High-efficiency pulp filter-pressing and dehydrating equipment

A technology for filter press dehydration and pulp, applied in the direction of pulp dehydration, etc., can solve the problems of poor pulp carrying, affecting pulp extrusion effect, insufficient line pressure extrusion, etc., to ensure integrity, improve filter press dehydration effect, mechanical Simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

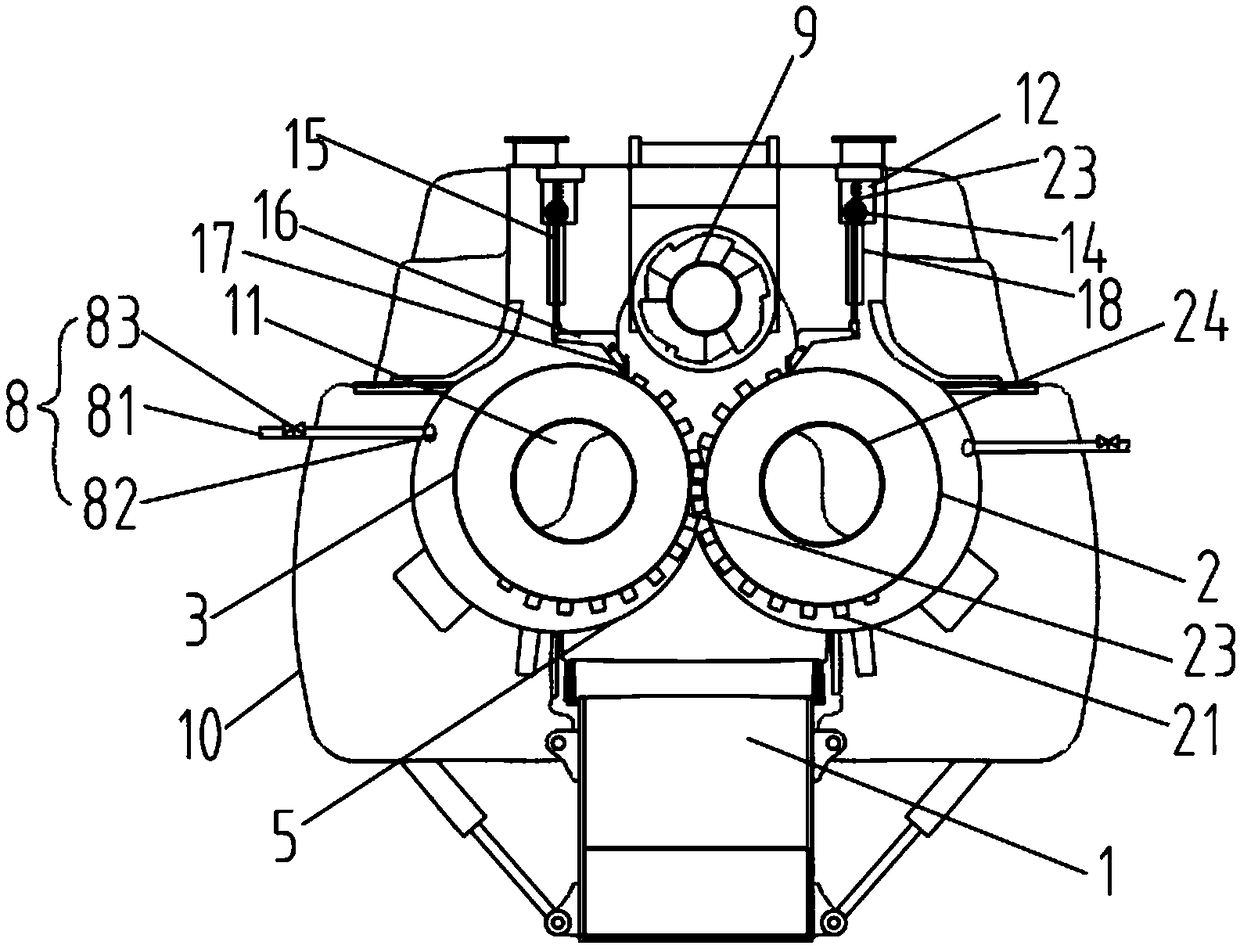

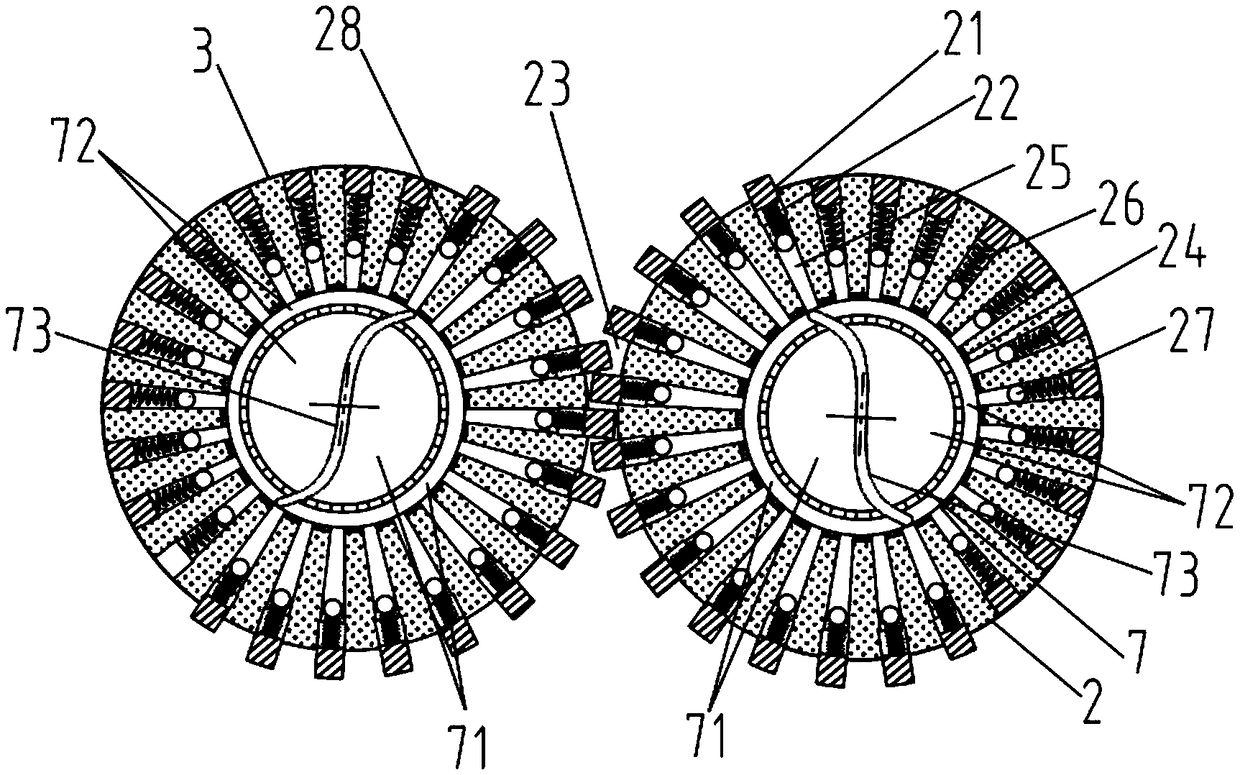

[0044] Embodiment 2 is basically the same as Embodiment 1, the difference is that this embodiment provides a kind of high-efficiency pulp filter press dehydration equipment, please refer to figure 1 As shown, this embodiment also includes a cleaning mechanism 8 for cleaning the two squeeze rolls on the left and right sides of the pulp tank support plate 5. Specifically, the cleaning mechanism 8 includes a cleaning pipeline 81, a nozzle 82, and a cleaning pipeline 81. The connected water pump and the nozzle 82 are connected to the end of the cleaning pipeline 81 and fixed on the slurry tank support plate 5; and the cleaning pipeline 81 is provided with a solenoid valve 83, and the solenoid valve 83 is connected to the controller. A filter hole communicating with the high-pressure area 71 or the low-pressure area 72 can be provided on the extrusion protrusion 21, so that when the extrusion protrusion 21 approaches the low-pressure area 72, the slurry can be filtered through the e...

Embodiment 3

[0046] Embodiment 3 is basically the same as Embodiment 2, the difference is that this embodiment provides a kind of high-efficiency pulp filter press dehydration equipment, please refer to figure 1 As shown, this embodiment also includes improvements to the doctor blades respectively arranged on the upper end surfaces of the two squeeze rolls. Specifically, an elastic mechanism is installed on the frame shell 10, and the elastic mechanism includes a blade fixed on the frame shell 10. The limit box 12 and the tension spring 13 and the iron block 14 located in the limit box 12, the scraper includes a scraper bar 15, a V-shaped connecting frame 16 and a scraper head 17 connected sequentially from top to bottom, and the upper end of the scraper bar 15 The iron block 14 is connected with the tension spring 13, and the frame housing is provided with a slide rail 18 for the scraper bar 15 to slide up and down. The frame shell 10 is hinged, and the other end is fixedly connected with...

Embodiment 4

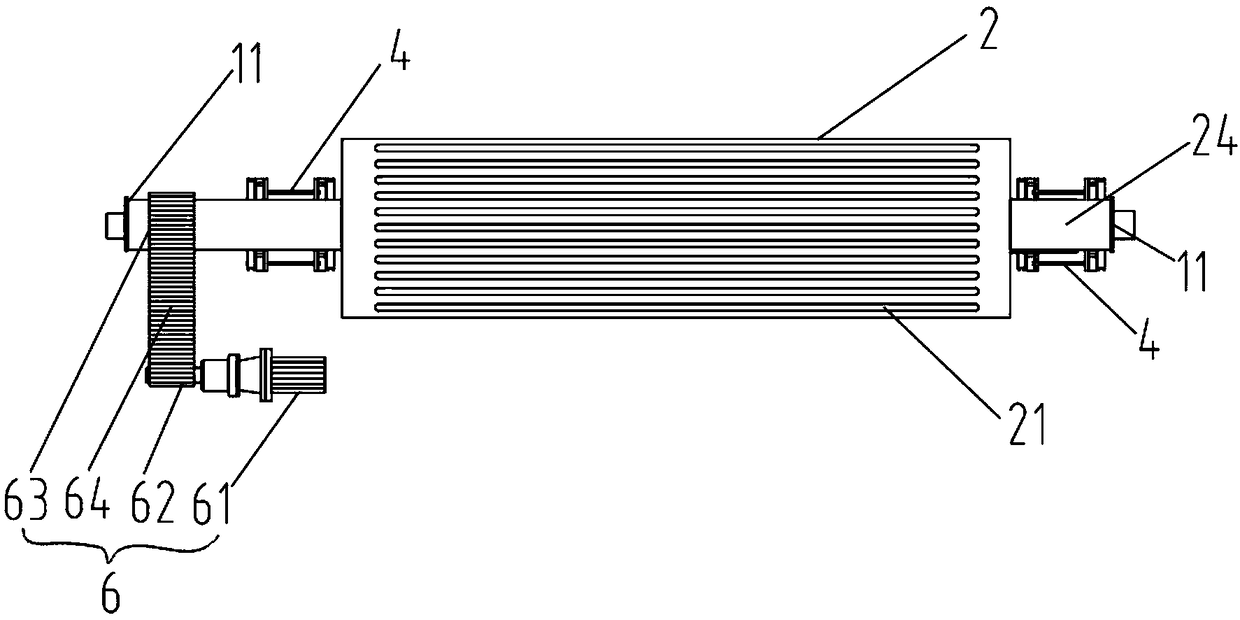

[0048] Embodiment 4 is basically the same as Embodiment 3, the difference is that this embodiment provides a kind of high-efficiency pulp filter press dehydration equipment, please combine figure 1 , Figure 4 and Figure 5 As shown, the screw conveying mechanism 9 is a screw structure with variable diameter and variable pitch, and the screw conveying mechanism 9 includes a casing 91, a servo motor 92, a rotating shaft 93 connected to the output shaft of the servo motor 92, and a telescopic shaft sleeved on the rotating shaft 93 Sleeve 94, telescopic shaft sleeve 94 is provided with helical blade 95, is provided with flexible section 96 on telescopic shaft sleeve 94 between adjacent two helical blades 95, is provided with The hydraulic pump 97 that rotates synchronously with the rotating shaft 93 is provided with a turntable that is fixedly connected to the rotating shaft 93 at the feed end 33 of the rotating shaft 93. The central axis of the turntable is on the same straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com