Nanometer mercury material with lasting adsorption performance

An adsorption performance and long-lasting technology, applied in the fields of alkali metal oxides/hydroxides, inorganic chemistry, gas treatment, etc., can solve the problems of unbalanced regional development, imperfect technology, low utilization of coal gangue, etc., and achieve cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

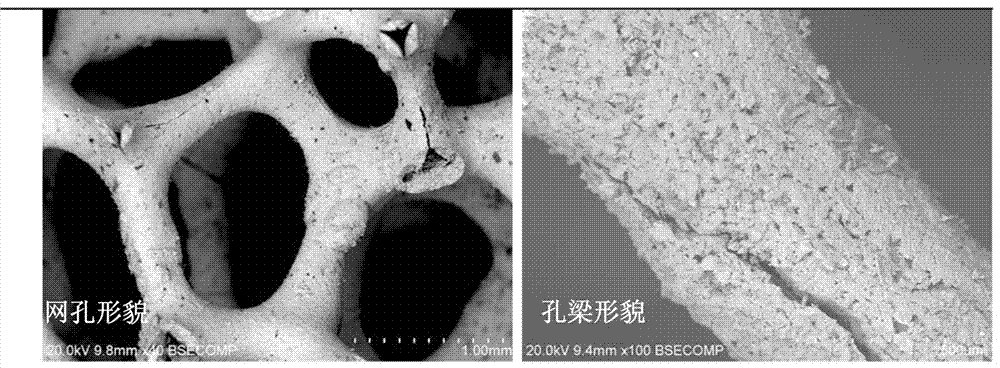

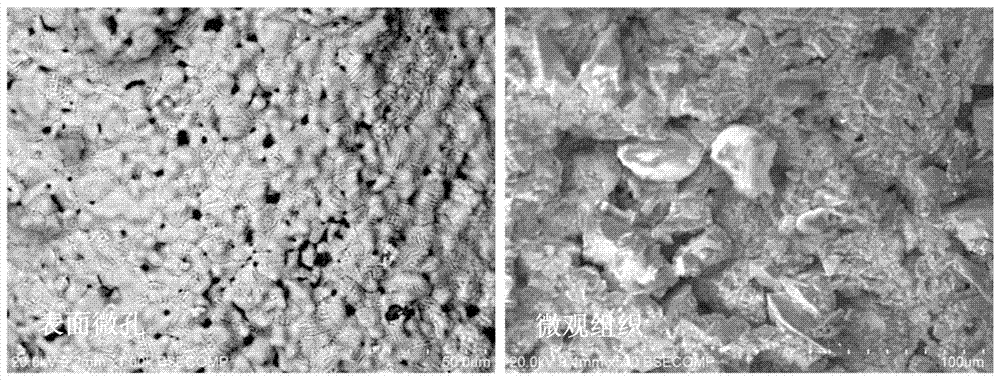

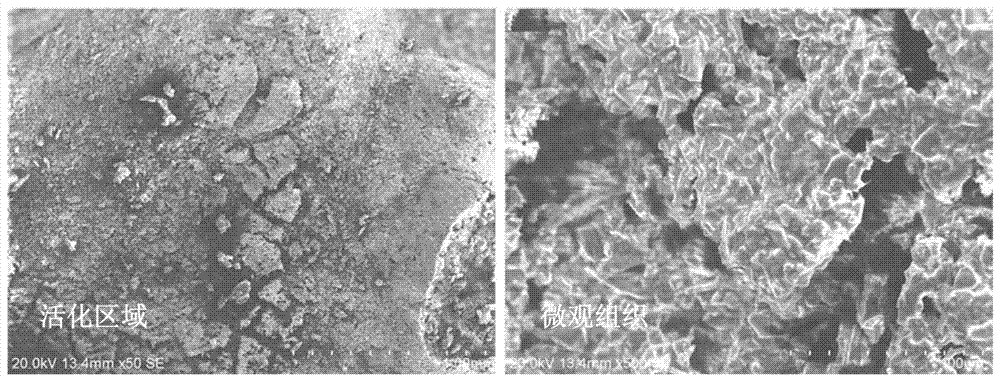

[0046] In this example, the composite ceramic carrier is prepared according to the method described in the technical solution of the present invention, which will include 33wt% Al 2 o 3 , 60wt% coal gangue, 7wt% charcoal powder main raw material and silica sol are mixed into a slurry at a weight ratio of 1:3, and then the polyurethane organic foam with a three-dimensional network skeleton structure or a honeycomb structure is immersed in the slurry, and then steamed Dry, repeat several times until the pores in the reticulated skeleton foam are filled. Finally, it is fired at 1300~1390°C for 4 hours, and air-cooled to room temperature to make a mesh or honeycomb composite ceramic carrier. Carrier samples are assembled and placed at an average concentration of 0.1mg / m 3 The application test was carried out in a mercury atmosphere, the sample continued to absorb mercury for 10 hours, and the average concentration of mercury at the outlet was 0.08mg / m 3 The adsorption rate is a...

Embodiment 2

[0048] In the present embodiment, first prepare the composite ceramic carrier according to the method described in the technical solution of the present invention, will comprise the Al of 35wt% 2 o 3 , 60wt% coal gangue, 5wt% starch main raw material and silica sol are mixed into a slurry at a weight ratio of 1:3, and then the polyurethane organic foam with a three-dimensional network skeleton structure or honeycomb structure is immersed in the slurry, and then dried , repeated several times until the pores in the reticulated skeleton foam are filled. Finally, it is fired at 1280~1390°C for 4 hours, and air-cooled to room temperature to make a mesh or honeycomb composite ceramic carrier. After the carrier is washed and dried, it is immersed in 0.1mol / L silver sulfate aqueous solution for 1~2h, and then placed in an oven at 80°C for drying. The sample is assembled and placed at a mercury content of 0.1mg / m 3 The test was carried out in an atmosphere, the sample continued to ...

Embodiment 3

[0050] In the present embodiment, first prepare the composite ceramic carrier according to the method described in the technical solution of the present invention, will comprise the Al of 30wt% 2 o 3 , 60wt% coal gangue, 10wt% charcoal powder and silica sol in a weight ratio of 1:3 are mixed into a slurry, and then three-dimensional network skeleton structure or honeycomb structure polyurethane organic foam is immersed in the slurry, and then dried , repeated several times until the pores in the reticulated skeleton foam are filled. Finally, it is fired at 1280~1390°C for 4 hours, and air-cooled to room temperature to make a mesh or honeycomb composite ceramic carrier. After the carrier is washed and dried, it is impregnated with 0.2mol / L silver chloride aqueous solution for 1~2h, and then placed in an oven at 80°C for drying. The sample is assembled and placed at a mercury content of 0.1mg / m 3 The test was carried out in an atmosphere, the sample continued to absorb mercur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com