Flocculation-horizontal drainage plate vacuum preloading combined multi-layer sealed geobag mud treatment technology and rapid mud treatment method

A horizontal drainage board, multi-layer sealing technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of complex production process, large resource consumption, turbid water, etc., to achieve flexible engineering processing capacity, improve pumping and drainage Efficiency, the effect of faster drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

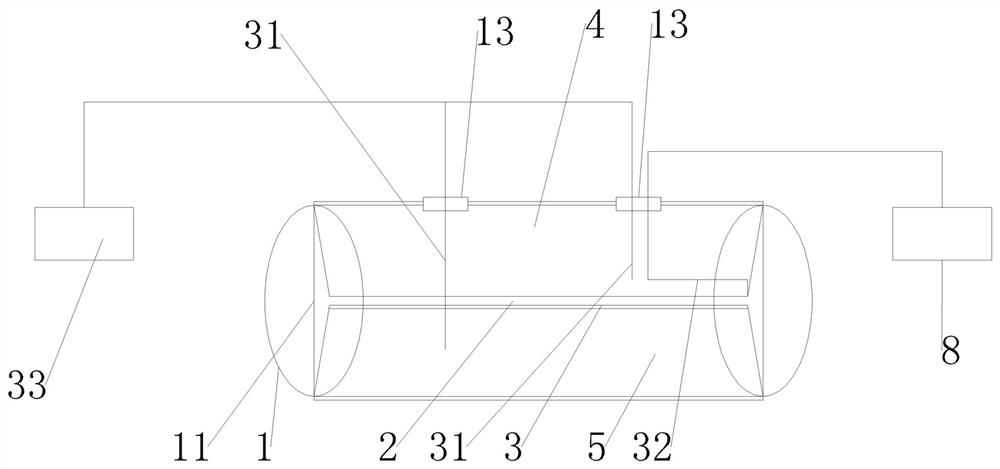

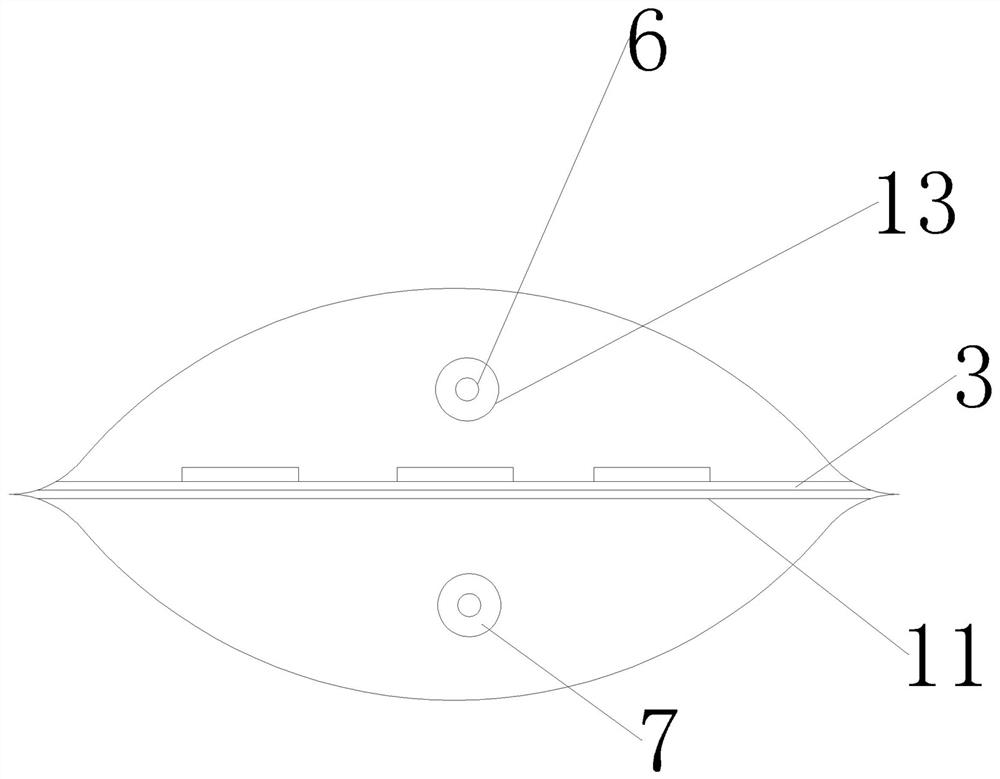

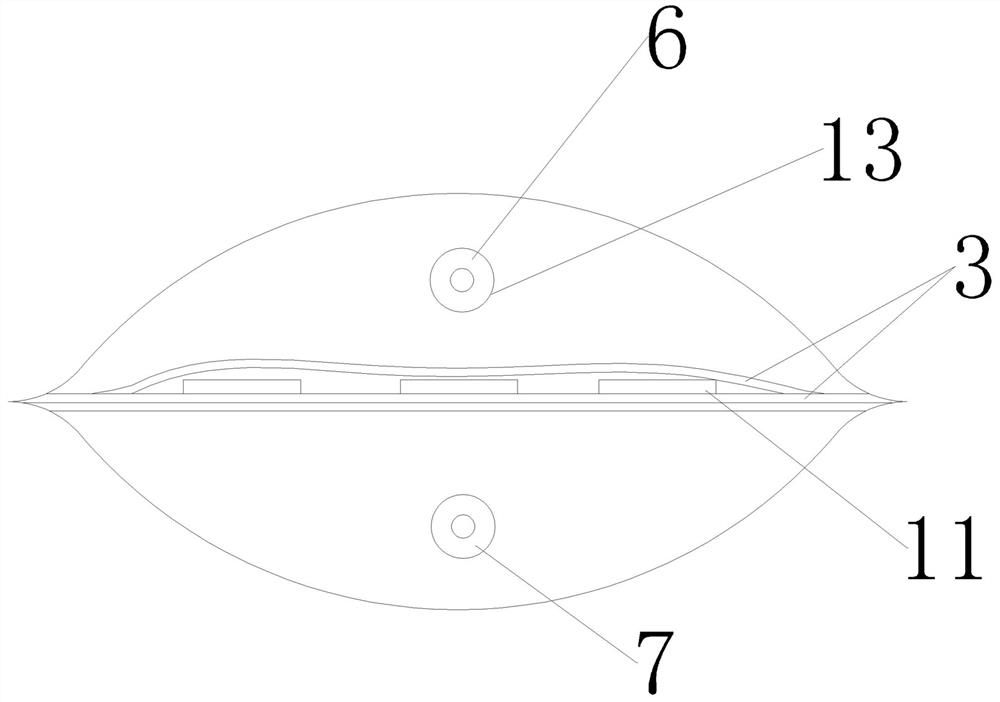

[0051] refer to Figure 1-8 As shown, the flocculation-horizontal drainage board vacuum preloading combined multi-layer sealed geotechnical bag sludge drying system provided in Example 1 of the present invention includes a horizontal drainage board system and a sealed geotechnical bag 1, that is, a geomembrane bag or a geotechnical tube bag, The sealed geotechnical bag 1 is composed of a geotextile lining or a geotechnical membrane, and the sealed geo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com