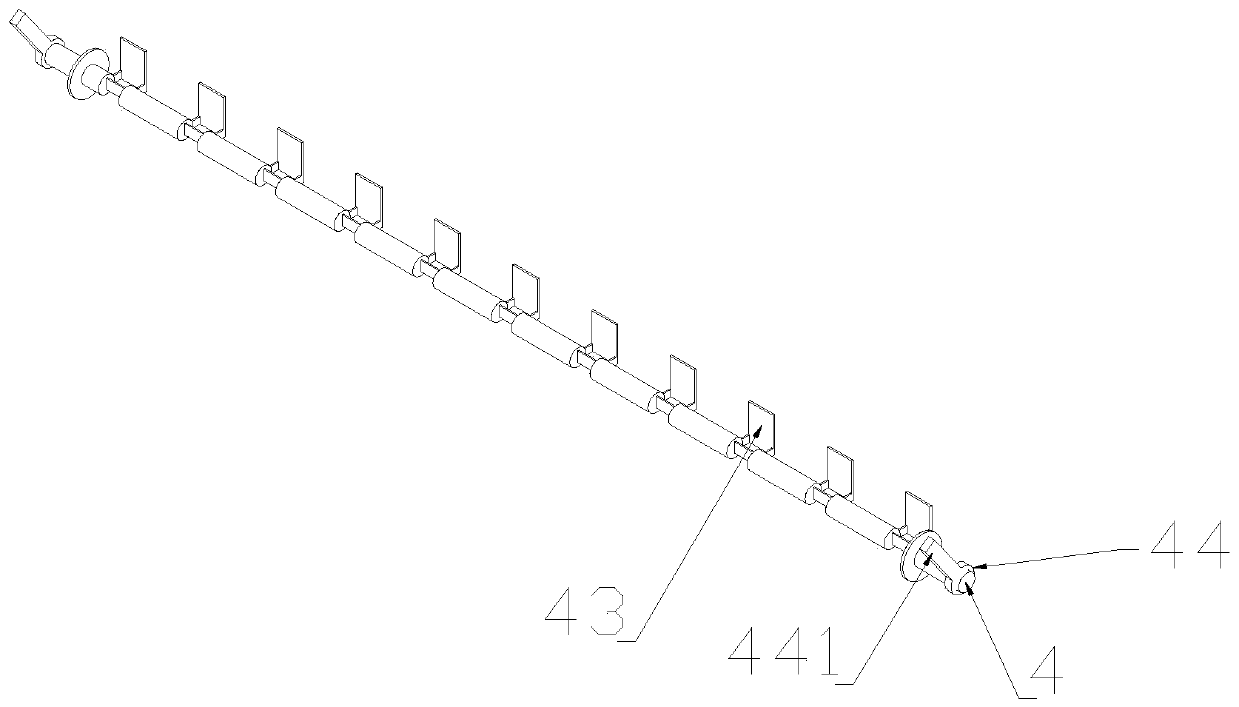

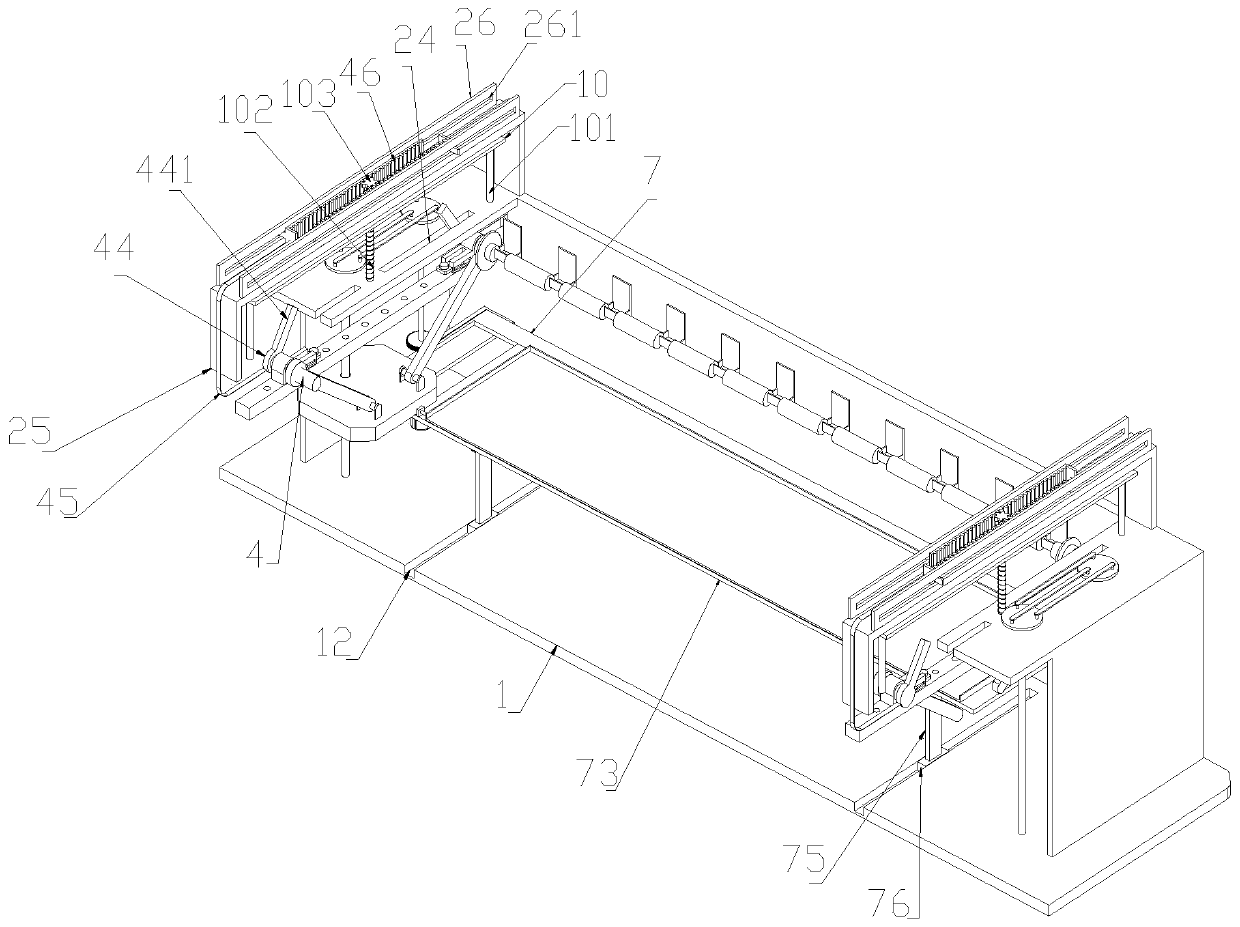

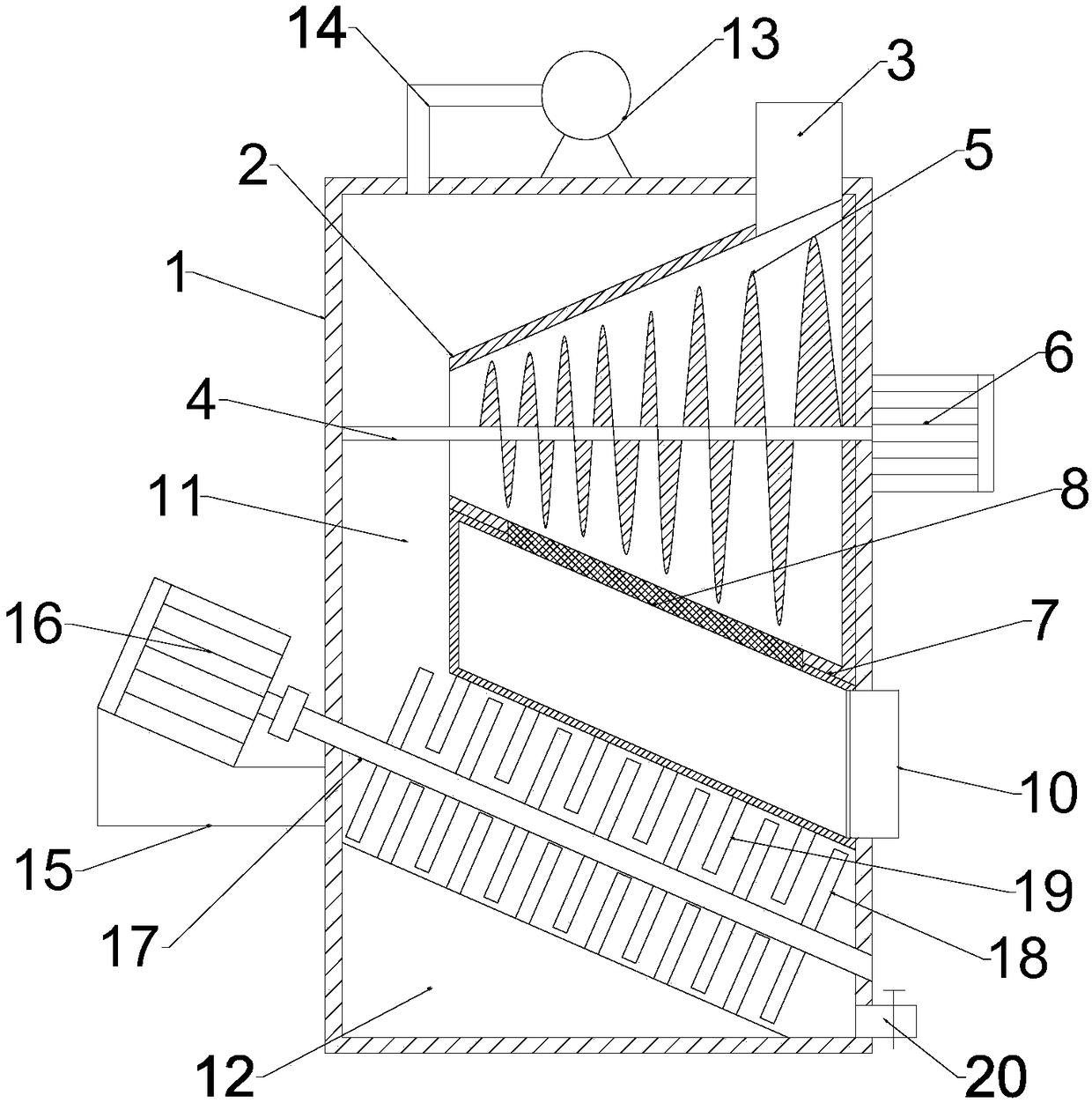

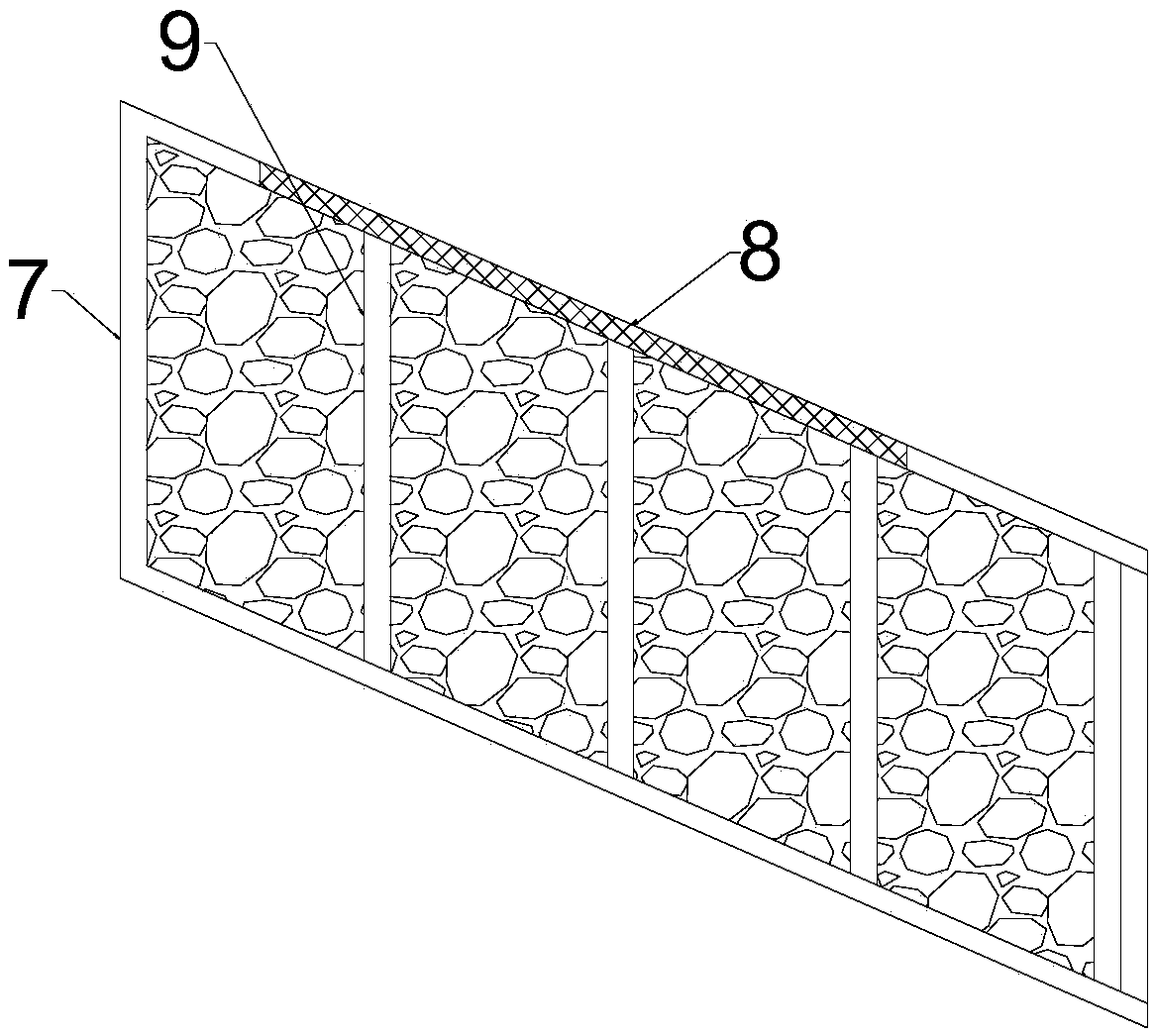

Shakeout machine facilitating recycling treatment of old sand and scrap iron and shakeout

PendingCN108015263AConvenience for centralized recyclingFully screenedMould handling/dressing devicesEngineeringMaterial resources

The invention discloses a shakeout machine facilitating recycling treatment of old sand and scrap iron and shakeout. The shakeout machine comprises crushing devices and a screening device, wherein thecrushing devices comprise first rotary motors and crushing rollers arranged at one output ends of the rotary motors. The screening device comprises a screening plate which is formed by two electromagnetic suction plates, baffles are arranged on the two sides of the screening plate, second rotating motors are arranged on the baffles, sand guide rollers are arranged at the output ends of the secondrotary motors, and sand collecting boxes are arranged at the bottom ends of the two electromagnetic suction plates of the screening plate. The device can be used for carrying out crushing treatment on the old sand generated in the shakeout process of casting, so that the falling of the old sand is facilitated, and the old sand is prevented from being pasted on the inner wall of a sand collectinghopper or blocking a sand outlet, and meanwhile, the scrap iron in the old sand can be screened and separated, so that the old sand and the scrap iron can be conveniently recycled and used, and the utilization of casting material resources is optimized.

Owner:绵阳易简环保科技有限公司

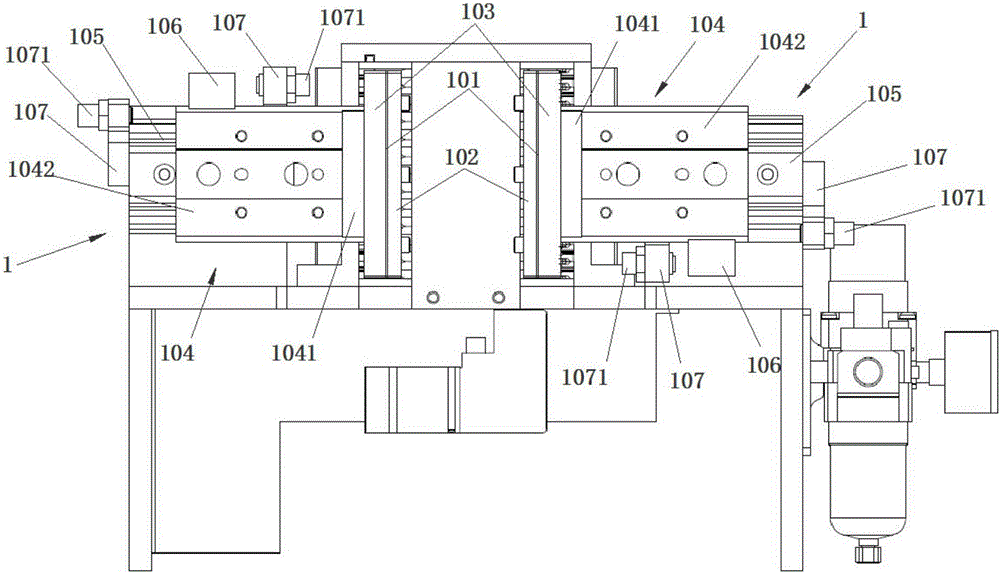

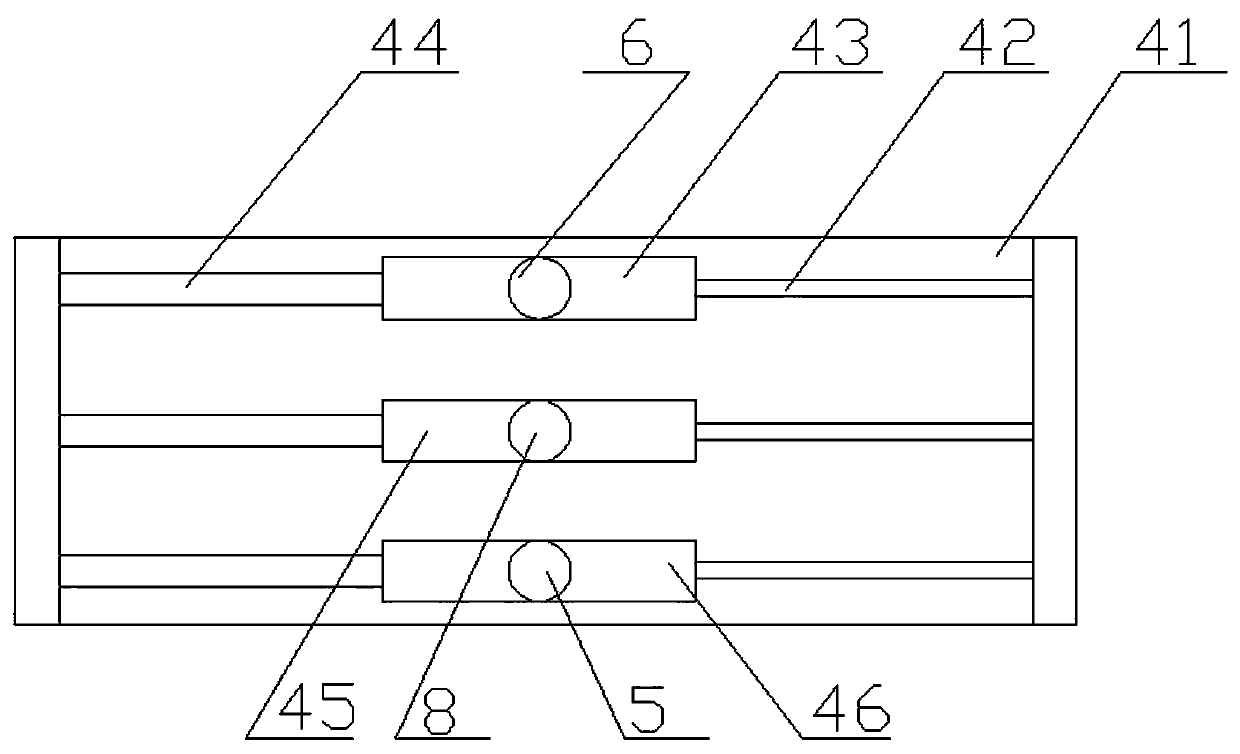

Detaching device

ActiveCN106392589AAccurate and quick insertionFast and efficient accessMetal working apparatusForeign matterRack unit

The invention discloses a detaching device. The detaching device comprises shifting separation units, a limiting unit, a rack unit and a control unit. According to the device, a plurality of sets of clamps can be accurately and rapidly placed in a clamp bin, and it can be guaranteed that the positions of all the clamps are fixed and aligned. The shifting separation units on the two sides of the clamp bin can detach the multiple sets of clamps of the clamp bin at a time, and efficiency is obviously improved. A baffle is designed in the detaching direction and can stop detached buckles and prevent the buckles from being scattered. The buckles can easily fall into a lower drawer to be recycled in a centralized manner. Shifting pieces are adopted in the shifting separation units to detach the whole row of buckles in parallel during detaching work, the positions of the adjusted shifting pieces do not rub with the clamps, and foreign matter cannot be generated.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

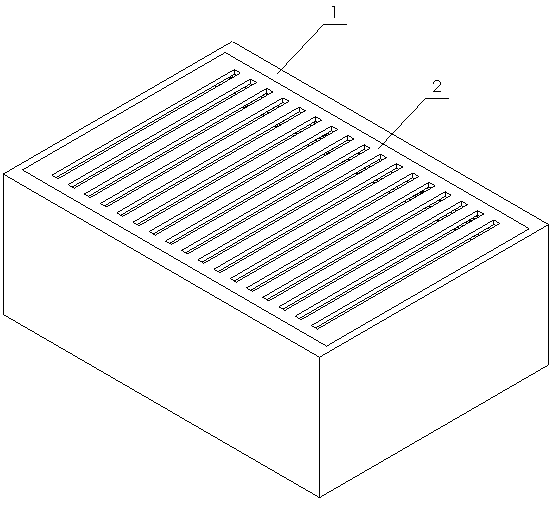

Sewer manhole cover with self-cleaning function

InactiveCN110409597AEffective recycling and cleaningReduce congestionSewerage structuresFixed frameEngineering

The invention relates to a sewer manhole cover with a self-cleaning function and discloses a sewer manhole cover of which a conveyor belt can be rotated by treading a cover plate so as to push garbageon the sewer manhole cover into a waste storage box. The sewer manhole cover is characterized in that two support plates are arranged in a manhole cover fixing frame in parallel; the two support plates are adjacent to the two opposite side walls of the manhole cover fixing frame correspondingly; limiting blocks are arranged under the two ends of the support plates correspondingly; the limiting blocks are connected with the inner walls of the manhole cover fixing frame; the two ends of the support plates are arranged on the limiting blocks in a lap-joint mode; a plurality of buffer springs arearranged on the support plates at equal intervals; the manhole cover is arranged at the top end of the manhole cover fixing frame; the bottom of the manhole cover and the buffer springs on the two support plates are connected; a plurality of drain tanks are formed in a cover plate at equal intervals; two drive rollers are arranged in the manhole cover fixing frame in parallel and are adjacent tothe two ends of the manhole cover fixing frame correspondingly; and the two ends of the drive rollers are rotationally connected with the two inner side walls of the manhole cover fixing frame throughbearings correspondingly.

Owner:李俏

Method of clearing material containing barrel for new material machining

InactiveCN109332319APlay a limiting effectEasy to holdHollow article cleaningEngineeringNew materials

The invention discloses a method of clearing a material containing barrel for new material machining. The clearing method is realized on the basis of a clearing device, the cleaning device comprises aworkbench, a plurality of supporting legs are fixedly connected to the side wall of the bottom of the workbench, two supporting plates are symmetrically arranged at the upper end of the workbench, and the upper ends of the two supporting plates are fixedly connected with a first fixing plate together; two supporting blocks are symmetrically arranged at the upper end of the workbench, the upper ends of the two supporting blocks are fixedly connected with a to-be-cleared barrel together, two first communicating grooves are formed in the side wall of the workbench in a penetrating mode, and a clamping mechanism is arranged on the side wall of the bottom of the workbench; the clamping mechanism penetrates through the two first communicating grooves and is in sliding connection with the side wall of the clamping mechanism, and the opposite side wall of the clamping mechanism abut against the outer side wall of the to-be-cleared barrel. According to the method, the structural design is reasonable, automatic cleaning can be realized, the safety threat to a human body is avoided, the clearing efficiency is improved, and the cleaning degree of the inner side wall of the material containingbarrel can be guaranteed.

Owner:欧彩容

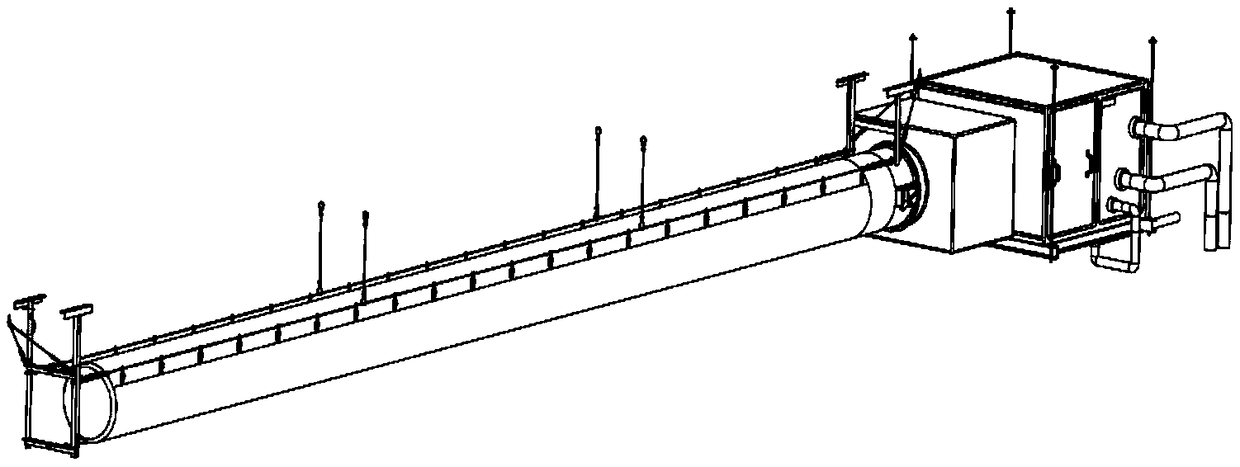

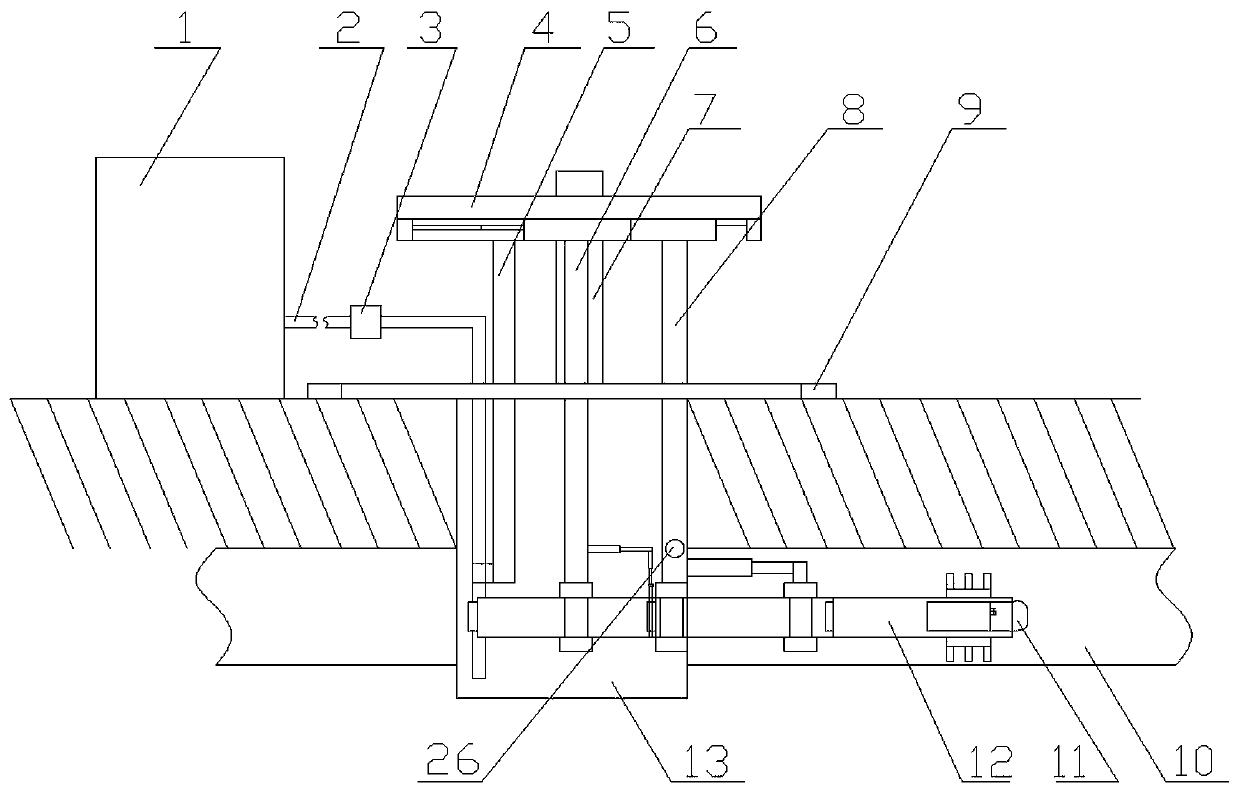

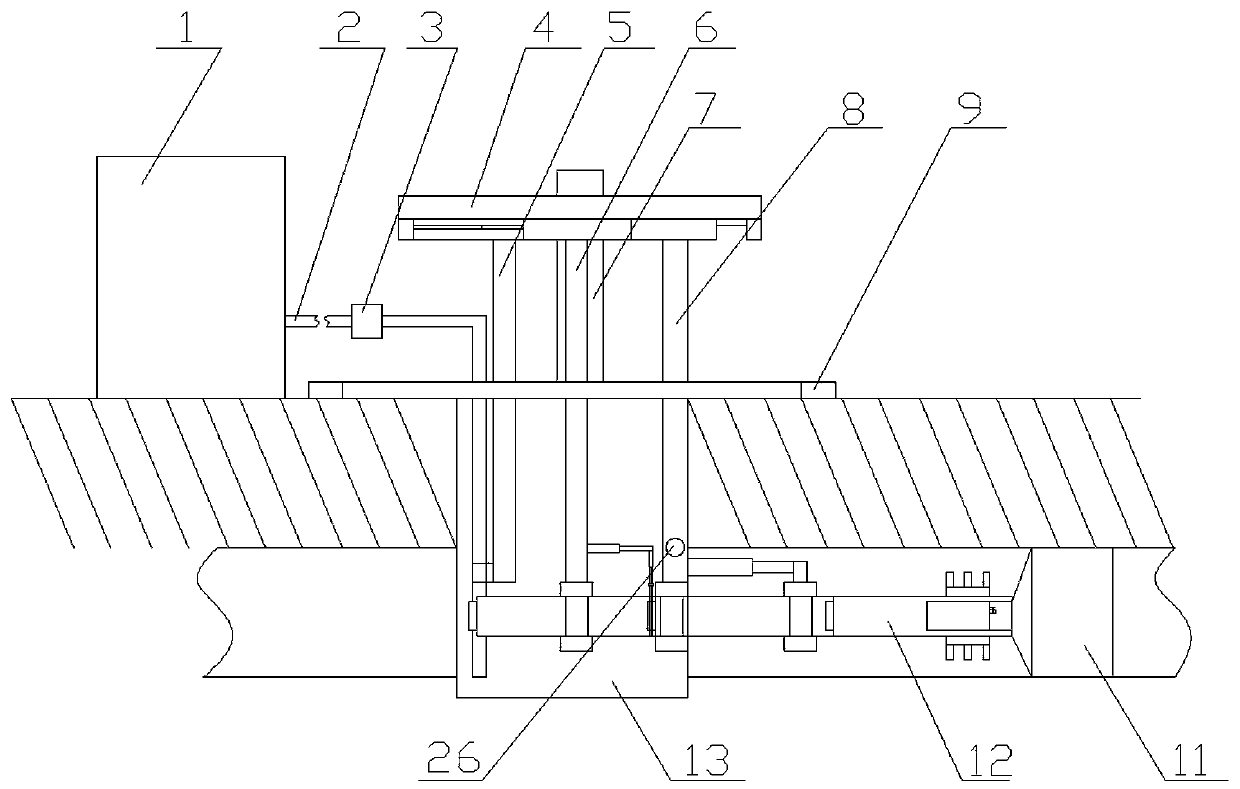

Dredging device for municipal sewer pipes

The invention provides a dredging device for municipal sewer pipes. The dredging device comprises a support mechanism arranged on the ground of a vertical shaft, a dredging mechanism arranged on the support mechanism and used for removing sludge, a propulsion mechanism arranged on the support mechanism, a collection mechanism arranged on the propulsion mechanism and used for collecting the sludge,a disassembly and assembly mechanism arranged on the support mechanism and used for cooperating with the propulsion mechanism, and a control mechanism arranged on the support mechanism and used for controlling the cooperation of the support mechanism, the dredging mechanism, the propulsion mechanism, the collection mechanism and the disassembly and assembly mechanism. By means of the dredging device, not only can a large amount of water not be consumed, but also narrow underground pipes can be efficiently cleaned, and by stirring the sewage and sludge in the vertical shaft, a dredging tube can achieve complete dredging.

Owner:浙江三水管道有限公司

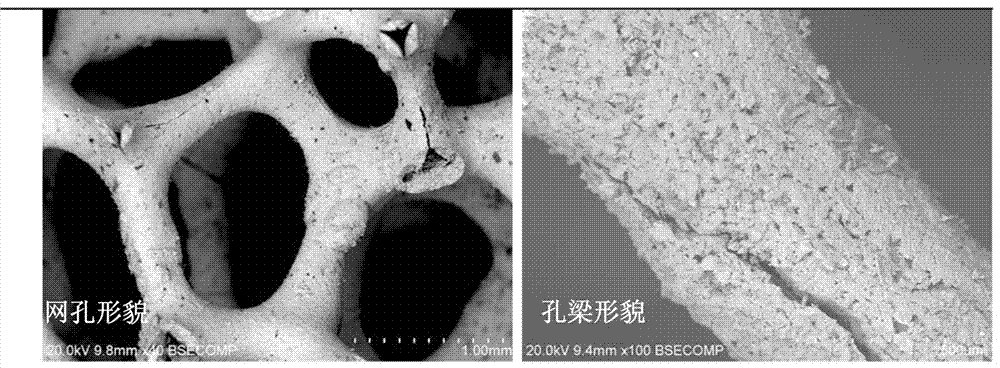

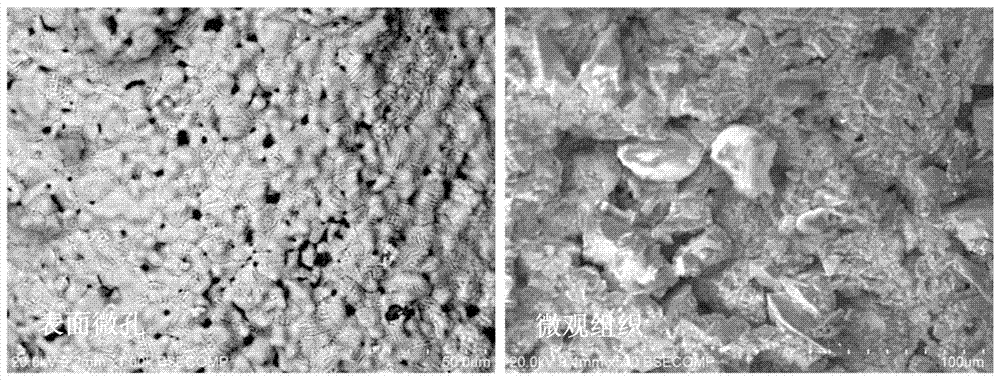

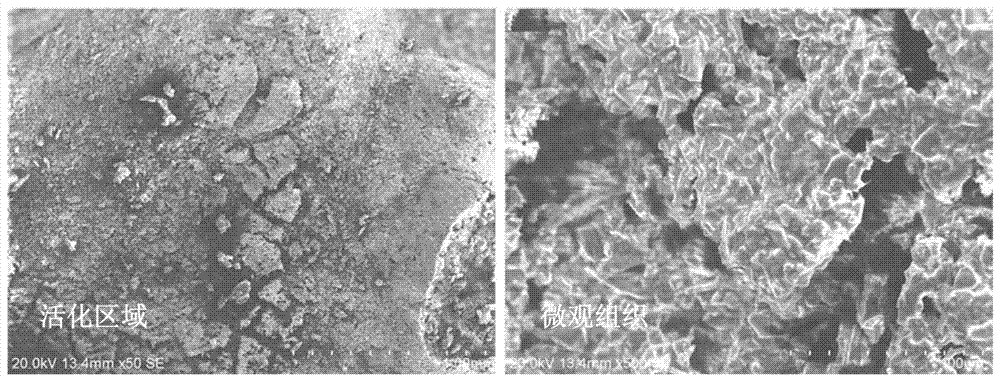

Nanometer mercury material with lasting adsorption performance

ActiveCN107159088AGuaranteed coverageGuaranteed adsorption effectGas treatmentOther chemical processesSulfate radicalsLow-temperature thermal desorption

The invention relates to the field of environment purification and protection, in particular to a nanometer mercury material with lasting adsorption performance. Firstly, a composite aluminum oxide ceramic material is prepared by an organic foam dipping process to serve as a carrier; secondly, an activator is loaded on the surface of the carrier and in a micro pore of the carrier by an immersion method, wherein the coverage area of the activator is 85 percent or more, oxidization of chloride ions, sulfate radicals and nitrate ions in the activator to mercury is used to fix elemental mercury, silver and mercury are formed into amalgam to react and solubilize the elemental mercury, and the huge surface of porous ceramic is used to absorb valence state mercury; and finally, the mercury is reclaimed through a low-temperature thermal desorption method, and circular utilization of the carrier is realized. The material has performances of large surface area, strong permeability, high compression strength, impact resistance, high temperature resistance, environmental friendliness, high chemical stability and the like, the carrier can be circularly used, mercury recovery is simple and feasible, and secondary pollution is not caused. Furthermore, a material preparation process is simple and low in cost. The nanometer mercury material has very good application potential and good social and economic benefits.

Owner:XUZHOU ZHENFENG NEW TYPE WALL MATERIAL CO LTD

Vagina cleaner with endoscope

InactiveCN110215555ASimple structureReasonable structureCannulasEnemata/irrigatorsIsolation layerEngineering

The invention discloses a vagina cleaner with an endoscope. The vagina cleaner comprises a delivery tube, wherein the head portion of one end of the delivery tube is provided with a conical curved surface, a port at the other end of the delivery tube is provided with an end cover, the portion, located under the head portion, the inner wall of the delivery tube is provided with an isolation layer for dividing the interior of a bidirectional liquid delivery tube into a cleaning liquid inlet chamber and a cleaning liquid return chamber, the tube wall, located at the lower end of the isolation layer, of the head portion is provided with a cleaning liquid spraying hole, and the tube wall of the delivery tube is provided with a cleaning liquid return through hole. A cleaning liquid guiding-in tube is connected between the isolation layer and the tube wall of the portion of the delivery tube or the end cover, a cleaning liquid guiding-out tube is connected on the end cover or the tube wall connected with the lower portion of the delivery tube, a pinhole medical camera and an LED light source packaged in a transparent plastic tube are embedded in a through hole at the top end of the head portion and are led out from the lower portion of the delivery tube to the outside of the delivery tube to be connected with a controller, and the controller transmits image signals acquired by the pinhole medical camera to a far-end image display device through a Bluetooth communication module connected with the controller.

Owner:JILIN UNIV

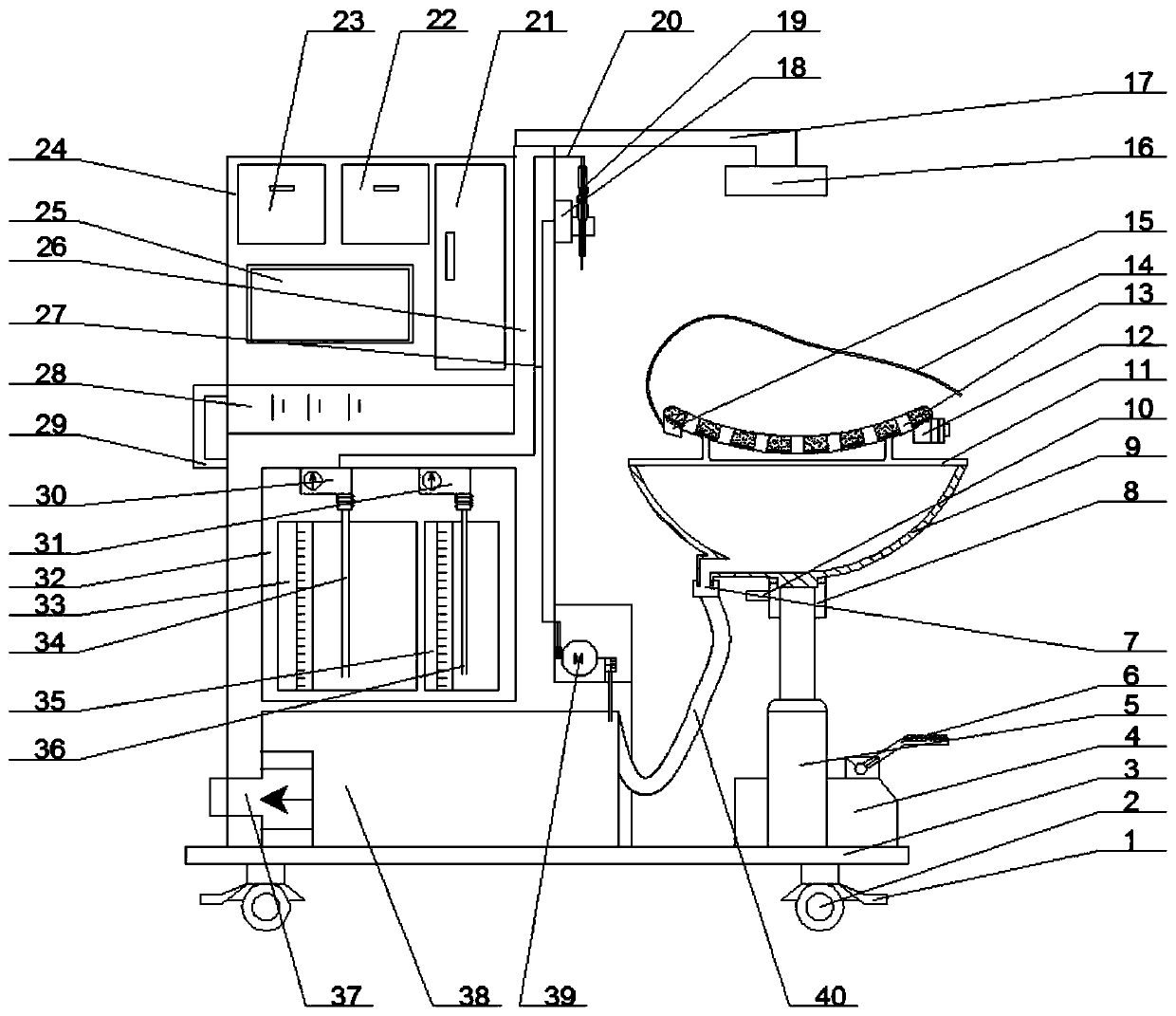

Multifunctional debridement device for general surgery department

InactiveCN109771726AHeight adjustableEasy to cleanEnemata/irrigatorsNursing accommodationEngineeringGeneral surgery specialty

The invention relates to a multifunctional debridement device for the general surgery department. The device comprises a moving support device, an affected limb support device, a cleaning system, a liquid suction device and a dryer, wherein the moving support device comprises a bottom plate and castors distributed on the bottom of the bottom plate, the upper portion of the left side of the bottomplate is provided with a water cabinet, the top of the water cabinet is provided with a power supply, and the upper portion of the power supply is provided with a cabinet body; the affected limb support device is arranged on the bottom plate, the affected limb support device comprises a pressure rod, a lifting driver, a rotating device, a collecting tank and a supporting tank, and the collecting tank is communicated with a waste water tank through a sewage discharge hose; the cleaning system comprises a normal saline box, a hydrogen peroxide box, a first water pump, a second water pump and a flusher which are arranged in the water cabinet; the liquid suction device comprises a liquid suction pump and an aspirator connected with the liquid suction pump through a liquid suction catheter; thedryer is arranged on a vertical plate through a connecting rod. The multifunctional debridement device for the general surgery department has the advantages that the structure is reasonable, the useis convenient, the functions are diverse, and the therapy time is saved.

Owner:梁晶

Tobacco raw material recycling device facilitating unloading

InactiveCN111578636AEasy to recycleNo extensive damageTobacco preparationDrying chambers/containersNicotiana tabacumAgricultural engineering

The invention discloses a tobacco raw material recycling device facilitating unloading. The device comprises a drying base, the upper end of the drying base is fixed with a drying rack, the upper surface of the drying rack is welded with a mounting rack, the mounting rack is provided with symmetrically arranged carriages, a drive plate is arranged between the carriages in a sliding mode, and a threaded rod is inserted in the middle of the mounting rack. Compared with the traditional technology, a free rotary drying rod is designed, completed dried tobacco recycling is facilitated, the large-area damage to tobacco leaves is avoided and the processing effect of the tobacco leaves is improved. According to the device, when a movable push plate moves to contact with a push block, the movable push plate moves downwards, the push block is pushed to squeeze downwards, at this time, the push block starts to rotate and drives the drying rod to rotate, so that the tobacco leaves on the drying rod automatically fall down, the centralized recycling is facilitated; and the tobacco starts to slide down from a drying plate until the tobacco completely slide down from the drying plate, and the discharging step is finished.

Owner:HEFEI ANLUYI TECH CO LTD

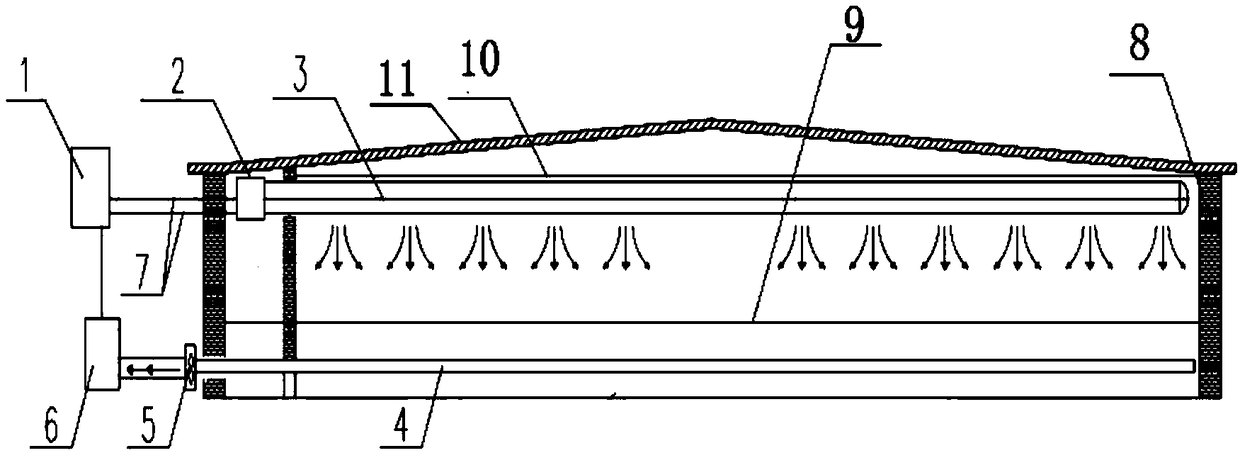

Setting machine applied to tie production and processing

ActiveCN105200693AEasy to operateEasy to useHeating/cooling textile fabricsAir blowerMechanical engineering

The invention discloses a setting machine applied to tie production and processing. The setting machine comprises a conveying table, a setting box, a spraying box and a drying box; a pressing device is arranged above the conveying table and comprises a horizontal guide rail, a telescopic rod and a jet disc; the setting box comprises a flattening chamber and a steam chamber, and hot-pressing rollers and a sweeping device are arranged in the flattening chamber; a water tank, a spraying pipe and a water collecting tank are arranged inside the spraying box; air blowers, a wind shield and a heating frame are arranged in the drying box. The setting machine is simple in structure and high in practicability, as an original pressing device is improved, the design of the jet disc is adopted, while being fixed, cloth will not be abraded, which is beneficial for processing the cloth in the next working procedure, and the working efficiency of the setting machine is improved; by means of internal design of the setting box, the spraying box and the drying box, the set cloth is higher in quality, the setting effect of the setting machine is improved, cost and resource waste are reduced, and the comprehensive use efficiency is improved.

Owner:徐州海坤服饰有限公司

Environment-friendly garbage crushing treatment device for solid-liquid separation treatment

InactiveCN108454153AEasy to recycleConvenience for centralized recyclingGrain treatmentsPressesWater storageSpiral blade

The invention discloses an environment-friendly garbage crushing treatment device for solid-liquid separation treatment. The environment-friendly garbage crushing treatment device comprises a shell. The upper portion of the shell is provided with a separation cavity. The upper end of the separation cavity is provided with a feed pipeline. A propelling shaft is arranged in the middle portion of theseparation cavity. A spiral blade is arranged on the periphery of the propelling shaft. A propelling motor is arranged on the right wall of the shell. A water storage cavity is arranged in the portion, located at the lower end of the separation cavity, of the interior of the shell. An air pump is riveted to the upper end of the shell. The exhaust end of the air pump is connected with an air spraypipeline. A support is welded to the lower portion of the left wall of the shell. A crushing motor is riveted to the upper end of the support. A crushing rotary shaft is arranged at the output end ofthe crushing motor. Multiple rotary blades are uniformly welded to the periphery of the crushing rotary shaft. Fixed blades are arranged on a bottom plate and below the water storage cavity, and thefixed blades and the rotary blades are arranged alternately. The environment-friendly garbage crushing treatment device can achieve solid-liquid separation and efficient filtering of treatment fluid in the garbage propelling process. Separated solid materials pass through the rotating fixed blades and the rotary blades under the action of gravity and driving of airflow, and crushing treatment is completed efficiently.

Owner:何玉静

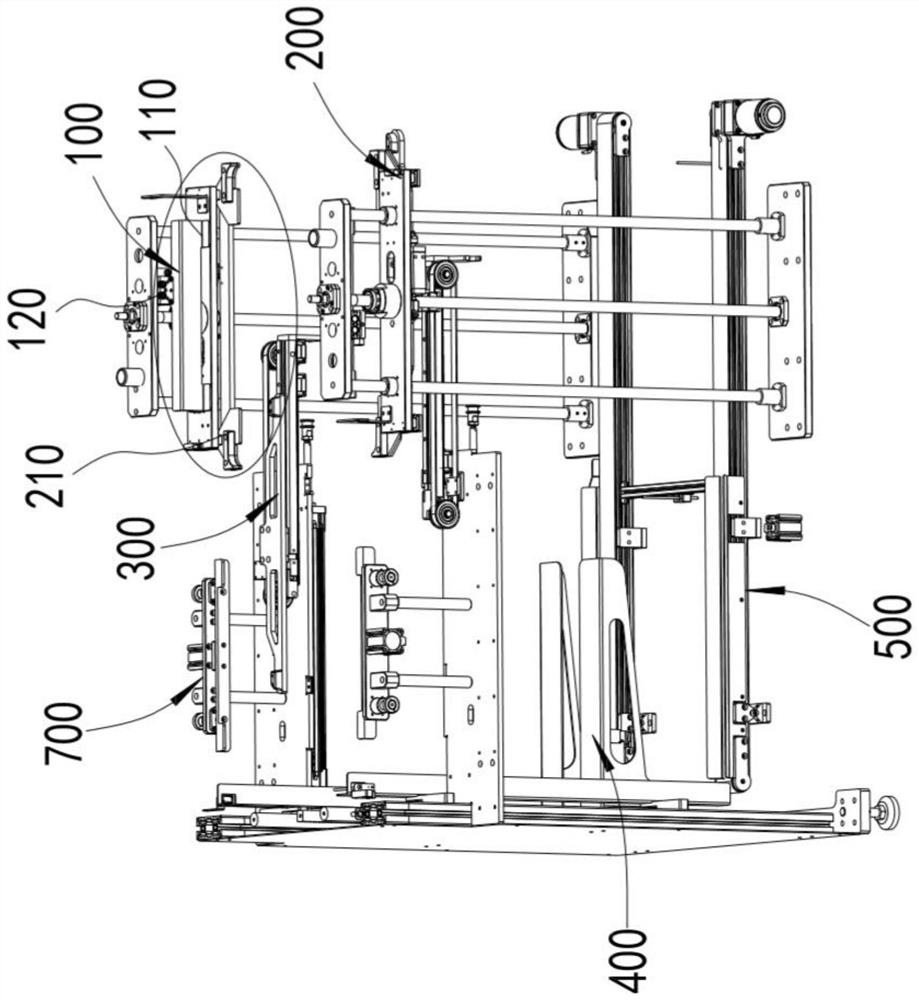

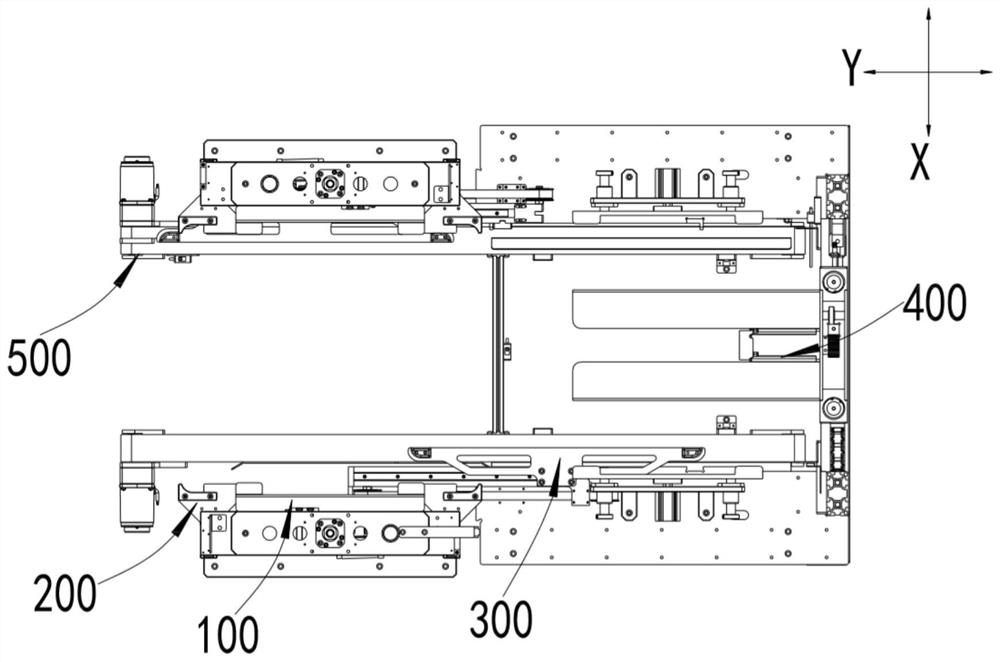

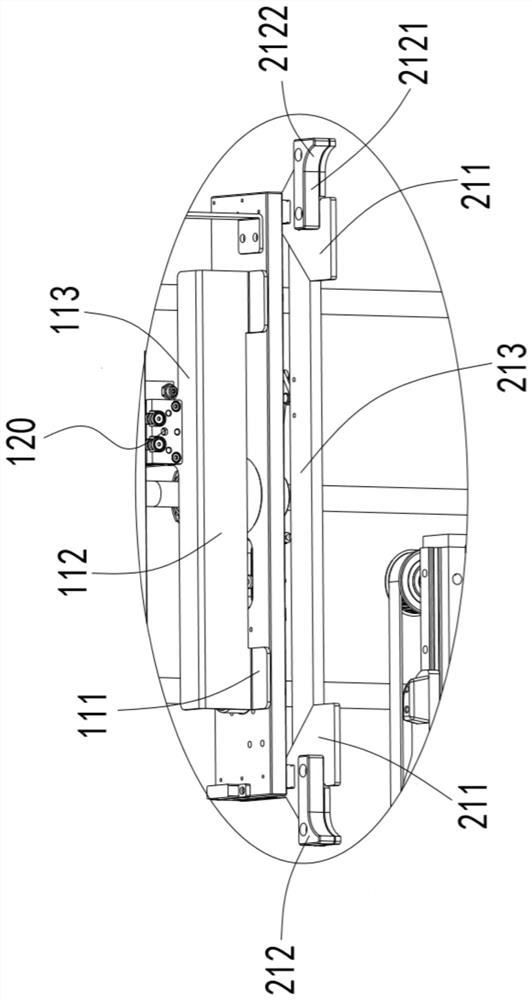

Feeding device and feeding method thereof

PendingCN112124981AMeet unloading requirementsEfficient releaseConveyorsStacking articlesEngineeringTransfer line

The invention discloses a feeding device and a feeding method thereof. The feeding device is used for separating multiple layers of stacked objects and comprises a bearing mechanism, a feeding lifter,a transferring device, a backflow lifter and a backflow conveying line. According to the scheme, a low-position tray can be lifted to a high position to be split through the feeding lifter, the high-position tray discharging requirements are effectively met, in addition, by arranging the transferring device, the feeding lifter can be effectively released, and when the tray is used for discharging, the tray of the feeding lifter can take materials again, so that the discharging time can be effectively utilized, the feeding efficiency can be improved, the backflow lifter and the backflow conveying line are further combined, backflow of the empty tray can be effectively achieved, and favorable conditions are created for rapid reutilization of the empty tray.

Owner:JIANGSU XINTIMU INTELLIGENT EQUIP CO LTD

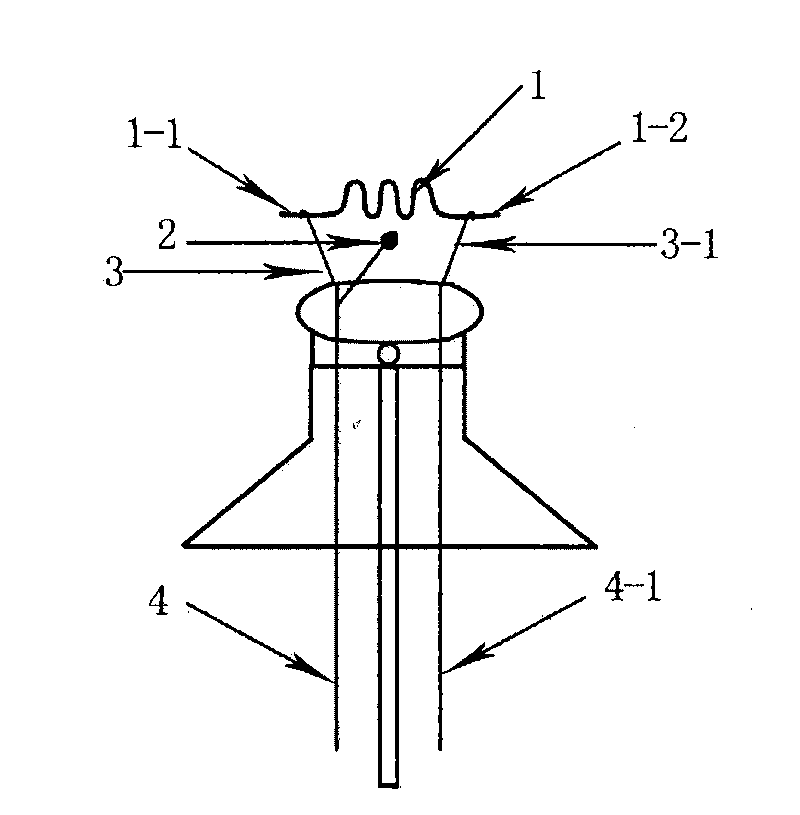

Mercury recycling fluorescent lamp

InactiveCN101728210AImprove efficiencyConvenience for centralized recyclingLow-pressure discharge lampsSolid matterElectron

The invention provides a mercury recycling fluorescent lamp comprising a tube and a pair of electrodes which are respectively arranged on two ends of the tube. The mercury recycling fluorescent lamp is characterized in that the electrodes contain different electronic powder and the end of the electrode contains less electronic powder is provided with mercury eliminating agent which can be combined with mercury to generate solid matter.

Owner:陈枕流

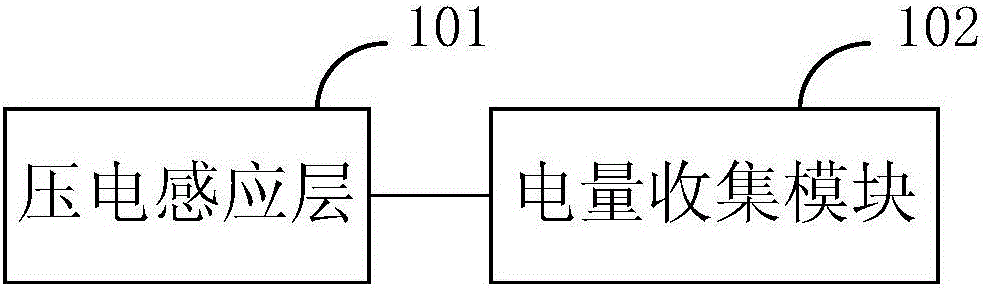

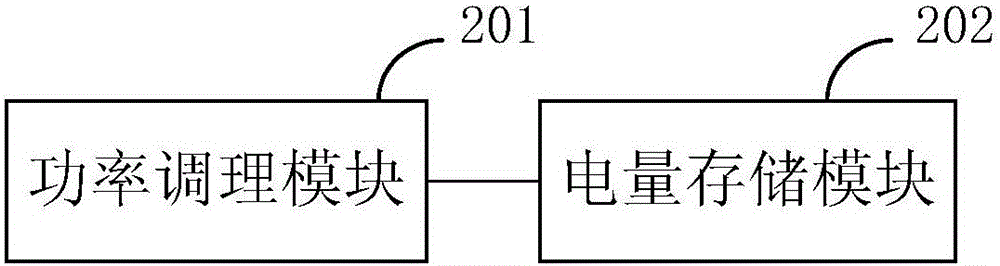

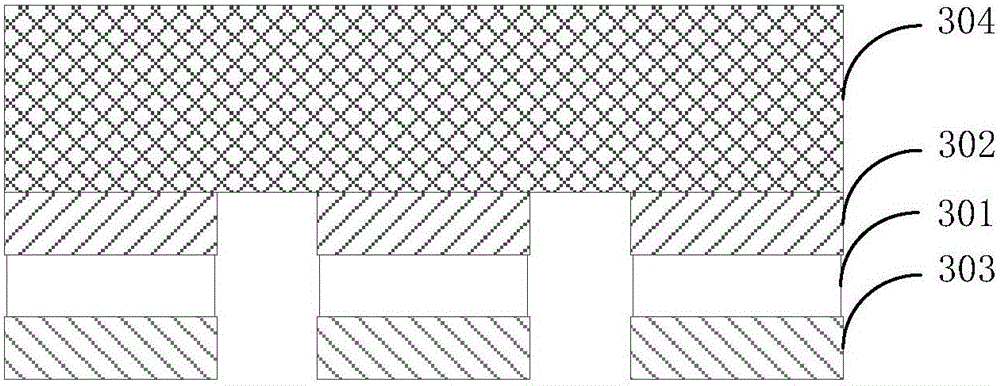

Touch screen, display panel, display device and method for storage electric energy

InactiveCN105094438AExtend the lifespanSolve the problem of low batteryDigital data processing detailsInput/output processes for data processingElectricityLiquid-crystal display

The invention relates to the technical field of liquid crystal display devices, in particular to a touch screen, a display panel, a display device and a method for storage electric energy. The touch screen, the display panel, the display device and the method are used for solving the problem that the electric quantity of portable electronic equipment is always insufficient in the use process. The touch screen comprises a piezoelectric induction layer and an electric quantity collecting unit. The piezoelectric induction layer is used for inducing external force to generate an electric signal and transmitting the electric signal to the electric quantity collecting unit. The electric quantity collecting unit is used for processing the electric signal and storing the electric energy under the driving of the electric signal. According to the touch screen, as the piezoelectric induction layer is deformed when sensing the external force, the electric signal is generated; the electric quantity collecting unit processes the electric signal, the required direct-current-amplification electric signal is obtained and collected, the electric energy is stored under the driving of the electric signal, the stored electric energy can be used for charging a battery, and therefore the problem that the electric quantity of the portable electronic equipment is always insufficient in the use process is solved.

Owner:BOE TECH GRP CO LTD +1

Pig house environment control system

PendingCN108812347AReduce the amount of exhaust gasConvenience for centralized recyclingHeat recovery systemsAnimal housingPipingAir volume

The invention discloses a pig house environment control system. The system comprises a house body, a heat pump heat recovery fresh air unit, an air treatment unit, a flexible accurate air supply system, a trench exhaust pipe, a trench fan, a waste gas purifying tower and a cold hot water pipe; an excrement leakage floor is arranged in the inner part of the house body; a house ceiling is arranged on the upper end of the house body; a suspended ceiling is arranged below the house ceiling; the heat pump heat recovery fresh air unit is arranged outside the house body; the air treatment unit is arranged inside the ceiling body; the cold hot water pipe is connected between the heat pump heat recovery fresh air unit and the air treatment unit; the flexible accurate air supply system is connectedto the air treatment unit; and the trench exhaust pipe is arranged under the excrement leakage floor and between the excrement leakage floor and the house body. The arranged system has the advantages of high temperature difference, low wind speed and small air volume, the waste gas quantity is reduced, the centralized recycle treatment of waste gas is easy, the temperature and humidity can be controlled accurately, the cold and heat stress is reduced, the ratio of materials to meat is reduce, the pregnancy rate is improved, the birth quantity is improved, the prevalence rate is reduced, thesurvival rate is improved, and the pigs per sow per year (PSY) are improved.

Owner:郑州法布瑞克智能科技有限公司

Underground pipeline sludge cleaning device

The present invention provides a dredging device for underground pipelines, including a supporting mechanism set on the ground floor, and a sealing module that is used to clean up the silt on the supporting mechanism to clean the mud., Set up the promotion agency on the supporting mechanism, set up a collection agency for collecting the mud on the promotion mechanism, and set it on the disassembly mechanism used by the supporting mechanism to cooperate with the promotion mechanism.And it is used to control the supporting mechanism, dredging mechanism, promoting agency, collecting agency, seal module and disassembly mechanism on the supporting mechanism;The narrow underground pipeline is efficiently cleaned, and the setting of the upstream sealing modules can avoid the continuous enrichment of upstream sewage, which causes some silt to be completely cleaned, and can be completely dredged by a single time.

Owner:张桂华

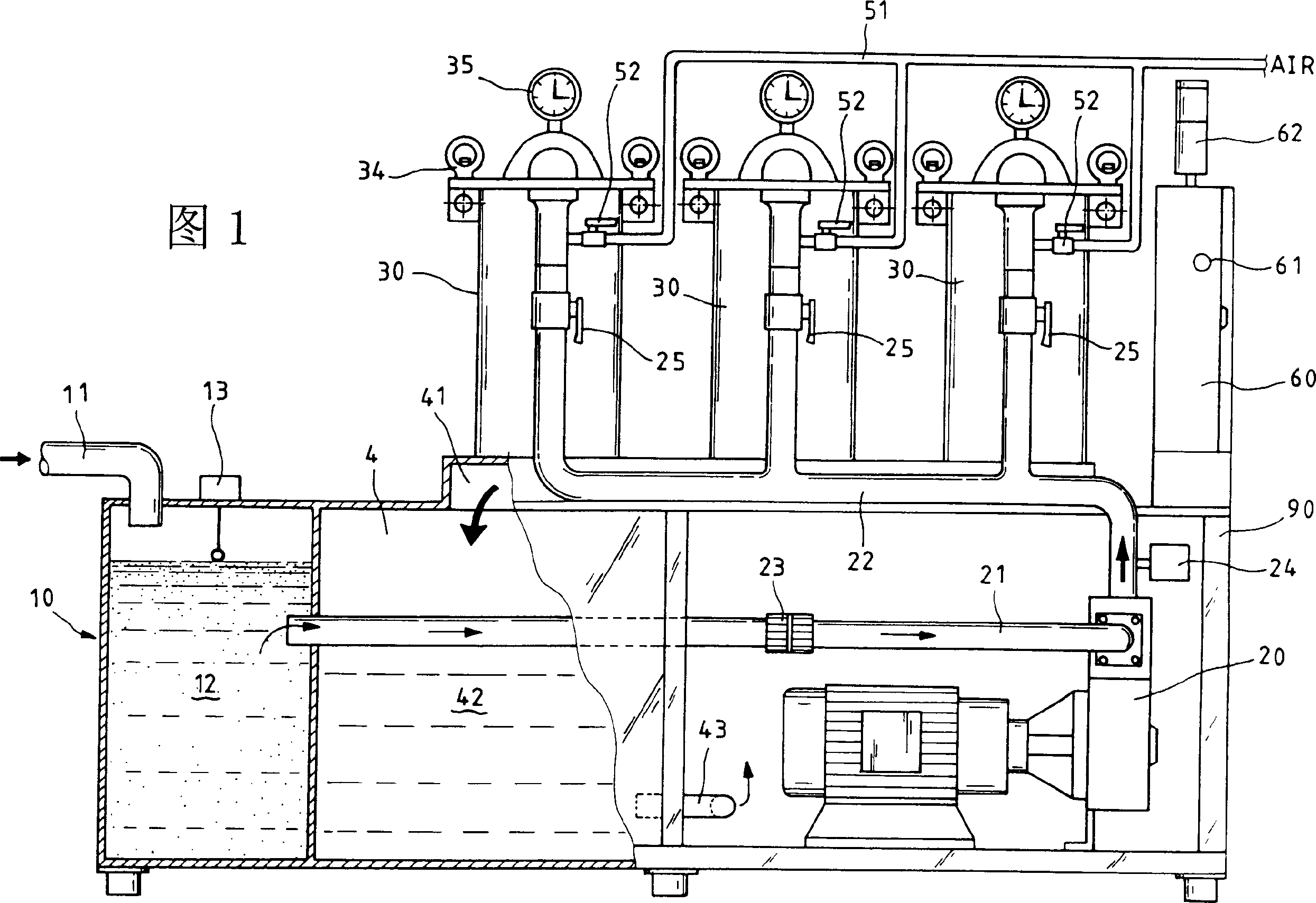

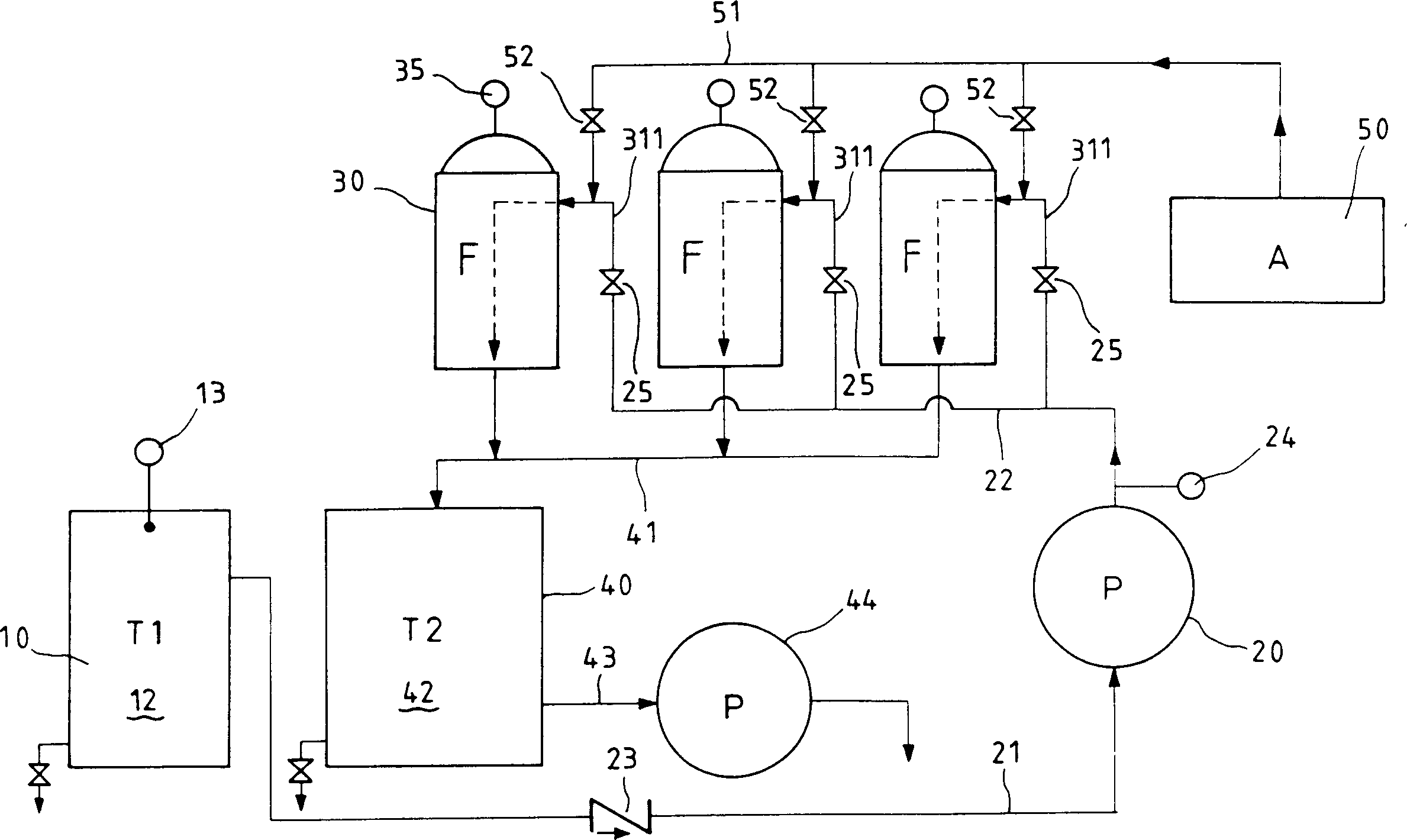

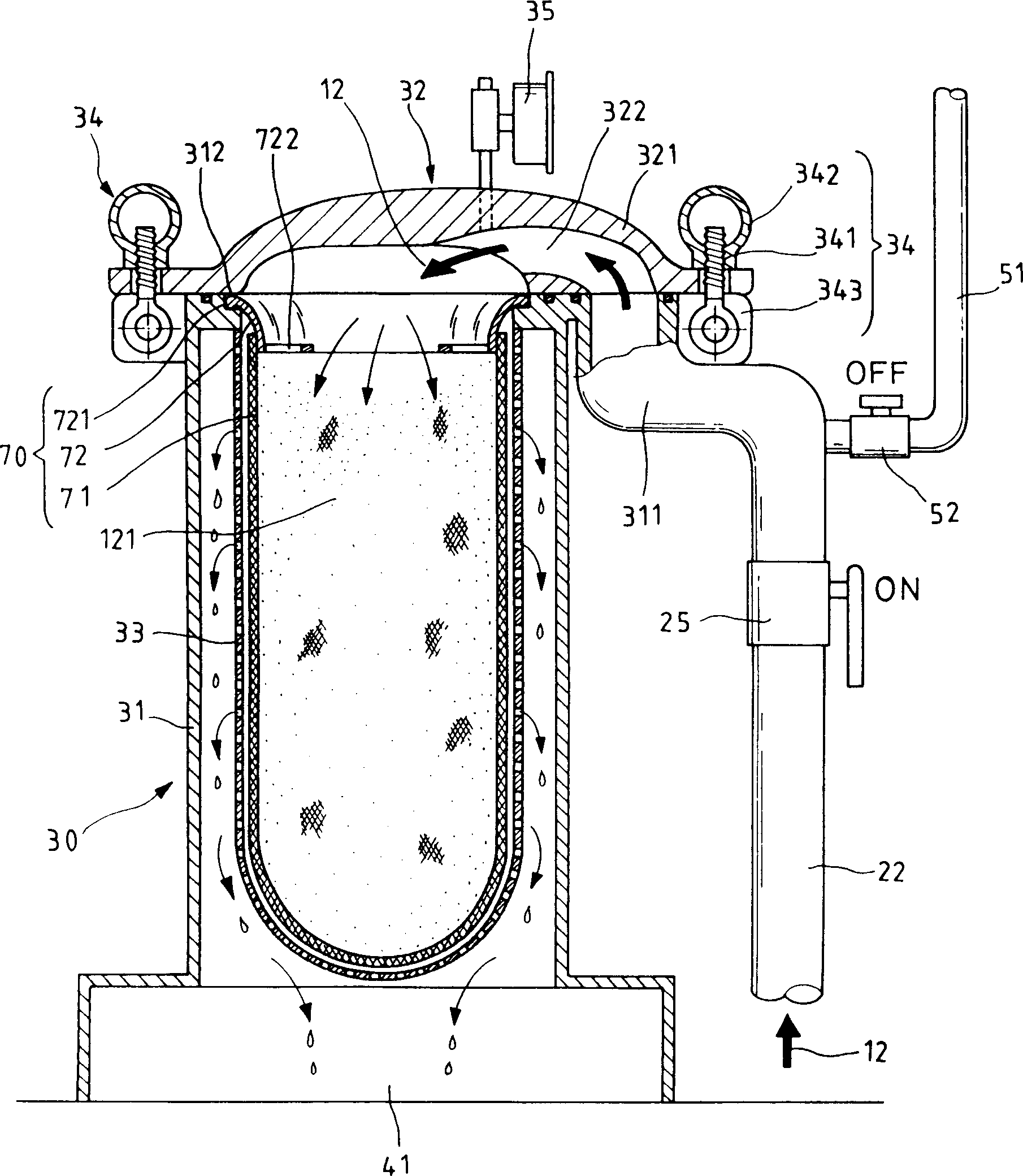

Precise water resource reclaiming machine

InactiveCN1704341AAchieve securityImprove filtration efficiencyWater/sewage treatmentFiltrationSpray nozzle

The invention relates to a water resource precise reclaiming machine, which comprises an exhausted liquid receiving tank, a pump exhausting end connected with the exhausted liquid receiving tank through a pumping pipe, an upper meshed groove is arranged in the filtration tube, the meshed groove is provided with a supporting surface for positioning a filtering bag consisting a bag body and a positioning frame, a tube cover is mounted on the upper portion of the tube through a locking piece, the tube cover is provided with an extension section on one side, the extension section is provided with a spray nozzle, the filtration water reclamation tank is arranged below the filtration cartridge reclamation tube.

Owner:邱 鸿芳

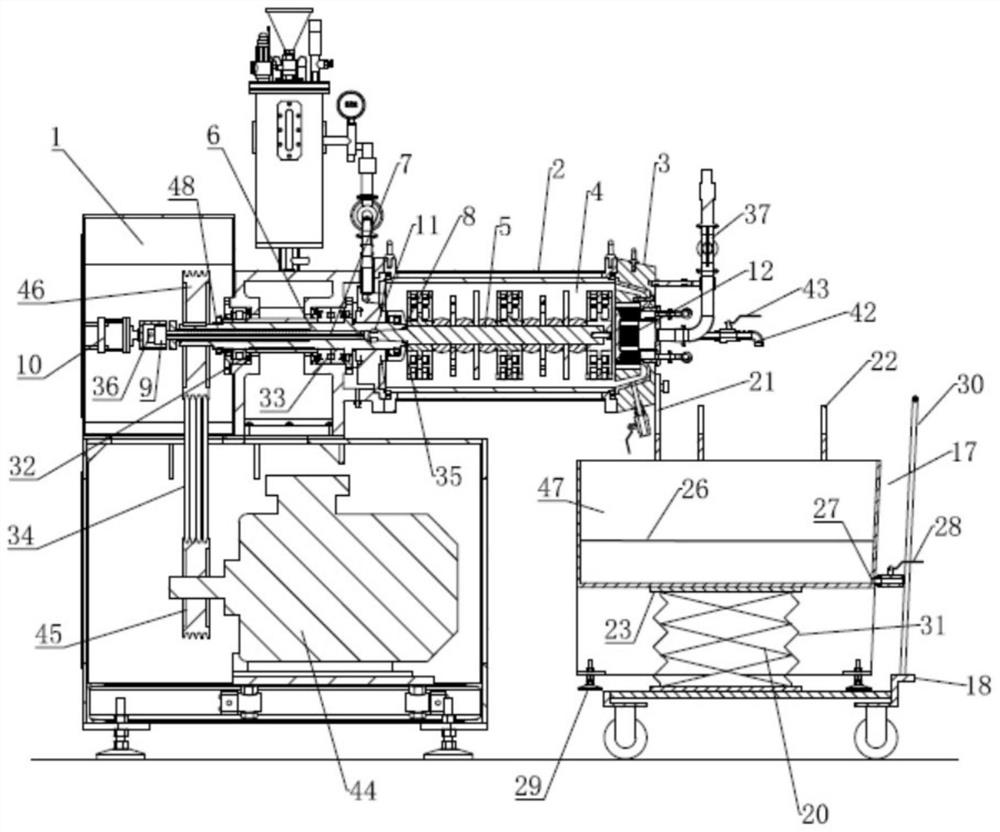

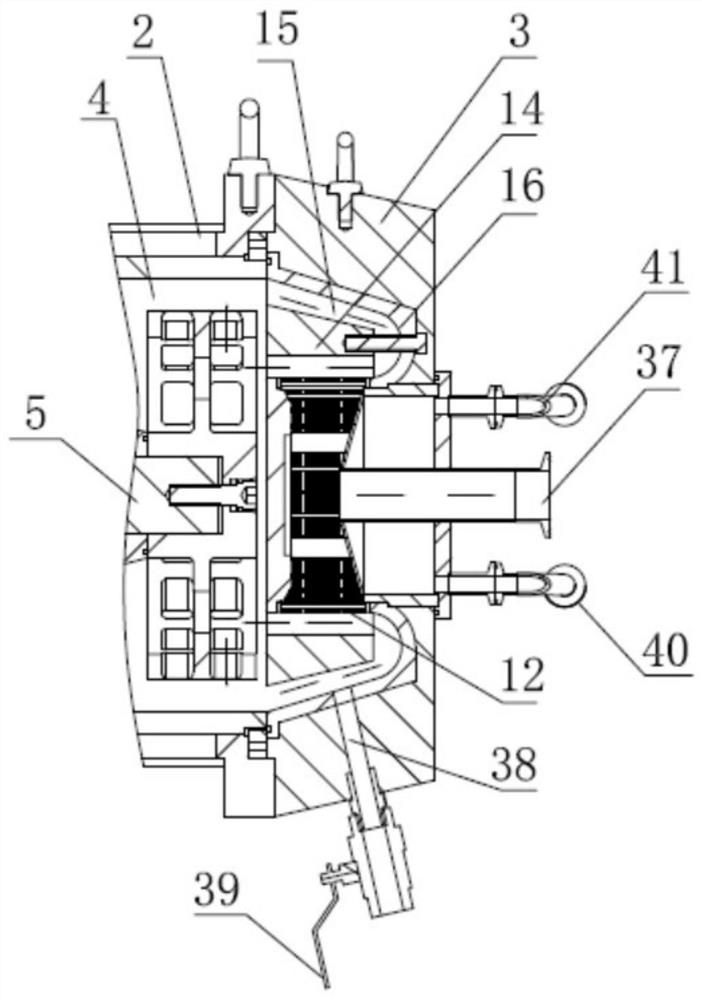

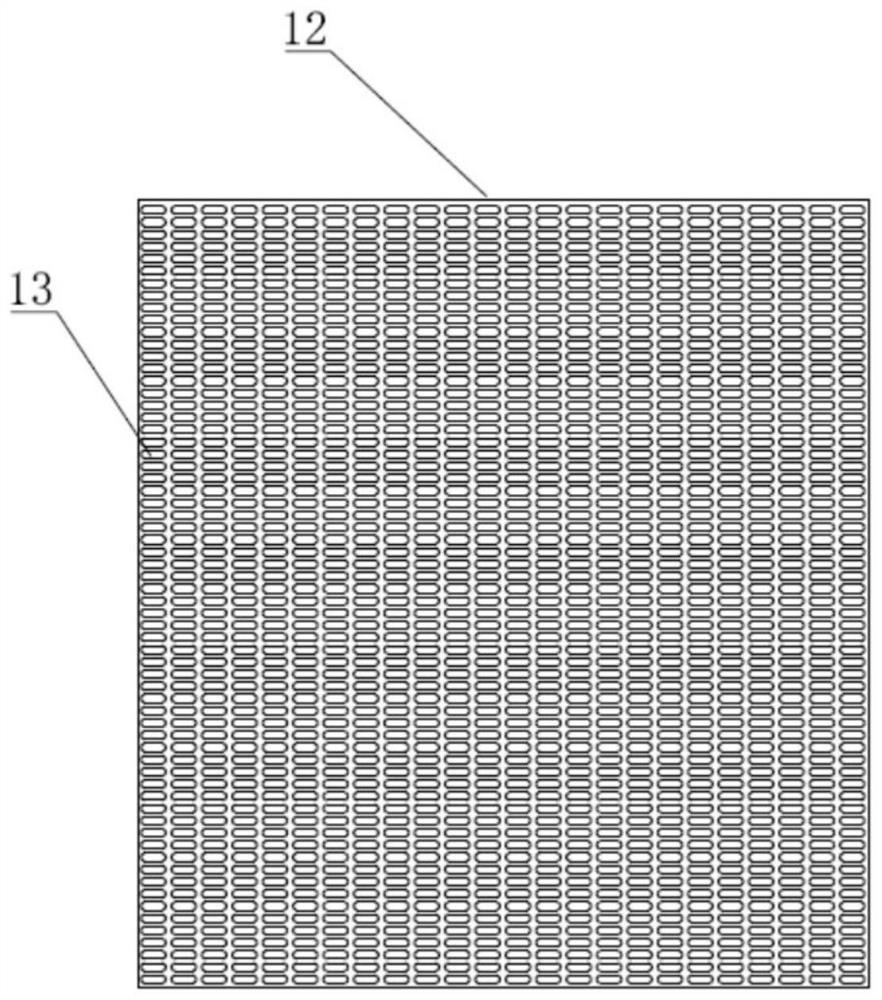

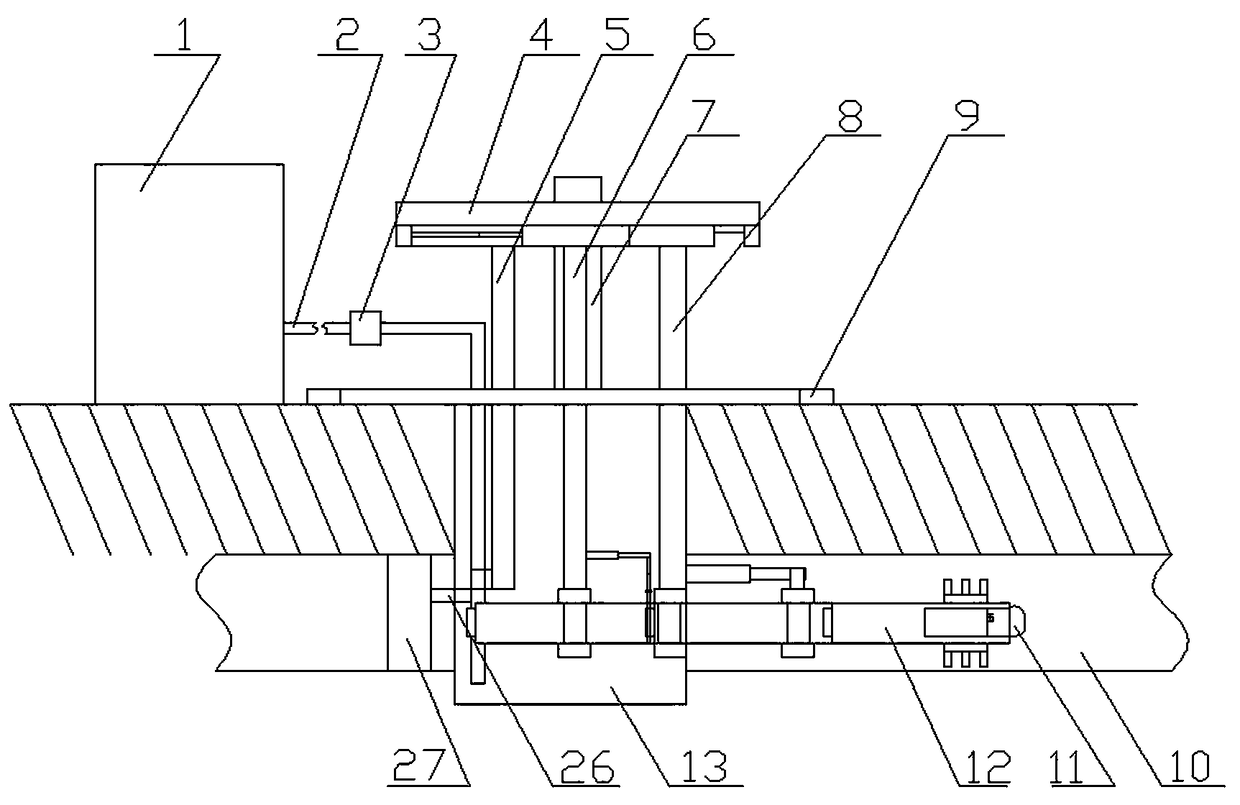

Efficient grinding machine

The invention provides an efficient grinding machine which comprises a rack, a grinding barrel, an end cover and a grinding rotor, wherein the end of the grinding rotor is connected with one end of apull rod, the other end of the pull rod is connected with a rotary joint, a hydraulic cylinder is arranged beside the rotary joint, a gap is formed between the rotary joint and the hydraulic cylinder,a clamping jaw is arranged at the end of the pull rod, the end of the grinding rotor is detachably connected to the clamping jaw, a screen is arranged at the front end of the grinding rotor, a large-flow dynamic anti-blocking separation system is further formed at the position of the screen, and a movable disassembly mechanism is further arranged below the rack. The grinding machine has the beneficial effects that the grinding rotor is detachably connected to the pull rod, and after the grinding barrel is opened, the pull rod can be pushed by controlling the hydraulic cylinder to push out thegrinding rotor, so that cleaning, maintenance and replacement of the grinding rotor are facilitated; and the grinding machine is further provided with the dynamic anti-blocking separation system andthe movable disassembly mechanism, and the purposes of large-flow blockage prevention and convenient disassembly are achieved.

Owner:广东京驰智能装备有限公司

Sludge removing device for underground pipelines

The invention provides a sludge removing device for underground pipelines. The sludge removing device comprises a supporting mechanism arranged on the ground of a vertical shaft, a sludge removing mechanism arranged on the supporting mechanism and used for removing sludge, a sealing module cooperating with the sludge removing mechanism, a propelling mechanism arranged on the supporting mechanism,a collecting mechanism arranged on the propelling mechanism and used for collecting sludge, a disassembling and assembling mechanism arranged on the supporting mechanism and used for cooperating withthe propelling mechanism, and a controlling mechanism arranged on the supporting mechanism and used for controlling the supporting mechanism, the sludge removing mechanism, the propelling mechanism, the collecting mechanism, the sealing module and the disassembling and assembling mechanism to cooperate. The sludge removing device can clean narrow underground pipelines efficiently without consumingmuch water; besides, the sealing module arranged on the upstream part can avoid the situation that due to continuous enrichment of upstream sewage, part of sludge cannot be thoroughly removed, and sludge can be thoroughly removed at a time.

Owner:张桂华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com