Patents

Literature

91results about How to "Guaranteed extrusion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D-printable copper slag electromagnetic wave-absorbing concrete and use method thereof

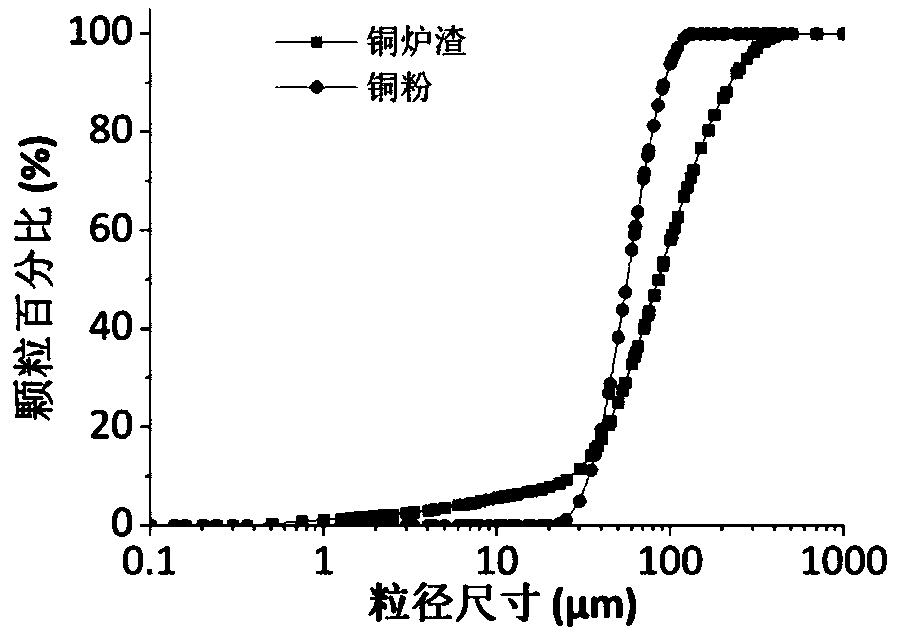

ActiveCN108609947ALow costImprove liquidityAdditive manufacturing apparatusBasalt fiberWater reducer

The invention relates to 3D-printable copper slag electromagnetic wave-absorbing concrete and a use method thereof. The concrete includes, by weight, 6.8-7.2 parts of quick-hardening ordinary Portlandcement, 6.9-7.1 parts of quartz sand, 1.65-1.75 parts of copper slag, and 0.28-0.71 parts of copper powder composed of brass powder and red copper powder according to the weight ratio of 7:2.5-3.5, 0.75-0.85 parts of silica fume, 0.09-0.15 parts of a water reducer, 0.04-0.07 parts of basalt fiber being 11-14 mm in length, 0.003-0.005 parts of hydroxypropyl methyl cellulose being 20,000-70,000 inviscosity, and 1.70-1.74 parts of water. With the copper slag and copper powder as raw materials, the concrete has both the printability and electromagnetic wave-absorbing effect of the copper slag and copper powder, so that the concrete allows 3D printing and can achieve more than 90% in electromagnetic wave absorption in the bandwidth of 3.4 GHz.

Owner:HEBEI UNIV OF TECH

6063 aluminum alloy profile extrusion grain control process

The invention belongs to the technical field of aluminum alloy extrusion, and relates to a 6063 aluminum alloy profile extrusion grain control process. The aluminum alloy raw materials are composed of0.50% to 0.55% of Si, less than or equal to 0.15% of Fe, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Mn, 0.45% to 0.50% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.05% of Ti, less than or equal to 0.05% of other single impurity, less than or equal to 0.15% of total impurity, and the balance Al, and the Si content is more than the Mg content, so that excess silicon is controlled between 0.25% to 0.30%. according to the 6063 aluminum alloy profile extrusion grain control process, an aluminum alloy ingot prepared by the process is subject to artificial aging after extrusion, online water-cooling quenching and stretch straightening, through the strict control of various process parameters, extruded products can meet the high precision standard of the extrusion tolerance GB / T14846, the yield strength is more than and equal to 210Mpa, the tensile strength is more than and equal to 230MPa, the elongation is morethan and equal to 10%, the elongation is far higher than the national standard, and especially, the average grain size which is less than and equal to 100mum is far better than the domestic average level of 200mum.

Owner:CHINA ZHONGWANG

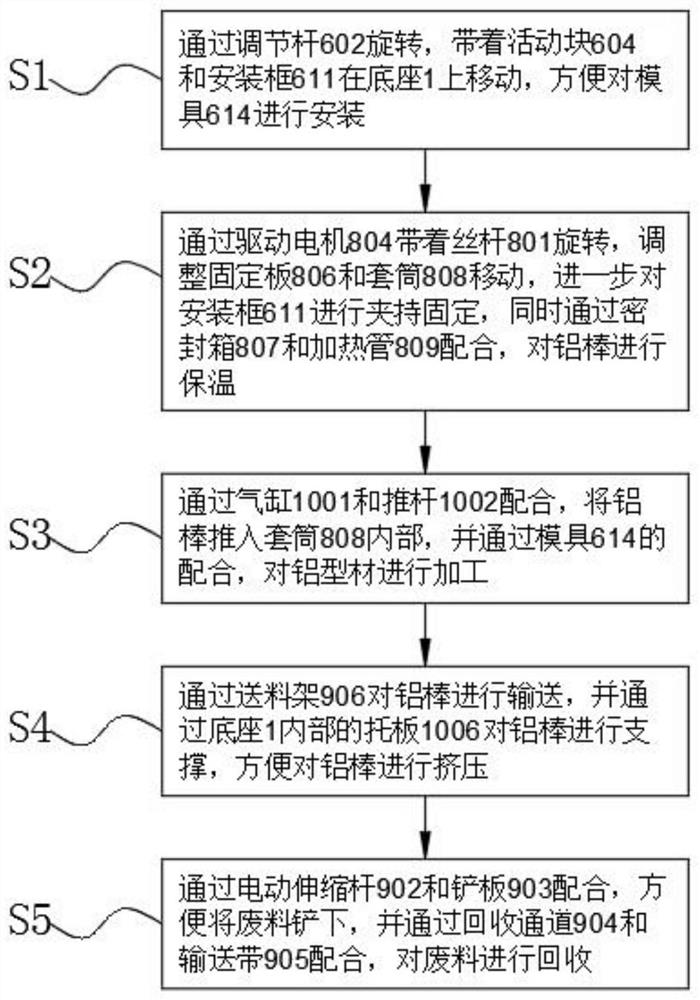

Efficient aluminum profile extrusion method

The invention discloses an efficient aluminum profile extrusion method. The method comprises the following steps that S1, a movable block and an installation frame are driven to move on a base through rotation of an adjusting rod to facilitate installation of a mold; and S2, fixing plates and a sleeve are adjusted to move through rotation of lead screws driven by driving motors to further clamp and fix the installation frame, and meanwhile an aluminum bar is cooled through cooperation of a sealing box and heating pipes. According to the method, the structure is scientific and reasonable, and use is safe and convenient. A mold plate assembly mechanism is arranged, arc-shaped plates are pushed by magnetic plates to clamp and fix the mold in the installation frame, the stability of the mold is guaranteed, the situation that the mold shakes during extrusion is avoided, and the aluminum profile extrusion quality is improved. Sliding rods and limiting plates are driven to move through the stretching and retracting characteristic of tensioning springs, so that the distance between the two limiting plates is reduced, the installation frame can be conveniently fixed to the movable block, and the mold installation speed is increased.

Owner:陕西良鼎瑞金属新材料有限公司

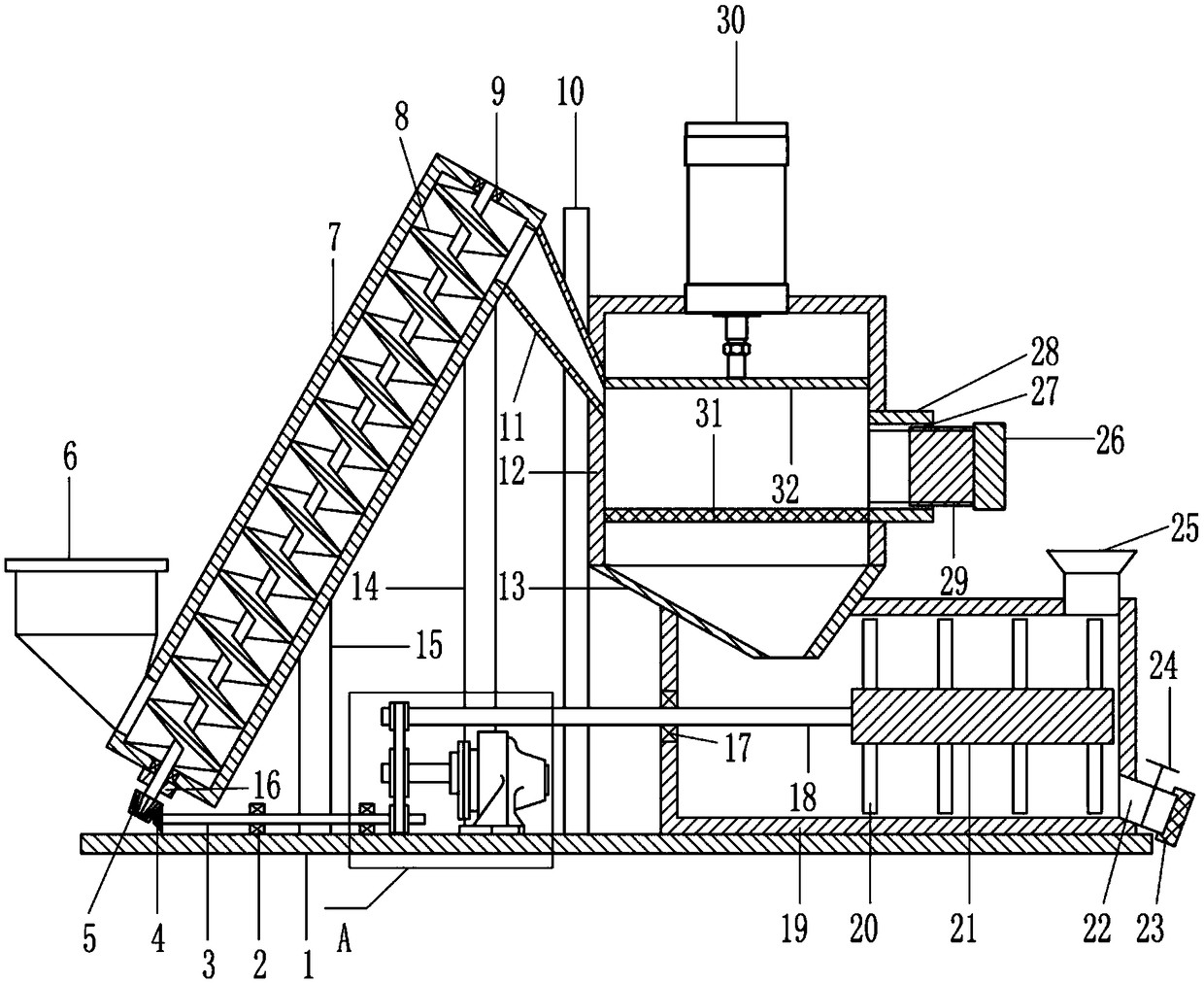

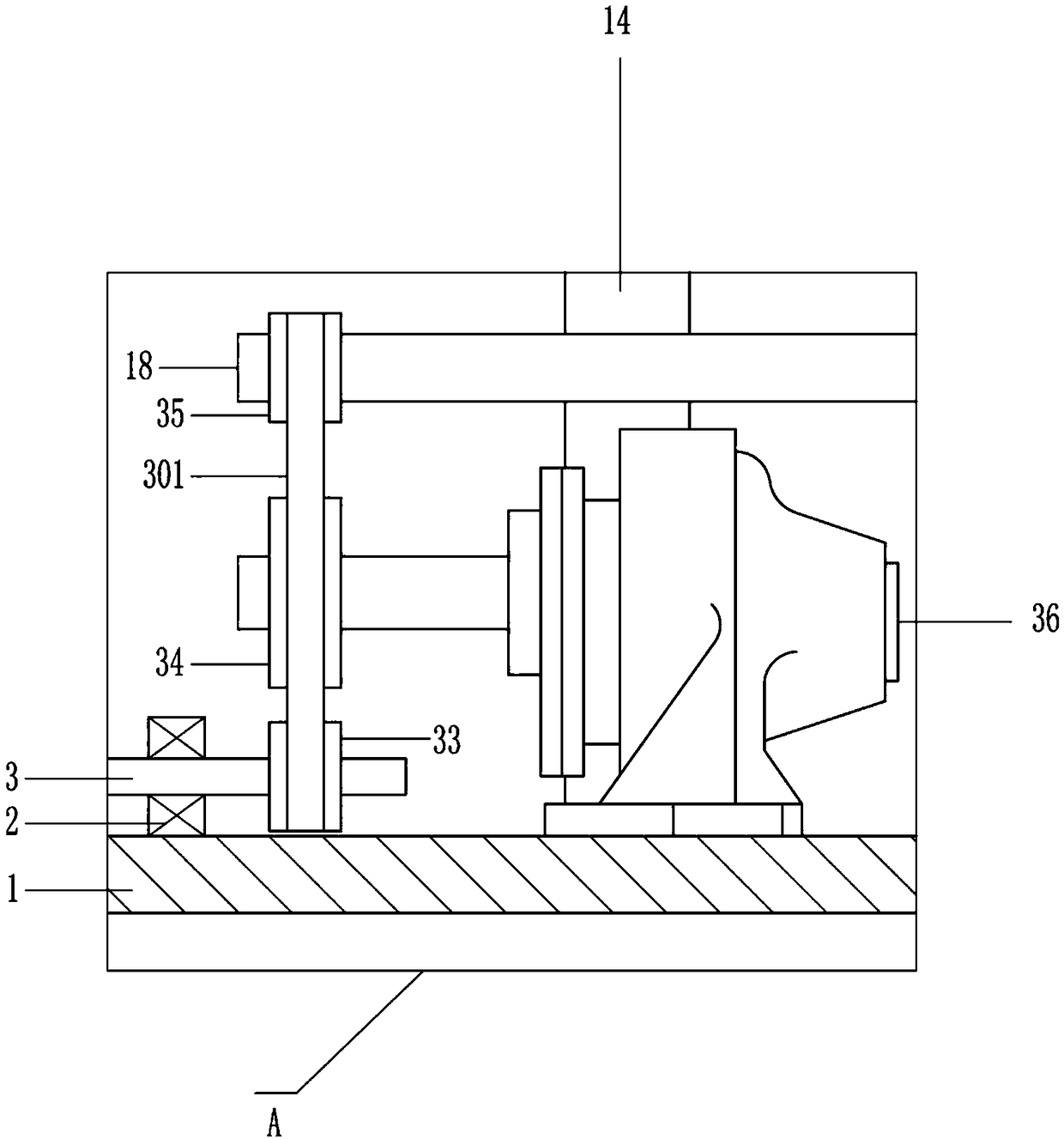

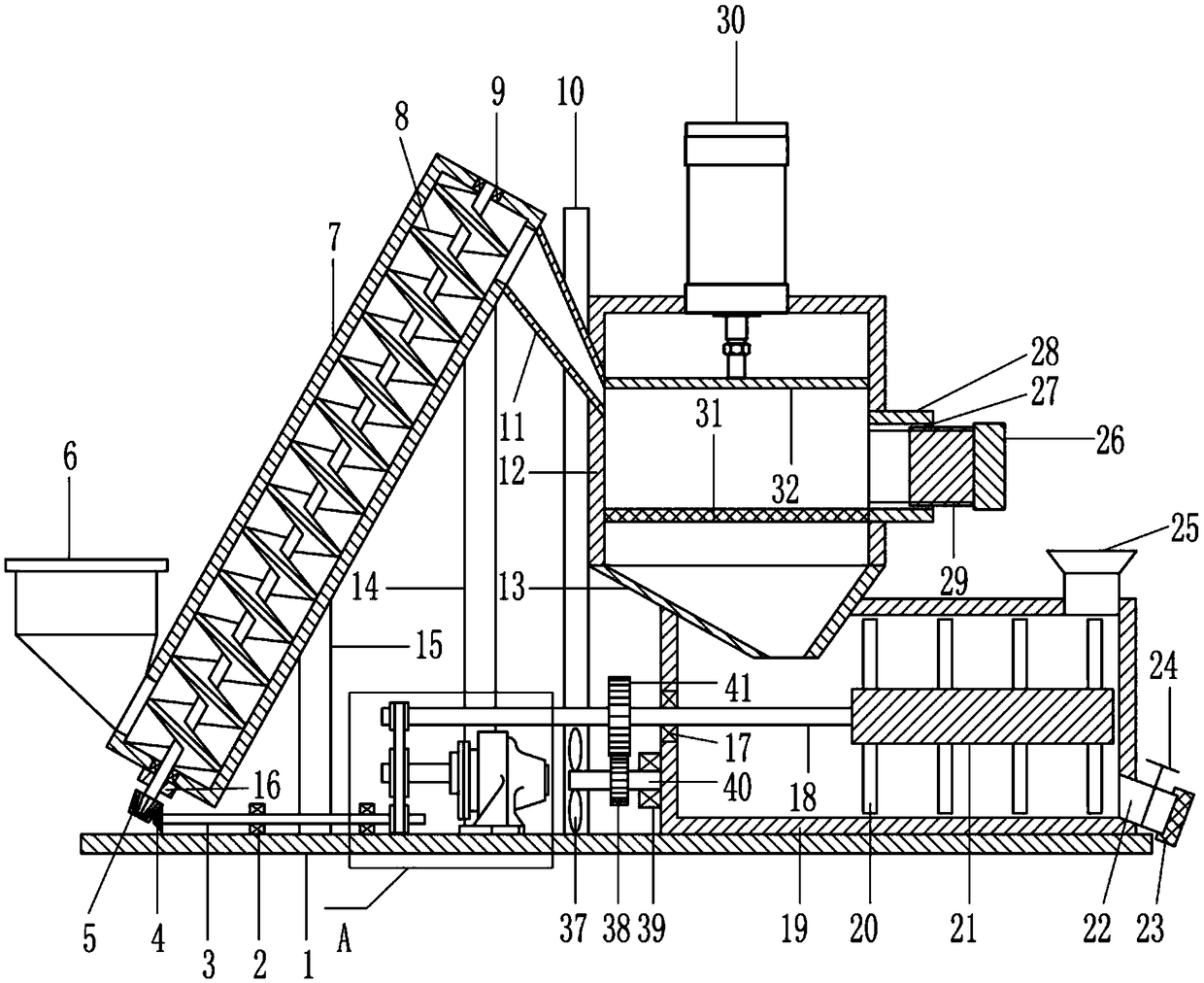

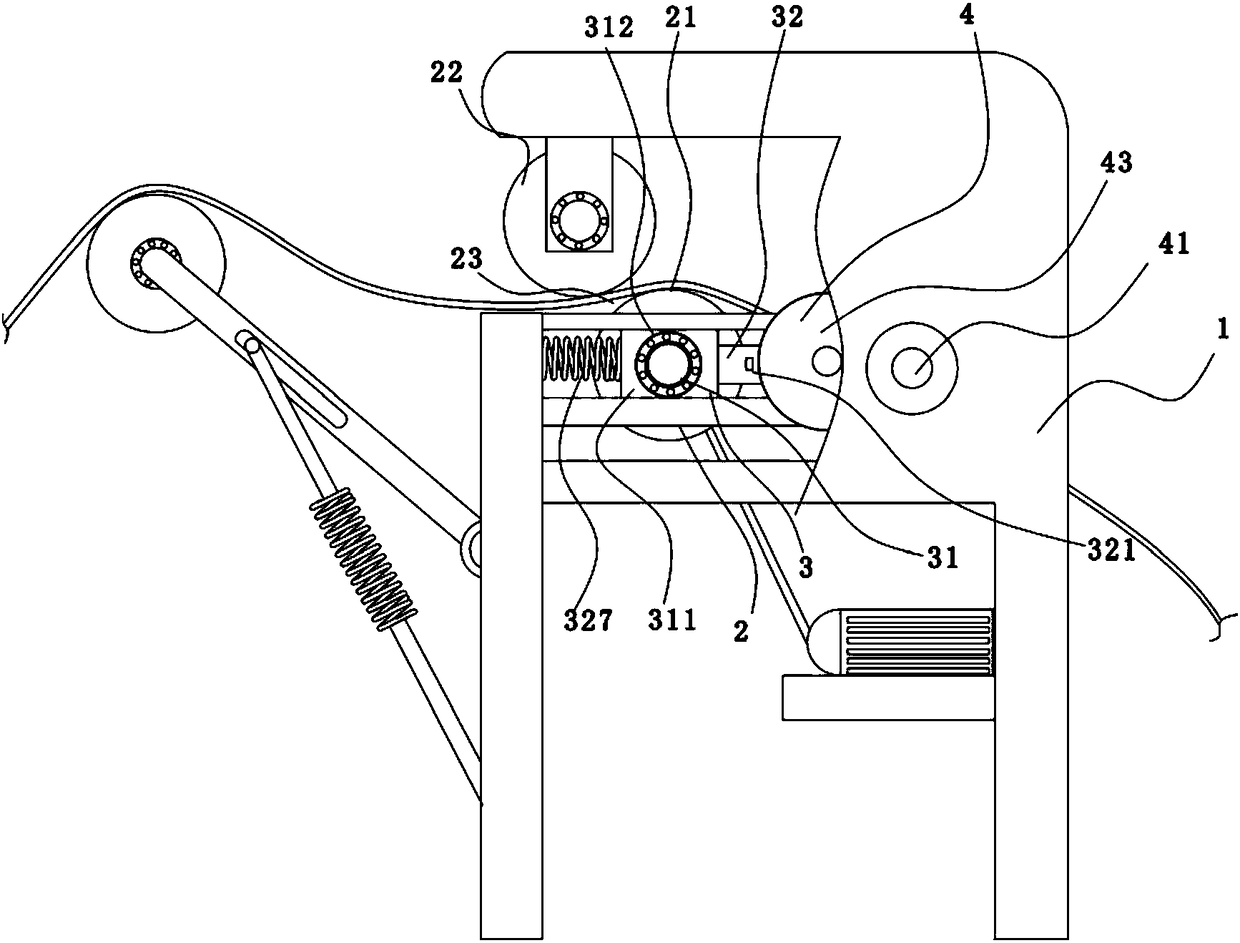

Biofuel particle normal-temperature forming machine

The invention belongs to the technical field of biofuel particle forming machines, and particularly relates to a biofuel particle normal-temperature forming machine. The forming machine comprises a rotary shaft, a bearing, a feed inlet, a smashing head, a rack, a motor, a charging barrel, a baffle, an installation plate, a cylinder, a piston rod, a push rod, a feeding push device, material holes, a lower pressing plate, a discharge opening, an upper pressing plate, a cam, a balance weight block, a bar A, a bar B, a worm and a turbine. The material holes are fixedly formed in the lower pressing plate and the upper pressing plate, the upper pressing plate is welded to the cam, the bar A is hinged to the cam, the bar A is hinged to the bar B, the bar B is hinged to the worm, the turbine is fixed to the rotary shaft, the rotary shaft is fixed to the bearing, the bearing is fixed to the rack, the feed inlet and the charging barrel are welded to the rack, the push rod is welded to the feeding push device, the lower pressing plate is welded to the rack, and the discharge opening is formed in the left end of the cam.

Owner:四川海和风科技有限公司

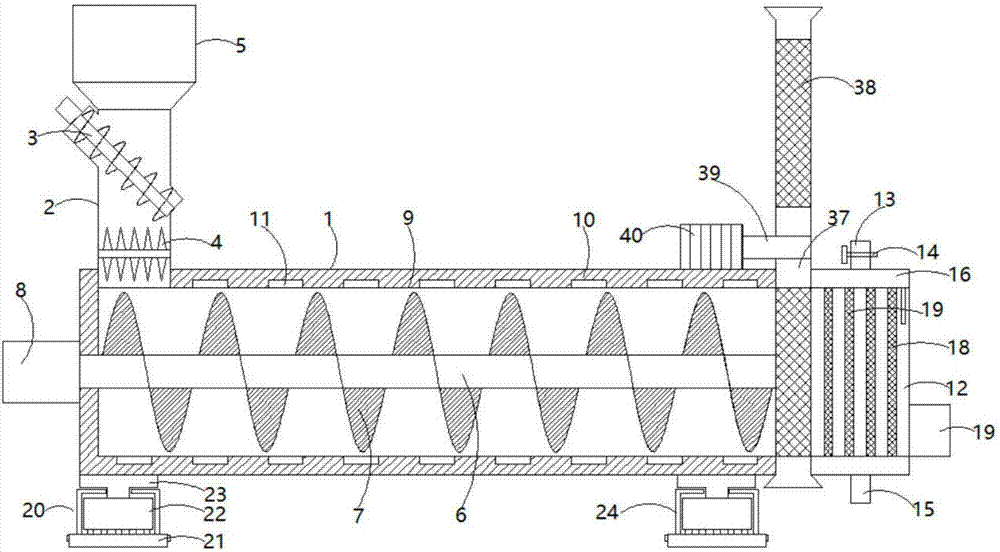

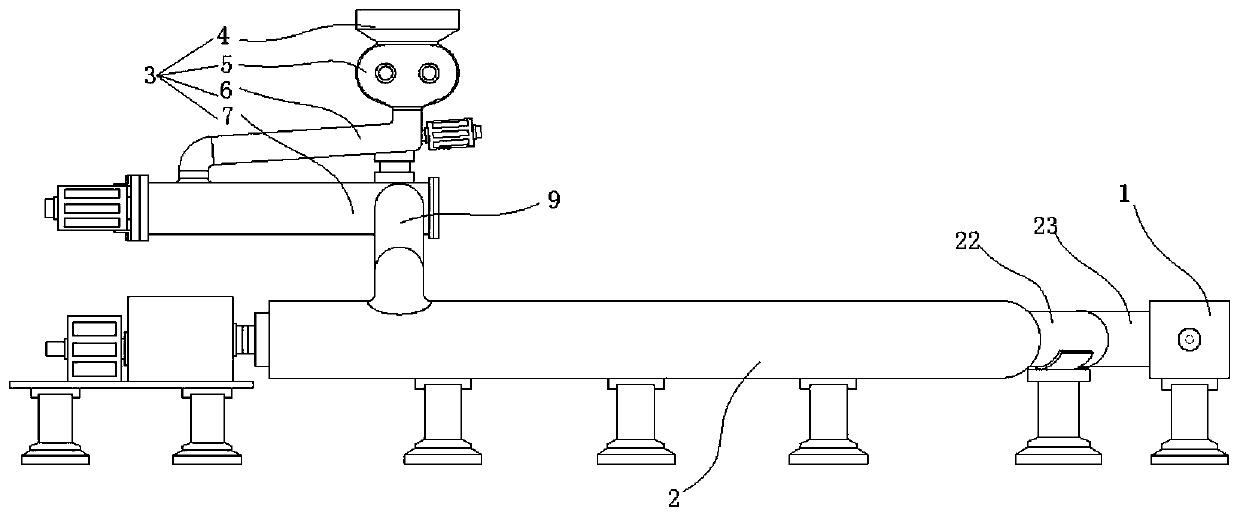

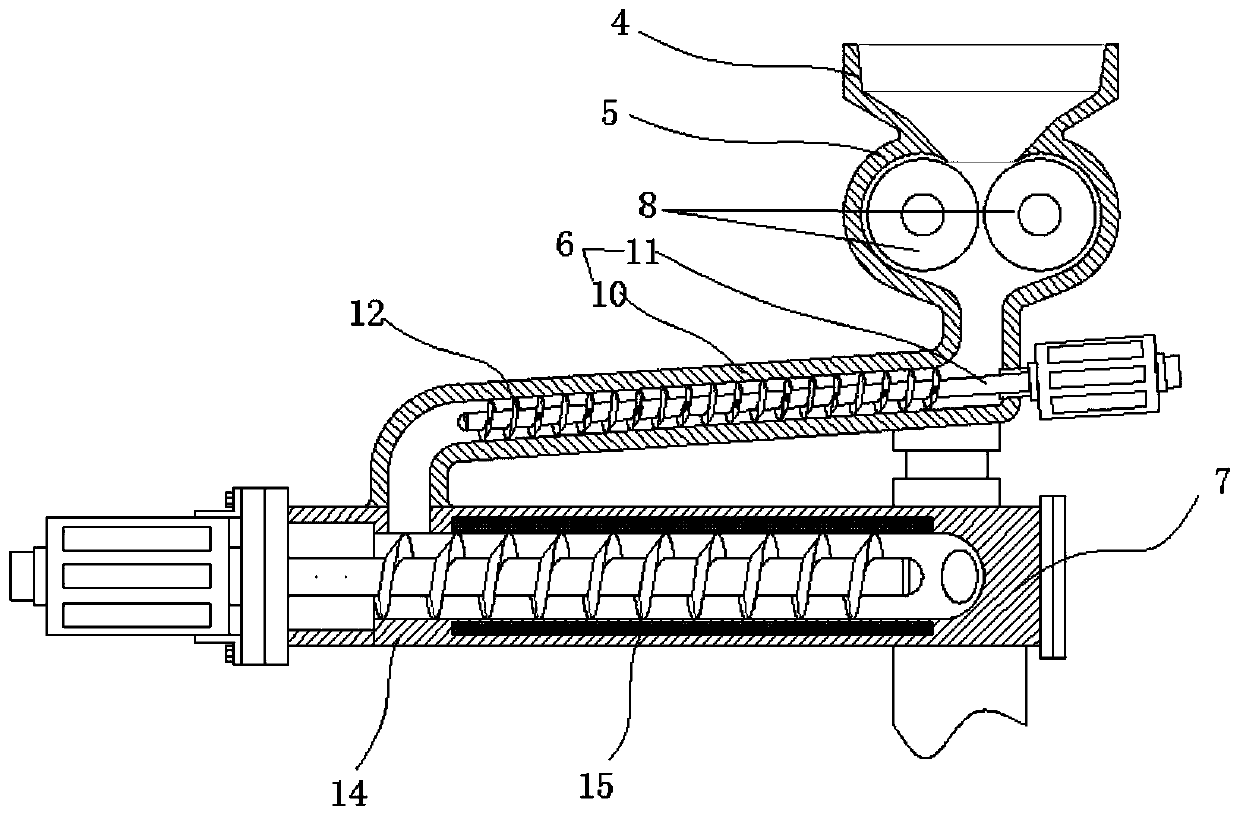

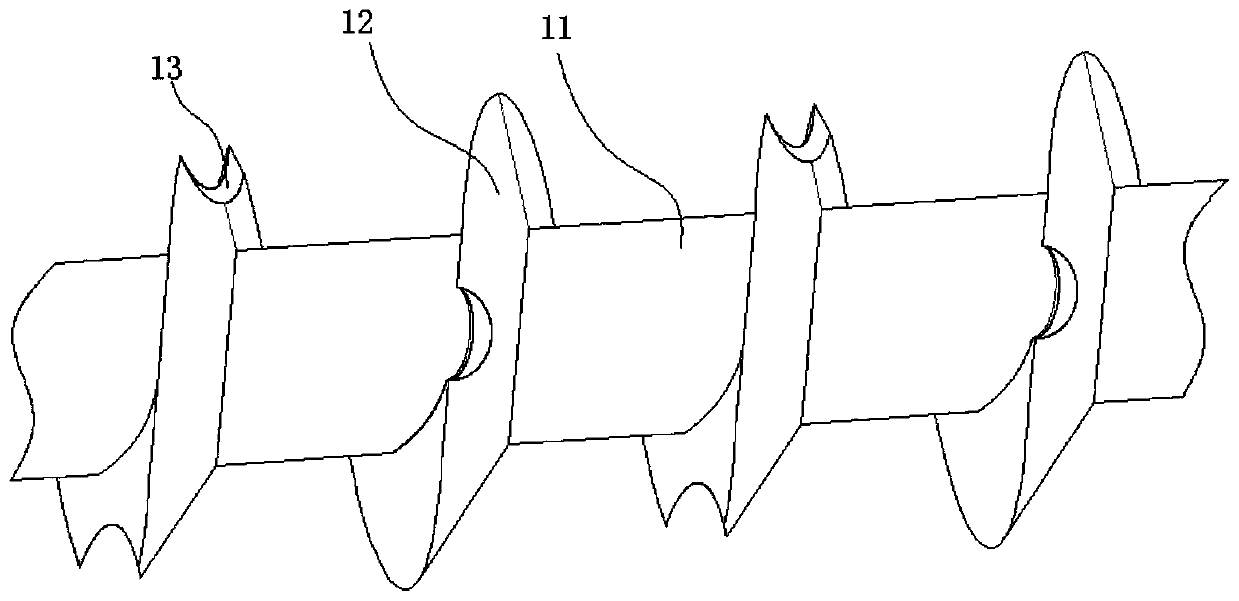

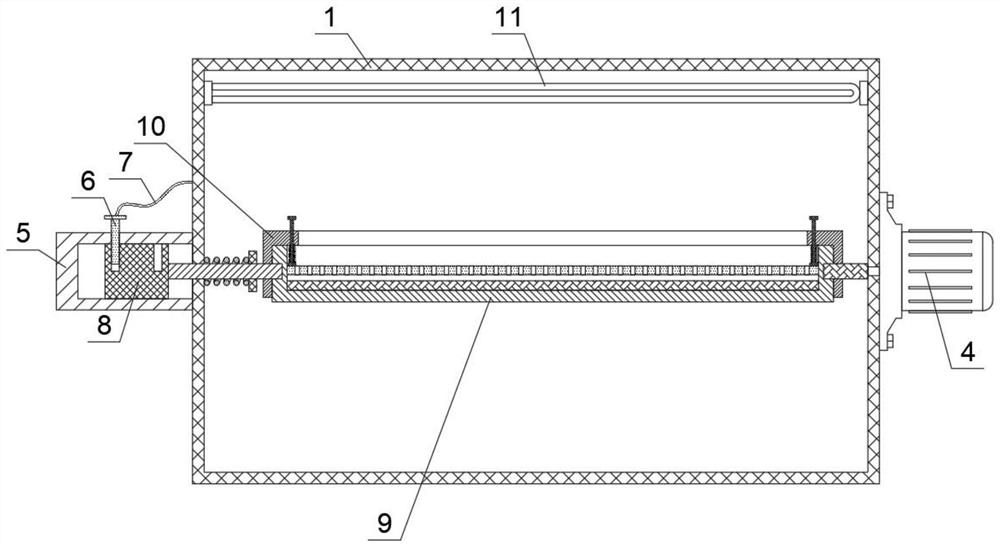

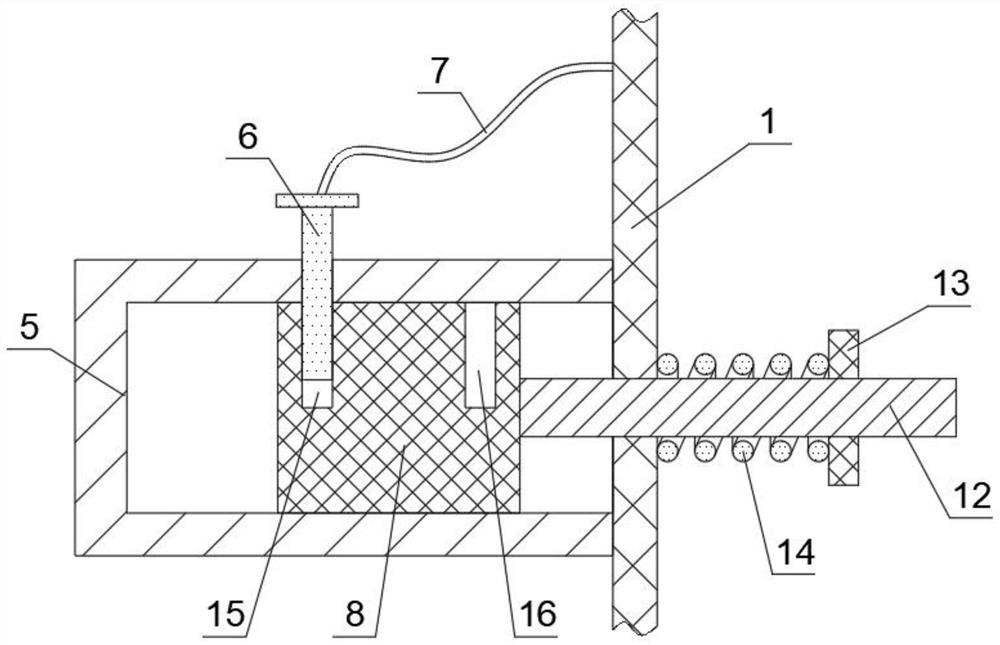

Hot melt extruder for thin film packaging material processing

InactiveCN107031010AAvoid cakingEasy extrusionNon-rotating vibration suppressionFlat articlesSolenoid valveCooling effect

The invention discloses a hot melt extruder for thin film packaging material processing. The holt melt extruder comprises a machine body which is a horizontally arranged cylinder, wherein an inner barrel is arranged inside the machine body; the inner barrel and the machine body are coaxially arranged; a material bin is arranged at the left upper side of the machine body; the bottom end of the material bin is connected with an unloading tube which is vertically arranged; a feeding connector is arranged at the upper side inside the unloading tube; and the feeding connector comprises a screw, a screw blade arranged on the outer wall of the screw and a motor connected with the screw. The hot melt extruder for thin film packaging can be used for continuously and uniformly feeding without a blocking phenomenon, can pre-pulverize raw materials, effectively improves extruding efficiency, can replace an extrusion mould head without stop, is convenient to clean and replace, an does not need manual operation; cooling speed in an extruding device can be controlled through a solenoid valve and a temperature sensor, so that the cooling effect is guaranteed; besides, the vibration reducing effect is good, the positioning effect is good, working stability of the extruder is improved, and noises generated by vibration are effectively reduced.

Owner:湖州多玛智能科技股份有限公司

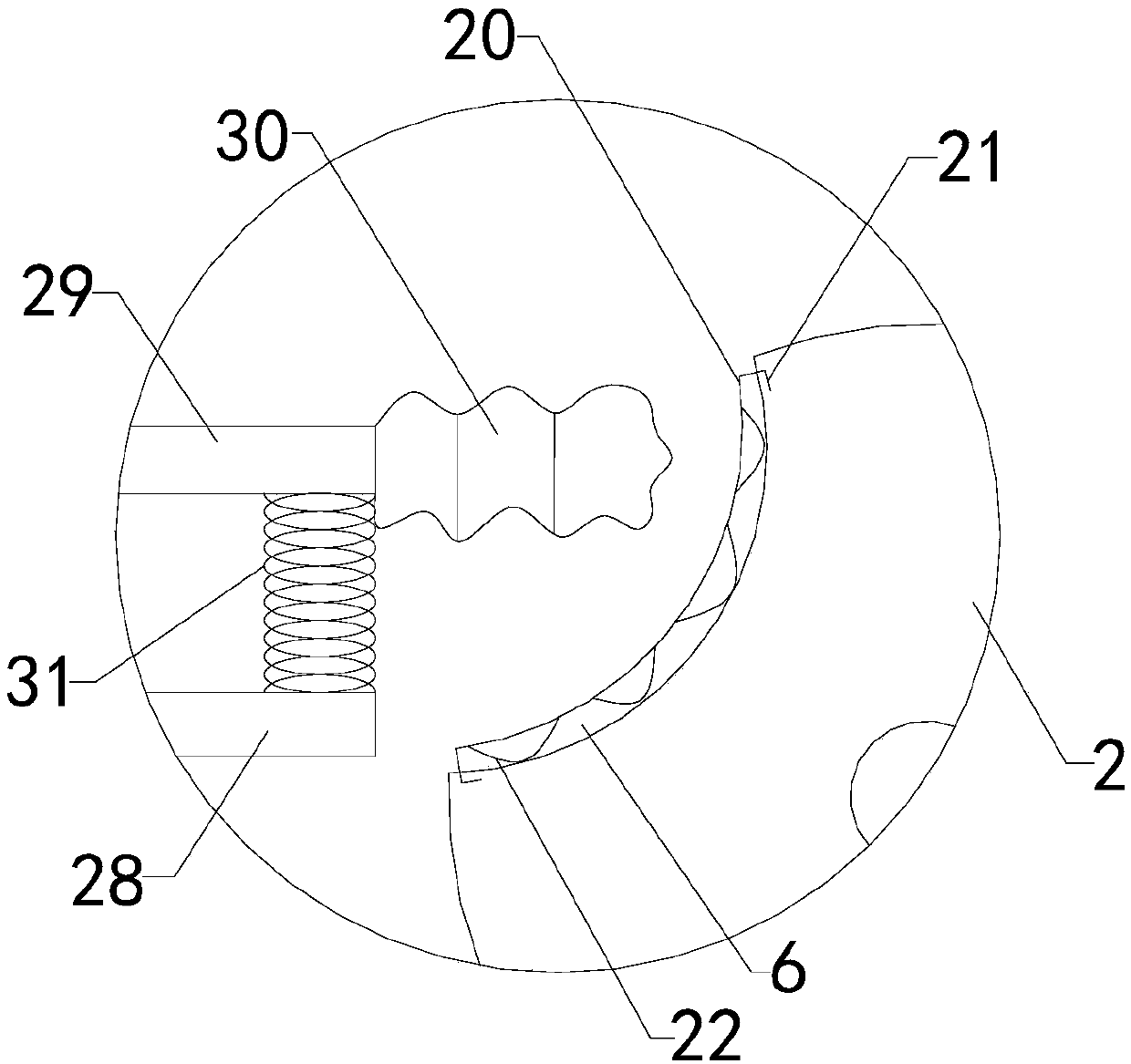

High-efficiency pulp filter-pressing and dehydrating equipment

ActiveCN109487611APerfect filter press dehydration effectPrevent backflowPulp de-wateringPulp and paper industryMechanical equipment

The invention discloses high-efficiency pulp filter-pressing and dehydrating equipment, and relates to the technical field of paper-making mechanical equipment. The equipment comprises a base, two pressing rollers, a spiral conveying mechanism and a frame shell arranged on two sides of the base, wherein a stock tank supporting plate and a driving mechanism driving the two pressing rollers to rotate are arranged on the base; and extruding bumps are uniformly distributed on the circumference of the two pressing rollers, and accommodating grooves for accommodating extruding bumps and power components which are used for driving the extruding bumps to extend out or retract along the accommodating grooves are arranged on inner sides of the two pressing rollers correspondingly. By implementing the technical scheme, the pulp carrying performance of the two pressing rollers can be effectively improved, pulp in an extruding area can be meshed and extruded with each other by utilizing the extruding bumps, the pulp discharge concentration can be 46 percent or more, and the filter-pressing and dehydrating effect of pulp can be effectively improved.

Owner:SICHUAN QIANWEI FENGSHENG PAPER LLC

Efficient juicer for improving juice yield

The invention discloses a high-efficiency juice extractor with improved juice yield, comprising a base, a juice extraction barrel, a hollow shaft, a movable rod and a pressing plate. In the juice extractor of the present invention, the fruit is processed by crushing and then extruding, which effectively improves the juice yield of the fruit, and can fully extract the juice in the pomace by repeatedly squeezing the pomace, thereby avoiding waste. ; Through the reverse rotation of the first blade and the second blade, the cutting force is increased and the crushing efficiency is improved; through the elastic connection between the sliding rod and the movable rod, the pressure plate can be closely fitted with the filter plate, thereby ensuring the extrusion The lever mechanism formed by the pressure plate and the vertical frame achieves the effect of saving labor and effectively reduces the energy consumption; through the setting of the pressure plate driving component, the crushing and extrusion are carried out at the same time, which ensures the continuity of the work, and also makes it easier to Start and stop operations.

Owner:南京辰略信息科技发展有限责任公司

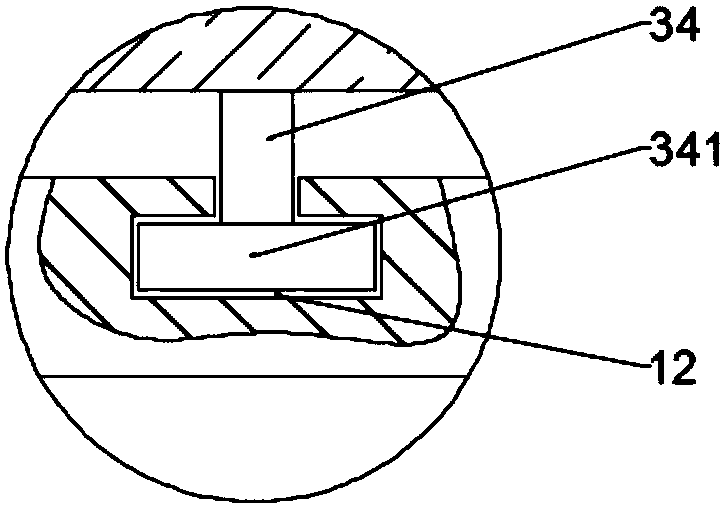

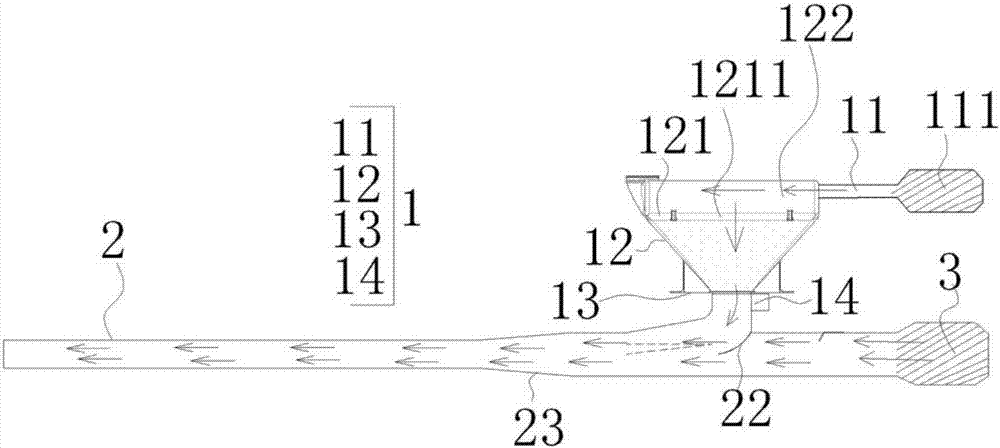

Portable high-stability press-filtering device

ActiveCN108975652AAvoid spillingGuaranteed extrusion effectSludge treatment by de-watering/drying/thickeningFiltration separationSludgeSewage

The invention relates to a press-filtering device and in particular to a portable high-stability press-filtering device. A technical problem to be solved is to provide the portable high-stability press-filtering device which is capable of avoiding splashing sludge in a loading process, guaranteeing the extruding effect to the sludge, performing purification treatment on extruded sewage in time, and effectively guaranteeing later-period utilization efficiency of the sewage. The portable high-stability press-filtering device comprises an installing plate, a first bearing base, a first rotating shaft, a first bevel gear, a second bevel gear, a sludge feeding hopper, a sludge conveying pipe, a spiral conveying shaft, a first support column, a conveying hopper, a press-filtering box, a draininghopper, a second support column, a third support column, a sealing ring, a third bearing base and the like. The portable high-stability press-filtering device achieves the effect of avoiding splashing the sludge in the loading process, guaranteeing the extruding effect to the sludge, performing the purification treatment on the extruded sewage in time, and effectively guaranteeing the later-period utilization efficiency of the sewage.

Owner:芜湖海创环保科技有限责任公司

Preparing method of novel thermal insulation material

The invention discloses a preparation method of a novel thermal insulation material. The preparation method of the novel thermal insulation material includes the steps of rubber cutting, first banburying, first milling, second banburying, second milling, extrusion, foaming, cutting, inspection and tail gas treatment. The invention has good quality and mechanical properties of the thermal insulation material, adopts two banburying and open refining so that the raw materials can be better dispersed and fused, the production efficiency is improved, and there is almost no generation of dust and leakage of waste gas in the production process, avoiding Environmental pollution, and the preparation method is energy-saving and environment-friendly.

Owner:杭州澳利斯橡塑保温材料有限公司

Nut shelling device with tapered millstone

A device for shelling dried fruit with conical grinding discs, including a rotating grinding disc and a fixed grinding disc, the fixed grinding disc is fixed on the frame, and the rotating grinding disc is installed on the fixed grinding disc through a vertically arranged transmission shaft, so that the rotating grinding disc is driven by the transmission shaft, thereby relatively It rotates on the fixed grinding disc, and there is a gap (and adjustable) larger than the outer diameter of the dried fruit between the rotating grinding disc and the fixed grinding disc to form a shelling space. The opposite surface is a downward-sloping conical surface so that a downward passage is formed around the shelling space. There are multiple ribs protruding outward on the opposite surface of the rotating grinding disc and the fixed grinding disc. The ribs are arranged around the transmission shaft and Each rib extends radially along the rotating grinding disc and the fixed grinding disc to cover the glide path of the entire shelling space, and the gap between the rib on the rotating grinding disc and the opposite surface of the fixed grinding disc is smaller than the outer diameter of the dried fruit and larger than the outer diameter of the dried nut. The device has high shelling efficiency, good shelling quality, low damage rate of dried nut kernels and stable discharge.

Owner:HUNAN AGRICULTURAL UNIV

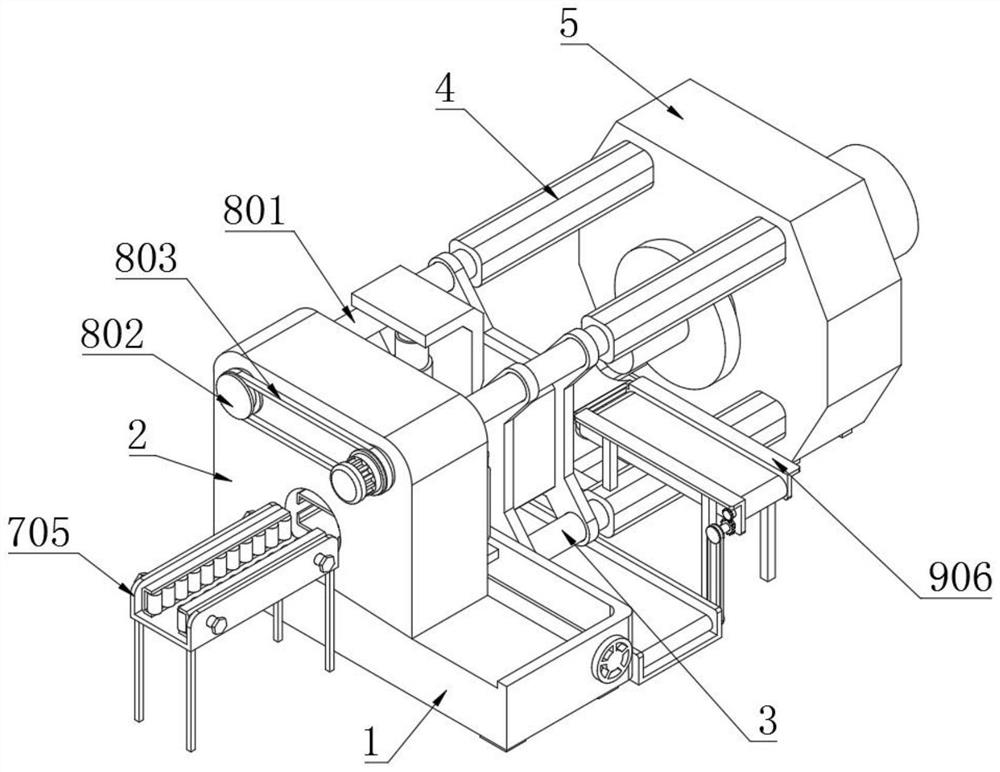

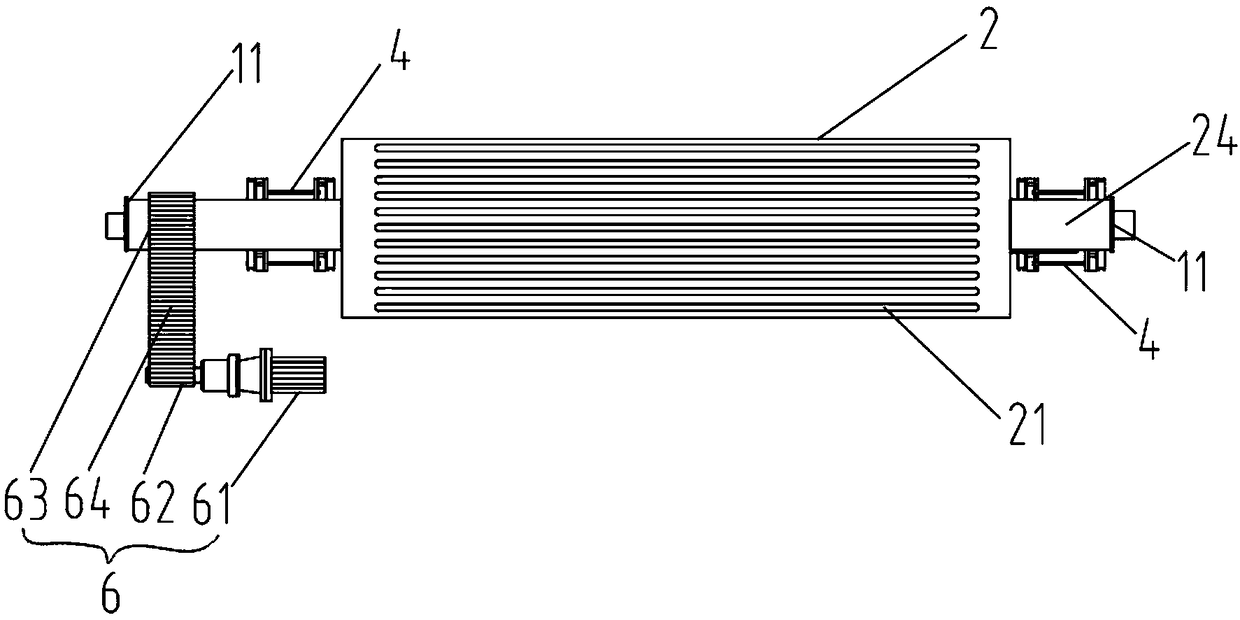

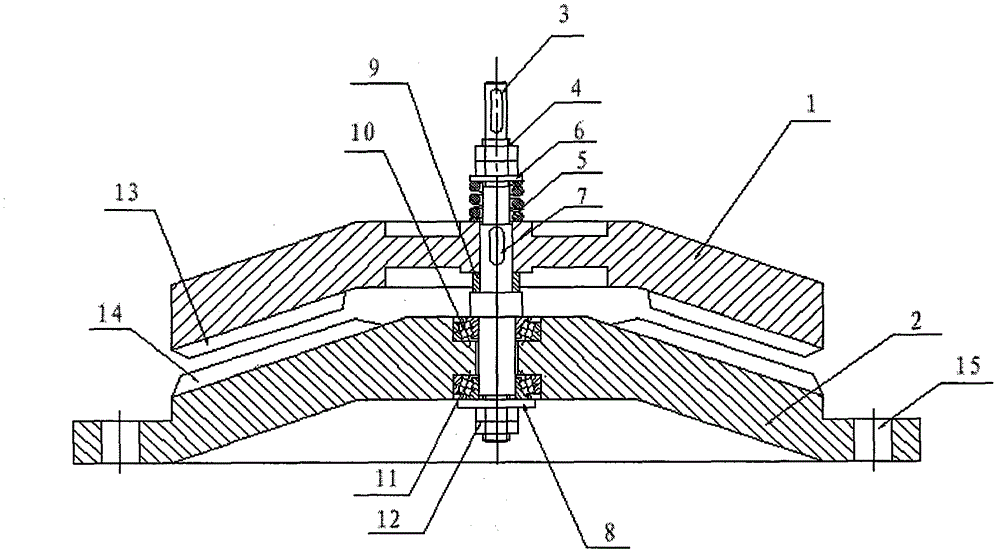

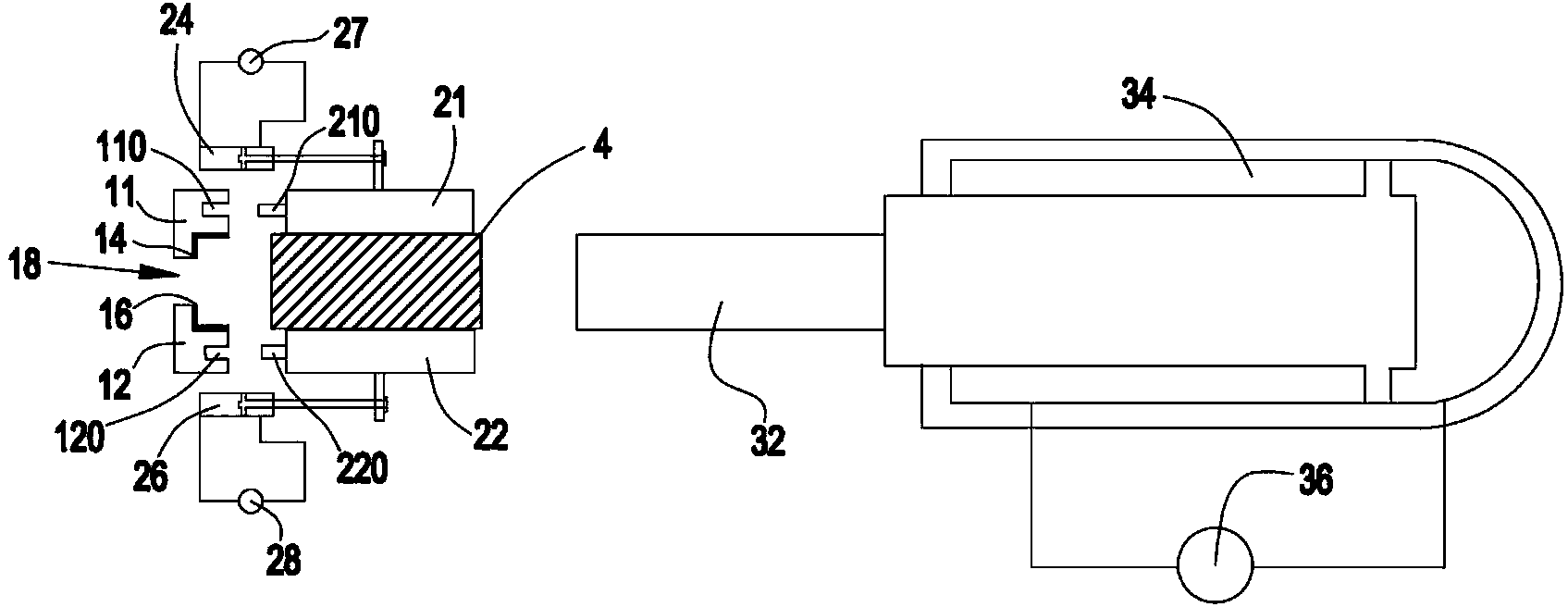

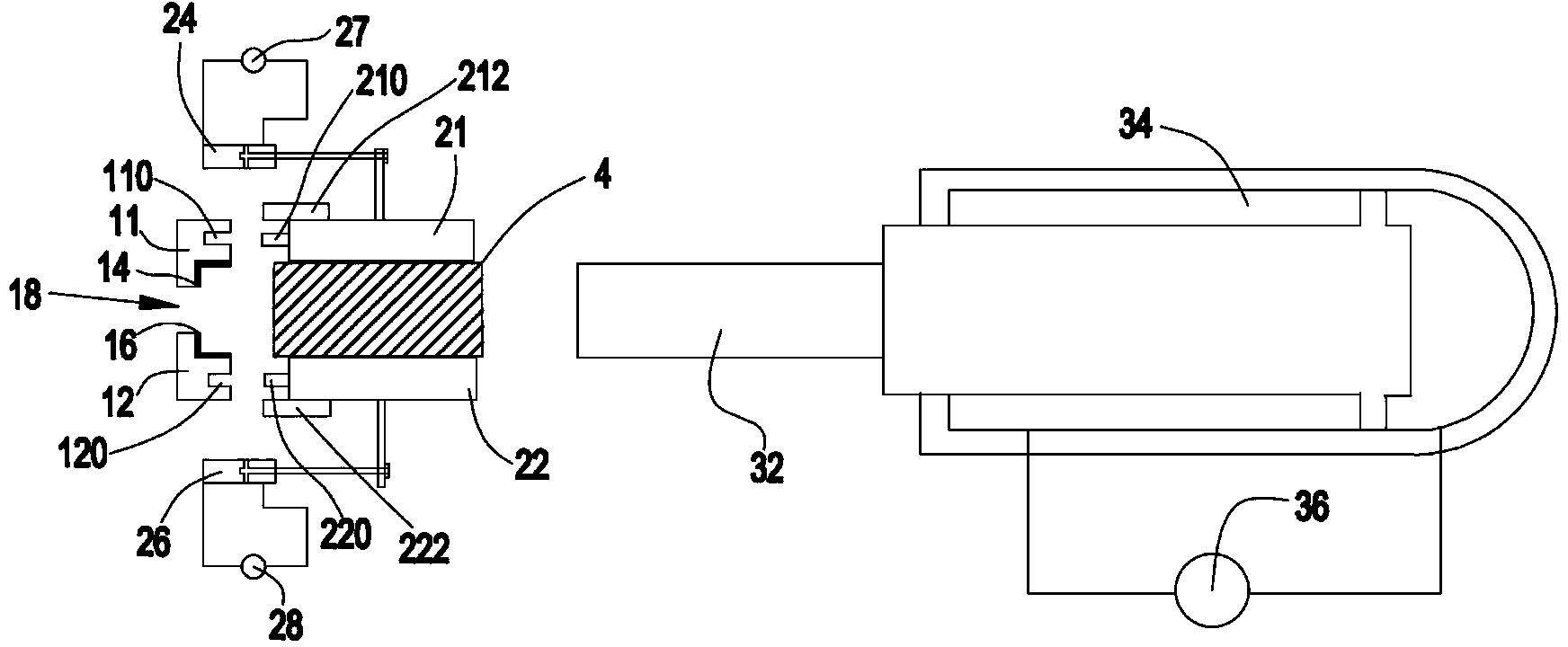

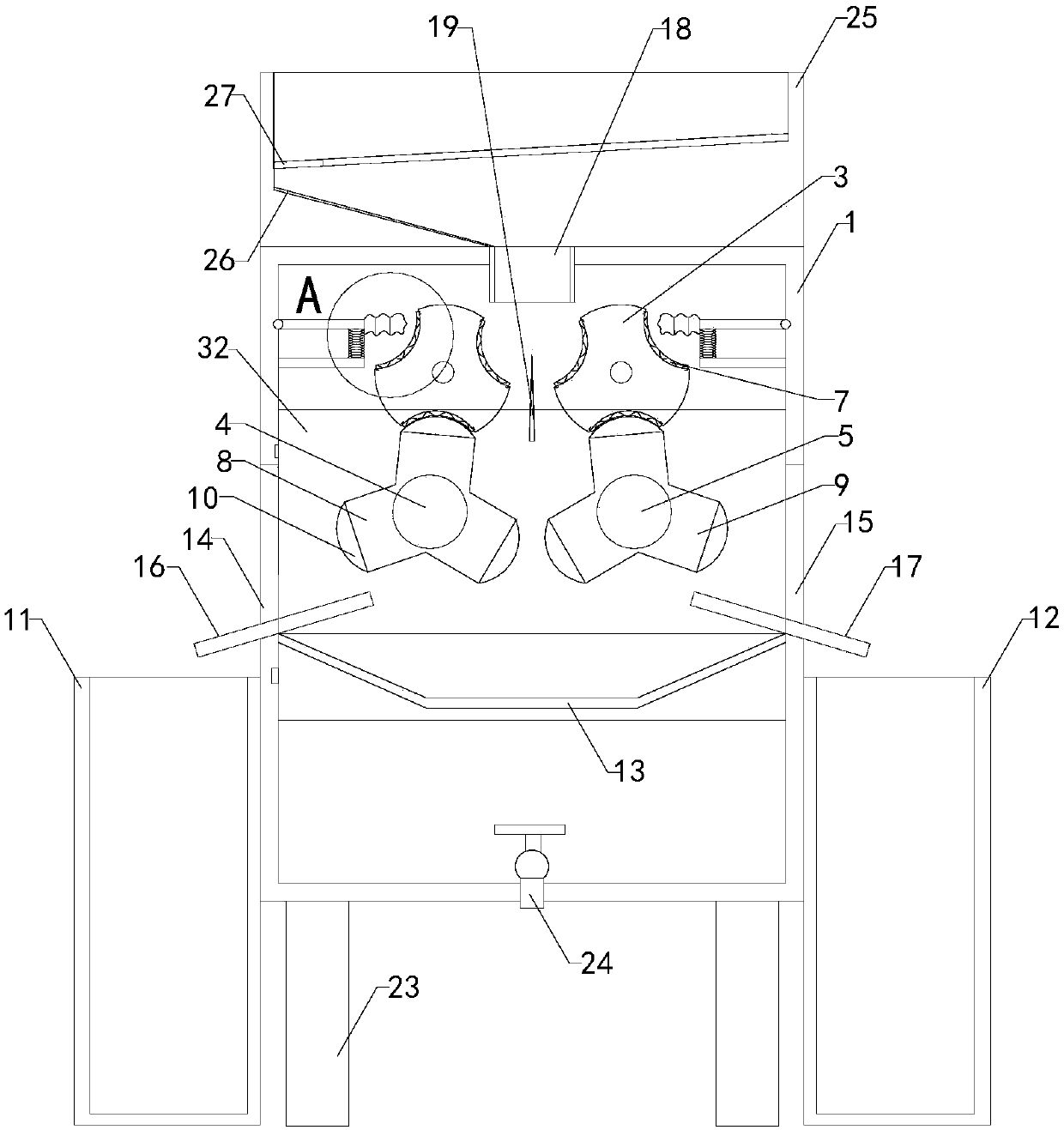

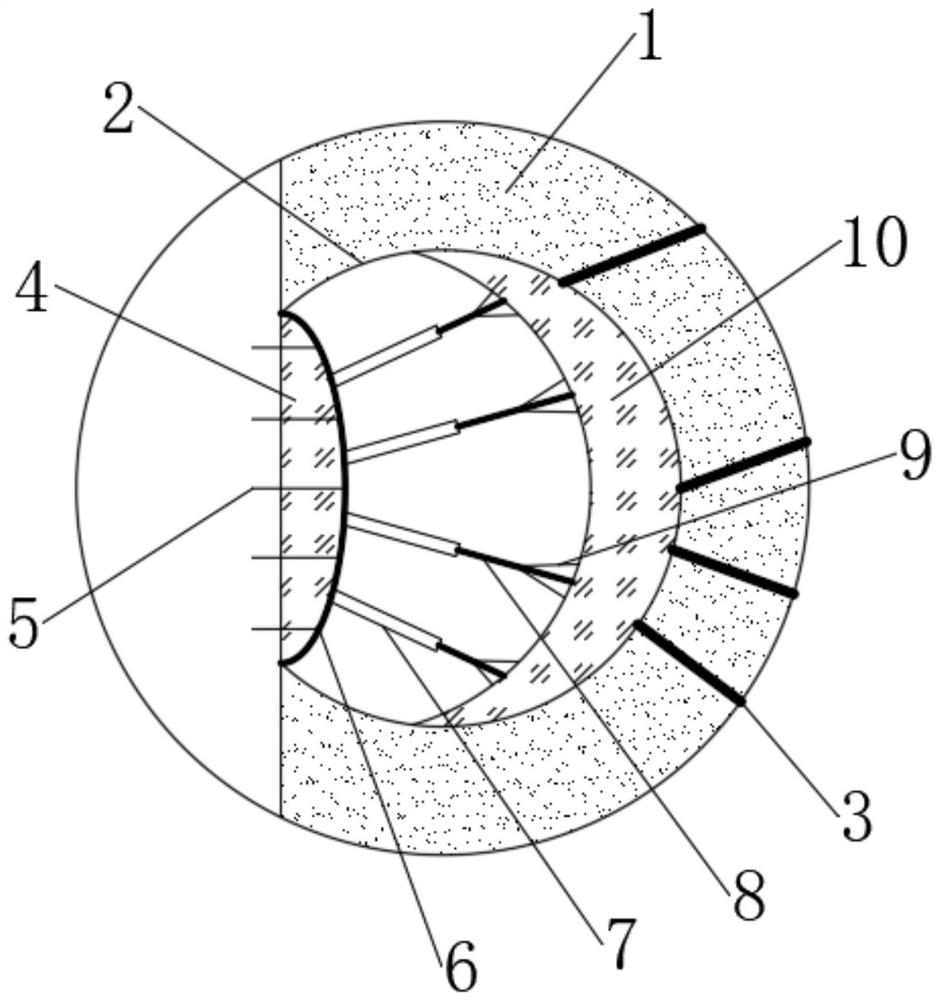

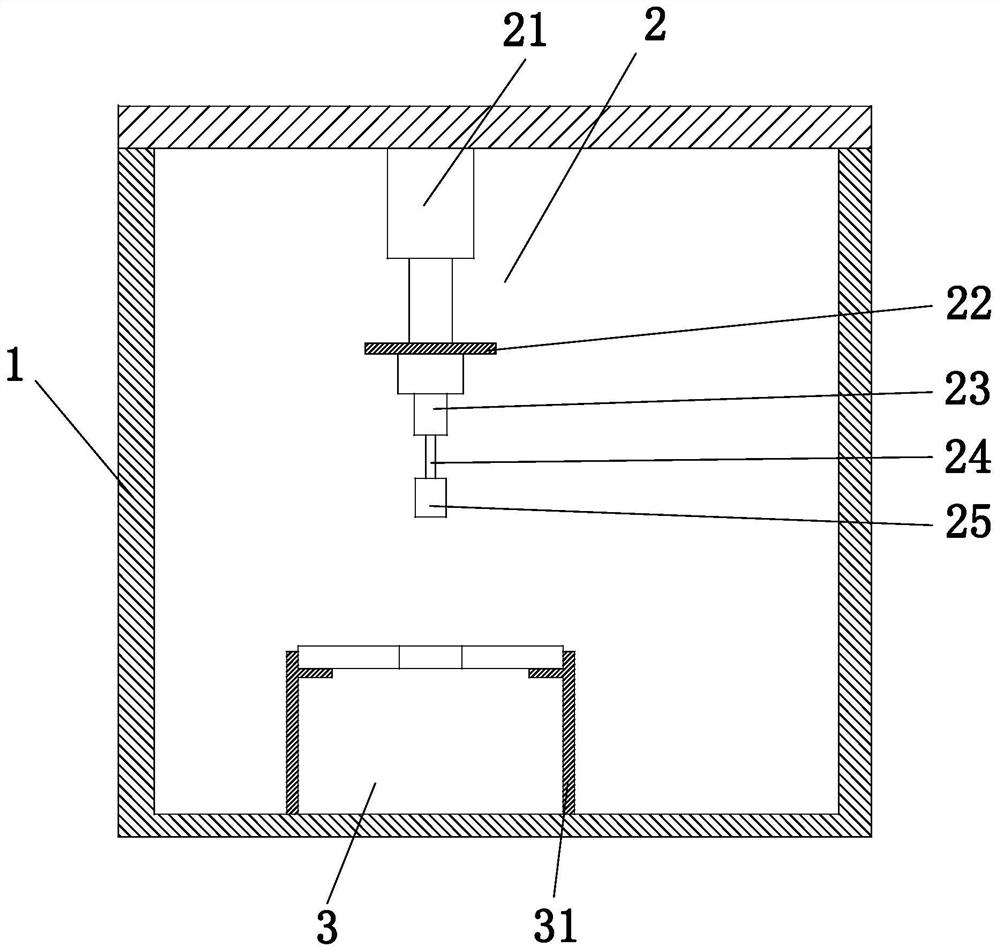

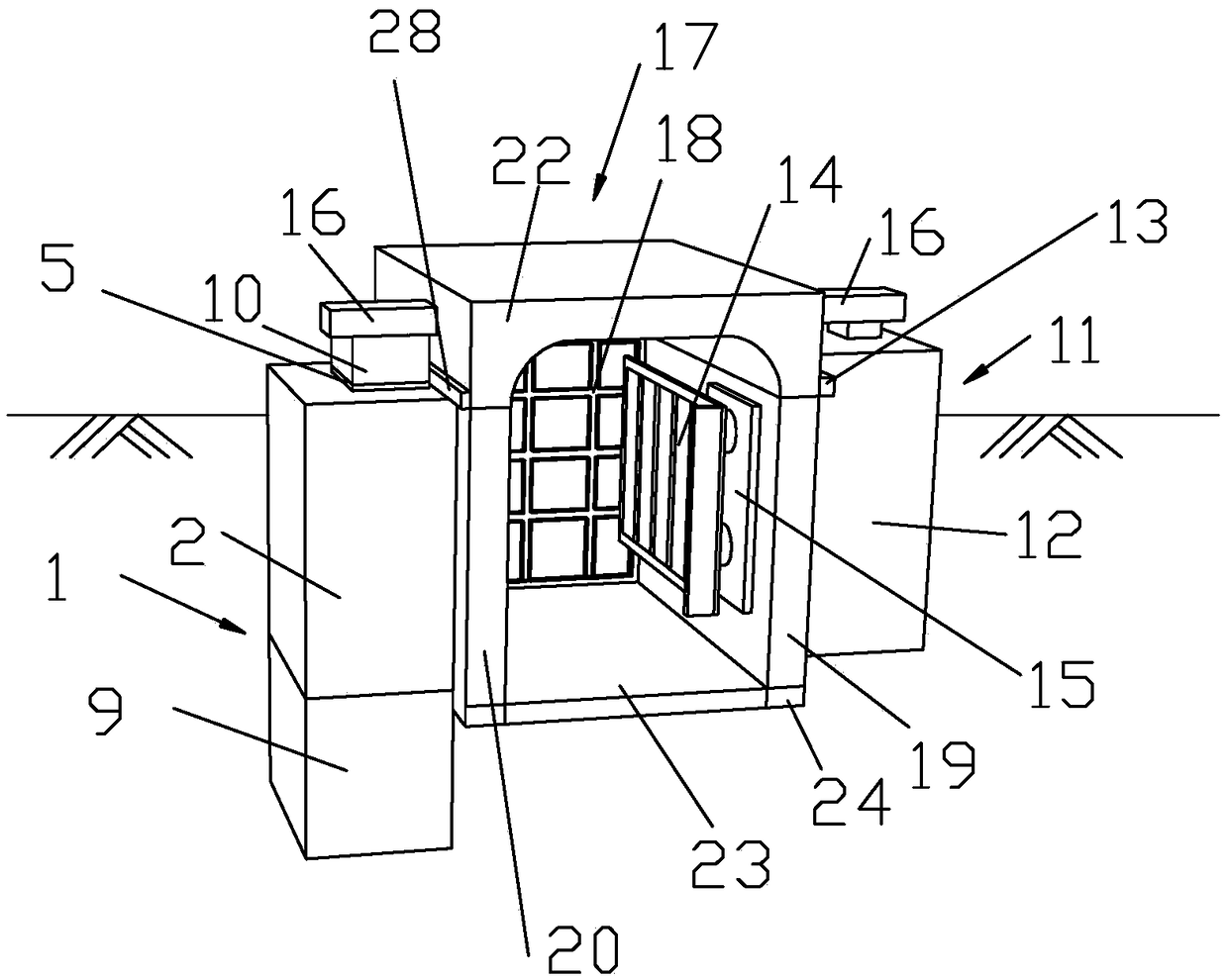

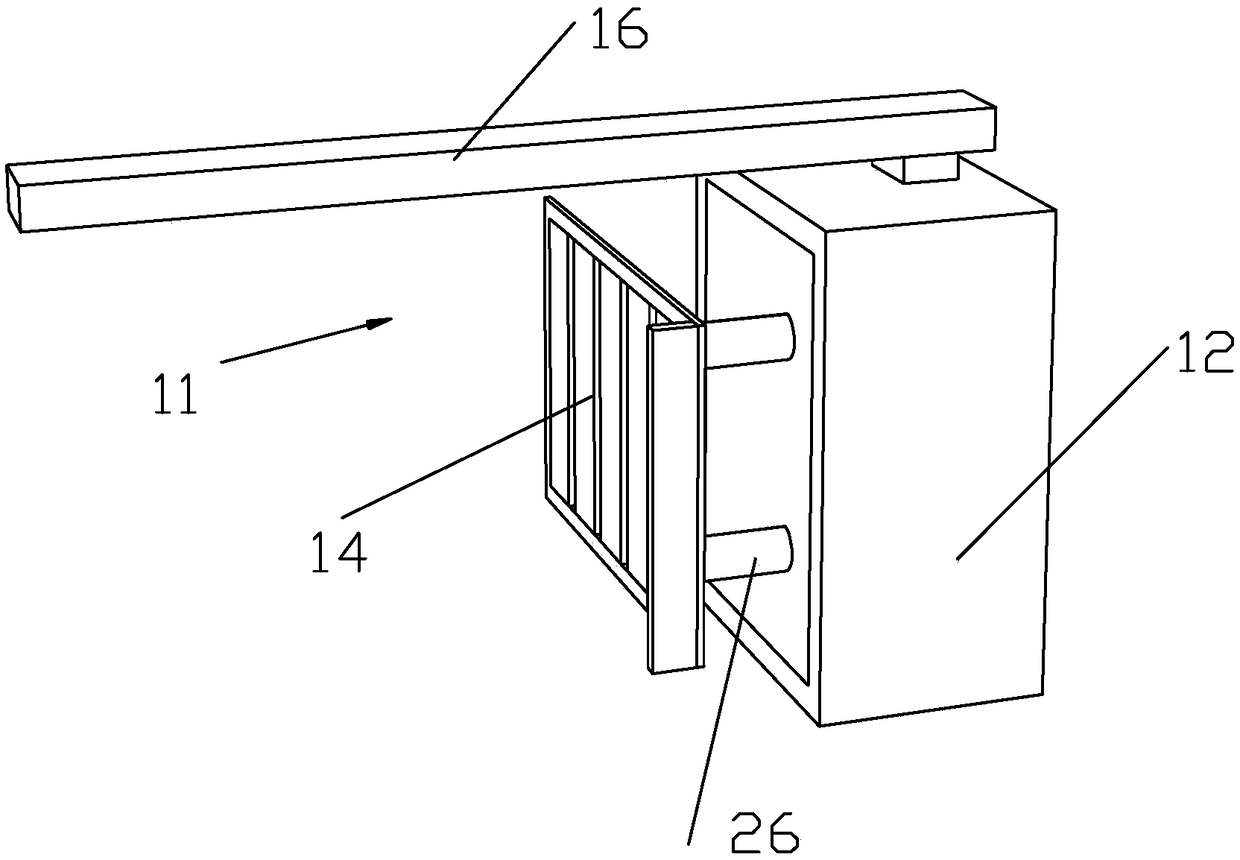

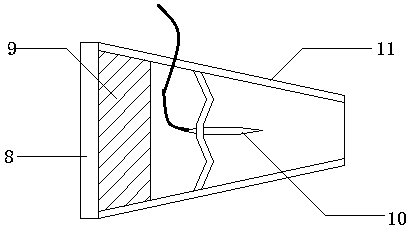

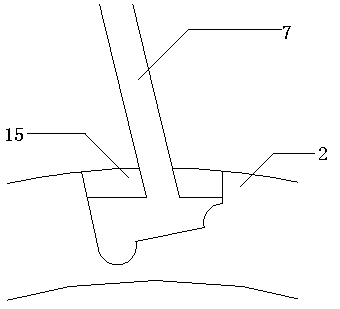

Aluminium profile extrusion device

InactiveCN103537508AAchieve mutual positioningGuaranteed extrusion effectExtrusion diesExtrusion containersExtrusionAluminium

The invention provides an aluminium profile extrusion device which comprises an extrusion rod and an aluminium profile extrusion chamber matched with the extrusion rod, wherein the aluminium profile extrusion chamber is defined by a first mould base, a second mould base, a first material liner and a second material liner together; a discharge hole for molding a product is formed between the first mould base and the second mould base; mold inserts are fixed in the first mould base and the second mould base; first matching parts are arranged on the first material liner and the second material liner; second matching parts are arranged on the first mould base and the second mould base; the first matching parts and the second matching parts are respectively formed on contact surfaces between the material liners and the mould bases. The mould bases and the material liners are respectively provided with concave parts and convex parts which are matched with each other, so that the relative location between the mould bases and the material liners can be realized, the mould bases and the material liners are prevented from being staggered from each other along the vertical direction, and furthermore, the extrusion effect of aluminium profiles and the long-term operation of the extrusion device are guaranteed.

Owner:张家港市昊天金属科技有限公司

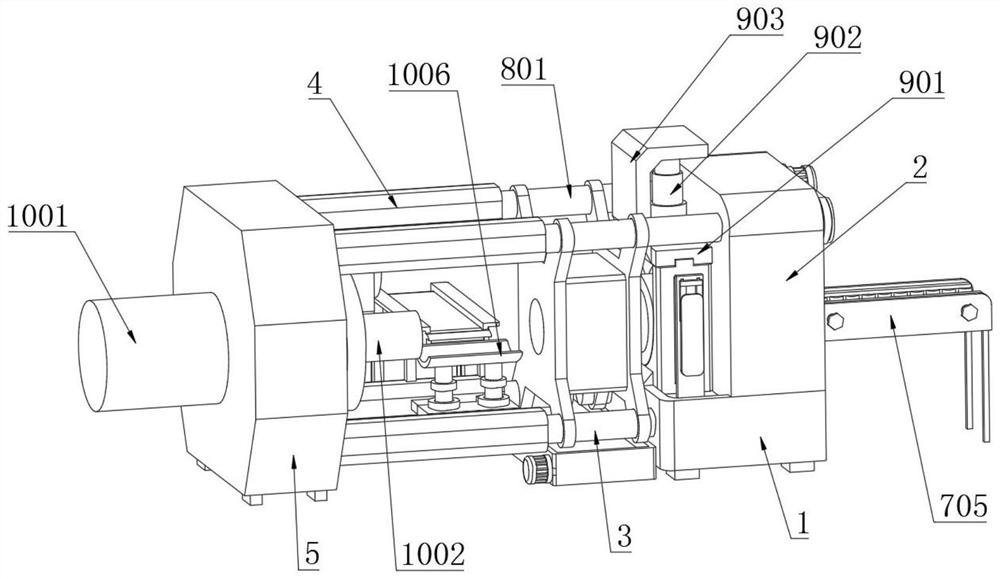

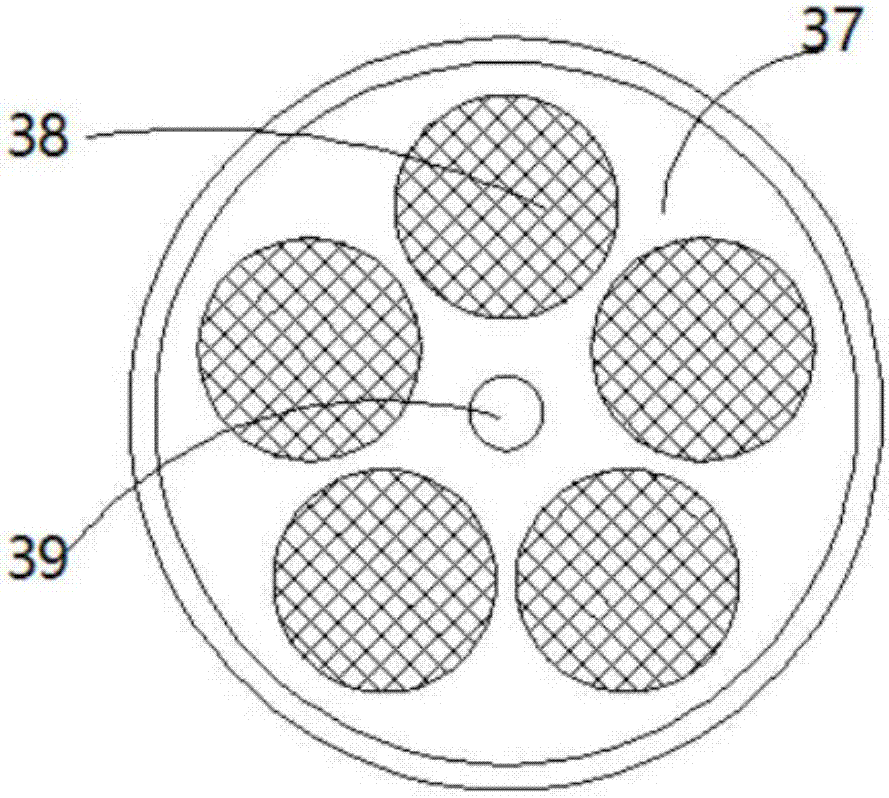

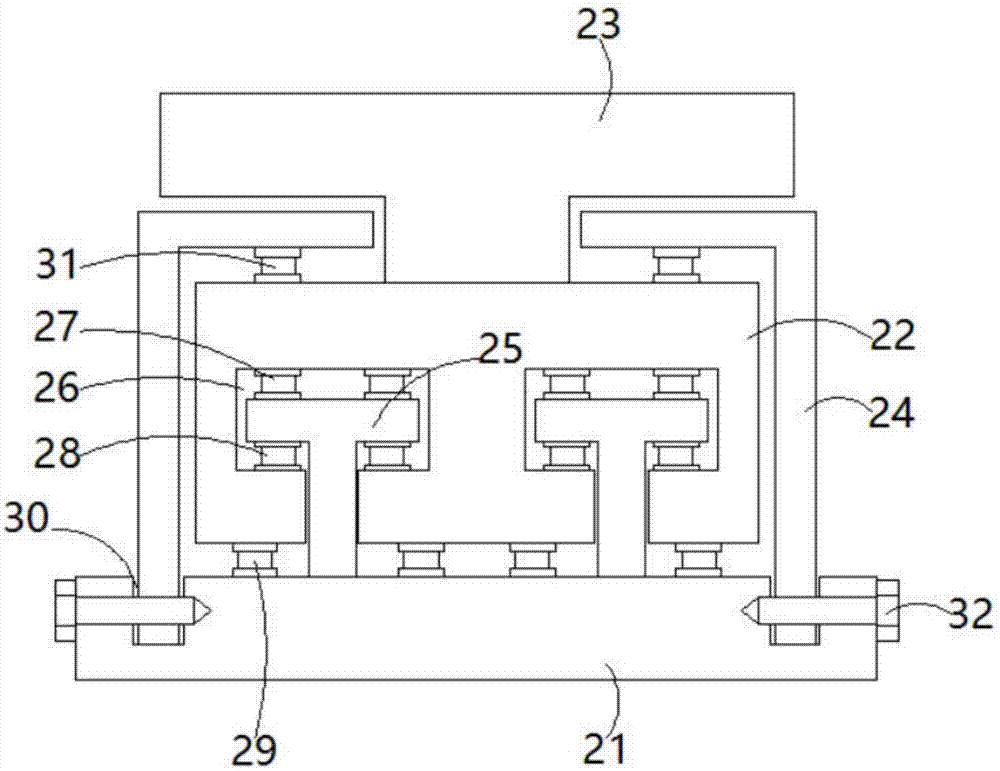

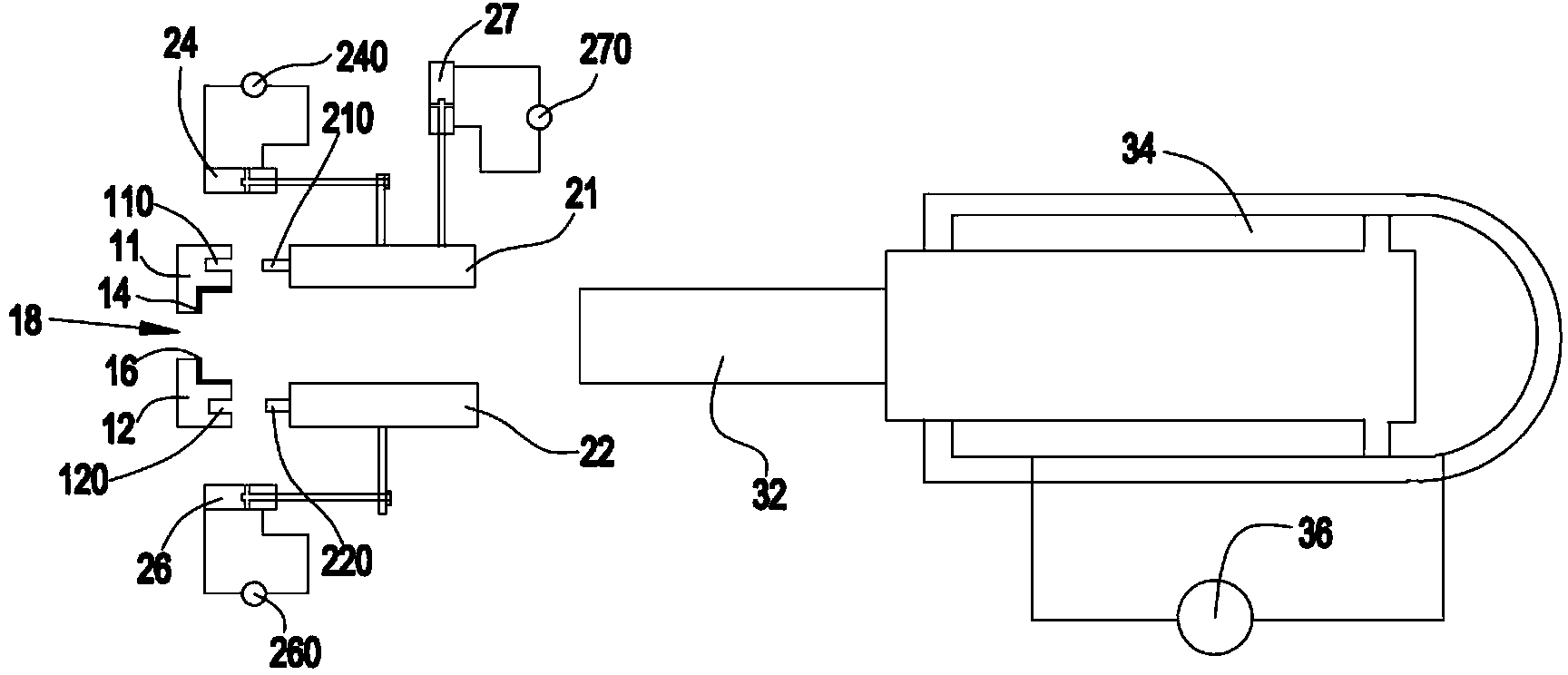

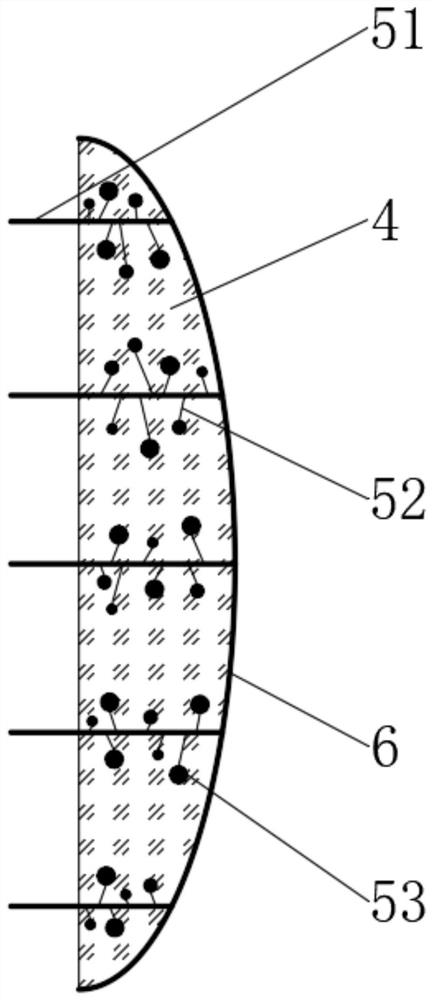

Insulating extrusion equipment for cable production

ActiveCN110667073AGuaranteed extrusion effectEnhanced external insulationDomestic articlesMixing effectElectric cables

The invention discloses insulating extrusion equipment for cable production. The insulating extrusion equipment for cable production comprises an extrusion molding handpiece and is characterized in that extrusion molding plasticizing mechanisms are arranged on one side of the extrusion molding handpiece, a discharging mechanism is arranged at the upper ends of the extrusion molding plasticizing mechanisms and comprises a hopper, a rolling and crushing assembly, a first feeding device and a second feeding device, and each extrusion molding plasticizing mechanism comprises an extrusion molding cylinder body and an extrusion molding screw. According to the insulating extrusion equipment for cable production, the structure is simple, design is reasonable, the functions of rolling and crushingcable materials are achieved, the cable materials can be preheated, and the melting difficulty is reduced; and the extrusion molding screws adopt a segmented design manner and have the effects of kneading the cable materials, increasing the shearing stress, accelerating exhausting and reducing extrusion backflow, the mixing effect, the exhausting efficiency and the melting efficiency can be effectively improved, the cable extrusion molding effect is guaranteed, and the external insulating property of cables is improved.

Owner:安徽虹都电缆集团有限公司

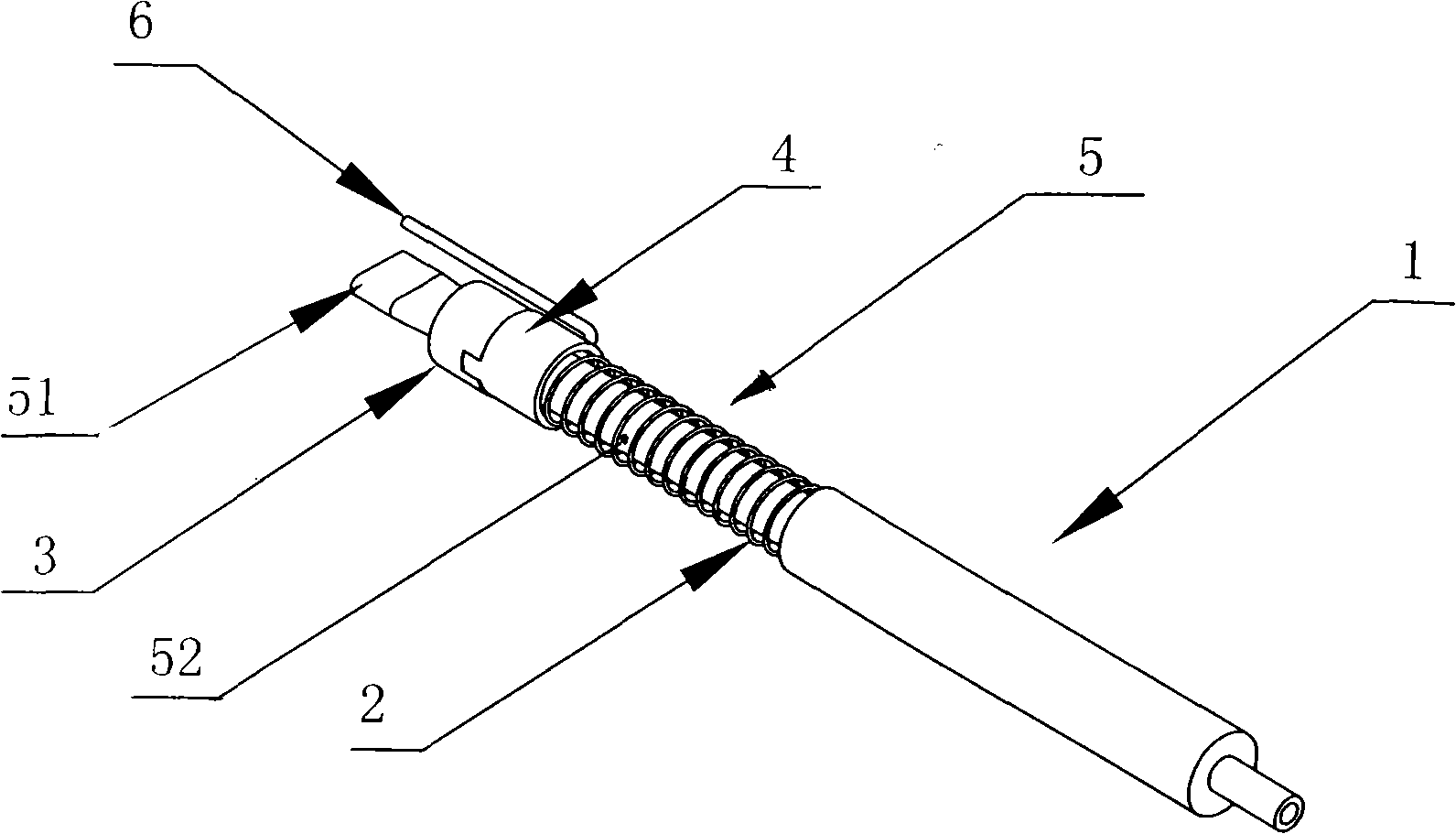

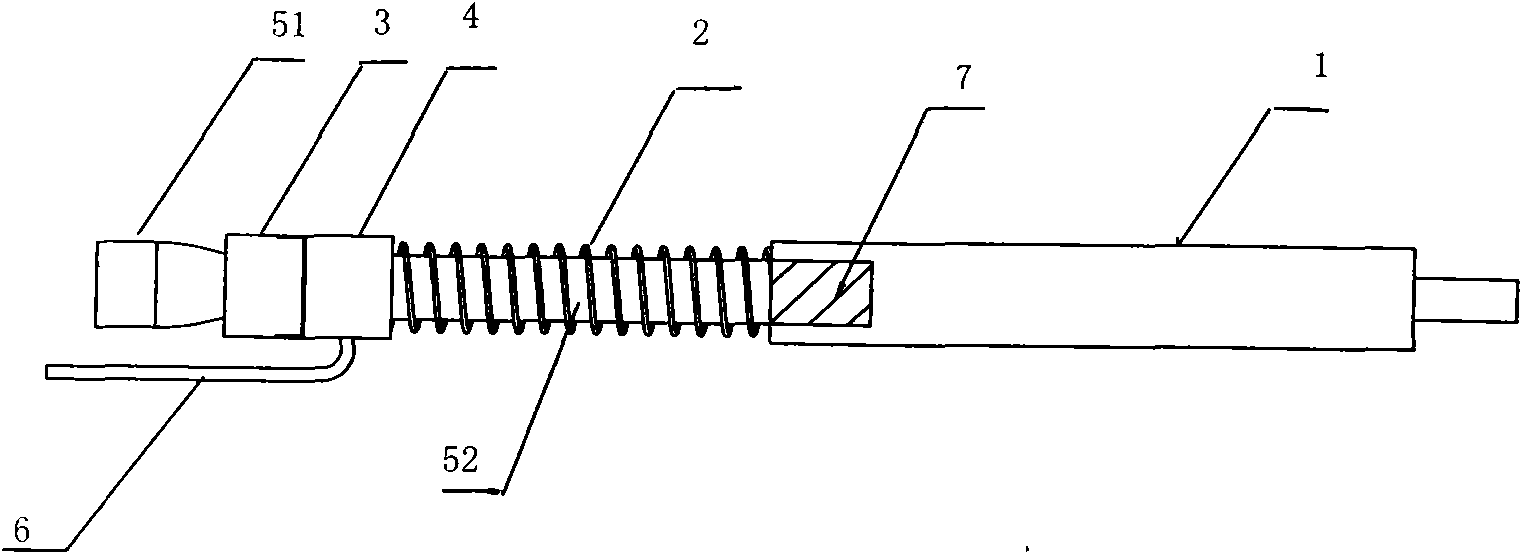

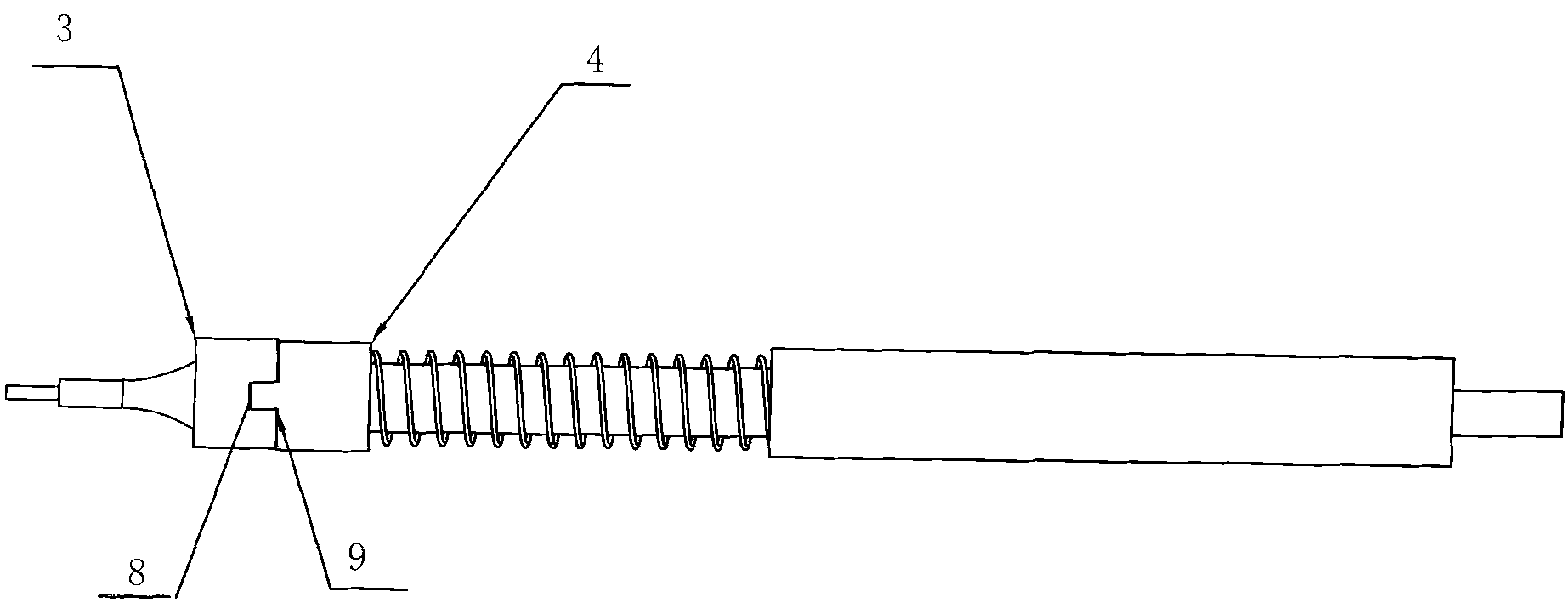

Sealant extruding gun nozzle assembly for automobile painting

The invention relates to a sealant extruding gun nozzle assembly for automobile painting, which comprises a straight connecting tube and a gun nozzle assembly. The gun nozzle assembly comprises a gun nozzle, a locking spring, a front limit stop, a rear limit stop and a door side limit rod. The front end of the gun nozzle is a flat nozzle head and the rear part of the gun nozzle is connected with the straight connecting tube. The front limit stop and the rear limit stop are sheathed at the external part of the rear end of the flat nozzle head and are connected together at the adjacent ends in a limiting way. The door side limit rod is welded on the rear limit stop, forward extends to a position slightly higher than the top end of the gun nozzle and is arranged on the side of the flat surface of the flat nozzle head. The locking spring is sheathed on a nozzle tube at the rear part of the gun nozzle. The two ends of the locking spring respectively lean against the rear limit stop and the straight connecting tube. The gun nozzle assembly has the advantages of simple structure and convenient operation, and can facilitate painting the sealant on the fastening side of the automobile door.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

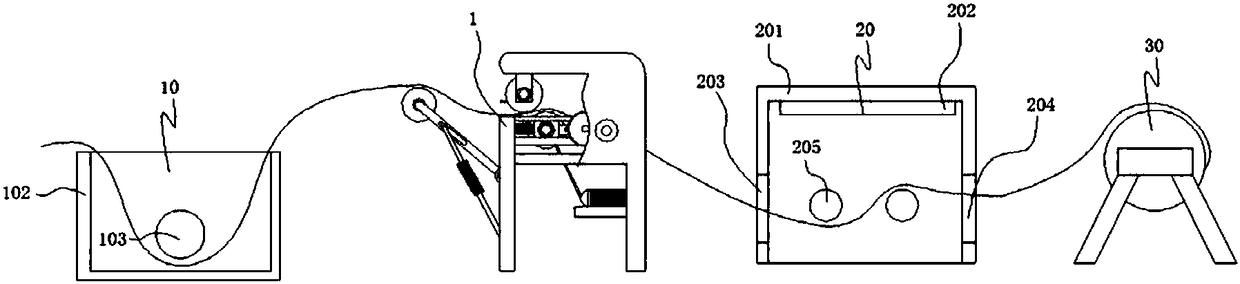

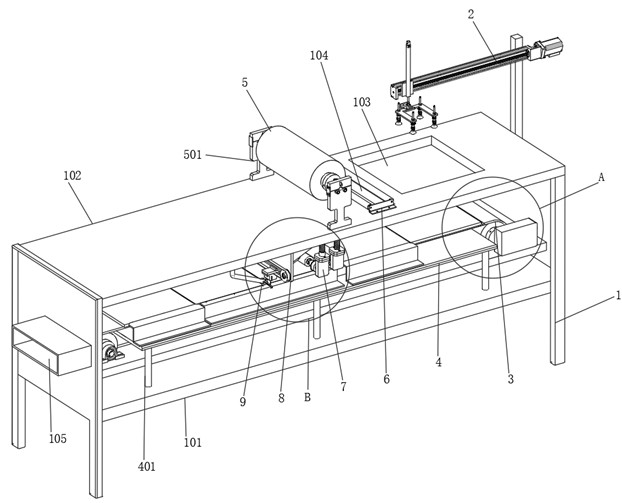

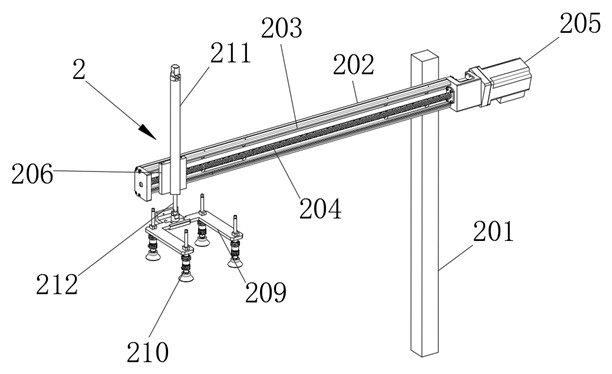

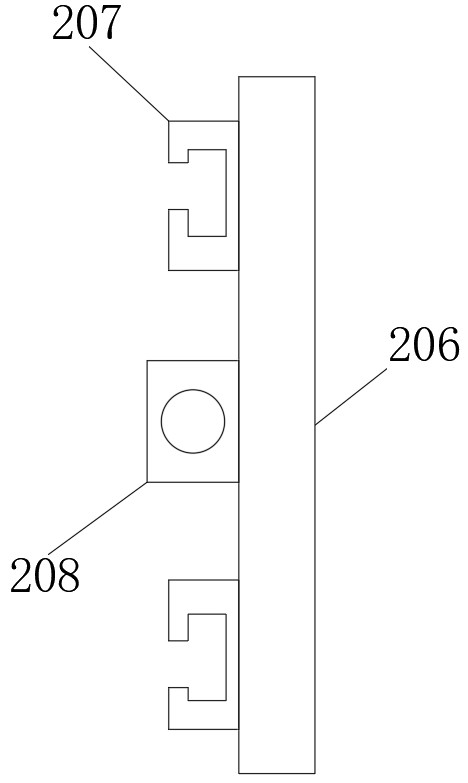

Production line for fabric processing

InactiveCN108103704AAchieve positioningWon't fall offLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentProduction lineWater content

The invention discloses a production line for fabric processing. The production line comprises a dyeing device, a dewatering device, a drying device and a collecting device; the dewatering device is used for squeezing water of dyed fabric, and the drying device is used for drying the dewatered fabric; the dewatering device is arranged between the dyeing device and the drying device and comprises arack, a first press roll, a second press roll and a regulating unit, the first press roll is spaced from the second press roll by a pressing interval, the regulating unit is used for regulating the pressing interval and comprises a fixing member matched with the first press roll and a pushing member for pushing the fixing member to do left and right movement. According to the production line, fabric is dewatered by the dewatering device before being dried by the drying device, and then the fabric with low water content is fed into the drying device to be dried within a short time; since the interval between the first press roll and the second press roll is regulated by the regulating unit, the production line is adaptable to fabric having different thickness.

Owner:陈式好

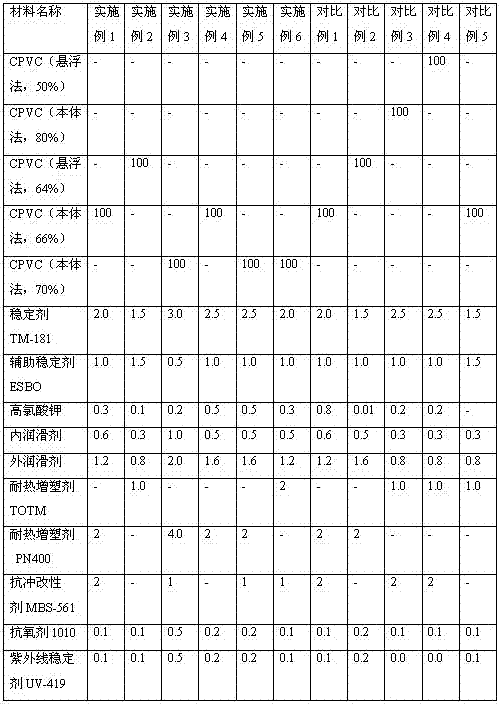

A heat-resistant and highly transparent cpvc composition

ActiveCN105295271BHigh light transmittanceHigh softening temperaturePlasticizerChlorinated polyvinyl chloride

A heat-resistant and highly transparent CPVC composition belongs to the technical field of chlorinated polyvinyl chloride compositions. It is characterized in that the composition in parts by weight is: 100 parts of CPVC resin, 1.5-3.0 parts of heat stabilizer, 0.5-1.5 parts of auxiliary heat stabilizer, 0.1-0.5 parts of perchlorate transparent modifier, and 0.3-1.0 parts of internal lubricant 0.8-2.0 parts of external lubricant, 1.0-4.0 parts of heat-resistant plasticizer, 0-2.0 parts of impact modifier; the chlorine content of CPVC resin is 64-70%. Mix the materials and raise the temperature to 100~120°C. After 10~15 minutes, cool to 40°C and discharge the materials for extrusion. In the present invention, a variety of additives are compounded with CPVC resin, and the perchlorate transparent modifier is used to change the complexation and electron cloud distribution in the CPVC chain, so that the light transmittance of the CPVC composition is as high as 80%, and the Vicat The softening temperature reaches above 110°C.

Owner:CHINA PETROLEUM & CHEM CORP

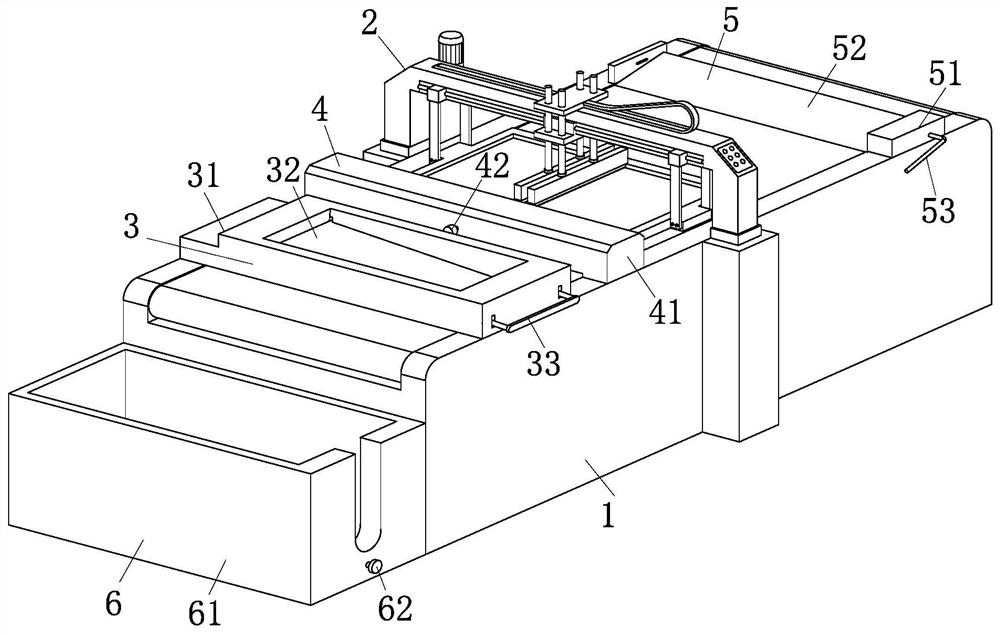

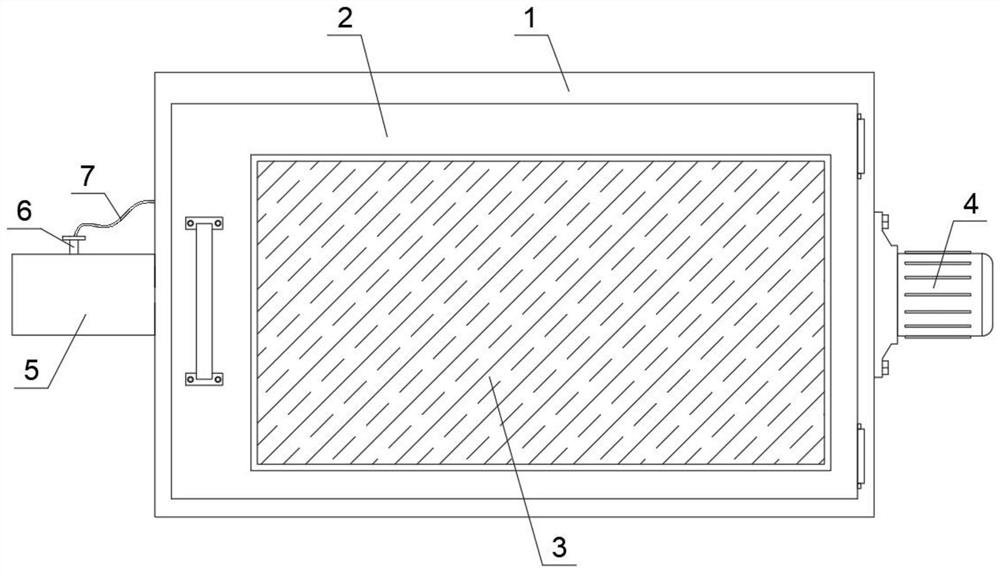

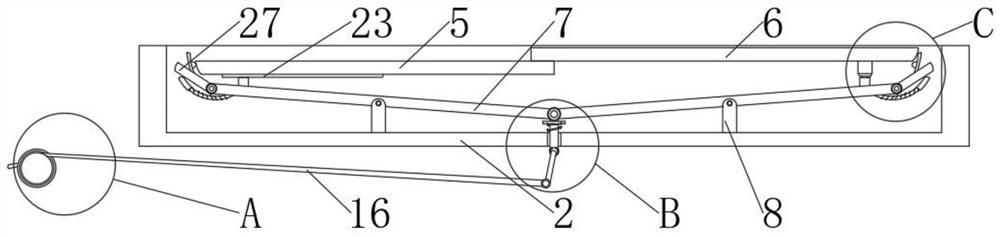

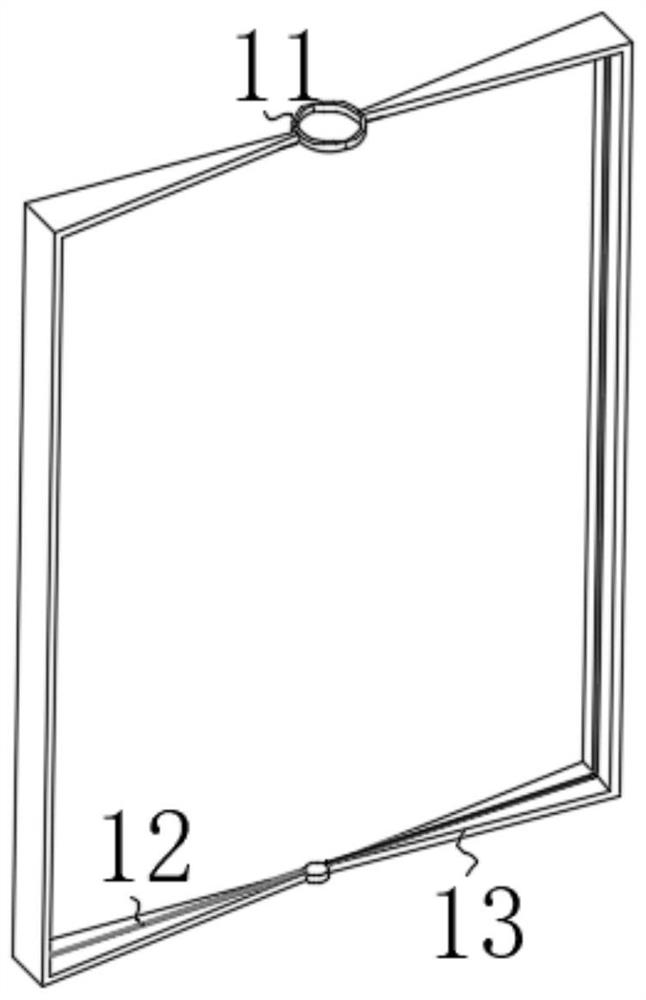

Film coating equipment for photovoltaic solar module production and working method thereof

ActiveCN114311644AHigh degree of automationAvoid injuryFinal product manufacturePhotovoltaic energy generationPhotovoltaic solar energyEngineering physics

The invention relates to the technical field of photovoltaic solar module film covering, in particular to film covering equipment for photovoltaic solar module production and a working method thereof.The film covering equipment comprises a supporting frame, a feeding assembly, a conveying assembly, a film covering roller, a film covering assembly, a film cutting assembly and a film pressing wheel; according to the film laminating equipment, the film laminating roller and the film laminating assembly are used for laminating in the conveying process, and the connected film is cut by the film cutting assembly, so that the film laminating equipment can be used for automatically laminating the photovoltaic solar panel in a streamlined manner, and all links of the film laminating equipment do not need to be manually operated by automatically laminating the film, so that the labor intensity of workers is reduced, and the production efficiency is improved. Compared with the prior art, labor is saved, meanwhile, the situation that personnel are hurt by the equipment or the photovoltaic solar panel in the manual operation process is avoided, and meanwhile, through film laminating streamline of the equipment, all links of film laminating of the equipment are matched more tightly, and the film laminating speed is higher.

Owner:ANHUI GUOCHENG PHOTOELECTRIC TECH CO LTD

Dust-removing printing machine

InactiveCN112277446AGuaranteed accuracyPrecise positioningCleaningRotary pressesTextile printerPaperboard

The invention relates to the technical field of printing, in particular to a dust-removing printing machine. The dust-removing printing machine comprises a conveying belt, a printing equipment body, alocating structure, a flattening structure, a picking structure, a placing structure and a cleaning structure. According to the dust-removing printing machine, the surface of the conveying belt can be continuously cleaned through the cleaning structure, so that the influence of dust on printing is avoided; the locating structure can guarantee that the location of a paperboard is more accurate when the paperboard is placed on the surface of the conveying belt, so that the precision of the printing location is guaranteed; wrinkles possibly appearing on the paperboard can be reduced through theflattening structure, so that the printing effect is guaranteed, meanwhile the tightness between the paperboard and the surface of the conveying belt is is released, and the paperboard is prevented from being transferred in the printing process; the printed paperboard can be quickly picked through the picking structure; and stacked paperboards can be conveniently taken out through the placing structure, so that the continuity of paperboard adding is guaranteed.

Owner:浙江美善美服饰有限公司

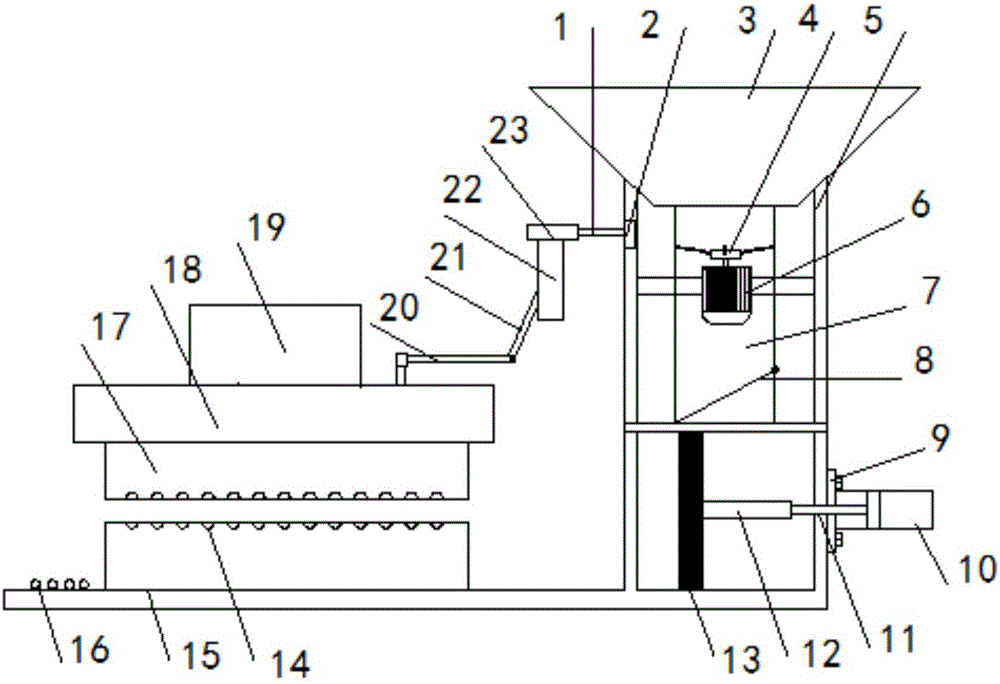

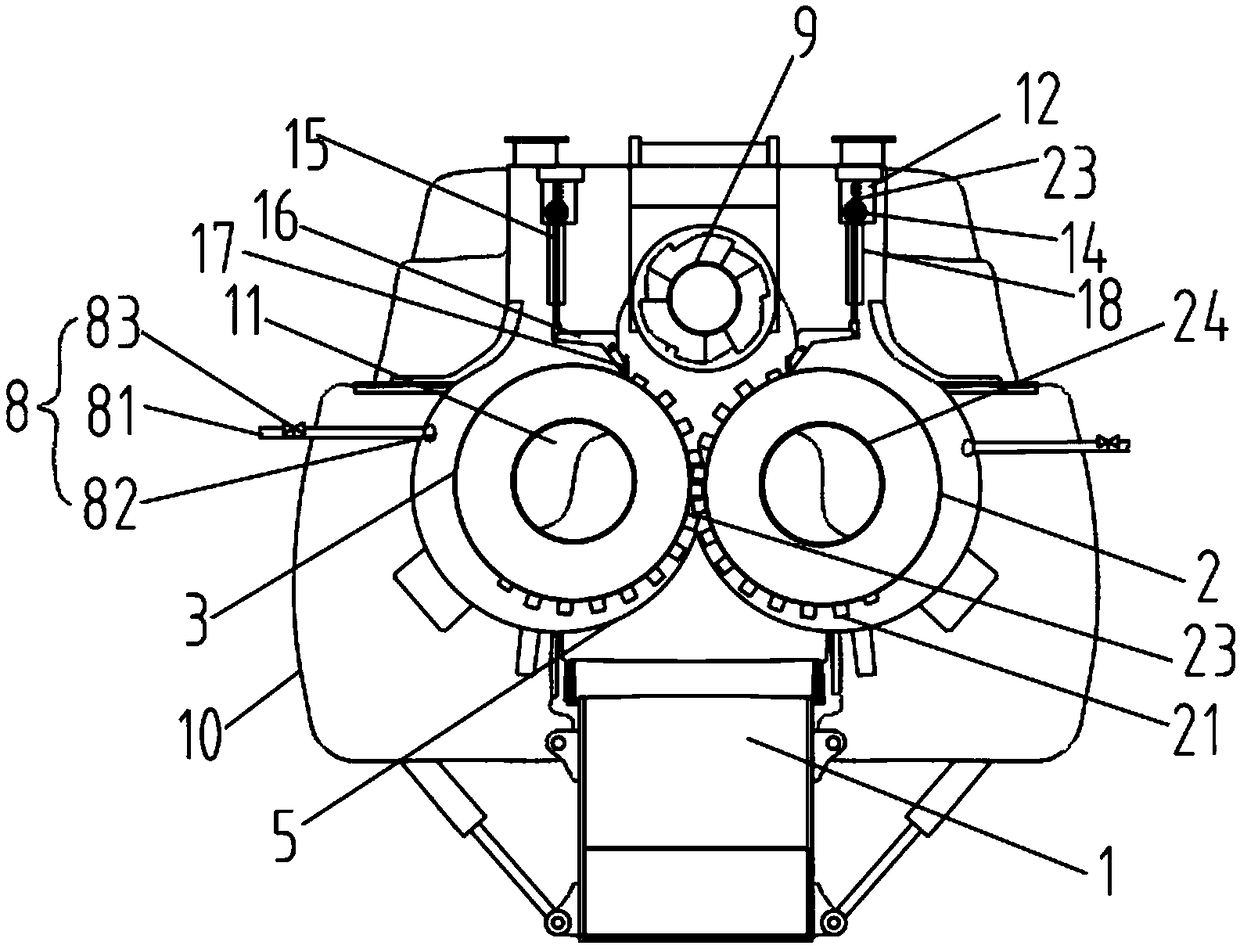

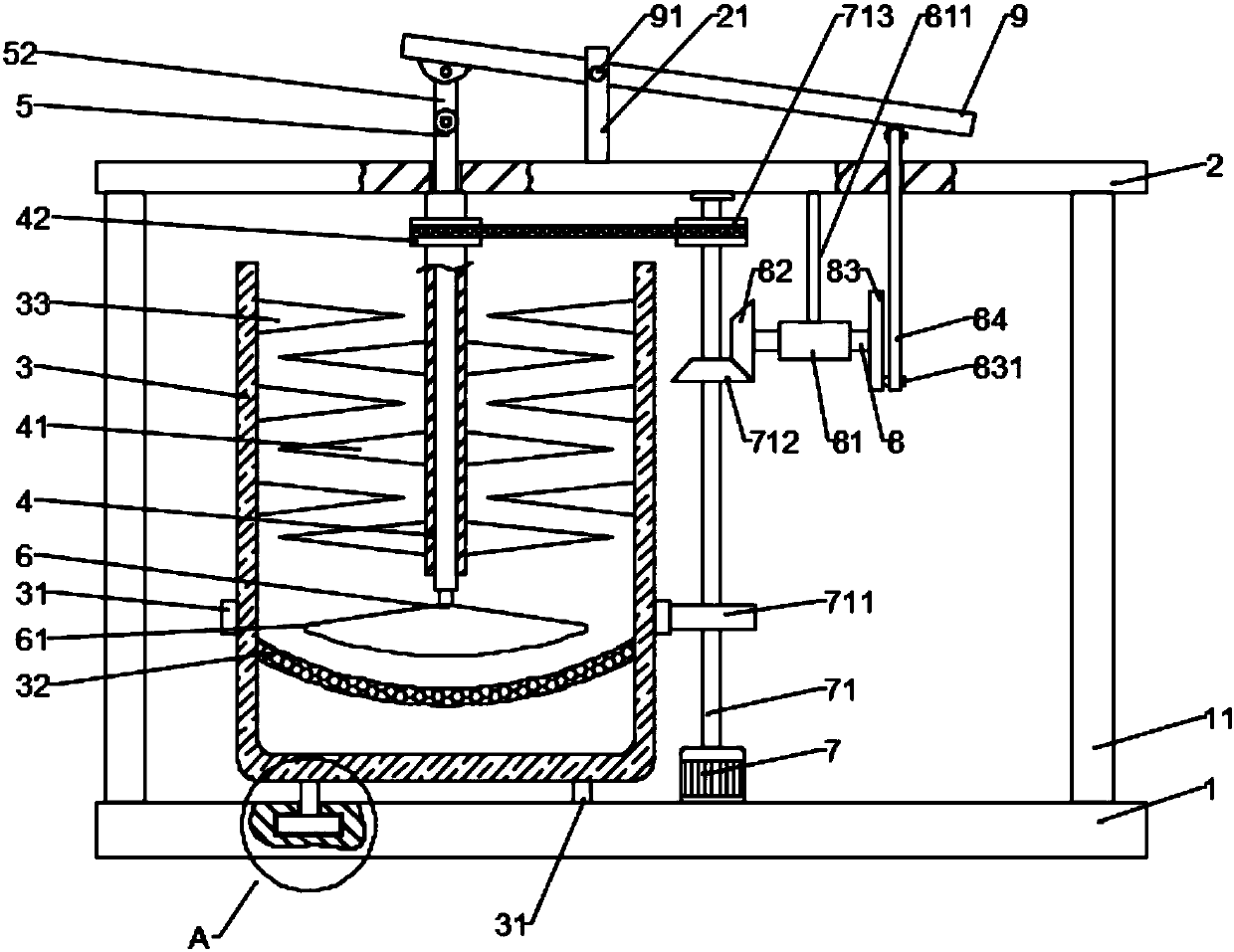

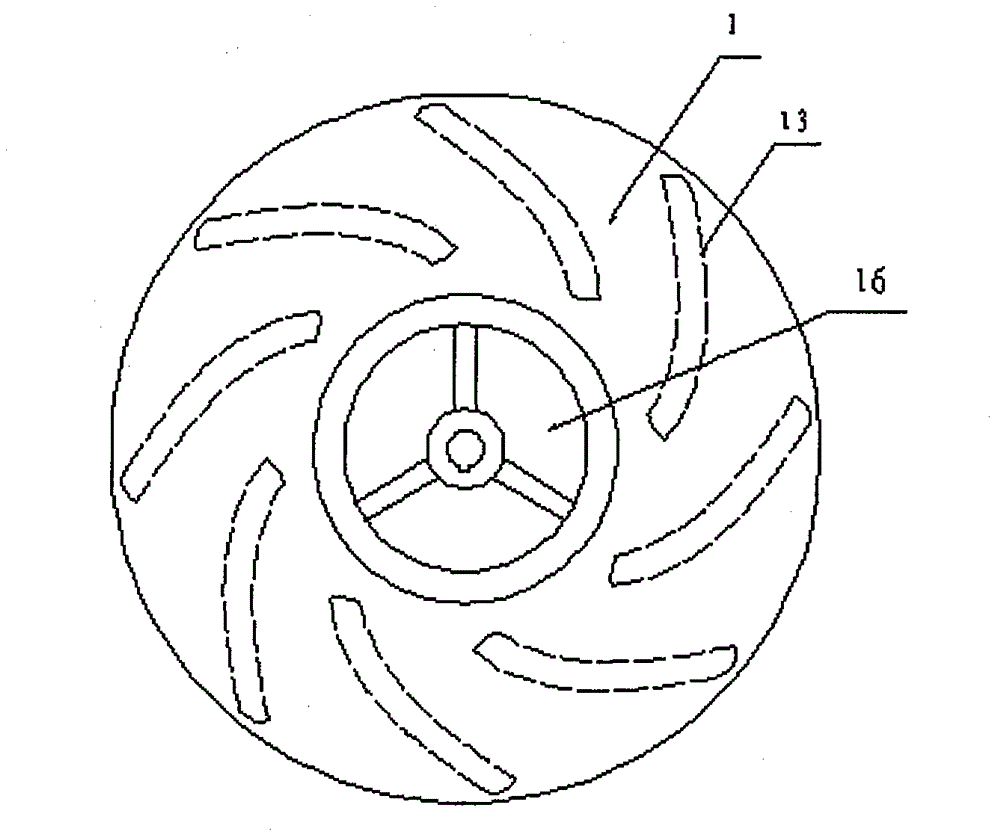

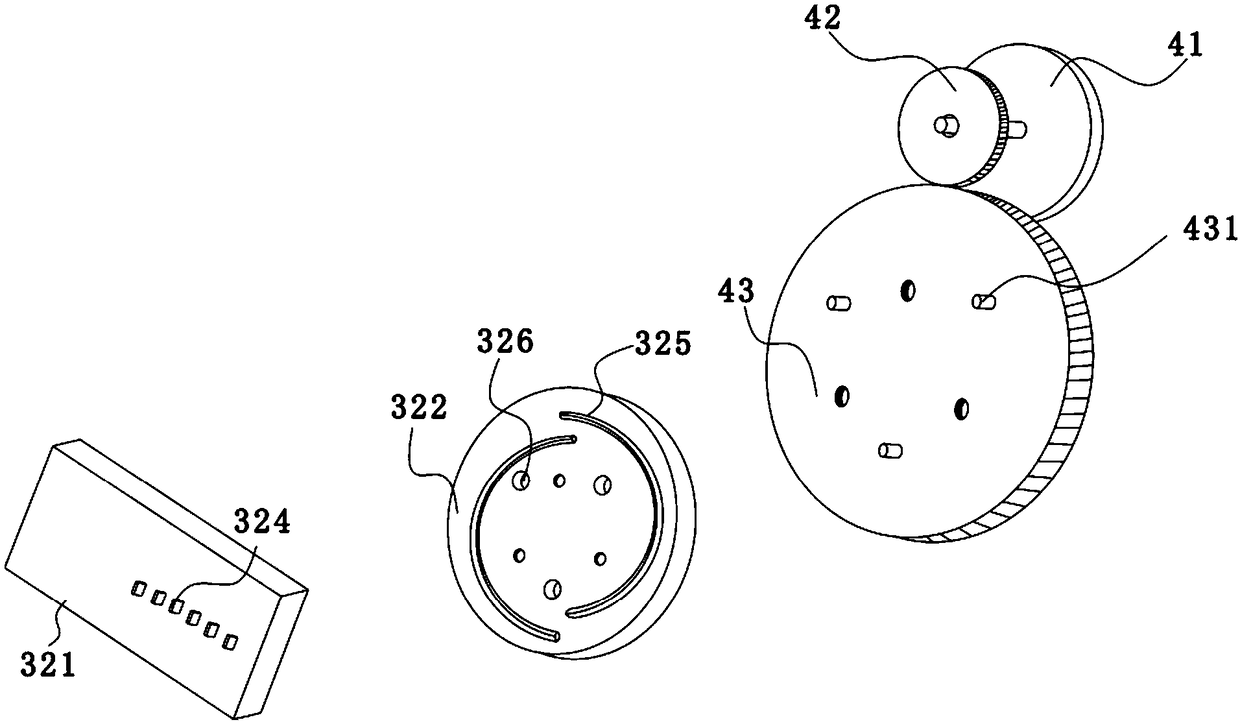

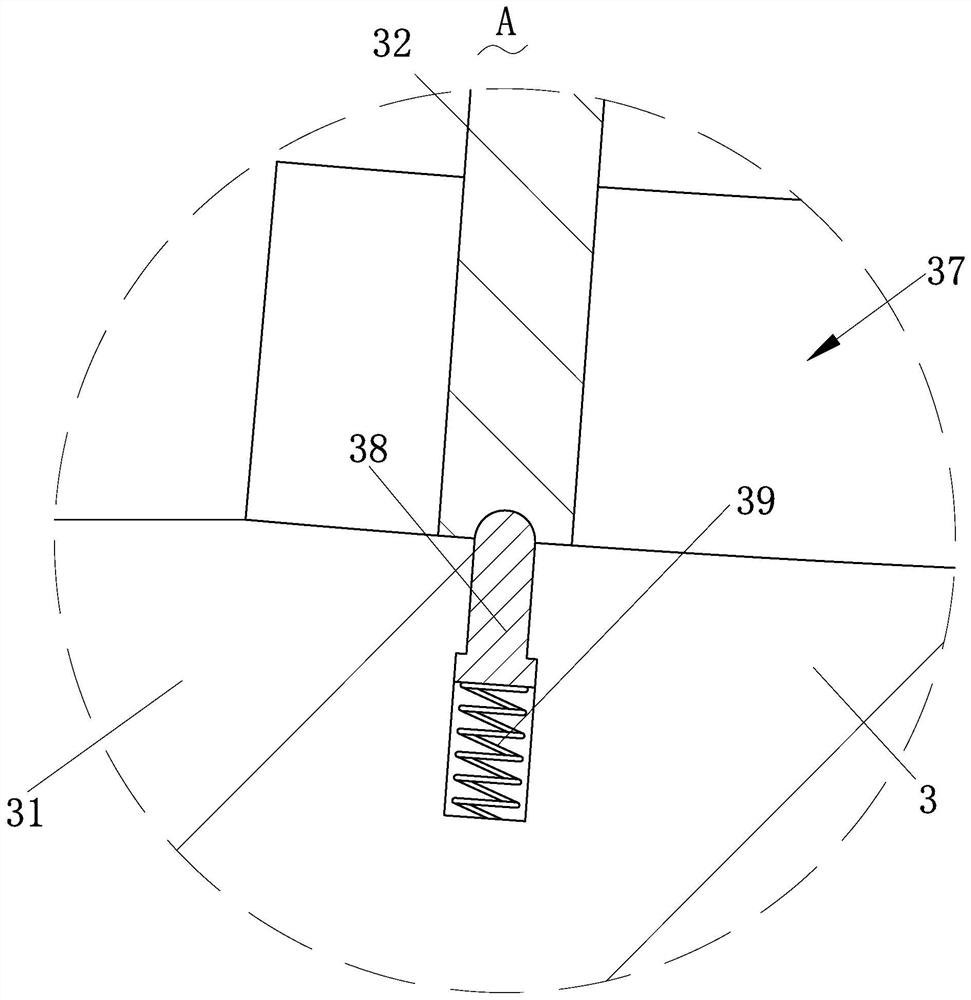

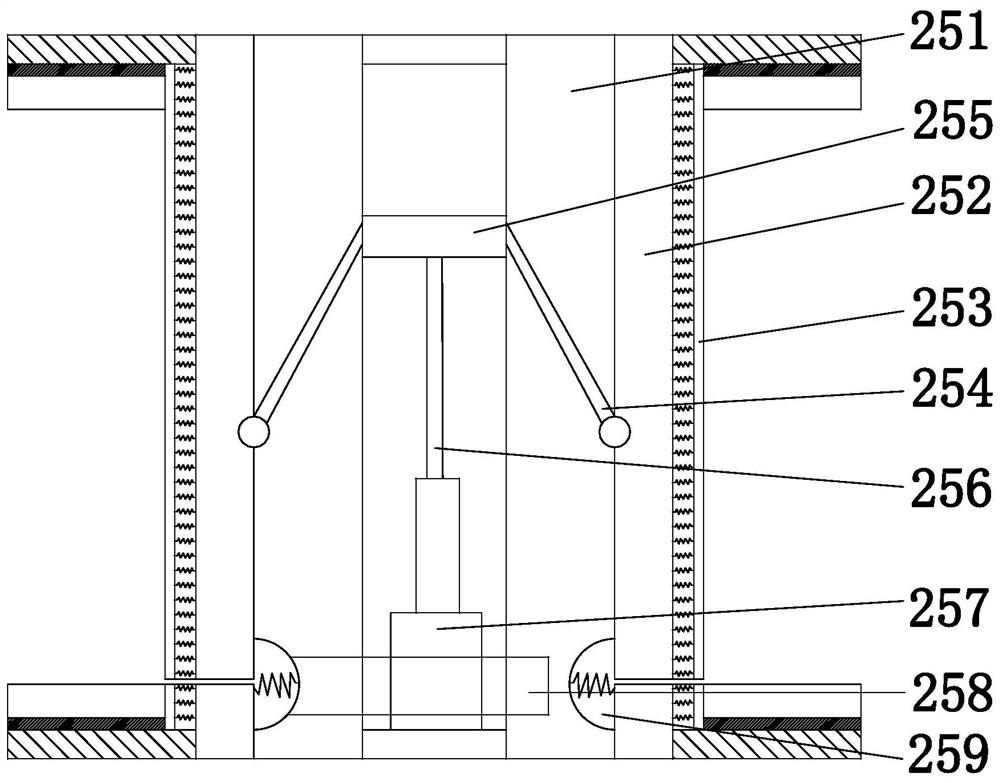

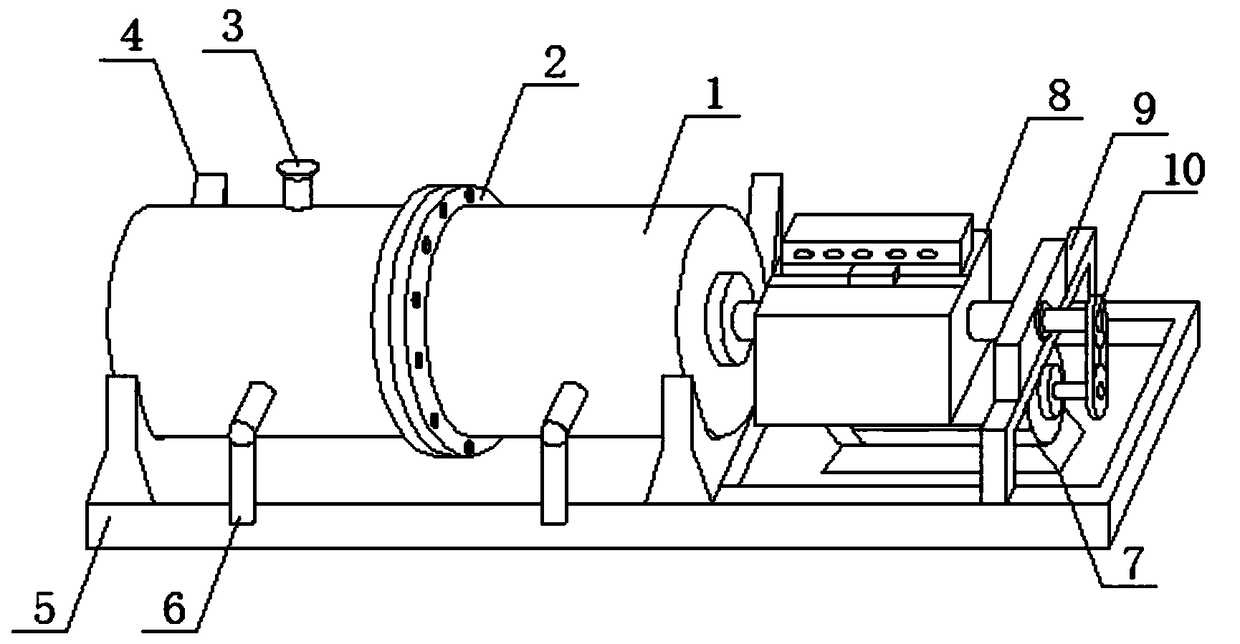

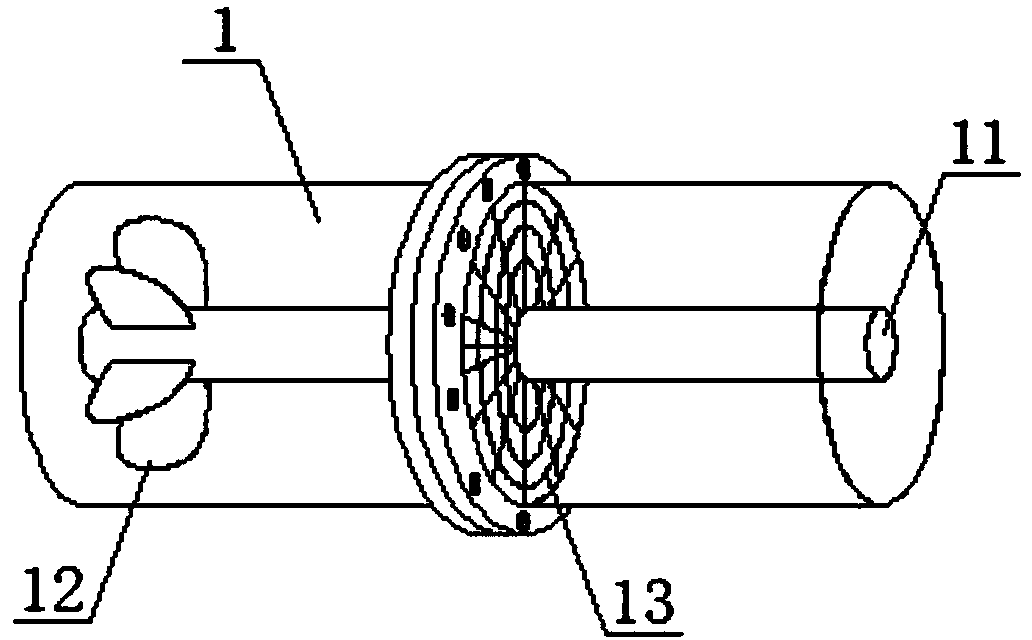

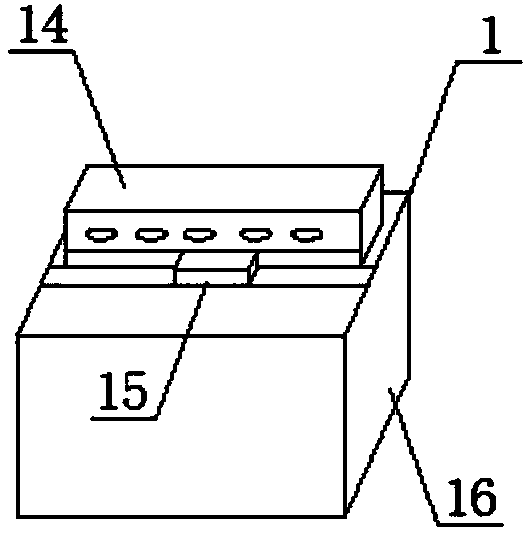

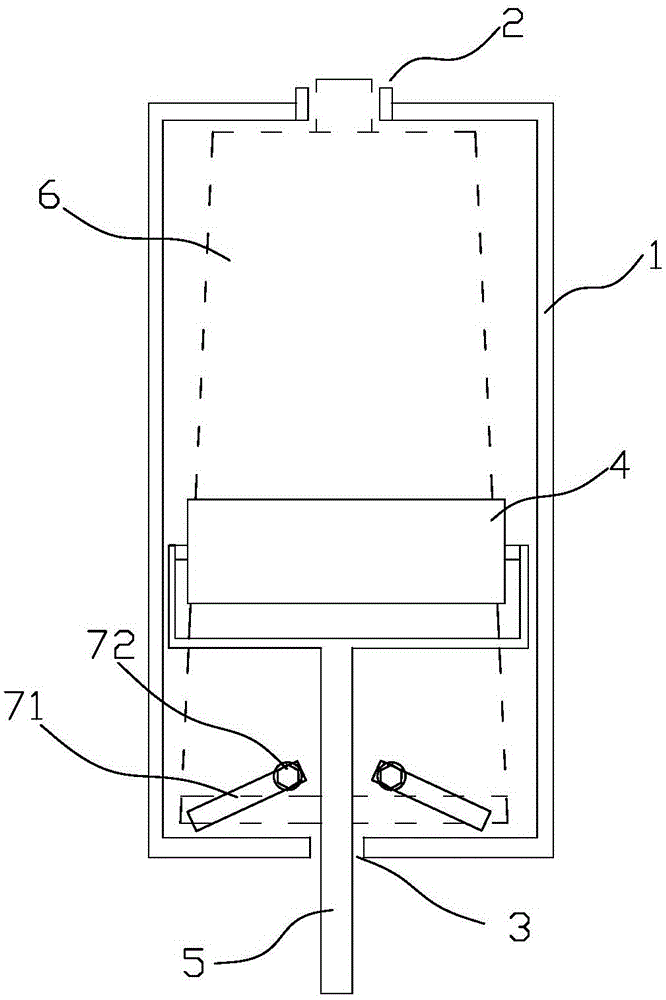

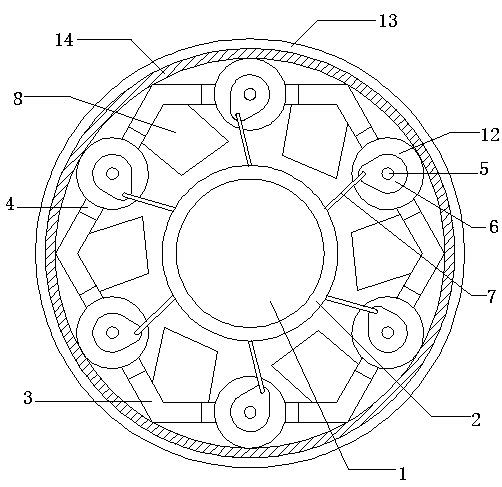

Full-automatic pomegranate juicer

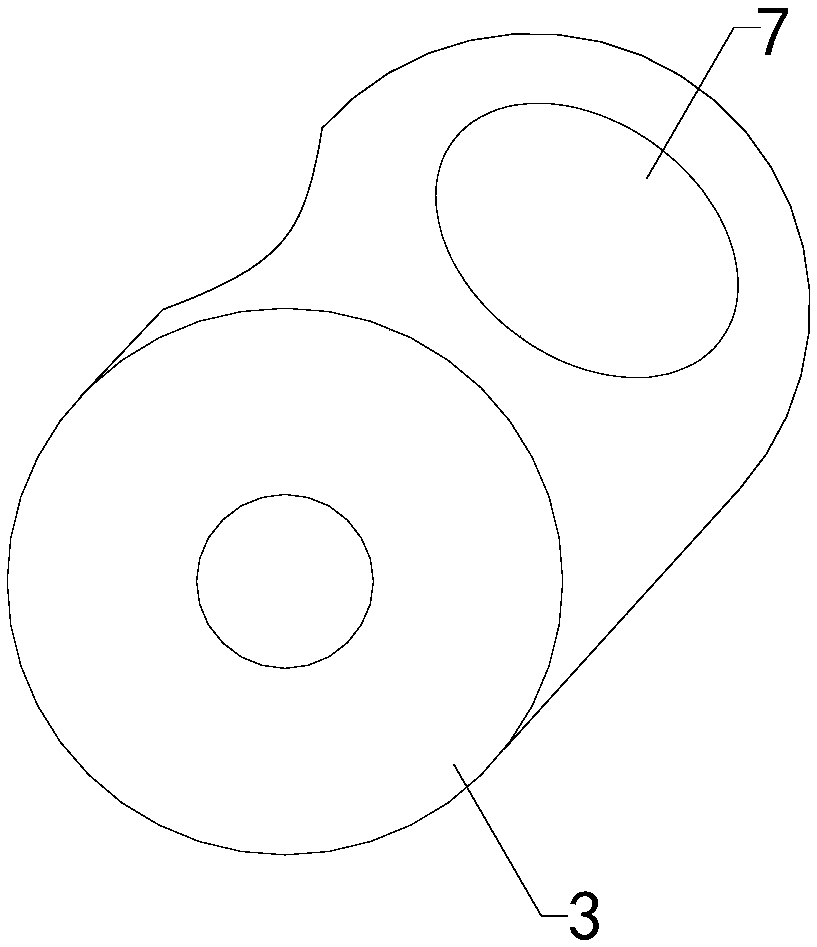

InactiveCN107692791AGuaranteed extrusion effectGuaranteed juice yieldStrainersDrive motorEngineering

The invention relates to the technical field of accessory devices of pomegranate processing, in particular to a full-automatic pomegranate juicer. The juicer runs in a full-automatic mode, so that theworking efficiency is improved; moreover, damage to a human body is avoided, so that the safety is improved, and the use reliability is improved; meanwhile, the juice yield of pomegranates can be guaranteed, so that the practicability is improved. The juicer comprises a body, a working cavity is formed in the body, a left roller, a right roller, a left rotating shaft and a right rotating shaft are arranged in the working cavity, left grooves and right grooves are formed in the roller surfaces of the left roller and the right roller respectively, left squeezing columns and right squeezing columns are arranged on the shaft surfaces of the left rotating shaft and the right rotating shaft respectively, hemispherical bulges are arranged at the squeezing ends of the left squeezing columns and the right squeezing columns respectively, and the left roller, the right roller, the left rotating shaft and the right rotating shaft are in transmission connection with a driving motor separately; thejuice further comprises a left peel barrel, a right peel barrel, a filtering net, a left exit, a right exit, a left guide board, a right guide board, a feeding pipe, a cutting blade, bowl squeezing sheets, clamping sheets and C-shaped elastic sheets.

Owner:钱欣妍

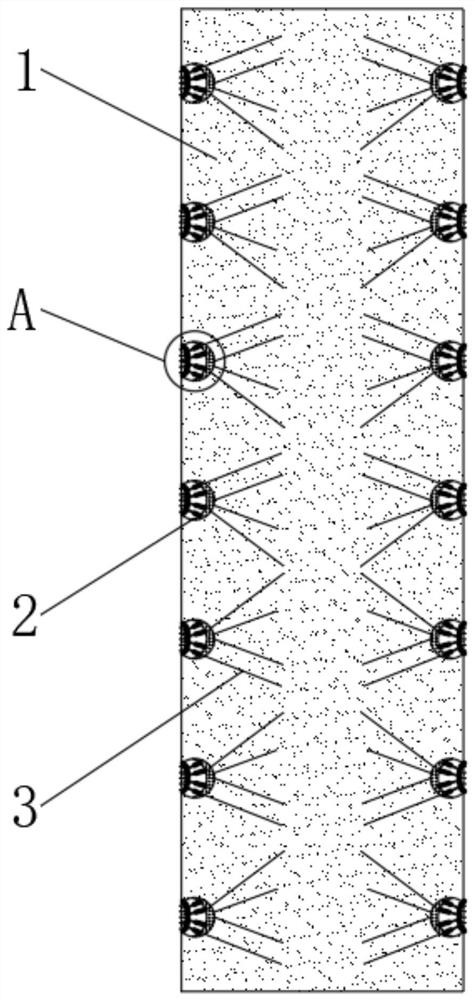

Self-drainage type impermeable concrete precast pile

InactiveCN112127357AImprove impermeabilityAvoid enteringBulkheads/pilesSoil preservationFiberStructural engineering

The invention discloses a self-drainage type impermeable concrete precast pile, and belongs to the technical field of concrete precast piles. The purpose of improving the strength of a pile body by extending into the concrete precast pile by pre-burying a pre-buried missing ball in the concrete precast pile based on the water guide characteristic of a water guide fiber rod can be achieved, meanwhile, seepage water in the concrete precast pile is concentrated and conveyed to the pre-buried missing ball position, the drainage action of a multi-point water conveying rod is triggered, water conveying connection with a surface one-way drainage bag is established firstly, and then the guided seepage water is synchronously conveyed while water on the one-way drainage bag is desorbed under the action of transformed magnetic force through the self-extrusion effect, therefore, seepage water in the concrete precast pile is drained to the outside, the initial state is recovered, water conveying connection is disconnected, outside water is prevented from entering the concrete precast pile from the pre-buried missing ball position, and the impermeability of the concrete precast pile is remarkably improved.

Owner:闫山

Wood plate finishing treatment equipment and finishing treatment process

InactiveCN111745497AGuaranteed extrusion effectTo achieve the purpose of deburringEdge grinding machinesGrinding wheel securing apparatusEngineeringIndustrial engineering

The invention relates to wood plate finishing treatment equipment and a finishing treatment process. The wood plate finishing treatment equipment comprise a frame body, a deburring device and a supporting device, wherein the deburring device is installed at the upper end of the frame body, and the supporting device is arranged at the bottom of the frame body. The wood plate finishing treatment equipment and the finishing treatment process can solve the problems that in a traditional surface burr treatment method after drilling of a wood plate, generally grinding is carried out by holding sandpaper with hands or using a grinding and polishing machine, the grinding method is time-consuming and labor-consuming, the inner wall of the aperture cannot be completely ground, the grinding effect cannot be guaranteed, and the efficiency is low.

Owner:吴思

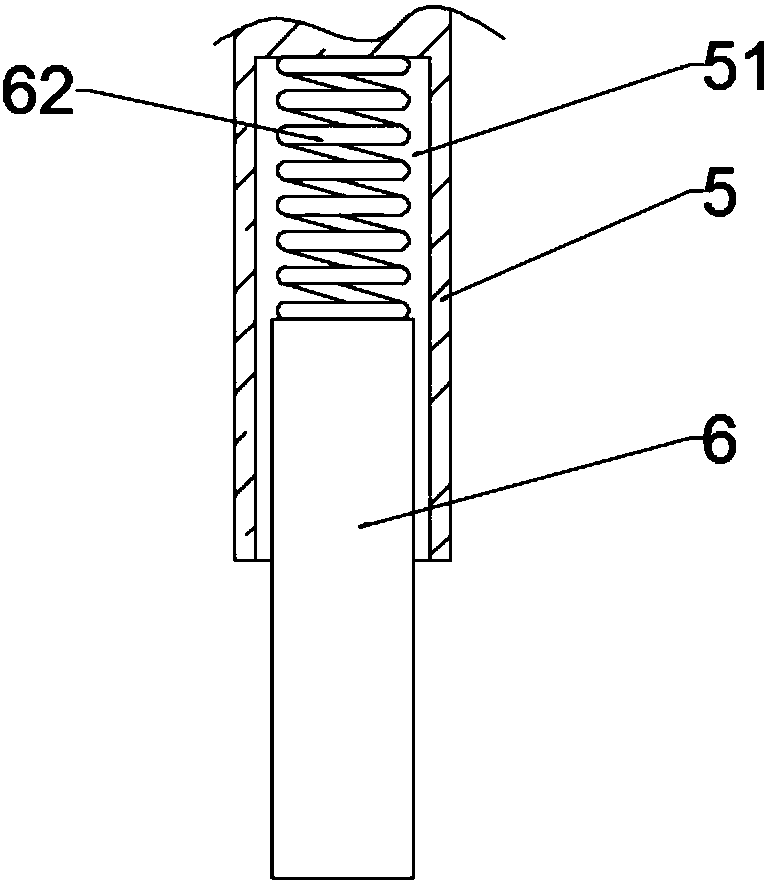

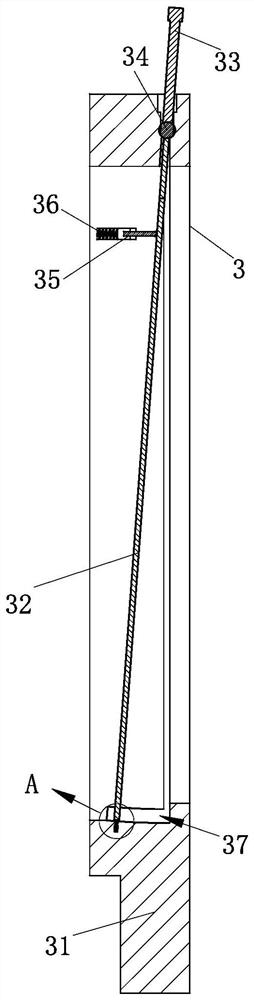

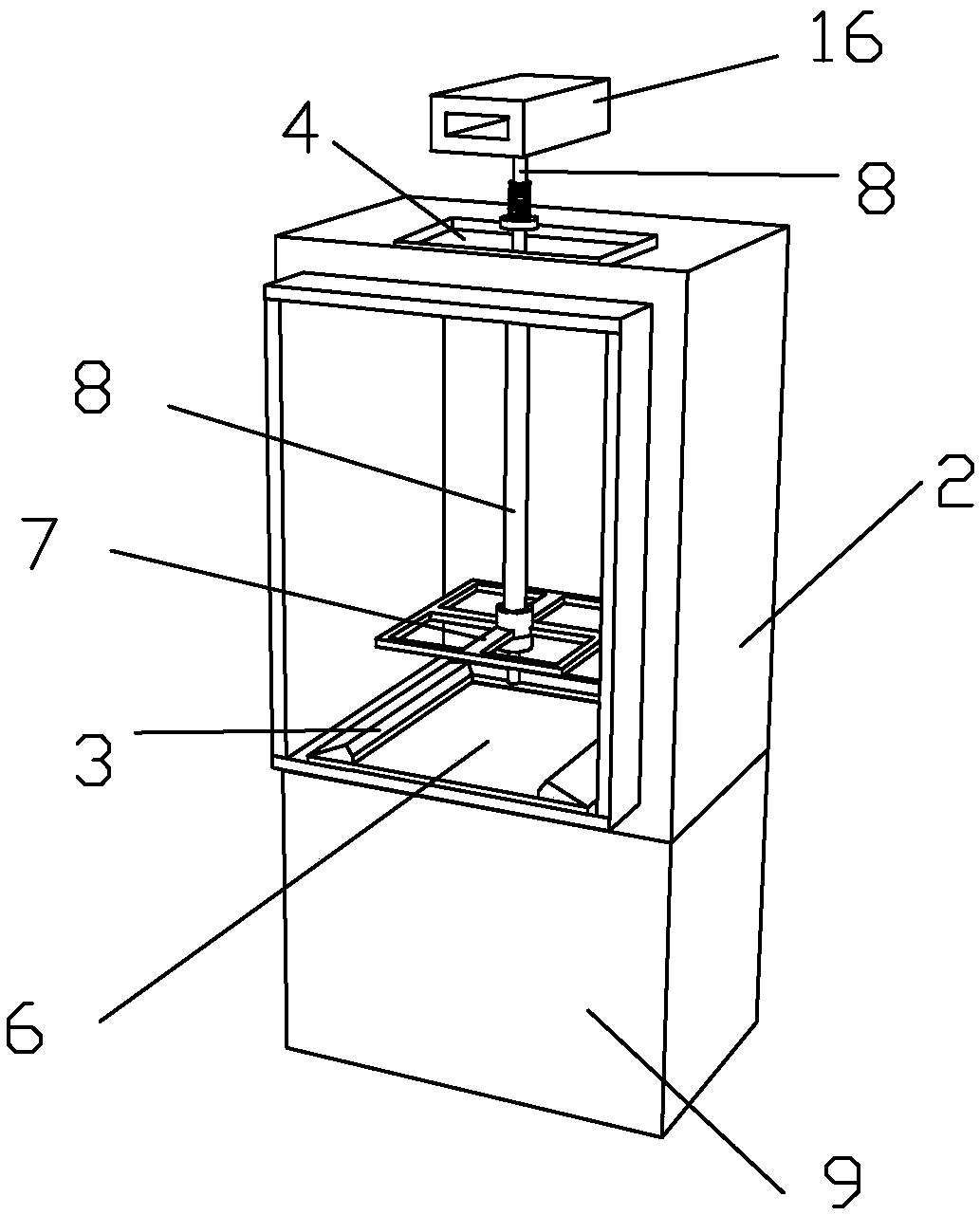

Drying and shrink-proof device for formed multi-shape tea leaves

InactiveCN113349265AGuaranteed extrusion effectPrevent shrinkagePre-extraction tea treatmentDrying solid materials without heatEngineeringMechanical engineering

The invention discloses a drying and shrink-proof device for formed multi-shape tea leaves. The drying and shrink-proof device comprises a drying box and a box door installed on the front end face of the drying box, a drying disc is arranged in the drying box, a macromolecule water absorption pad is arranged at the bottom of the inner side of the drying disc, a metal pressing net is embedded in the inner side of the drying disc in a sliding mode, the top of the drying disc is sleeved with a supporting pressing frame of a structure with the outer periphery bent downwards, at least two sliding rods which penetrate through the supporting pressing frame and are of an I-shaped structure are embedded in the top of the supporting pressing frame in a sliding mode, the bottom ends of the sliding rods abut against the metal pressing net, and the outer end faces of the sliding rods are sleeved with extrusion springs. According to the drying and shrink-proof device for formed multi-shape tea leaves, firstly, a fixed tea leaf drying structure is adopted, so that the drying shrinkage prevention performance of tea leaves is improved, secondly, a rotary drying structure is adopted, so that the tea leaf drying effect is improved, and finally, a combined detachable structure is adopted, so that the convenience of dismounting and mounting of the drying disc is improved.

Owner:湖南省沅陵碣滩茶业有限公司

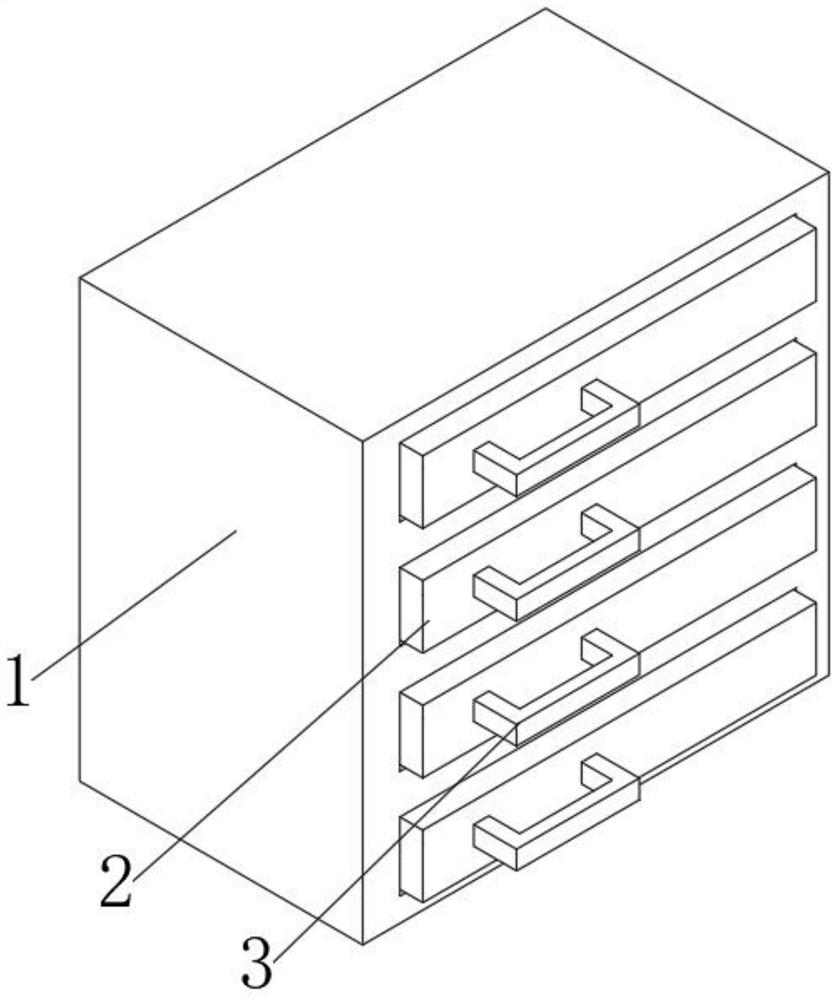

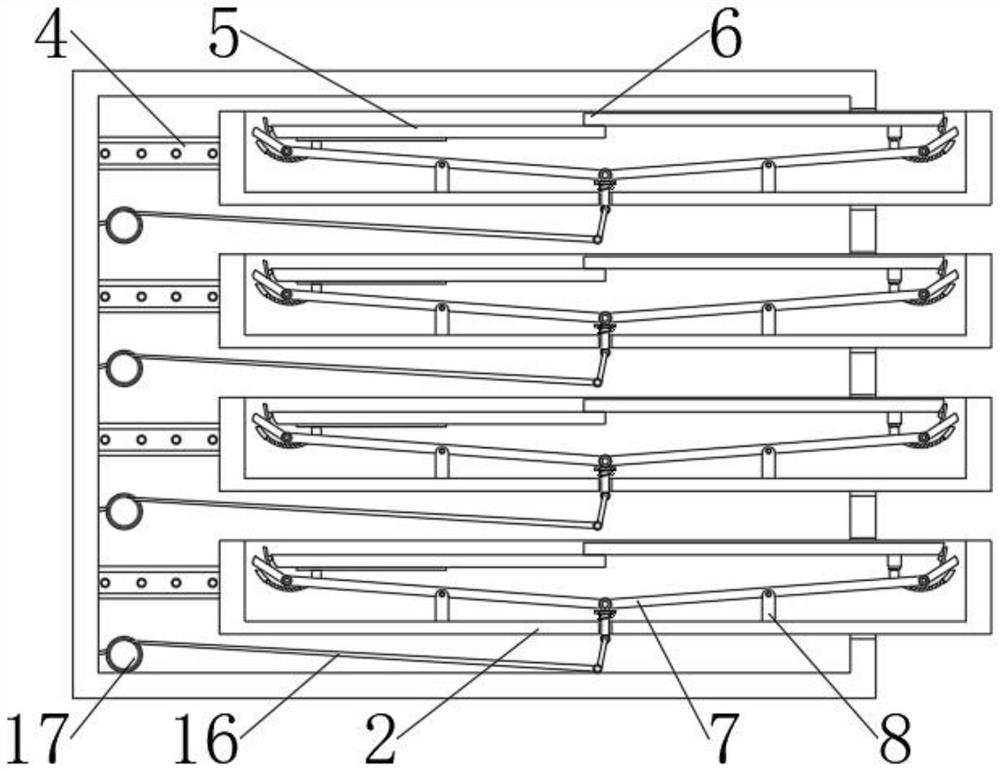

Lentivirus kit refrigerating box for clinical laboratory department

ActiveCN112815595AEasy to placeIncrease spacingLighting and heating apparatusDomestic refrigeratorsCold airLentivirus

The invention provides a lentivirus kit refrigerating box for a clinical laboratory department, and relates to the field of kits. The lentivirus kit refrigerating box for the clinical laboratory department comprises a box body, a plurality of drawing boxes which are randomly placed in cavities in a one-to-one correspondence manner; a plurality of left half box frames and right half box frames, supporting plates which are correspondingly arranged at the bottoms of the left half box frames and the bottoms of the right half box frames; a stretching mechanism and a binding mechanism which are used for achieving the traction effect on a pull rope; and a coating mechanism which is arranged at the end, far away from the hinge seat, of any supporting plate. According to the lentivirus kit refrigerating box for the clinical laboratory department, an operator can conveniently place reagent bottles on the placement plates, the distance between the left half box frame and the right half box frame and the pulling boxes at the top is increased, so that cold air in the box body can be rapidly diffused into each pulling box, the cold and heat transfer rate is increased, and the better heat preservation effect is achieved.

Owner:立凯生物技术(杭州)有限公司

Treatment apparatus for filtering wastewater

ActiveCN108379890AThere will be no re-contamination of clean waterEasy squeezeStationary filtering element filtersSludgeWastewater

The invention discloses a treatment apparatus for filtering wastewater. The treatment apparatus comprises a reaction tank, a flange, a water inlet hopper, a bottom support, a base, discharge pipes, amotor, a telescopic device, a bracket, a belt pulley, a drive rod, a spiral unit, a filter mesh, a controller, a clamping-connecting block and a protecting box, and the like. The treatment apparatus has the beneficial effects that the treatment apparatus can be used for effectively extracting fresh water in sludge through an extrusion means, so that people perfectly utilize a water resource; meanwhile, for some sewage abstracted from nature, the treatment apparatus can be used for sufficiently and effectively removing aquatic organisms possibly existing in the sewage, and the death, which causes the re-pollution of the sewage, of these aquatic organisms in the process of treating the sewage is avoided.

Owner:ZHEJIANG HUADAO ENVIRONMENTAL PROTECTION EQUIP

Toothpaste extrusion box

InactiveCN105083659AGuaranteed extrusion effectReduce thrustUnpacking by expelling contentsEngineeringToothpaste

The invention provides a toothpaste extrusion box. The toothpaste extrusion box comprises a strip-shaped box body for placing a strip-shaped toothpaste tube, an extrusion opening formed in one end of the box body and an opening formed in the other end of the box body, wherein a roller is arranged in the box body, the line where a shaft of the roller is positioned is perpendicular to the line where the strip-shaped box body is positioned, a push rod is fixed to the shaft of the roller, the push rod penetrates through the opening, sliding slots are formed in the box body, sliding pressing components used in cooperation are arranged in the sliding slots, and the line where the sliding slots are positioned is not perpendicular to the line where the box body is positioned. According to the toothpaste extrusion box provided by the invention, due to the existence of the roller capable of linearly rolling on the toothpaste tube, a toothpaste body in the toothpaste tube can be conveniently extruded out of the extrusion opening; and in use, the tail of the toothpaste tube is pressed by the sliding pressing component, and the line where the sliding slots are positioned is not perpendicular to the line where the box body is positioned, so that the toothpaste extrusion box is suitable for various sizes of toothpaste tubes.

Owner:QIDONG JIANGTIAN HYDRAULIC

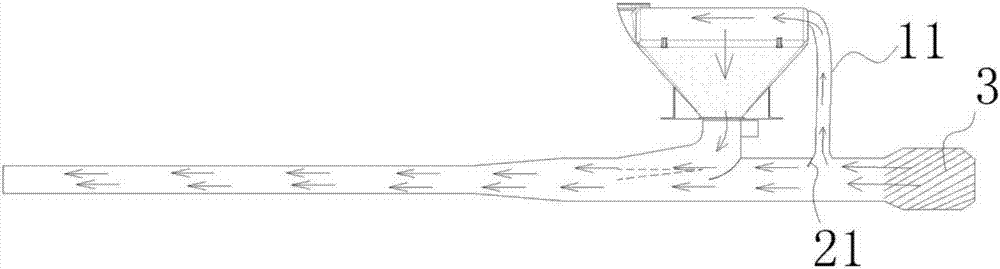

Construction method of automatic sewage interception closed conduit

The invention discloses a technical solution of a construction method of an automatic sewage interception closed conduit. The construction method comprises the following steps: 1, making a slag removal device; 2, making a moving device; 3, making a conduit body; and 4, implementing on-site construction. The construction method provided by the invention is not only simple in structural compositionbut also low in closed conduit maintenance cost; the construction method provided by the invention, which is enough in structural intensity, can collect solid waste and residues in the closed conduit,so as to prevent the closed conduit from getting blocked by the solid waste in discharge, and to enhance underwater and rainwater discharge functions of the closed conduit; and therefore, a risk of flood due to river blockage can be avoided.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

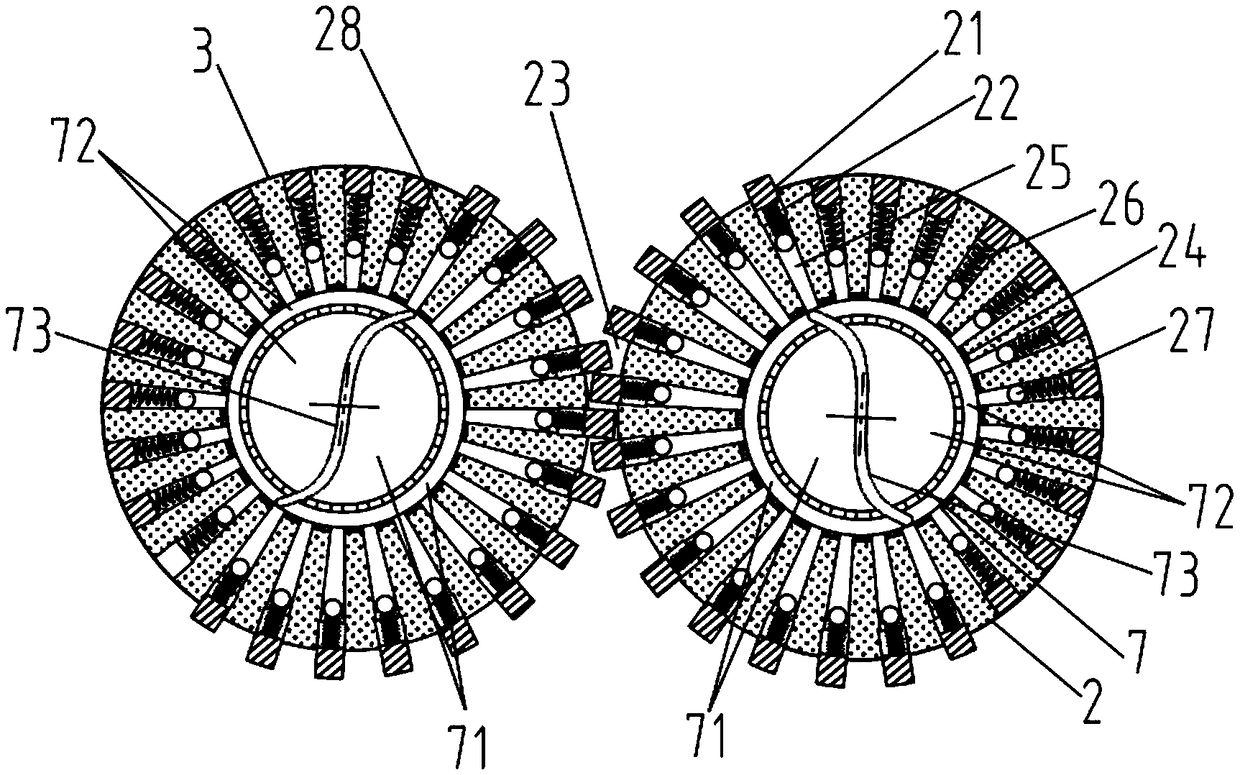

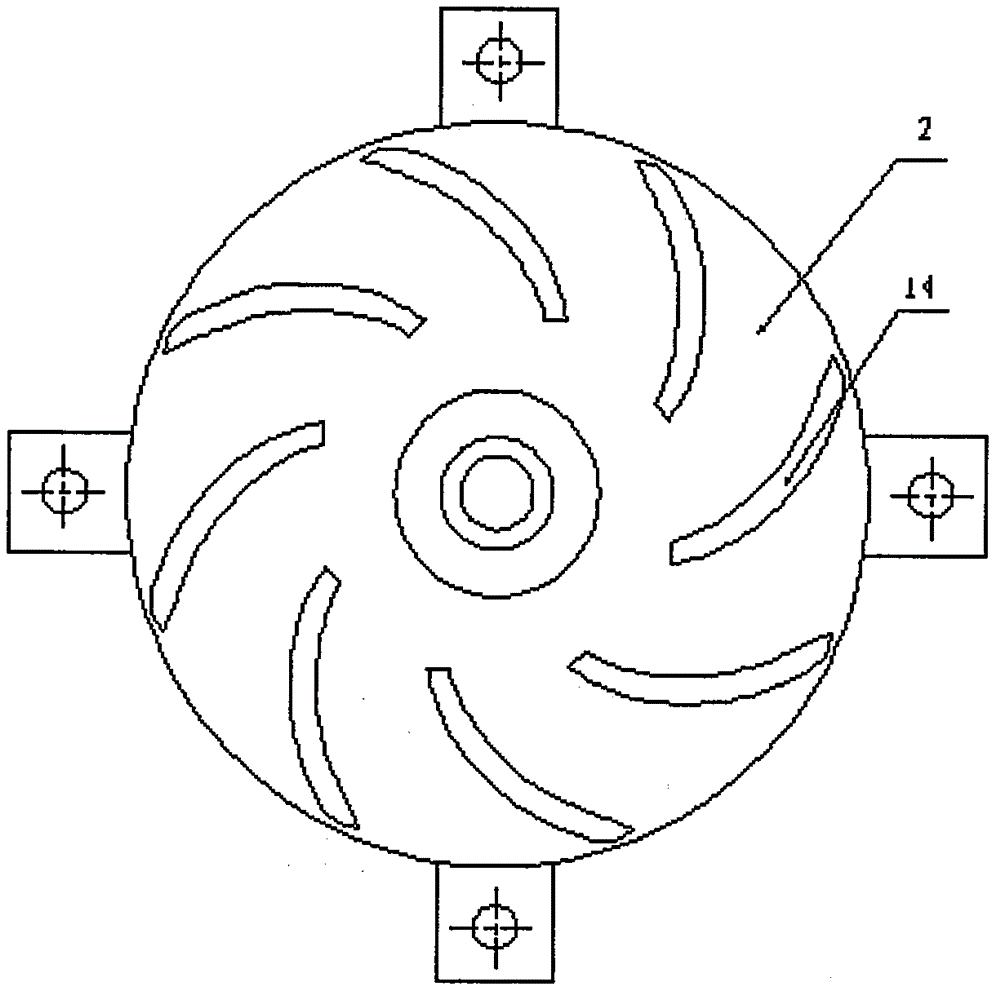

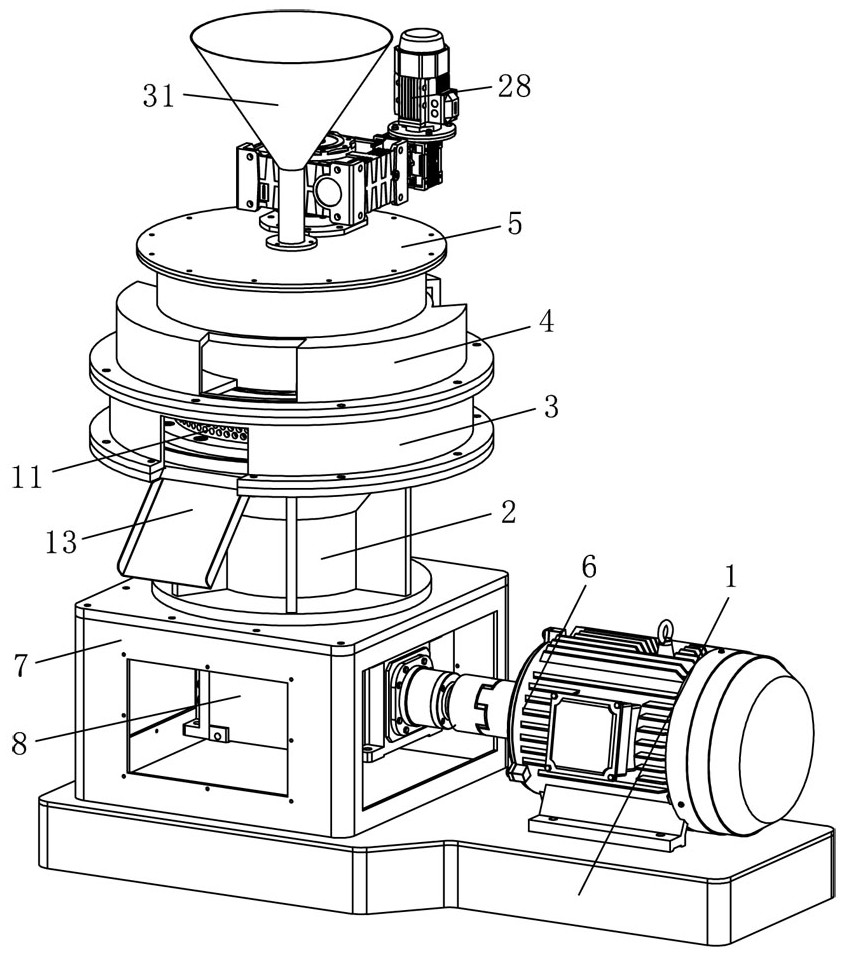

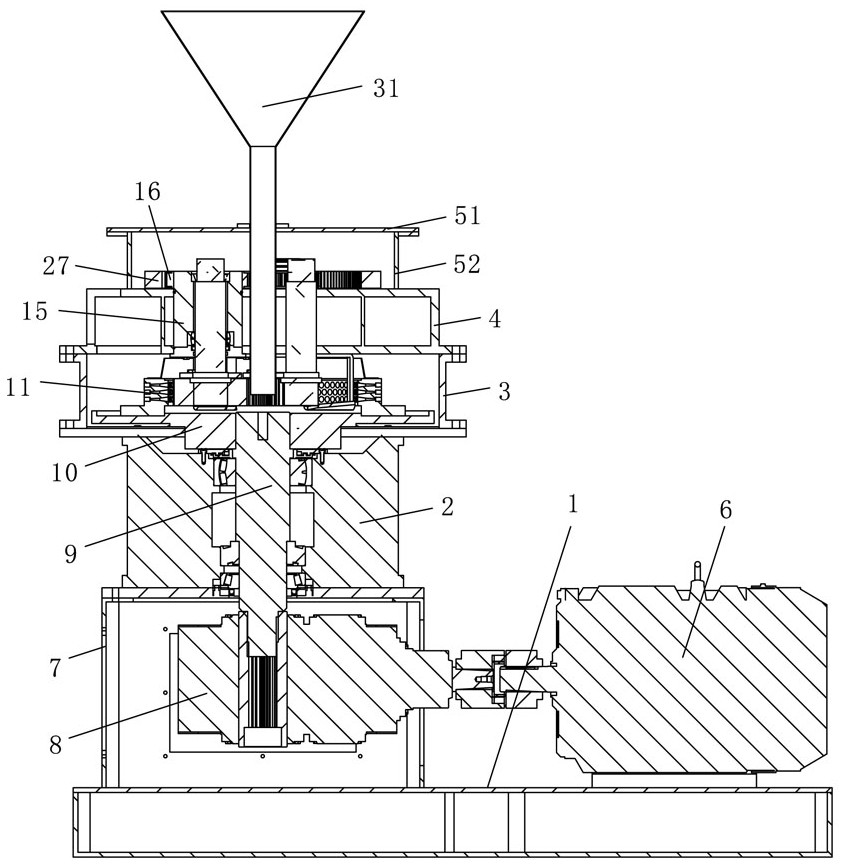

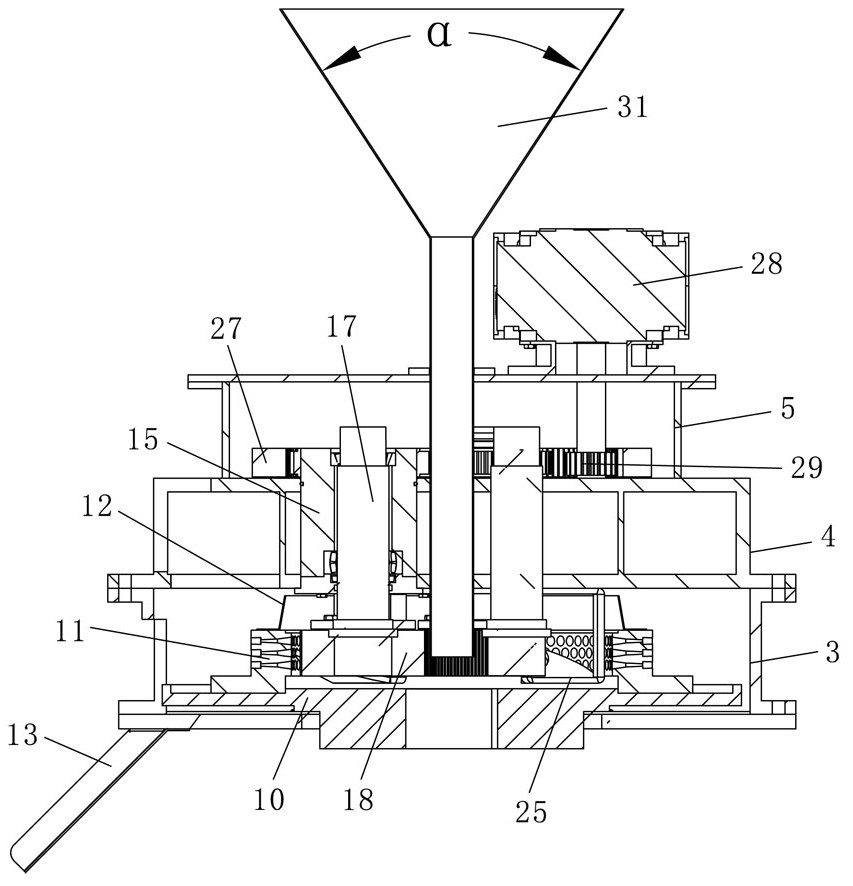

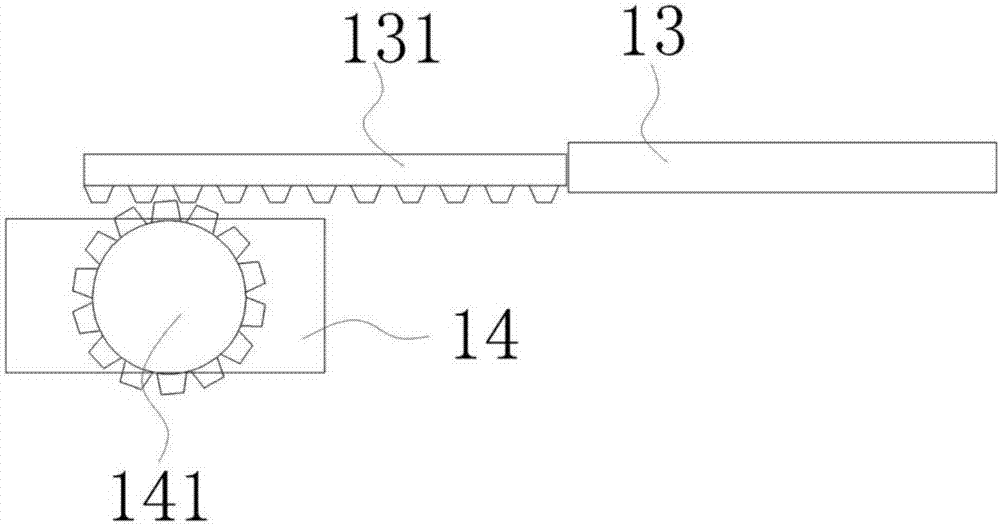

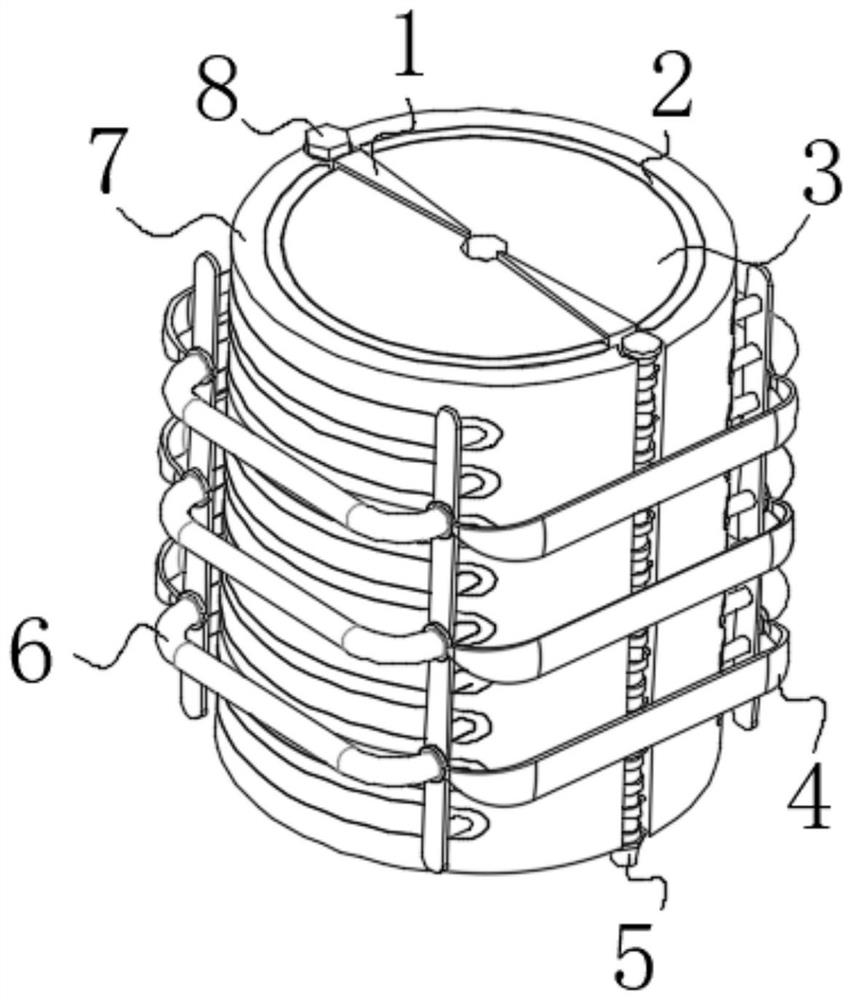

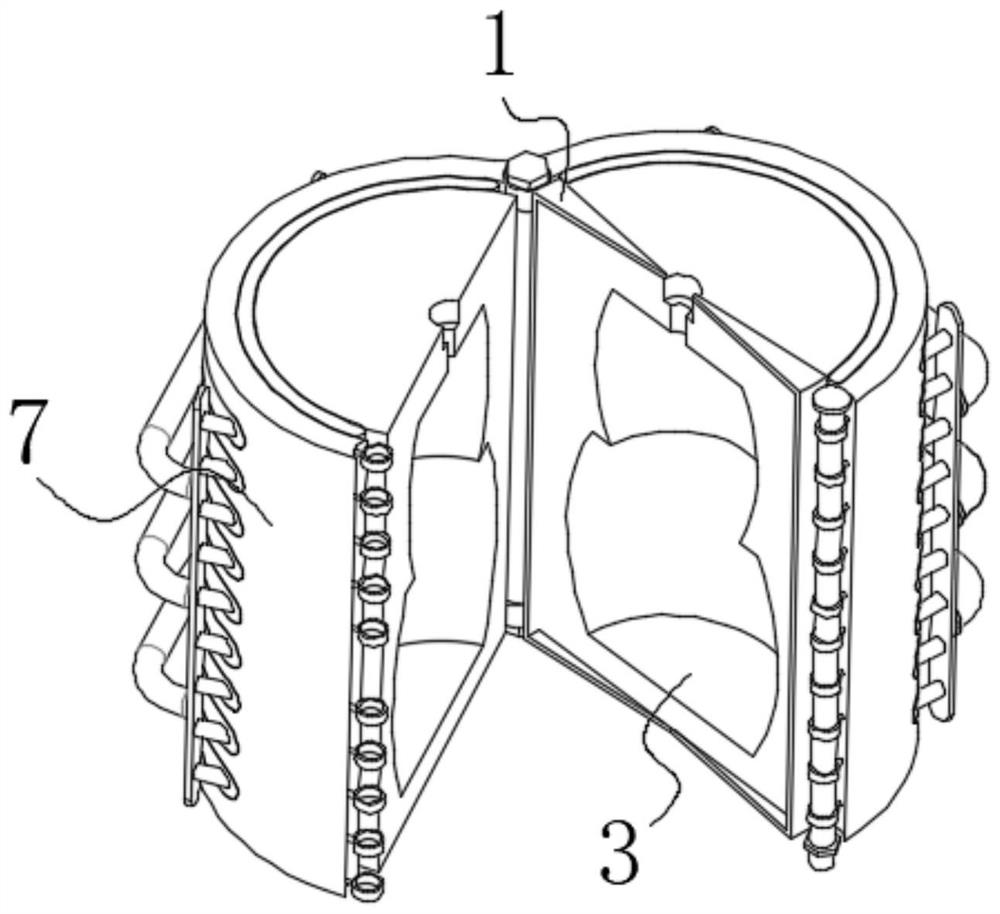

Suspended sludge granulator

PendingCN114768676AGuarantee of distribution uniformityGuaranteed automatic lubrication effectGranulation by material expressionSludgeGear wheel

The invention relates to a suspension type sludge granulator which comprises a machine base, a driving mechanism, a box body, a supporting cavity, a mounting cavity and a lubricating cavity, the supporting cavity, the mounting cavity and the lubricating cavity are sequentially arranged above the box body, and a bottom plate, a circular mold and a guide ring are arranged in the supporting cavity; three compression roller assemblies are arranged in the mounting cavity in the circumferential direction, and each compression roller assembly comprises an eccentric sleeve, an adjusting gear, a compression roller shaft and a compression roller; the eccentric sleeve and the compression roller shaft are not coaxial, a material raising frame is arranged below the mounting cavity, and the material raising frame and the compression roller are alternately arranged in the ring die in the ring direction; a gap adjusting mechanism is arranged on the lubricating cavity, the gap adjusting mechanism comprises an inner gear ring and a speed reducer which are in gear transmission connection, and three adjusting gears are meshed with the inner gear ring respectively; a discharging pipe is arranged on the lubricating cavity, and the lower end of the discharging pipe extends downwards to be arranged in the middle of the circular mold. The problems of non-uniform feeding, lubricating of rotating parts, difficulty in adjustment of roller die gaps, overflow of raw materials and abrasion of parts of the sludge granulator are solved.

Owner:郑州市格沃环保开发有限公司

Powder drive type fire extinguishing cannon

A powder drive type fire extinguishing cannon comprises a powder containing box, a cannon pipe and a main pressure source; the main pressure source pressurizes a cannon pipe from the cannon tail of the cannon pipe, the powder containing box is fixed to the peripheral face of the cannon pipe, the powder containing box comprises an auxiliary pressurizing pipe, a box body, a flow control plate and a steering engine, the auxiliary pressurizing pipe is communicated with the top of the box body, the box body is communicated with the cannon pipe, the connecting position of the box body and the cannon pipe is a flow combining fork, the flow control plate partitions a channel for communicating the box body with the cannon pipe, and the steering engine controls the flow control plate. Powder fire extinguishing agents can be continuously sprayed out, and the beneficial effects of being small in recoil and small in weight are achieved.

Owner:重庆国飞通用航空设备制造有限公司

Glass bottle forming die applied to glass bottle blowing process

The glass bottle forming die applied to the glass bottle blowing process comprises an outer frame, a rotating column is arranged in the outer frame, the inner wall of the outer frame is movably connected with the outer surface of the rotating column, fastening devices are symmetrically arranged in the outer frame, and the outer surfaces of the fastening devices are fixedly connected with the inner wall of the outer frame. A mold is arranged in the fastening device, the outer surface of the mold is movably connected with the inner wall of the fastening device, a sealing device is arranged on the outer surface of the mold, the inner wall of the sealing device is movably connected with the outer surface of the mold, a heat insulation device is arranged in the outer frame, and the inner wall of the outer frame is movably connected with the outer surface of the heat insulation device. In order to overcome the defects in the prior art, the invention provides the glass bottle forming die applied to the glass bottle blowing process, and the problems that a traditional glass bottle blowing process is slow in forming and affects the working efficiency are solved.

Owner:江苏晶瑞玻璃有限公司

Preparation method of polyvinyl chloride neon light tube material

The invention discloses a preparation method of a polyvinyl chloride neon light tube material. The preparation method comprises the following steps: (1) material blending: weighing the following components in parts by weight: 100-120 parts of PVC resin, 35-40 parts of dioctyl phthalate, 10-15 parts of tritolyl phosphate, 0.5-1 part of triphenyl phosphite, 1-1.5 parts of epoxidized soybean oil, 2-2.5 parts of dibutyl tin laurate, 5-8 parts of chlorinated paraffin, 0.05-0.1 part of oxidized polyethylene wax, 0.5-1 part of a barium / cadmium liquid stabilizer, 0.2-0.4 parts of an ultraviolet absorber, 0.05-0.1 part of an antioxidant and a proper amount of an optical brightener; (2) extrusion granulation: firstly, mixing the chlorinated paraffin, barium / cadmium liquid stabilizer and dibutyl tinlaurate evenly in a high-speed mixer, then adding the remaining components, heating to 90-100 DEG C, then carrying out high-speed mixing for at least 30min, cooling to normal temperature, adding the mixture into an extruder for granulation for extrusion, and carrying out air cooling and granulation. The preparation method provided by the invention has the advantages of simple process steps, strongoperability, low production cost and suitability for industrial production, and the prepared product has the characteristics of tough performance, high transparency, heat resistance, cold resistanceand the like.

Owner:东阳市特意新材料科技有限公司

An intelligent digital display bus bar

PendingCN109087732AIncrease wind speedImprove the effect of cooling and dust removalCooling bus-bar installationsInsulated cablesCamSafe operation

The invention provides an intelligent digital display bus bar, comprising a digital display bus bar body, a bus bar sleeve, a protective sleeve, a connecting piece and a cooling and dust removing piece. The digital display bus bar body is fitted in the bus bar sleeve; The bus bar sleeve is a transparent fireproof sleeve, and is installed in the protective sleeve through the connecting piece; the inner side of the protective sleeve is provided with a spiral airway along the length direction, and four mounting holes are evenly distributed in the inner middle of the inner side of the protective sleeve; the connecting piece comprises a protective sleeve shaft, a connecting cam and a connecting rod; the cooling and dust removing piece is annularly arranged between the protective sleeve and thebus bar sleeve, and comprises a mounting plate, an ion blower, a tungsten electrode needle and a cooling and dust removing drum. The invention can effectively lower the high temperature generated by the operation of the bus slot system and periodically remove accumulated dust particles, thereby ensuring the stable and safe operation of the bus slot system and further guaranteeing the normal operation of the power trunk system; the intelligent digital display bus bar has the advantages of novel structure, moderate production and installation cost, and intelligent operation and management.

Owner:雷朋电气集团有限公司

Popular searches

Improve the extrusion effect Improve electromagnetic absorption performance To achieve the effect of green environmental protection Meet construction requirements Good for physical and mental health Reduce the effects of electromagnetic interference Improve stealth performance Well mixed Shorten the resting time Improve early strength

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com