Efficient grinding machine

A grinding machine, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of uneven speed of materials, difficult to control gaps, unevenness, etc., to reduce the probability of screen blockage, narrow particle size distribution of materials, increase The effect of filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

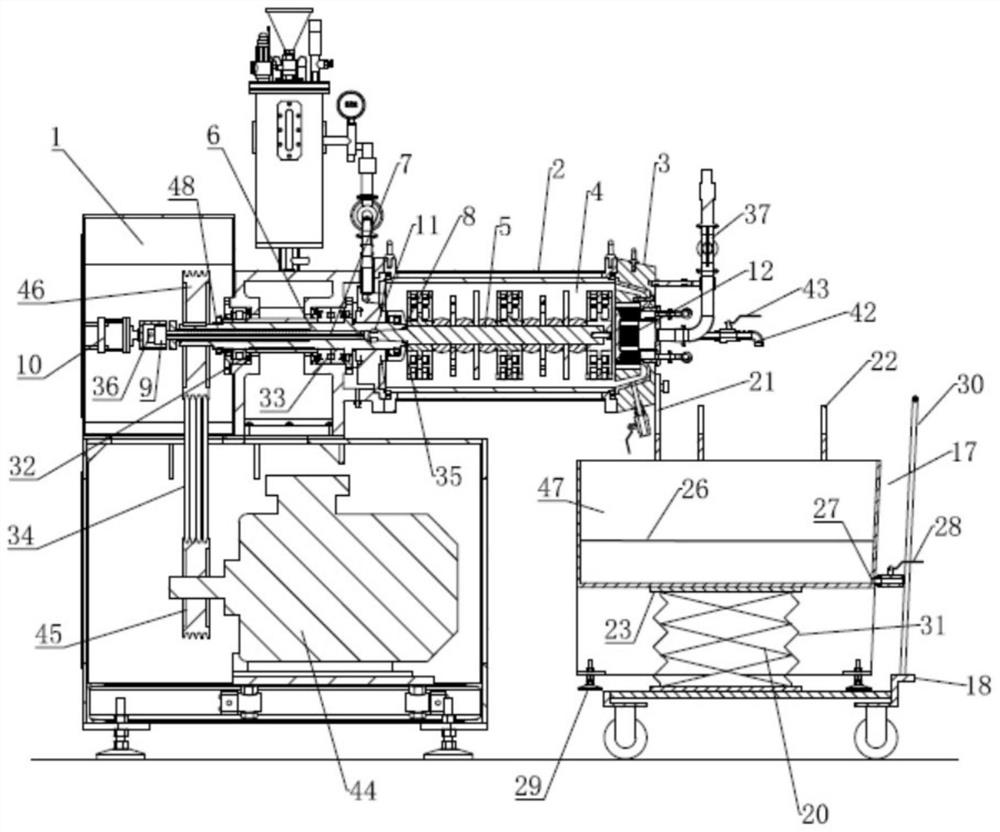

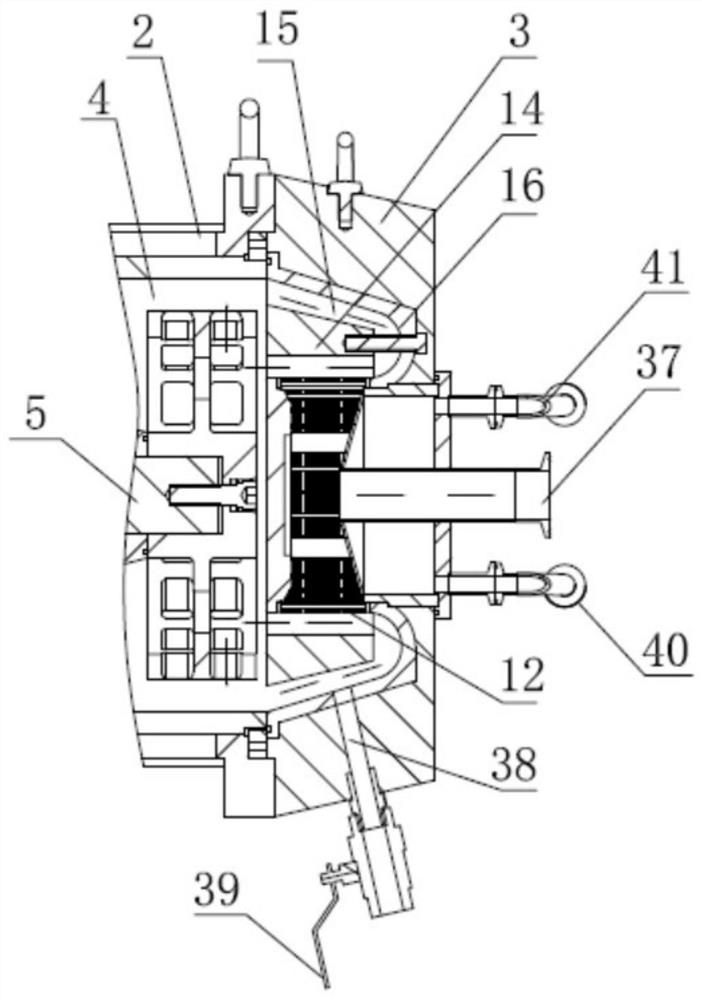

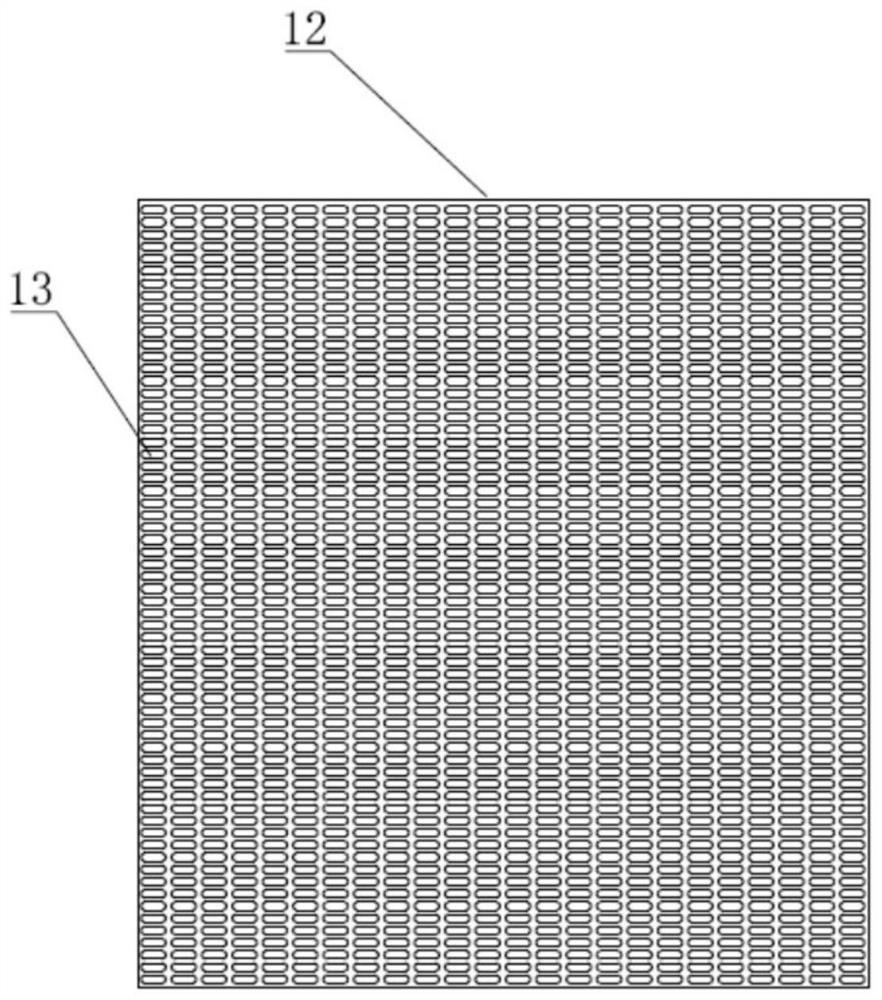

[0031] like Figures 1 to 6As shown, a high-efficiency grinding machine includes a frame 1, including a frame 1 and a grinding barrel 2. The front end of the grinding barrel 2 is detachably provided with an end cover 3, and the end cover 3 is installed on the grinding barrel 2 by bolting. The front end of the grinding barrel 2 and the end cover 3 are sealed to form a grinding cavity 4, the grinding cavity 4 is provided with a grinding rotor 5, a rotating shaft 6 is rotated on the frame 1, and the rotating shaft 6 is provided with a first bearing 32 and a second The bearing 33, the first bearing 32 and the second bearing 33 are installed on the bearing seat of the frame 1, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com