Self-drainage type impermeable concrete precast pile

A self-draining technology of prefabricated concrete piles, which is applied in the direction of sheet pile walls, soil protection, construction, etc., can solve problems such as expansion cracking, impermeability decline, and difficulty in controlling the quality of expansive concrete, so as to avoid damage and improve The effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

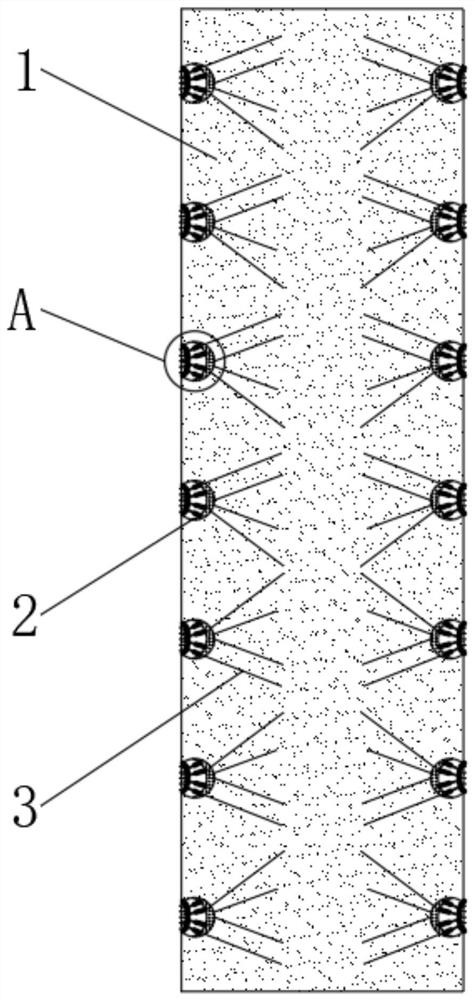

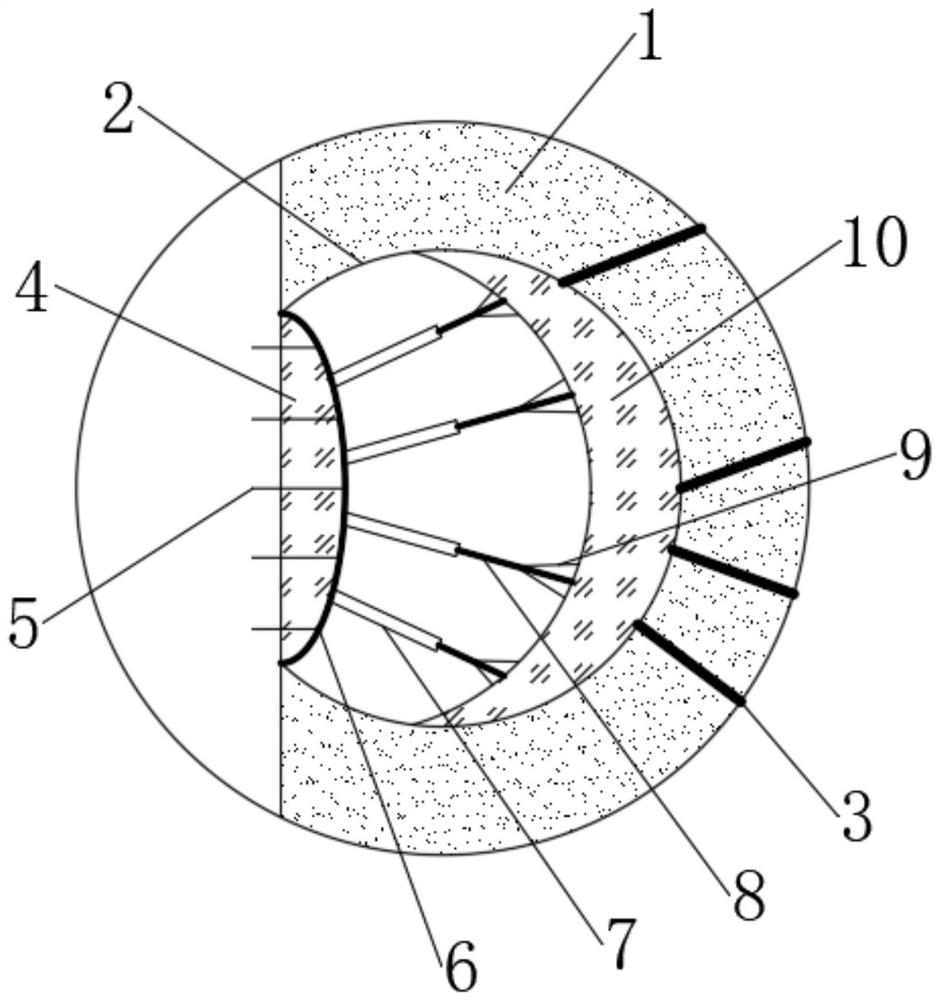

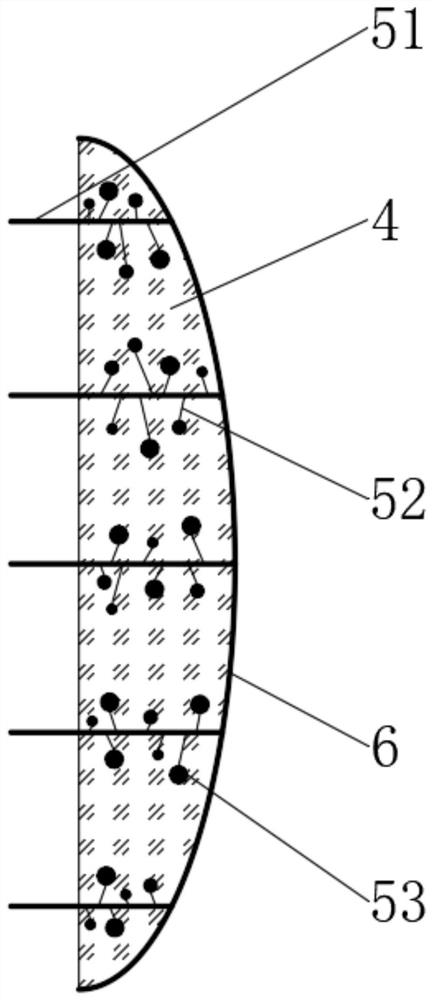

[0042]SeeFigure 1-2, A self-draining impermeable concrete prefabricated pile, comprising a prefabricated pile body 1, the outer surface of the prefabricated pile body 1 is inlaid and connected with a plurality of evenly distributed embedded missing balls 2, and the openings of the embedded missing balls 2 are connected with one-way The drainage package 4, the unidirectional drainage package 4 is inlaid and connected with a plurality of evenly distributed multi-magnetic-point drainage wires 5, and the multi-magnetic-point drainage wires 5 extend to the outside of the embedded missing ball 2, and the inner end of the embedded missing ball 2 is connected with The water collection bag 10 is inlaid and connected with a plurality of radially distributed water diversion fiber rods 3, and the water diversion fiber rod 3 penetrates the embedded missing ball 2 and extends into the precast pile body 1. The water collection bag 10 is close to the single A plurality of evenly distributed multi-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com