Oil-water separation device

An oil-water separation device, oil-water mixture technology, applied in separation devices, liquid separation, separation methods, etc., can solve the problems of low treatment efficiency, incompatibility of oil and water, etc., and achieve good results, high-efficiency separation, and easy centralized recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described below with specific examples, but protection scope of the present invention is not limited thereto:

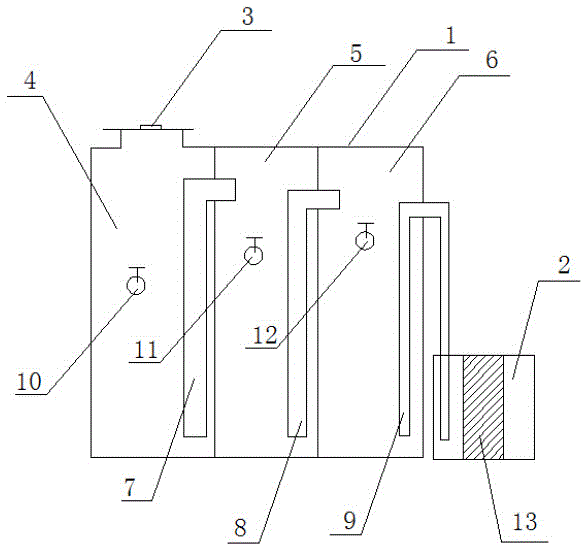

[0025] Such as figure 1 As shown, an oil-water separation device, the main body of the device includes a closed first tank body 1, the top of the first tank body 1 is provided with an oil-water mixture inlet 3, and two partition plates are arranged in the first tank body 1 The first tank body 1 is divided into three compartments, namely the first compartment 4, the second compartment 5 and the third compartment 6, and the first infusion pipeline 7 connecting the two compartments is respectively provided between the adjacent compartments , the second infusion pipeline 8, the third compartment is provided with an output pipeline 9 communicating with the outside of the tank body 1, the entrance of the infusion pipeline 7, 8 and the output pipeline 9 is close to the bottom of the compartment, the infusion pipeline 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com