Patents

Literature

1096results about How to "Improve pumping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

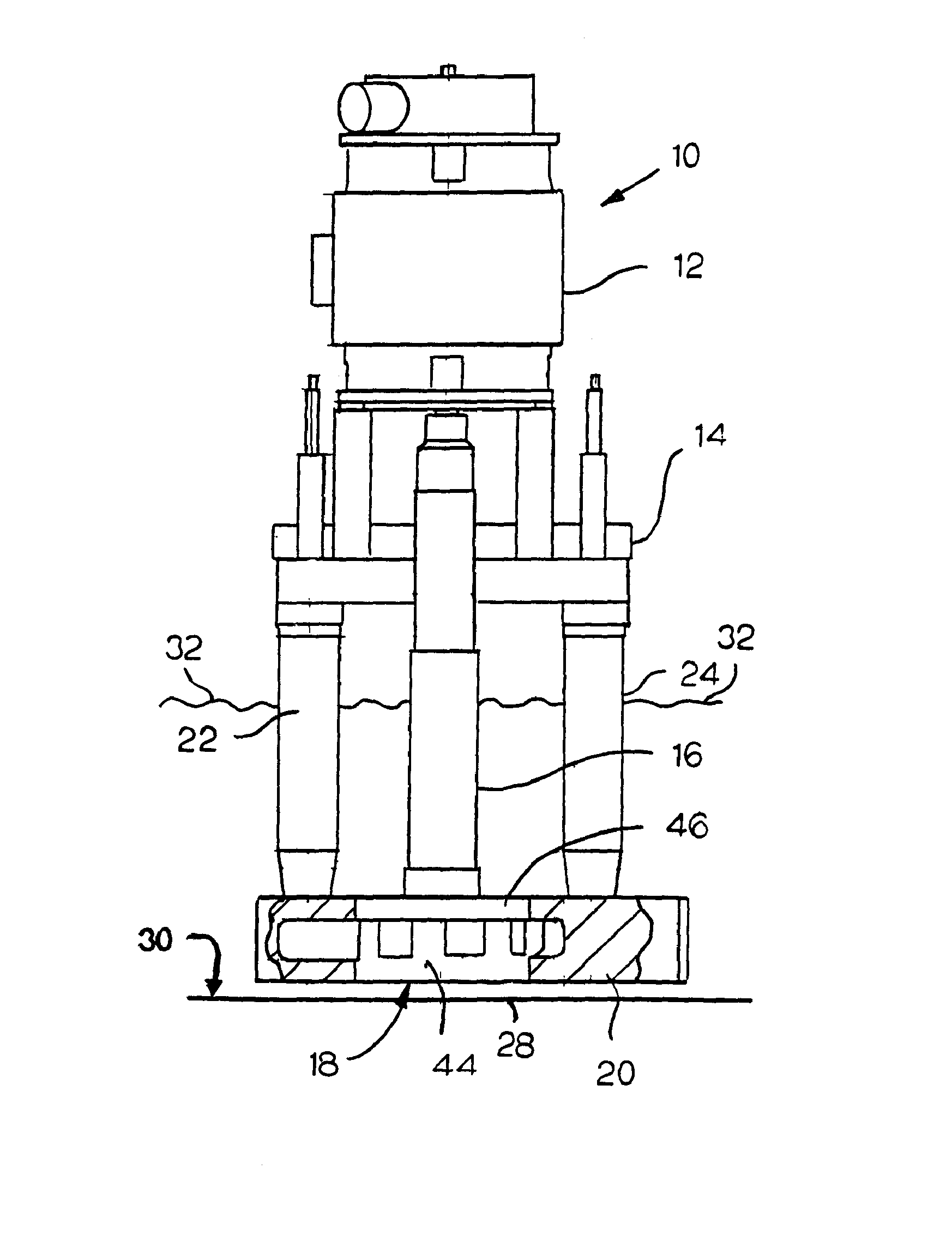

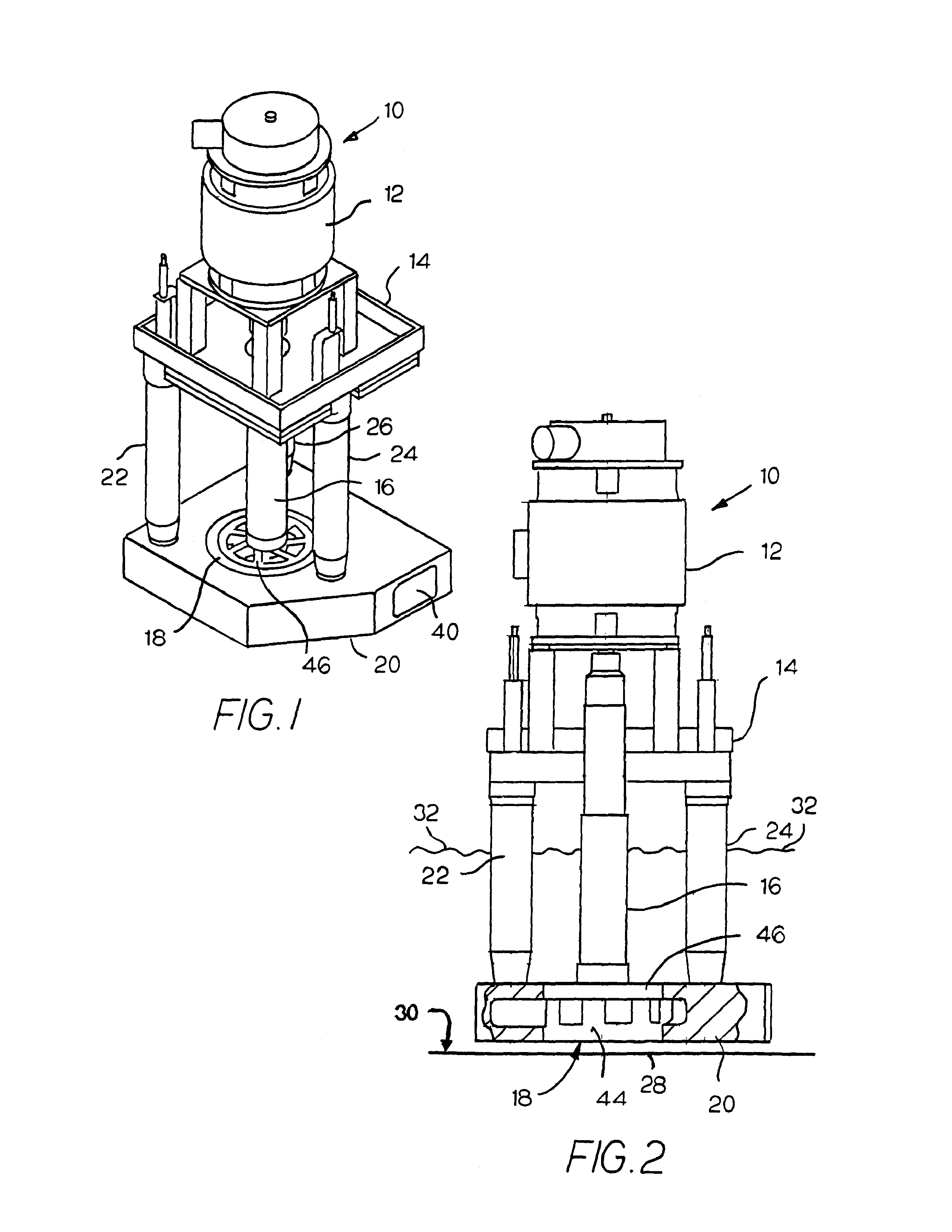

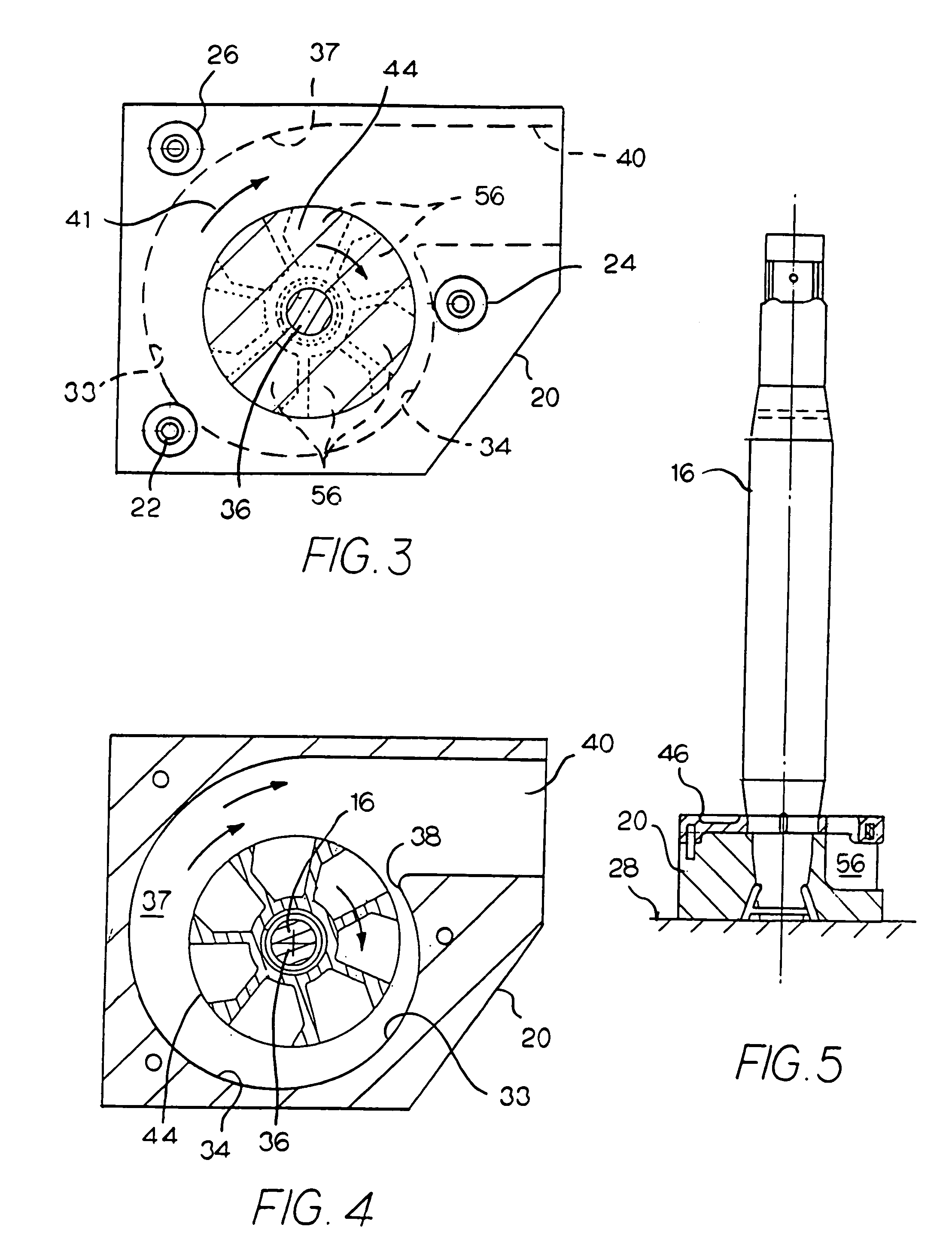

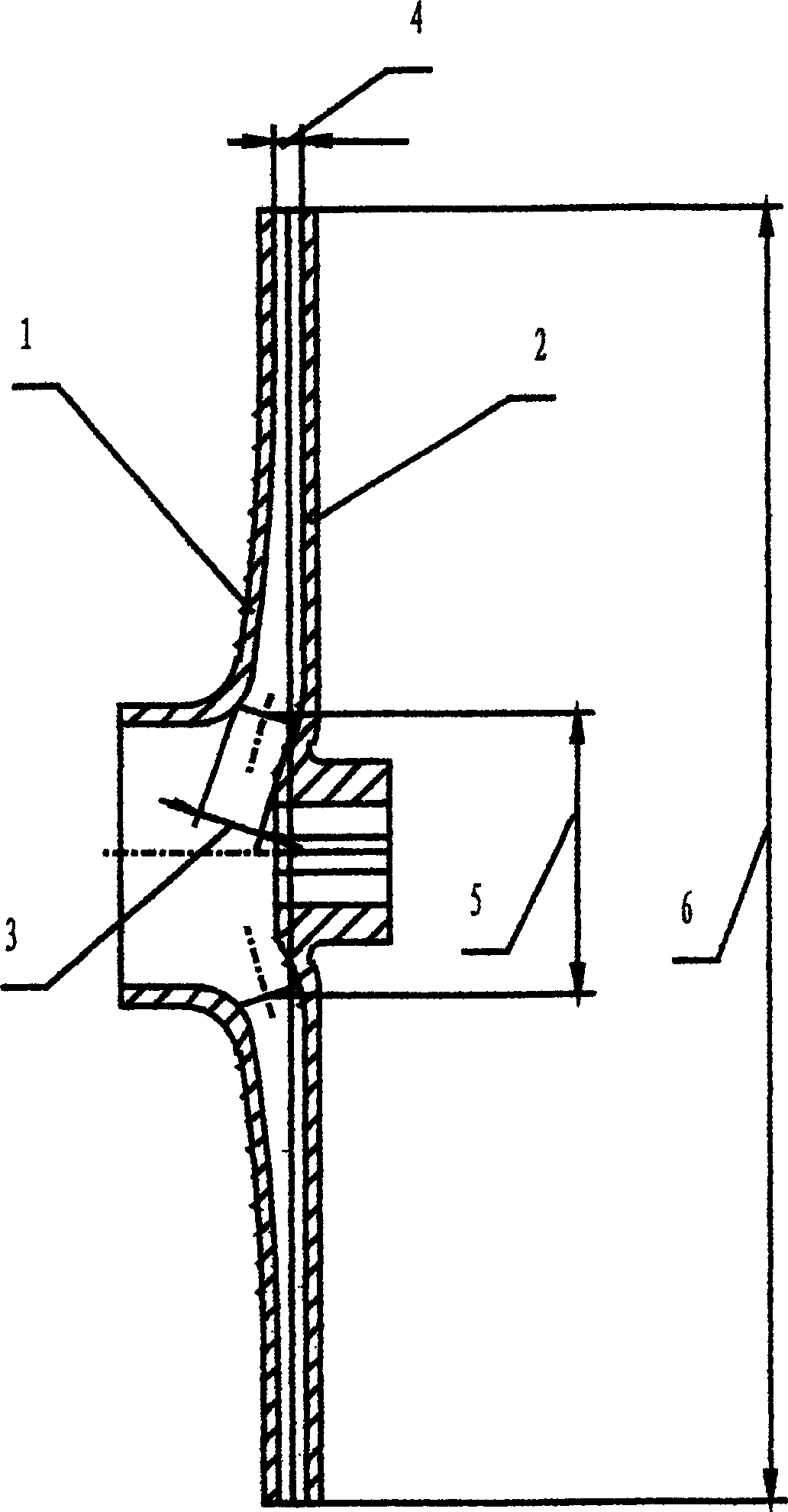

High flow/dual inducer/high efficiency impeller for liquid applications including molten metal

A centrifugal pump has a pump base with inlet inducer openings that receive molten metal into an impeller chamber. An impeller structure in the impeller chamber passes the metal in a radial direction through an outlet inducer opening into a volute passage for discharge into the pool of metal in which the pump is located.

Owner:MORANDO JORGE A

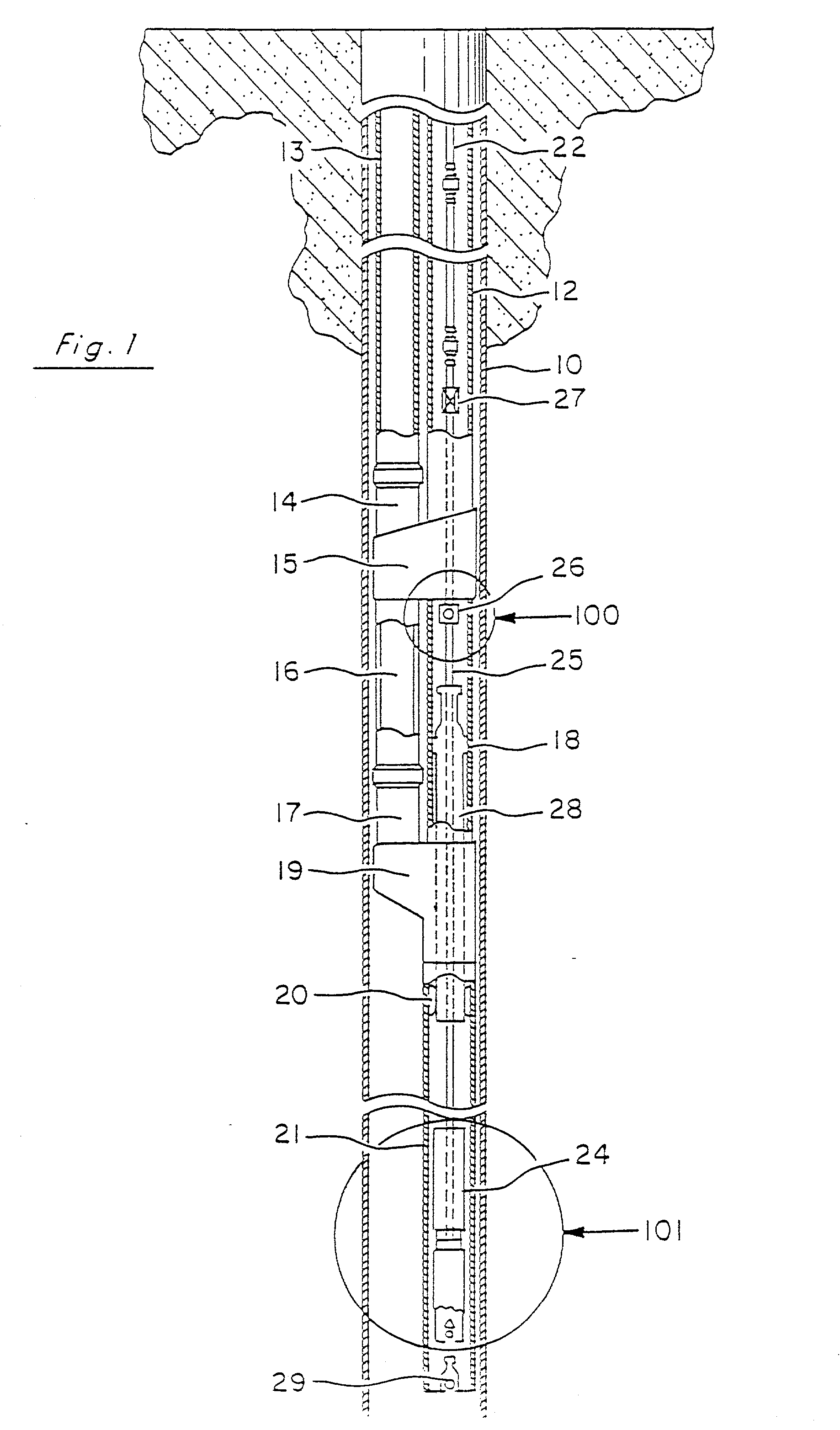

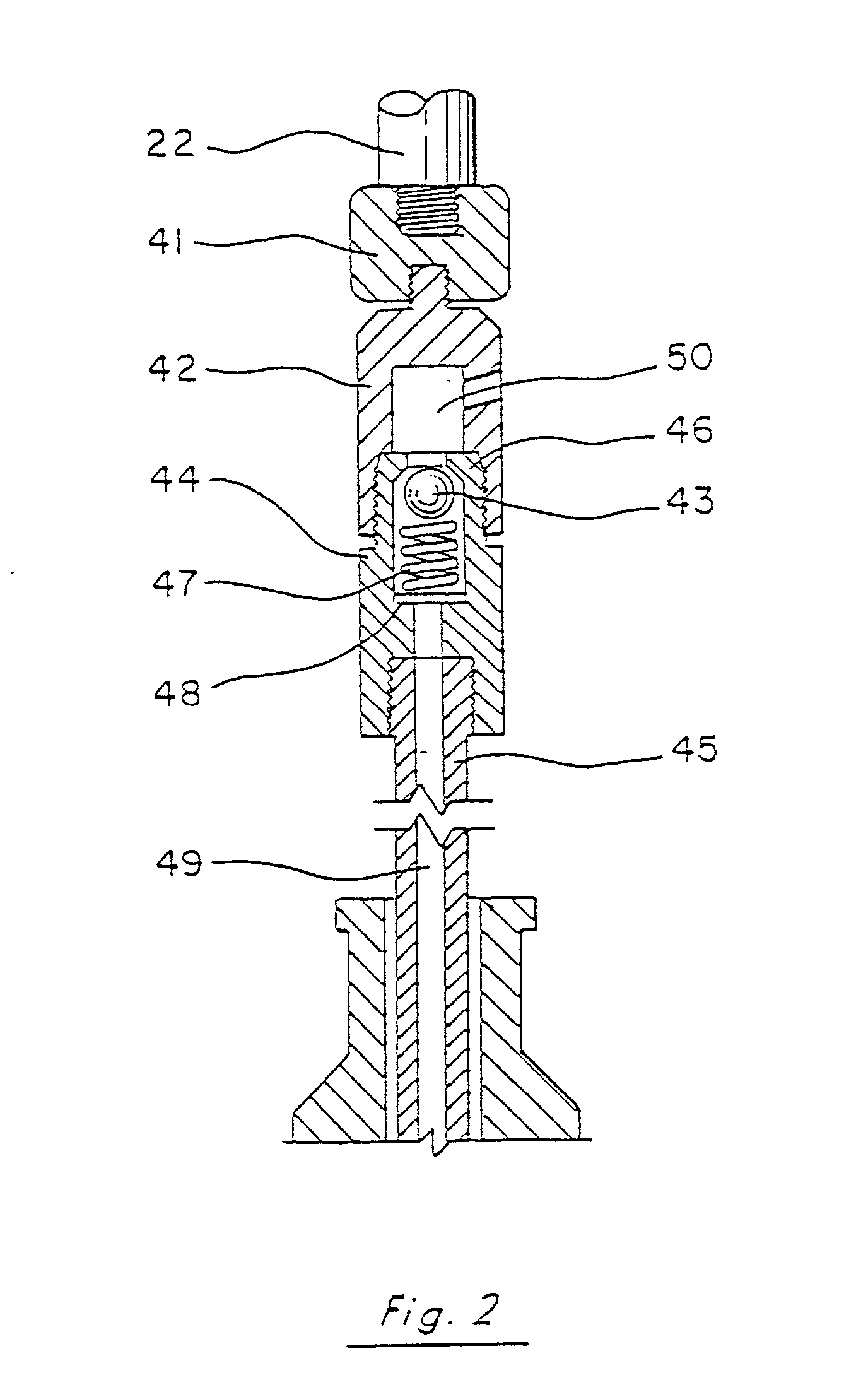

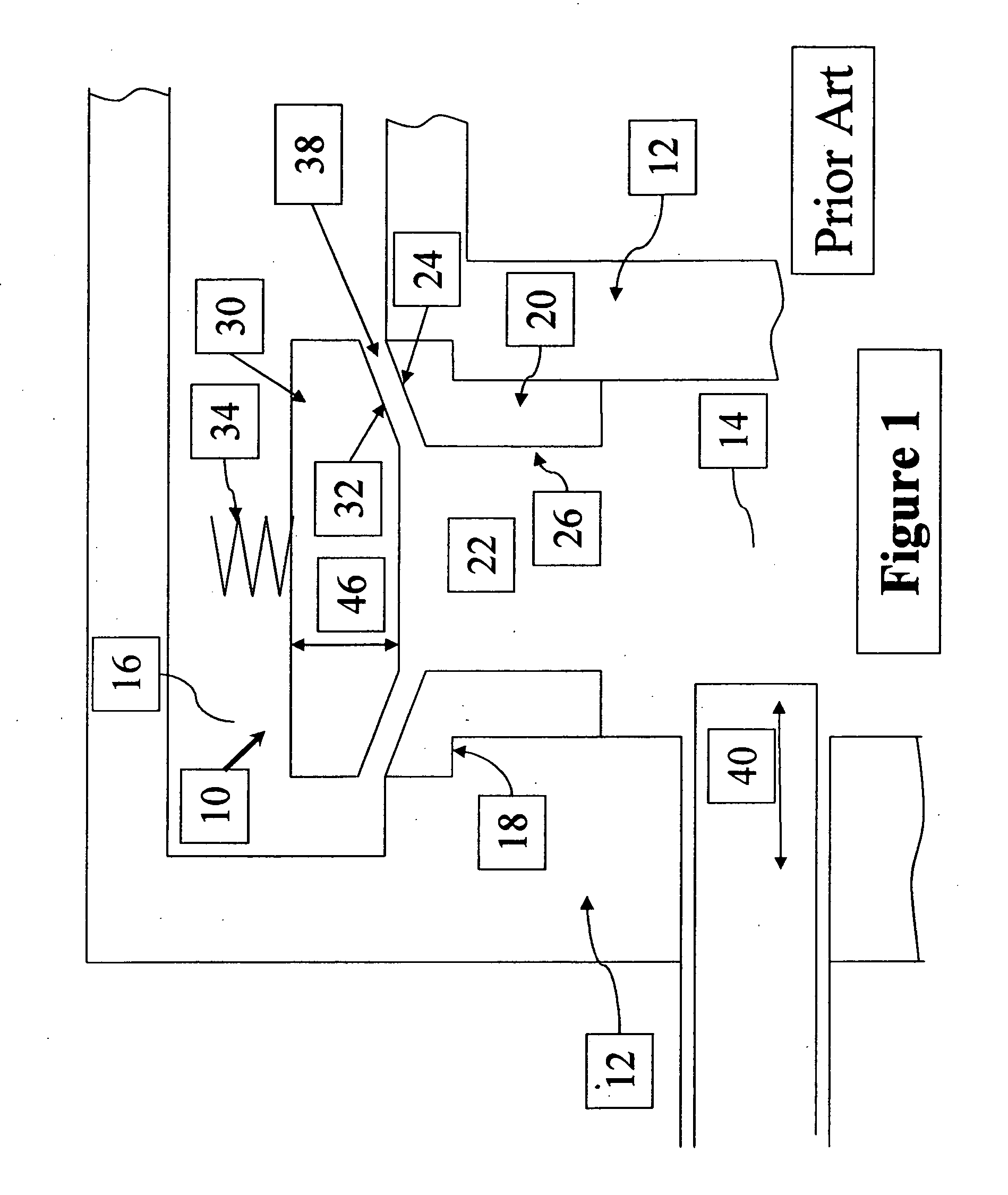

Pump systems and methods

InactiveUS6543543B2Increase pressureInhibit productionPositive displacement pump componentsConstructionsParticulatesReciprocating motion

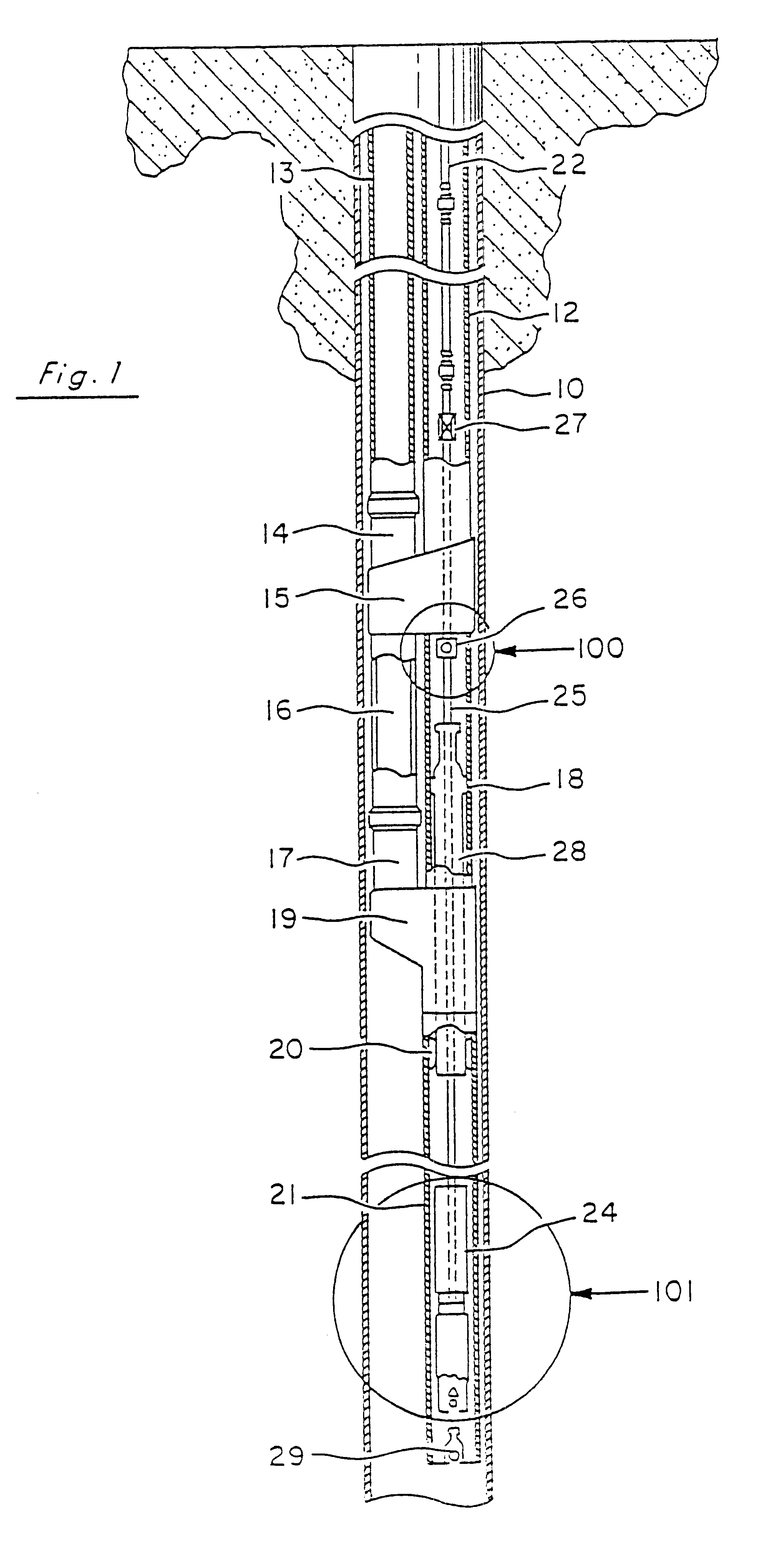

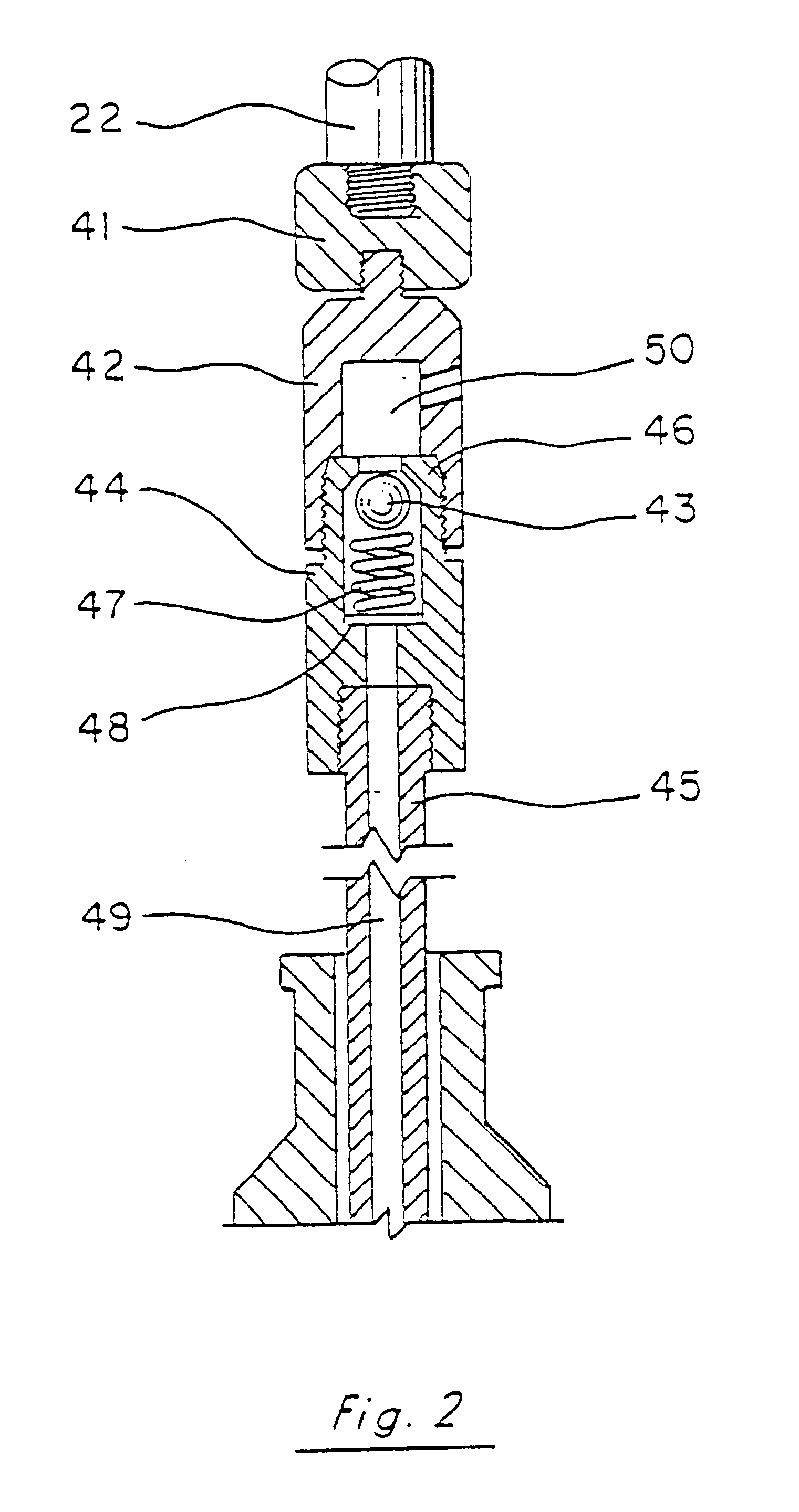

A pumping system comprises a pump barrel that is adapted to be placed into a well casing. A plunger is reciprocatably positioned within the pump barrel and has an open top end, a bottom end, and a traveling valve at the bottom end. A connector is coupled to the plunger below the top end. A rod is coupled to the connector and is translatable to reciprocate the plunger within the pump barrel using an upstroke and a downstroke. Further, the top end of the plunger is adapted to direct particulate into the plunger and away from the pump barrel upon each upstroke.

Owner:MUTH PUMP

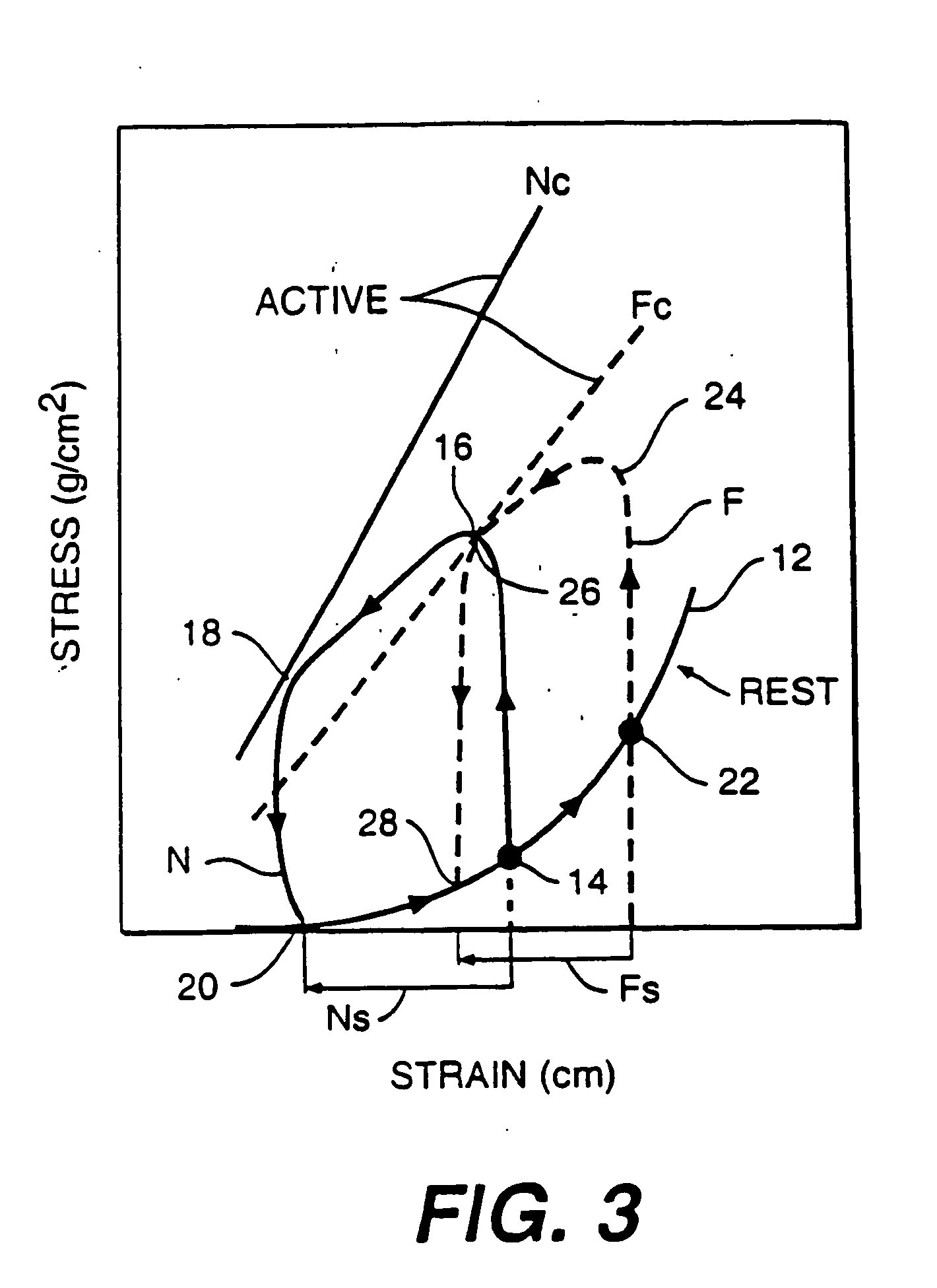

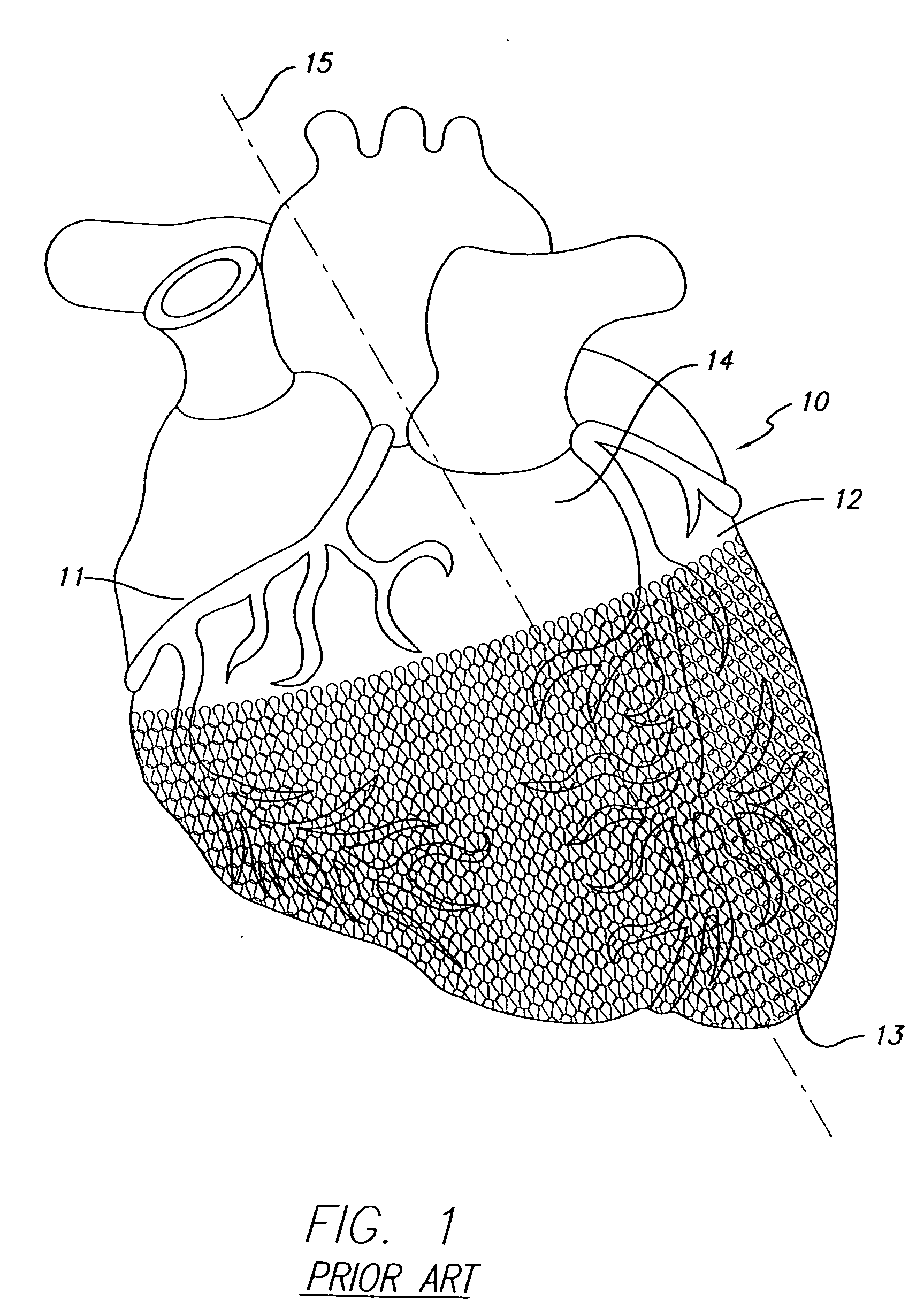

Stress reduction apparatus and method

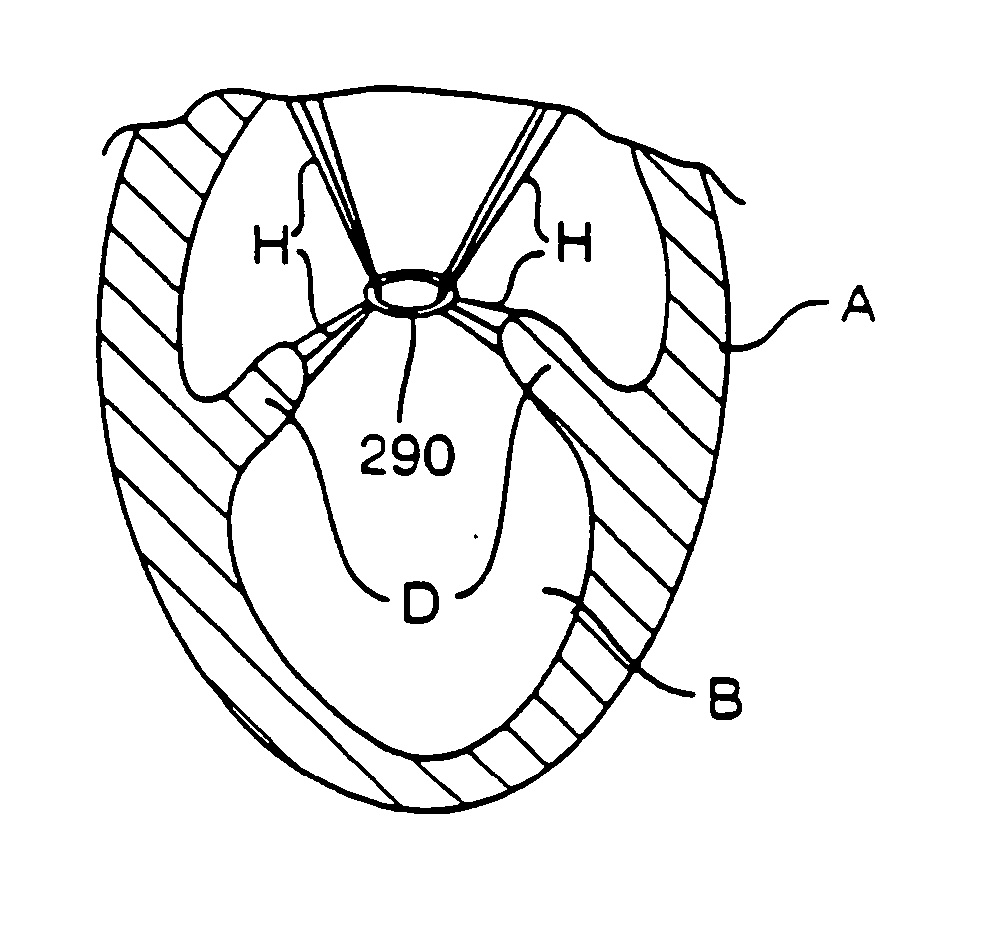

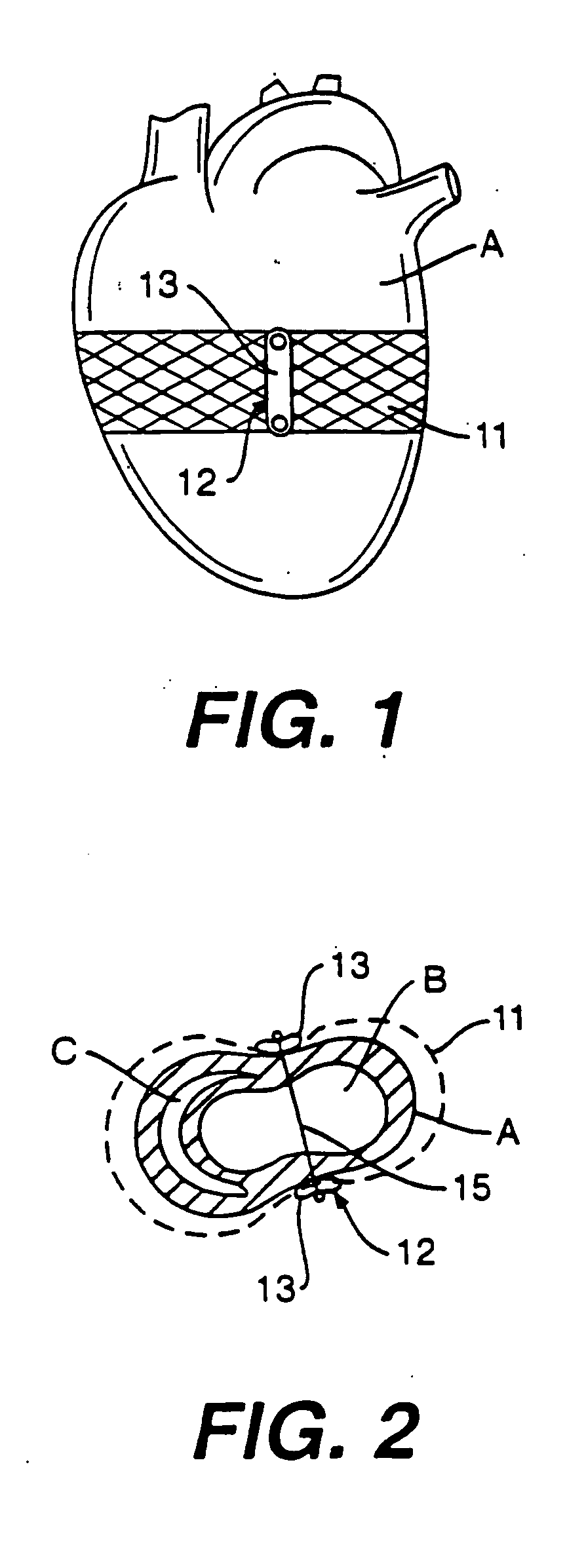

InactiveUS20050143620A1Relieve pressureRelieve muscle stressSuture equipmentsHeart valvesCardiac cycleStress reduction

The device and method for reducing heart wall stress. The device can be one which reduces wall stress throughout the cardiac cycle or only a portion of the cardiac cycle. The device can be configured to begin to engage, to reduce wall stress during diastolic filling, or begin to engage to reduce wall stress during systolic contraction. Furthermore, the device can be configured to include at least two elements, one of which engages full cycle and the other which engages only during a portion of the cardiac cycle.

Owner:EDWARDS LIFESCIENCES LLC

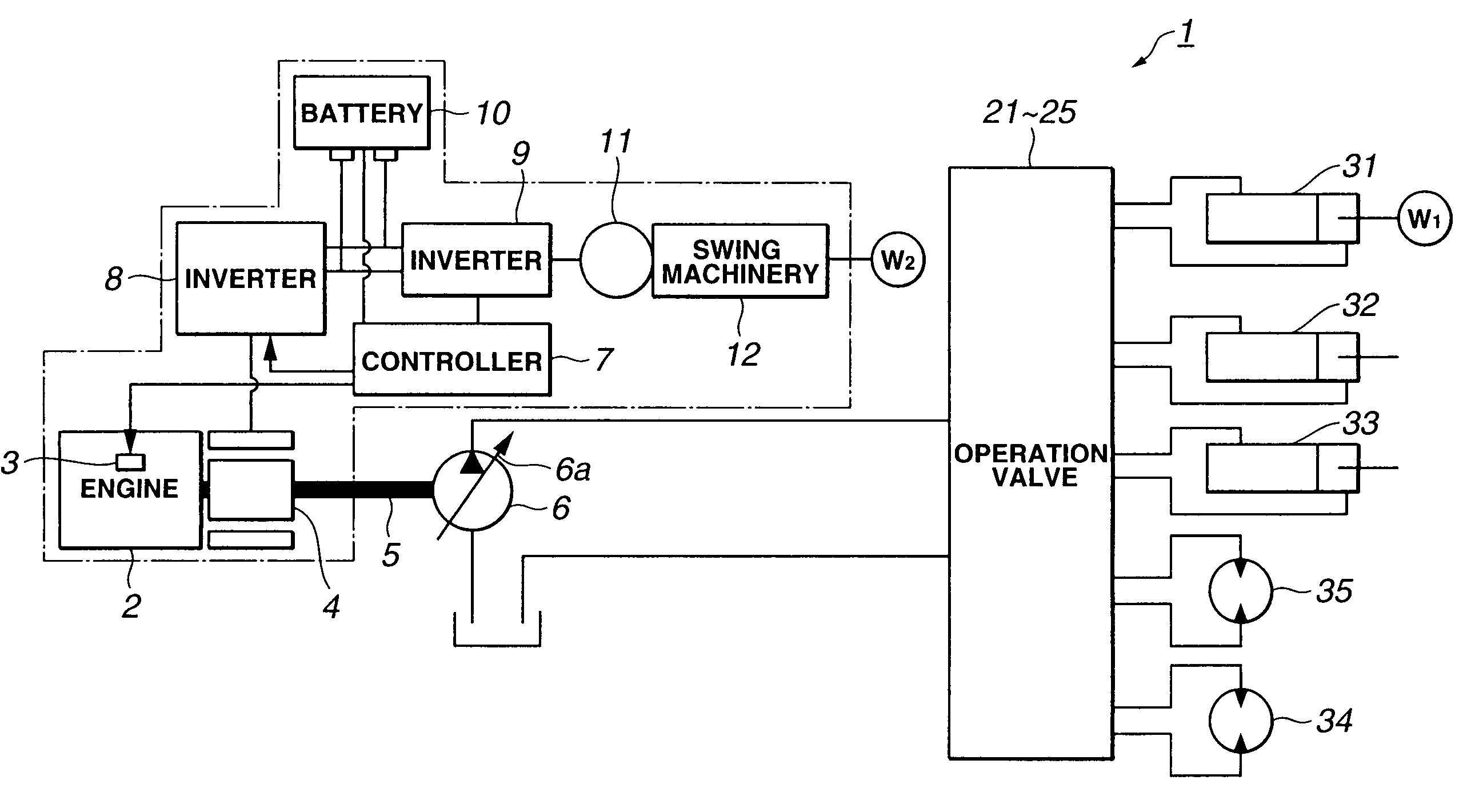

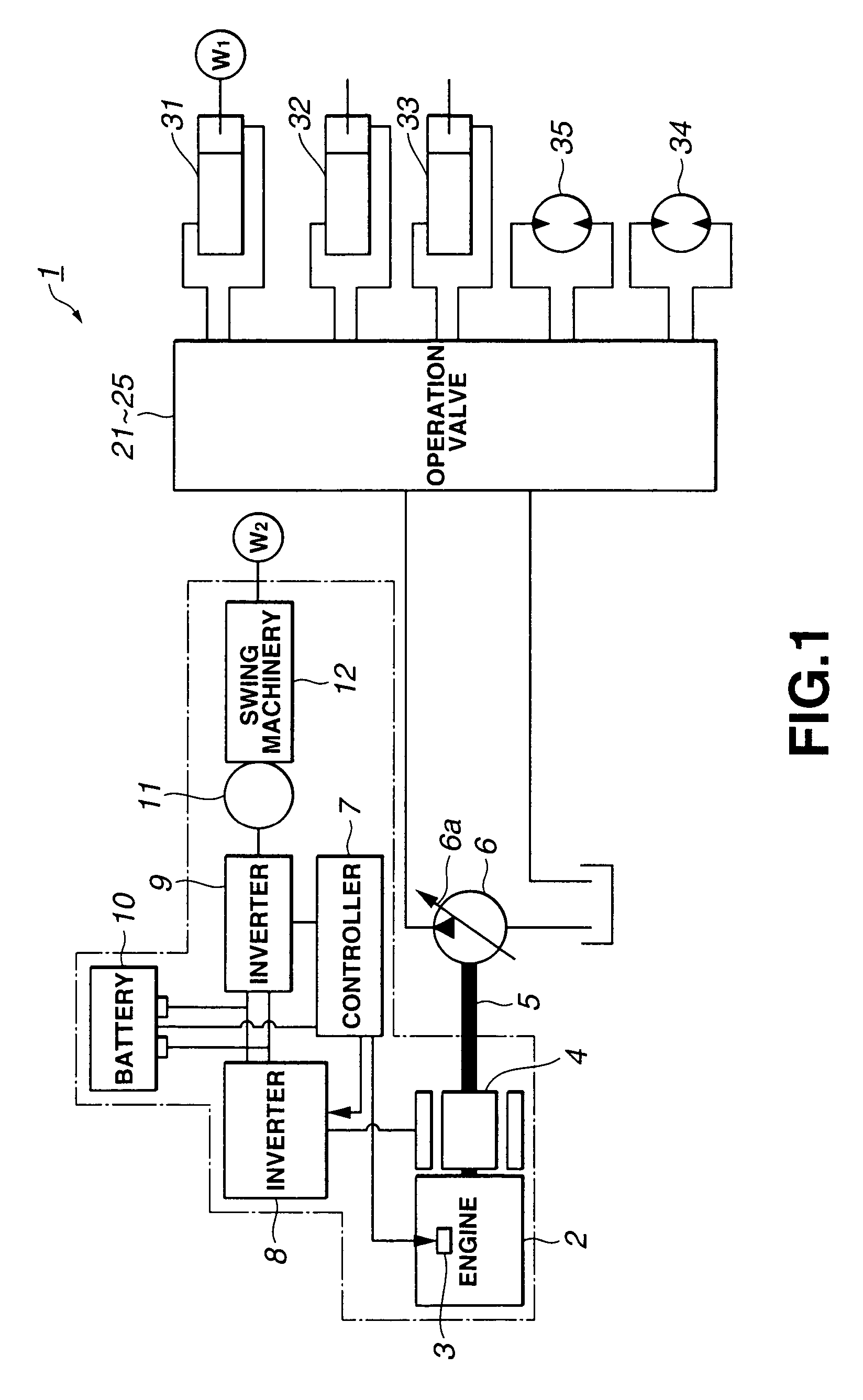

Engine control device

InactiveUS6959241B2Short timeImprove responsivenessAnalogue computers for vehiclesElectrical controlEngine efficiencyResponsivity

An engine control device capable of improving engine efficiency by operating the engine in an area where fuel consumption is small (good) while allowing high responsivity of the engine to be maintained. The object can be achieved by operating to match at a point on a target torque line of a torque diagram and operating an electric motor when a matching point moves on the target torque line in a direction in which a load applied to the engine output shaft becomes large.

Owner:KOMATSU LTD

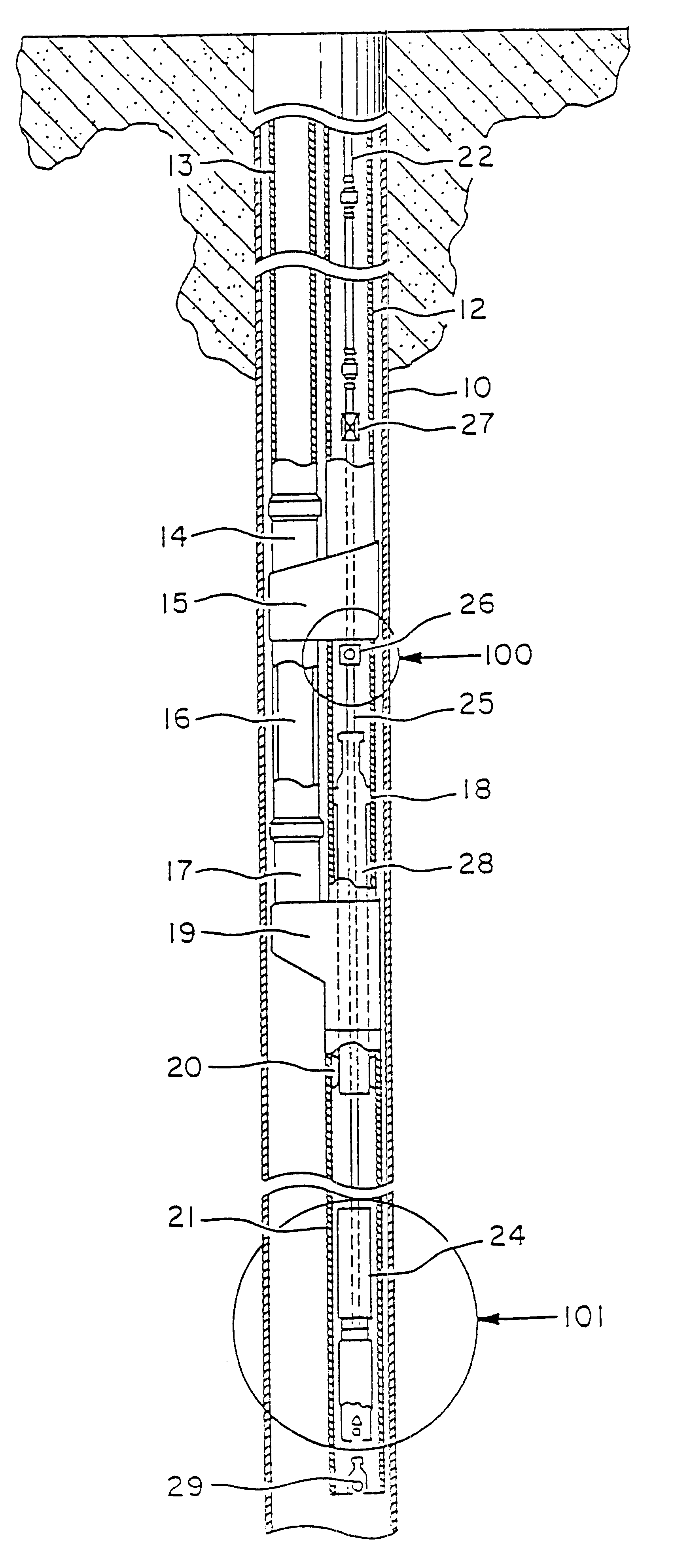

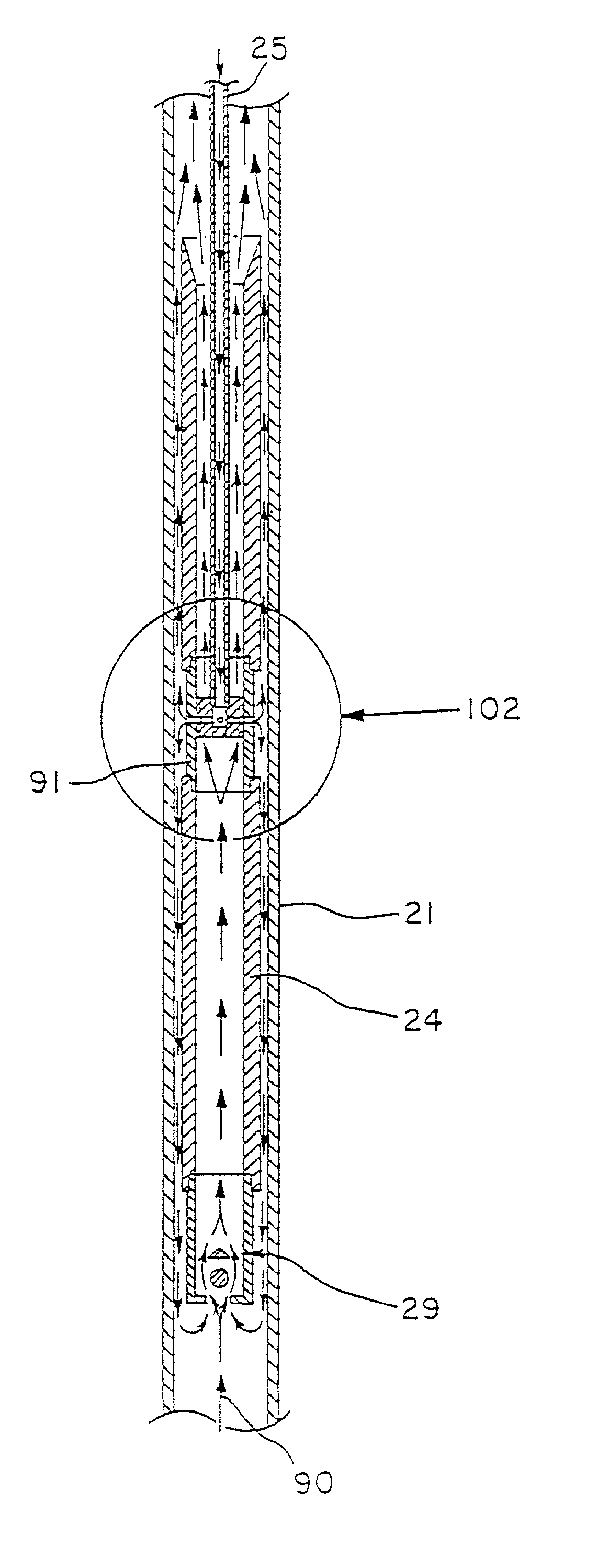

Pump systems and methods

InactiveUS20020066572A1Increase pressureInhibit productionPositive displacement pump componentsConstructionsParticulatesReciprocating motion

A pumping system comprises a pump barrel that is adapted to be placed into a well casing. A plunger is reciprocatably positioned within the pump barrel and has an open top end, a bottom end, and a traveling valve at the bottom end. A connector is coupled to the plunger below the top end. A rod is coupled to the connector and is translatable to reciprocate the plunger within the pump barrel using an upstroke and a downstroke. Further, the top end of the plunger is adapted to direct particulate into the plunger and away from the pump barrel upon each upstroke.

Owner:MUTH PUMP

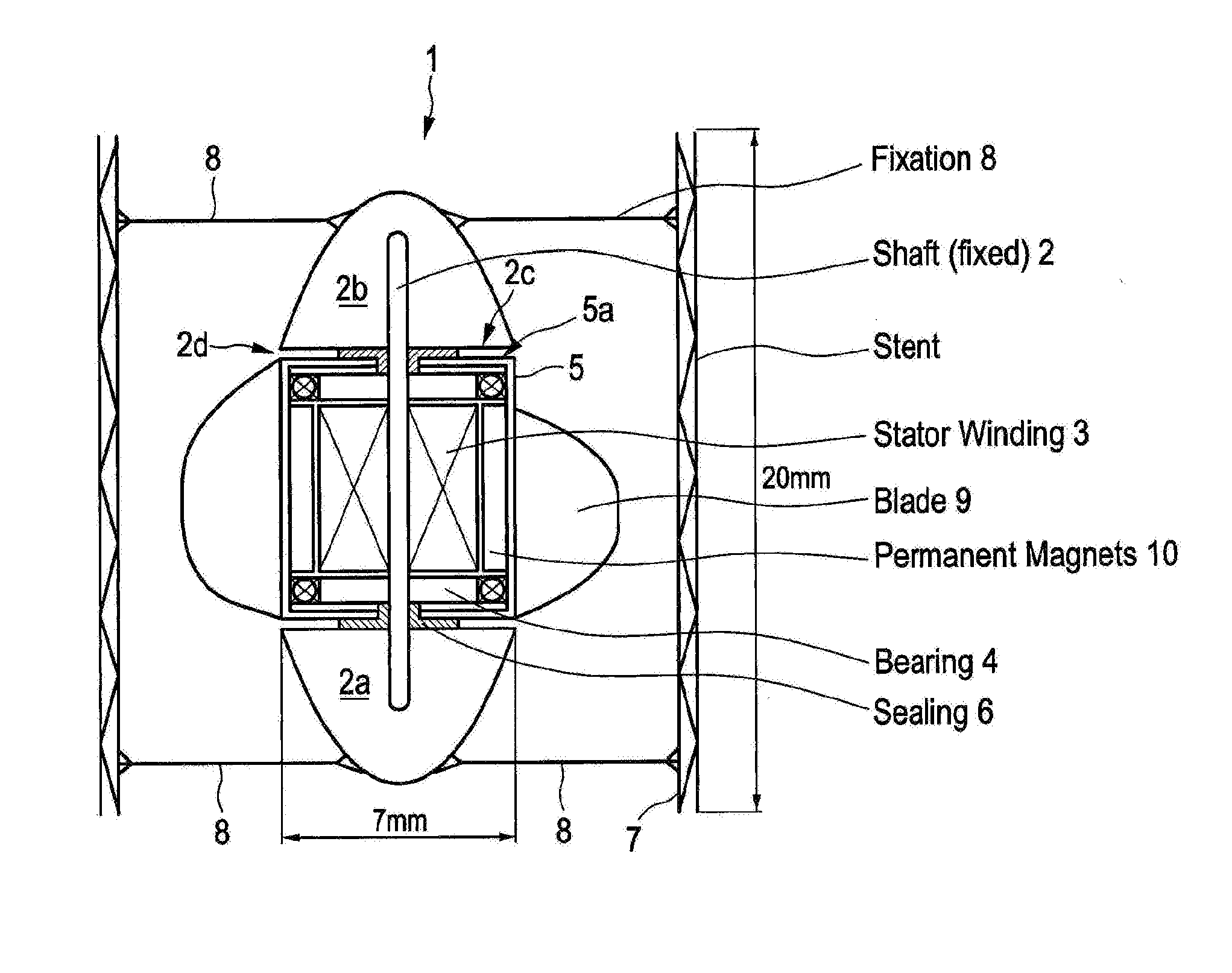

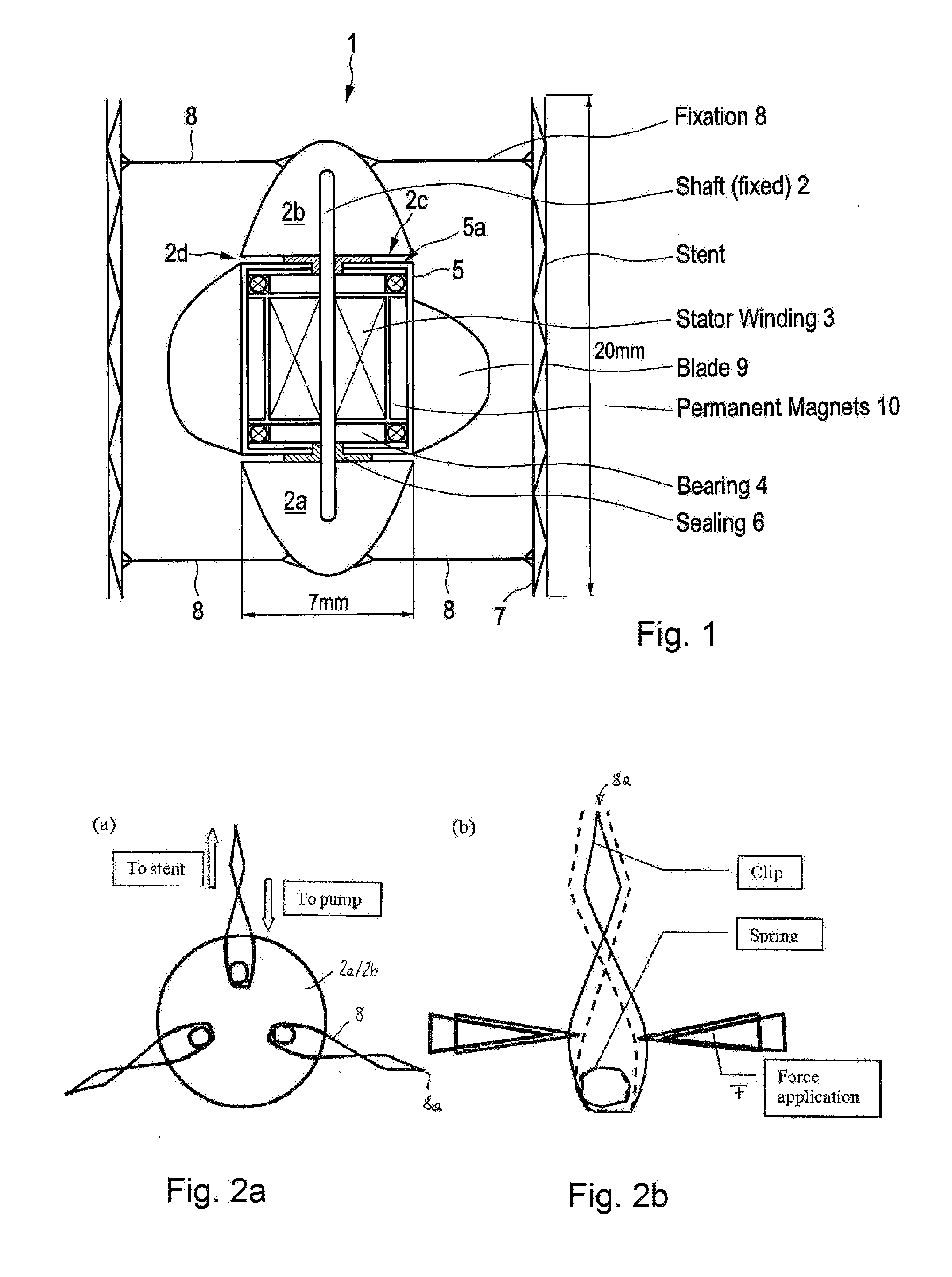

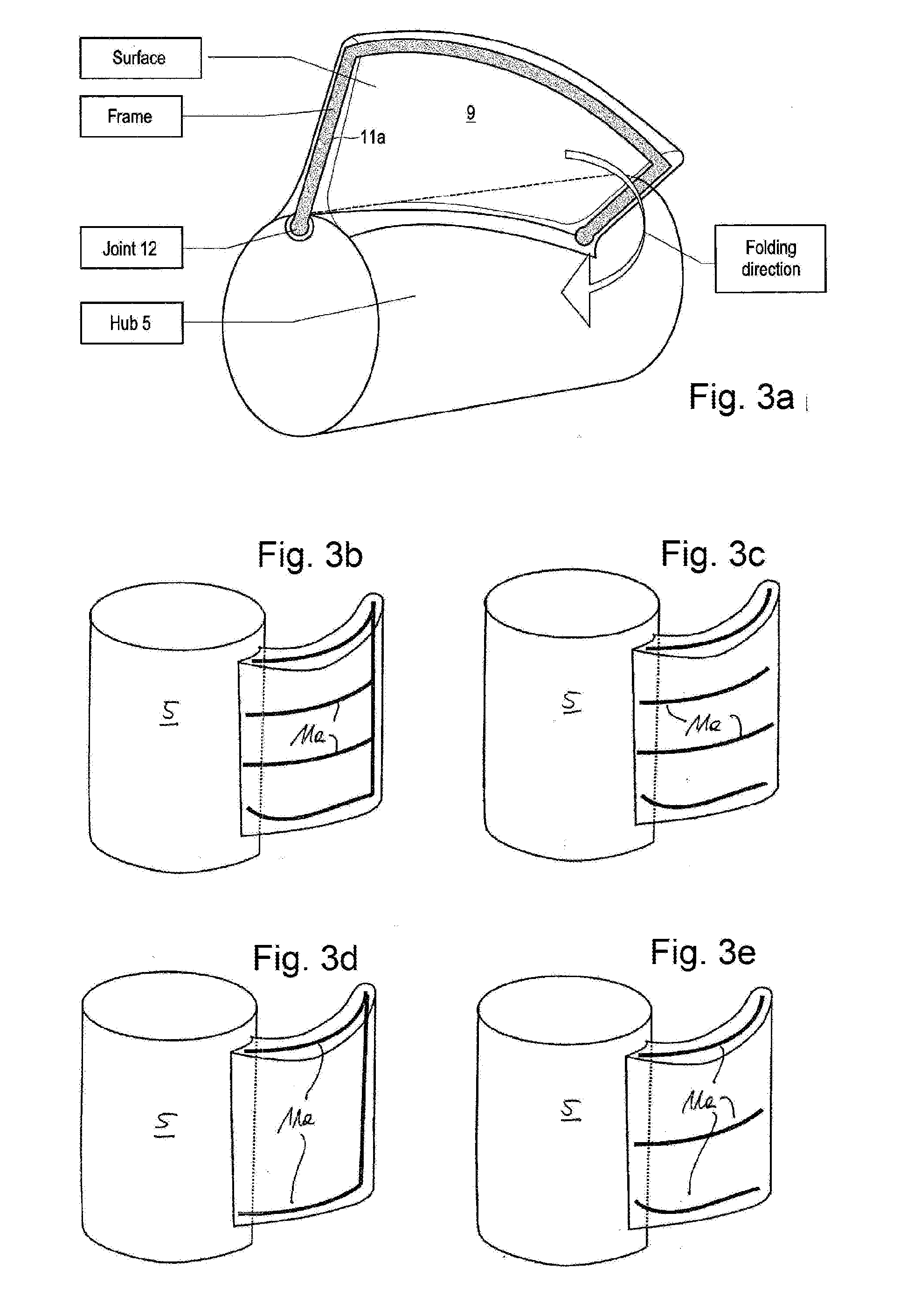

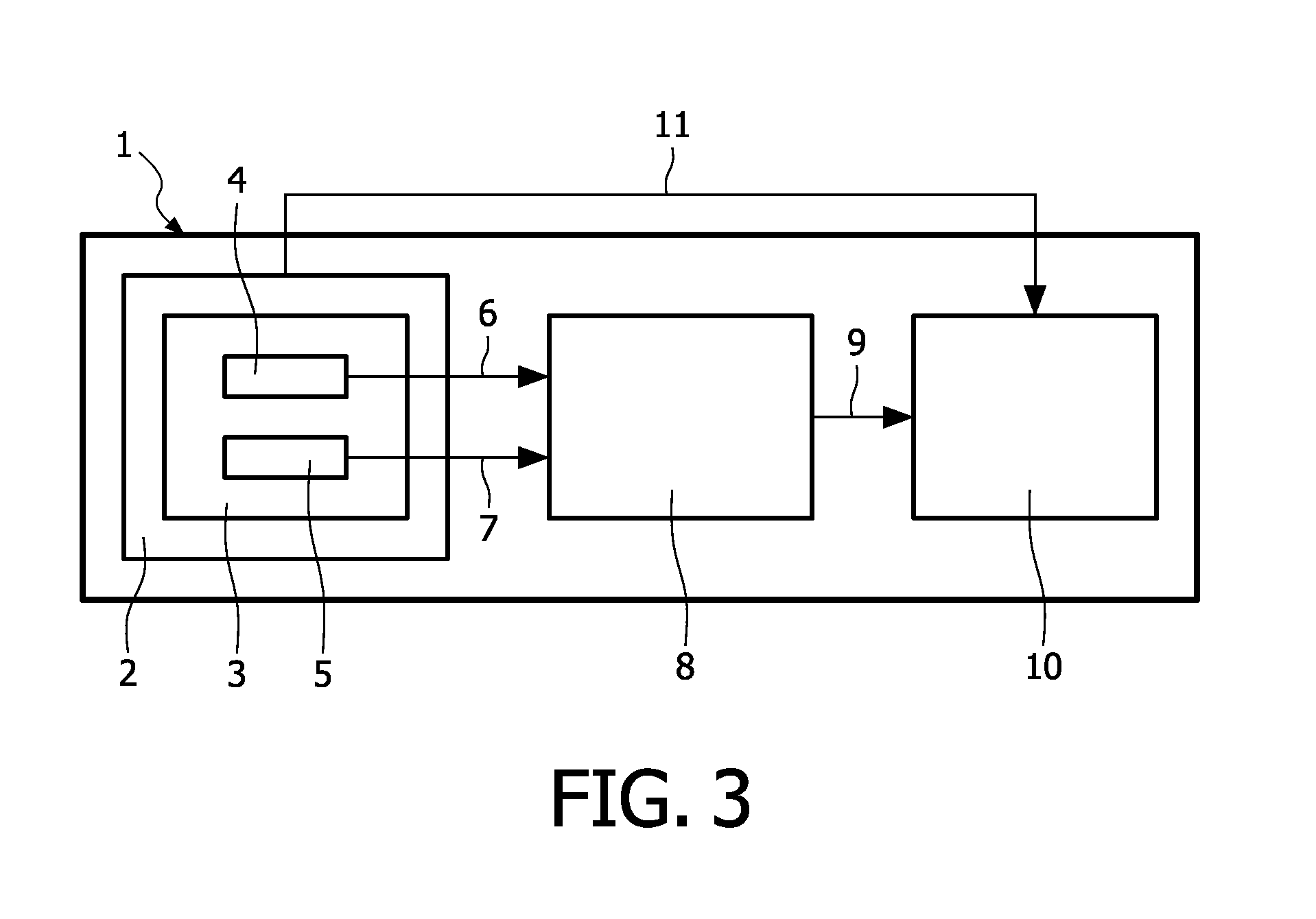

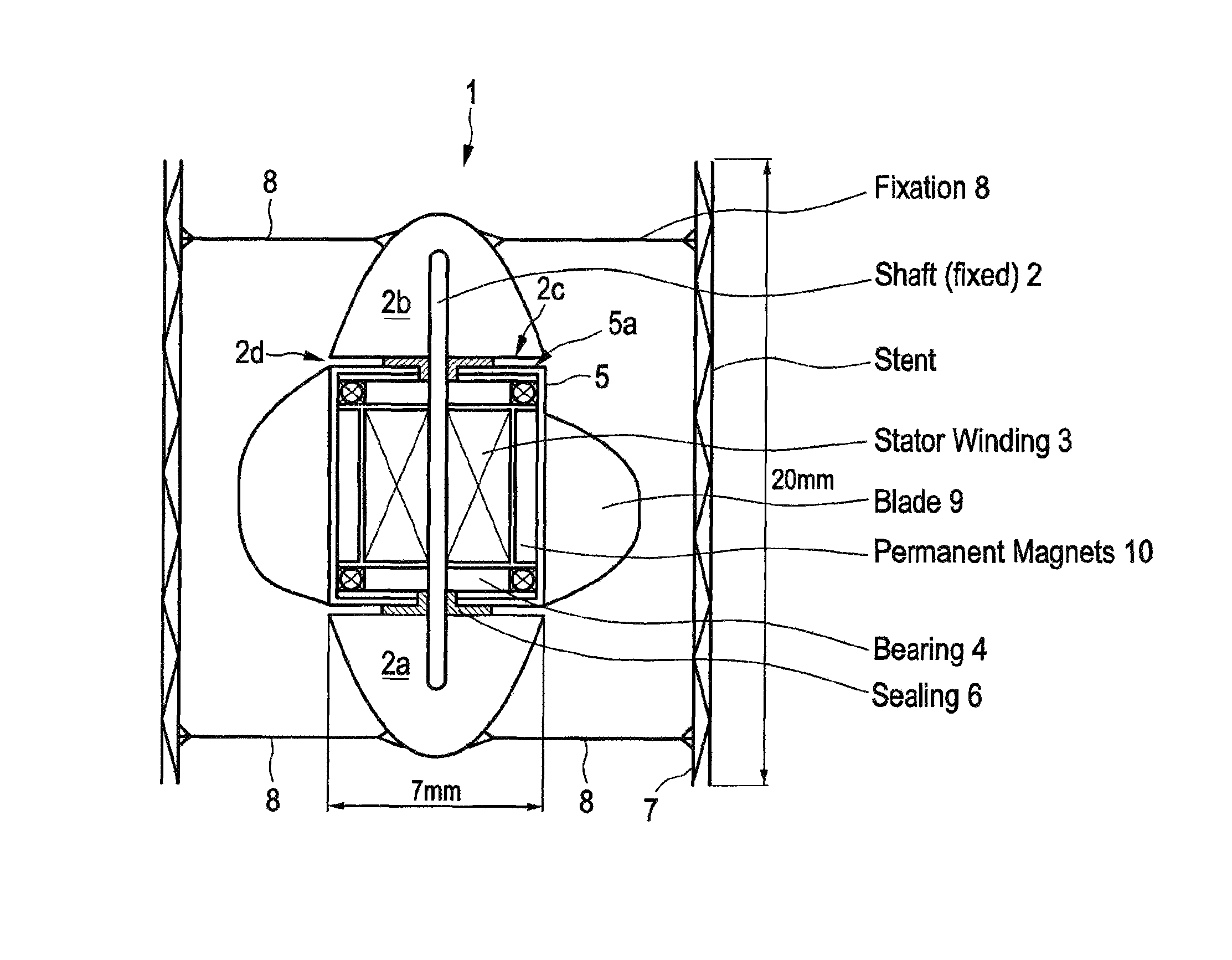

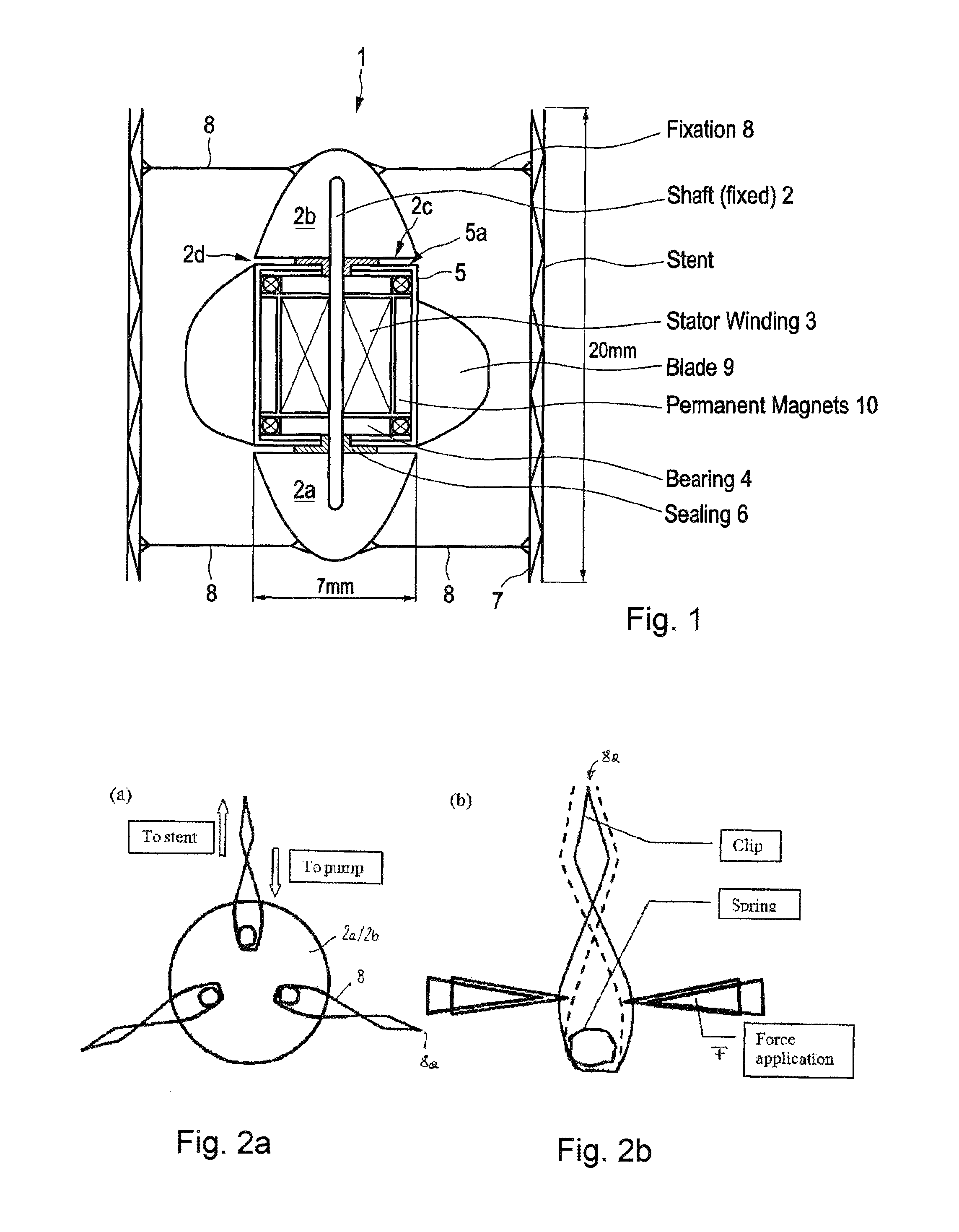

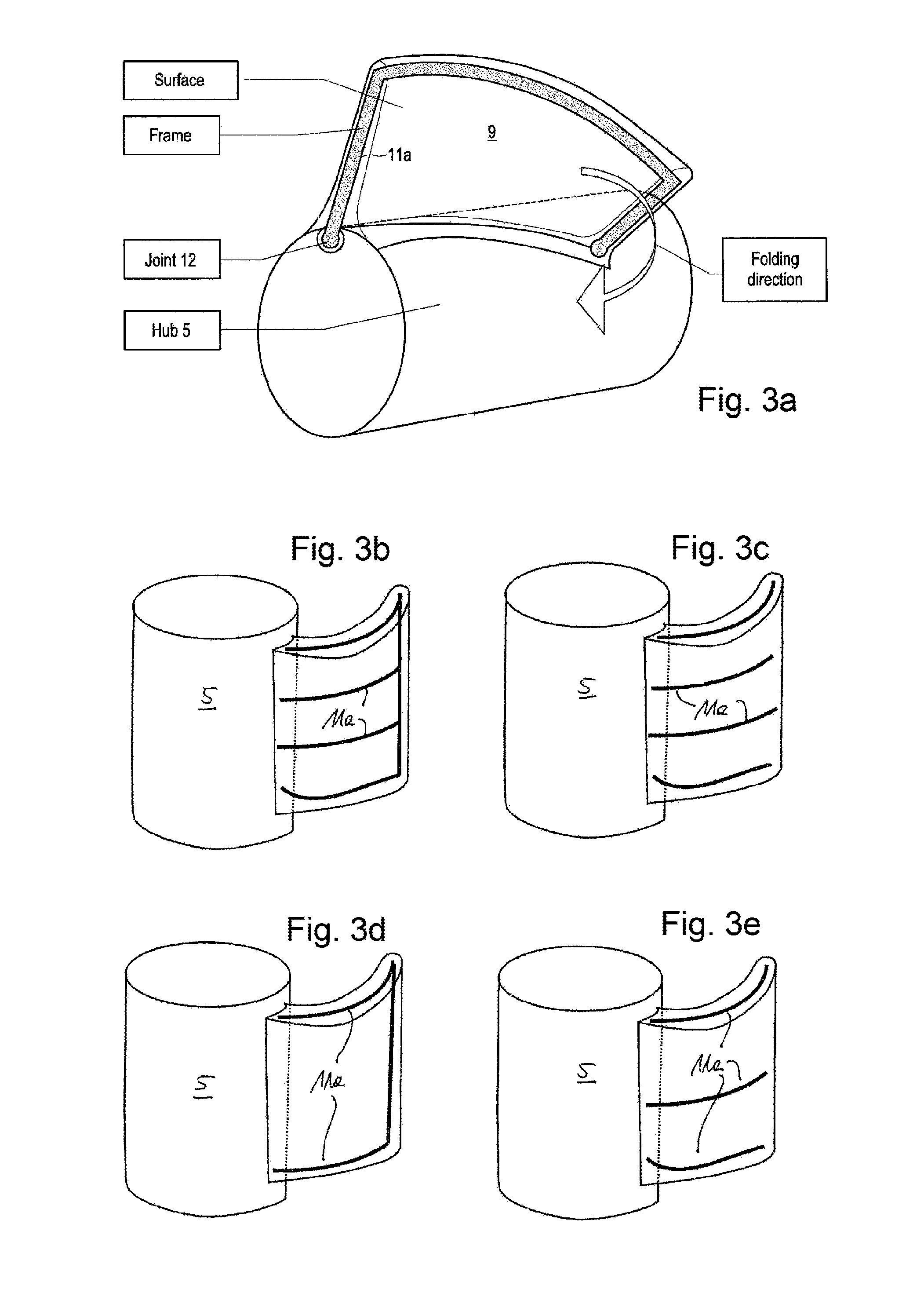

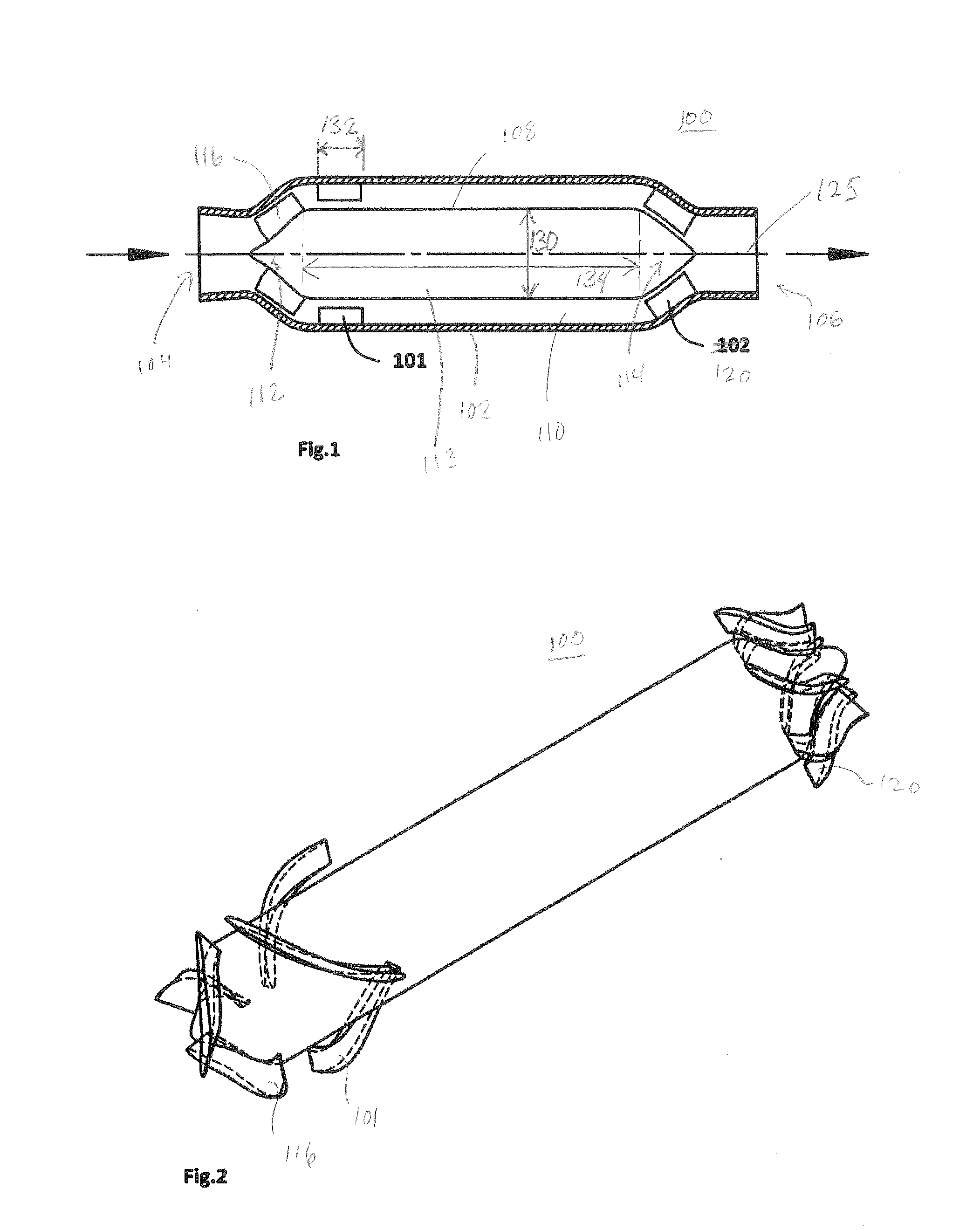

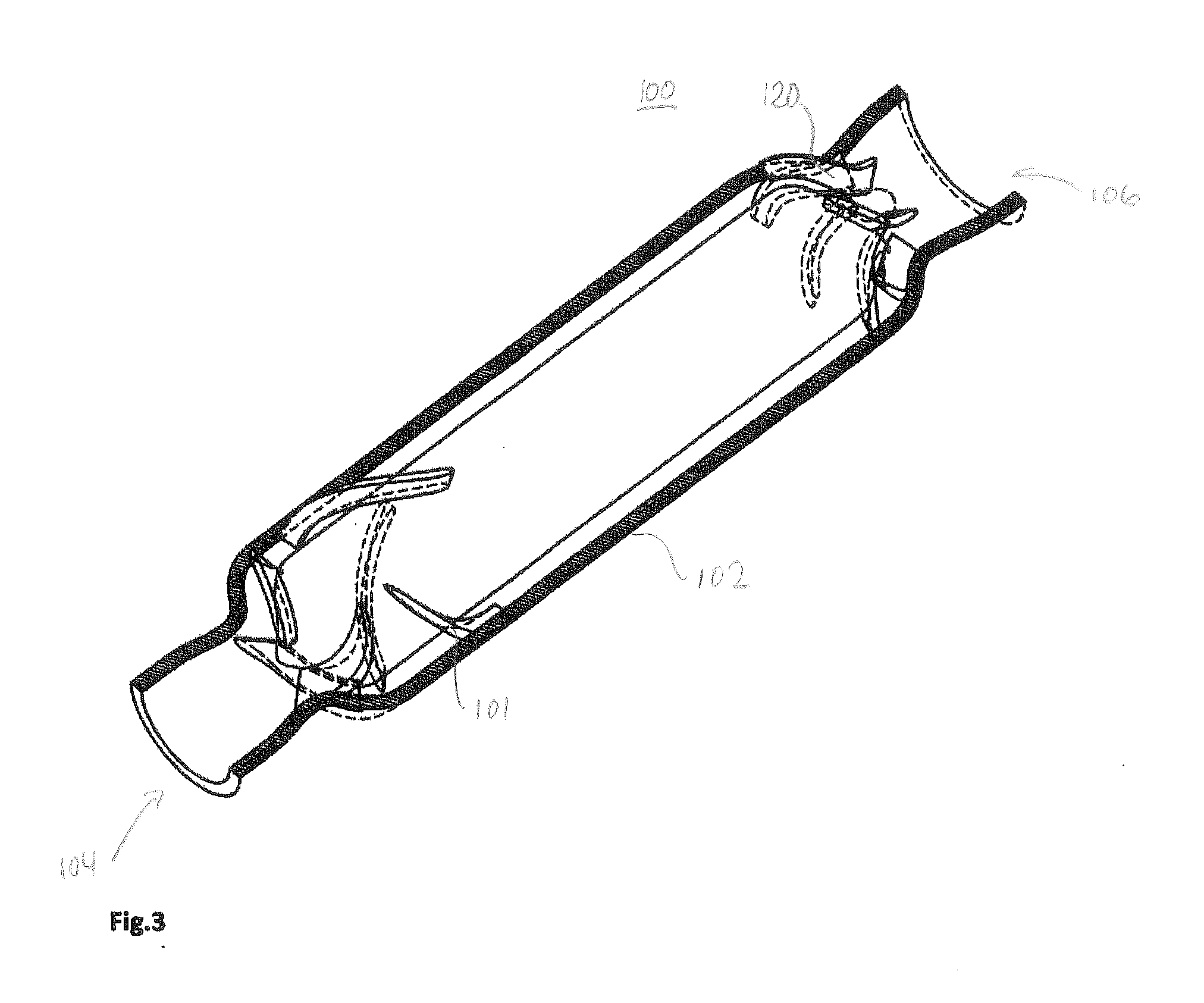

Axial-flow blood pump

The invention relates to an axial flow blood pump device comprising an integrated electromagnetic drive with a stationary stator assembly and a rotatable impeller assembly, wherein the stationary stator assembly at least comprises stator windings (3) and a bearing system (4) supporting the rotatable impeller assembly, the impeller assembly comprising at least one blade (9) and permanent magnets (10) interacting with the stator windings (3), wherein the stationary stator assembly comprises supporting elements (8) for mounting, in particular coaxially mounting the device in the interior of an anchoring system (7) being implantable into a vessel. The invention furthermore relates to a system comprising a device according to any of the preceding claims and a anchoring system (7), in particular a stent (7) surrounding the device, wherein the anchoring system (7) and the device, in particular the at least one blade (9) and the supporting members (8) of the device are in a collapsed / compressed / folded state for implanting the system into a vessel, the system being expandable / unfoldable after implantation.

Owner:MAGASSIST INC

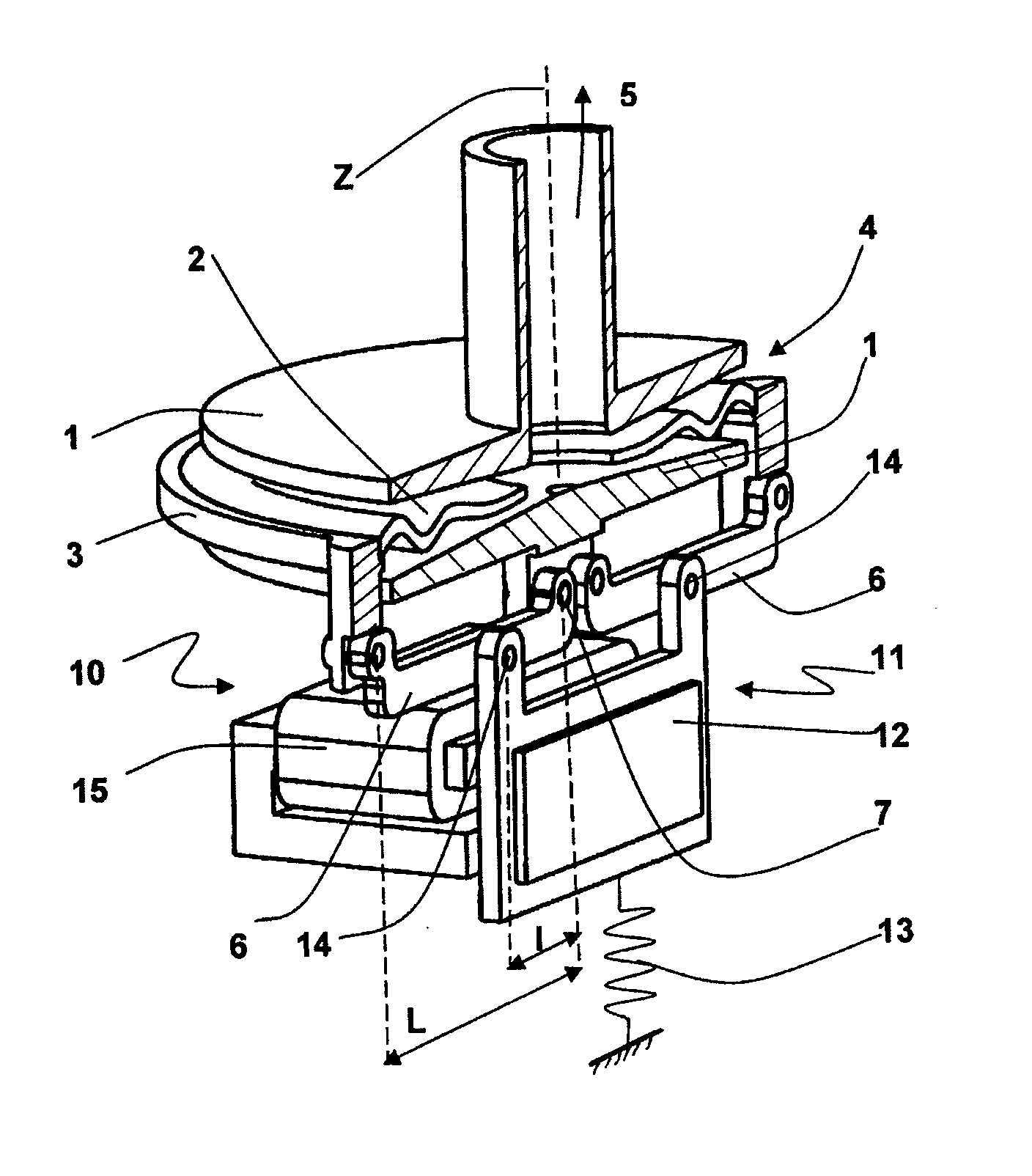

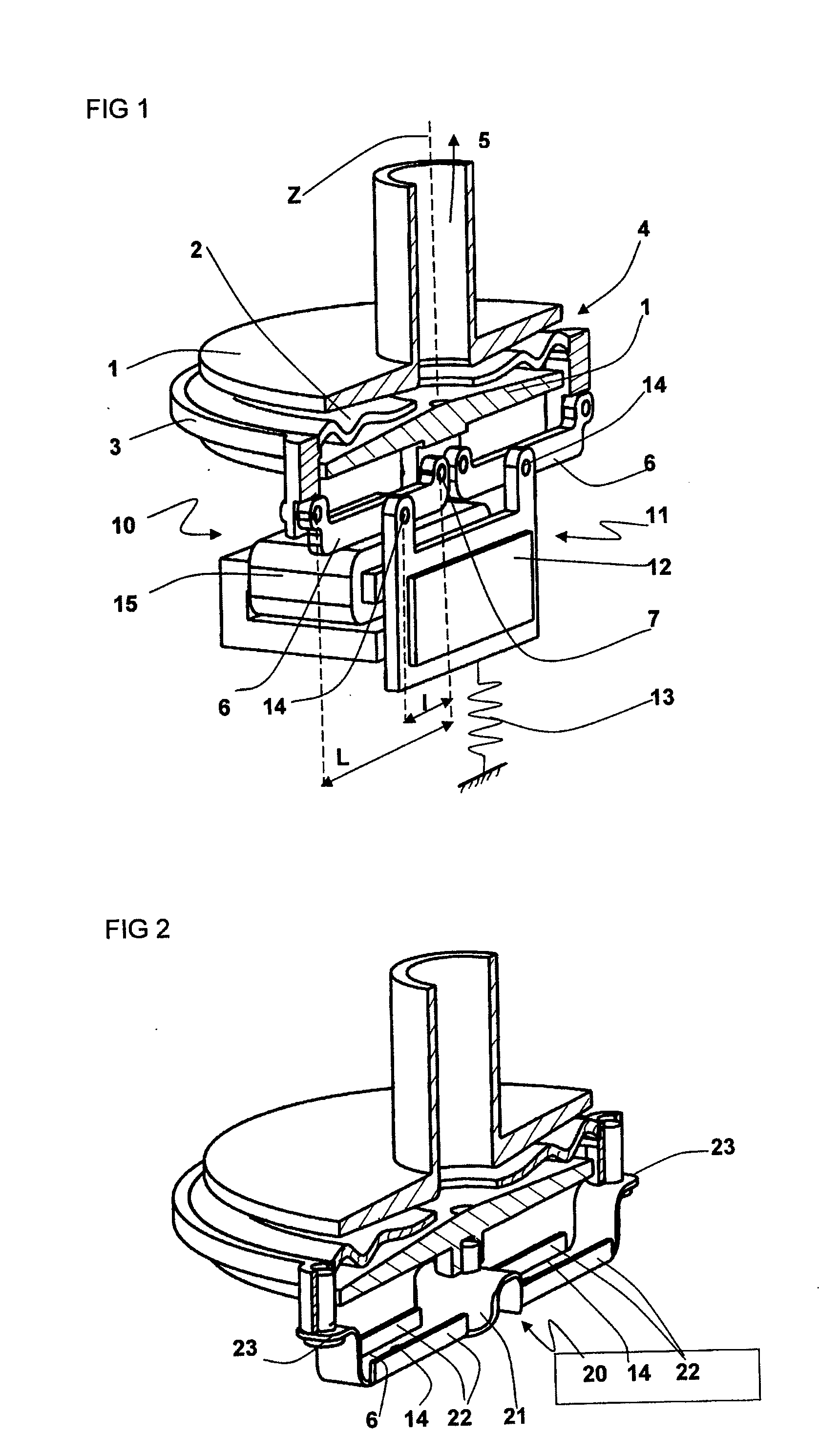

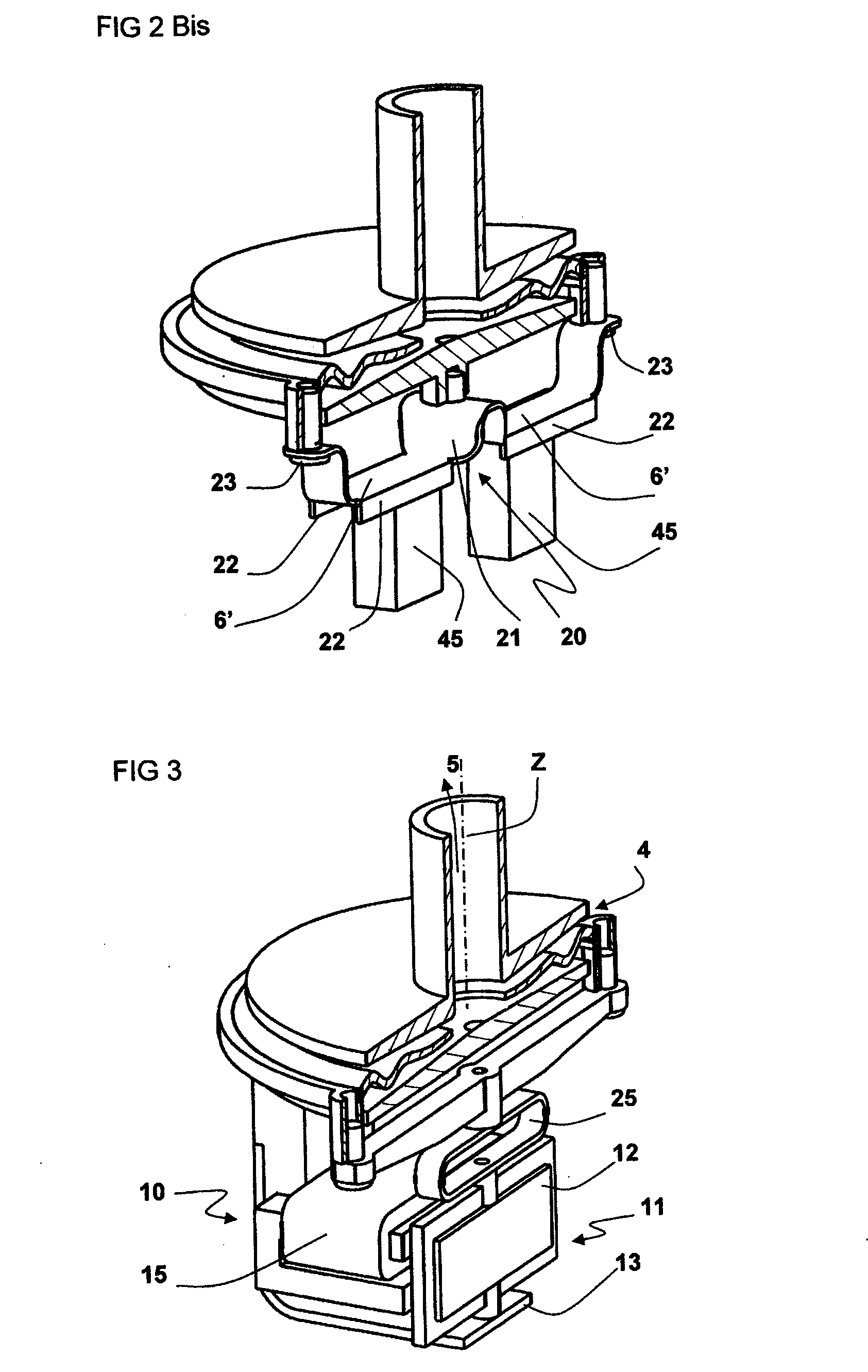

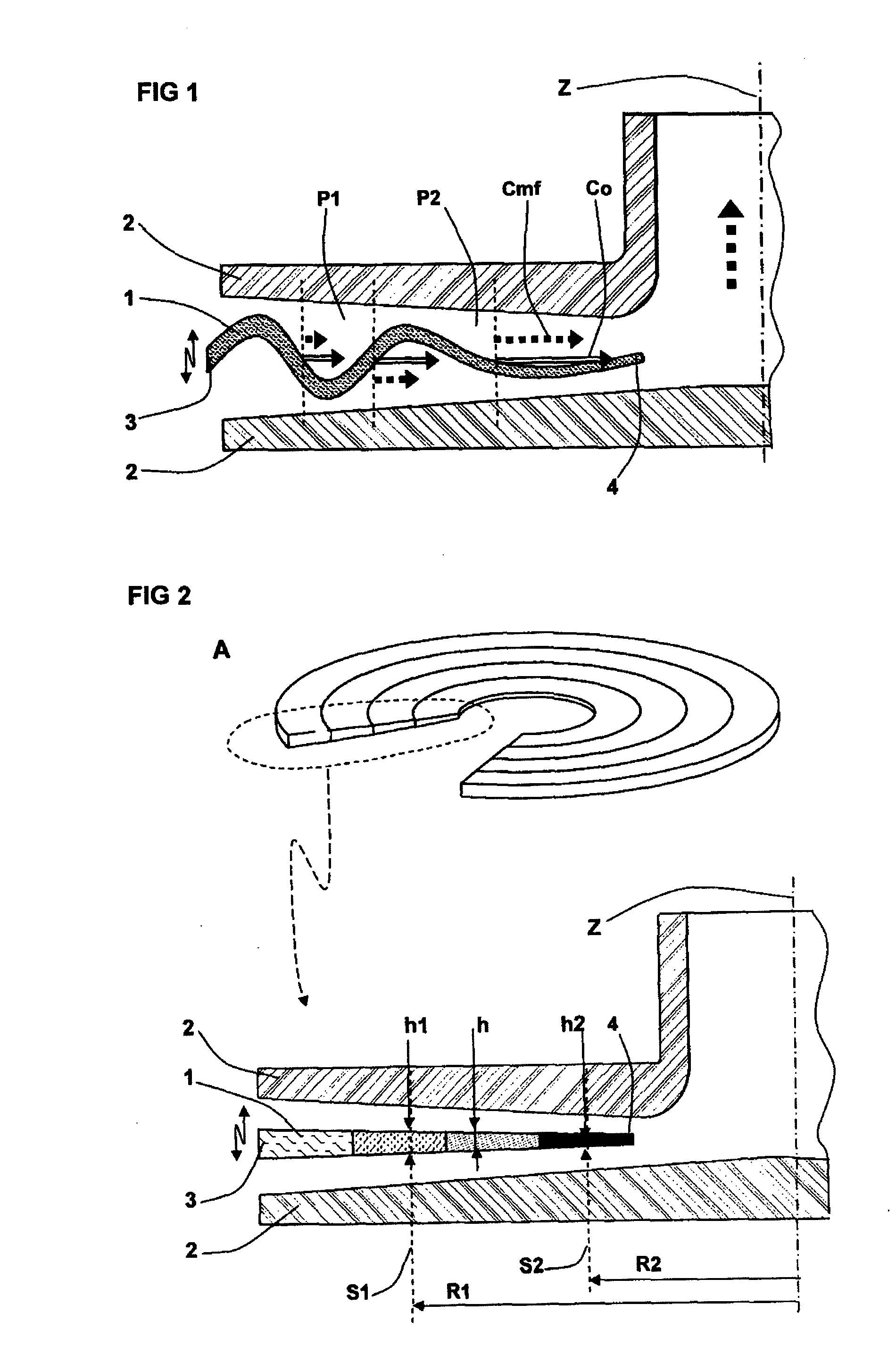

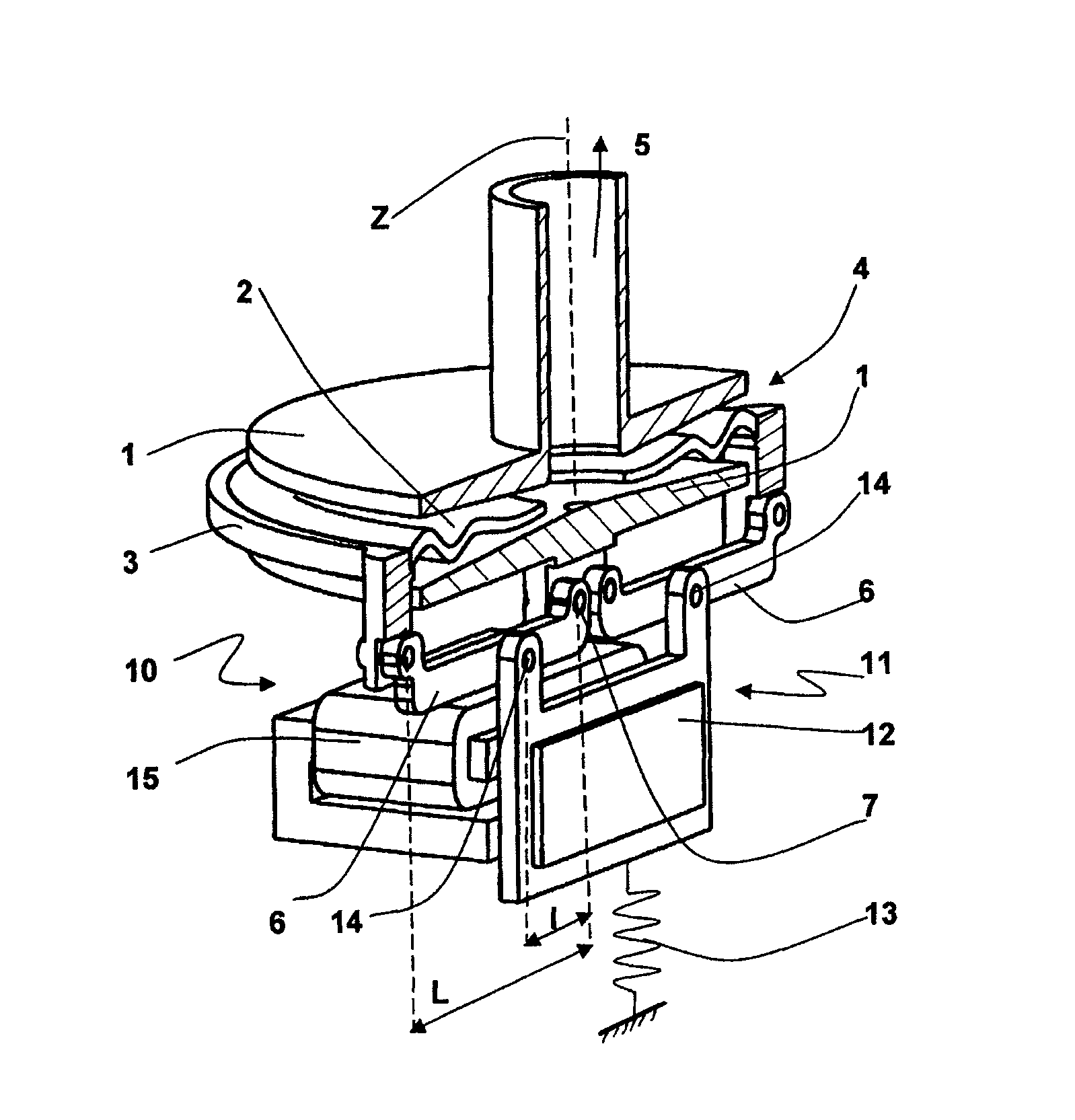

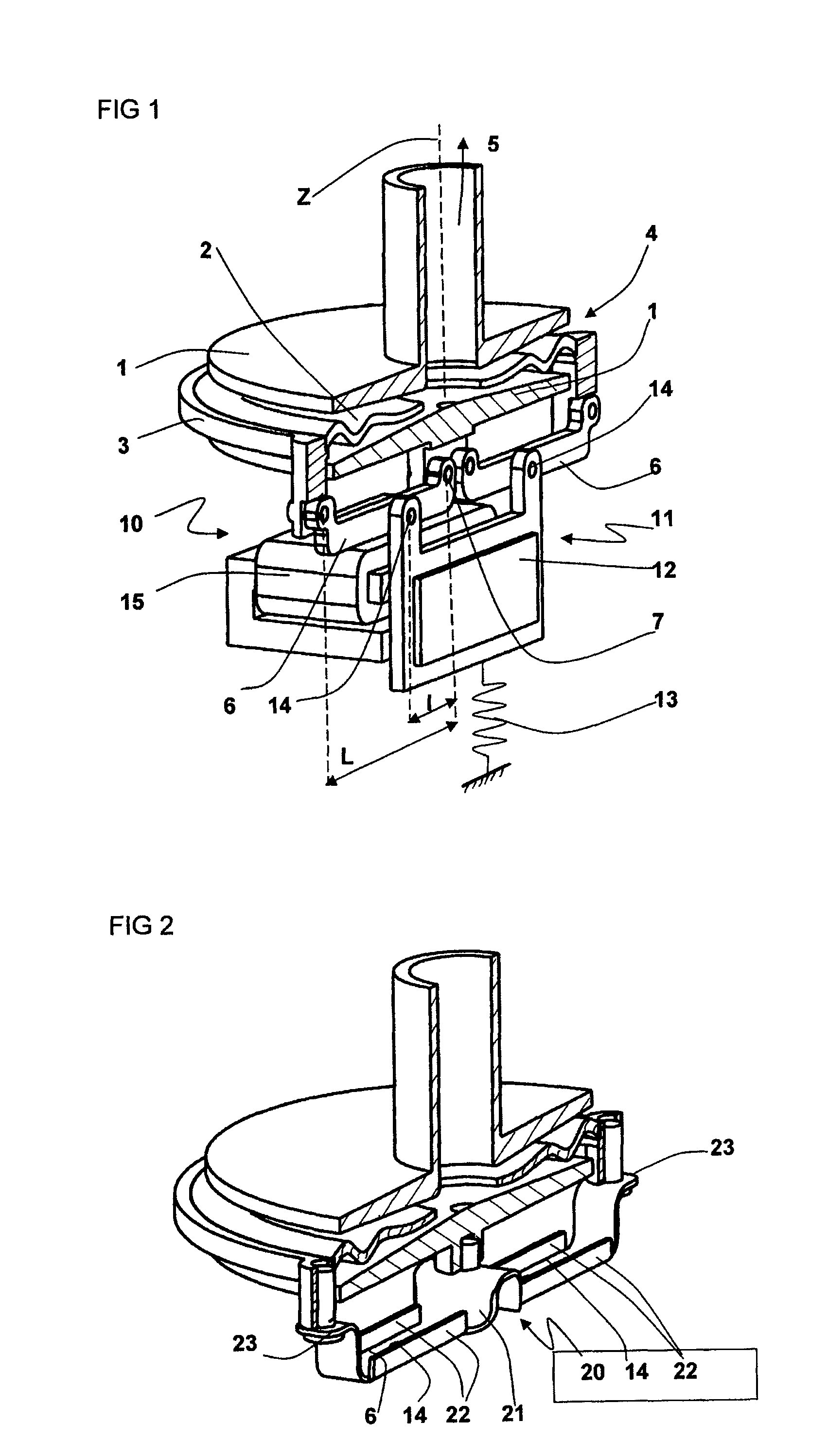

Diaphragm pump with a crinkle diaphragm of improved efficiency

ActiveUS20110176946A1Short strokeReduce vibrationFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

A pump having an undulating diaphragm mounted for undulating between two end plates under drive from at least one electromagnetic actuator in order to transfer a fluid between an inlet of the pump and an outlet of the pump. The pump includes adapter means connecting the diaphragm support to a movable portion of the actuator in order to shorten the stroke of the movable mass of the actuator such that its stroke is shorter than the stroke of the diaphragm support.

Owner:AMS R&D

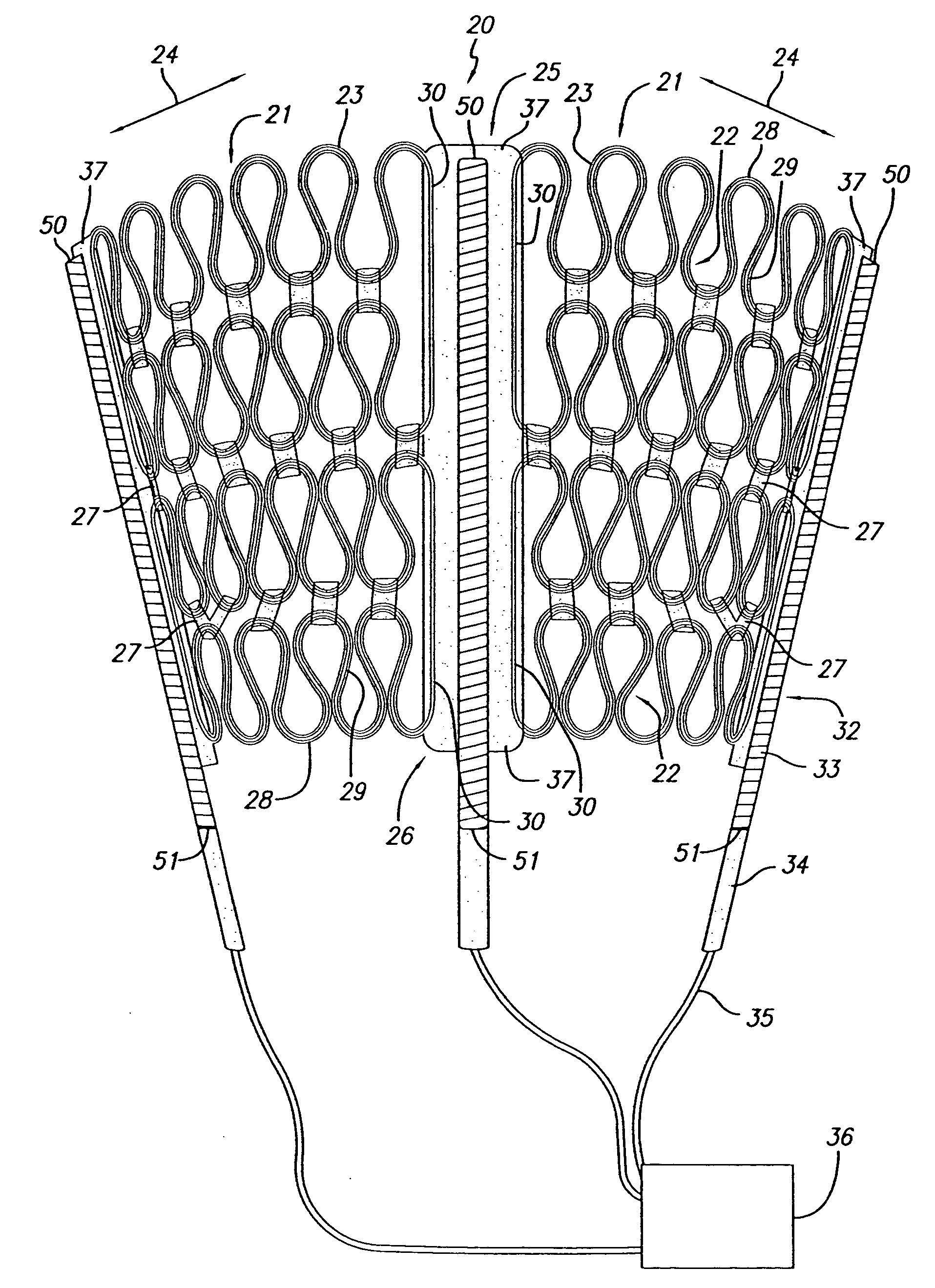

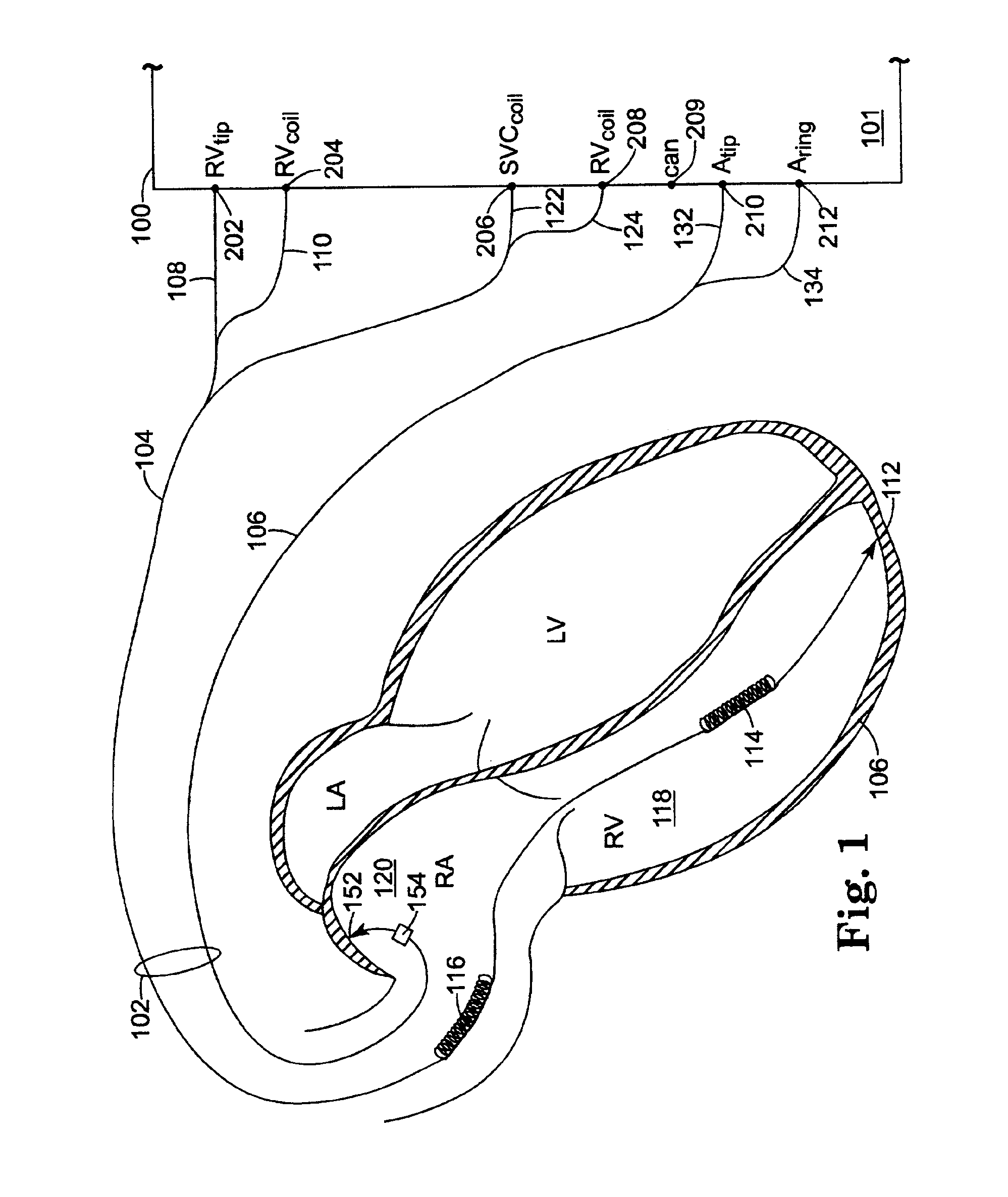

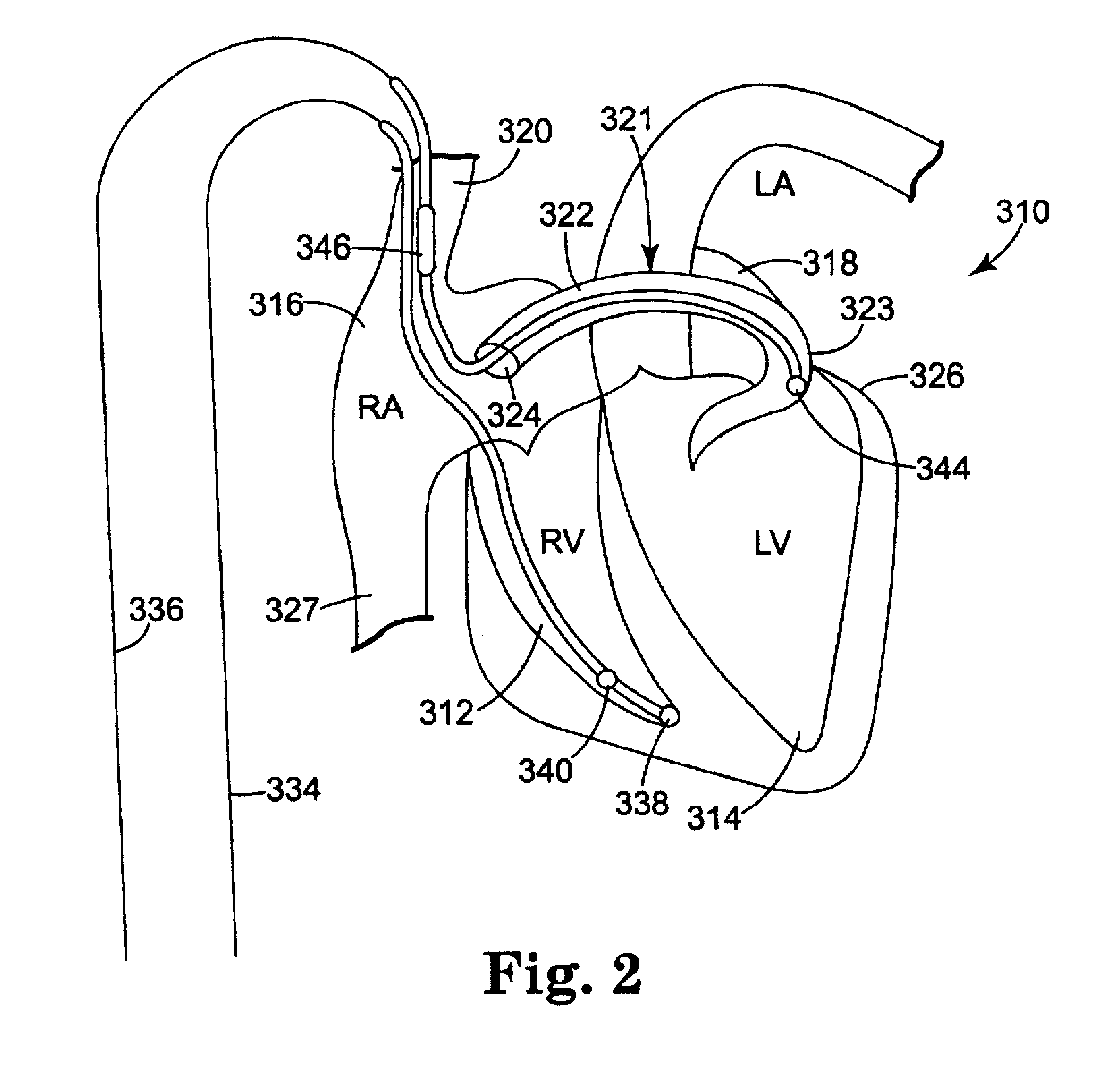

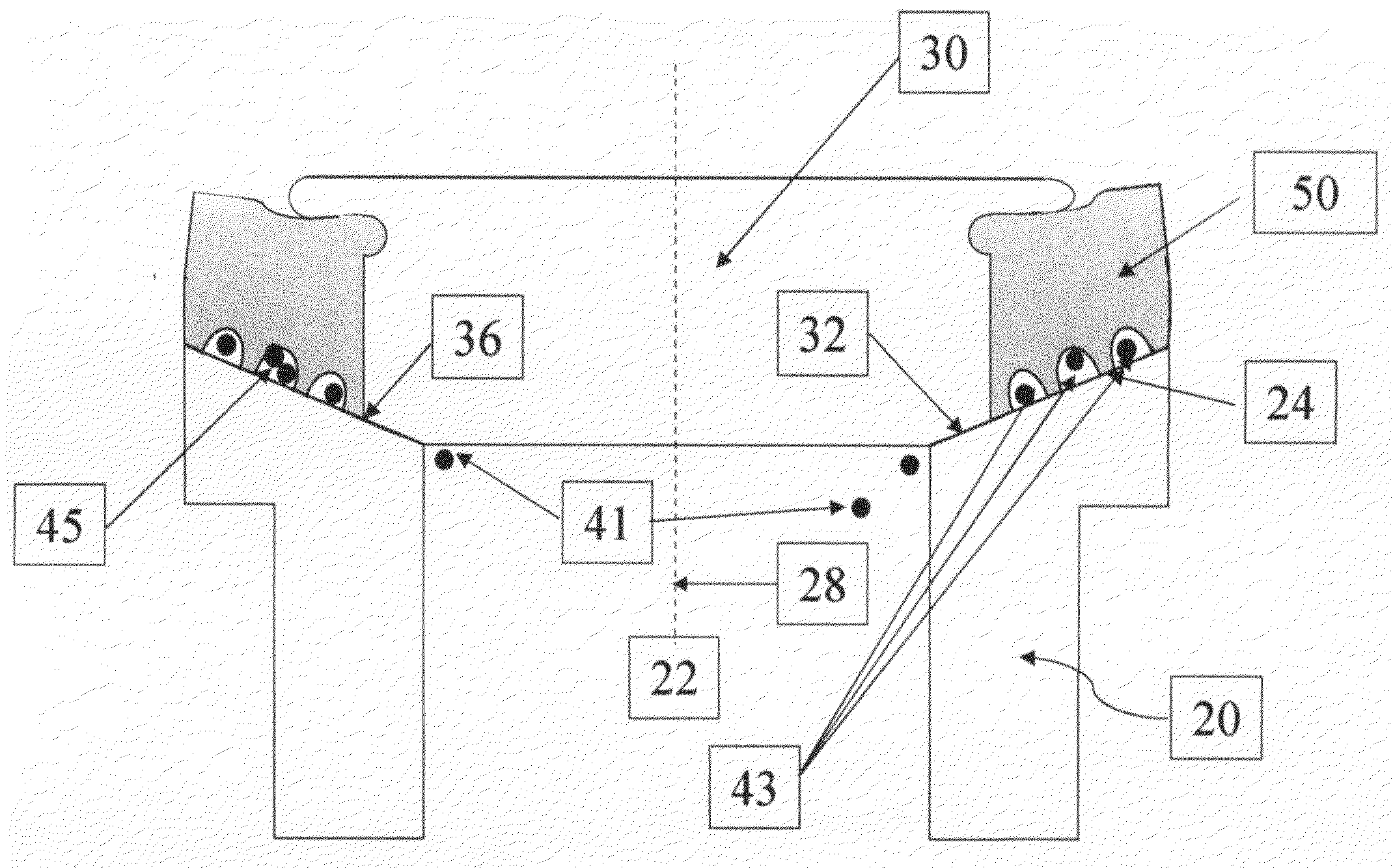

Cardiac harness assembly for treating congestive heart failure and for pacing/sensing

InactiveUS20070106359A1Low profileResists side-to-side movementElectrocardiographyEpicardial electrodesMinimally invasive proceduresCongestive heart failure chf

A pace / sense electrode is associated with a cardiac harness for treating the heart. The pace / sense electrode is positioned on the epicardial surface of the heart, preferably under the cardiac harness, to provide pacing and sensing therapy to the heart. Compressive forces from the cardiac harness serve to hold the pace / sense electrode in place and to push the electrode into direct contact with the epicardial surface of the heart. Various means are provided for placing the pace / sense electrode under the cardiac harness in a minimally invasive procedure.

Owner:PARACOR MEDICAL

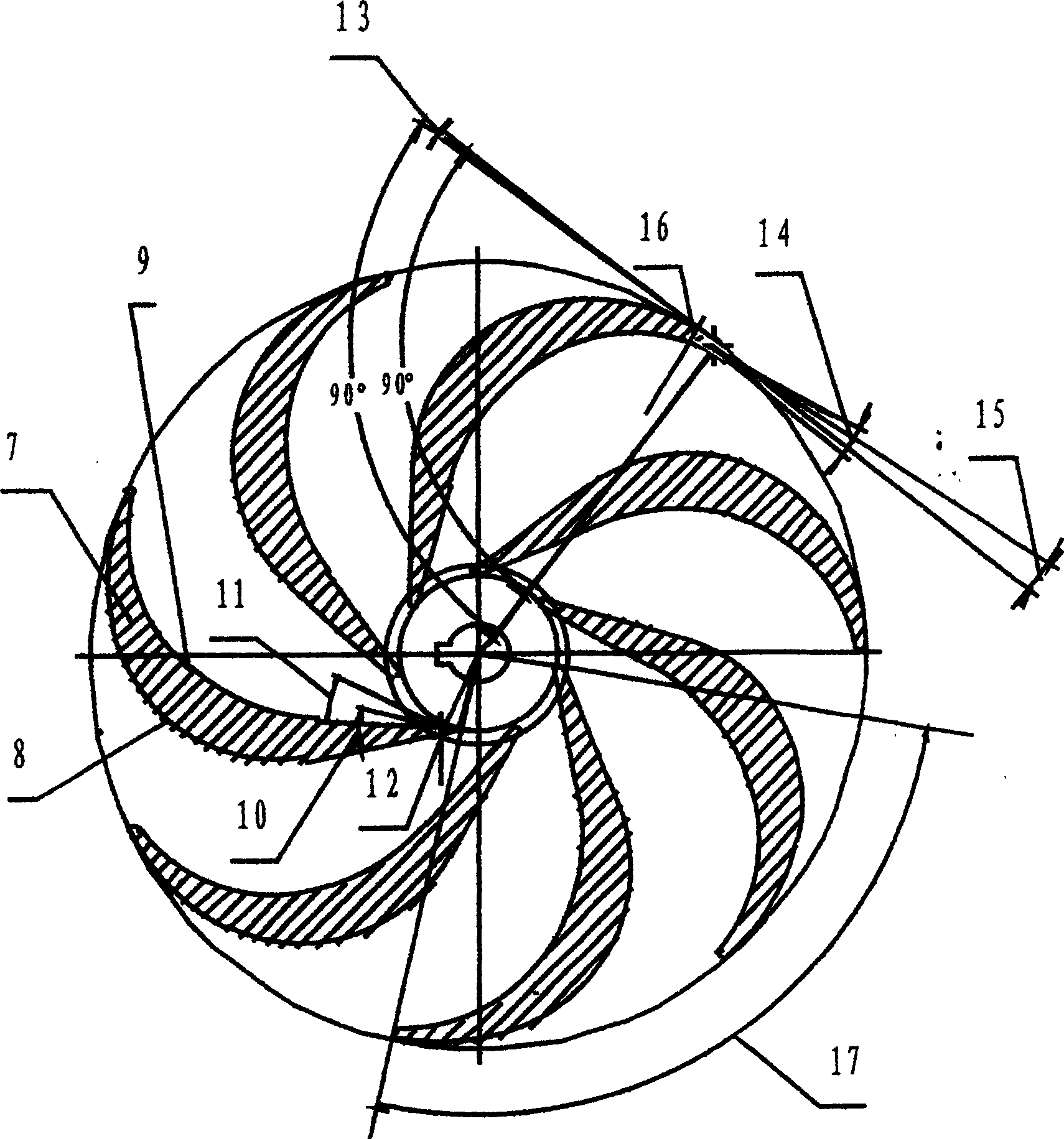

Method for designing low-rate revolution centrifugal pump impeller

InactiveCN1580577AEfficient and reliable to useMeet head requirementsPump componentsPumpsEngineeringMaximum efficiency

This invention relates to a vane wheel designing method for a low ratio revolution certrifugal pump used in the behavior of low ratio revolution of high ratio revolution namely high delivery lift small flow characterizing in namely low delivery lift big flow linking the geometric parameters of the vane and the designed behavior point performance by several new relation formulas to reach the designing result of coincidence of the used situation of the design and the behavior of the maximum efficiency point and the power maximum point.

Owner:JINING ANTAI MINING EQUIP MFG CO LTD

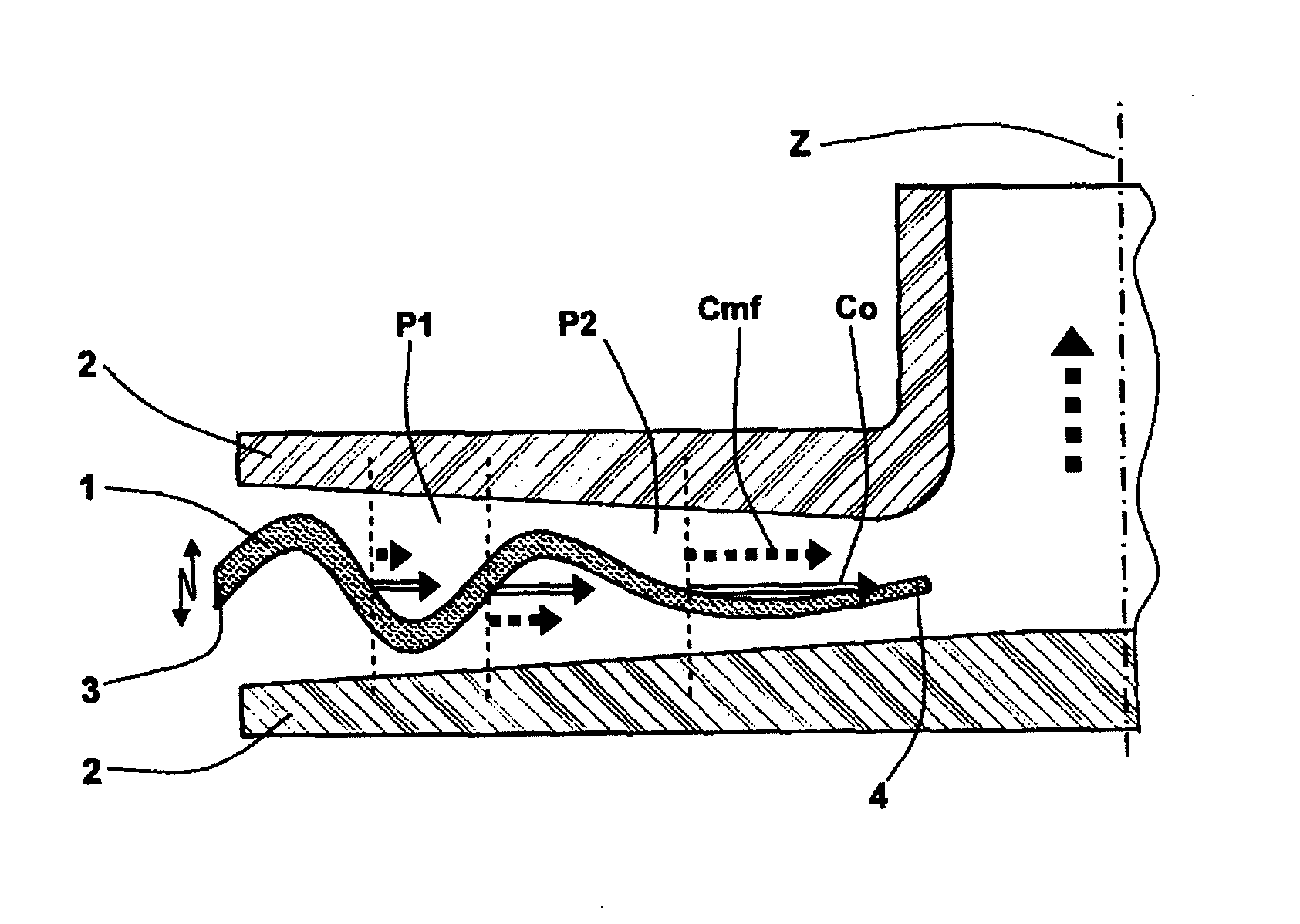

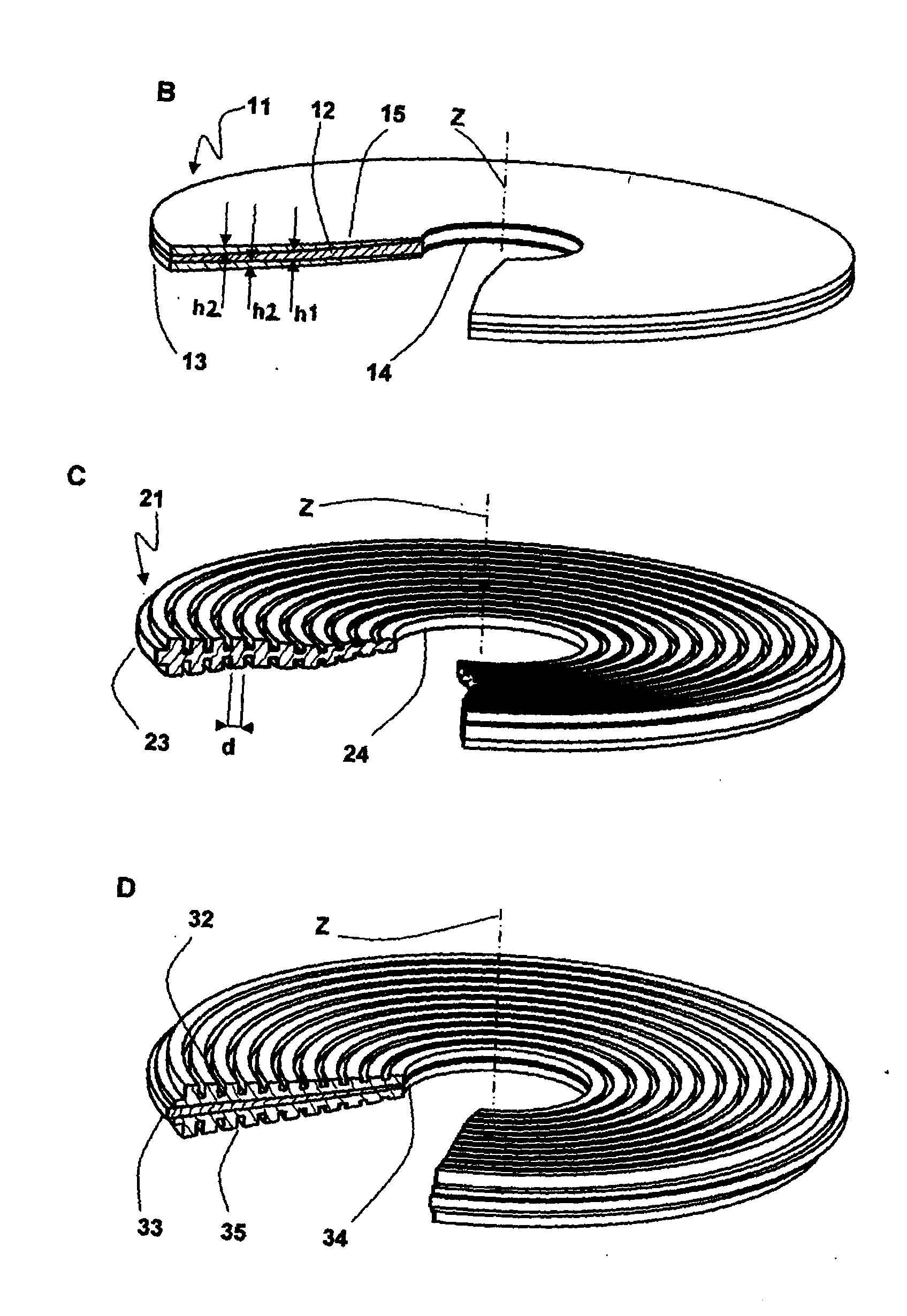

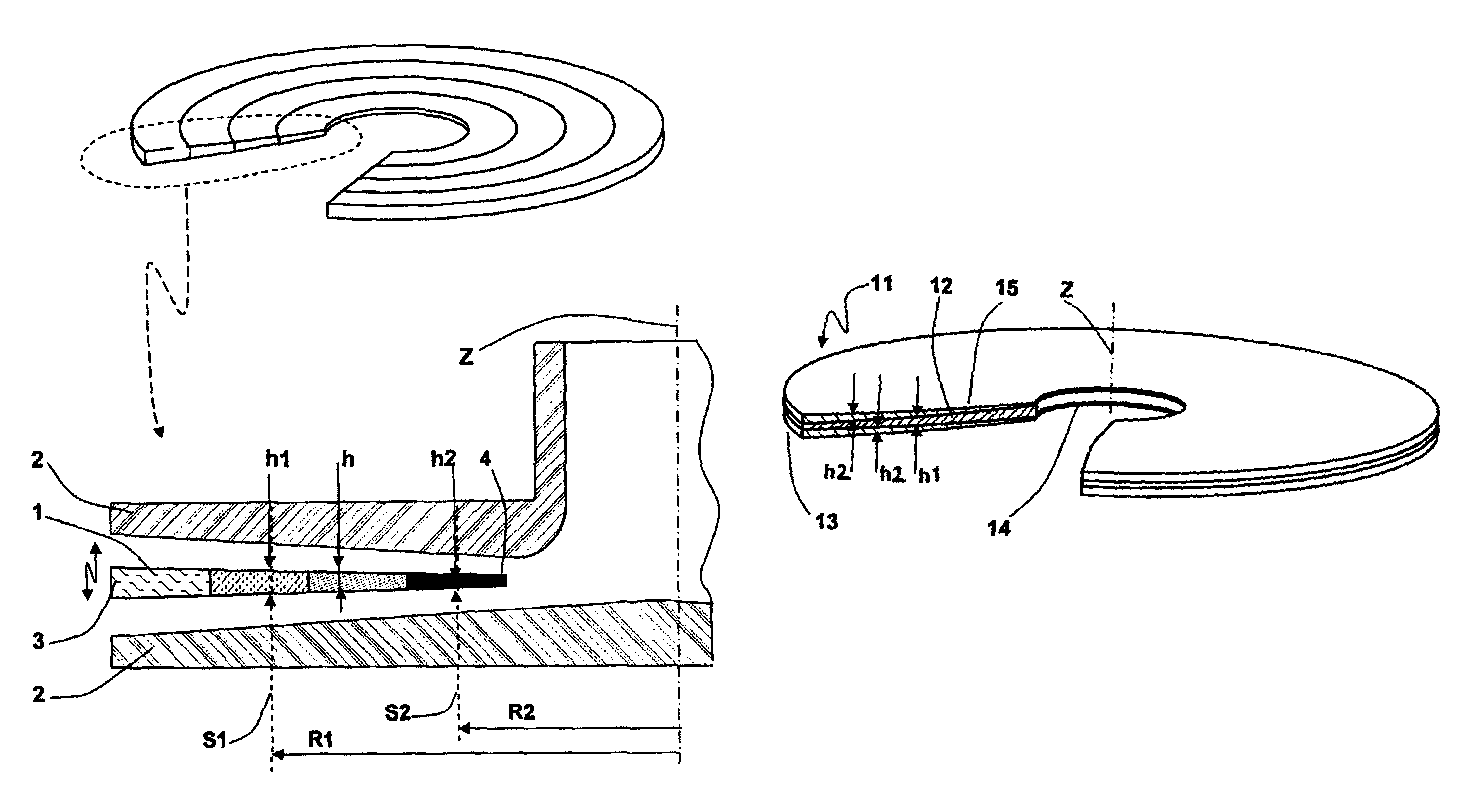

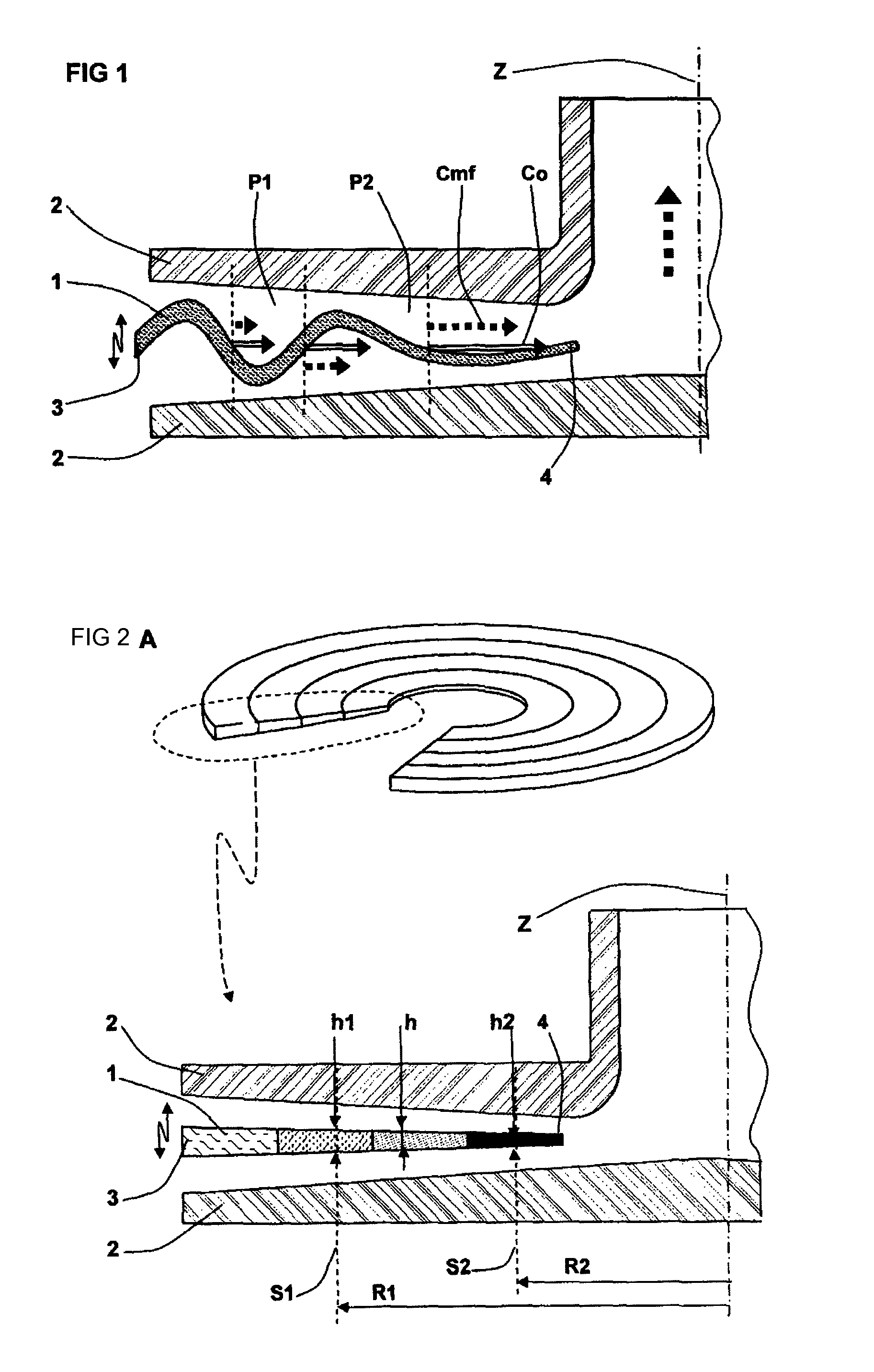

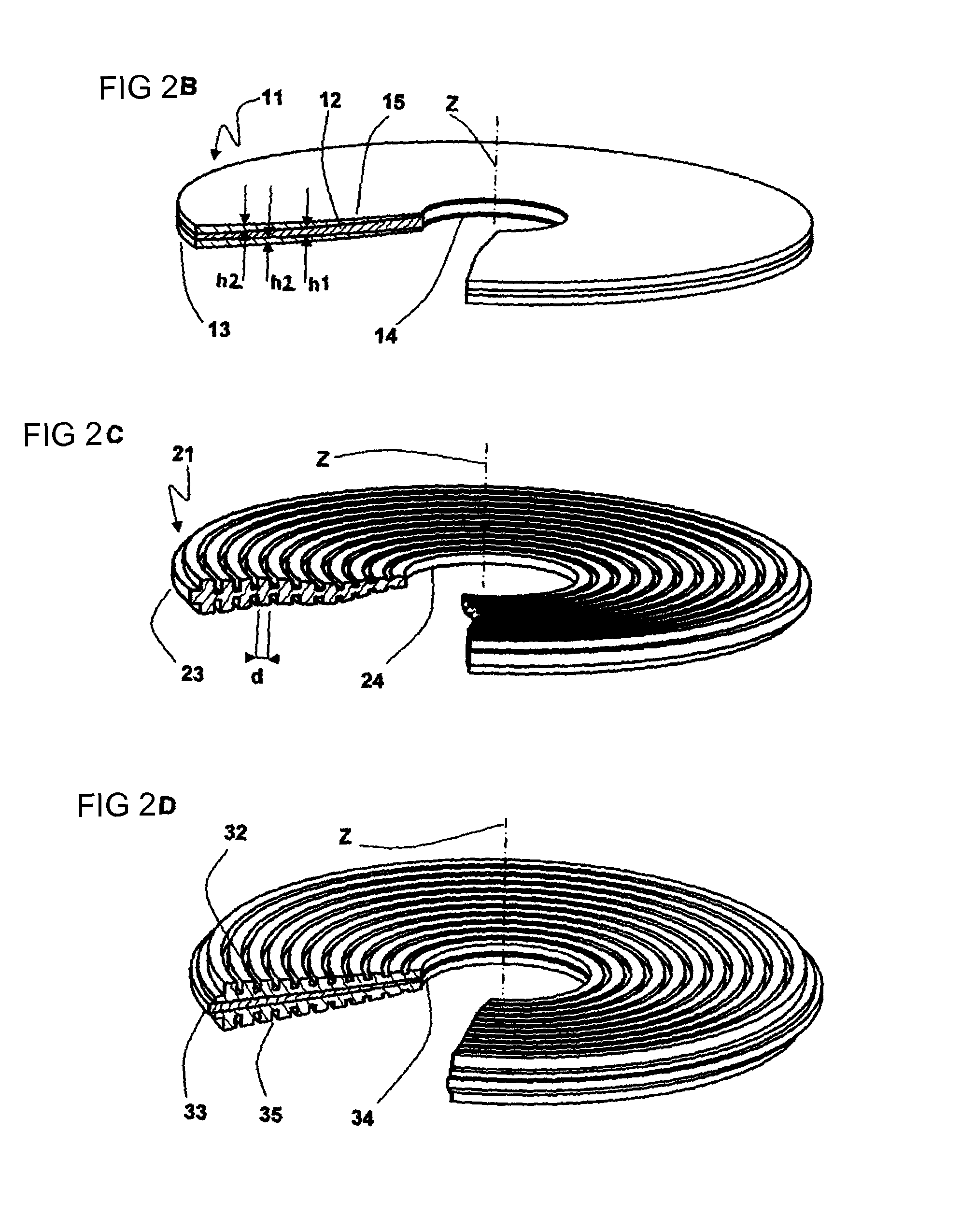

Crinkle diaphragm pump

ActiveUS20110176945A1Great efficiencyImprove pumping efficiencyFlexible member pumpsPositive-displacement liquid enginesEngineeringDiaphragm pump

An undulating diaphragm pump having a propulsion chamber for receiving said diaphragm, wherein the diaphragm has mechanical characteristics that vary from an inlet of the propulsion chamber towards an outlet of the propulsion chamber in such a manner that, when the diaphragm is actuated to deform with a traveling wave that propagates from the inlet towards the outlet of the propulsion chamber in order to propel the fluid, the propagation speed of the wave in the diaphragm in any cross-section relative to the movement of the fluid inside the propulsion chamber is equal to or greater than the mean travel speed of the fluid in said section.

Owner:AMS R&D

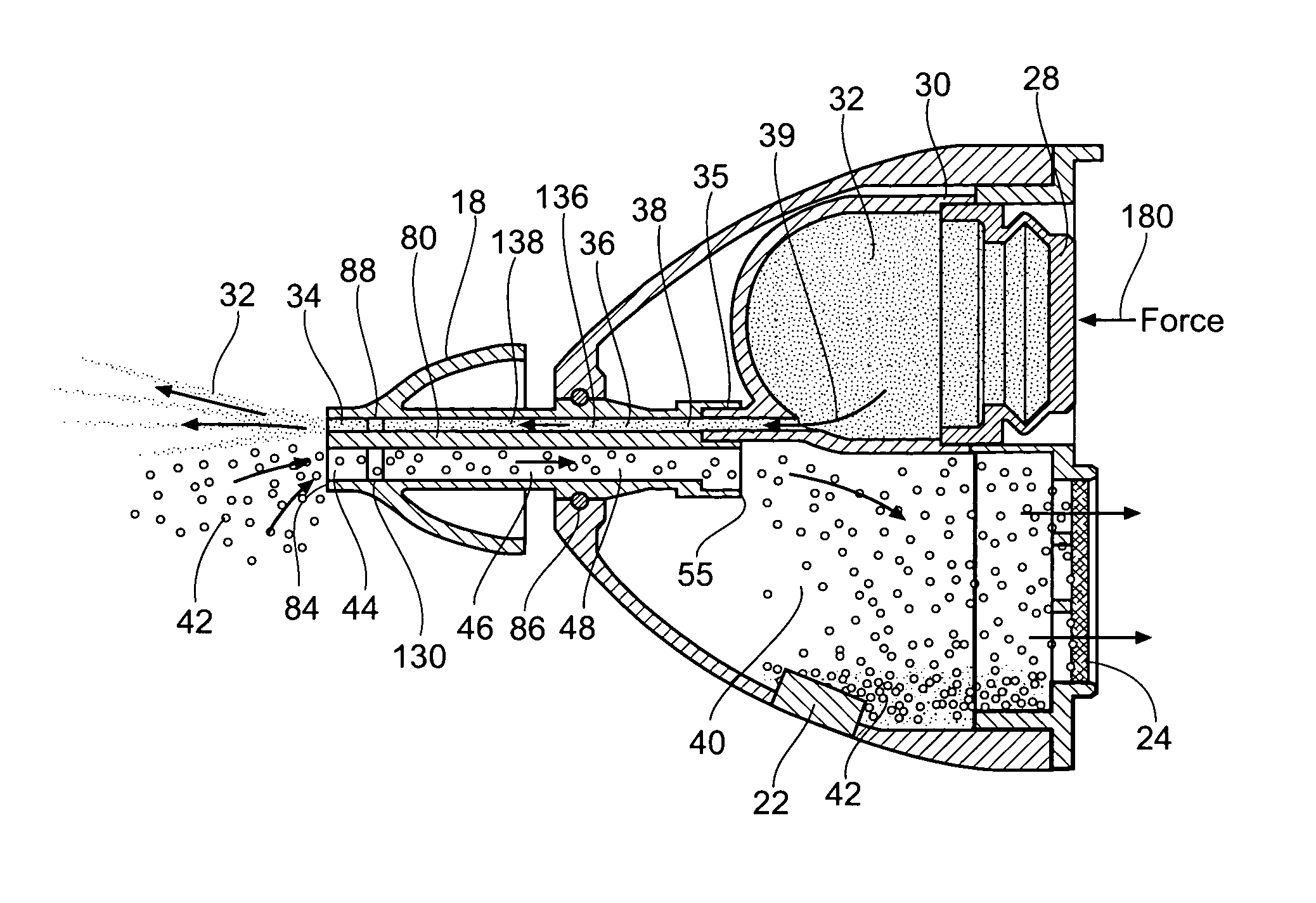

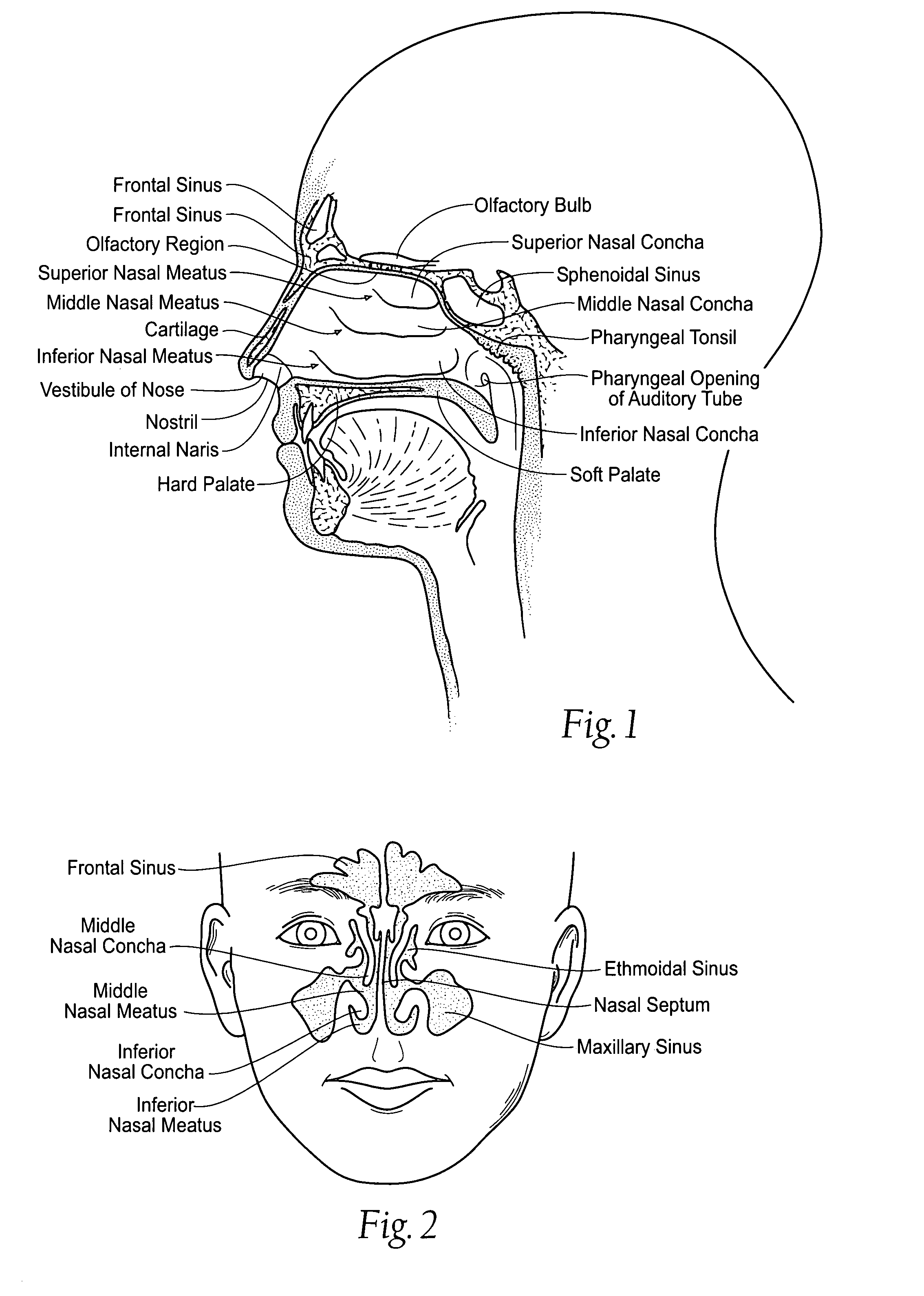

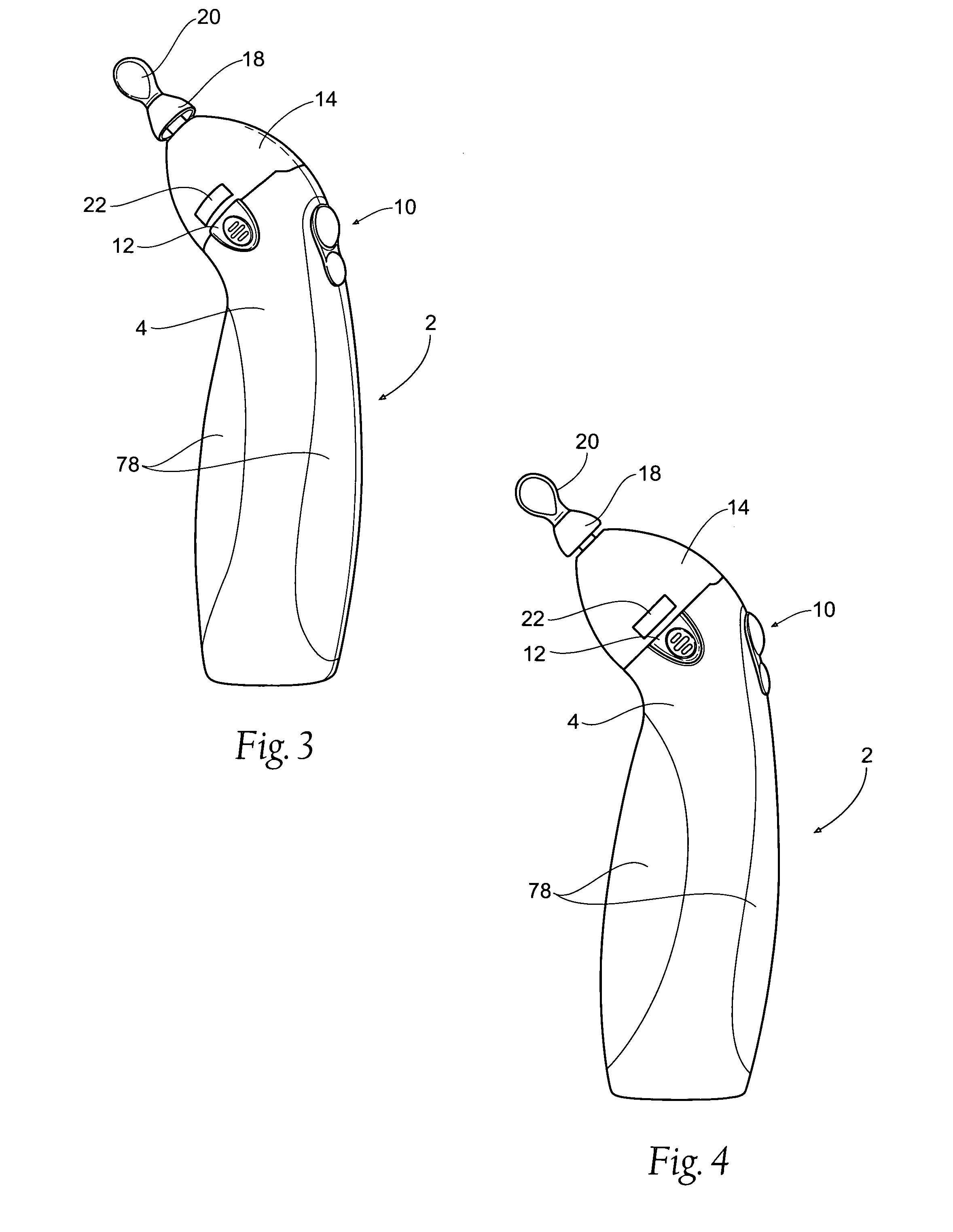

Irrigation and aspiration devices and methods

ActiveUS8414521B2High trafficImprove pumping efficiencySurgeryMedical devicesAutomatic controlSurgery

Irrigation and / or aspiration devices and methods may be configured to aspirate and irrigate alone, sequentially, or concurrently. The devices and methods may provide a base with a removable head, and adapted for partial or complete separation of the irrigation and aspiration functions. The devices and methods can be configured to aspirate and / or irrigate the nasal and sinus cavities. The devices and methods may be manually and / or automatically controlled. The devices and methods may include removable, and / or replaceable, and / or refillable, and easily cleanable reservoirs for aspirant and irrigant. The device head and / or aspirant reservoir may comprise a diagnostic device, i.e., test device and / or container after use of the devices and methods.

Owner:AARDVARK MEDICAL

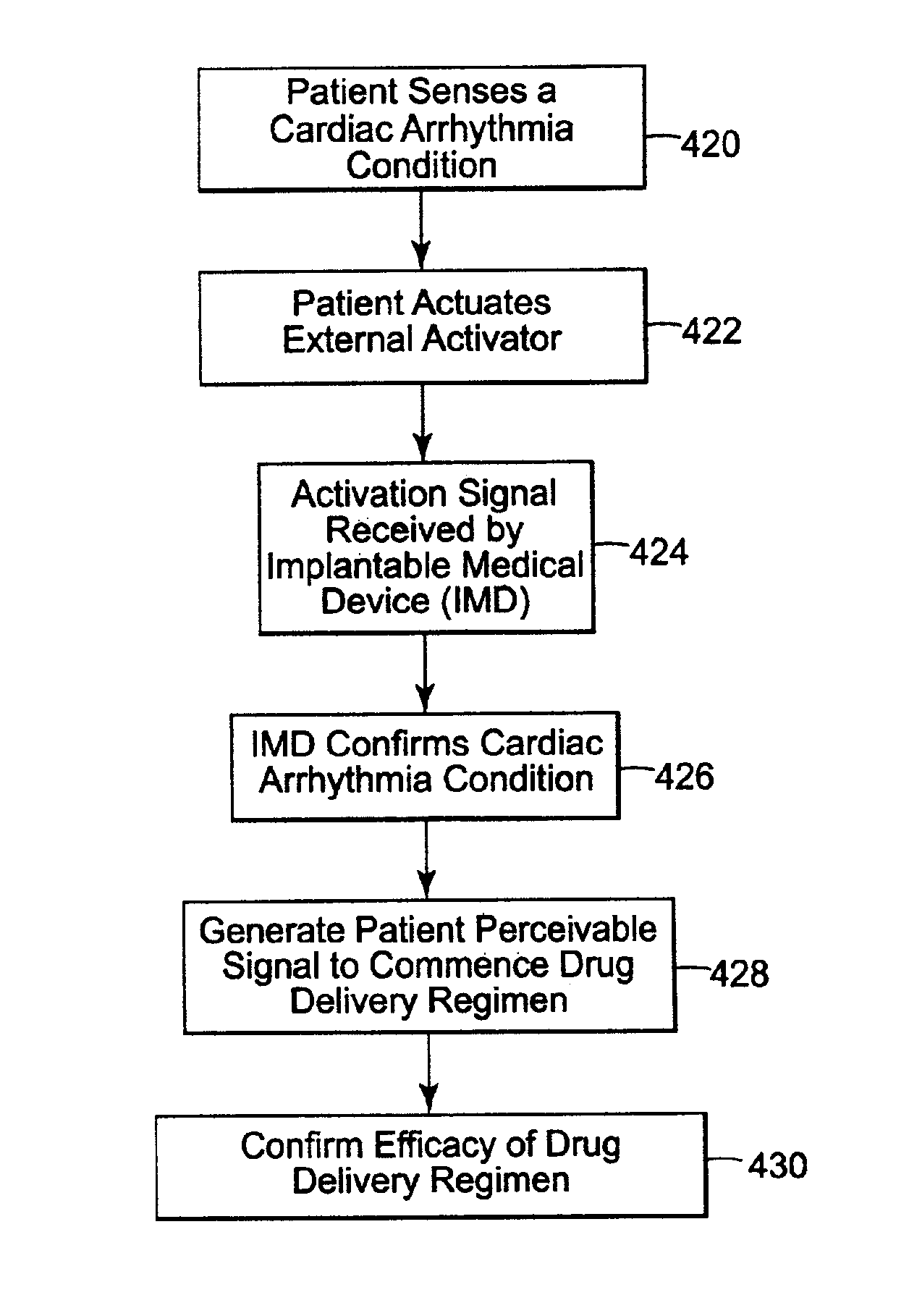

System and method for treating an adverse cardiac condition using combined pacing and drug delivery

InactiveUS6941168B2Reduce riskImprove pumping efficiencyHeart defibrillatorsHeart stimulatorsRegimenCardiac arrhythmia

A system and method of treating an adverse cardiac condition, such as cardiac arrhythmia or a non-arrhythmic event, involves producing, by use of a patient actuatable non-implanted activator, an activation signal in response to a patient sensing a perceived adverse cardiac condition. The method further involves confirming, by an implantable medical device provided within the patient, that the patient is experiencing an actual adverse cardiac condition. A perceivable initiating signal instructing the patient or a physician to commence with a drug delivery regimen to treat the actual cardiac adverse condition is generated by the non-implanted activator. In one approach, the implantable medical device operates in a safe mode of pacing during drug treatment of the actual adverse cardiac condition. In another approach, an appropriate pacing, cardioversion or defibrillation regimen is initiated to treat the actual adverse cardiac condition.

Owner:CARDIAC PACEMAKERS INC

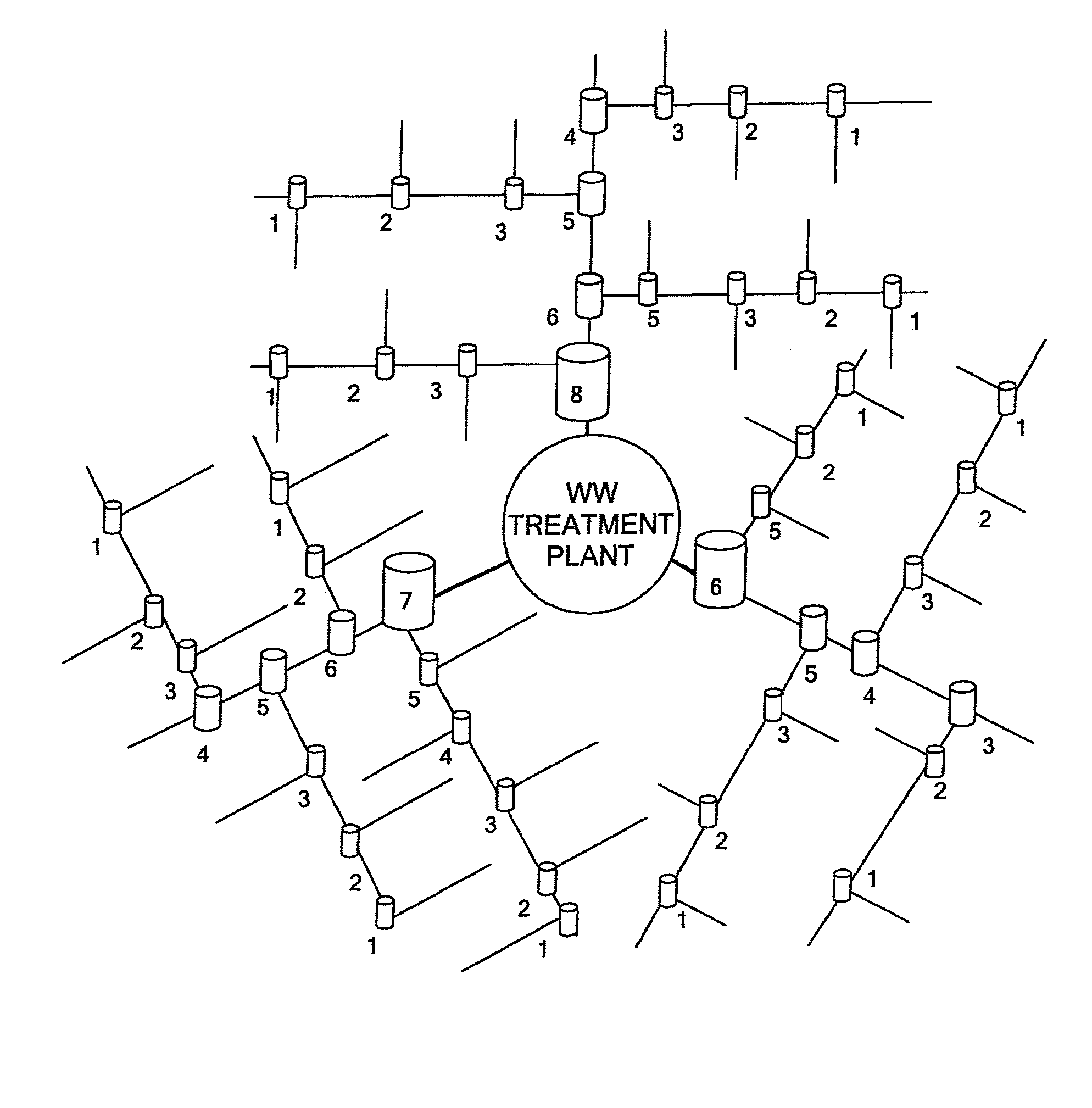

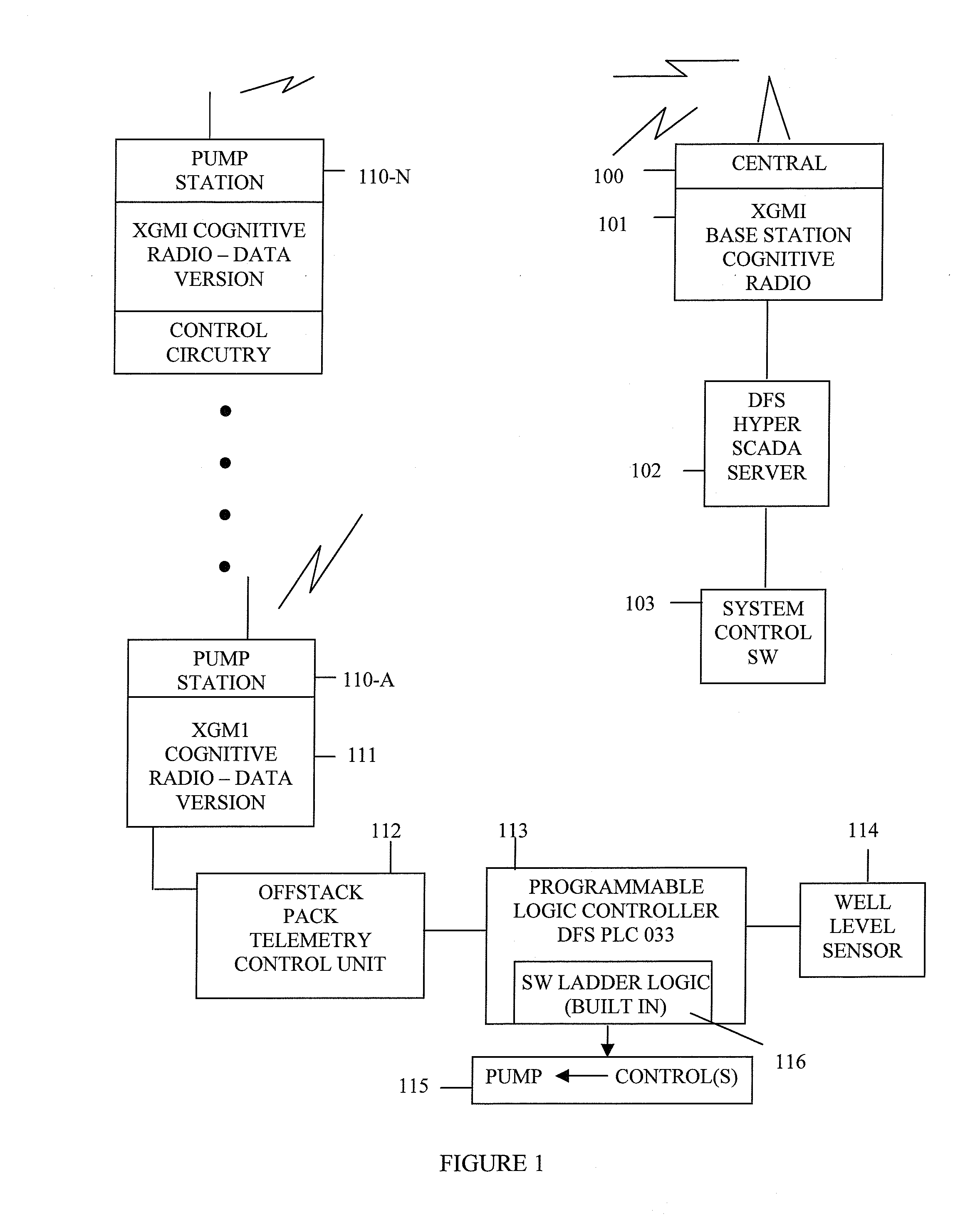

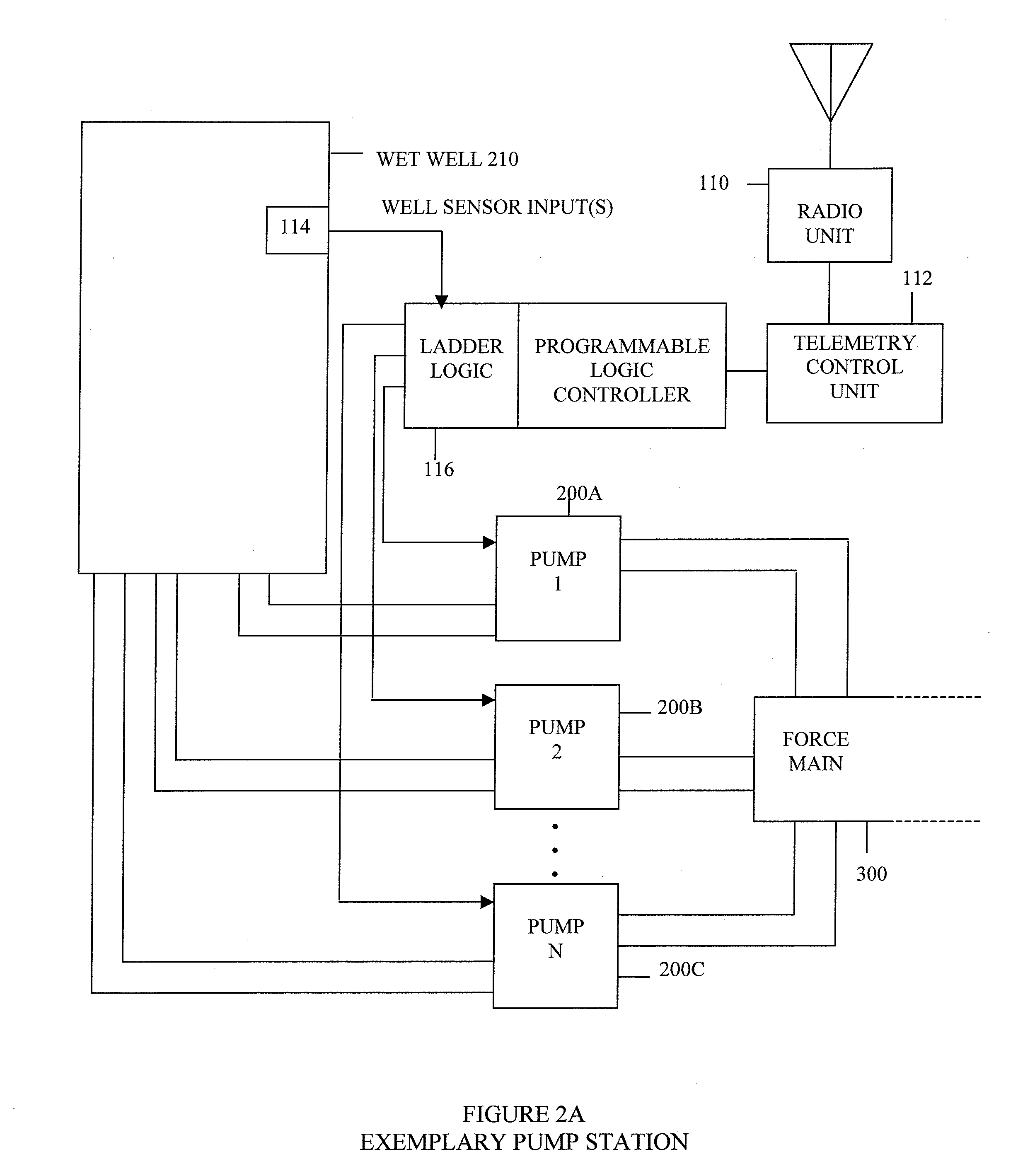

Wastewater collection flow management system and techniques

ActiveUS8594851B1Reduce maintenanceIncrease threshold level of activationFuel supply regulationLevel controlPeak valueEnergy expenditure

Reductions in energy consumption and maintenance requirements for operating a wastewater treatment plant are achieved by controlling the operation of pumps at pump stations along a force main in a systematic fashion. The operation of the pumps is controlled to manage the flow of wastewater along the force main to minimize energy consumption, to eliminate sediment, to manage peak pressures encountered by smaller pumps and to avoid septic conditions.

Owner:DATA FLOW SYST

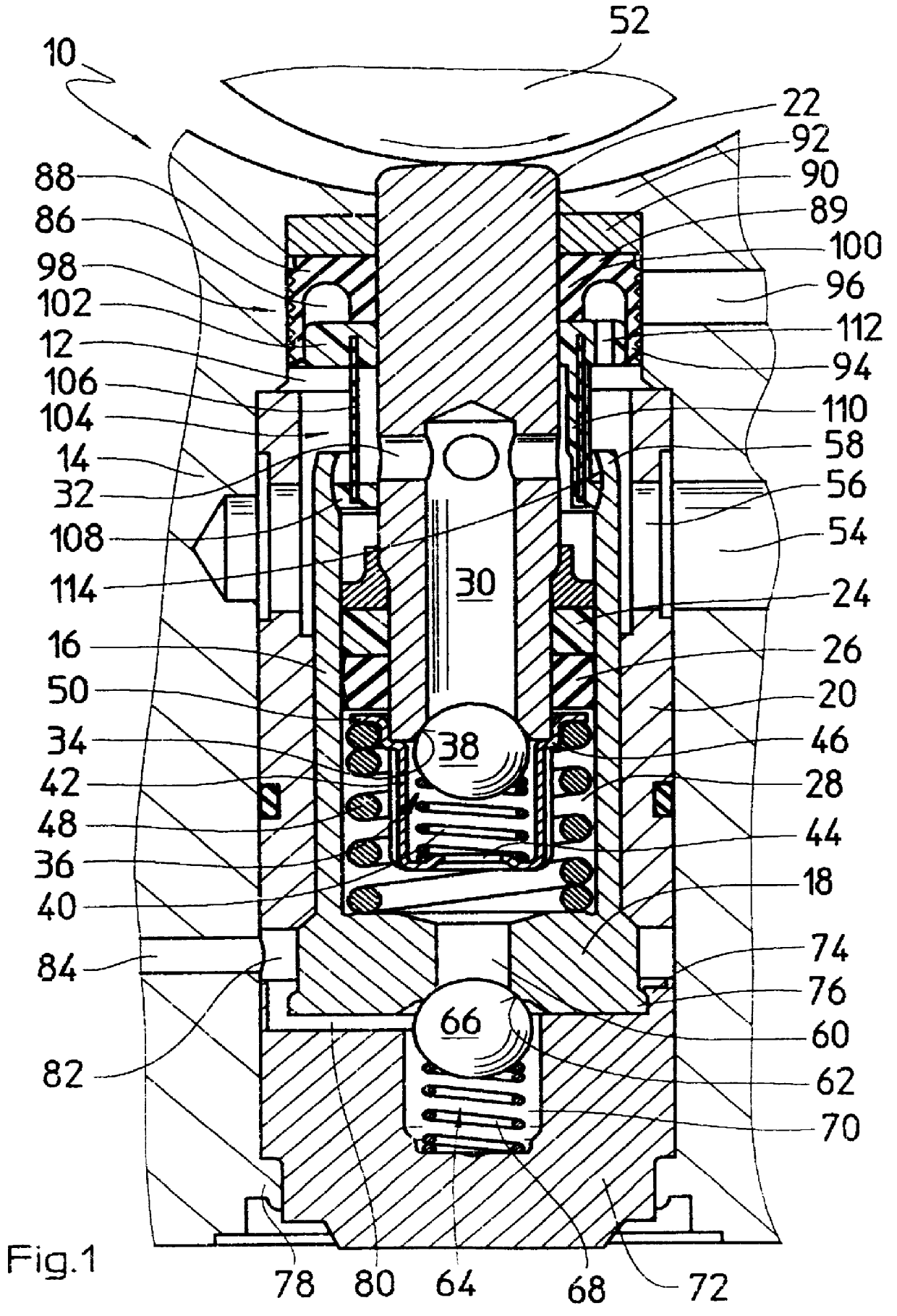

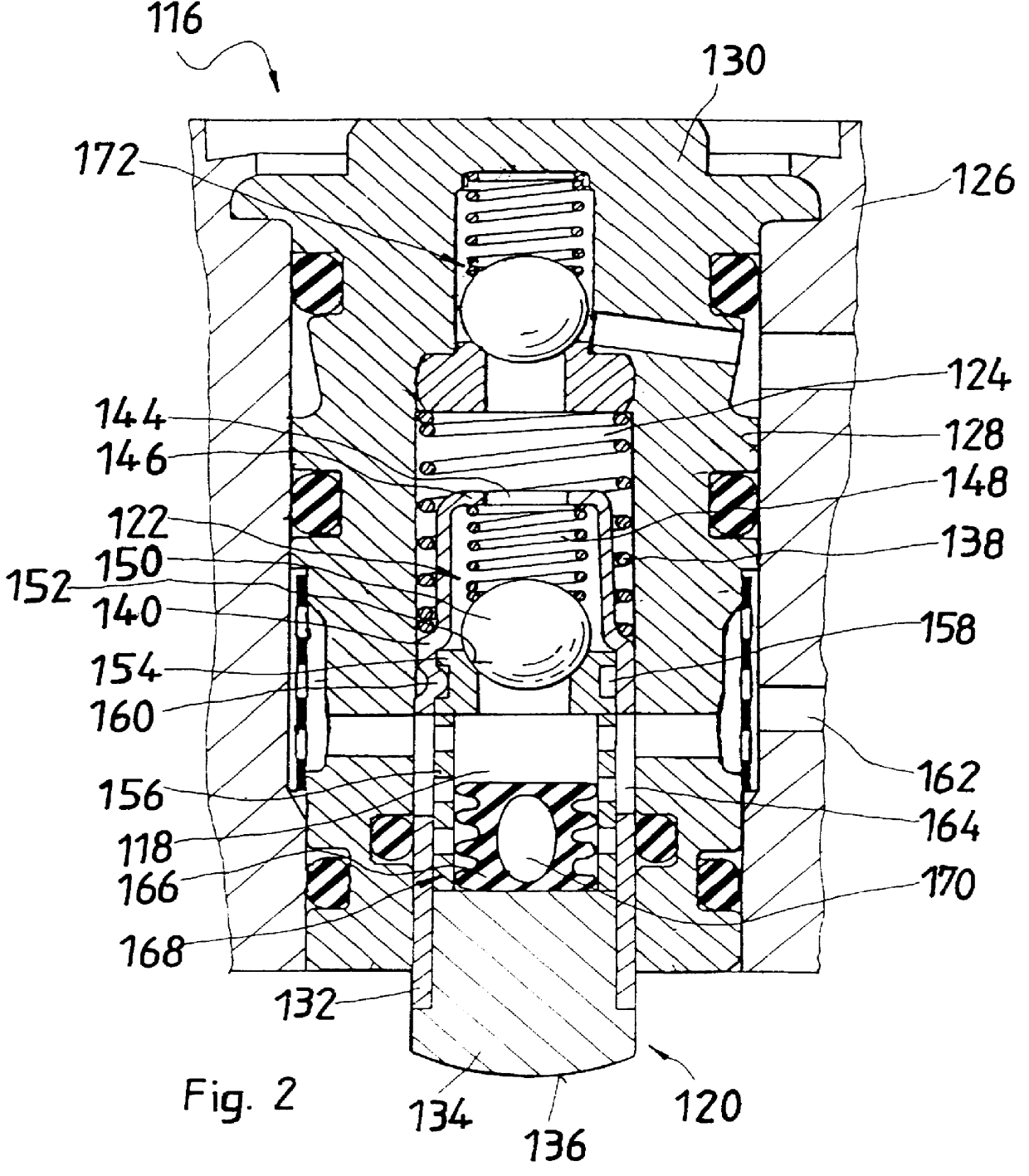

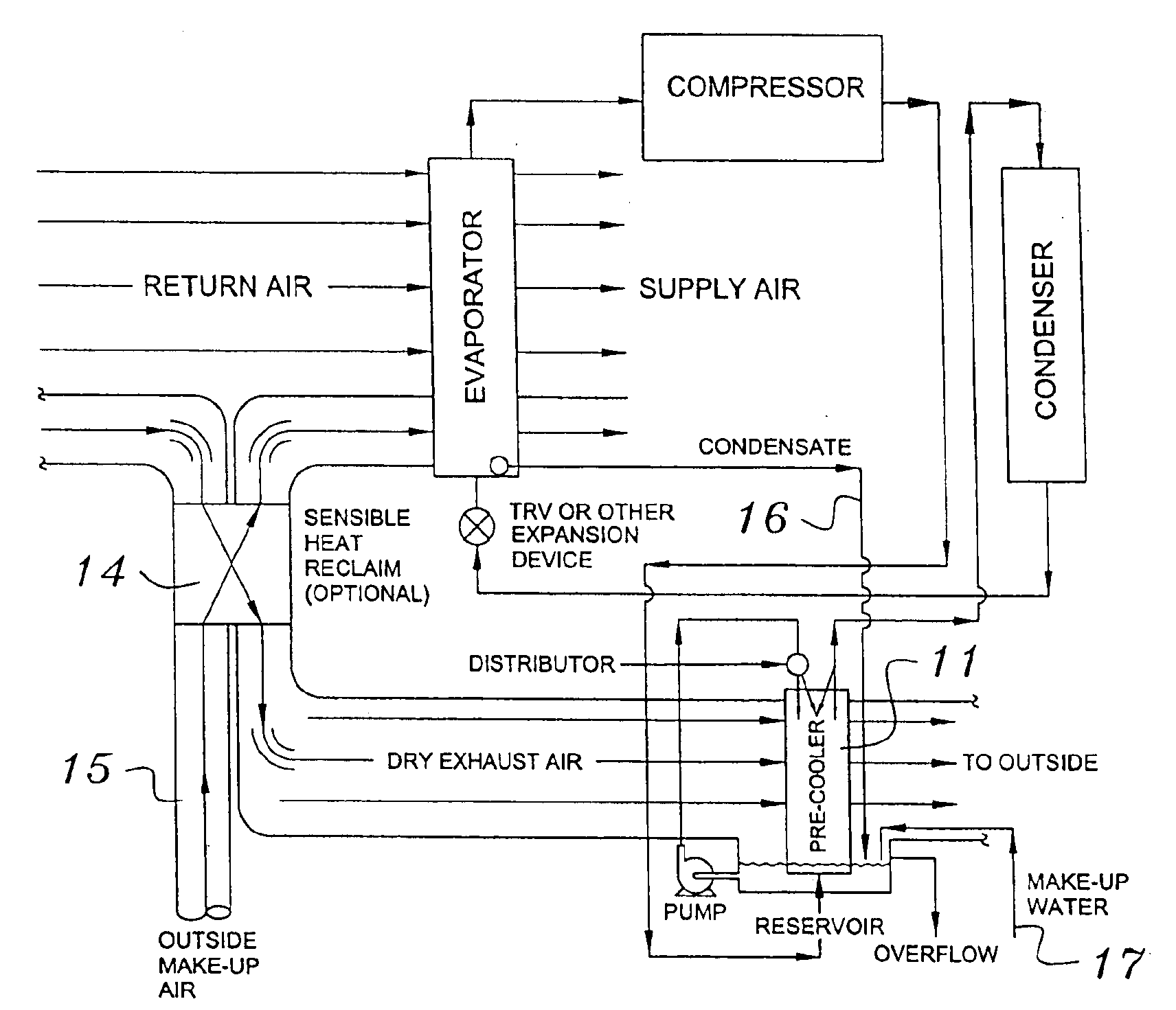

Piston pump

InactiveUS6093003AOptimal aspiration performanceImprove pump efficiencyPositive displacement pump componentsPiston pumpsAmbient pressureEngineering

The invention relates to a piston pump with a piston received axially displaceably in a pump bore. To improve the aspiration performance of the piston pump. A cuff with a U-shaped annular cross section is provided, the cuff is inserted into the pump bore surrounding the piston, an outer lip forms a diaphragm, which rests against a wall of the pump bore and is acted upon on its outside with ambient pressure through a venting bore. The cuff is part of a fluid storage element, which makes an additional fluid volume available to the piston pump. The diaphragm acted upon by ambient pressure creates a pumping effect, if a fluid pressure in the fluid storage element drops below ambient pressure in an intake stroke of the piston.

Owner:ROBERT BOSCH GMBH

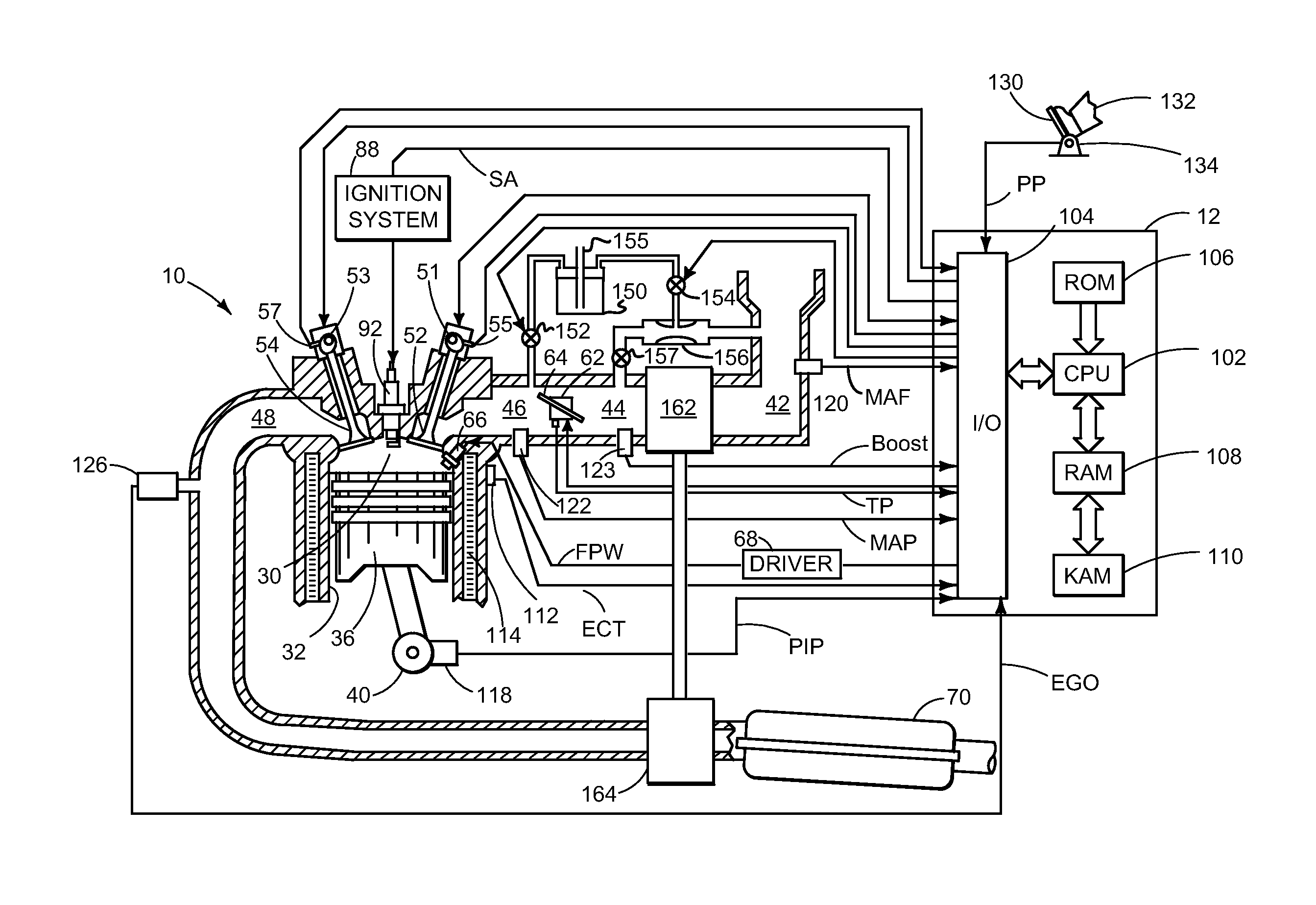

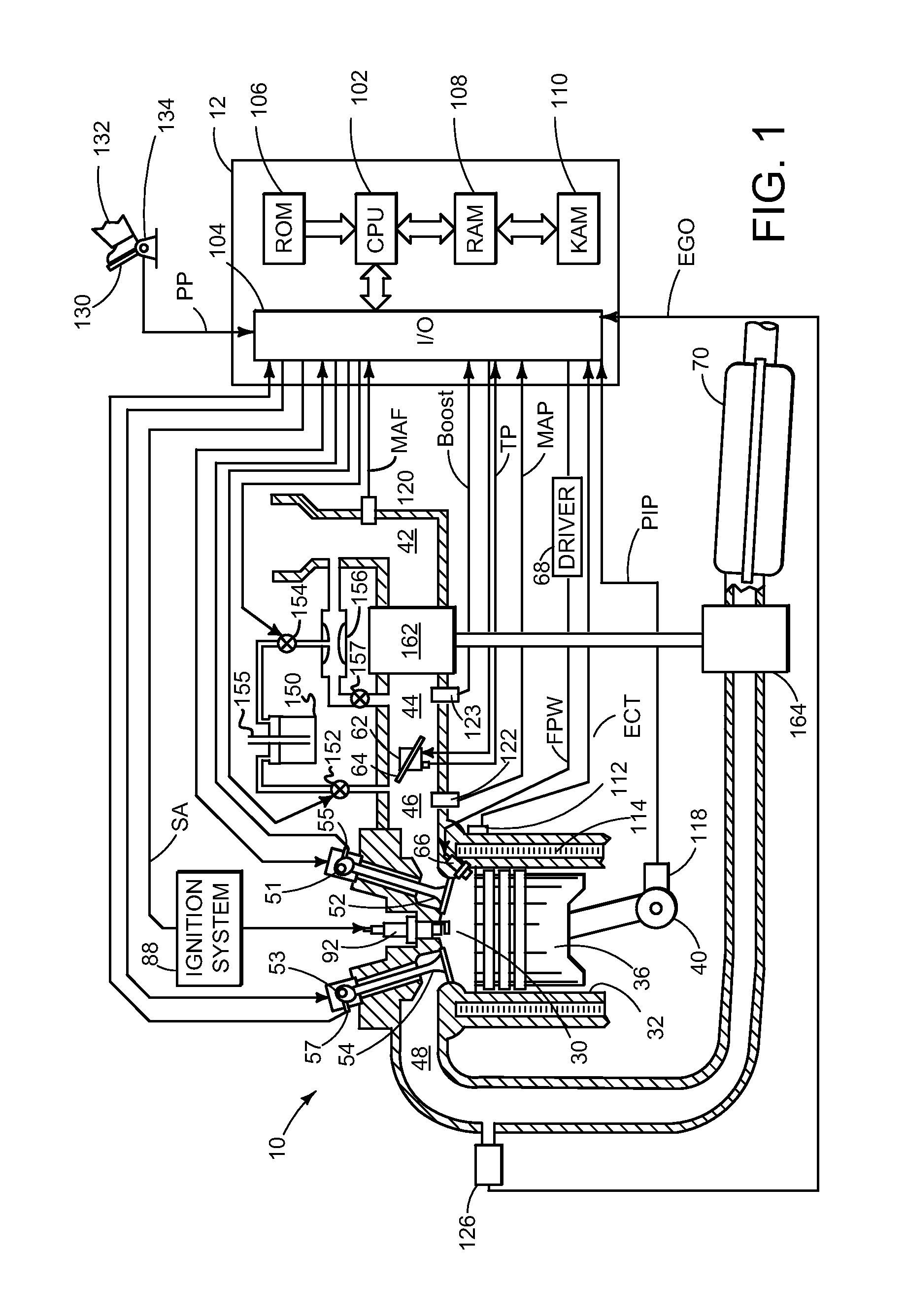

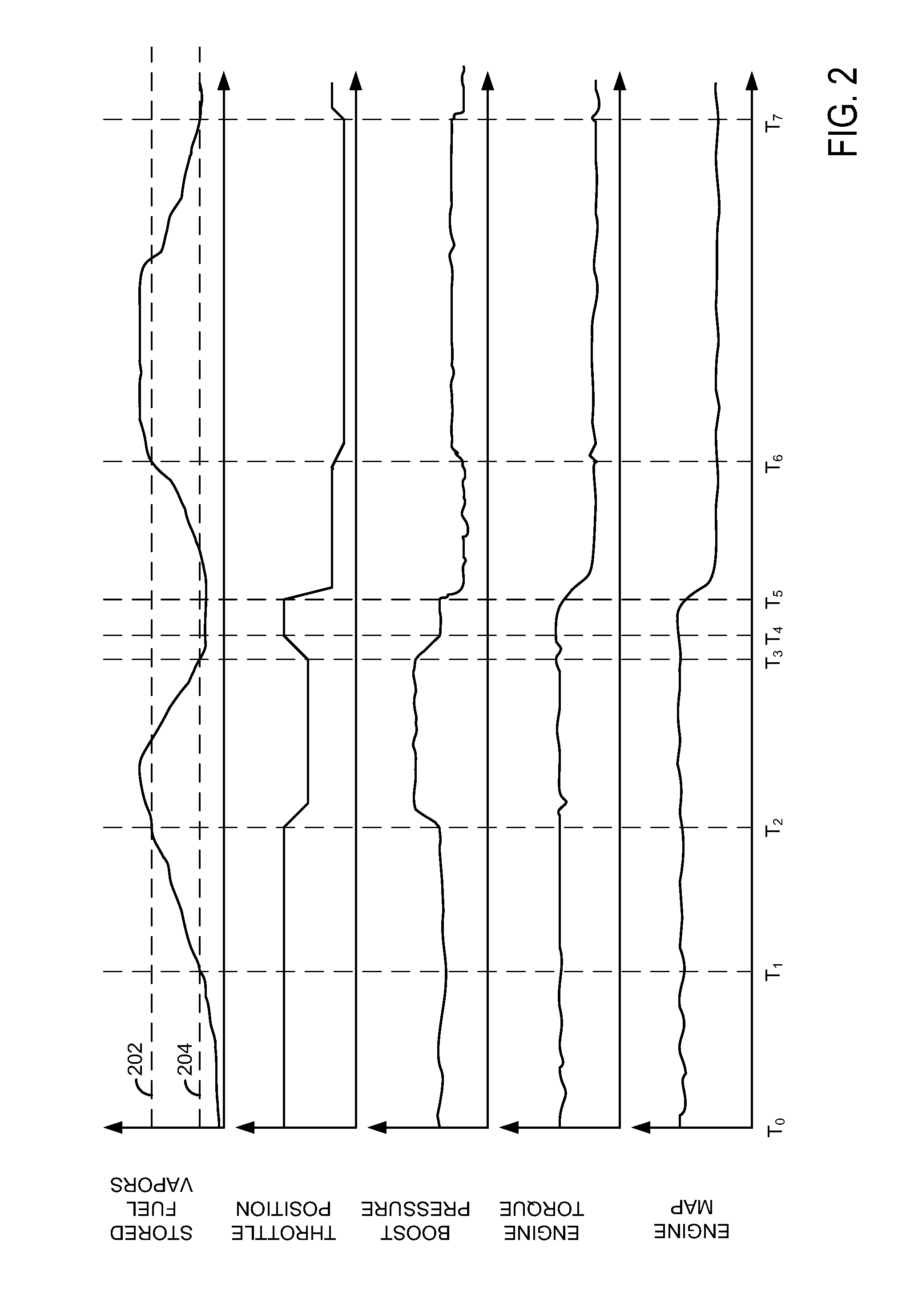

Method for Purging Fuel Vapors

ActiveUS20120016566A1Improve engine efficiencyReduce engine displacementElectrical controlNon-fuel substance addition to fuelFuel vaporAutomotive engineering

Owner:FORD GLOBAL TECH LLC

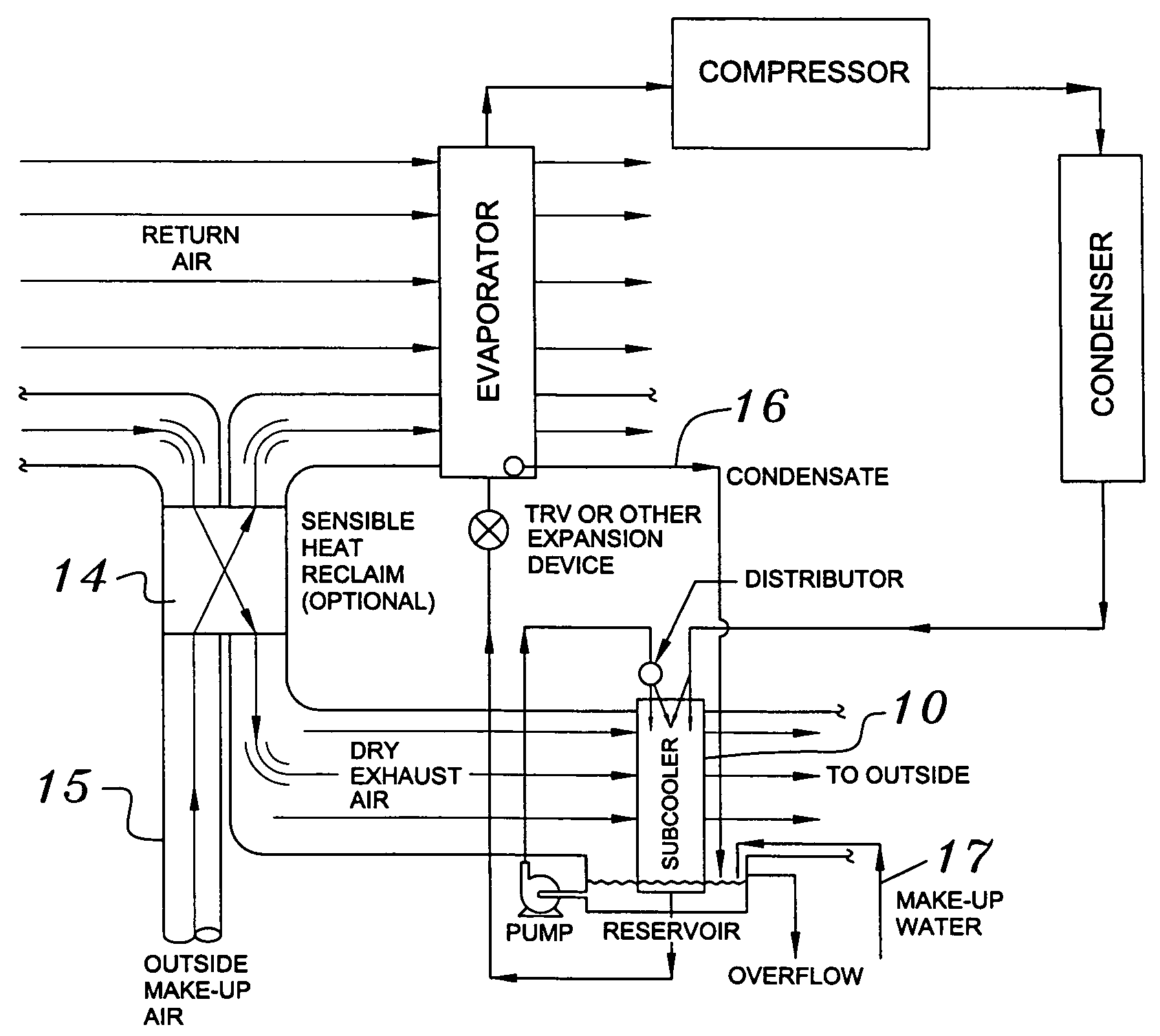

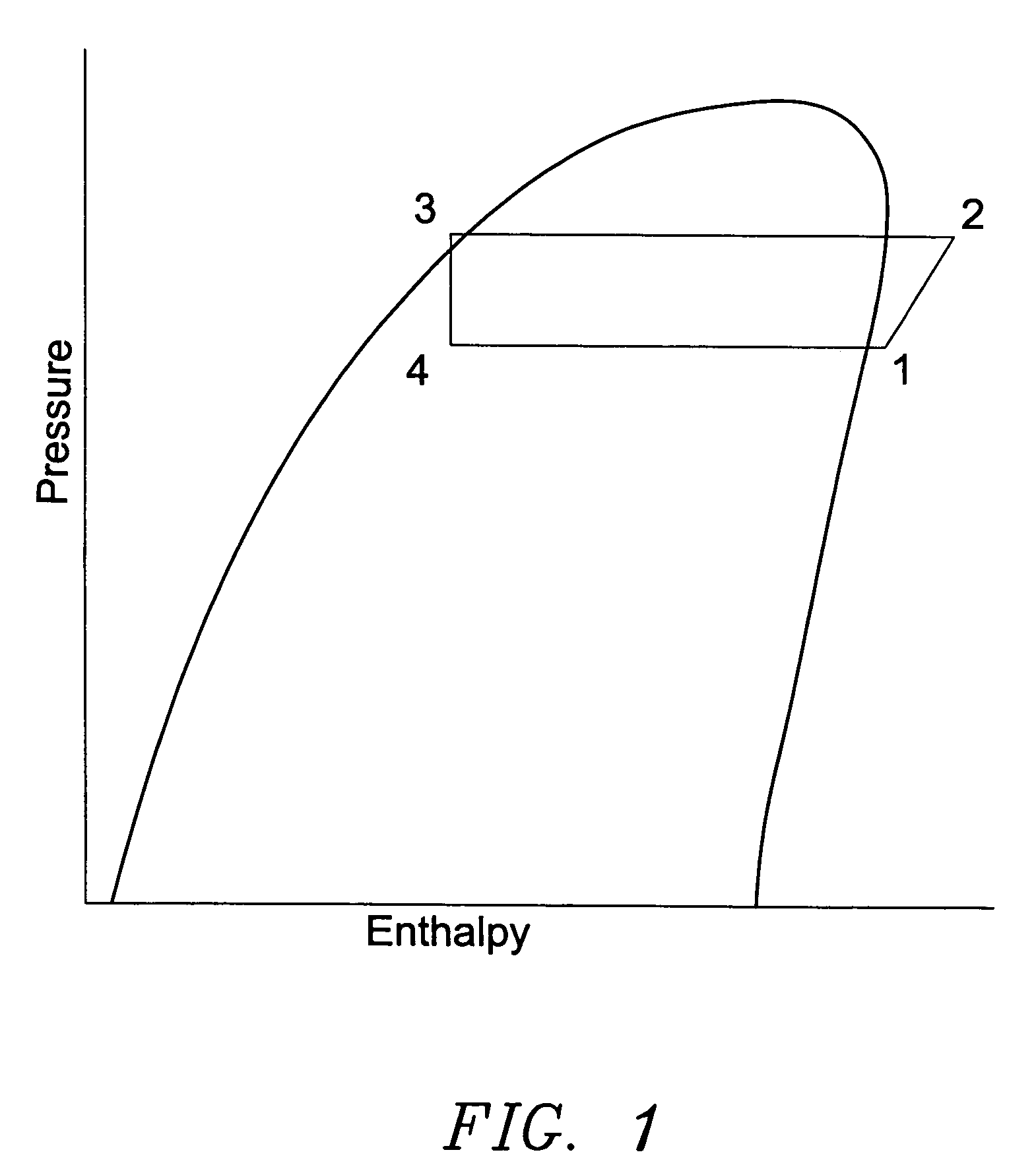

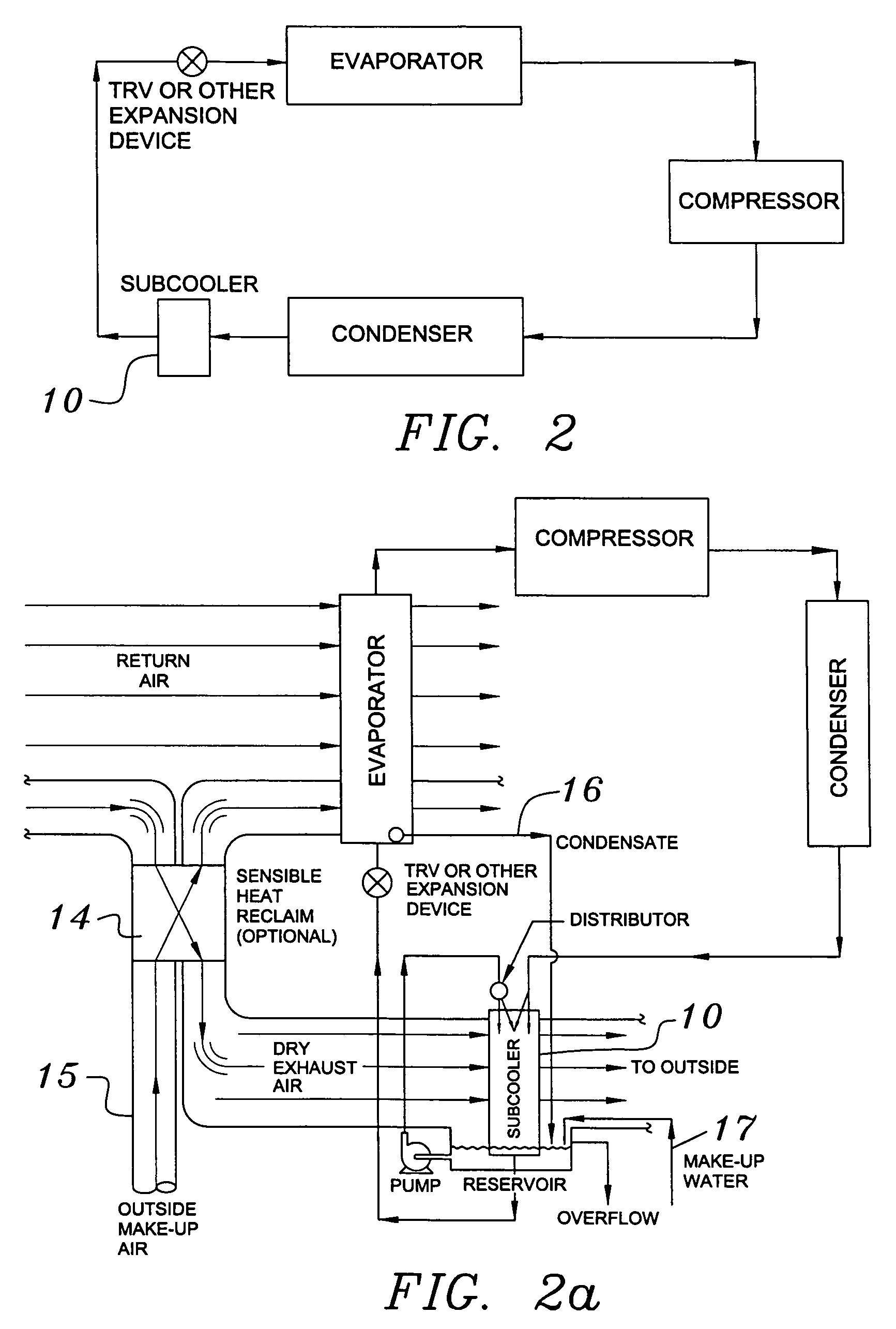

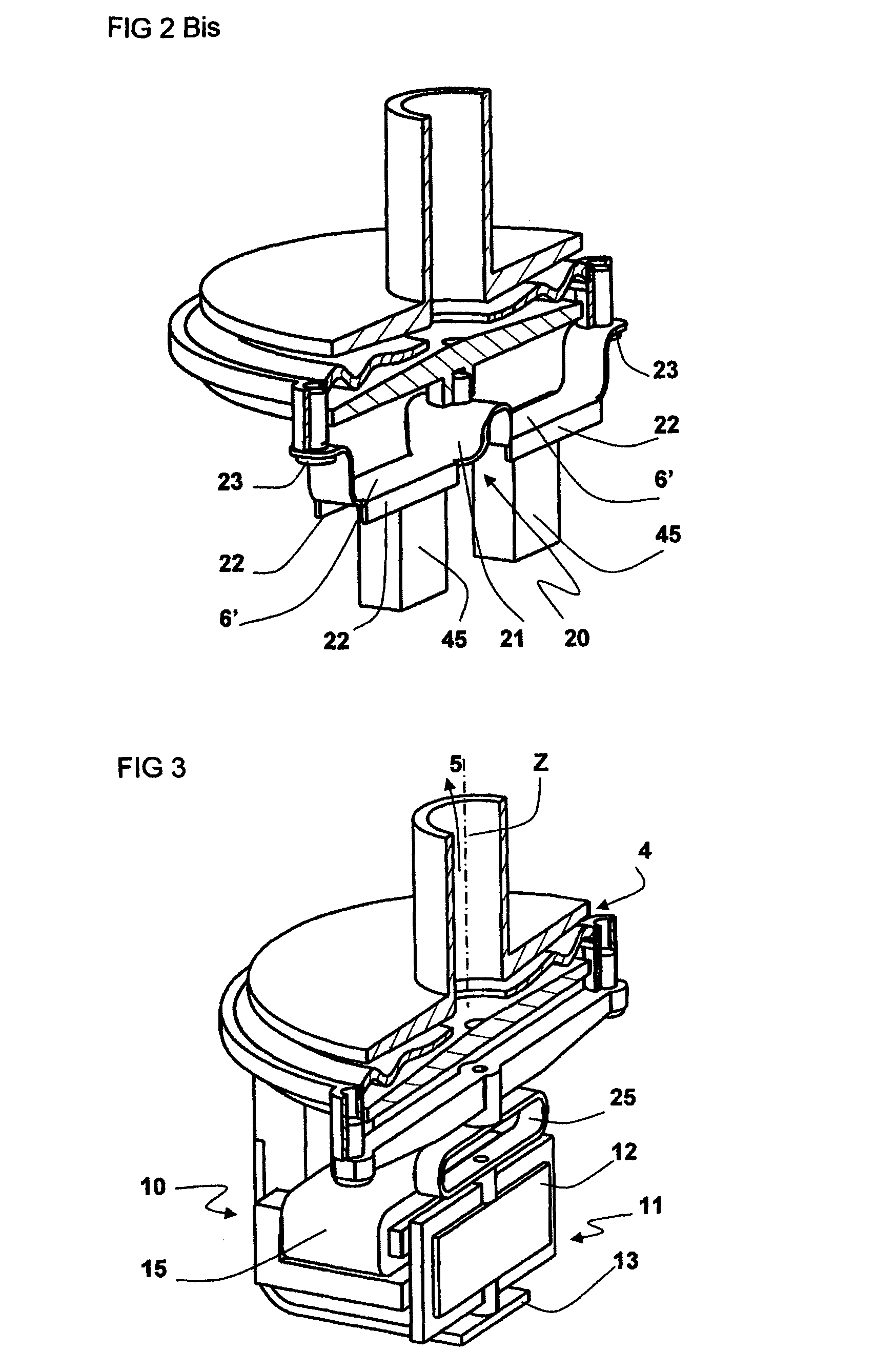

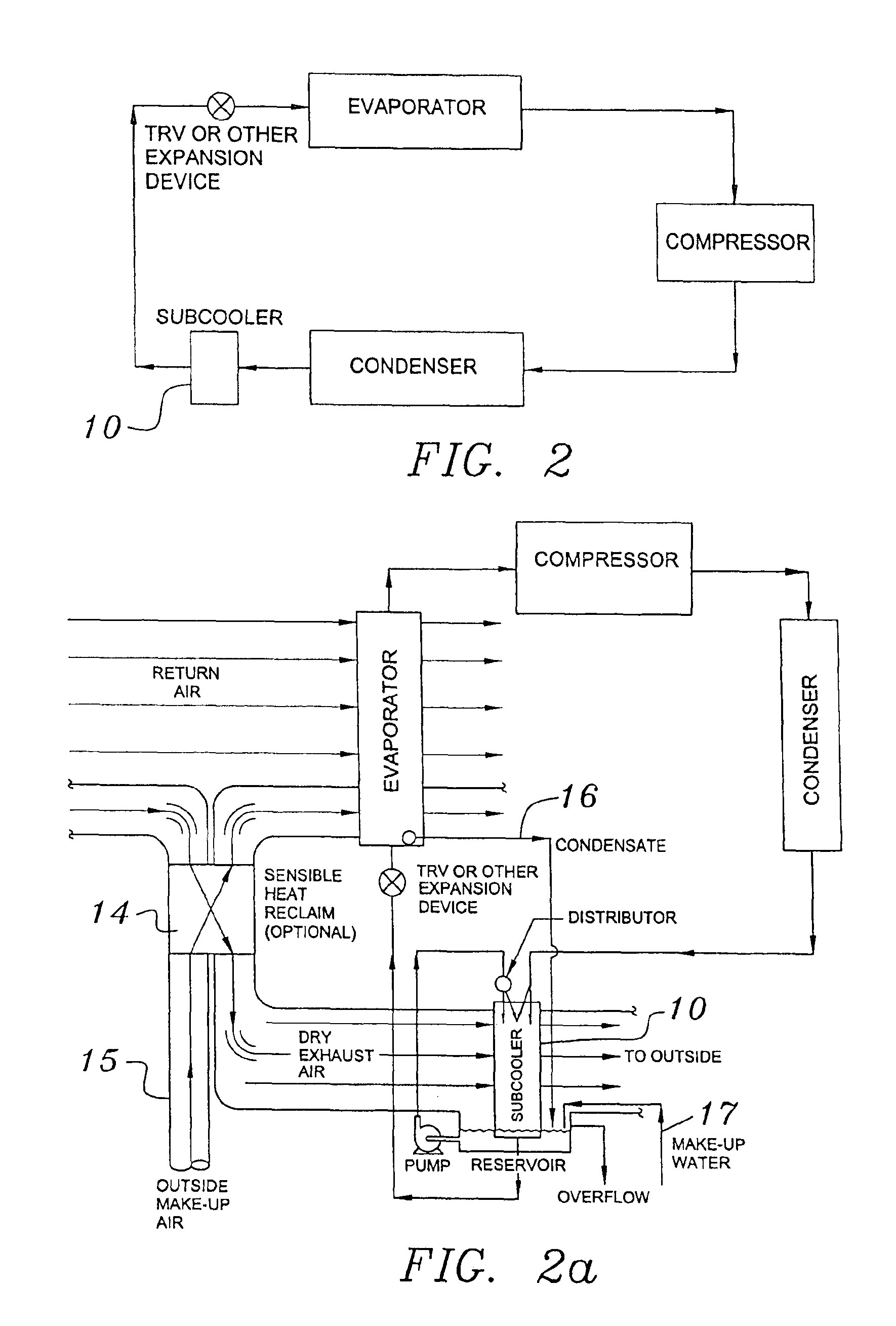

Building exhaust and air conditioner condensate (and/or other water source) evaporative refrigerant subcool/precool system and method therefor

InactiveUS7150160B2Improve pumping efficiencyReduce power consumptionCondensate preventionDomestic cooling apparatusWater wetWater source

Owner:OLIVE TREE PATENTS 1

Valve apparatus

InactiveUS20090314979A1Reduces percentage deformationReduce distortionPositive displacement pump componentsCheck valvesSolid particleEngineering

A valve apparatus that has a longitudinal axis therethrough comprises a valve seat member, a valve closure member, a fluid flow path, and a resilient valve insert member. The valve seat member comprises a hollow bore and a first frustoconical contact surface that has an inner perimeter and an outer perimeter. The valve closure member comprises a valve body and a second frustoconical contact surface that is adapted to seal against the first frustoconical contact surface in a strike face area. The valve closure member is movable along the longitudinal axis of the valve apparatus. The fluid flow path extends through the bore of the valve seat member and between the valve seat member and the valve closure member. This fluid flow path is closed when the second frustoconical contact surface is sealed against the first frustoconical contact surface. The resilient insert member is attached to the valve closure member. It has an inner perimeter and an outer perimeter, the inner perimeter being adjacent to the strike face area on the second frustoconical surface. The resilient insert member is offset and adapted to contact the first frustoconical contact surface and form a hydraulic seal therewith at the inner perimeter of the insert member, before the first frustoconical contact surface comes in contact with the second frustoconical surface as the valve closes. The offset of the insert member is greater at its outer perimeter than at its inner perimeter, and is greater at its outer perimeter than the diameter of the largest particle in any fluid to be pumped. The insert is deformable but substantially non-compressible and comprises a particle retaining means to accommodate solid particles that are trapped between the insert and the valve seat member when the valve closes. The particle retaining means has at least one cavity (void space) that is in fluid contact with the flow path for fluids between the valve seat member and valve closure member when the valve is open. The cavity has an opening in fluid contact with the flow path for fluids when the valve is open and is large enough to accommodate one or more solid particles within the interior of the cavity. The volume of the cavity contracts as the valve closes, whereby solid particles are screened from the fluid and retained within the cavity, and whereby clear fluid is forced out of the cavity into the flow path and directed inwardly toward the bore of the valve seat member through the gap between the first and second frustoconical contact surfaces.

Owner:MCINTIRE WILLIAM RAY

Sucker rod apparatus and methods for manufacture and use

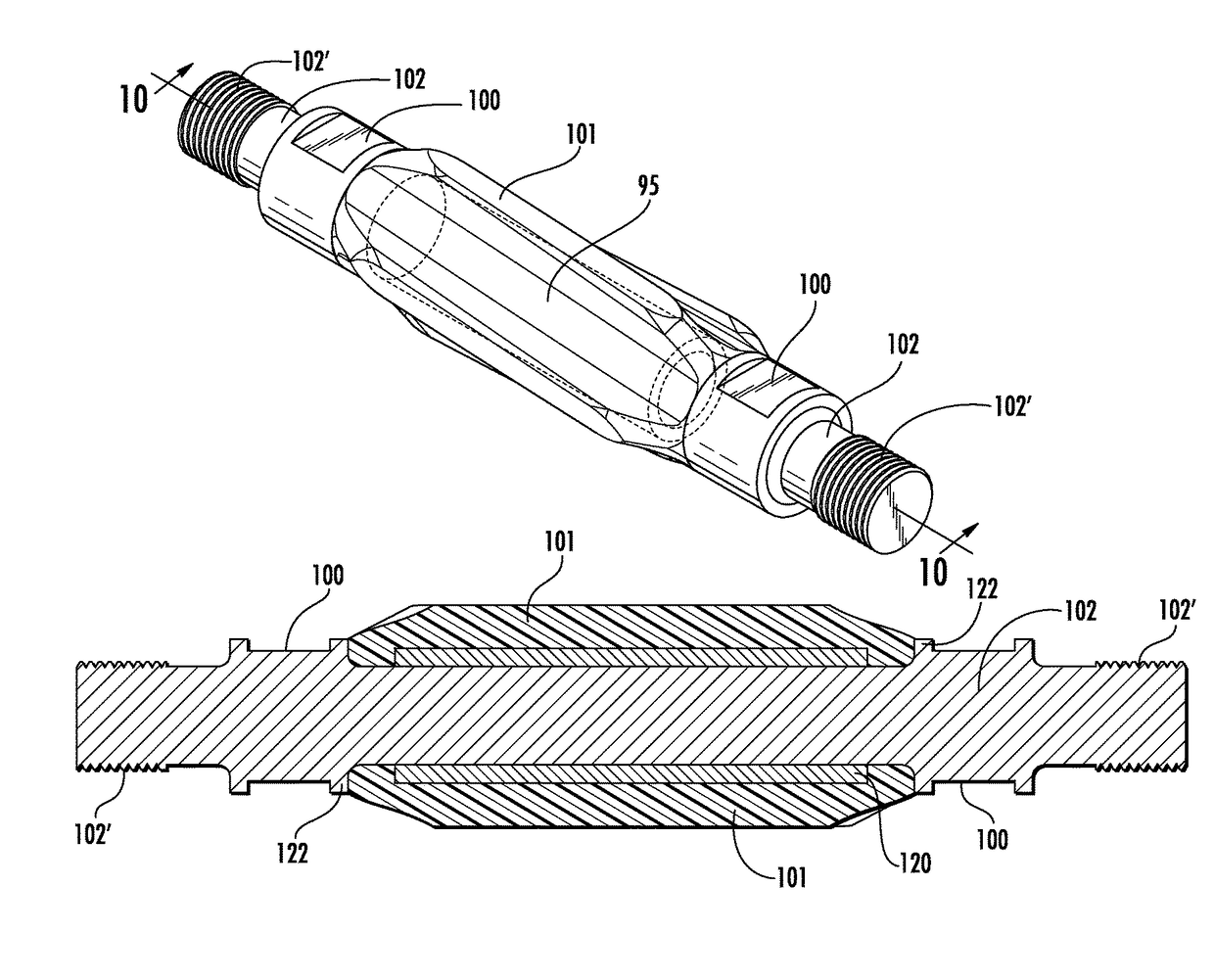

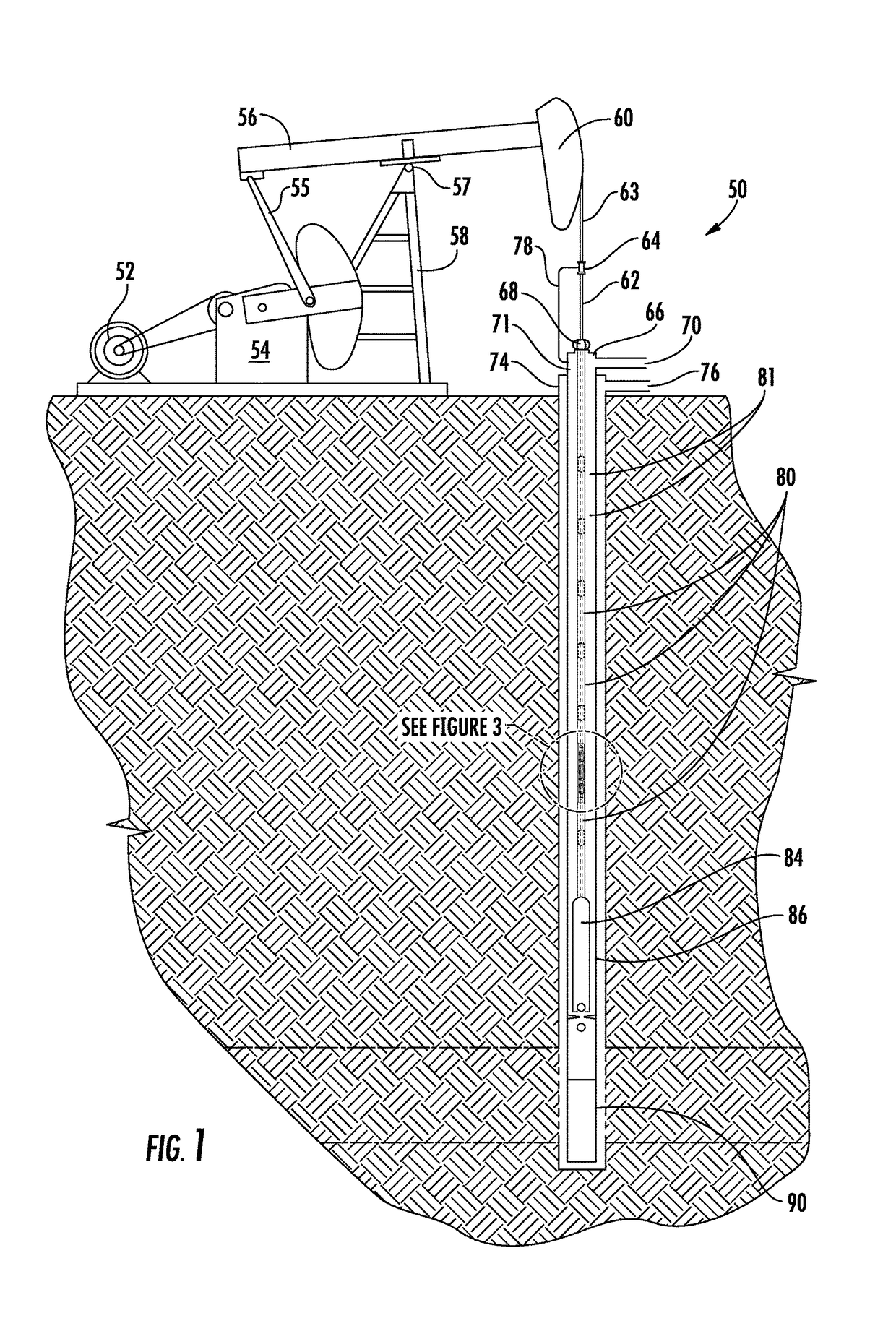

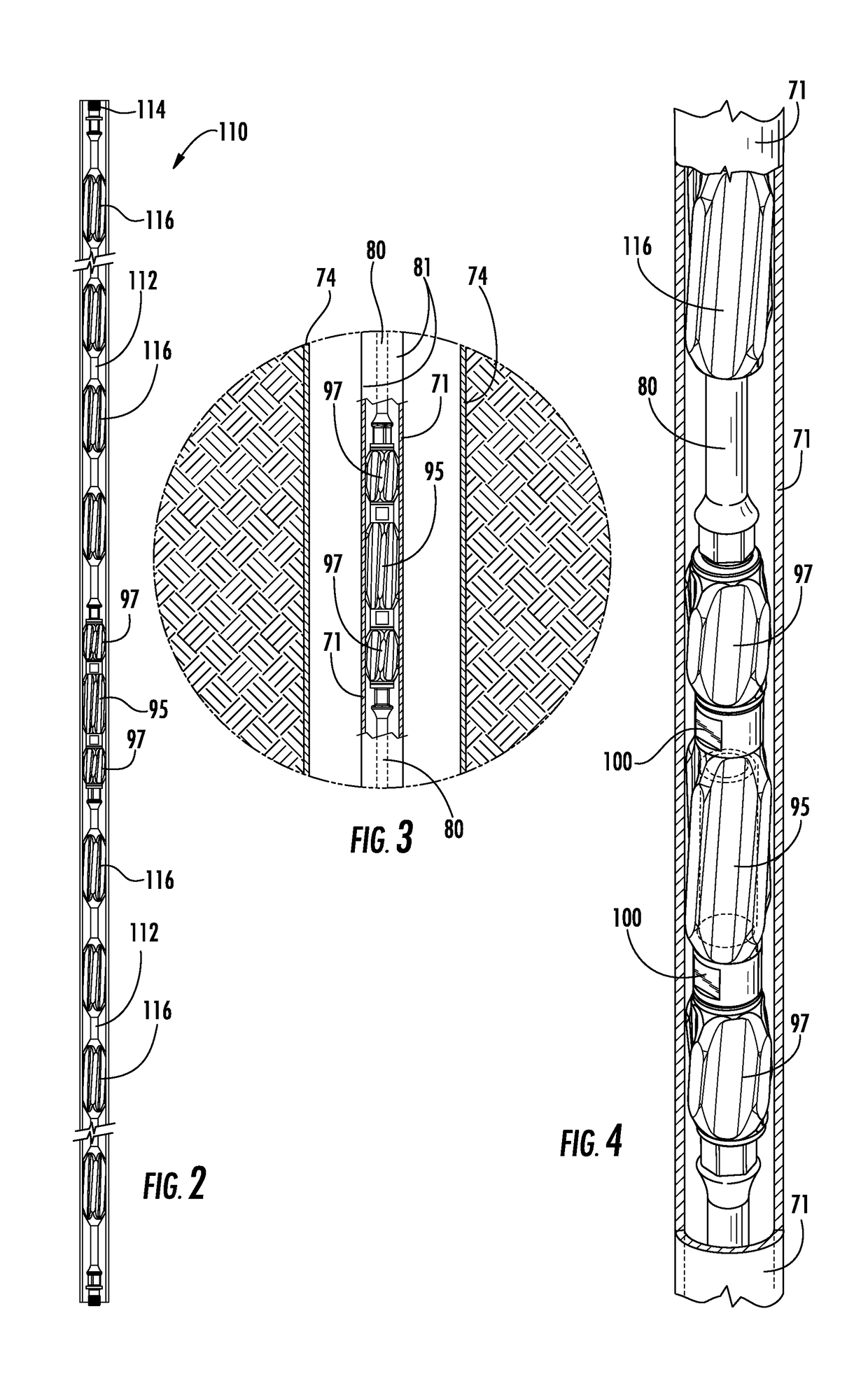

ActiveUS9869135B1Improve wear resistanceReduce capital investmentDrilling rodsMetal-working apparatusFiberCoupling

A sucker rod string improved by the use of wear resistant, high temperature resistant, fiber-reinforced phenolic composite materials as centralizing guides on sucker rods and couplings, both molded on the rod and prepared as snap-on couplings for in-the-field use, and on magnet rod inserts, both rod box and pin magnet rod inserts, in which the thermosetting composites are used as sleeves, encapsulating housings, and centralizing guides. The magnet rod inserts and couplings are designed to be machined so that worn phenolic composite can be removed and replaced with fresh composite without removing or damaging the magnet. Processes are disclosed for integrating composite thermoset molding into sucker rod, coupling, and magnet rod insert manufacture and for refurbishing used components of a sucker rod string.

Owner:RFG TECH PARTNERS LLC

Breast pump for expressing milk from a breast

ActiveUS8376986B2Improve accessibilityOptimising breast pump settingsMilking pumpMedical devicesBiomedical engineeringUdder

Owner:KONINK PHILIPS ELECTRONICS NV

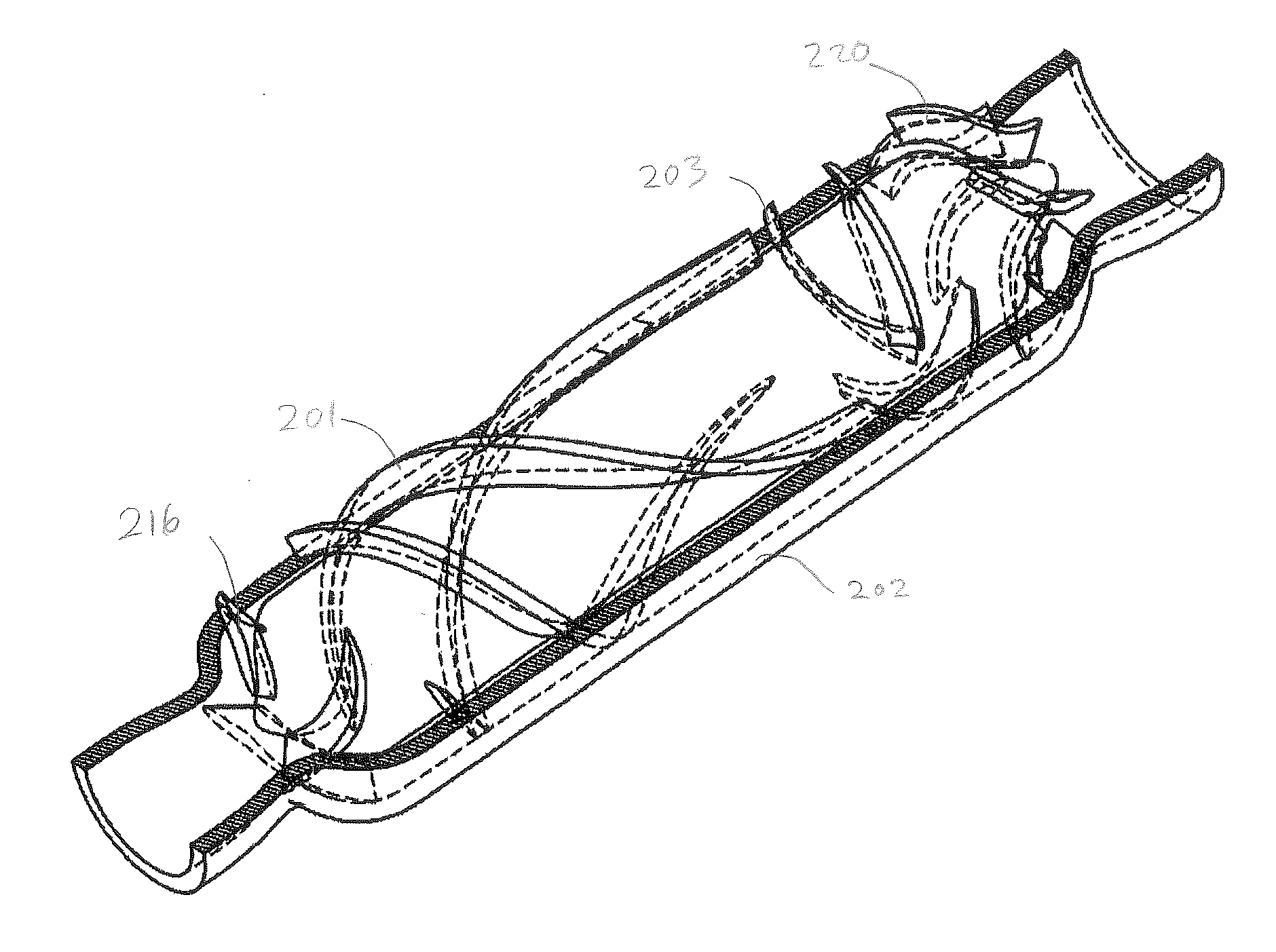

Axial-flow blood pump

An axial-flow blood pump has a rotatable impeller assembly rotatable about an axis and itself having a radially projecting blade and permanent magnets, A stationary stator assembly has stator windings interacting with the permanent magnets and a bearing system supporting the rotatable impeller assembly for rotation about the axis relative to the stator assembly. A stent implantable into a blood vessel is connected to ends of supports for coaxially mounting the stator assembly carrying the impeller assembly in the stent.

Owner:MAGASSIST CO LTD

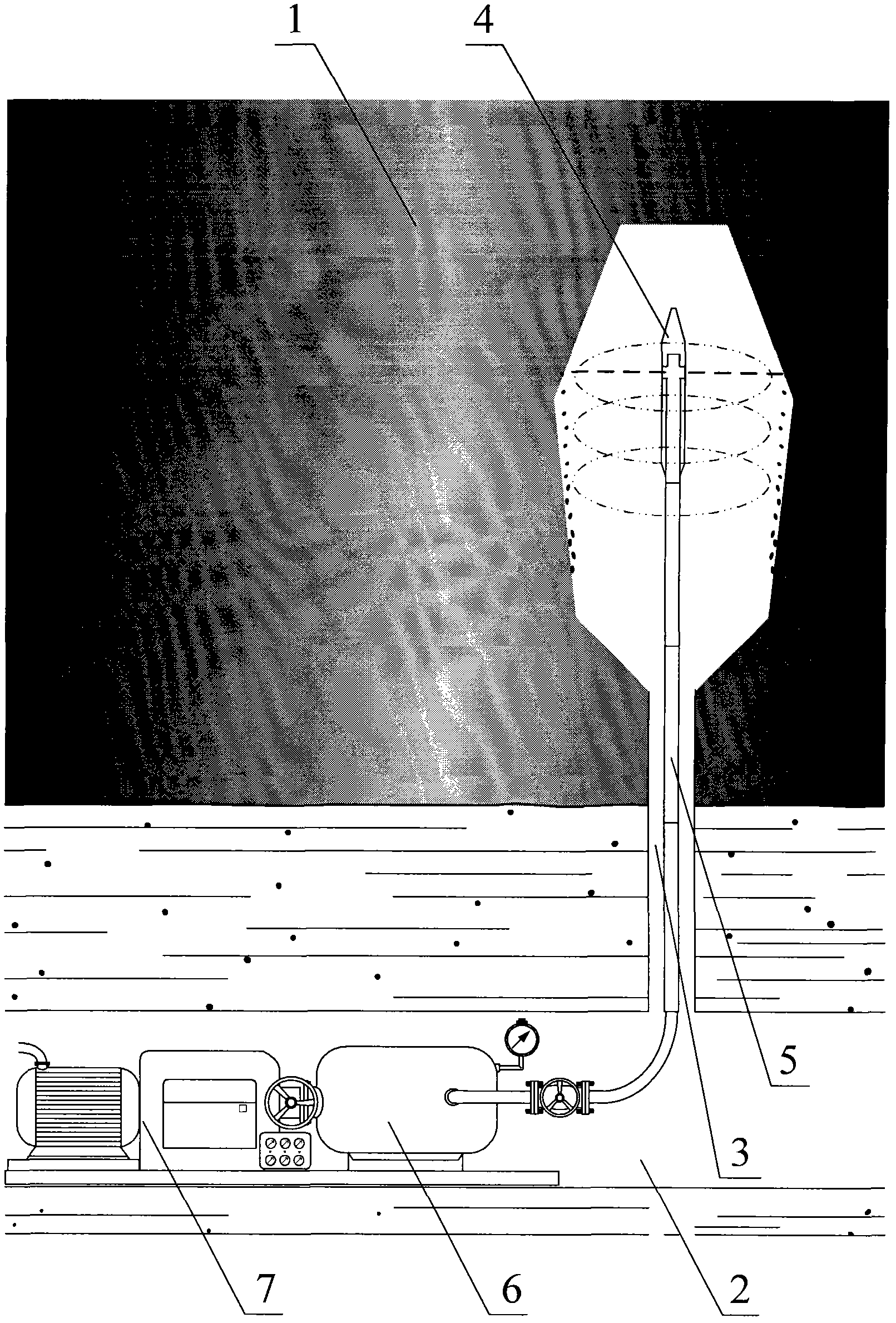

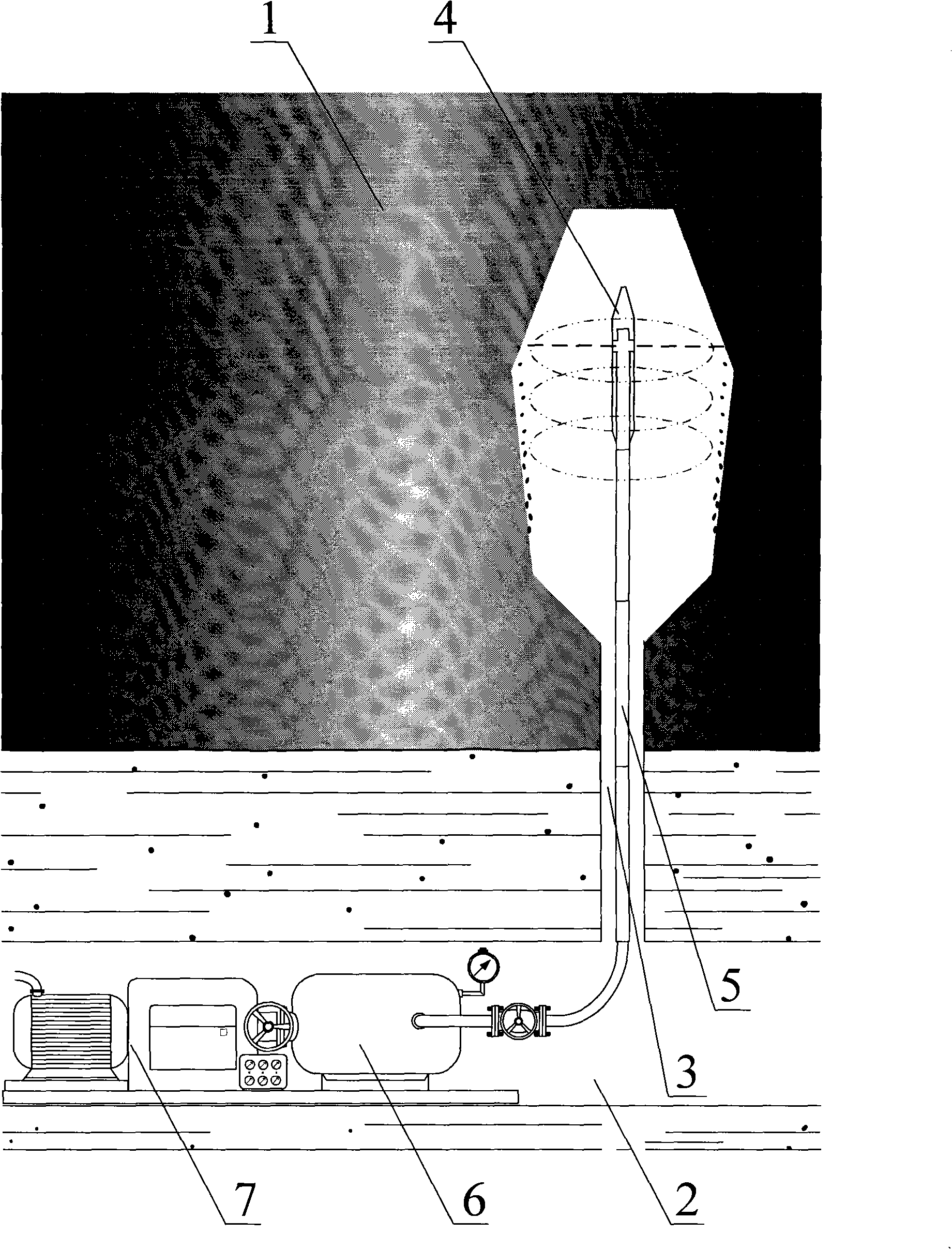

High-pressure gas injection hole-drilling pressure-releasing outburst prevention method

ActiveCN102080525AIncrease the exposed areaImprove breathabilityLiquid/gas jet drillingFluid removalEngineeringHigh pressure

The invention discloses a high-pressure gas injection hole-drilling pressure-releasing outburst prevention method which comprises the steps of: firstly, carrying out common drilling operation in a bottom plate stone drift (2) of a coal bed (1) in front of a coal mining or driving face; after a drill hole (3) enters a design depth of the coal bed, drawing back a drill, sending a jet nozzle (4) anda high-pressure drill rod (5) connected with the jet nozzle into the drill hole, and connecting a high-pressure gas-storing device (6) connected with the tail of the high-pressure drill rod (5) with a high-pressure gas compressing device (7) through a high-pressure tube; starting the high-pressure gas compressing device (7), carrying out near cylinder rotary impacting, cutting and holing on the hole wall of the drill hole in the coal bed (1) by using high-pressure impact wave as a power source through the jet nozzle (4) capable of jetting high-pressure airflow and automatically rotating to ensure that the coal body around the drill hole (3) is gradually crushed and separated from the hole wall to form pressure releasing space and subjected to the pressure balanced permeability increase through ground pressure and gas pressure action. According to the invention, the drainage efficiency of the gas in the coal bed is greatly improved and the outburst damage of the coal bed is reduced.

Owner:河南省迪卡尔机电设备制造有限公司

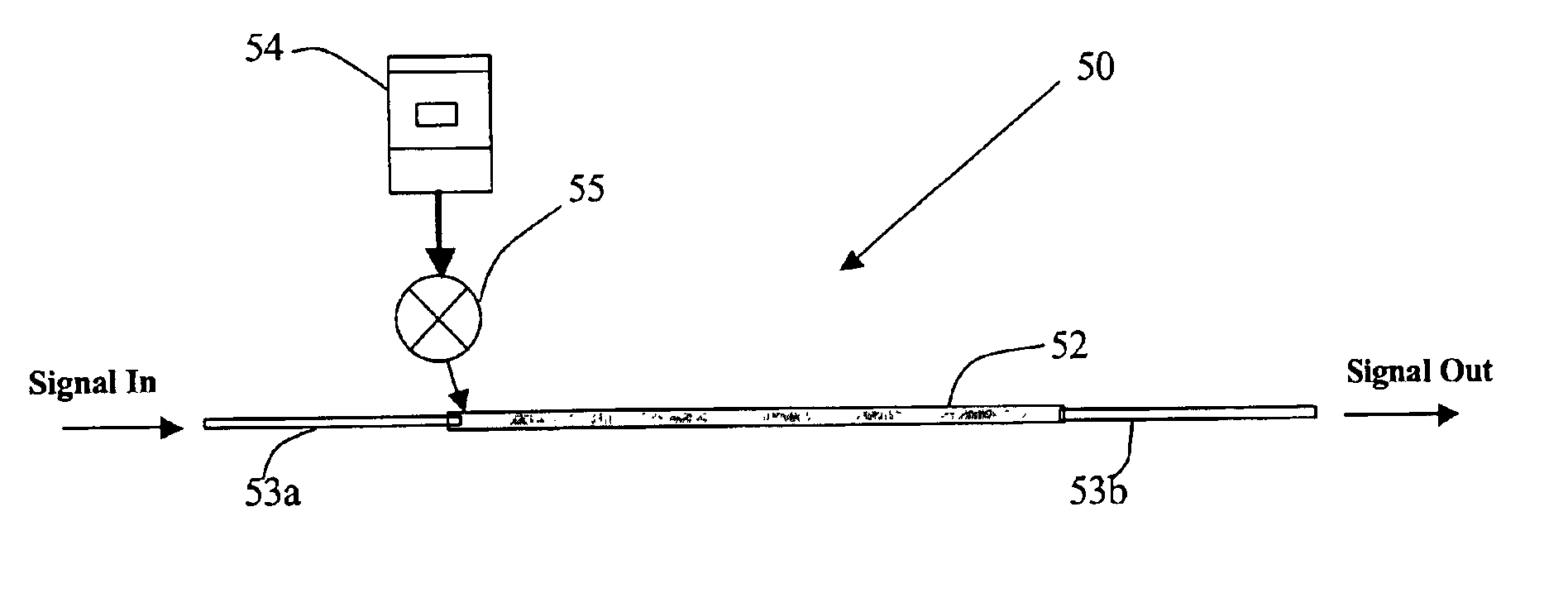

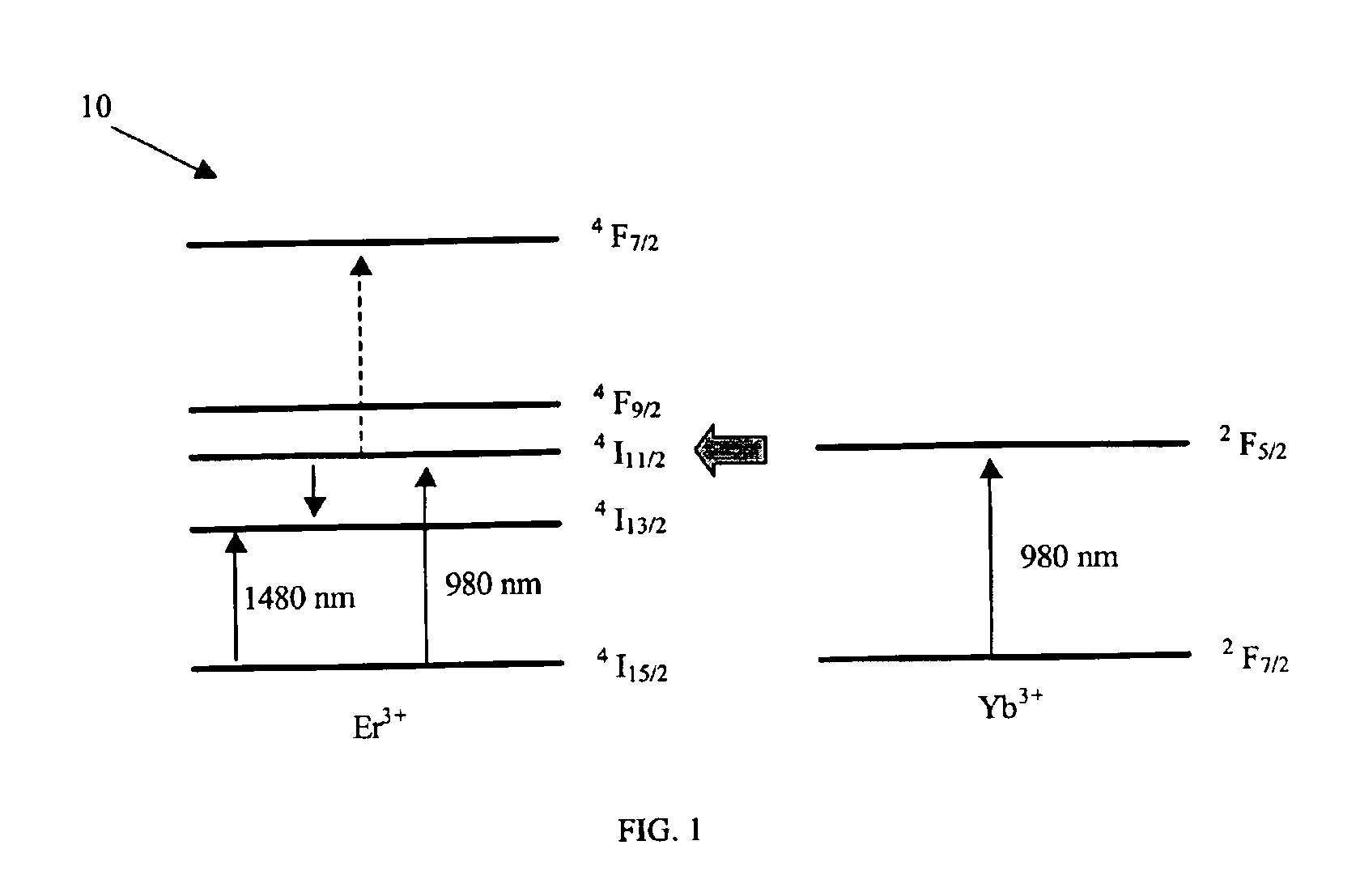

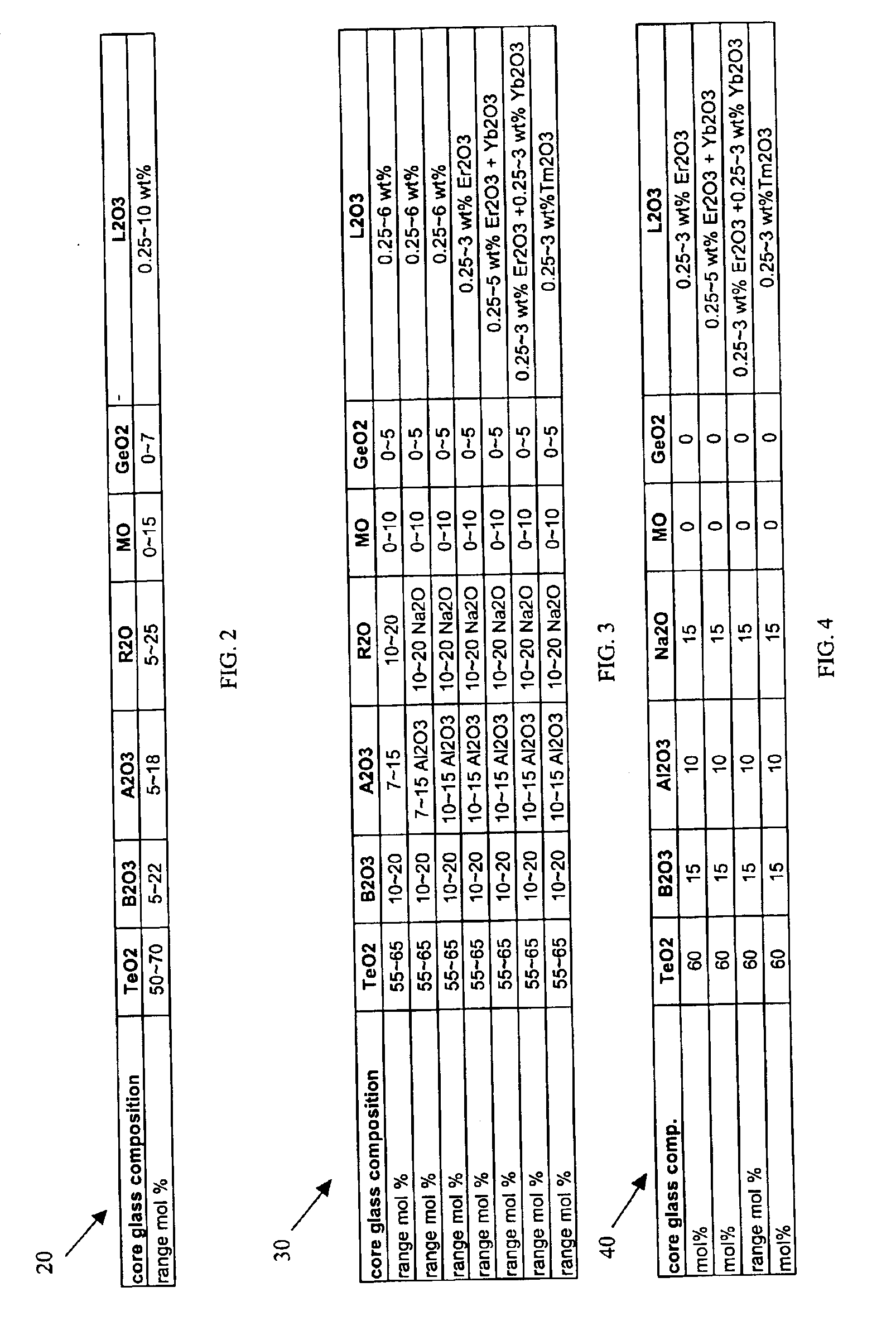

ER3+ doped boro-tellurite glasses for 1.5 mum broadband amplification

InactiveUS6859606B2Lower average energyHigher propertiesActive medium materialActive medium shape and constructionBroadbandBoron oxide

A tellurite-based glass composition for use in EDFAs exhibits higher phonon energy without sacrificing optical, thermal or chemical durability properties. The introduction of boron oxide (B2O3) into the Er3+-doped tellurite glasses increases the phonon energy from typically 785 cm−1 up to 1335 cm−1. The inclusion of additional glass components such as Al2O3 has been shown to enhance the thermal stability and particularly the chemical durability of the boro-tellurite glasses. Er:Yb codoping of the glass does further enhance its gain characteristics.

Owner:NP PHOTONICS A CORP OF DELAWARE

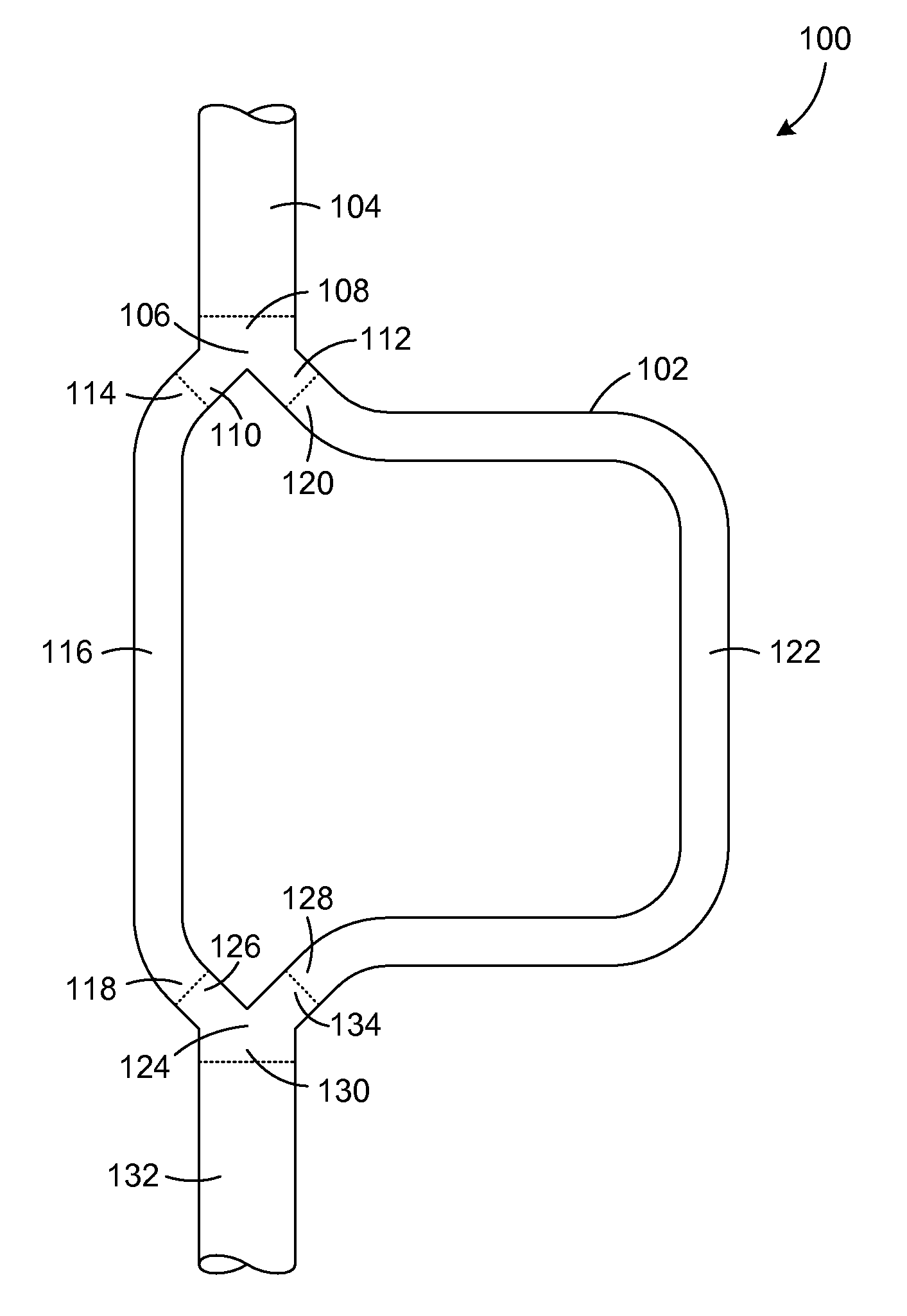

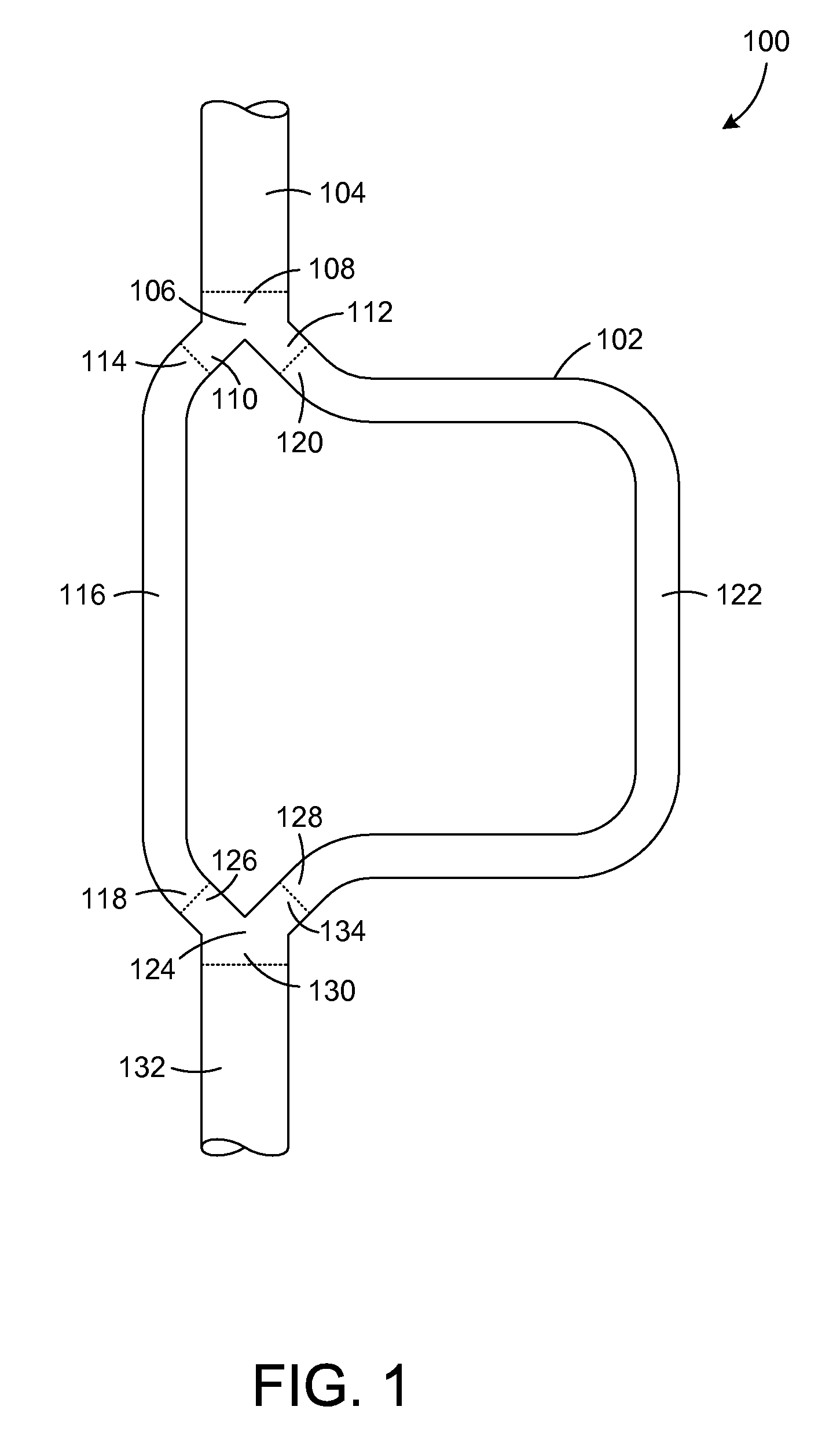

Blood pump with separate mixed-flow and axial-flow impeller stages and multi-stage stators

InactiveUS20140341726A1Reduce circumferential componentReduce risk of damagePump componentsBlood pumpImpellerMixed flow

A pump for a fluid which can be blood has a stator housing and a rotor hub with leading and trailing portions and an intermediate portion disposed therebetween. At least one impeller blade at the leading portion drives circumferential and axial components of a flow into a pump annulus or intermediate pathway portion. At least one stator blade extends radially inward from the stator housing within the intermediate pathway portion and is configured to reduce a circumferential component of the flow.

Owner:HEARTWARE INC

Pulsation Attenuation

ActiveUS20090038684A1Increase pressureImprove pumping efficiencyInternal combustion piston enginesPipe elementsUltrasound attenuationManufacturing engineering

Owner:OPTIMUM POWER TECH LP

Elastomeric dispensing pump that can be made with as few as two components

InactiveUS20090302064A1Improve pumping efficiencyReduce manufacturing costSingle-unit apparatusPortable flexible containersRigid coreMembrane configuration

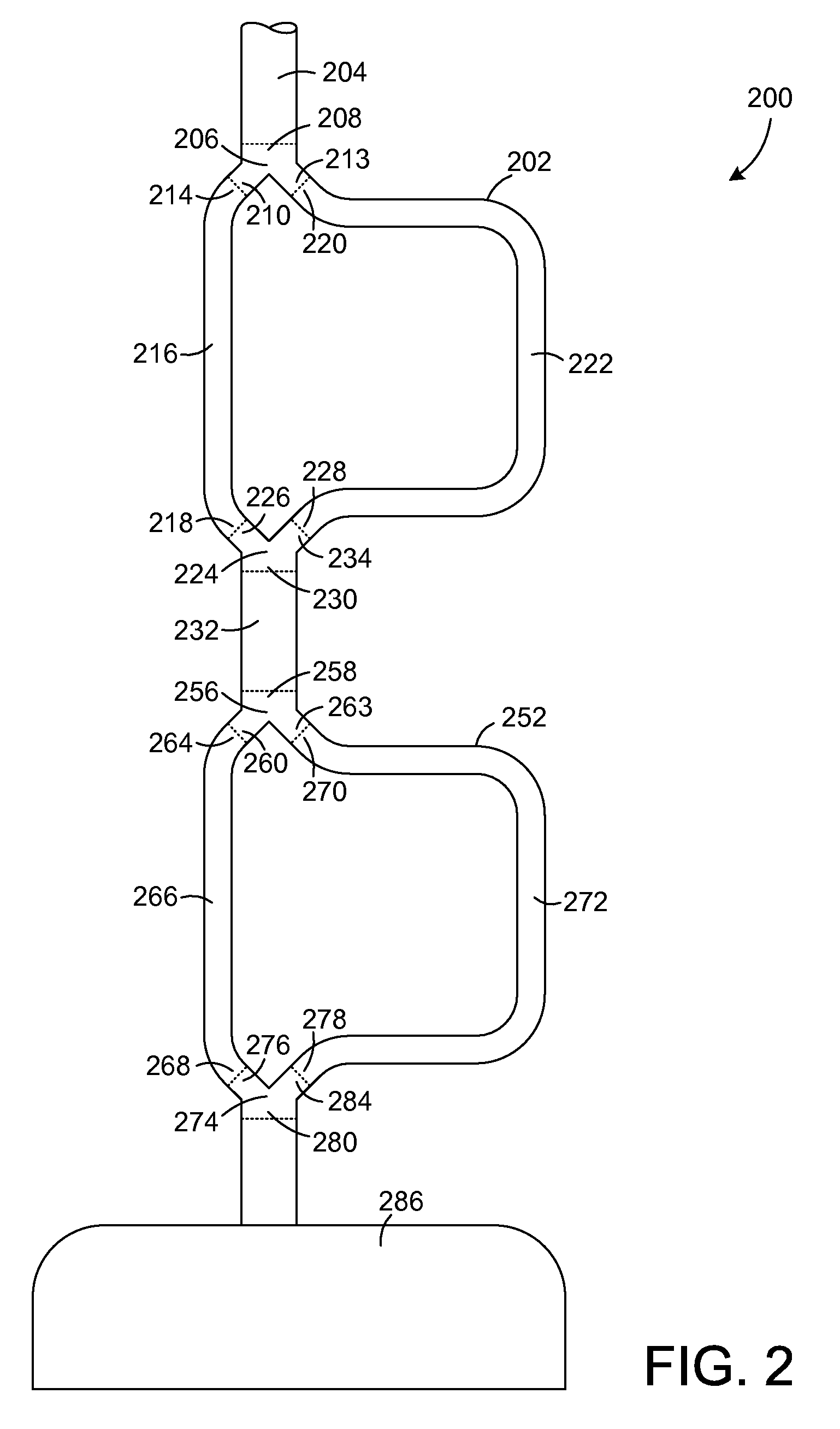

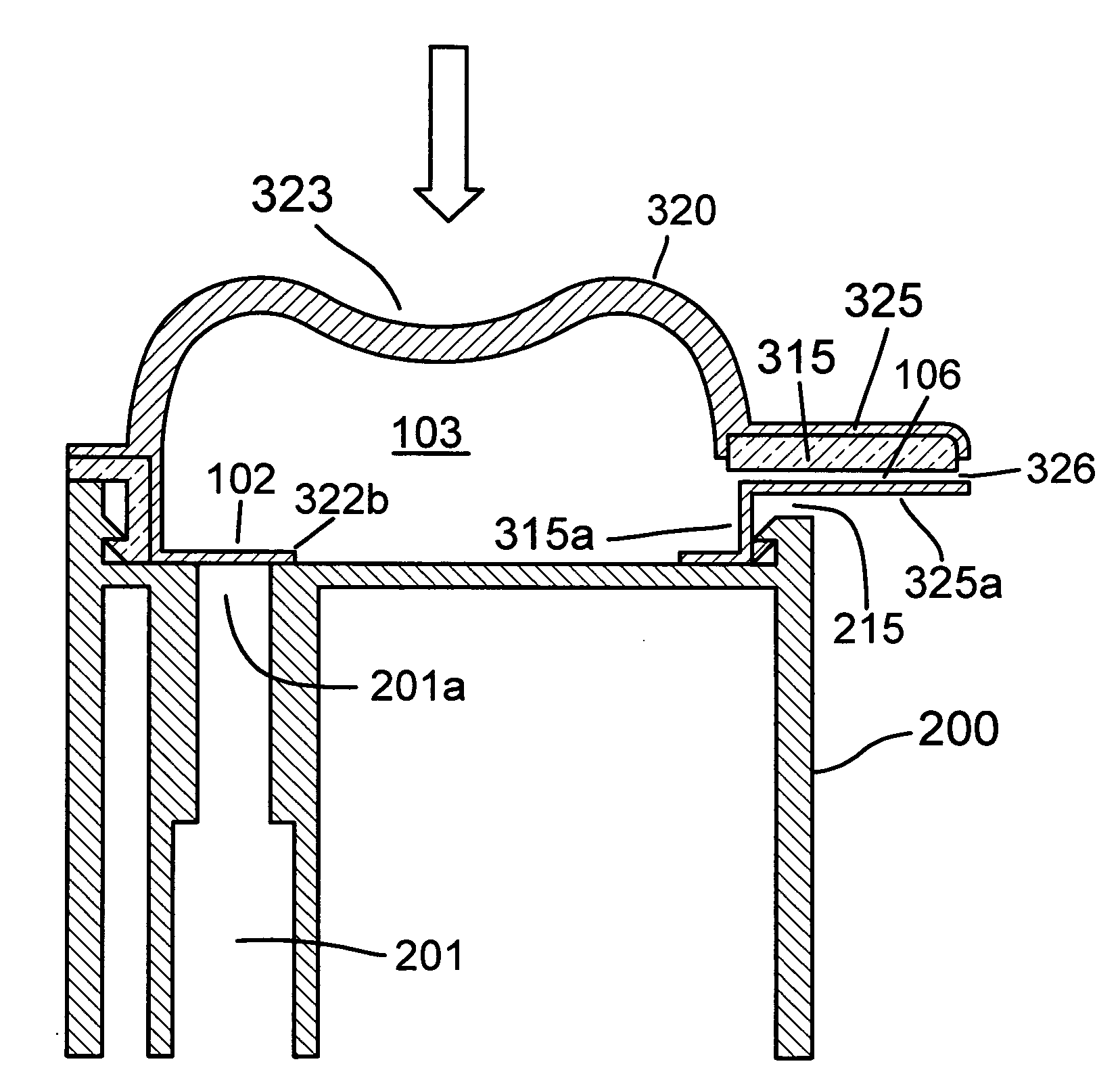

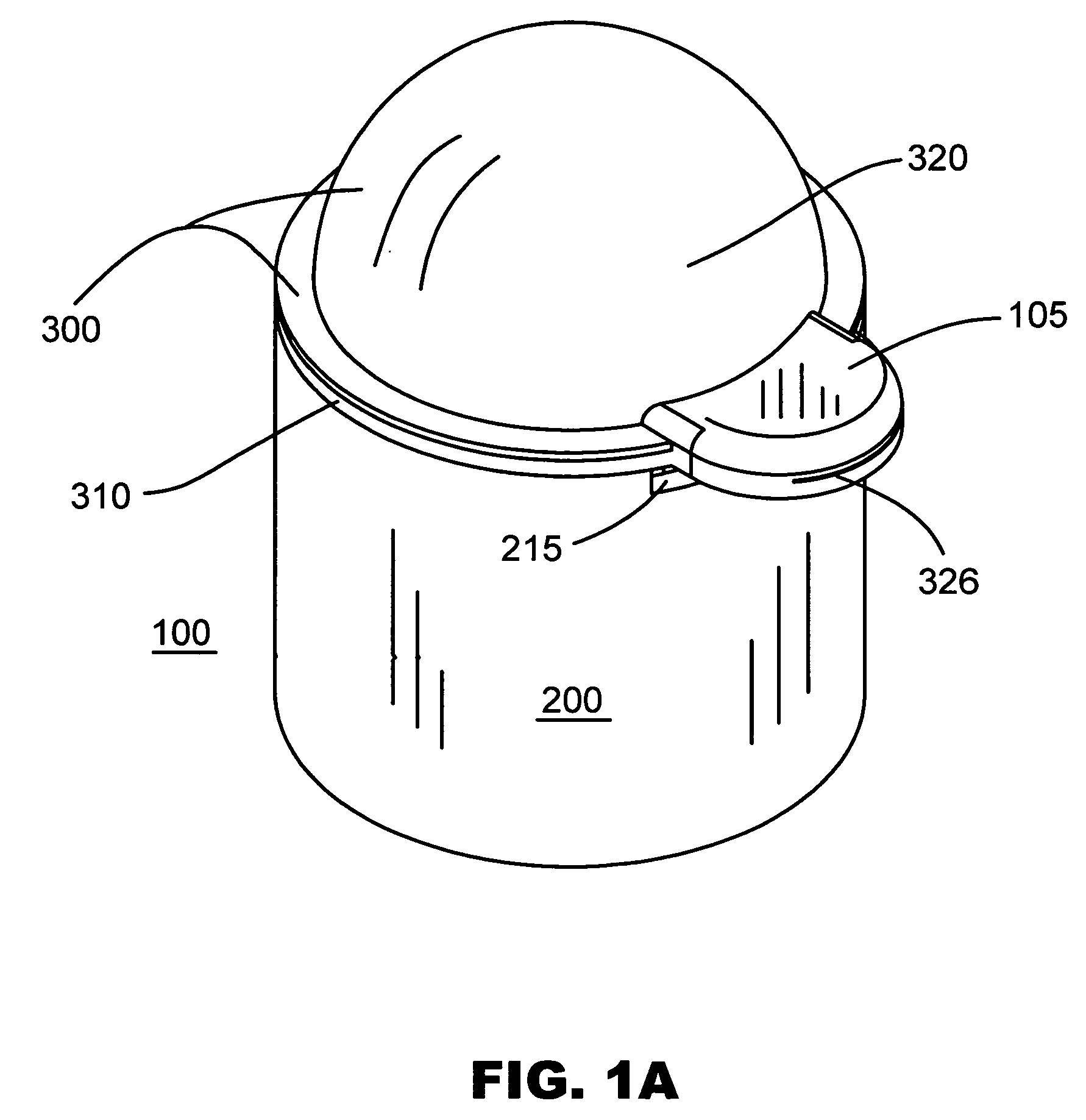

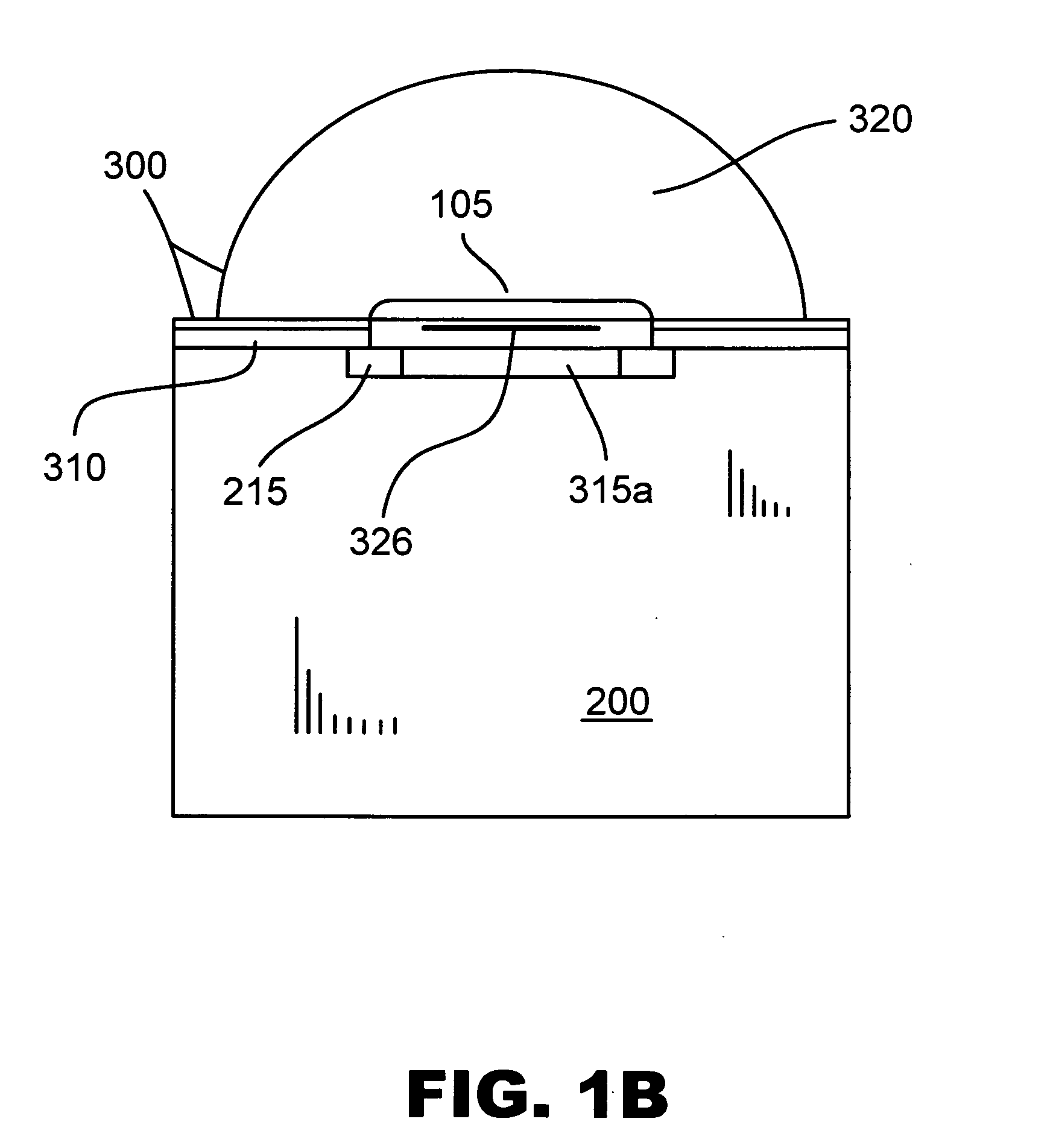

A fluid dispensing pump that can be manufactured from as few as two parts: a stationary pump base (200) provided with an inlet passageway (201), and an integral pump top (300) provided with a fluid-tight attachment to the pump base and including a generally rigid core (310) and a self-restoring elastomeric layer (320). The generally rigid core (310) has a base attachment portion (311) and a dispensing valve core (315). The elastomeric layer (320) includes a resilient self-restoring pump wall (323) and a dispensing valve membrane (325). Upon assembly of the pump base and the pump top, a fully functional dispensing pump (100) is created with an inlet passageway (101), a one-way inlet valve (102), a self-restoring resilient pump cavity of variable volume (103) and a one-way dispensing valve (105). The one-way dispensing valve is preferably self-closing. The integral pump top (300) may have a rigid or semi-rigid actuator portion (314) bound to or imbedded into the resilient self-restoring pump wall (323). The dispensing pump of the present invention may have a valved venting passage for those applications that require it and may have a secure lock-in mechanism for leakage prevention during storage or transportation.

Owner:MABEL

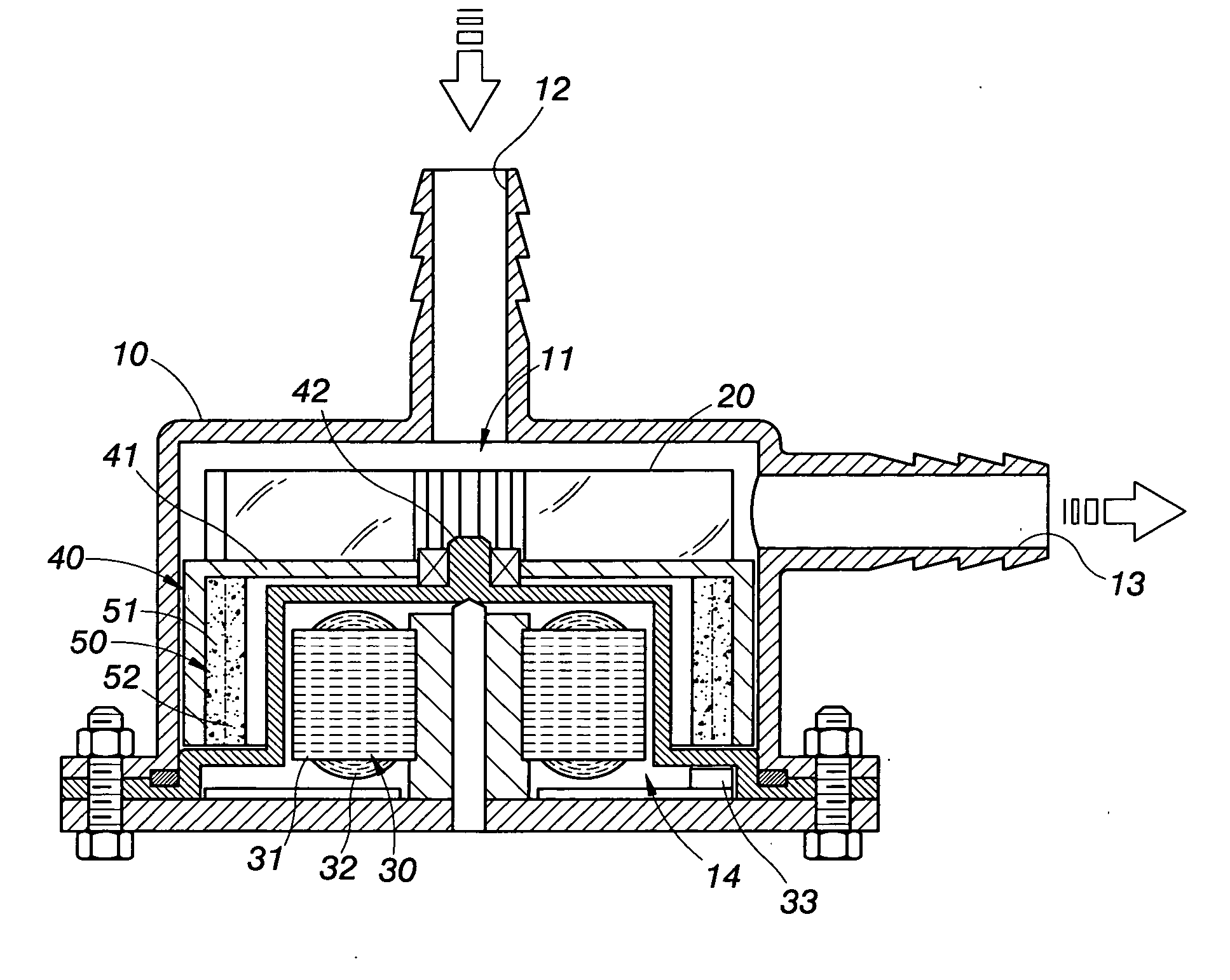

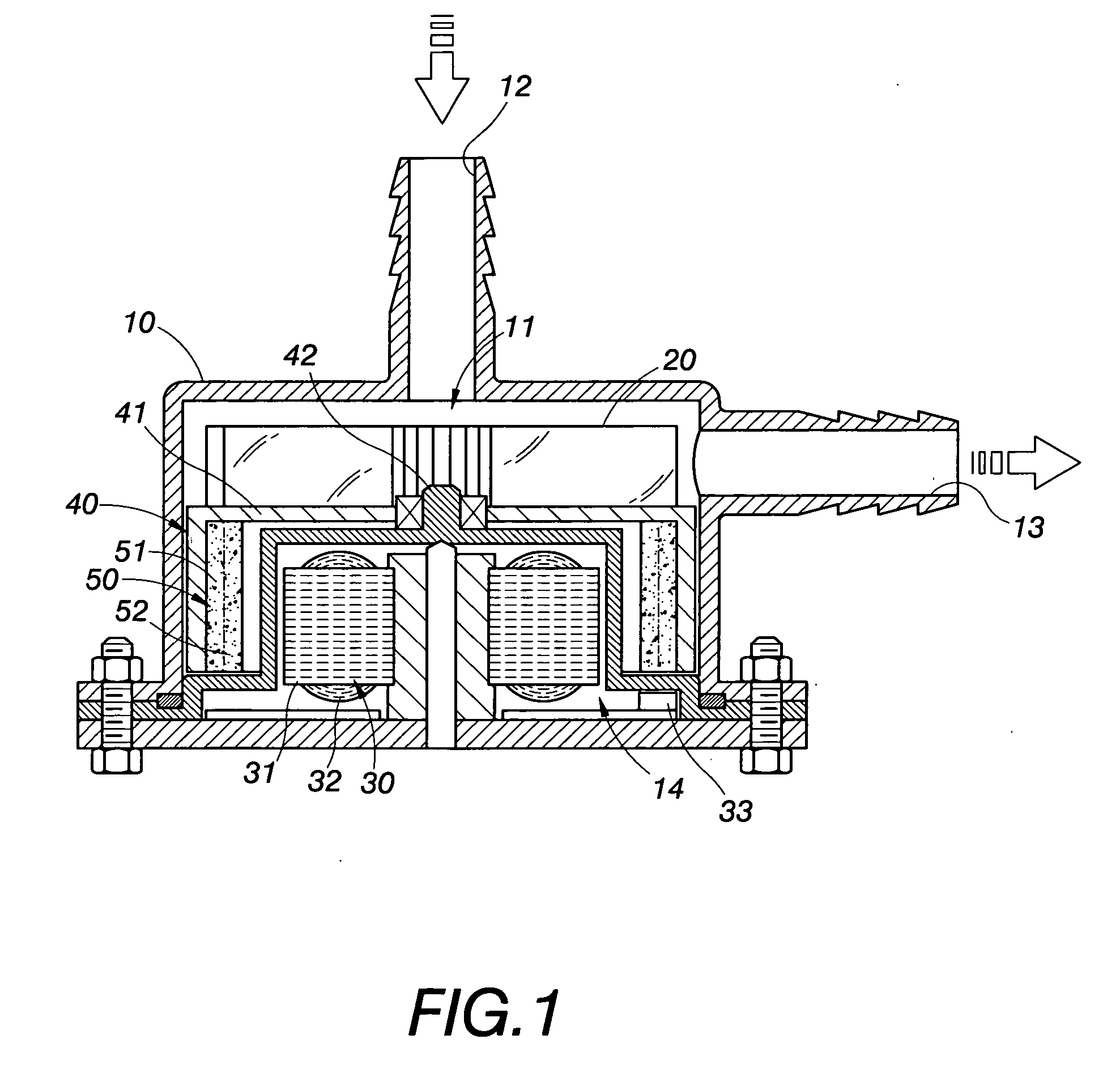

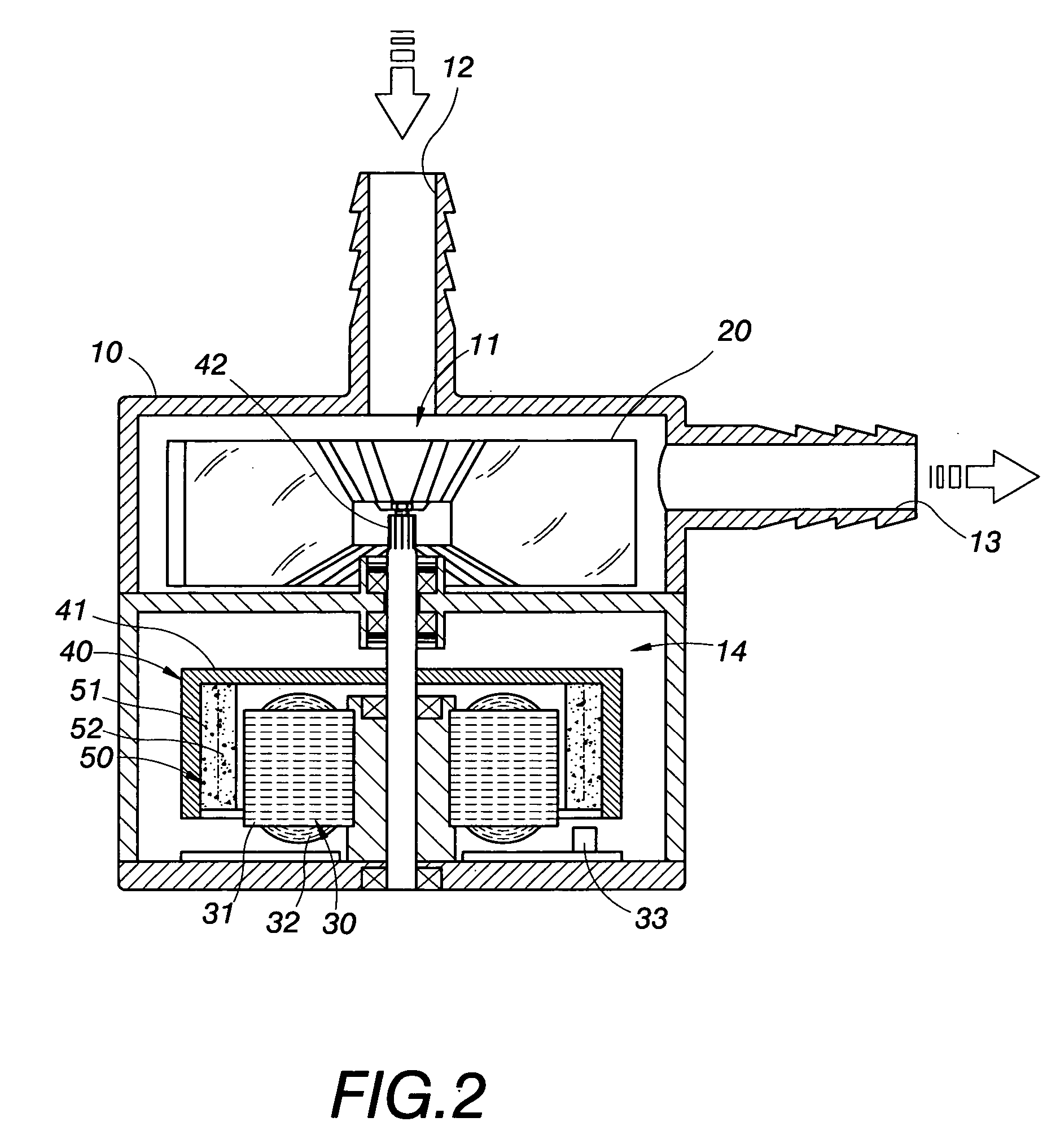

Outer-rotor-driving pump having annular ferrite magnet with grain alignment on its inner periphery

InactiveUS20070090704A1Improve efficiencyEnhanced magnetic forceMagnetic circuitPiston pumpsEngineeringMagnetic energy

A pump driven by an outer rotor and having an annular ferrite magnet with grain alignment on its inner periphery comprising a housing, a wheel blade, a stator and an outer rotor surrounding the stator, wherein the pump uses the wheel blade to draw and deliver fluid in the water sucking area. The pump is characterized in that: the rotor includes a rotating disk and the annular ferrite magnet fixed on the inner periphery of the disk, the magnet is a multipolar anisotropic permanent magnet, the main body of the magnet is divided into a magnetic conductive outer layer and a magnetic inner layer, in order that fluxes of the magnetic inner layer turn back right away when they pass the outer layer to thereby shorten magnetic loops, to increase magnetic force and the effect of magnetic energy accumulation, and to increase the efficiency of the pump rotated by the rotor.

Owner:SUPER ELECTRONICS

Diaphragm pump with a crinkle diaphragm of improved efficiency

ActiveUS8714944B2Short strokeRaise the ratioFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpControl theory

Owner:AMS R&D

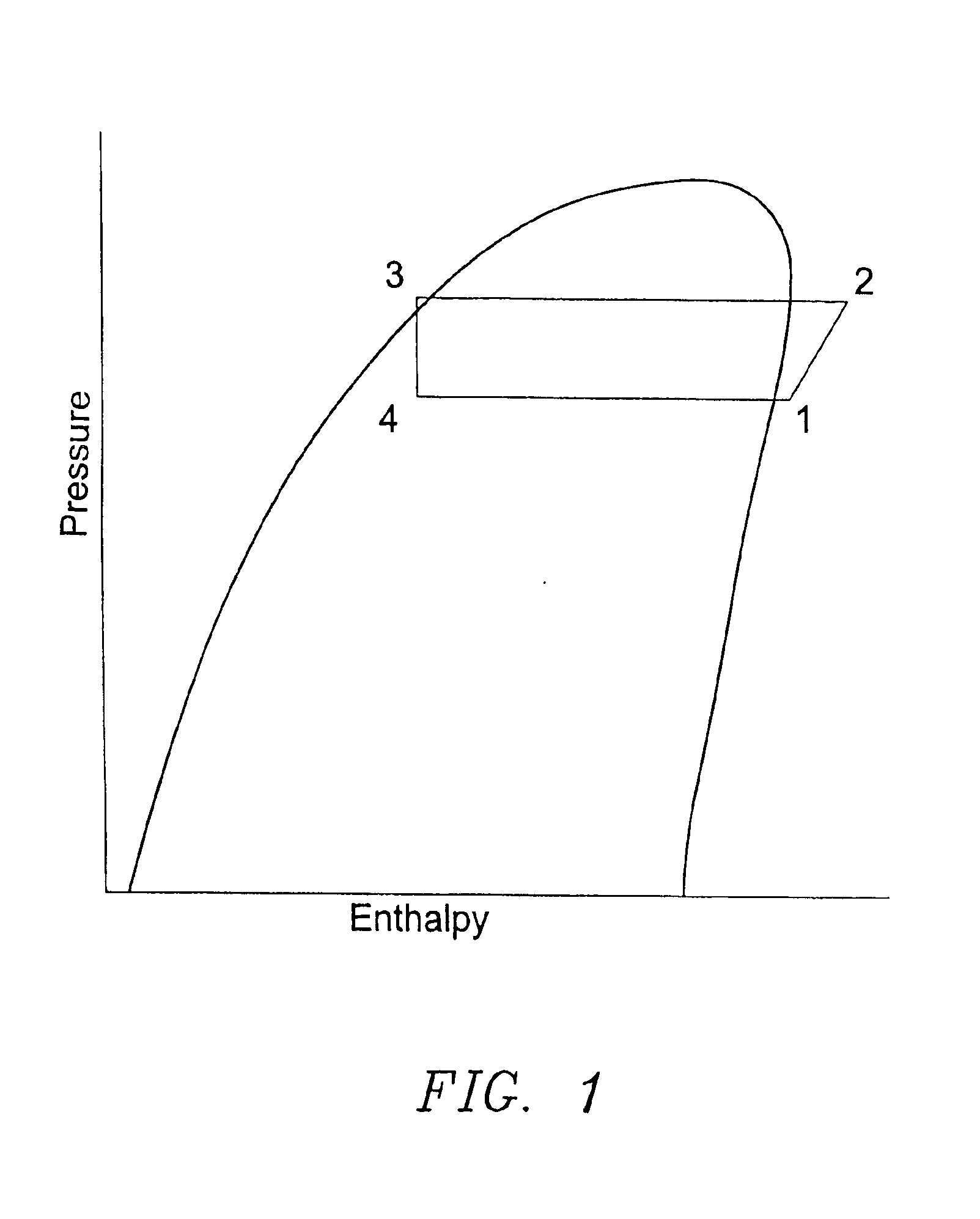

Building exhaust and air conditioner condensate (and/or other water source) evaporative refrigerant subcool/precool system and method therefor

InactiveUS6857285B2Improve pumping efficiencyReduce power consumptionEnergy recovery in ventilation and heatingHeat recovery systemsWater wetWater source

A system for providing liquid refrigerant subcooling, by means of evaporative cooling utilizing the condensate water of said air conditioner, refrigeration / heat pump system and / or some other water supply to wet the surface of the subcool heat exchanger and pass the dry exhaust air across the wetted surface of the subcool heat exchanger. A system for providing hot gas discharge refrigerant precooling into the primary condenser of an air conditioner, refrigation or heat pump system by evaporative cooling utilizing the condensate water of said system and / or other water supply to wet the surface of the precool heat exchanger and then passing the cold, dry exhaust air across the wetted surface of the precool heat exchanger. A combination subcooler / precooler system where the cold dry building exhaust air is used to evaporatively subcool the liquid refrigerant in the water wetted (or dry) subcooler and then used to conductively cool the hot gas refrigerant.

Owner:OLIVE TREE PATENTS 1

Crinkle diaphragm pump

ActiveUS8834136B2Improve pumping efficiencyEnhanced couplingFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

Owner:AMS R&D

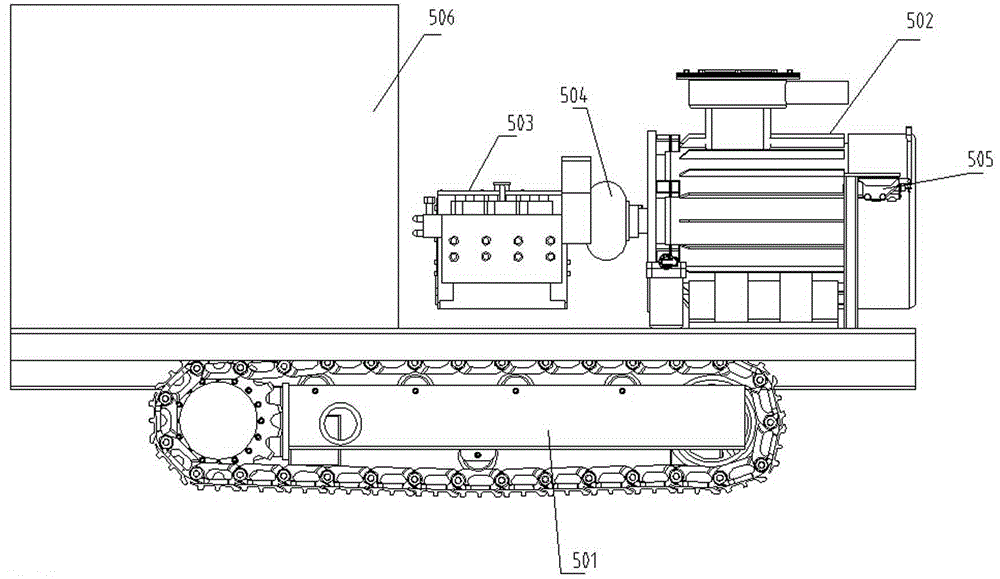

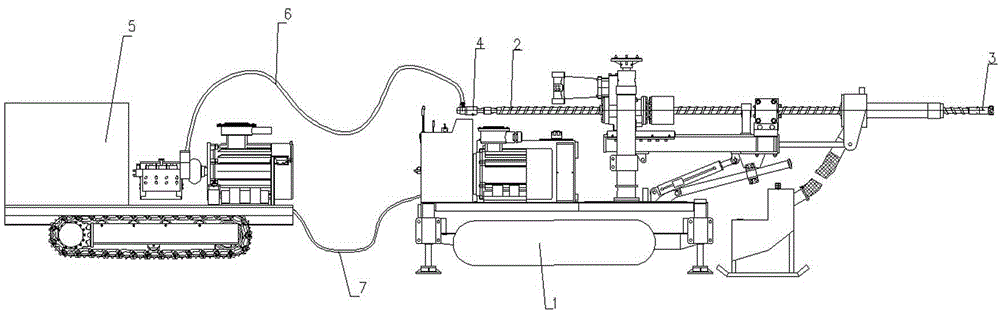

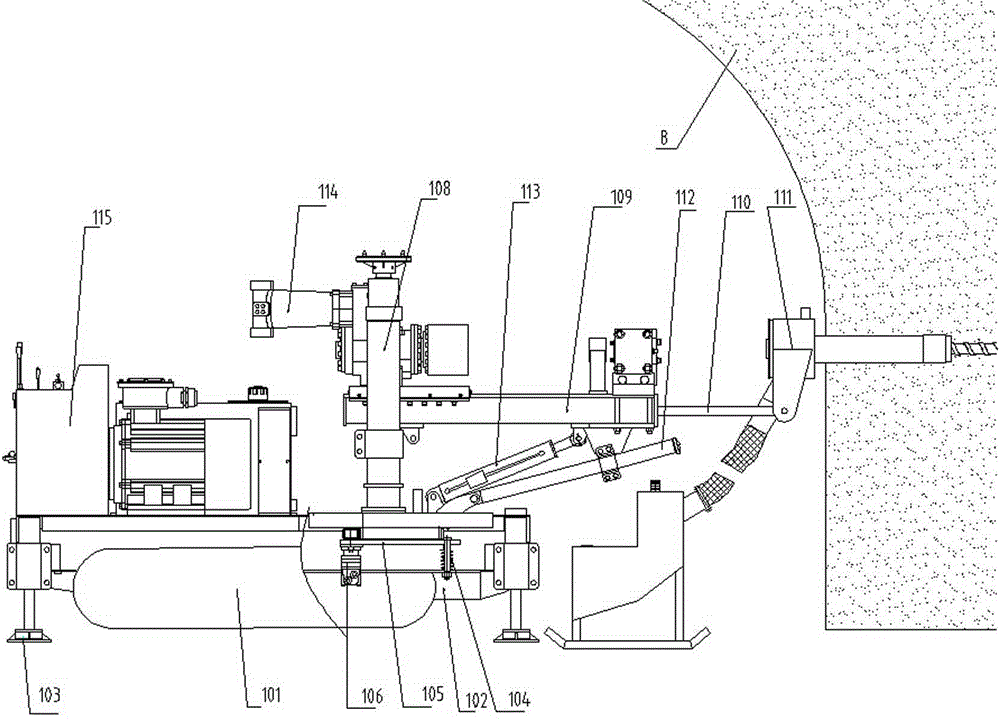

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com