Powder drive type fire extinguishing cannon

A fire extinguishing cannon and barrel technology, applied in the field of fire extinguishing cannon, can solve the problems of limited dry powder on the warhead, explosion around the fire point, and no high-rise fire, etc., to achieve the effect of reducing instantaneous momentum, reducing volume and weight, and being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

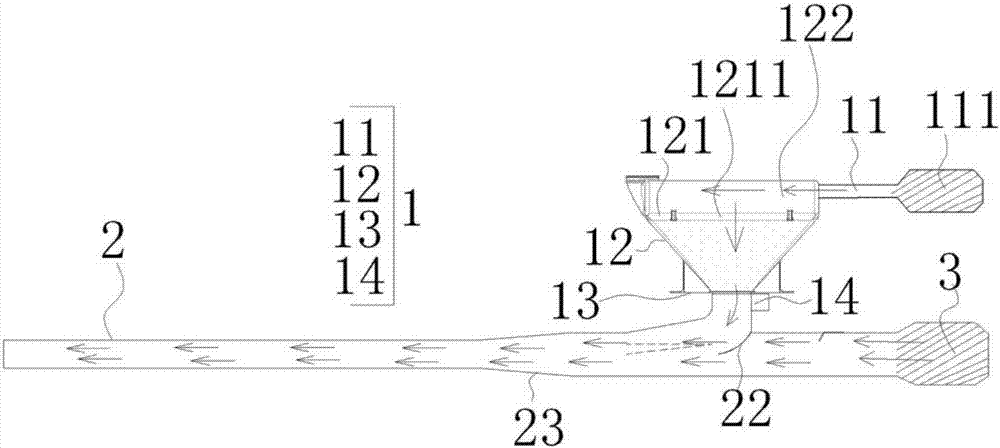

[0031] like figure 1 As shown, a powder-displacement type fire extinguisher includes a powder box 1, a gun barrel 2 and a main pressure source 3, such as figure 1 As shown, the main pressure source 3 is a ducted fan. The main pressure source 3 pressurizes the gun barrel 2 from the breech of the gun barrel 2, and the powder filling box 1 is fixed on the outer peripheral surface of the gun barrel 2;

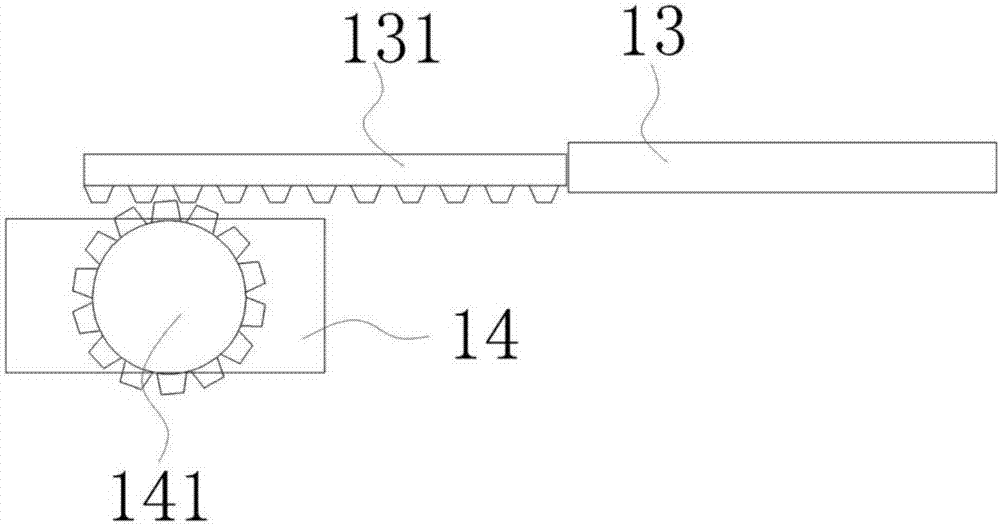

[0032] like figure 1 As shown, the powder filling box 1 includes an auxiliary pressurizing pipe 11, a box body 12, a flow control plate 13 and a steering gear 14, the auxiliary pressurizing pipe 11 communicates with the top of the box body 12, and the auxiliary pressurizing pipe 11 communicates with the top of the box body 12. The pressure pipe 11 communicates with an auxiliary pressure source 111, and the auxiliary pressure source 111 is a ducted fan. like figure 1 As shown, the box body 12 has a bell-mouth structure, and the connection end with the gun barrel 2 is a small-dia...

Embodiment 2

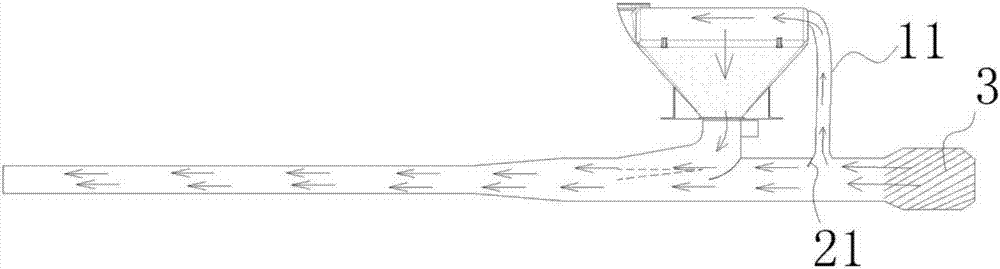

[0038] like figure 2 As shown, a powder-displacing fire extinguisher includes a powder box 1, a gun barrel 2 and a main pressure source 3, and the main pressure source 3 is a ducted fan. The main pressure source 3 pressurizes the gun barrel 2 from the breech of the gun barrel 2, and the powder filling box 1 is fixed on the outer peripheral surface of the gun barrel 2;

[0039] like figure 2 As shown, the powder filling box 1 includes an auxiliary pressurizing pipe 11, a box body 12, a flow control plate 13 and a steering gear 14, and the auxiliary pressurizing pipe 11 communicates with the top of the box body 12, as figure 2 As shown, the box body 12 is a bell mouth structure, and the connection end with the gun barrel 2 is a small diameter end. The box body 12 is communicated with the gun barrel 2, and the connection between the box body 12 and the gun barrel 2 is a confluence fork, and the confluence fork is provided with a backflow prevention plate 22, and the backflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com