Peanut shell removing and peanut seed peeling integrated device enabling peeled peanut seed and peanut seed coat to be separated

An all-in-one peanut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high shelling breakage rate, low efficiency, and the inability to collect and use peanut skins, so as to reduce the shelling breakage rate and easy to peel. , The effect of improving the efficiency of shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

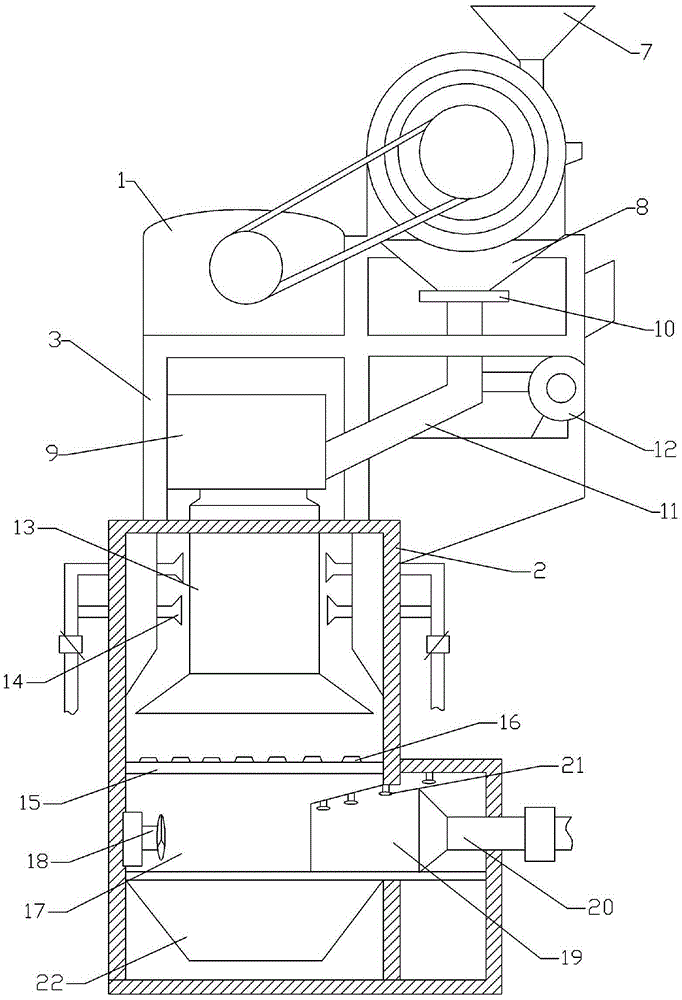

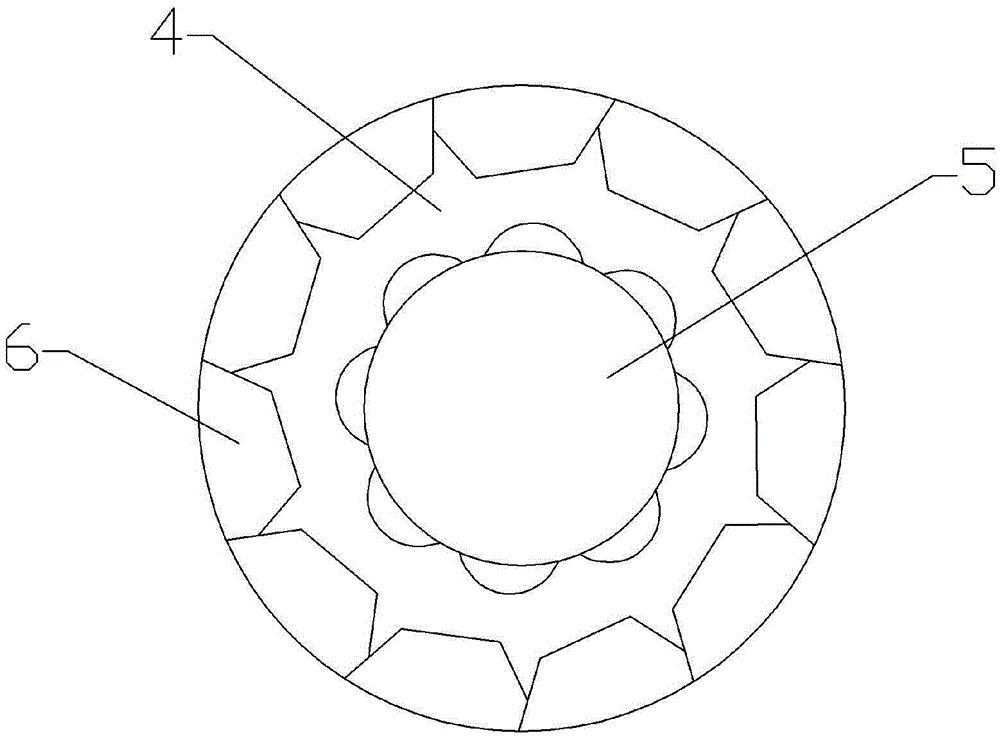

[0016] The reference signs in the accompanying drawings of the description include: motor 1, machine base 2, frame 3, housing cavity 4, shelling disc 5, protruding teeth 6, feeding hopper 7, distribution chute 8, storage barrel 9, Horizontal filter screen 10, material collecting pipe 11, first fan 12, spray chamber 13, nozzle 14, rotating roller 15, protrusion 16, distribution chamber 17, second fan 18, groove 19, leather outlet pipe 20, Drying lamp 21, collection chamber 22.

[0017] The embodiment is basically as attached figure 1 , attached figure 2 Shown: an integrated device for peeling and peeling peanuts, including a motor 1, a machine base 2, and a machine frame 3 on the machine base 2, and also includes a shelling mechanism, which includes a housing cavity 4 and an installation In the shelling disc 5 in the housing cavity 4, the inwall of the housing cavity 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com