Patents

Literature

115results about How to "Increase drainage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

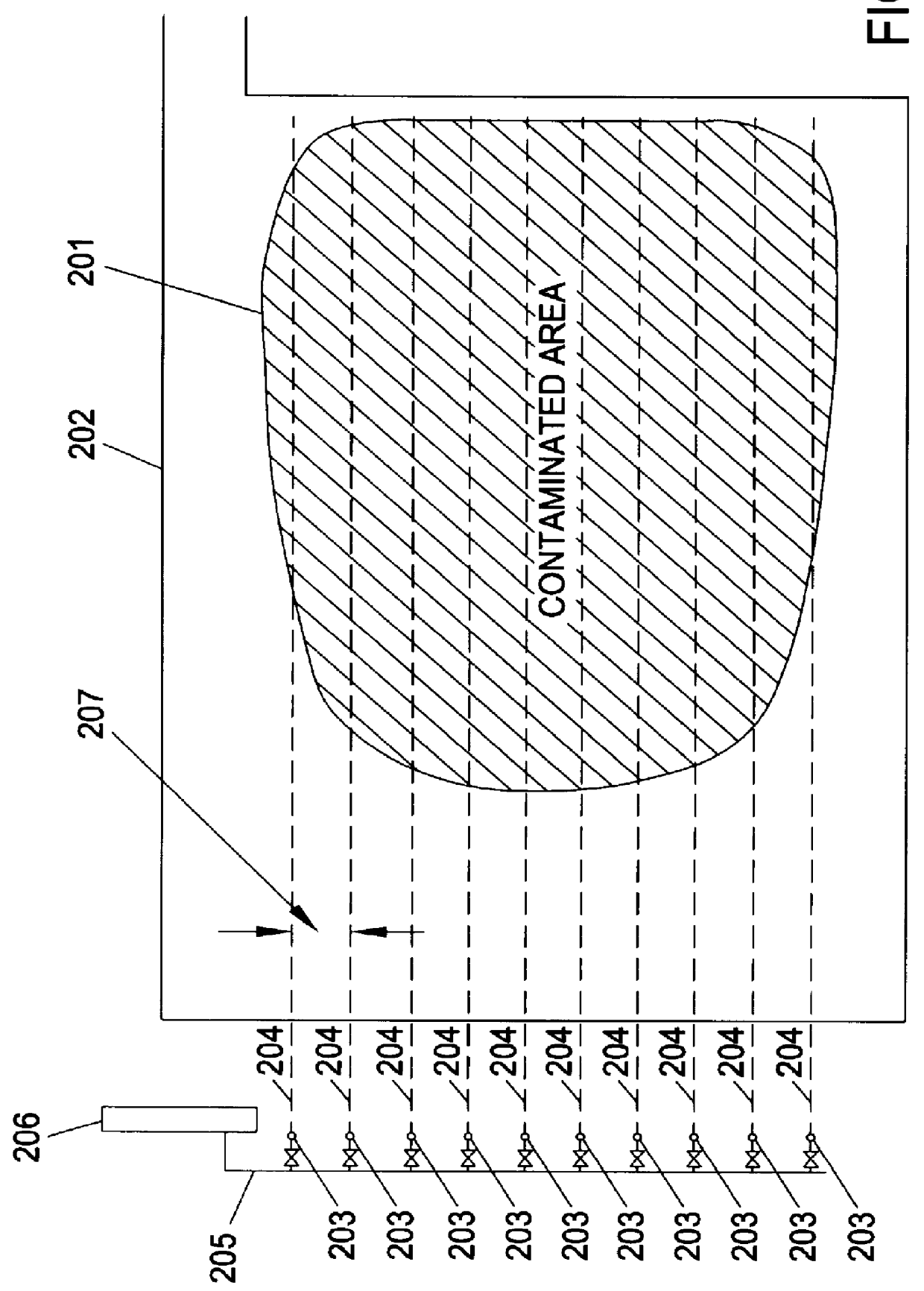

Remediation method

InactiveUS6102622AHigh concentration of pollutantsLow viscosityConstructionsSolid waste disposalPollutantWellhead

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

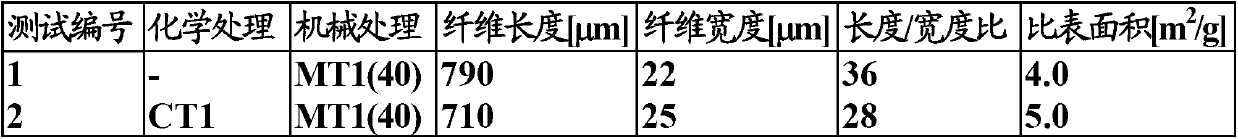

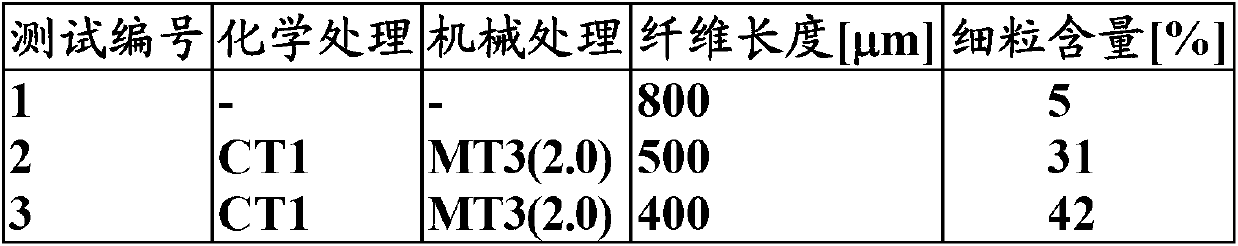

Cellulosic fibre composition

InactiveCN102971462AEasy to prepareWithout significant loss of qualityWood working apparatusPaper/cardboardChemical treatmentNitroxyl radicals

The invention relates to a composition comprising cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25, and DEG a length weighted mean fibre length up to 1,100 [mu]m and a length weighted mean fibre width over 10 [mu]m, or DEG a length weighted mean fibre length up to 1,100 [mu]m, and wherein at least 50 % by weight of the cellulosic material is insoluble in water, or DEG a length weighted mean fibre length / width ratio up to 30, or DEG a length weighted mean fibre width over 35 [mu]m. The invention also relates to a composition comprising cellulosic fibres having a specific surface area of at least 1.5 m2 / g, a length weighted mean fibre length / width ratio up to 30, and a dry solids content of at least 5 % by weight, based on the weight of the composition, or up to 30 % by weight, based on the total weight of the cellulosic fibres, of cellulosic fibres with a length weighted mean fibre length up to 100 [mu]m. Method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres to chemical treatment and mechanical treatment, wherein the chemical treatment comprises treating cellulosic fibres with (i) at least one agent containing a carboxyl group, optionally substituted, (ii) at least one oxidant and at least one transition metal, or (iii) at least one nitroxyl radical, and the mechanical treatment comprises subjecting cellulosic fibres to extrusion with a twin-screw extruder or a planetary roller extruder. The invention also relates to a method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25 to extrusion. The invention also relates to a composition comprising cellulosic fibres obtainable by the methods, a process for producing a cellulosic pulp mixture which comprises mixing the composition with cellulosic pulp, a cellulosic pulp mixture obtainable by the process, and the use of the composition and cellulosic pulp mixture as an additive in the production of paper and board, processes for producing paper and board in which the composition or cellulosic pulp mixture is used, paper and board obtainable by the processes, and various uses of the paper and board.

Owner:AKZO NOBEL CHEM INT BV

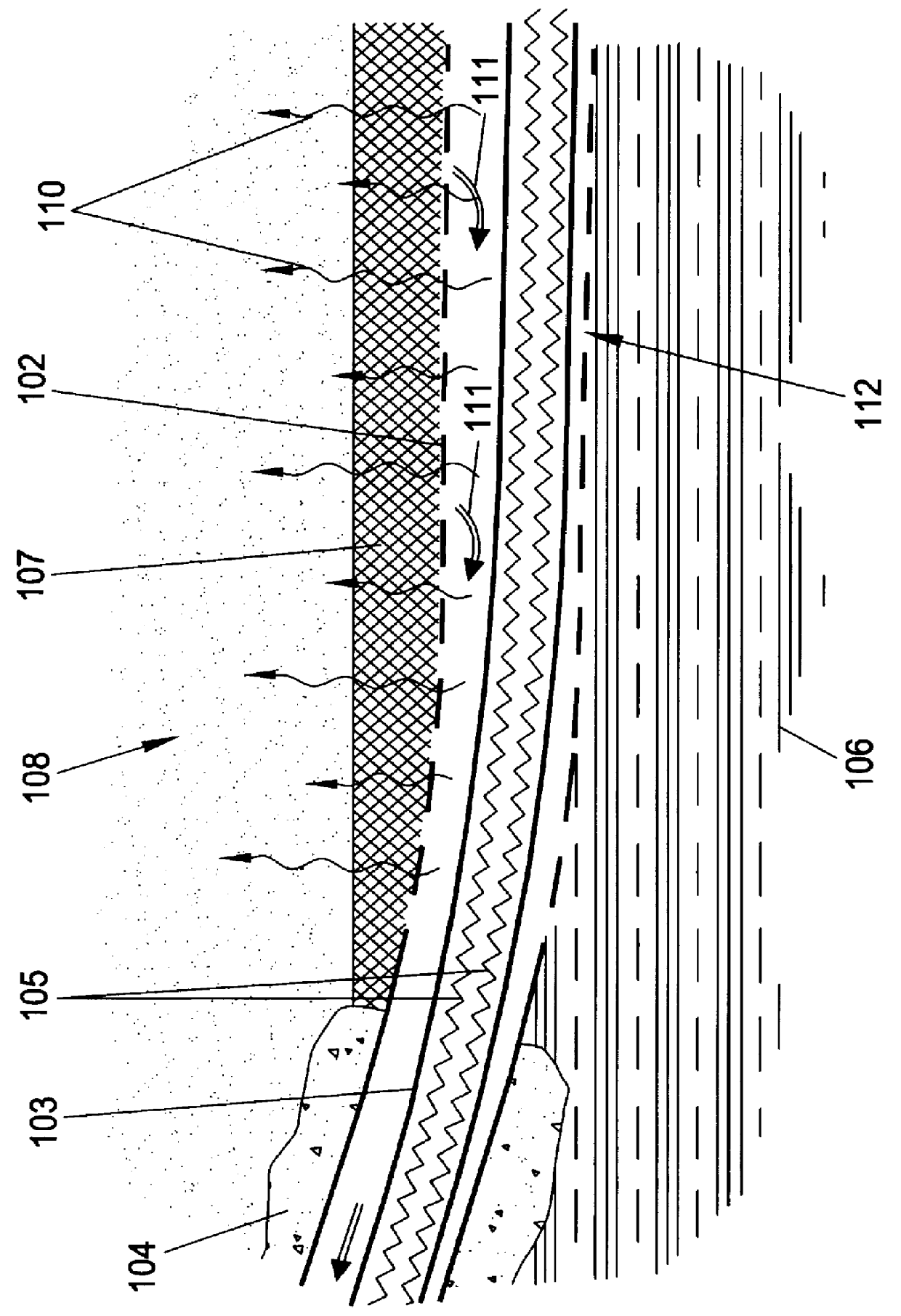

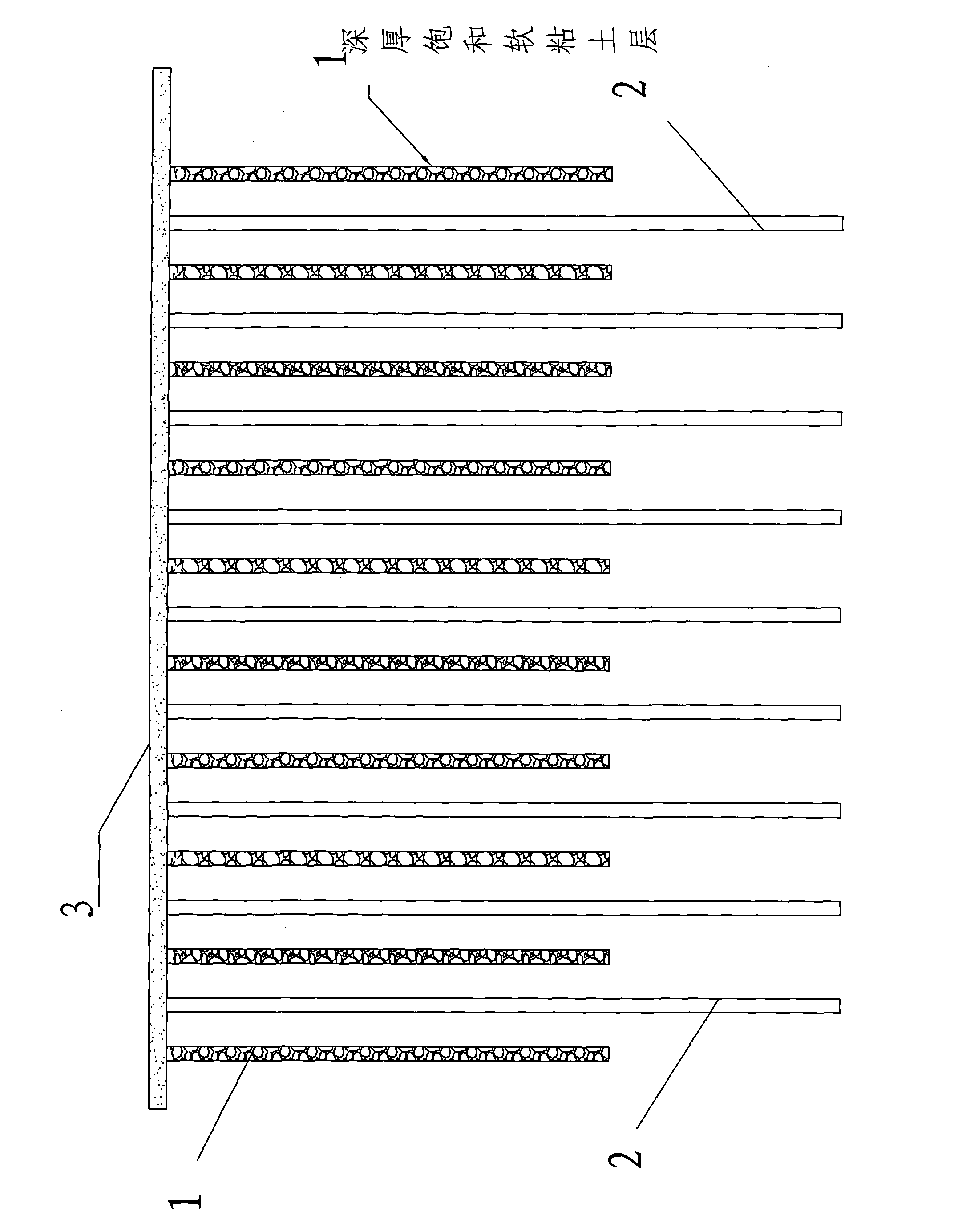

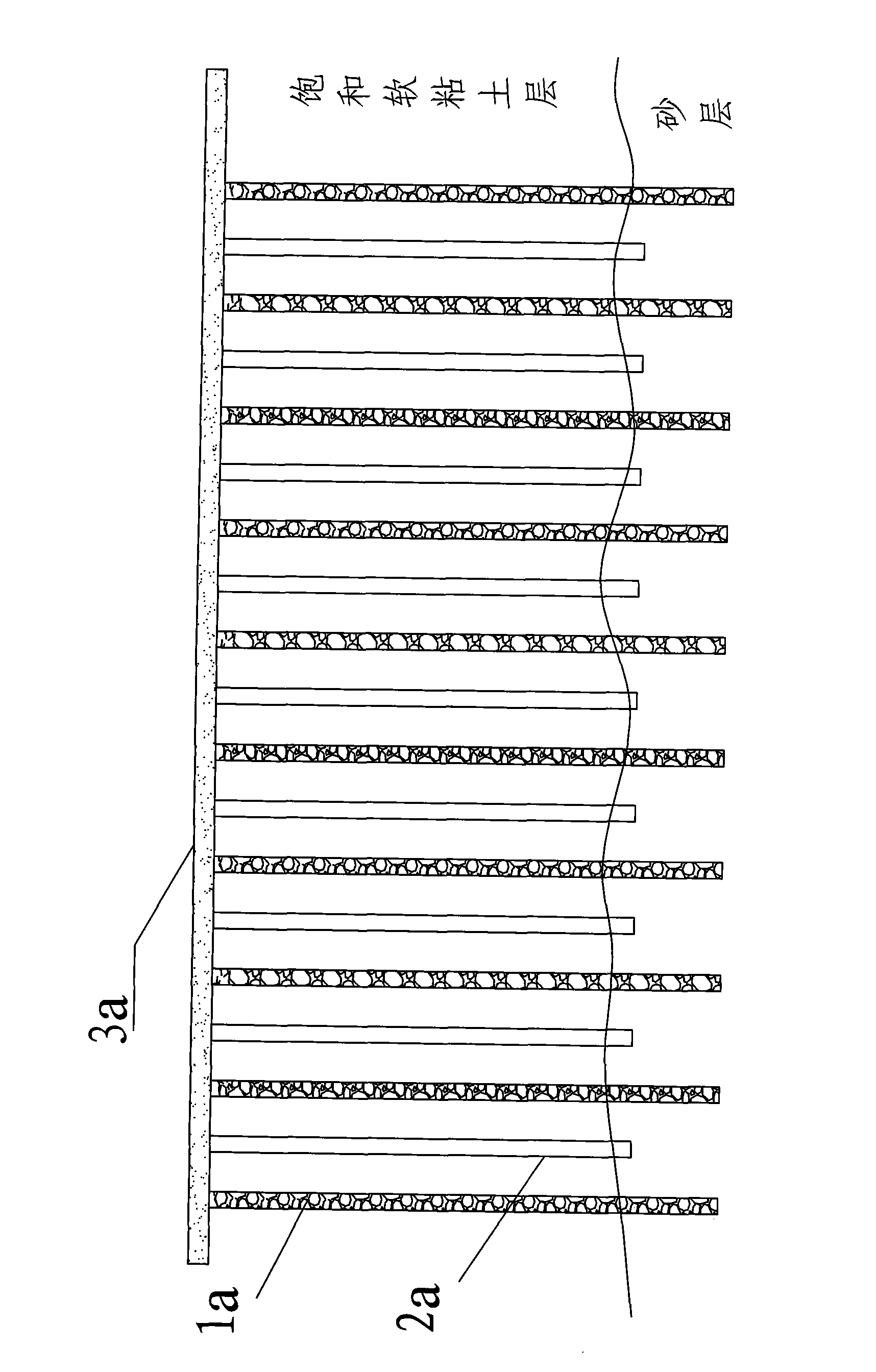

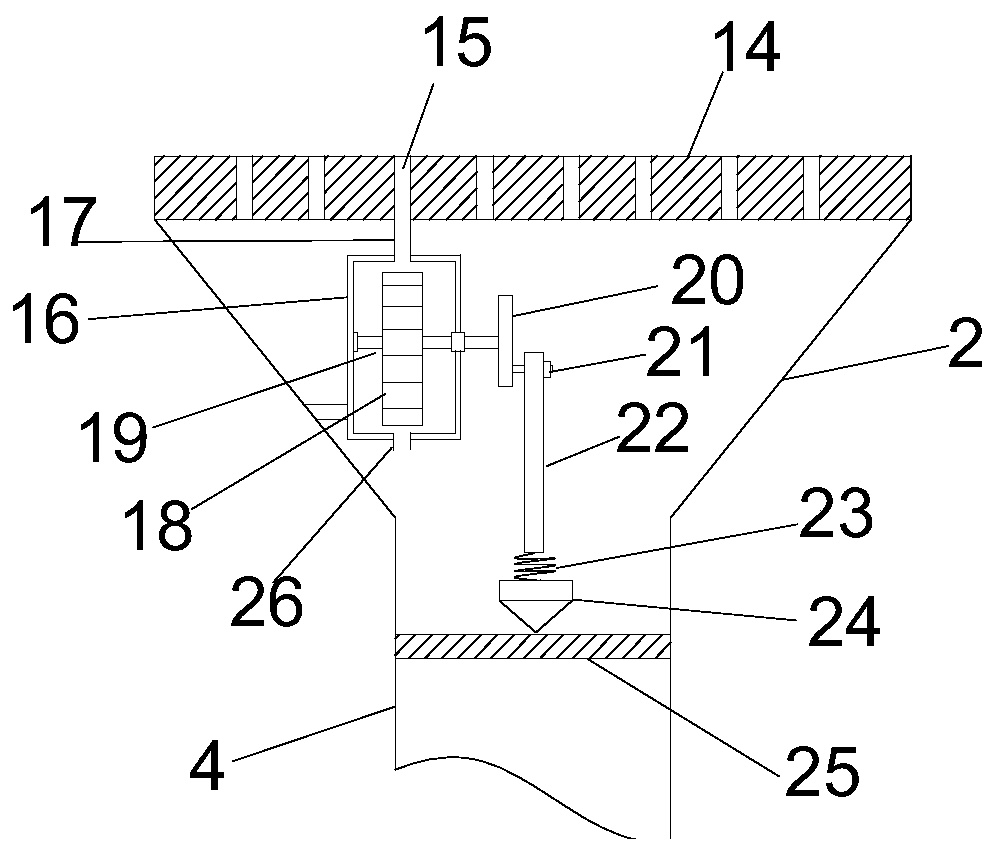

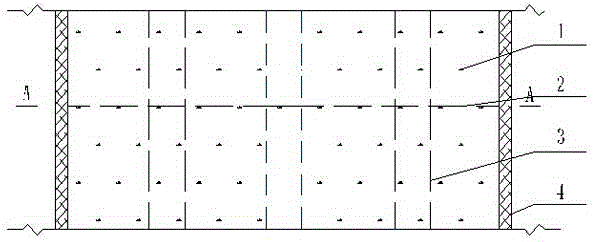

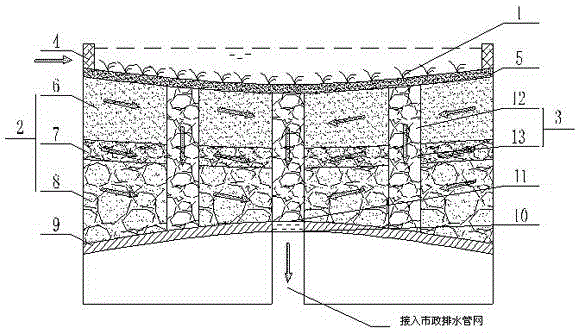

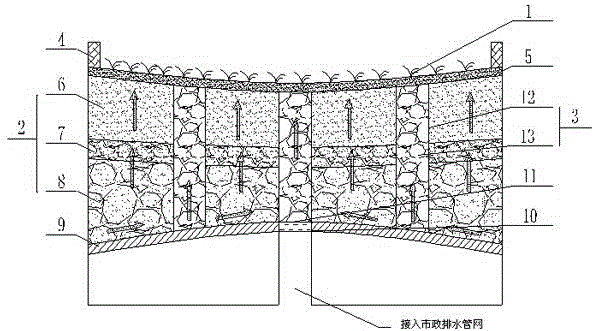

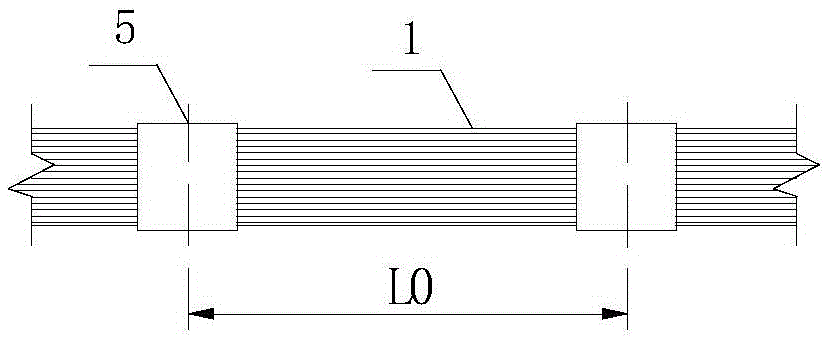

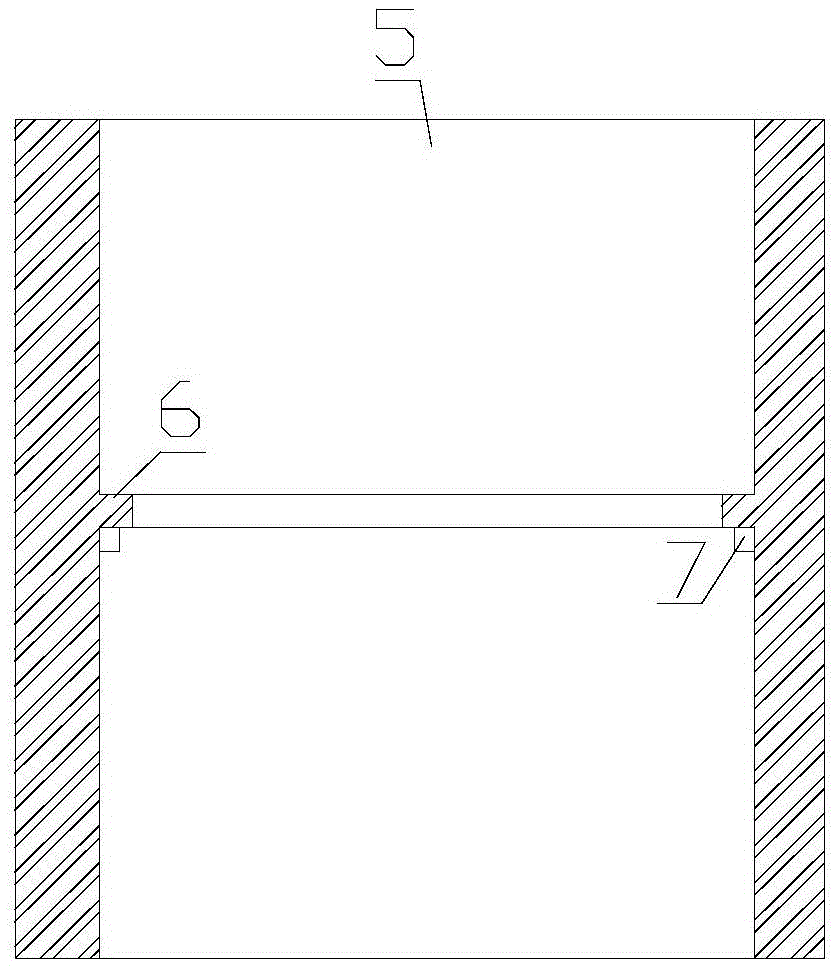

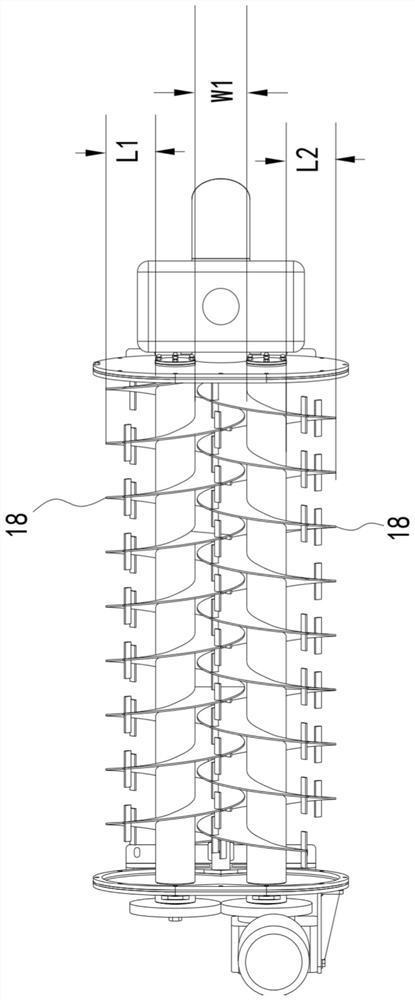

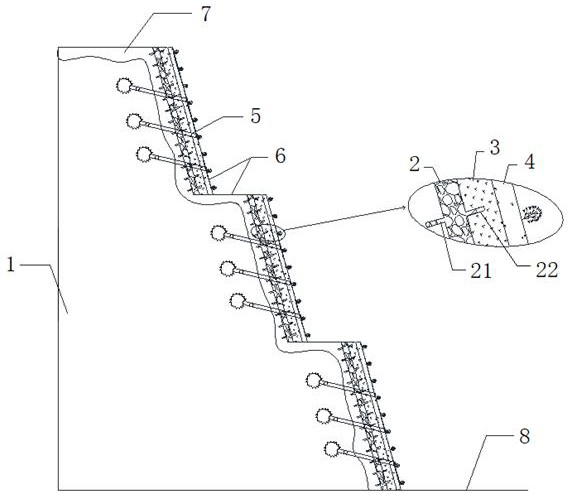

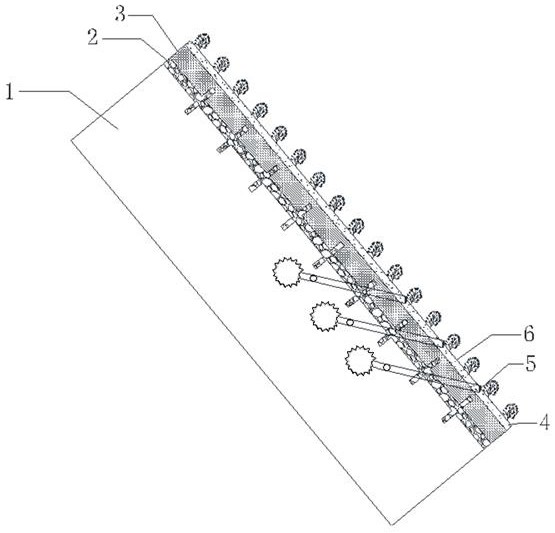

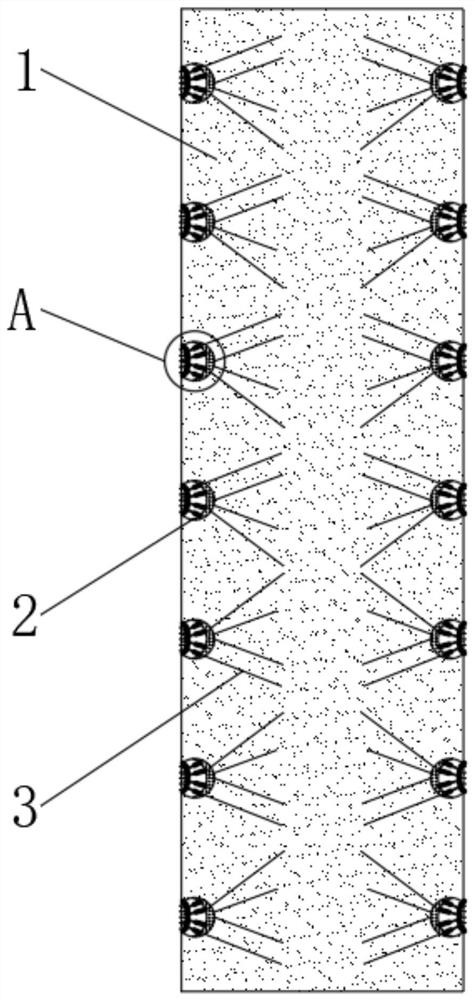

Method for treating spiral oil-extruding filling pile composite foundation in stratum containing soft clay

InactiveCN101634143AIncrease drainage rateAccelerated consolidationBulkheads/pilesSoil preservationSoft clayUltimate tensile strength

The invention relates to a construction method of a spiral oil-extruding filling pile composite foundation in the stratum containing soft clay, which comprises the following steps: determining the structural size, the position and the number of spiral oil-extruding filling piles; manufacturing and constructing a vertical drainage well in the middle part of the design positions of every two adjacent spiral oil-extruding filling piles; manufacturing and constructing each spiral oil-extruding filling pile according to the design position in the middle part between every two finished vertical drainage wells; and then paving drain liner layers on the foundation surface. The invention aims at providing a method for treating the spiral oil-extruding filling pile composite foundation in the stratum containing the soft clay, which avoids the negative oil-extruding effect of the spiral oil-extruding filling piles, improves the drain speed of saturated clay around piles, improves the strength of soil bodies around the piles and under the piles, substantially reduces the settlement after construction, improves the effectiveness and the use range of the spiral oil-extruding filling piles, increases the space length between the piles, reduces the pile number, saves the engineering investment, and accelerates the construction progress.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

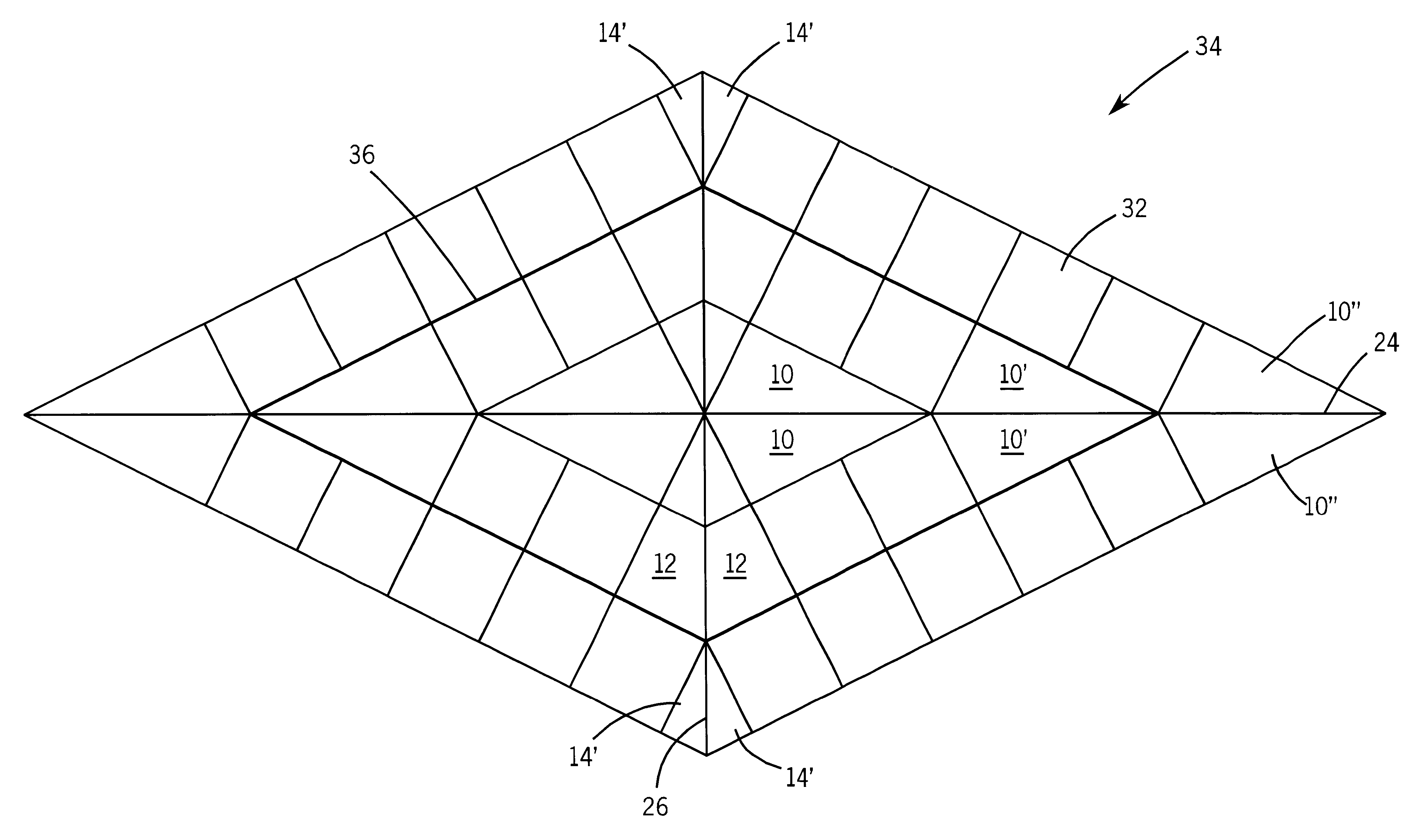

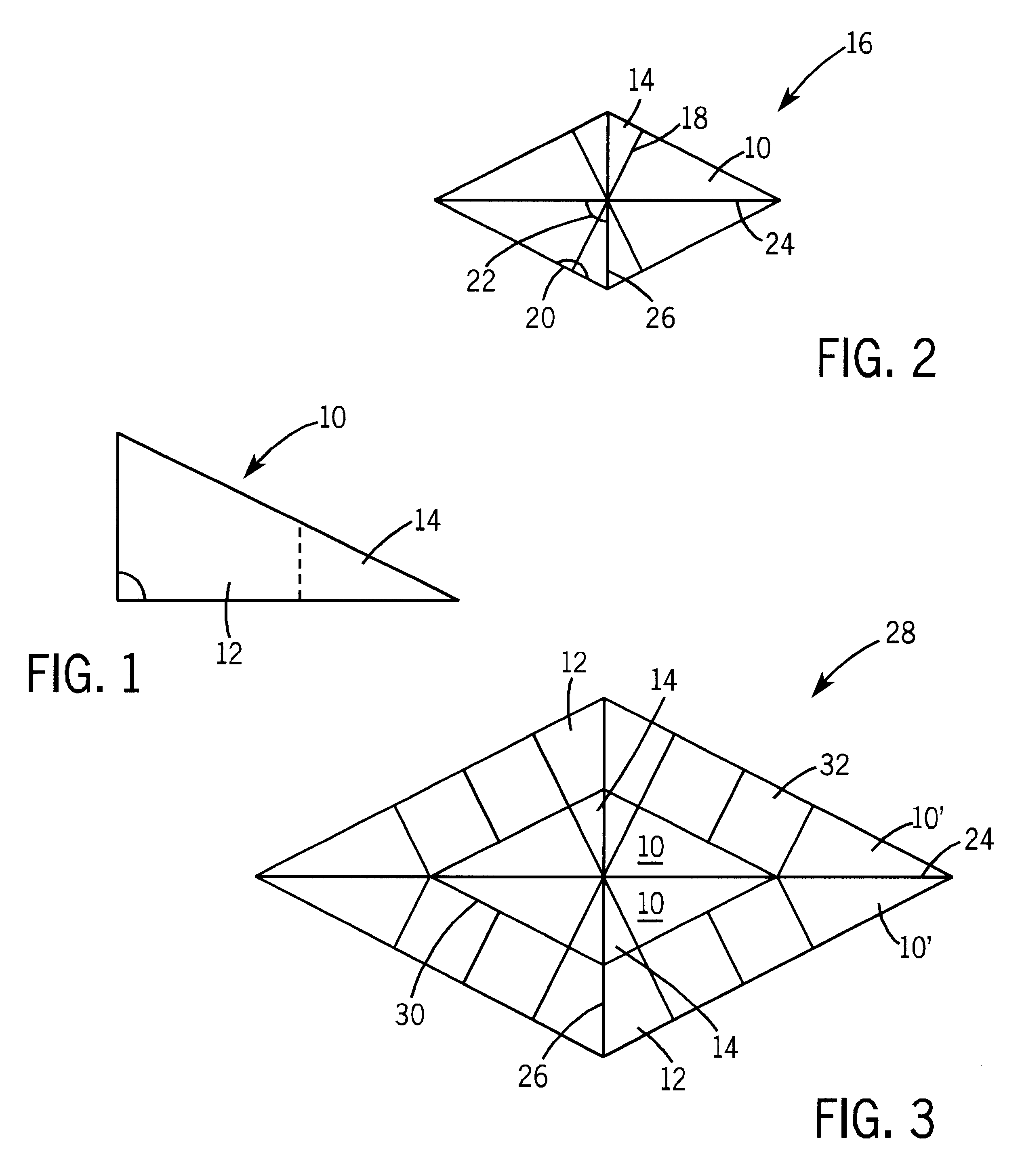

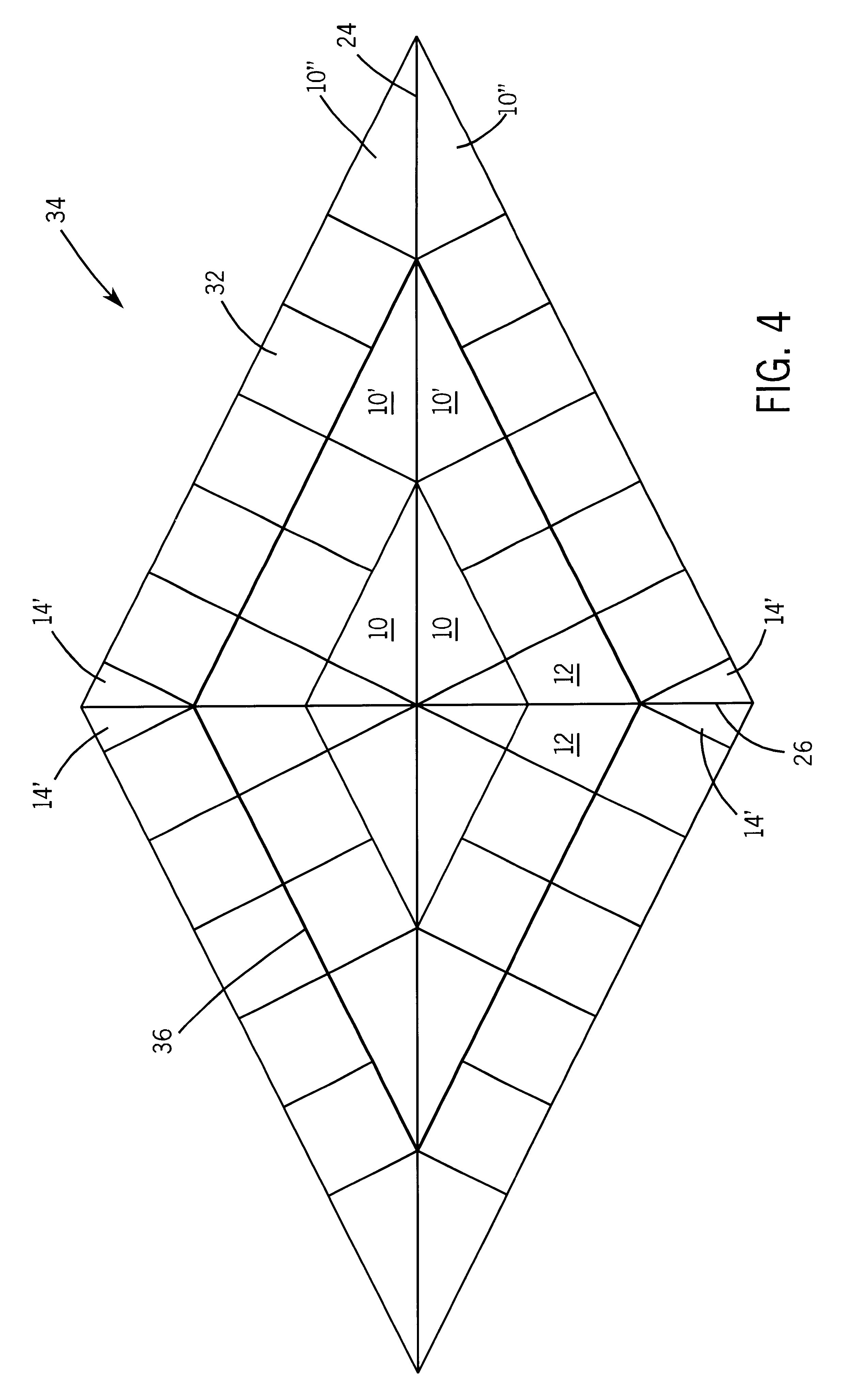

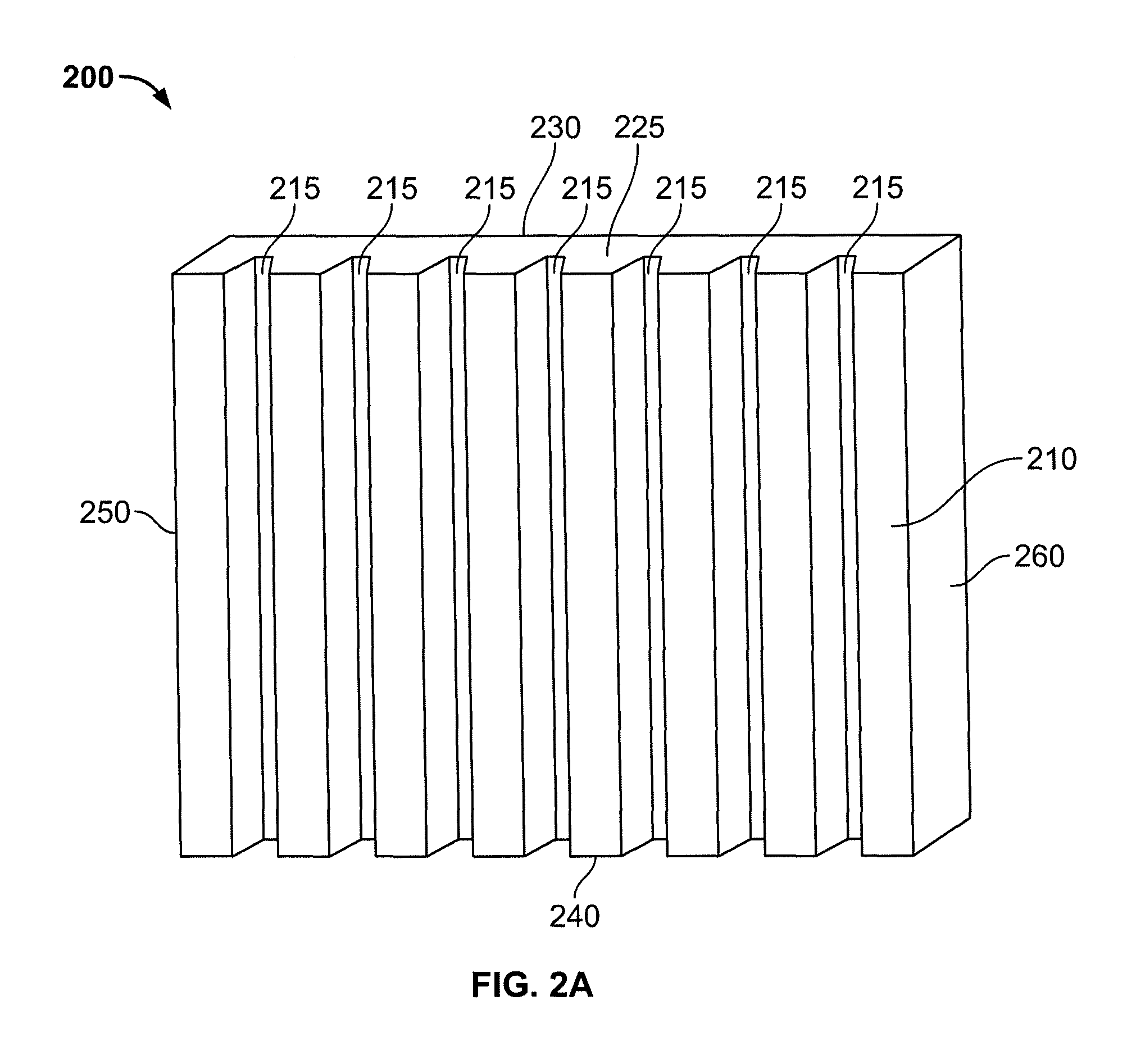

Modular roofing system and assembly

InactiveUS6415570B1Optimize manufacturing efficiencyMinimize wasteBuilding roofsRoof drainageModularityEngineering

Owner:FRANCIS STEPHEN R

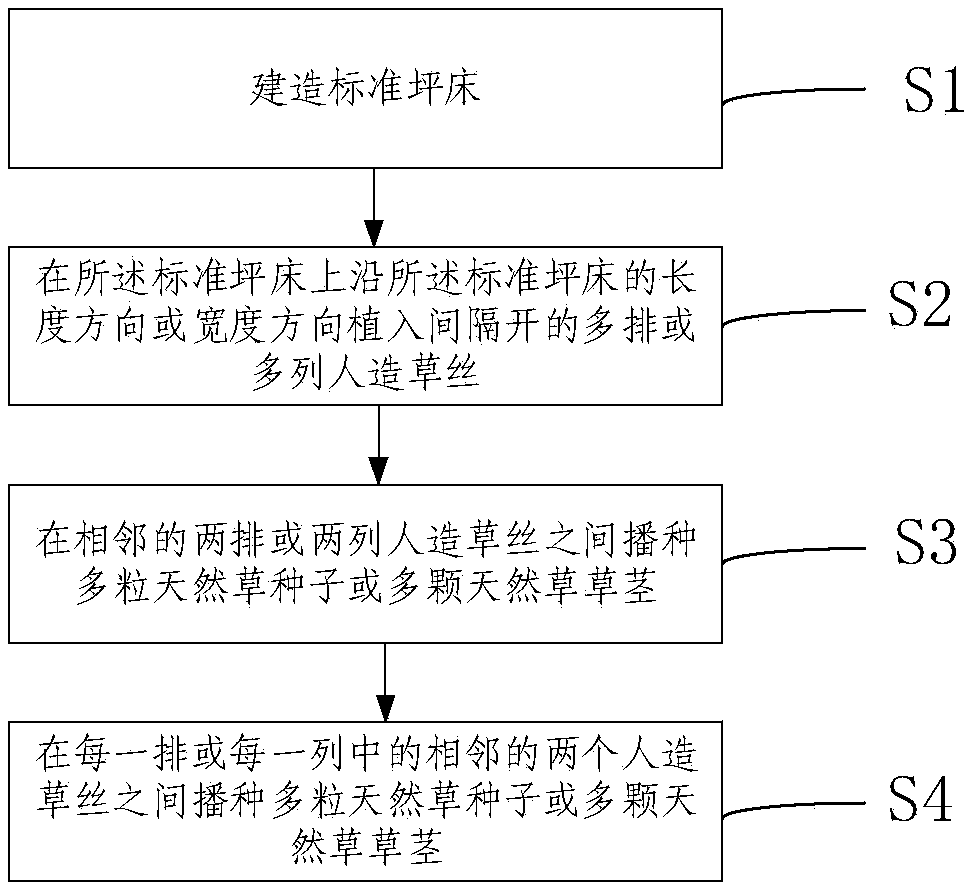

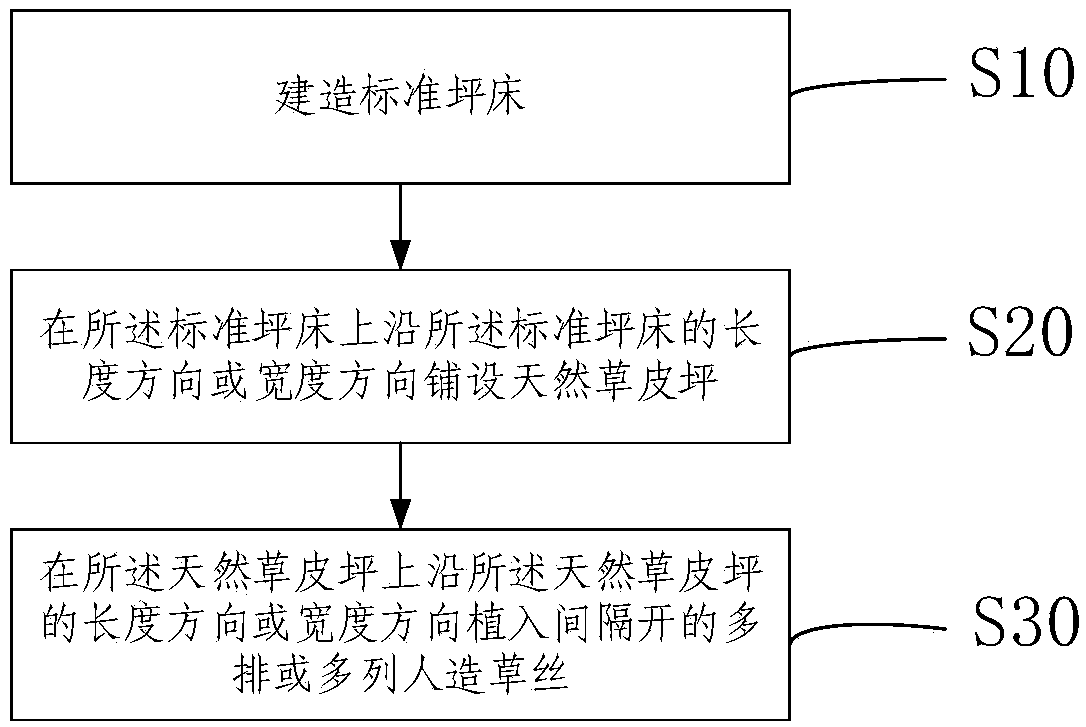

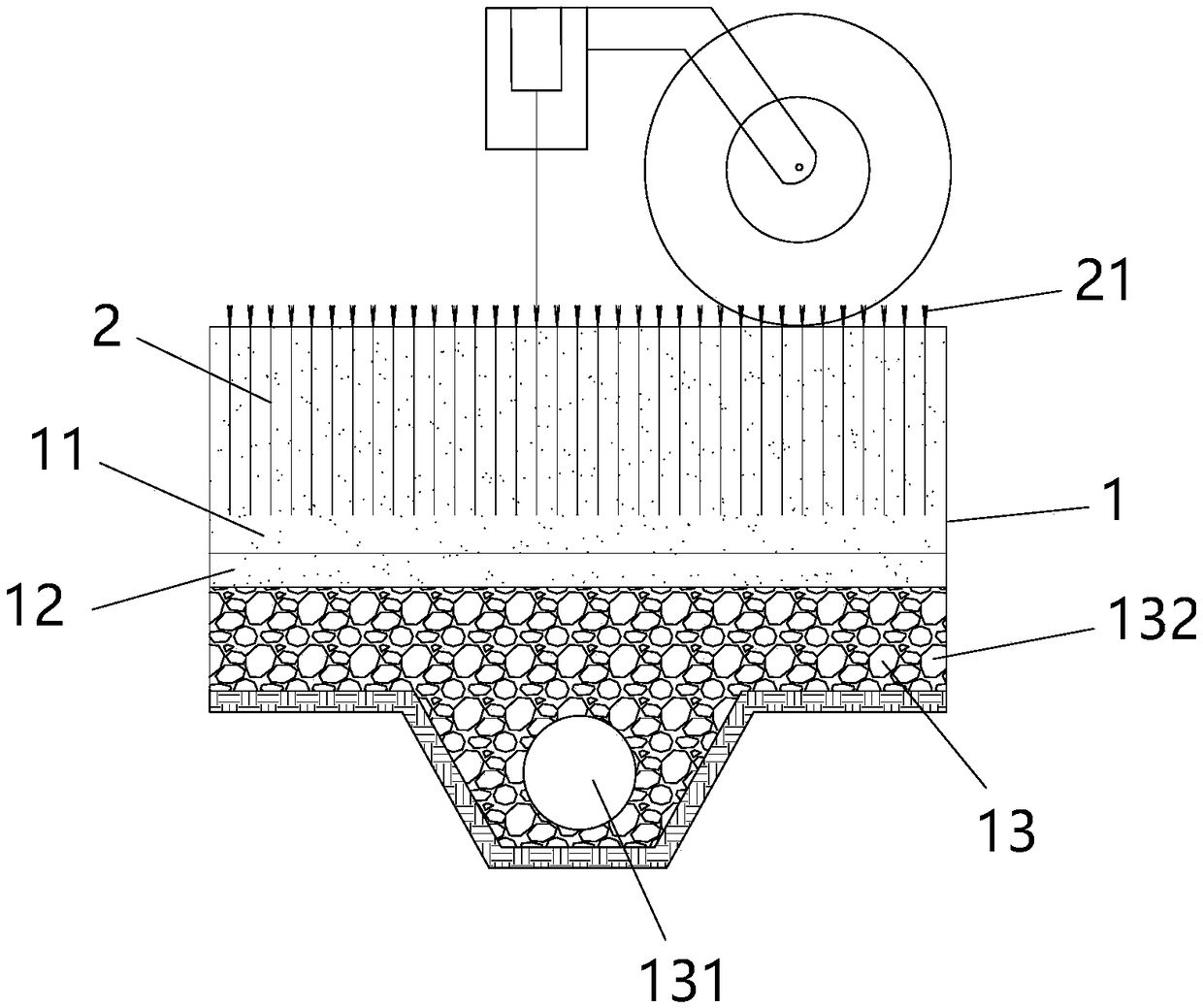

Method for building and planting natural grass and artificial grass mixed lawn and mixed lawn

PendingCN109197399AReduce harmImprove buffering effectHops/wine cultivationTurf growingHigh resistanceRoot growth

The invention relates to the technical field of lawn building and planting, and discloses a method for building and planting a natural grass and artificial grass mixed lawn and a mixed lawn. The method comprises the steps of building a standard lawn bed; planting multiple spaced rows or columns of artificial grasses on the standard lawn bed along the length direction or the width direction of thestandard lawn bed; sowing multiple natural grass seeds or multiple natural grass stems between two adjacent rows or columns of artificial grasses; sowing multiple natural grass seeds or multiple natural grass stems between two adjacent artificial grasses in each row or each column. The method has the advantages of high use frequency, high resistance, good quality, ability of promoting the root growth of the natural grasses and wide application.

Owner:BEIJING TEAMRUN TECH DEV CO LTD

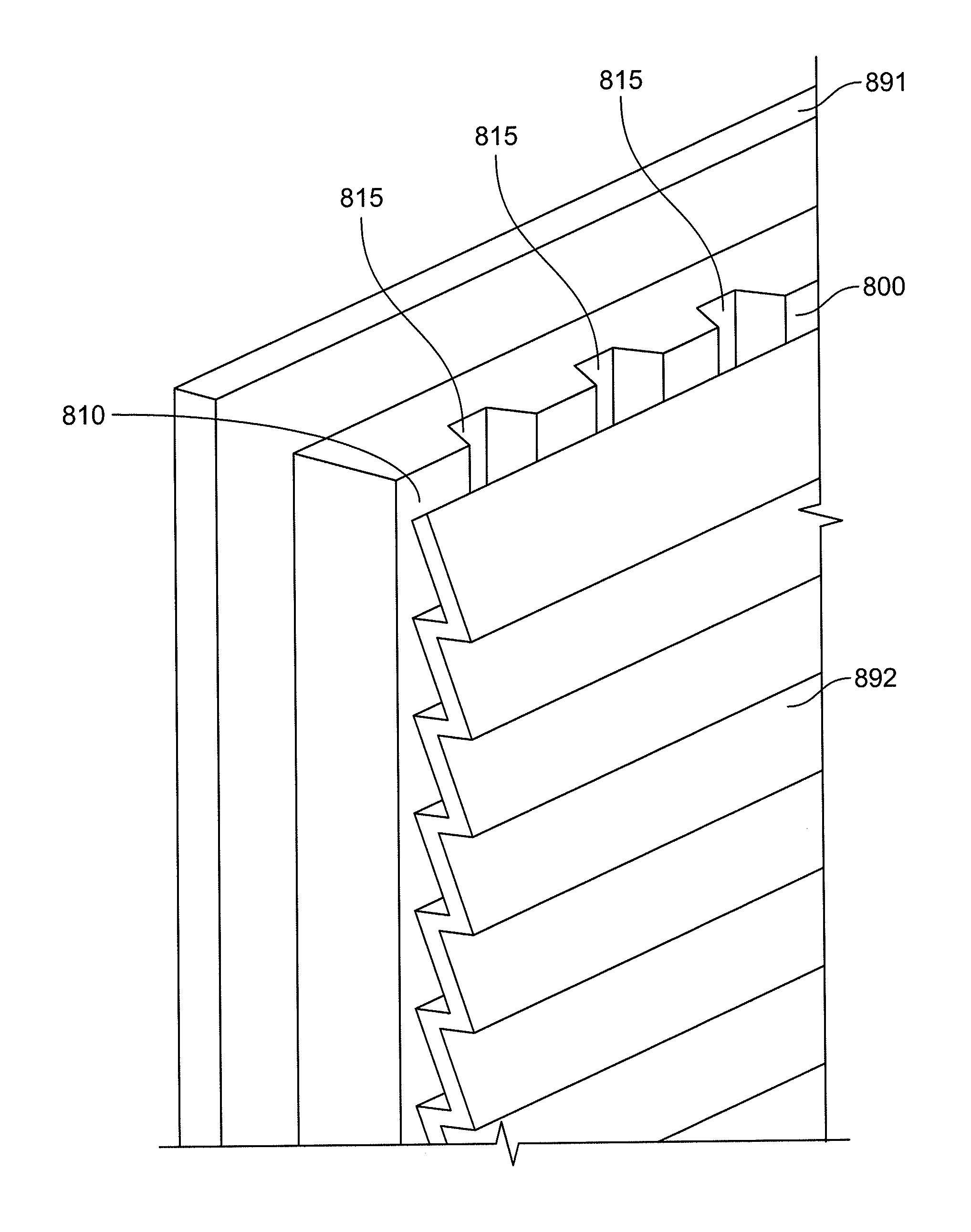

Underlayment with improved drainage

ActiveUS8572917B2Increase drainage rateReduce water penetrationBuilding repairsFoundation engineeringEngineering

An underlayment with improved drainage is disclosed. Particularly, the invention relates to an underlayment board having a first surface and a second surface, wherein the board further includes a top edge and a bottom edge and includes at least one channel defined in the first surface with each of the at least one channel extending from the top edge to the bottom edge to form a drainage path therebetween. More particularly, the underlayment board can include at least one funnel defined proximate at least the top edge or the bottom edge, wherein the at least one funnel is in fluid communication with a corresponding one of the at least one channel. A method of finishing an exterior of a structural substrate and a building assembly are also disclosed.

Owner:KINGSPAN INSULATION LLC

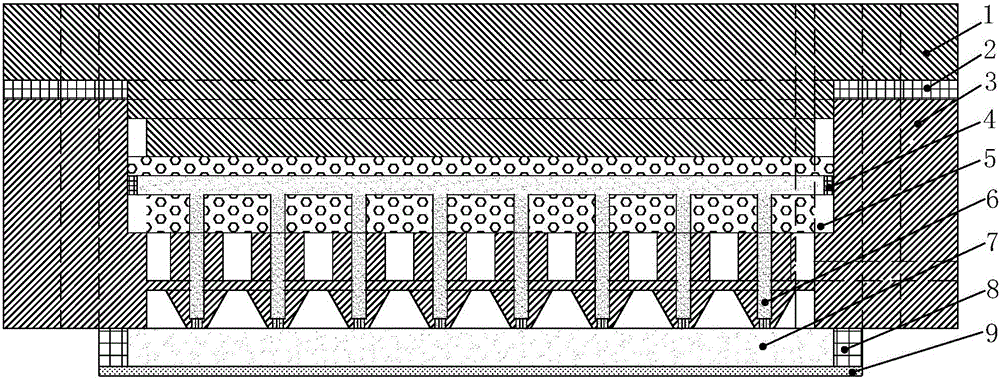

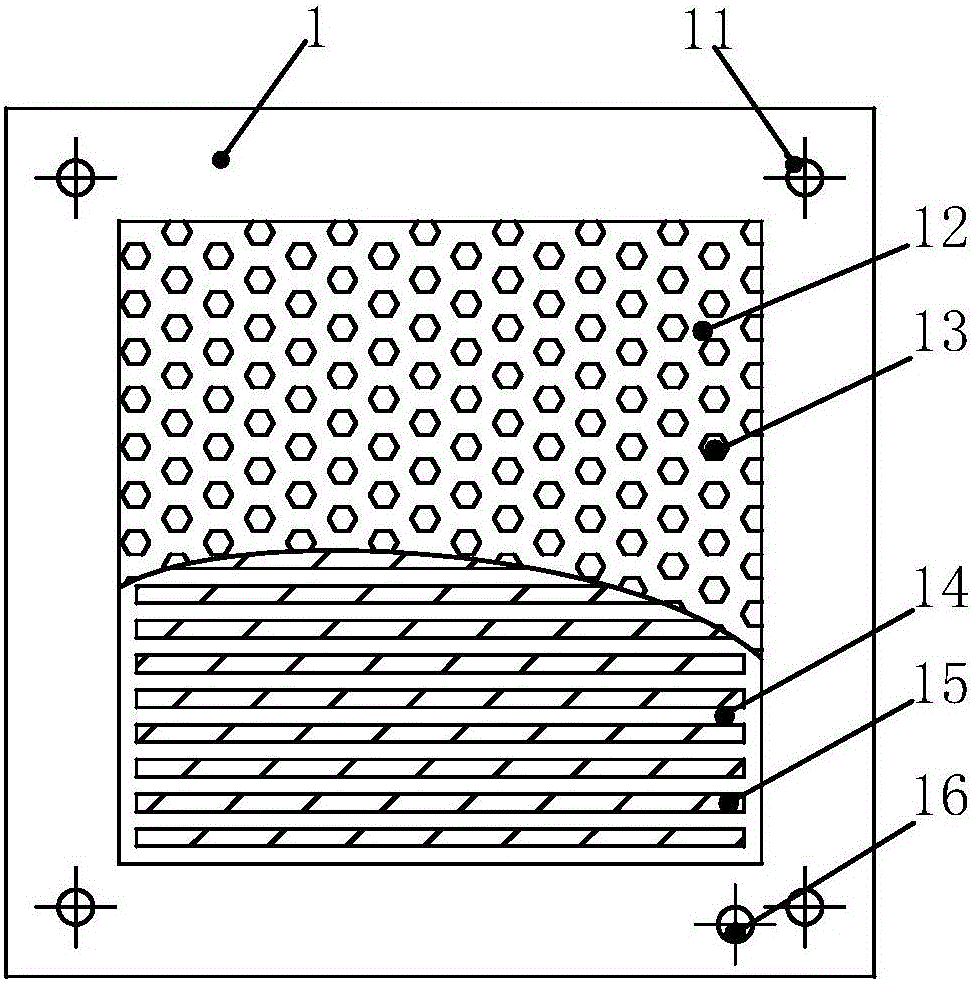

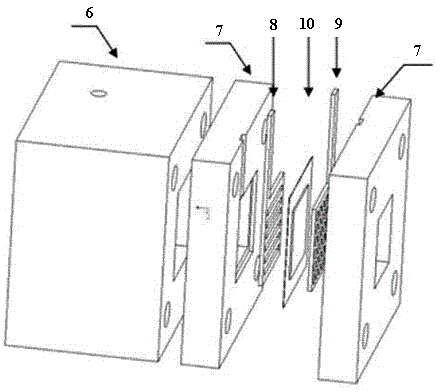

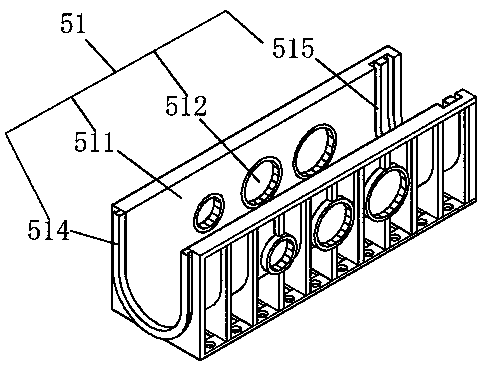

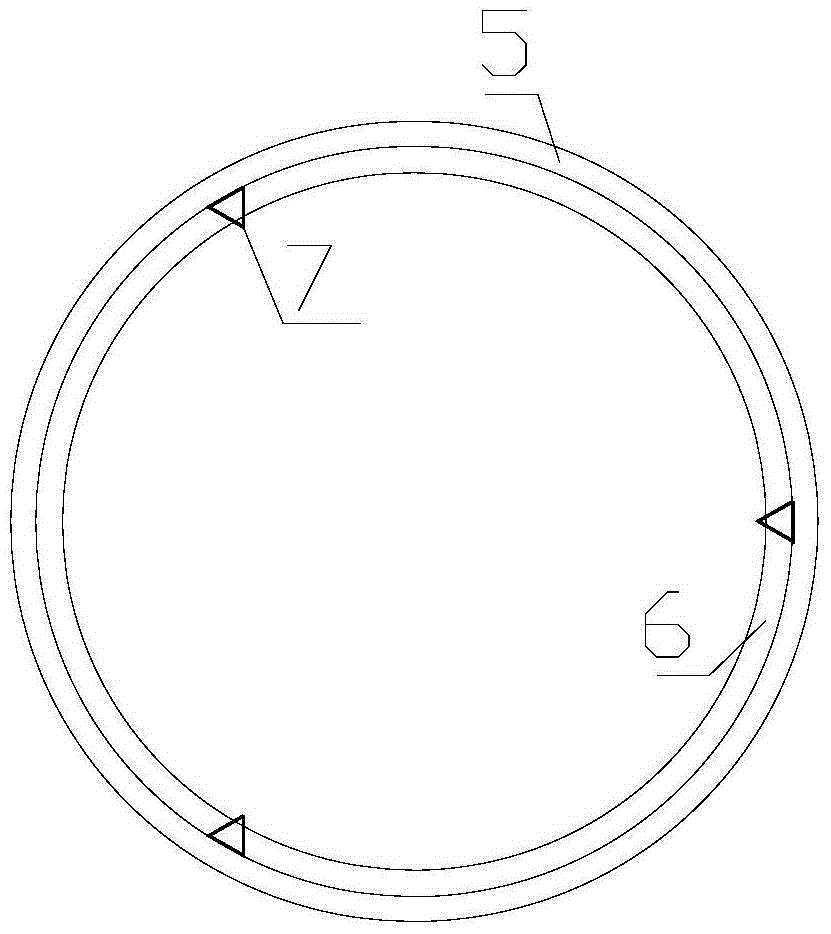

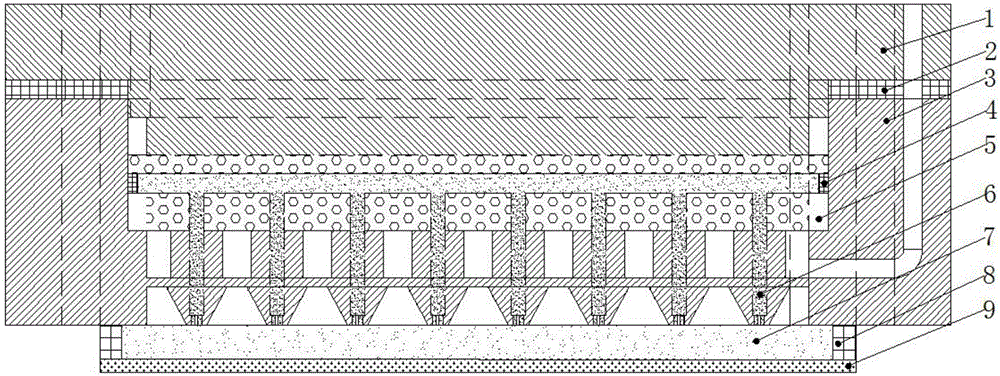

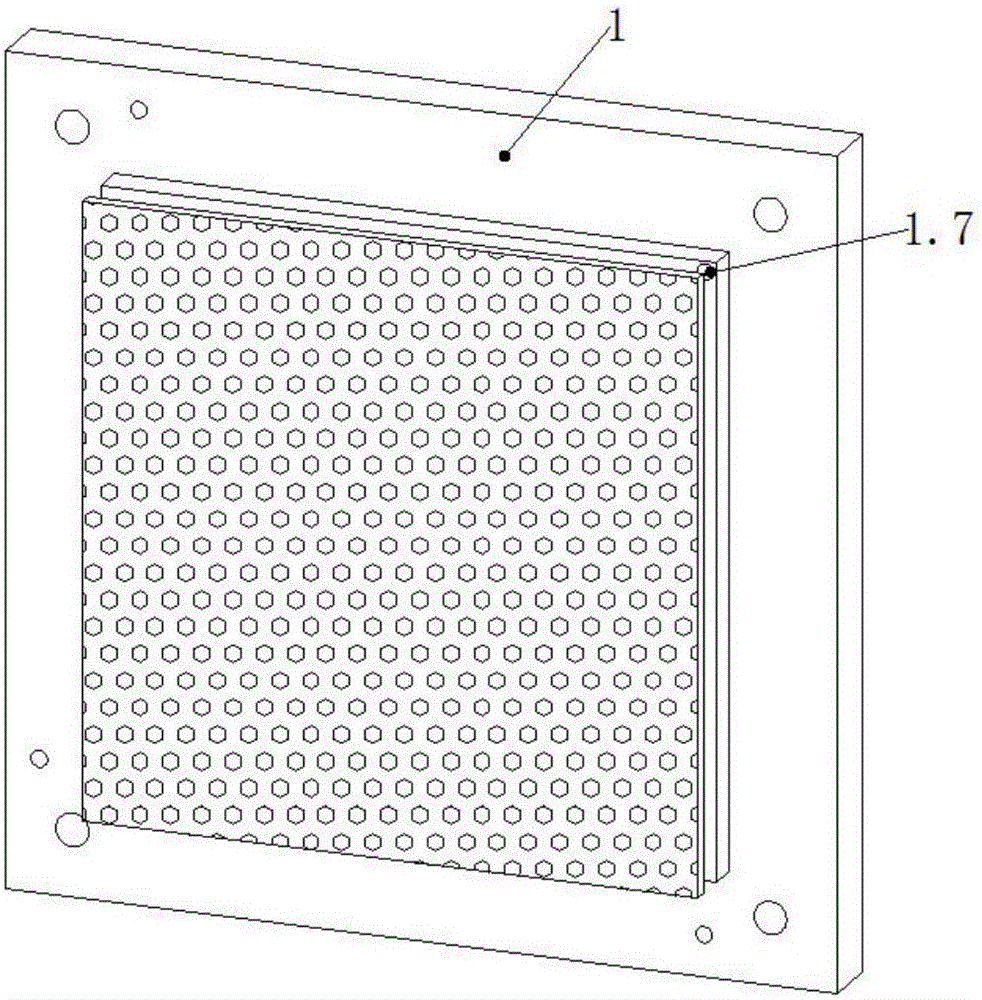

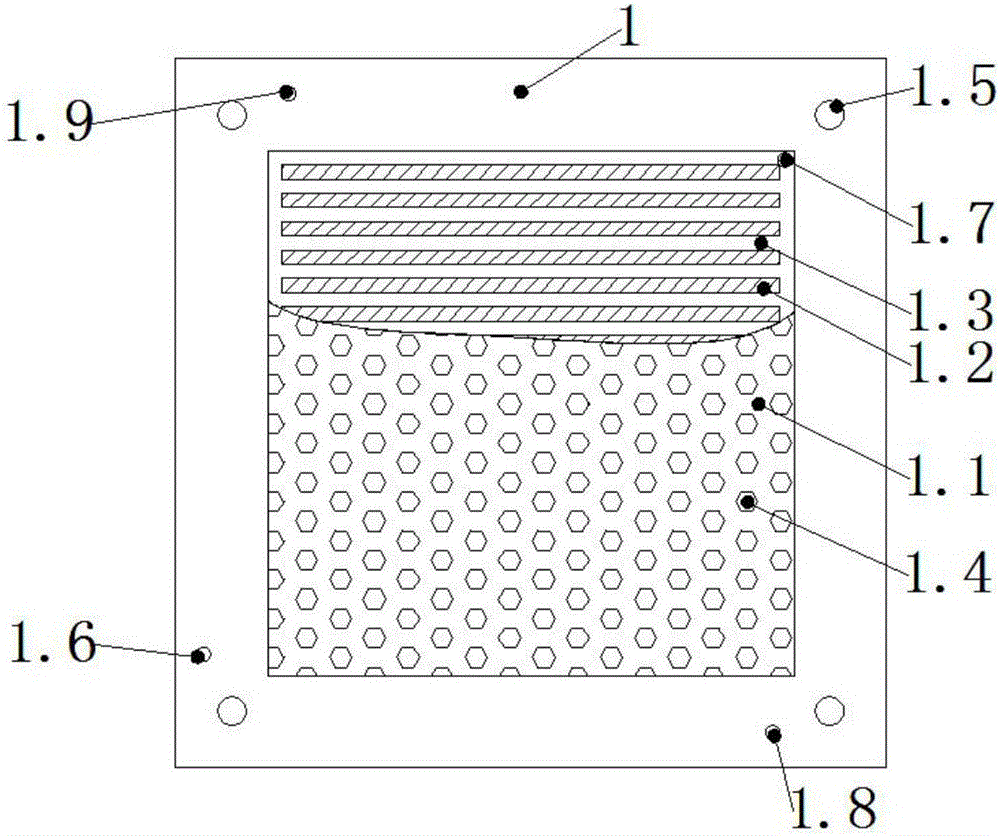

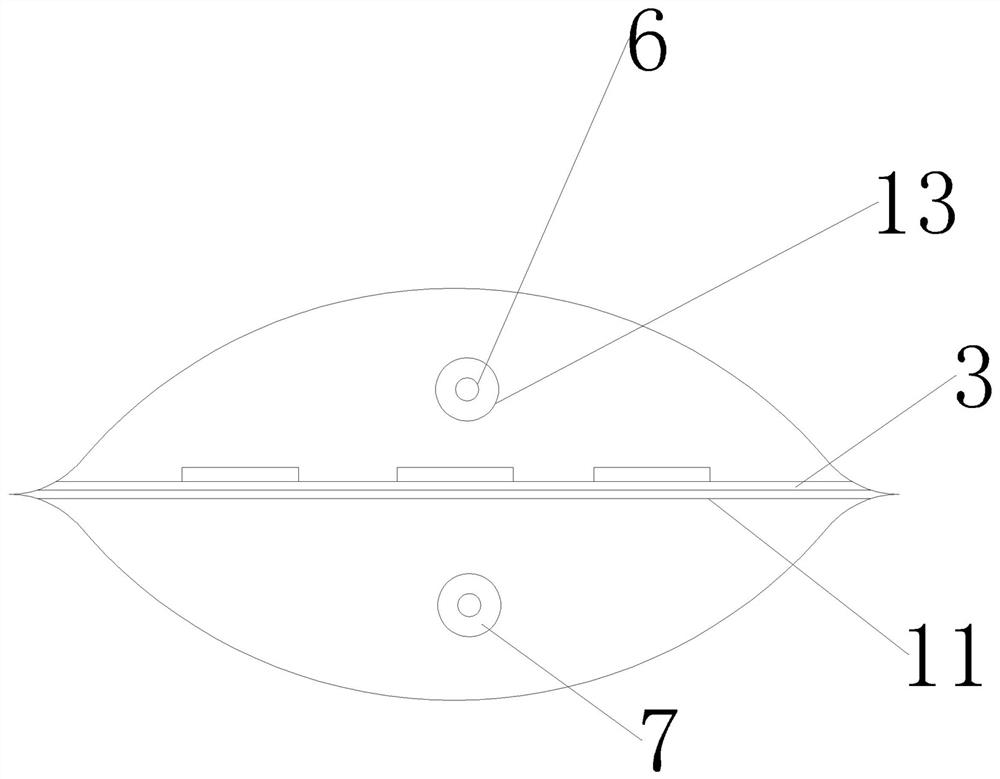

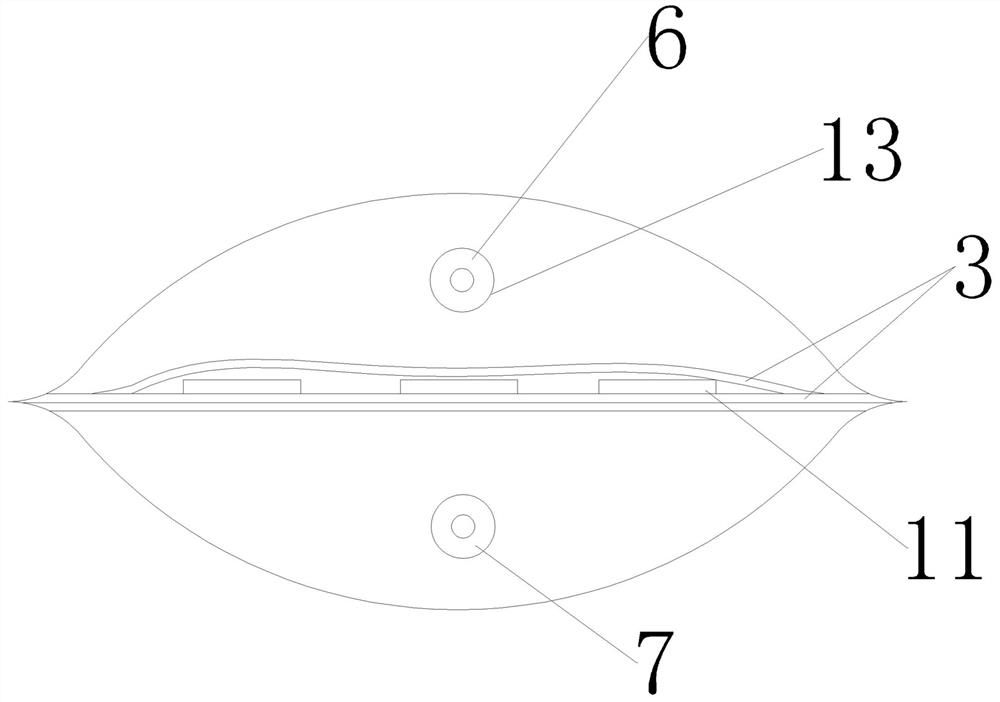

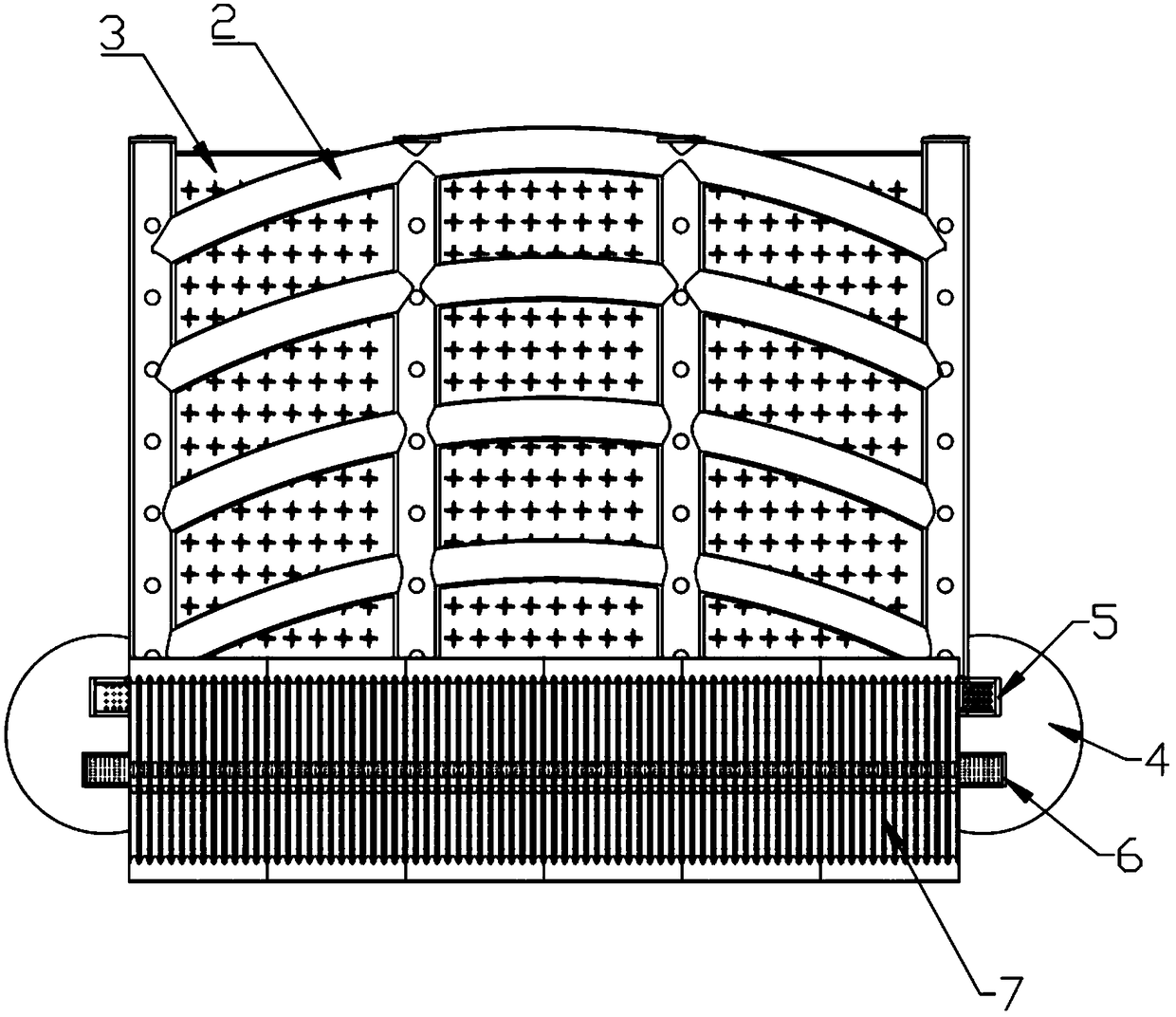

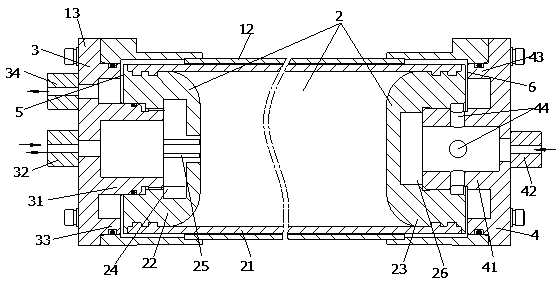

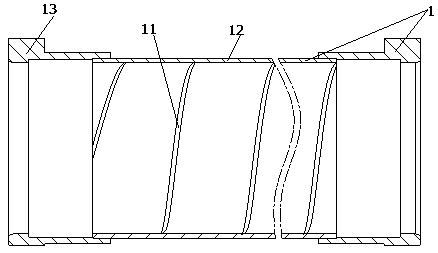

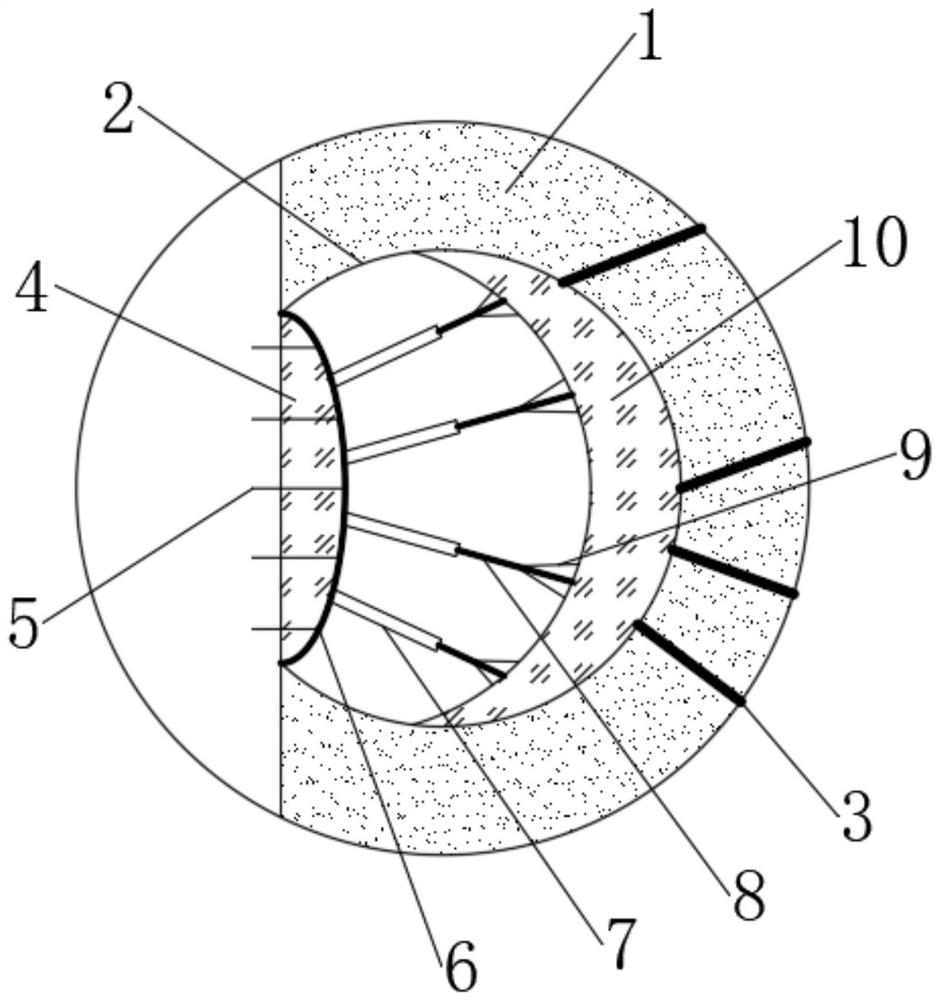

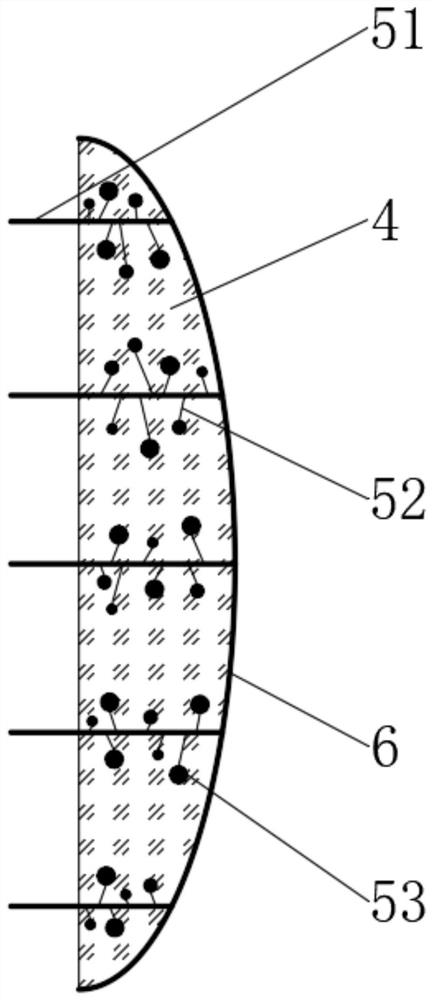

Negative electrode flow field plate bionic structure capable of improving drainage performance of fuel cell

InactiveCN105742667AIncrease drainage ratePrevent floodingCollectors/separatorsFuel cellsEngineering

The invention relates to the technical field of fuel cells, and specifically to a negative electrode flow field plate bionic structure capable of improving the drainage performance of a fuel cell. The bionic structure comprises an upper supporting layer, an outer gasket, a negative electrode flow field plate, an inner gasket, a lower supporting layer, a liquid-absorbing material, a negative electrode gas diffusion layer, a gasket and a negative electrode catalyst layer, wherein the outer gasket is arranged between the upper supporting layer and the negative electrode flow field plate; the inner gasket is arranged between the negative electrode flow field plate and the liquid-absorbing material; the negative electrode gas diffusion layer is arranged between the liquid-absorbing material and the negative electrode catalyst layer; and the gasket is arranged between the negative electrode flow field plate and the negative electrode catalyst layer. By adoption of the structure, the design of the bionic structure can better satisfy the bioengineering principle, so that the drainage speed of the fuel cell can be improved to a large extent; the bionic structure can be widely applied to fuel cells of multiple specifications; and a water-logging phenomenon in the fuel cell can be effectively prevented.

Owner:WUHAN UNIV OF TECH

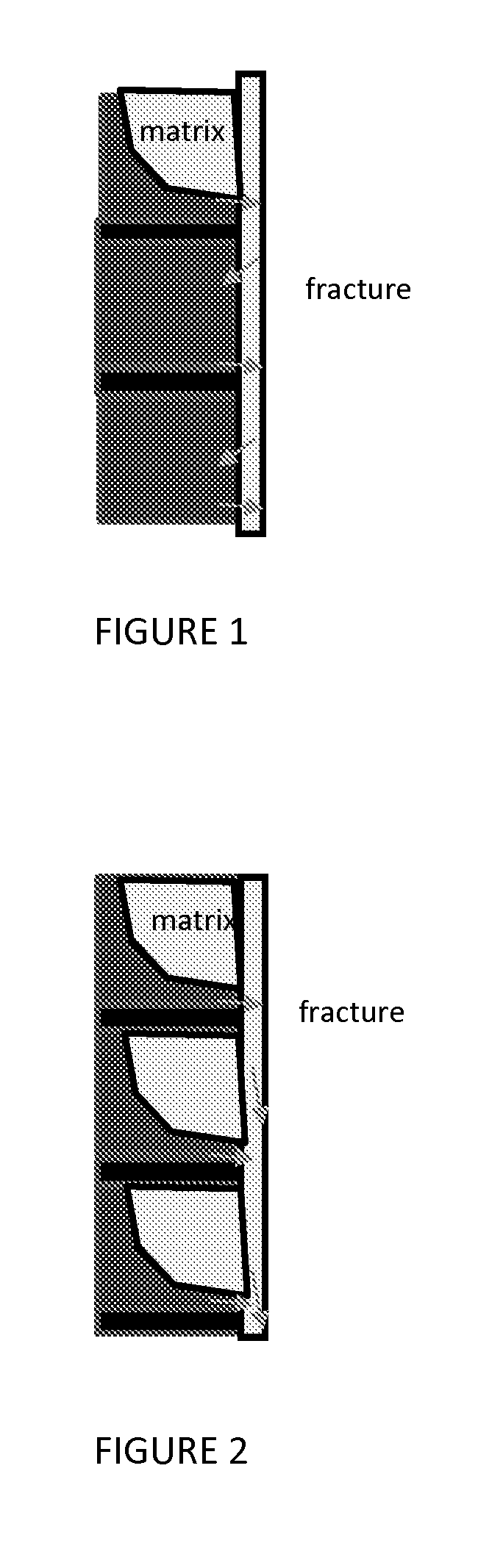

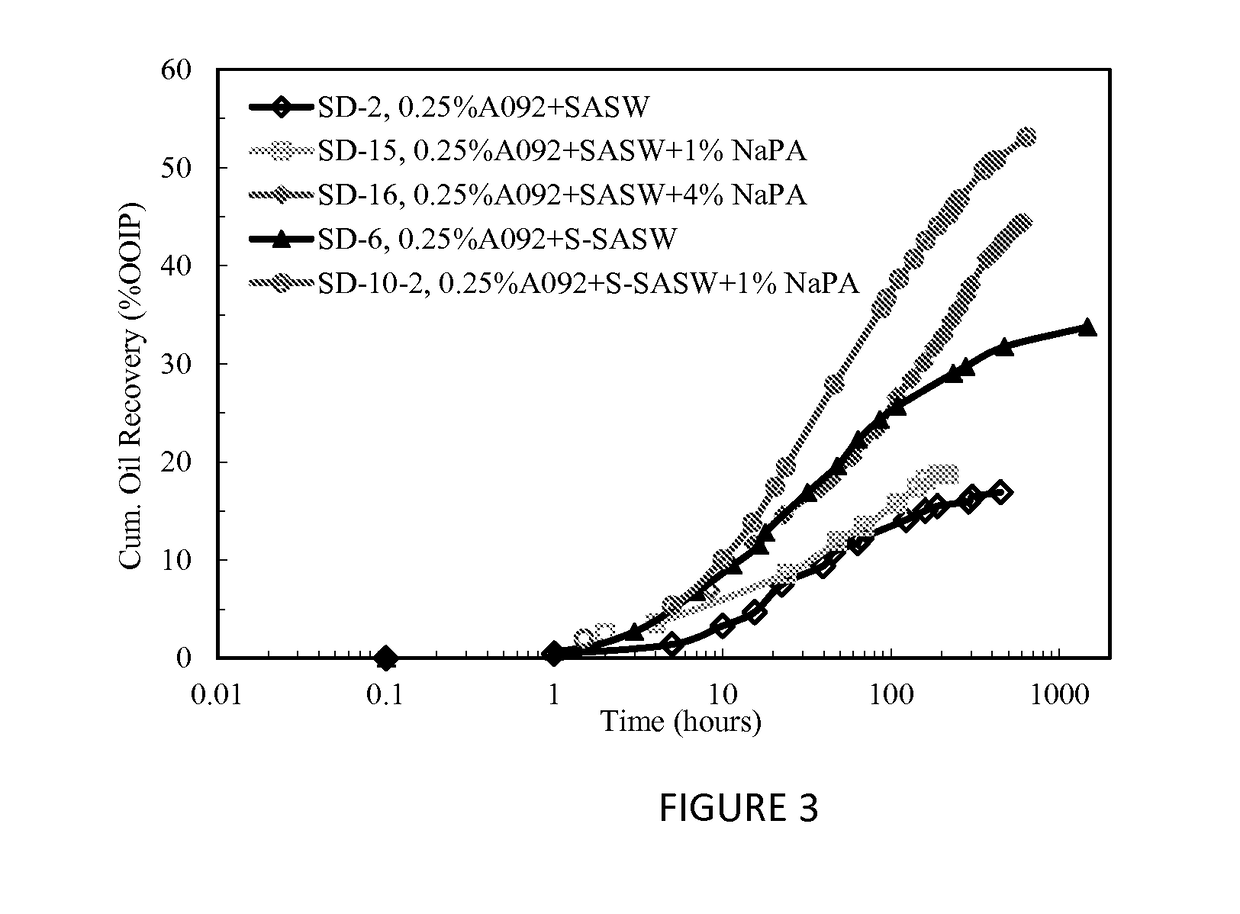

Method to increase gravity drainage rate in oil-wet/mixed-wet fractured reservoir

InactiveUS20170137696A1Increase oil drainage rateOil reimbibition can be preventedFluid removalDrilling compositionGravitationIncreased Gravity

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

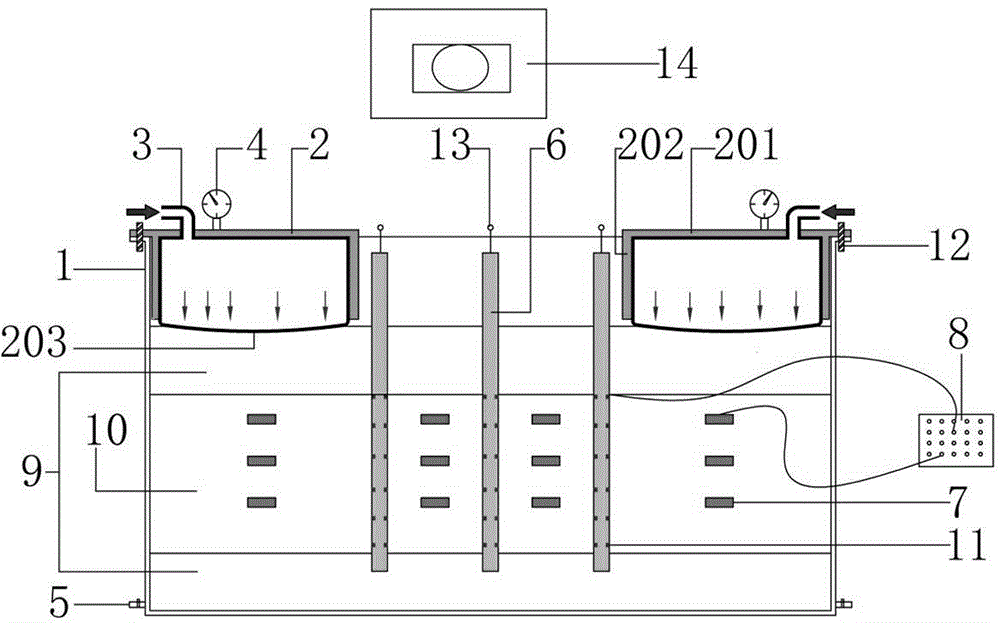

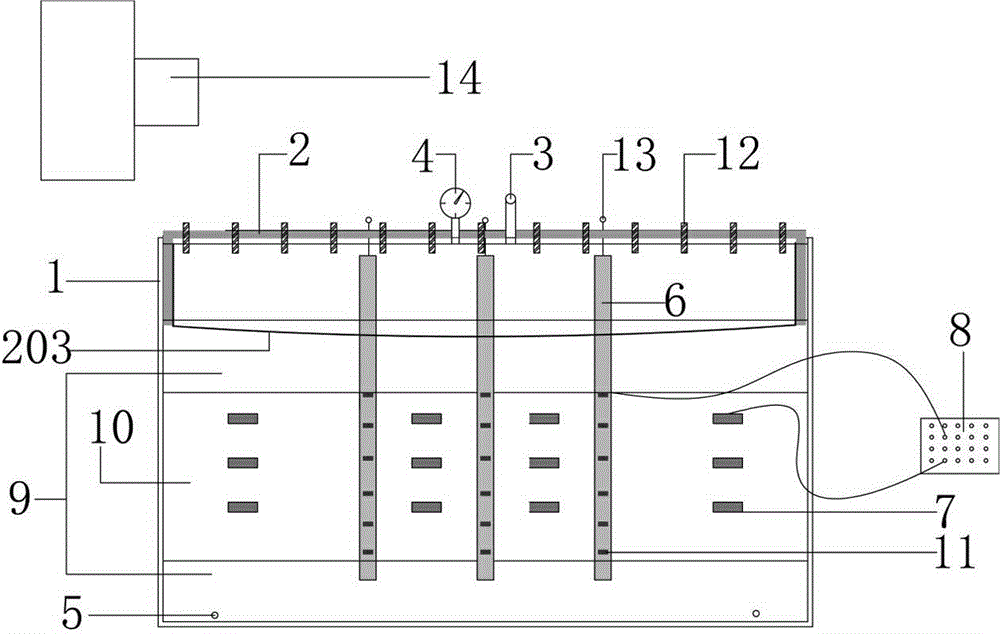

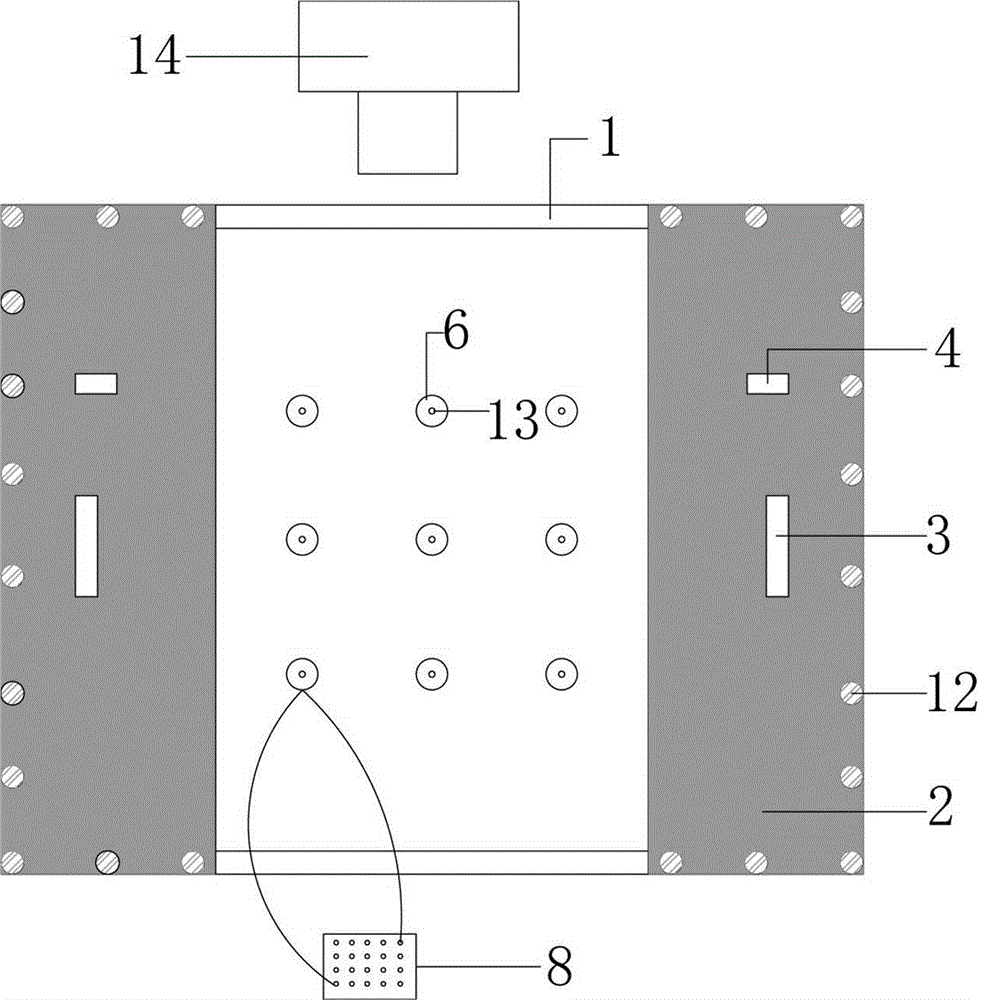

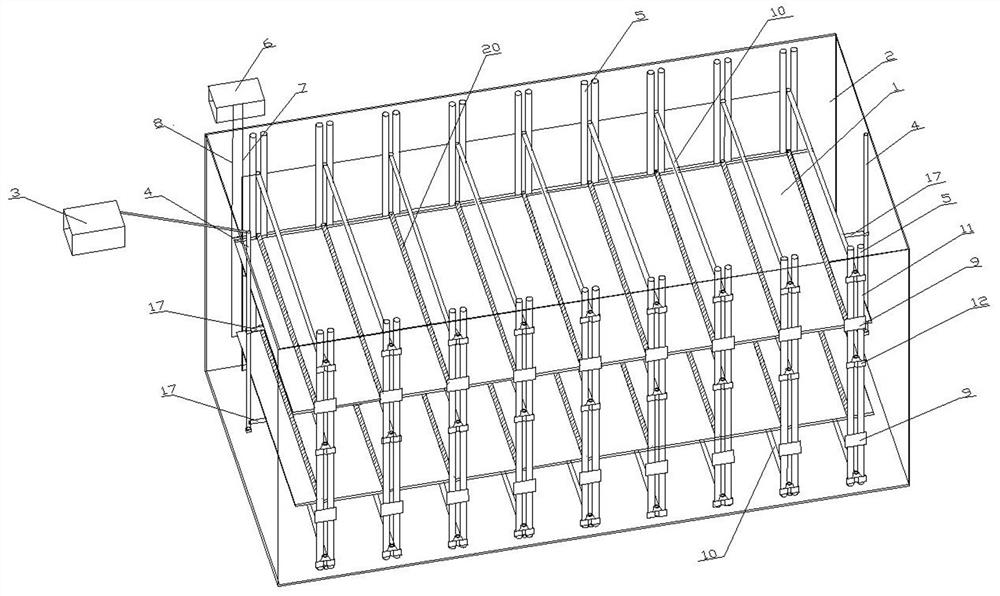

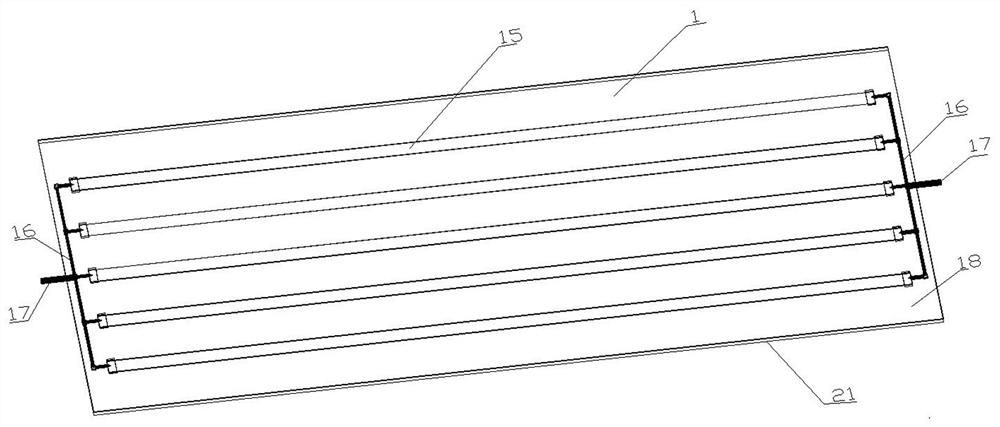

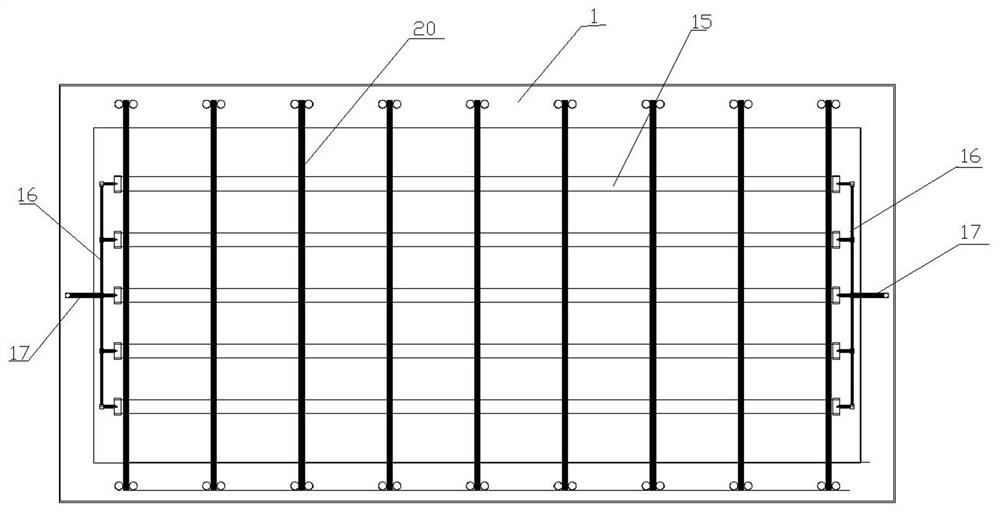

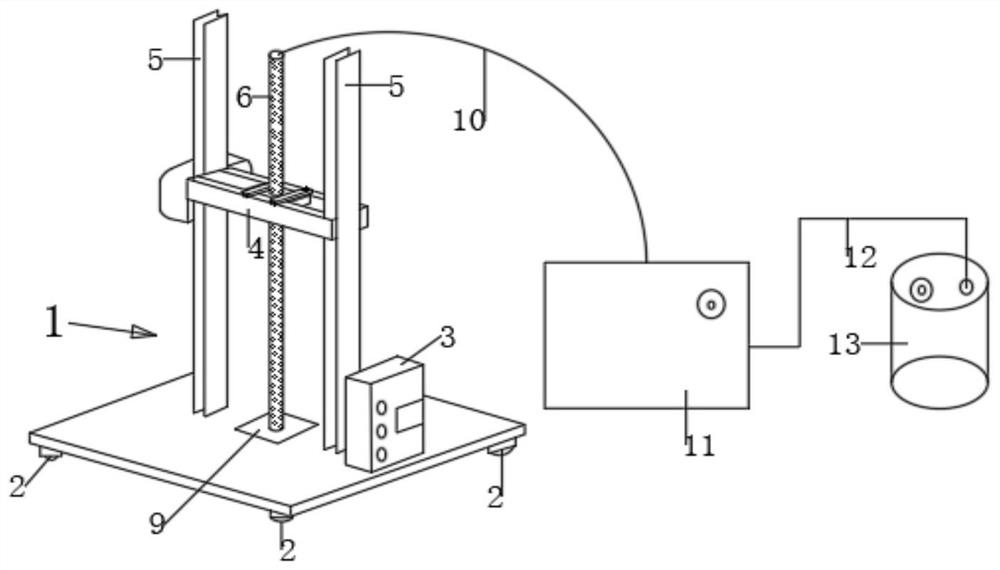

Device for testing stress condition of pile group under asymmetric edge loads

InactiveCN104988956AIncrease drainage rateHigh precisionFoundation testingStress conditionsEngineering

The invention discloses a device for testing the stress condition of a pile group under asymmetric edge loads. The device is characterized in that the device comprises a testing case, a loading case, model piles, a pore pressure meter, an acquisition instrument and a high definition camera, a layered soil body is arranged in the testing case, and the acquisition instrument and the high definition camera are arranged outside the testing case. The device for testing the stress condition of the pile group under the asymmetric edge loads is advantaged in that 1. the soil body is loaded by high pressure air, during the loading process, the load application value can be controlled easily, and the condition of asymmetric edge loads can be simulated easily; and 2. the high pressure air loading manner is configured in a way that air pressure is applied to the soil body through a rubber film, the soil body is contacted with the load flexibly, and the condition that heaped loads are applied to the surface of soft soil in actual engineering can be met.

Owner:HOHAI UNIV

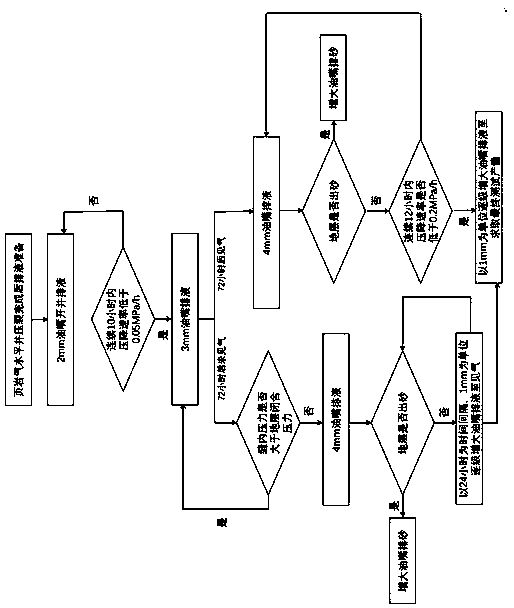

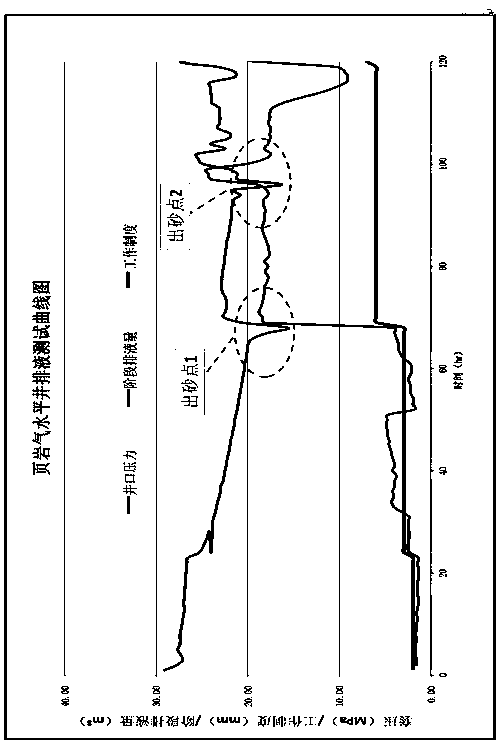

Sand control flowback process after shale gas horizontal well fracturing

ActiveCN110173225AReduce the risk of sand productionReduced risk of sand burying horizontal sectionsFlushingShale gasWellhead

The invention discloses a sand control flowback process after shale gas horizontal well fracturing. A 2mm oil nozzle is adopted for carrying out well opening liquid discharge on a fractured shale gashorizontal well, the well opening pressure changes are recorded, and if the pressure drop rate within continuous 10 hours is lower than 0.05MPa / h, the oil nozzle is increased to a 3mm oil nozzle for draining; after well opening draining is carried out for 72 hours, and measures are taken according to whether gas breakthrough appears or not; if gas breakthrough does not appear, according to the well opening pressure, the pressure in the well bottom seam is calculated, and if the pressure in the seam is larger than the closing pressure of the regional stratum, the 3mm oil nozzle is continuouslyadopted for draining until the stratum is closed; if the pressure in the seam is smaller than the regional stratum closing pressure, at the moment, the stratum is closed, if gas breakthrough appears,the oil nozzle is directly increased to a 4mm oil nozzle for draining, on the premise that the sand production does not appear in the stratum, when the pressure drop rate is lower than 0.2 MPa / h within continuous 12 hours, the oil nozzle is increased stage by stage with 1 mm as the unit to the test work system, and the well test yield is solved. According to the method, in the flowback process, the crack closing degree, the gas and liquid ratio and the well cylinder flow state are judged in real time, the flowback system is optimized in real time, and the shaft sand production rate at the flowback primary period can be effectively controlled.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

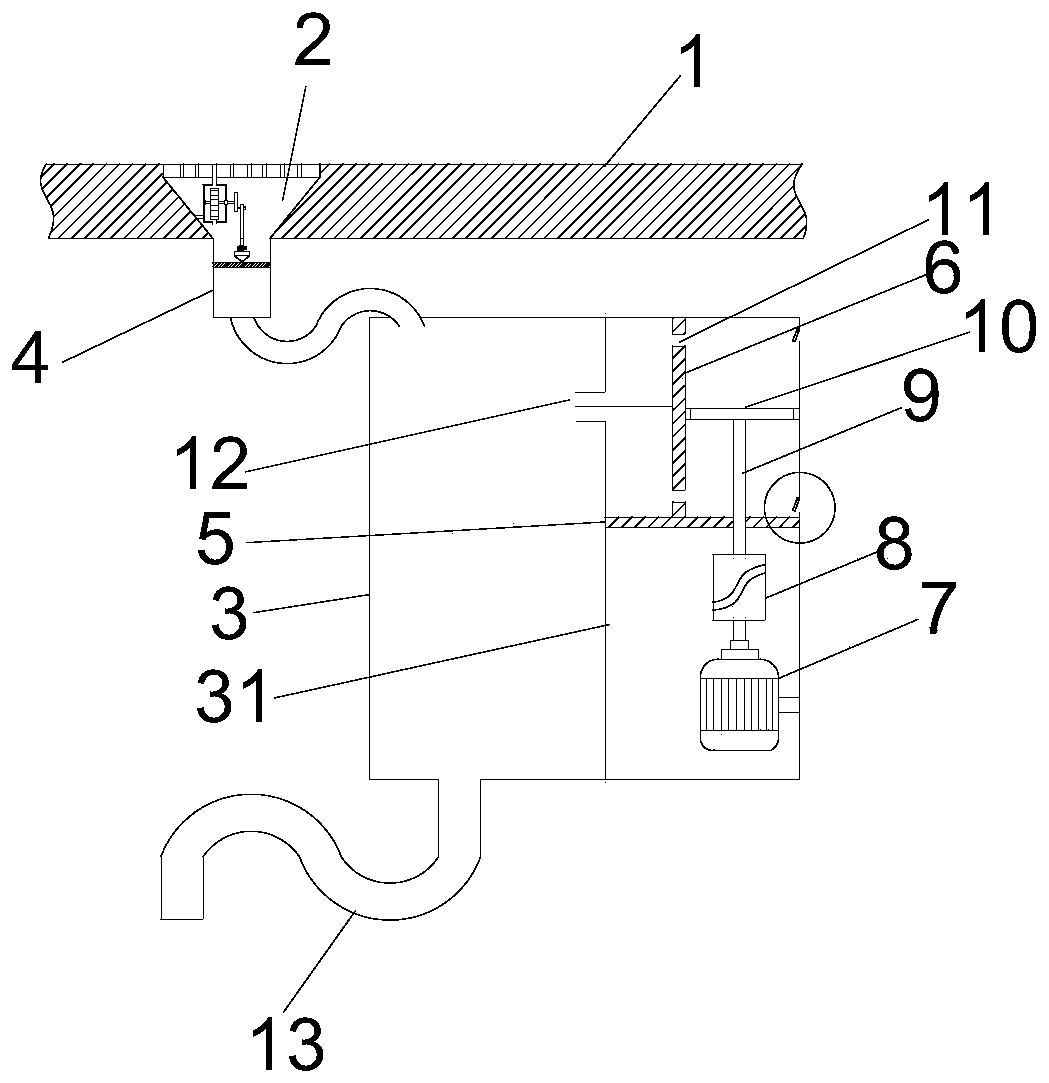

Highway engineering-based pavement drainage device and method

ActiveCN111364354AAvoid cleaningAvoid cloggingBridge structural detailsStationary filtering element filtersWater storageWater discharge

The invention discloses a highway engineering-based pavement drainage device and method. The pavement drainage device comprises a viaduct body, gutter channels and a shell; a plurality of V-shaped gutter channels are pre-buried in the two sides of the viaduct body, and cleaning mechanisms are arranged in the gutter channels; a water guide pipe is connected to the lower portion of each gutter groove and extends to the lower portion of the viaduct body, and the other end of each gutter pipe communicates with the upper portion of the shell; and a pressurizing mechanism is arranged in the shell, and the shell is in a closed state. The cleaning mechanism is arranged in each gutter channel, so that during drainage, a filter screen is effectively cleaned, and influence of sediment deposition in the drainage process on normal drainage is prevented; the pressurizing mechanism is arranged in the shell, and a siphonic effect is formed in a water storage chamber of the shell, so that the instantaneous water discharge amount of flowing water is increased, and the water discharge rate is increased; and a certain cleaning capability is realized through a negative pressure suction effect.

Owner:河南锦路路桥建设有限公司

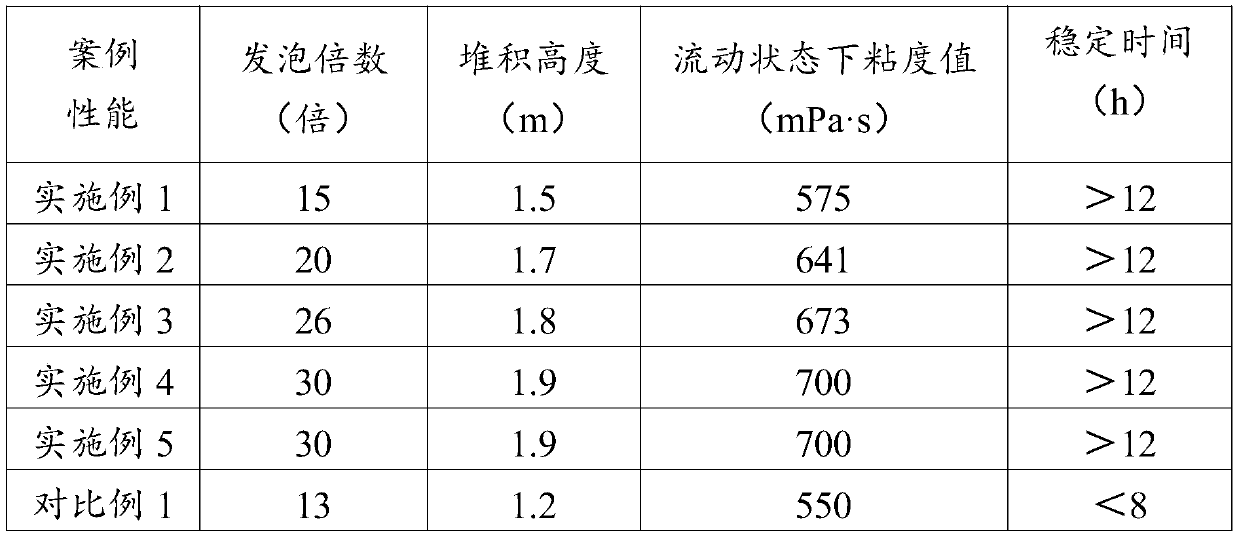

Foam fire preventing and extinguishing material, and preparation method and application thereof

InactiveCN110812771AImprove stabilityImprove heat insulation and flame retardant effectFire rescueFire extinguisherFoaming agentArchitectural engineering

The invention belongs to the technical field of fire extinguishing materials for coal mines, and particularly relates to a foam fire preventing and extinguishing material, and a preparation method andapplication thereof. The foam fire preventing and extinguishing material provided by the invention comprises the following preparation raw materials in parts by weight: 2-4 parts of a foaming agent,2.5-3.5 parts of a foam stabilizer, 10-16 parts of expandable graphite and 100 parts of water. Results of embodiments in the invention show that the foam expansion of the foam fire preventing and extinguishing material provided by the invention is up to 15-30 times, so the foam fire preventing and extinguishing material has good foaming performance; meanwhile, the material has good flow diffusivity, and in the flowing state, the material has a viscosity of only 700 mPa.s and foam stabilizing time of longer than 12 h. After being conveyed to an ignition point in a goaf through a grouting pipeline of mine, the foam fire preventing and extinguishing material can be diffused and accumulated in a large area in the goaf and can cover and block low-altitude float coal and high-altitude float coal, and an accumulation height reaches 1.5 m or above.

Owner:ANHUI UNIV OF SCI & TECH

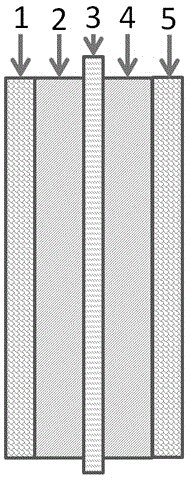

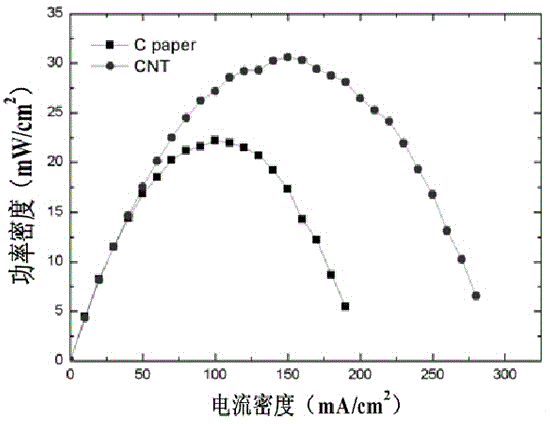

High-stability direct methanol fuel cell membrane electrode based on CNT material

InactiveCN104577147AIncrease drainage rateSolve the problem of cathode floodingCell electrodesFuel cell detailsElectrical batteryInternal resistance

The invention discloses a high-stability direct methanol fuel cell membrane electrode based on a CNT material, and belongs to the technical field of proton exchange membrane fuel cells. The membrane electrode is composed of an anode diffusion electrode, a Nafion proton exchange membrane and a cathode diffusion electrode, wherein a diffusion layer of the cathode diffusion electrode is prepared from CNT material paper. According to the membrane electrode disclosed by the invention, the structure of a direct methanol fuel cell can be simplified; the volume of the fuel cell is reduced; meanwhile, the water logging problem on one side of the cathode in the direct methanol fuel cell is well solved, so that the oxygen mass transfer of the cathode is increased; the stability of the cell for lastingly working for a long period of time is improved; the contact resistance between a collector plate and the membrane electrode is significantly reduced; the problem of internal resistance increase caused by PTFE used as the mass transfer baffle layer in a traditional structure is avoided; and the performance of the battery is improved.

Owner:HARBIN INST OF TECH

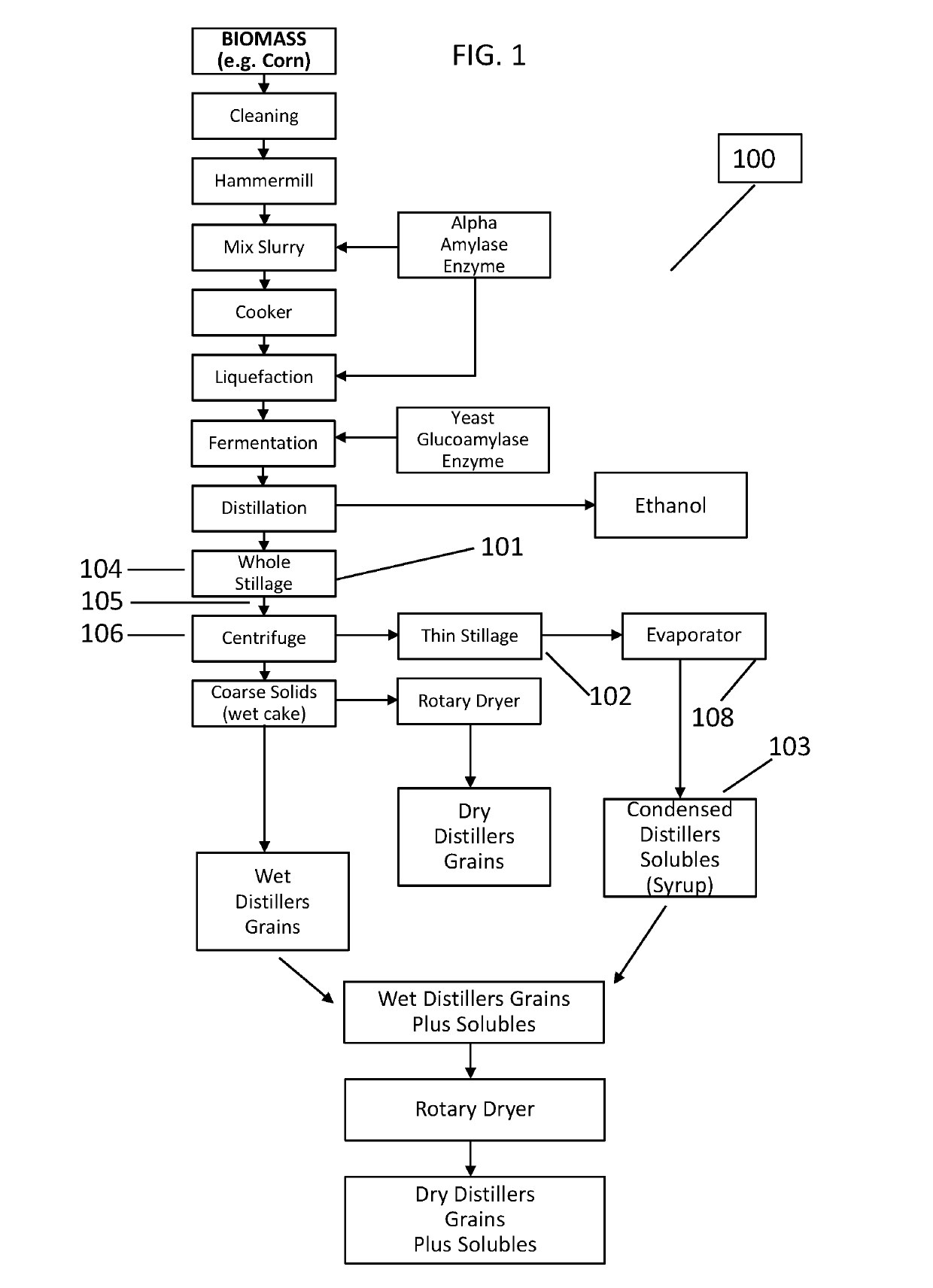

Methods To Lower Oil Content In Distillers Grains

ActiveUS20190159479A1Reduce surface tensionHigh oil contentFatty oils/acids recovery from wasteBy-product recoveryChemistryEthanol

Owner:BUCKMAN LAB INT INC

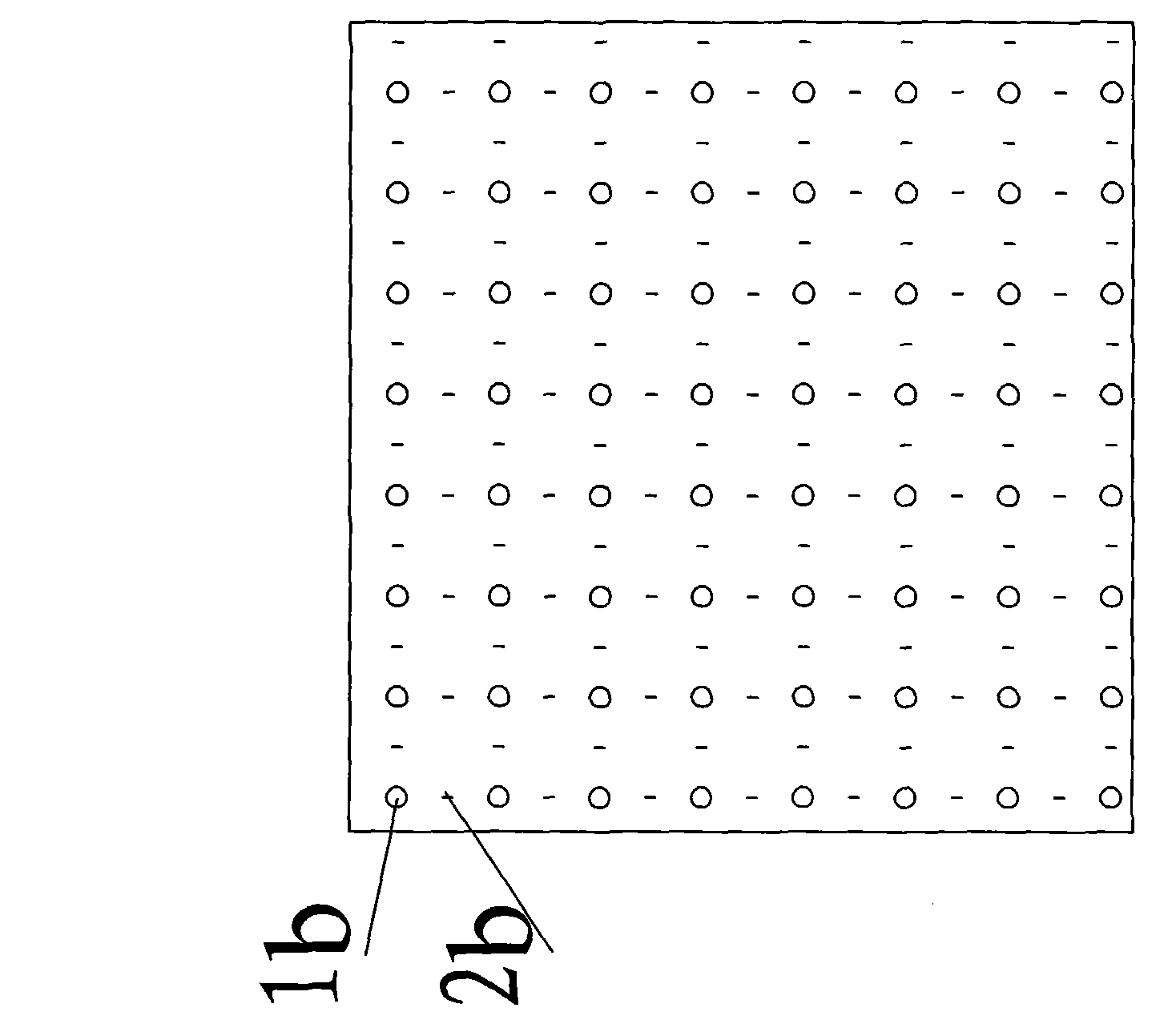

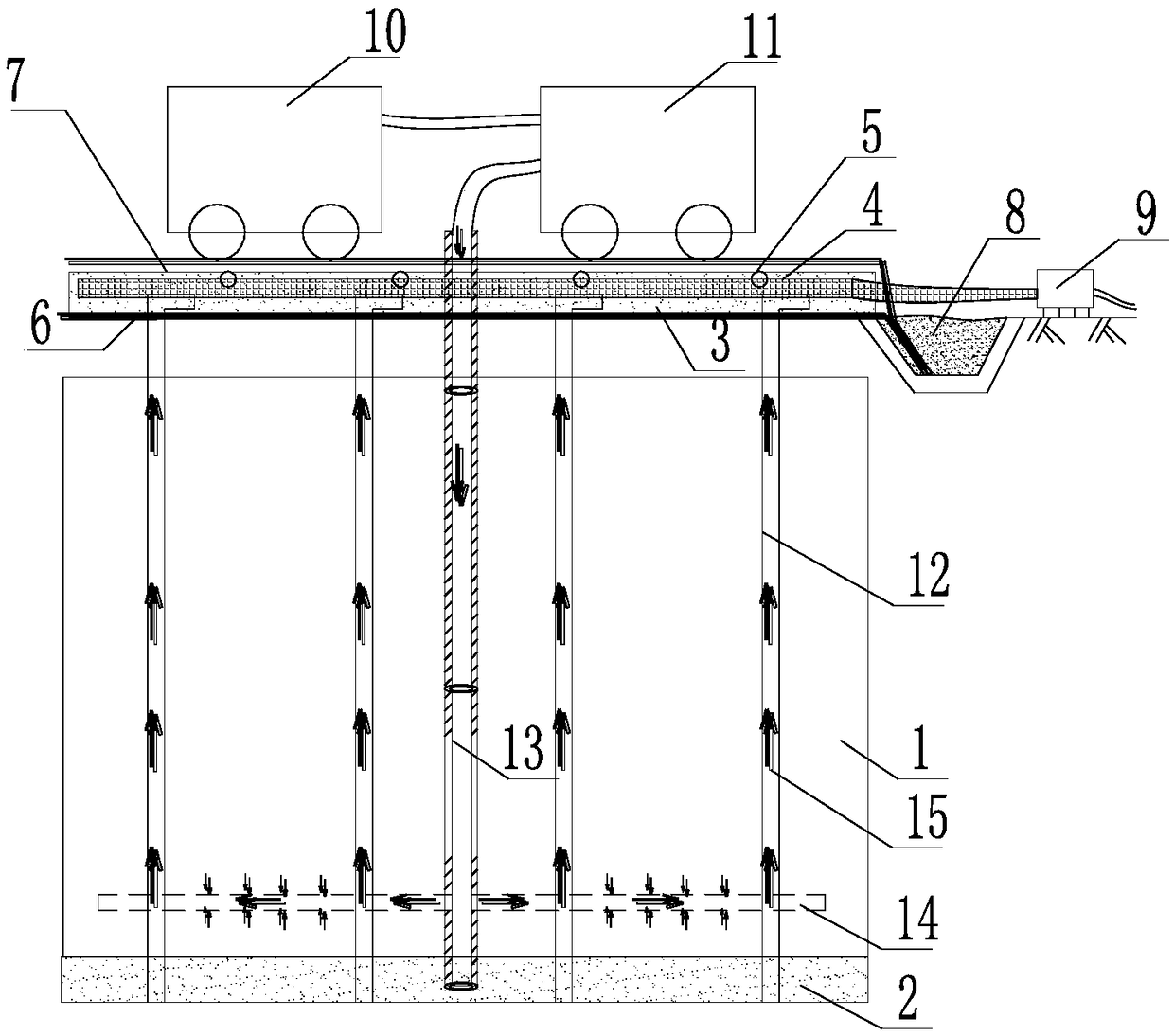

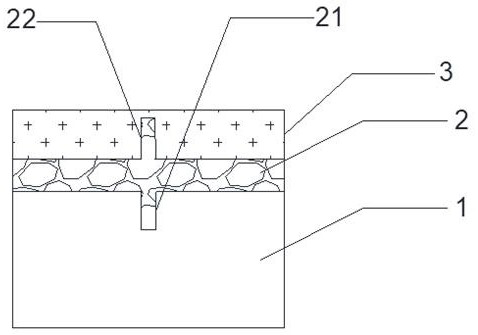

Integrated green belt system based on flood drainage and water conservation and flood drainage and water conservation method

ActiveCN104145673AAvoid churnIncrease resource retentionSoil drainageHorticultureWater holdingSoil horizon

Provided are an integrated green belt system based on flood drainage and water conservation and a flood drainage and water conservation method. The system comprises a planting soil layer with plants planted, a filter and drainage water conservation system and a waterproof material layer are arranged on the lower portion, the filter and drainage water conservation system is formed by stacking an inward concave sand permeable layer, a sand-gravel material permeable layer and a gravel permeable layer, the waterproof material layer is in an upward protruding arc shape, and gravity water holding and flood draining channel arrays are arranged in the filter and drainage water conservation system and vertically penetrate through the filter and drainage water conservation system. According to the method, the waterproof material layer in the upward protruding arc shape is arranged, water drainage holes are formed in the highest position of the waterproof material layer, the gravel permeable layer in an upward protruding arc shape, the sand-gravel material permeable layer in a downward concave shape, the sand permeable layer and the planting soil layer are laid on the waterproof material layer in sequence, and the gravity holding and draining channel arrays are arranged in the gravel permeable layer, the sand-gravel material permeable layer and the sand permeable layer.

Owner:HOHAI UNIV

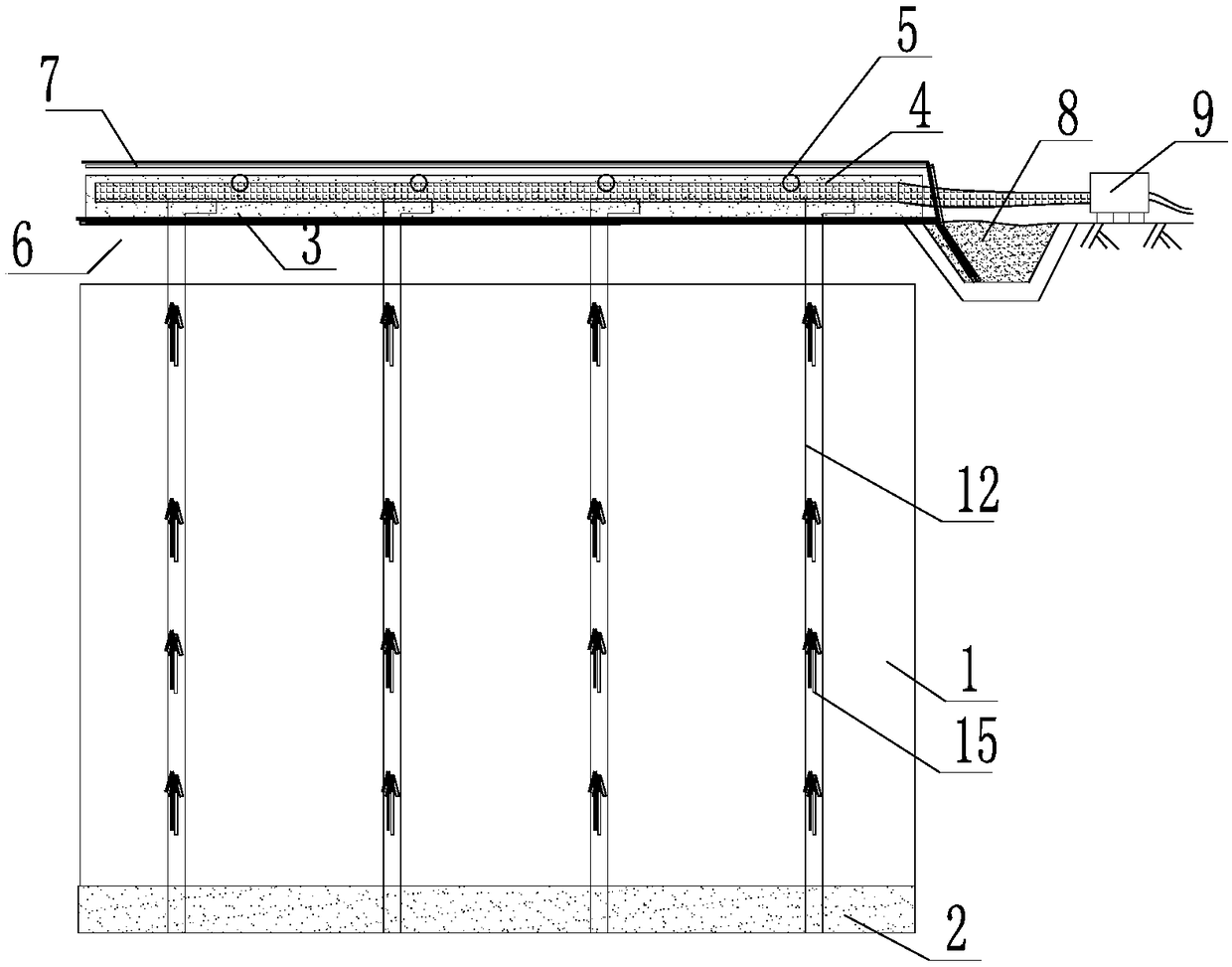

Foundation treatment method for reclamation project combined with layered drainage method

The invention discloses a foundation treatment method for a reclamation project combined with a layered drainage method, comprising a mud blow filling layer, a sand blowing layer, a sand bedding layer, a rotary spray rod, a virtual drainage channel and a virtual drainage direction. The construction steps are as follows: blow filling sand with the thickness being 1-1.5m to a to-be-filled site, blowfilling the mud with the same design height; after standing still for 2-3 months, pumping the surface bleeding, preparing for vacuum pumping, paving geotechnical cloth, bedding a sand cushion with the thickness being 30-50cm, covering a sealing film, pumping, uncovering the sealing film, and carrying out the treatment of layered drainage method. Combined with the foundation treatment method of the layered drainage method, the invention has the advantages of vertical drainage water passing through three layers of foundation structures, namely the sand blowing layer, the mud blow filling layerand the sand bedding layer, so that the drainage distance of the foundation soil layer is shortened and a double-face drainage structure is formed. The foundation soil layer is cut into multiple horizontal drainage channels by the layered drainage method, so the drainage rate of the foundation is greatly quickened, the construction period is shortened and the project cost is reduced.

Owner:吴慧明

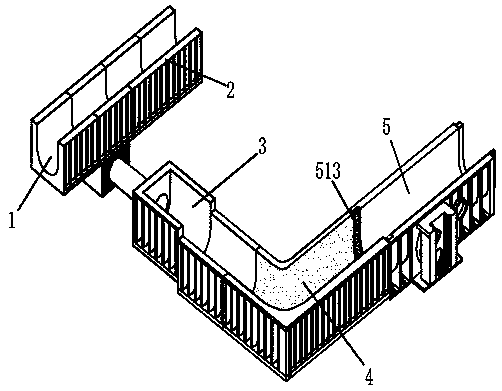

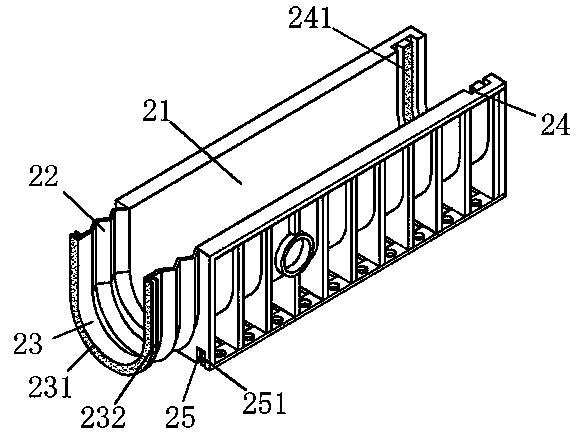

Finished drainage gutter drainage system

ActiveCN109339204AReduce shockShorten the lengthSewerage structuresClimate change adaptationPath distanceTube drain

The invention provides a finished drainage gutter drainage system, which comprises a drainage pipe connected with a municipal pipe. The drainage pipe comprises a multi-section pipe unit, a trapezoidalpipe unit, a corner pipe unit and a split pipe unit. The multi-section pipe unit, the trapezoidal pipe unit, the corner pipe unit and the split pipe unit are connected detachably and separately. Thefinished drainage gutter drainage system can save more materials by assembling an arc route through the multi-section pipe unit, while reducing the path distance. The trapezoidal pipe unit is used forlaying the slope unit to strengthen the support of the slope unit gutter. The split pipe unit is used for increasing the water drainage. The corner pipe unit is assembled at a large angle, which makes the whole drainage system drain faster and safer while saving material and reducing cost.

Owner:安徽海米新材料有限公司

Water nail drainage system for railway roadbed slope and construction method of system

The invention discloses a water nail drainage system for a railway roadbed slope and a construction method of the system. The water nail drainage system comprises water nails formed by covering a PVC (polyvinyl chloride) pipe or a PE (polyethylene) pipe with a capillary permeable drainage tape layer, cocks and tees that connect the water nails and a water collection pipe, water nail connectors each connecting two water nails, and elbows each mounted at a water outgoing end of one water collection pipe or one water nail. The system overcomes the defects of ease of blockage and low efficiency in a traditional drainage material and successfully solves the problems of water collection and drainage in soil. The construction method comprises: testing the nail, setting out, drilling, mounting, and connecting the water collection pipe. The existing roadbed slope is drilled, the water nails are placed in the drilled holes, comprehensive full-length drainage is achieved, long-term drainage efficiency is high, construction is fast, and silt entrainment prevention and blockage prevention are featured. This system can be constructed in narrow space and under railway train operation conditions, construction speed is high, and economic benefit is high.

Owner:CENT SOUTH UNIV +3

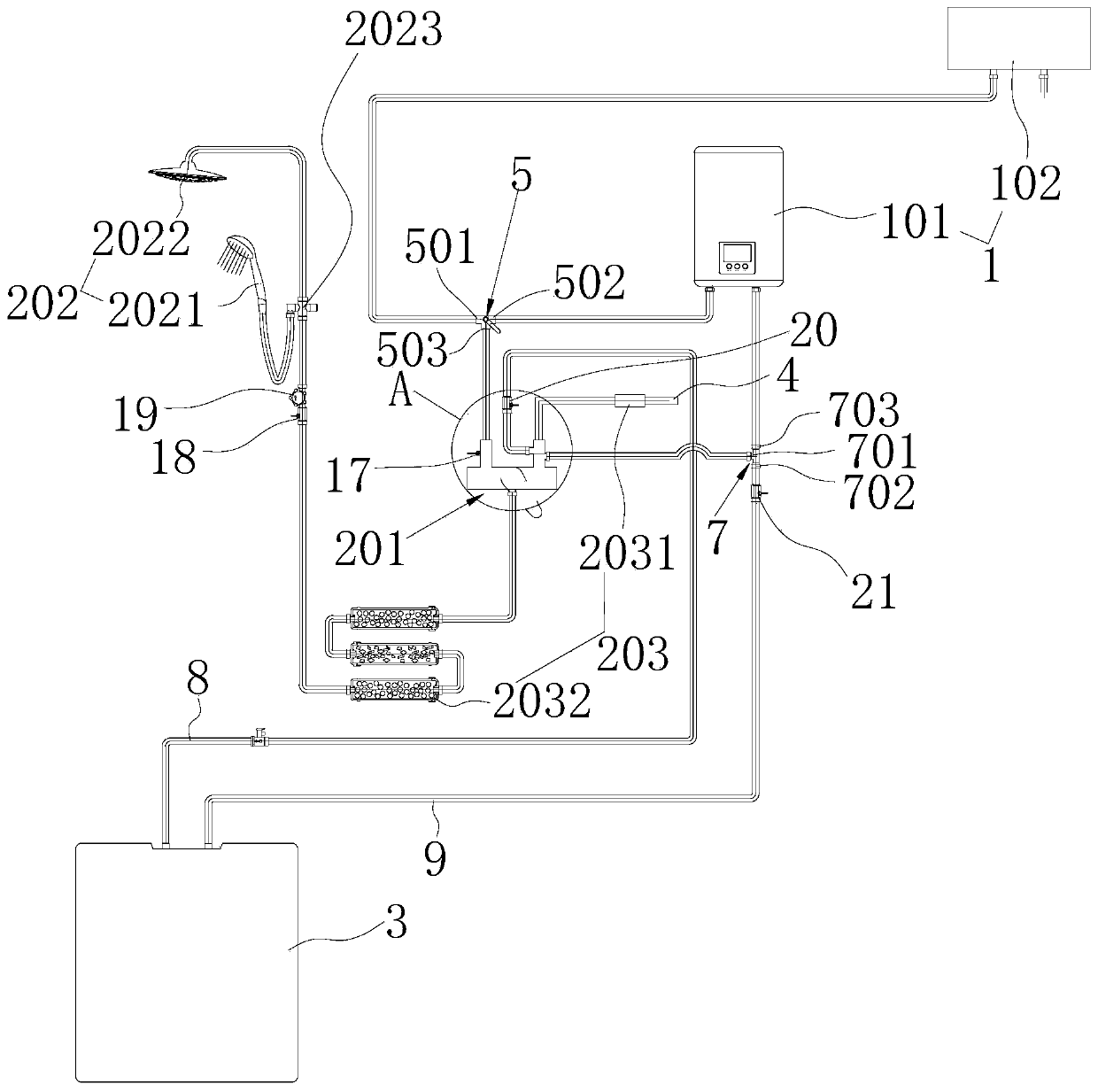

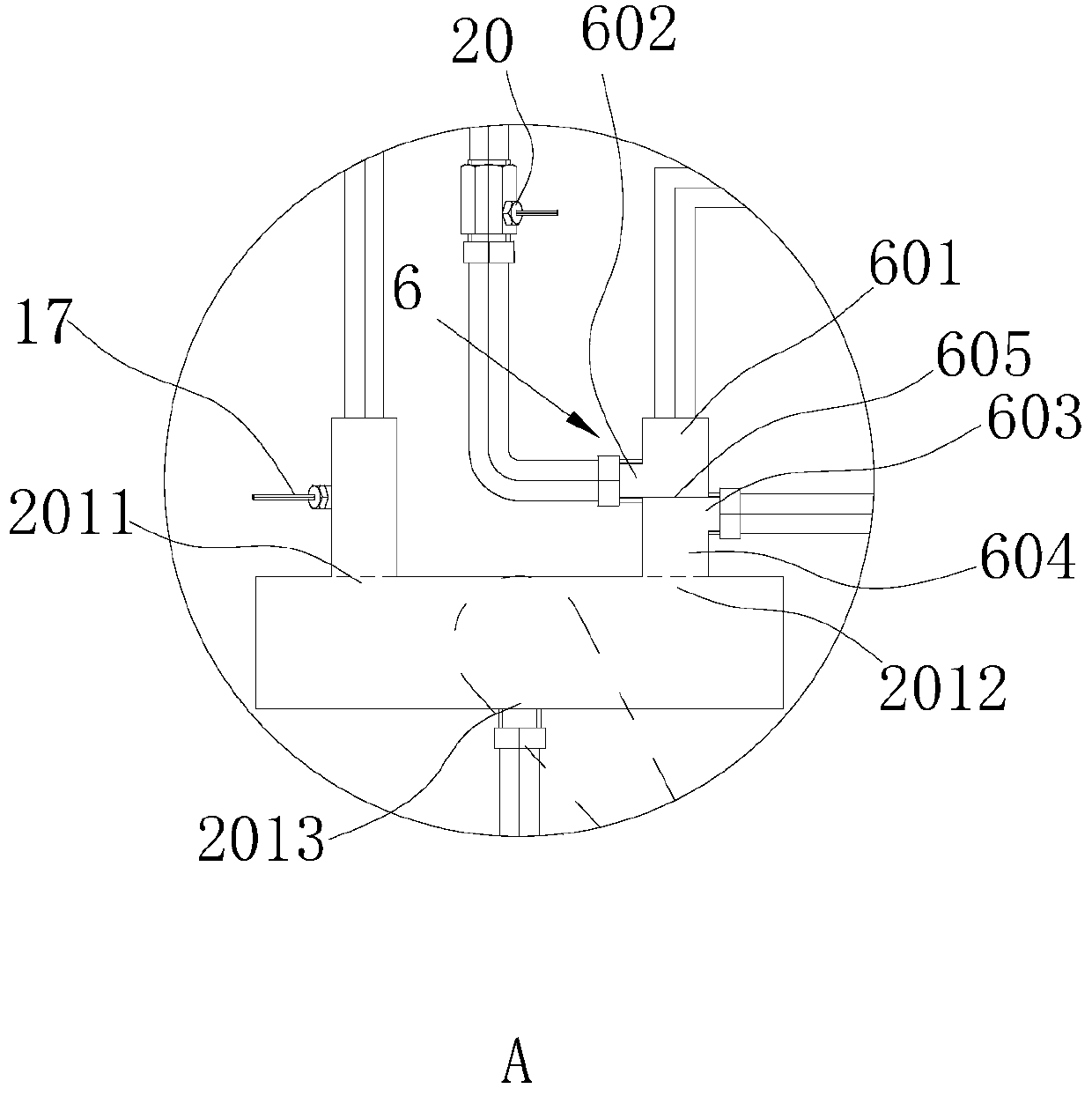

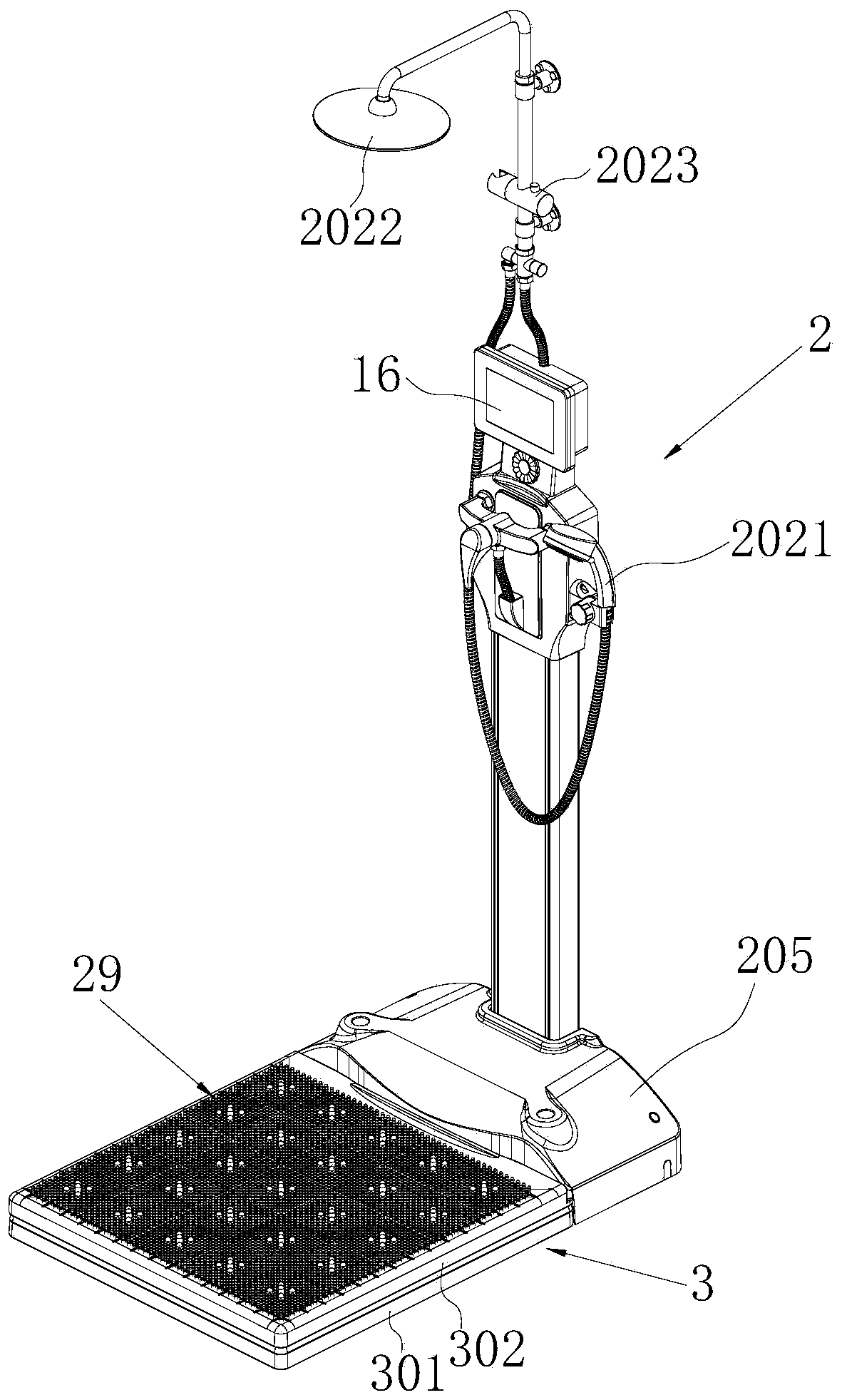

Bathing system

PendingCN111536694ABeneficial technical effectEasy to assemble and disassembleFluid heatersMechanical apparatusWater useEnvironmental engineering

The invention discloses a bathing system. According to the scheme adopted by the invention, the bathing system comprises a hot water generator, a bathing device and a heat energy recycling device, wherein the bathing device comprises a water mixing valve, a bathing spray head and a filter device; the water mixing valve comprises a first water inlet, a second water inlet and a water mixture outlet;the filter device comprises a sand filter and a secondary filter assembly; the bathing device further comprises a water purifier bottom plate; the secondary filter assembly comprises an elastic clamping base and a filter body; the filter body comprises a tank body; the elastic clamping base is fixedly arranged on the water purifier bottom plate and is provided with an upward opening; and the elastic clamping base is matched with the tank portion of the tank body to clamp the tank body. The sand filter and the secondary filter assembly are arranged for purifying bathing water, so that cleanness of bathing water is improved, reliable operation of the bathing system is guaranteed, and bathing experience is favorably improved; and the elastic clamping base is matched with the tank body, a water tube connecting head is spliced and matched with the connecting end part of the tank body, and the secondary filter assembly is dismounted conveniently, so that production and replacement are convenient.

Owner:广东三角洲环保科技有限公司

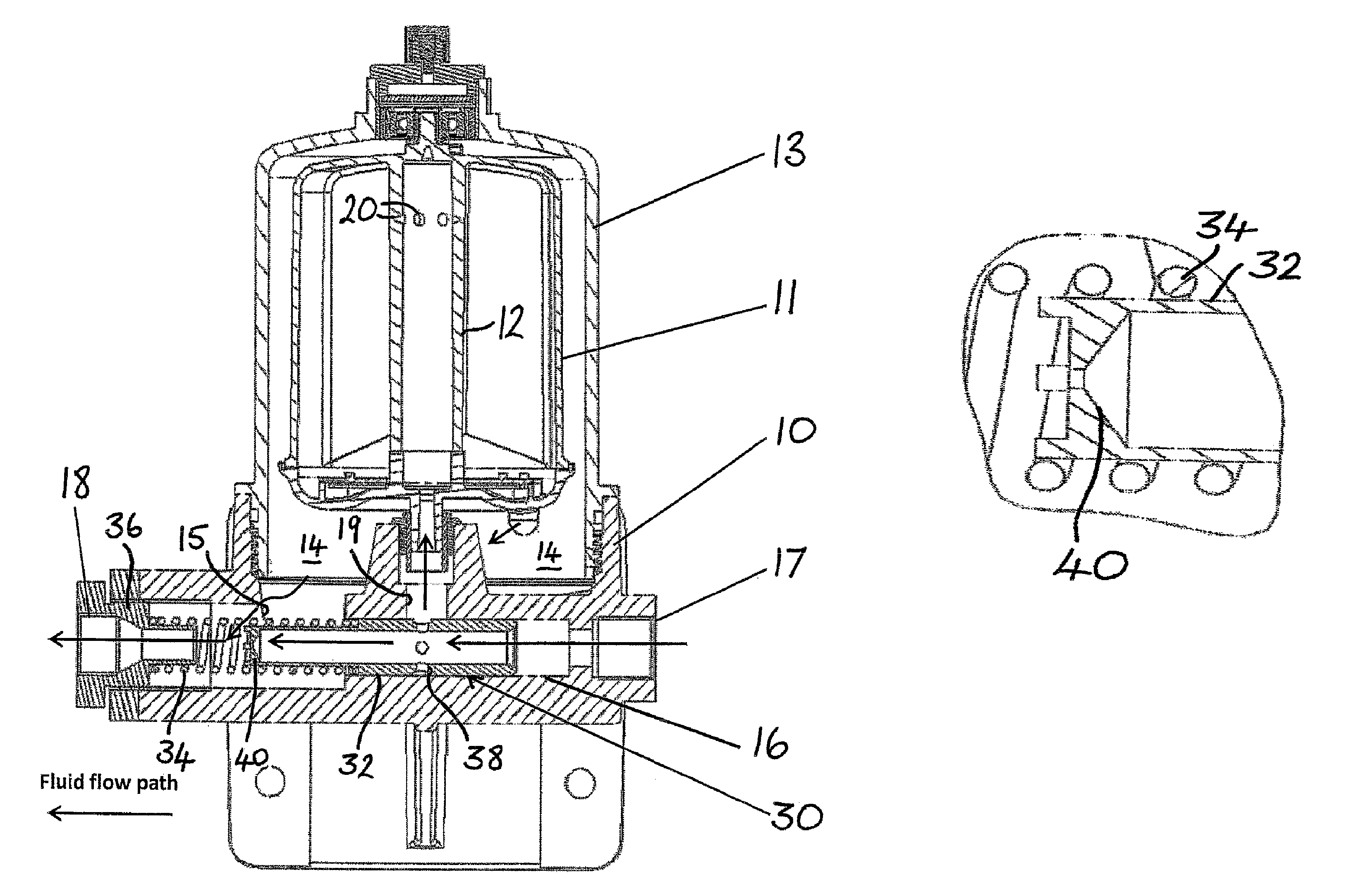

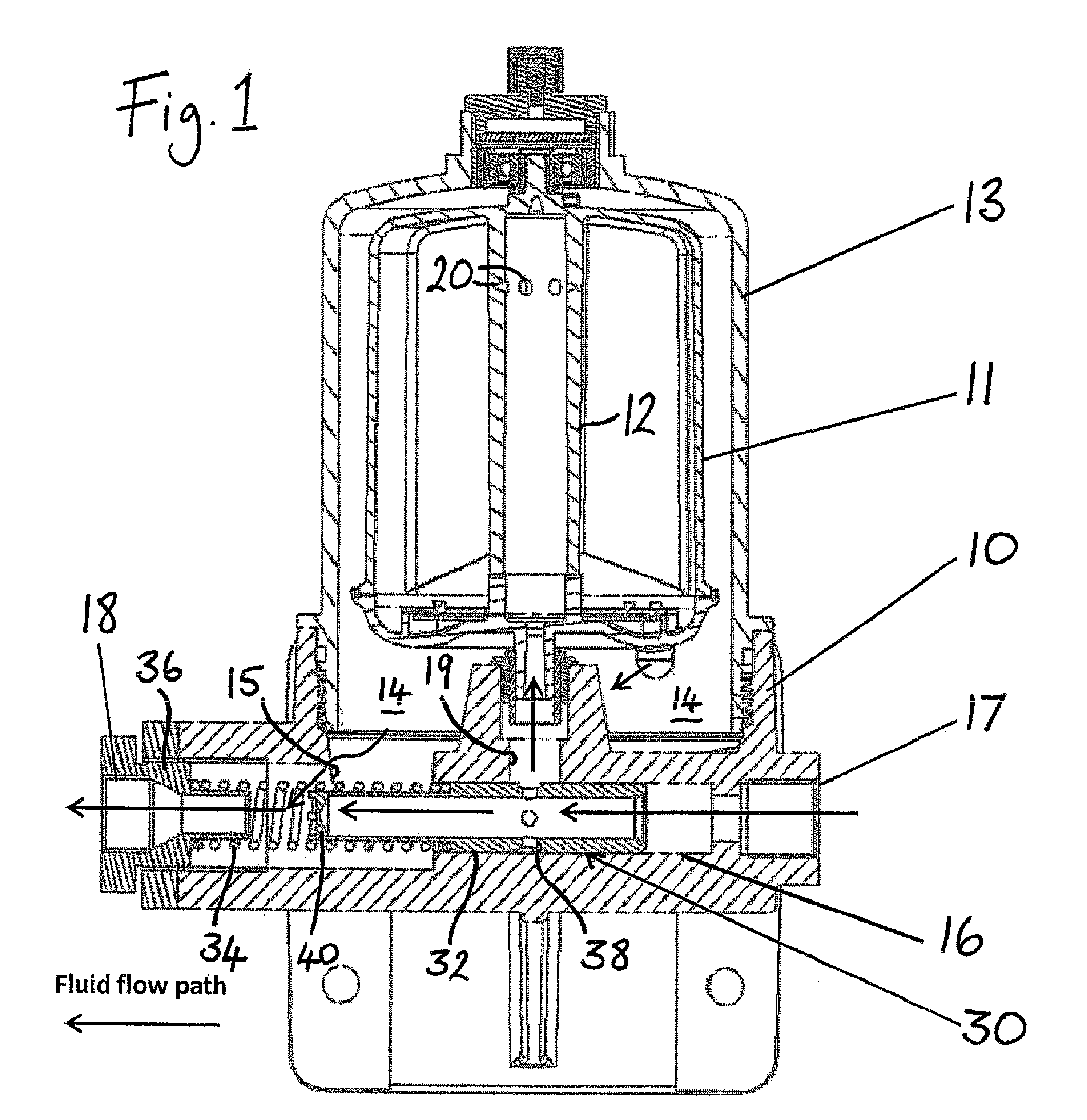

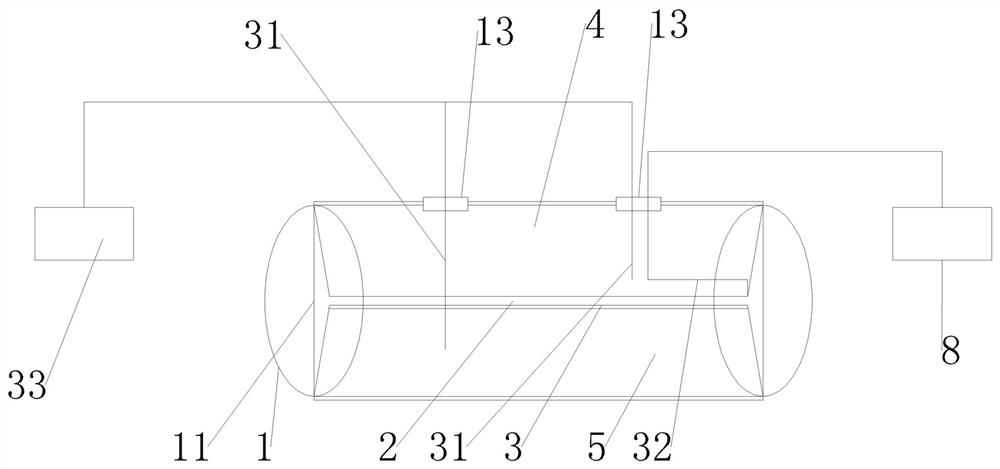

Centrifugal separator with venturi arrangement

The invention describes a self-powered centrifugal separator comprising a base, a rotor mounted on an operably substantially vertical axis for rotation thereabout by reaction to fluid emission from rotor nozzles therein, a housing mounted on the base and enclosing the rotor, a sump formed in the base below the rotor, a fluid passageway through the base extending from an inlet port to an outlet port and including a diversion port to supply fluid to the interior of the rotor by way of the rotation axis, a drain passage in the base for draining fluid from the sump to the fluid passageway, and a venturi arrangement provided in the fluid passageway in the base to develop suction pressure to draw fluid from the drainage passage into the fluid passageway, whereas a spring loaded valve body is provided in the fluid passageway, said body being configured and arranged to shut off supply of fluid to the interior of the rotor when pressure of fluid entering the inlet port falls below a predetermined minimum pressure value and also to restrict and / or shut off supply of fluid to the interior of the rotor when pressure of fluid entering the inlet port rises above a second predetermined pressure value.

Owner:MANN HUMMEL GMBH

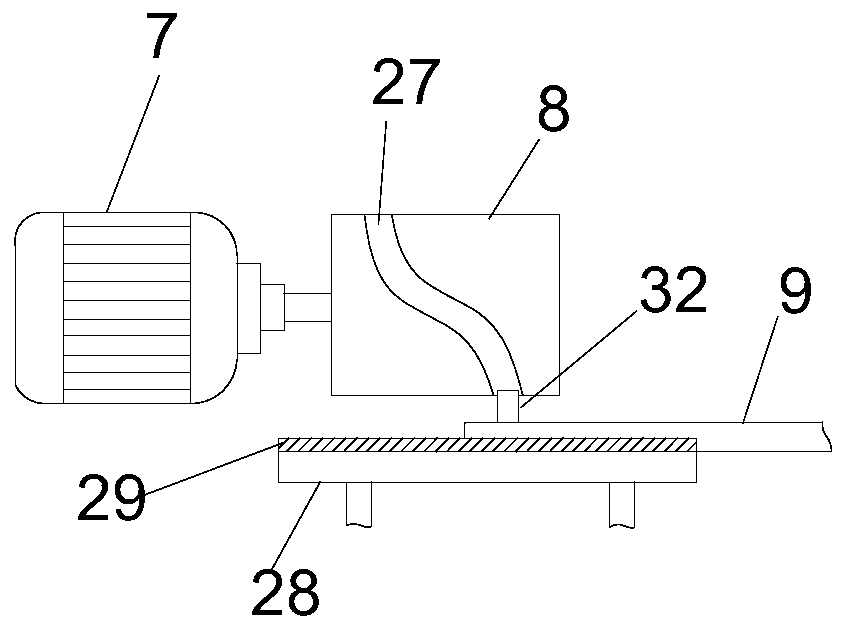

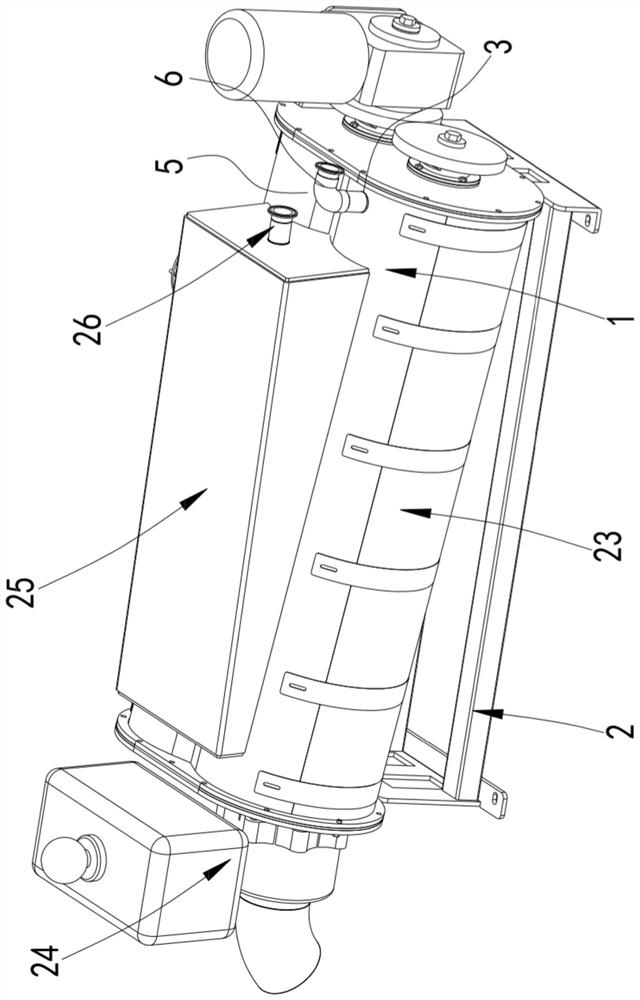

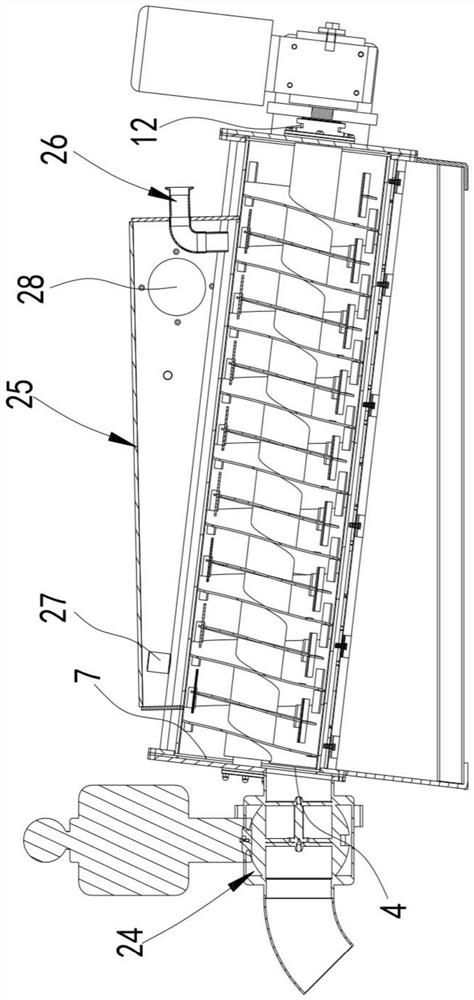

Drying device, garbage treatment device and material machining method

PendingCN112414017AMeet the requirements of stable deliveryGreat driving forceDrying solid materials without heatGrain treatmentsEngineeringRefuse Disposals

The invention discloses a drying device, a garbage treatment device and a material machining method. The drying device comprises a bin body with a feed port and a discharge port and further comprisestwo rotating shafts, a drying device and a heating device, wherein the two rotating shafts are arranged in the bin body in parallel, each rotating shaft is provided with a spiral conveying blade, thedistance between the two rotating shafts is larger than the linear distance between the edge of any spiral conveying blade and the rotating shaft where the spiral conveying blade is located and smaller than the sum of the linear distances between the two spiral conveying blades and the respective rotating shafts where the spiral conveying blades are located, the driving device drives the two rotating shafts to rotate around own axes, the rotating directions of the two rotating shafts are opposite, and the heating device is used for heating the interior of the bin body. According to the scheme,the two mutually-engaged spiral conveying blades are adopted for synchronous conveying, the driving force during conveying is effectively increased, the stable conveying requirement of crushed solidwaste with certain humidity and viscosity can be met, and the drying stability can be guaranteed beneficially.

Owner:环川环保设备(苏州)有限公司

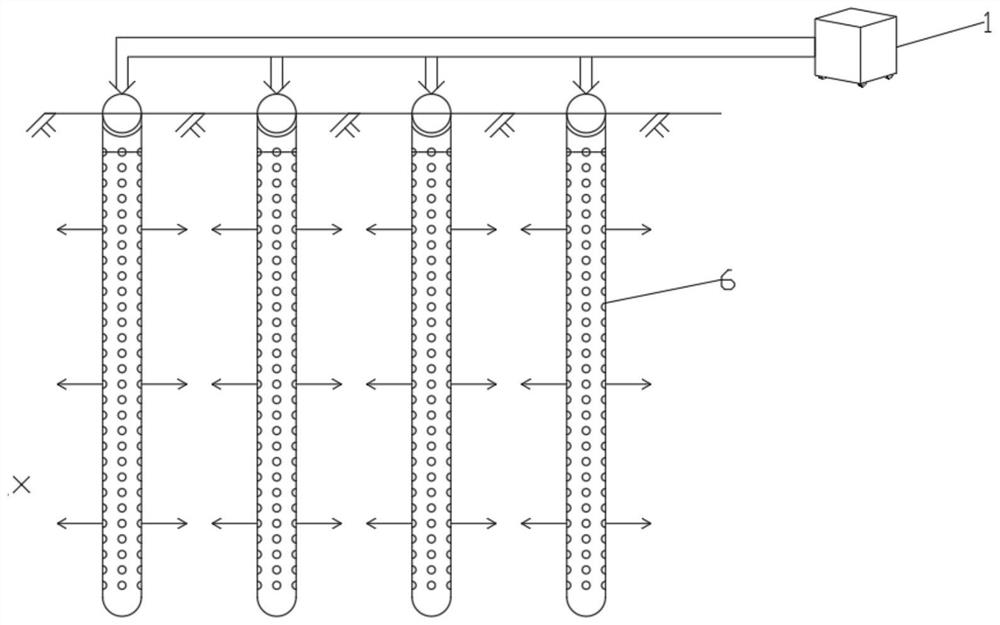

Flow field plate structure for increasing drainage performance of fuel cell

The invention provides a flow field plate structure for increasing drainage performance of a fuel cell, wherein the flow field plate structure comprises a flow field plate, an upper support layer, a liquid absorbing material, a gas diffusion layer and a catalytic layer; the top of the flow field plate is provided with the upper support layer, and the edge of the bottom face of the upper support layer is connected with the edge of the top face of the flow field plate; the middle of the bottom face of the upper support layer is provided with a hollow-out layer; the bottom of the flow field plate is provided with the gas diffusion layer and the catalytic layer from top to bottom; the liquid absorbing material is arranged vertically, the lower part of the liquid absorbing material makes contact with the gas diffusion layer, and the upper part of the liquid absorbing material passes through the flow field plate and is connected with the upper support layer; the upper support layer and the flow field plate are respectively provided with dry gas inlets, reaction gas inlets and reaction gas outlets which communicate correspondingly, the upper support layer is provided with a dry gas outlet, and the dry gas inlets communicate with the liquid absorbing material. The flow field plate structure has the advantages that the flow field plate structure is provided with dry gas flow channels alone, dry gas is used for achieving transpiration of the liquid absorbing material, and flow of the dry gas of the fuel cell and flow of reaction gas of the fuel cell are not interfered with each other.

Owner:WUHAN UNIV OF TECH

Flocculation-horizontal drainage plate vacuum preloading combined multi-layer sealed geobag mud treatment technology and rapid mud treatment method

The invention discloses a flocculation-horizontal drainage plate vacuum preloading combined multi-layer sealed geobag mud treatment technology. The technology comprises a sealed geobag and a geomembrane which are used for filling mud, the sealed geobag and the geomembrane have two splicing modes, among which one mode is that a layer of geomembrane is placed inside the sealed geobag and is tightlyattached to the inner side of the sealed geobag, and the other mode is that the geomembrane is wrapped around and seals the outer side of the geobag; a horizontal drainage system used for vacuumizingto drain water is arranged inside the sealed geobag, one end of the horizontal drainage plate is connected to a vacuum drainage pipeline, and the drainage pipeline penetrates through the sealed geobagthrough a flange plate to be connected to a vacuum pump used for pumping water in the sealed geobag; and mud comprises engineering waste slurry, river mud and industrial sludge. The horizontal drainage system is added into the sealed geobag, mud is dewatered in combination with a flocculating agent, the sealed geobag can be arranged in a multi-layer stacking mode, a stacking effect is formed on alower-layer structure through a dead weight of an upper layer, the drainage effect is faster, and the dewatering efficiency is higher.

Owner:WENZHOU UNIVERSITY

Soft rock slope ecological protection structure and construction method thereof

ActiveCN113174973AImprove liquidityImprove adhesionClimate change adaptationGrowth substratesVegetationDrainage tubes

The invention discloses a soft rock slope ecological protection structure and a construction method thereof. The soft rock slope ecological protection structure comprises an ecological protection layer and a drainage system, wherein the ecological protection layer comprises a permeable drainage layer, a soft rock matrix ecological concrete layer and a vegetation base soil layer, the permeable drainage layer is attached to the slope surface of the soft rock slope body, and the soft rock matrix ecological concrete layer and the vegetation base soil layer are sequentially arranged on the upper surface of the permeable drainage layer; and the drainage system comprises in-slope drainage pipes embedded in the soft rock slope body and a slope surface drainage structure arranged on the upper surface of the vegetation base soil layer. According to the protection structure, all the protective layers work together, multiple anti-seepage and drainage functions are achieved, the soft rock slope is stabilized together, and the construction cost is low; and meanwhile, the slope greening effect is improved, and the stability of the interior of the soft rock slope is enhanced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

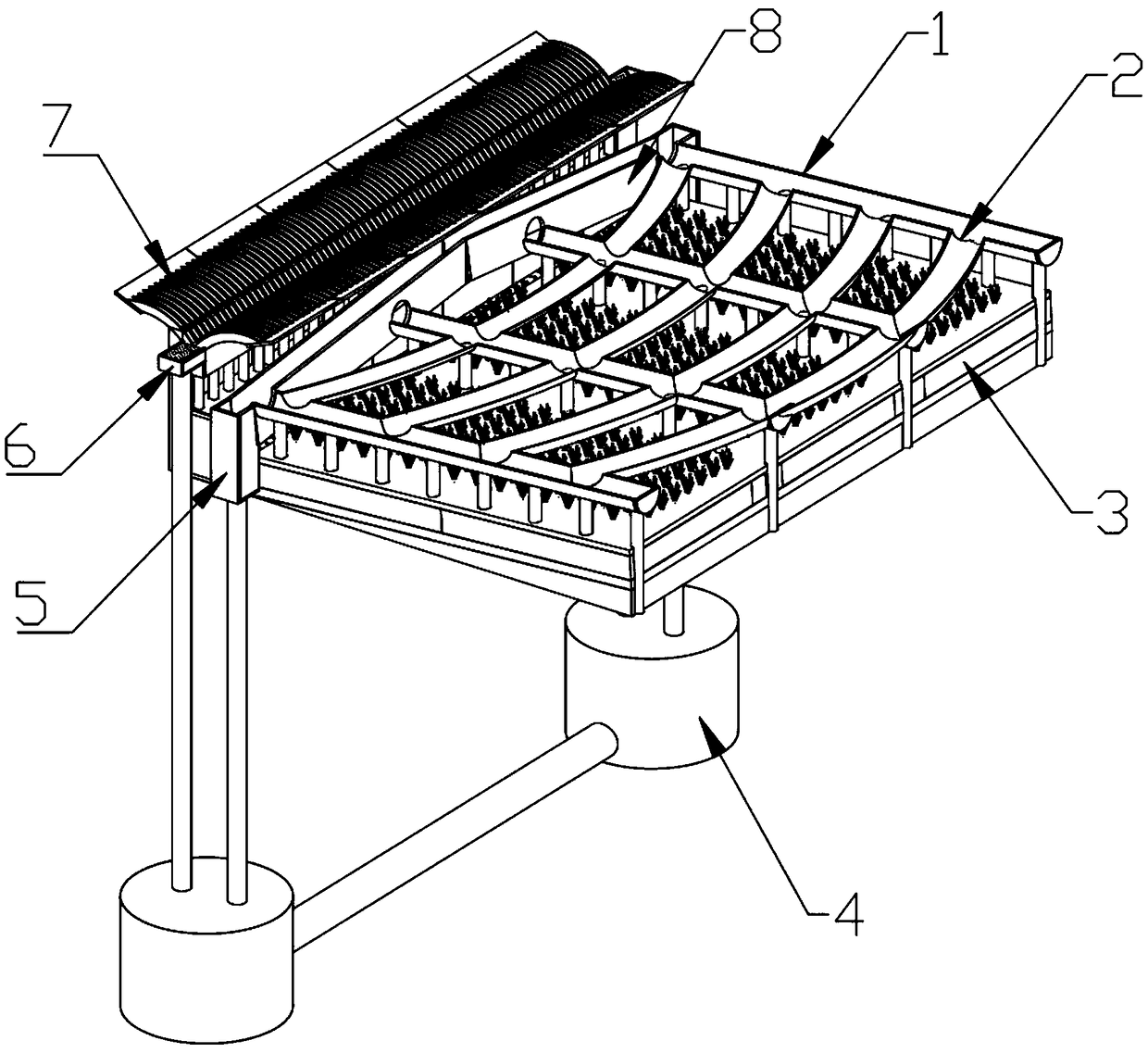

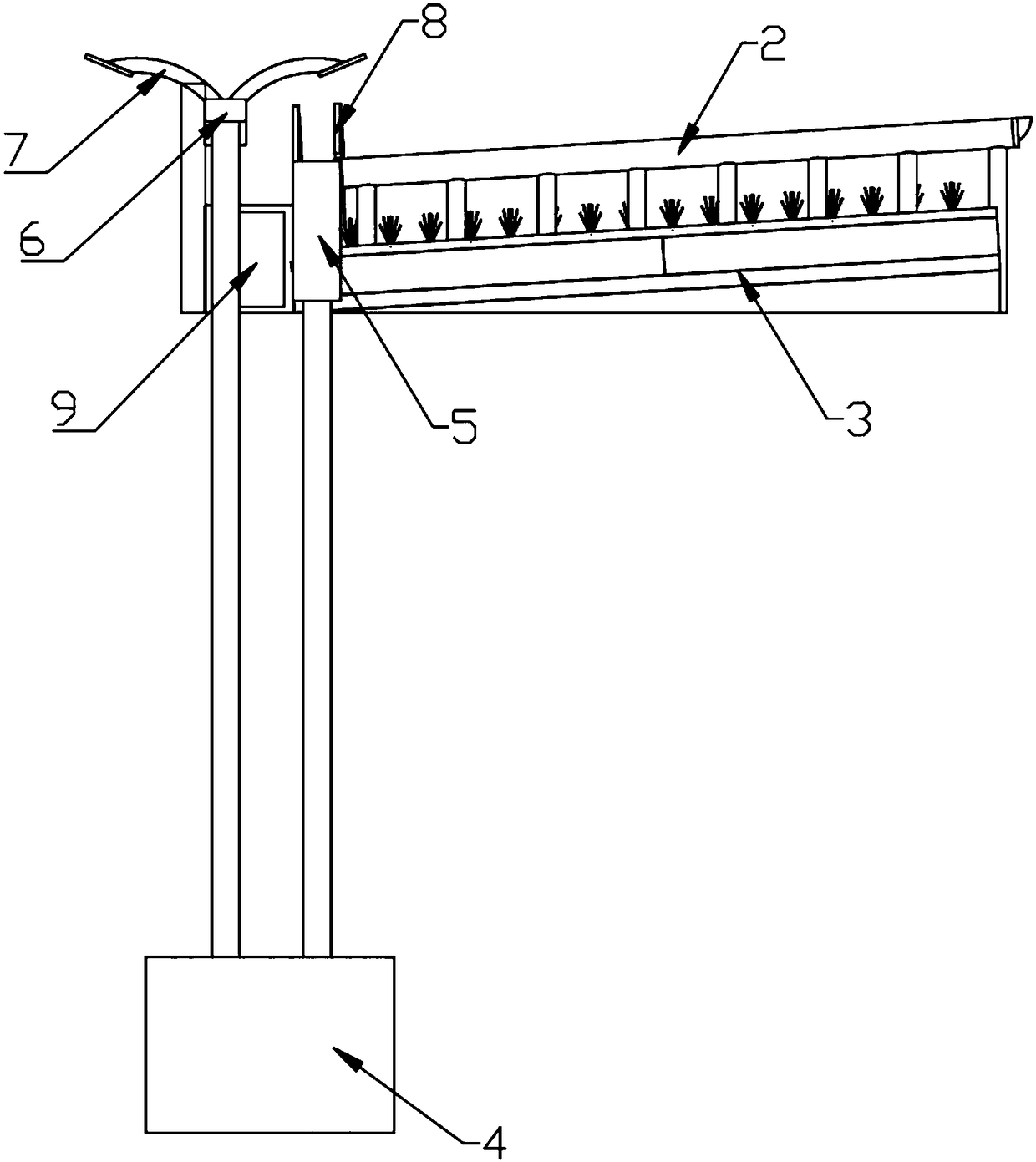

Sponge city green roof facilitating accomplishment of emission reduction and purification of rainwater for roof surface

InactiveCN109138293AEasy to collectConvergence flowGeneral water supply conservationHops/wine cultivationEavesWater storage tank

The invention provides a sponge city green roof facilitating accomplishment of emission reduction and purification of rainwater for the roof surface. The sponge city green roof facilitating the accomplishment of the emission reduction and the purification of the rainwater for the roof surface comprises layered rainwater collecting grooves, a roof greening layer and a roof water storage tank; the roof greening layer is arranged on a roof body; the layered rainwater collecting grooves are fixedly formed in the upper side of the roof greening layer in a supporting mode through supporting rods; confluence grooves are fixedly formed in the end heads of the lower sides of the layered rainwater collecting grooves; a rainwater collection ditch is formed in one side of two sides of the roof greening layer, and the upper side of the rainwater collection ditch is covered with a greening layer rainwater collecting filter net; the roof water storage tank is arranged on the adjacent side of the roofgreening layer; and eave confluence grooves are connected to the upper side of the roof water storage tank in a supporting mode through water pipes. According to the sponge city green roof facilitating the accomplishment of the emission reduction and the purification of the rainwater for the roof surface, a rainwater collecting eave is designed in an arc-shaped structure, arc-shaped grooves are equidistantly formed in the top surface of the rainwater collecting eave in an arrangement mode, and the collection of rainwater by the arc-shaped grooves rapidly enabling the rainwater to be collectedand flow into the eave confluence grooves is facilitated.

Owner:汤文健

Horizontal drainage plate-vacuum preloading combined electroosmosis system and sludge treatment method thereof

The invention discloses a horizontal drainage plate-vacuum preloading combined electroosmosis system. The horizontal drainage plate-vacuum preloading combined electroosmosis system comprises a horizontal drainage plate system, an electroosmosis system and a vacuum preloading system, wherein the electroosmosis system comprises a plurality of vertical insulating assemblies, a plurality of anode steel bars, wires and a power supply; the wires comprise a positive wire and a negative wire; the plurality of vertical insulating assemblies are vertically distributed at the transverse edges of the twosides of a vacuum preloading groove; anode steel bar layers are distributed between the vertical insulating assemblies; horizontal drainage systems are arranged between the anode steel bar layers; thehorizontal drainage systems are in conduction connection with a vertical main pipe through branch pipes; cathode steel bar layers are fixed on the horizontal drainage systems; the anode steel bar layers are connected with the positive wire through branch wires; the cathode steel bar layers are connected with the negative wire through branch wires; and the wires penetrate through a sealing film and are connected with the power supply. The system can realize hydraulic filling and consolidation drainage at the same time, is simple and convenient to construct, saves energy consumption, avoids severe bending of plates, guarantees effective vacuum transfer, guarantees the treatment effect and increases the turnover utilization rate of a storage yard.

Owner:温州市铁路与轨道交通投资集团有限公司 +1

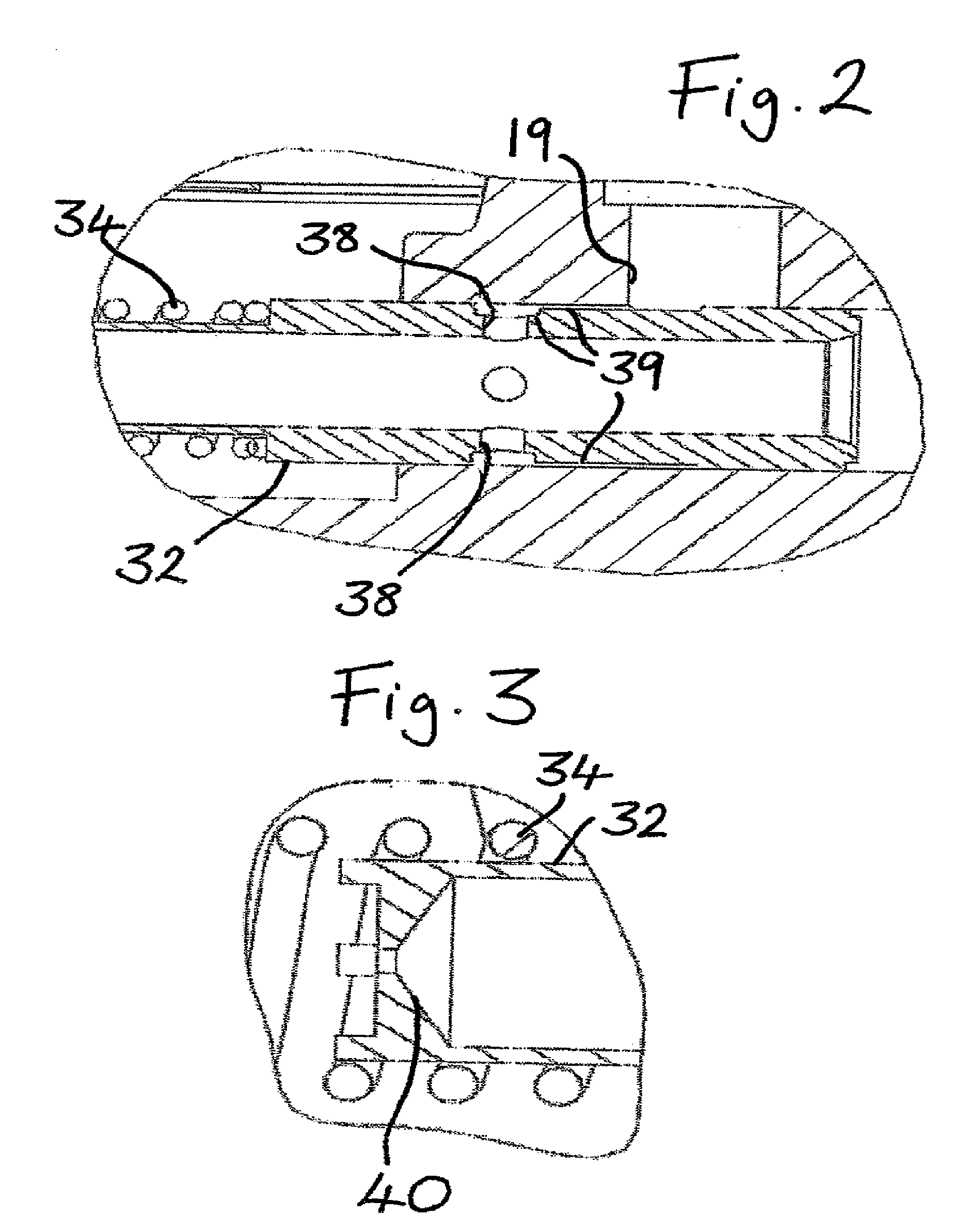

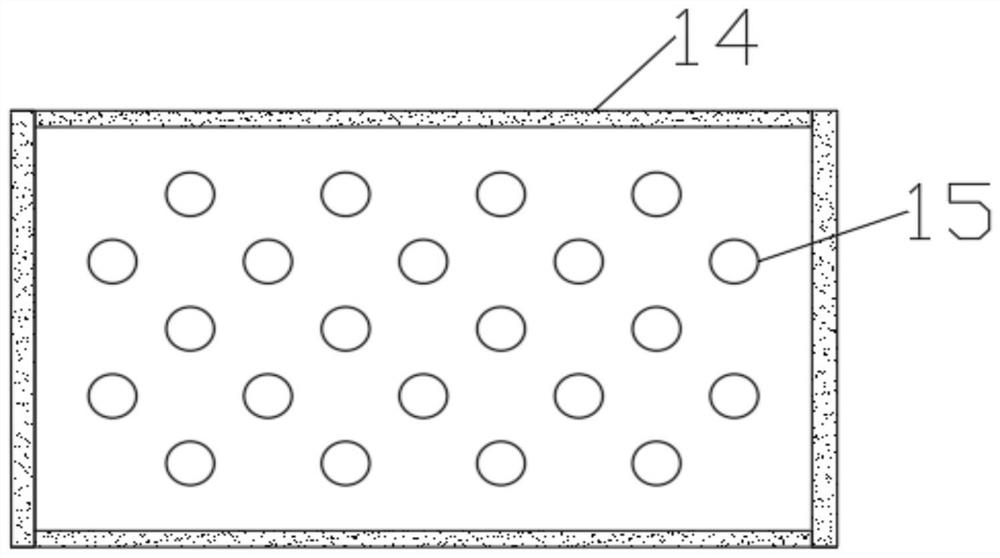

Buoyancy adjusting device

ActiveCN109501987AConvenient and efficient buoyancy adjustmentGood buoyancy adjustmentUnderwater vesselsUnderwater equipmentEngineeringFlange

The invention discloses a buoyancy adjusting device and aims to provide the buoyancy adjusting device capable of quickly draining water. The buoyancy adjusting device comprises a cabin body, an air bag positioned in the cabin body, a front cover arranged at one end of the cabin body, and a rear cover; the cabin body comprises a shell and flanges, wherein the inner wall of the shell is provided with a spiral drainage groove, and the flanges are arranged at two ends of the shell; the air bag comprises a pipe body made of rubber, an air inlet end which is in liquid-tight connection with a pipe body and is close to the front cover, and a water inlet end which is in liquid-tight connection with the pipe body and is close to the rear cover; an air inlet groove is arranged at one end of the air inlet end facing the outside of the pipe body, and a vent hole communicated with the pipe body is arranged at the bottom of the air inlet groove; the inner end of the front cover is provided with an air inlet inner ring which is hermetically connected with the air inlet groove, and the outer end of the front cover is provided with an air inlet and outlet joint which is communicated with the vent hole and is used for air inlet and outlet; the inner end of the front cover is arranged on an air inlet outer ring which is in fluid-tight fit with the inner wall of the shell, and a front gap is formedbetween the air inlet outer ring and the adjacent end surface of the air inlet joint.

Owner:云南昆船机械制造有限公司

On-site grouting system and method for reinforcing flocculated sludge by combining vacuum preloading and grouting

ActiveCN113322958ACutting costsGuarantee the construction qualitySoil preservationFlocculationSoil science

The invention discloses an on-site grouting system and a method for reinforcing flocculated sludge by combining vacuum preloading and grouting. The on-site grouting system is composed of an engineering mechanical vehicle, a grouting pipe, a vertical drainage plate, a control electric box, a foam plate, a flocculant pump, a vacuum pump and some conveying pipelines. According to the method for reinforcing the flocculated sludge by combining vacuum preloading and grouting, lime pipe grouting is used as a main process, traditional vacuum preloading is improved through an electrical control technology, modern mechanical equipment is adopted for construction, and therefore, the high efficiency and refinement of construction are achieved, the construction process is simplified, manpower participation is reduced, the safety coefficient of labor is increased, and the working efficiency is greatly improved; and the requirement of traditional vacuum preloading on a site is reduced through a lime grouting mode, the flocculation effect in a soil body is improved, the application range of vacuum preloading is widened, the flocculation effect in the soil body is improved, and the construction period is greatly shortened.

Owner:WENZHOU UNIVERSITY

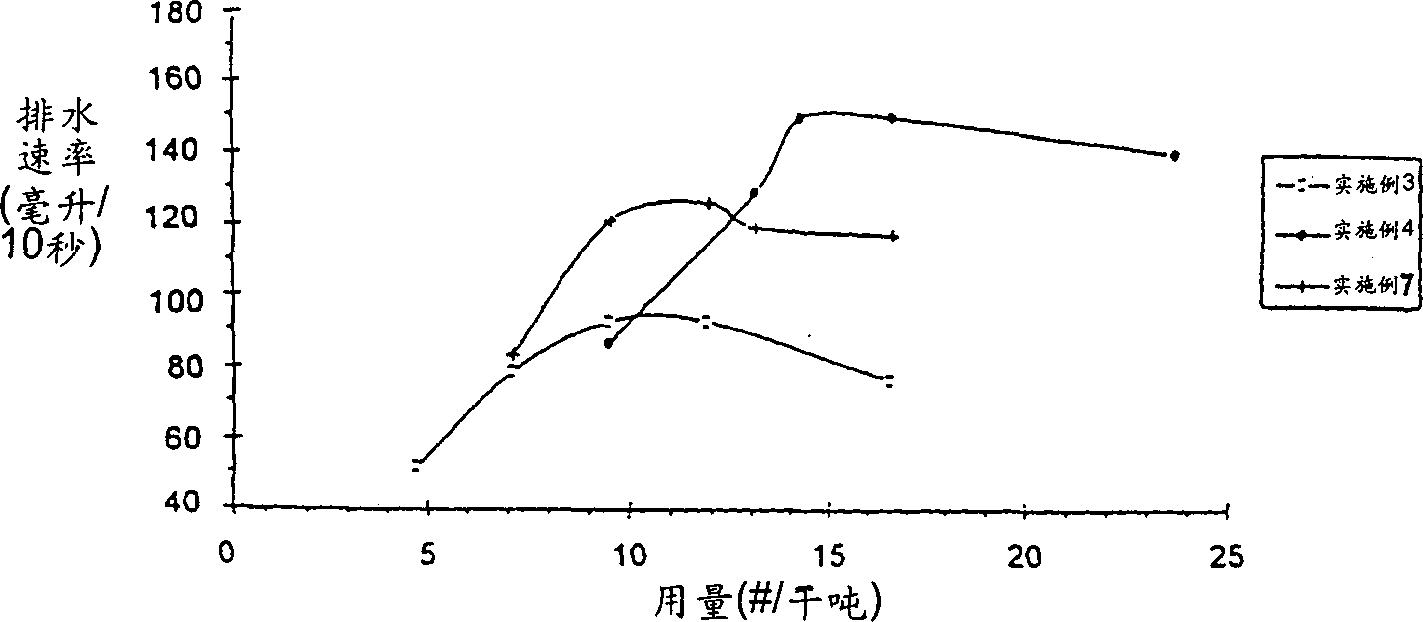

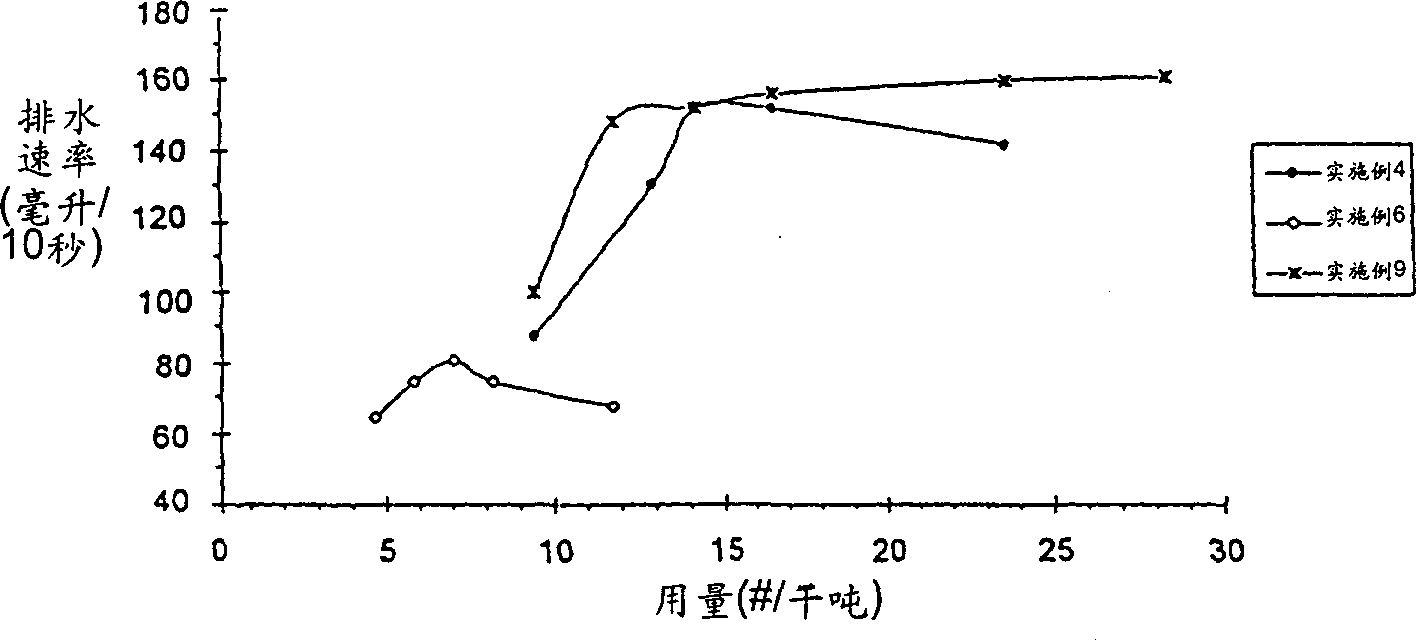

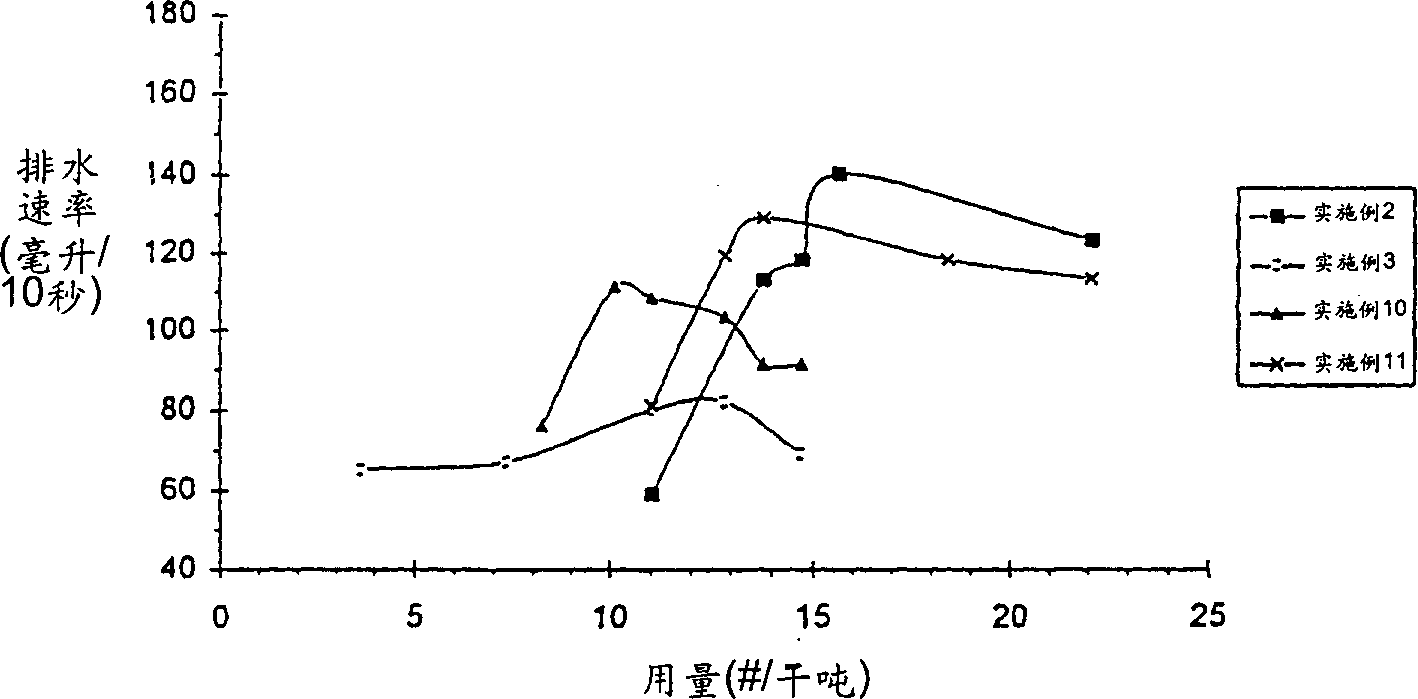

Improved polymer blends for dewatering

InactiveCN1290279AIncrease drainage rateWater/sewage treatment by flocculation/precipitationCationic polymerizationWater soluble

The present invention provides blends of high molecular weight, water soluble cationic structured polymers with linear or less structured high molecular weight, water soluble, cationic polymers. The blend can be used to dewater dispersions of suspended solids, and good dehydration rates can be achieved at lower dosages.

Owner:KEMIRA OY

Self-drainage type impermeable concrete precast pile

InactiveCN112127357AImprove impermeabilityAvoid enteringBulkheads/pilesSoil preservationFiberStructural engineering

The invention discloses a self-drainage type impermeable concrete precast pile, and belongs to the technical field of concrete precast piles. The purpose of improving the strength of a pile body by extending into the concrete precast pile by pre-burying a pre-buried missing ball in the concrete precast pile based on the water guide characteristic of a water guide fiber rod can be achieved, meanwhile, seepage water in the concrete precast pile is concentrated and conveyed to the pre-buried missing ball position, the drainage action of a multi-point water conveying rod is triggered, water conveying connection with a surface one-way drainage bag is established firstly, and then the guided seepage water is synchronously conveyed while water on the one-way drainage bag is desorbed under the action of transformed magnetic force through the self-extrusion effect, therefore, seepage water in the concrete precast pile is drained to the outside, the initial state is recovered, water conveying connection is disconnected, outside water is prevented from entering the concrete precast pile from the pre-buried missing ball position, and the impermeability of the concrete precast pile is remarkably improved.

Owner:闫山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com