Patents

Literature

206results about How to "Strong flow ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

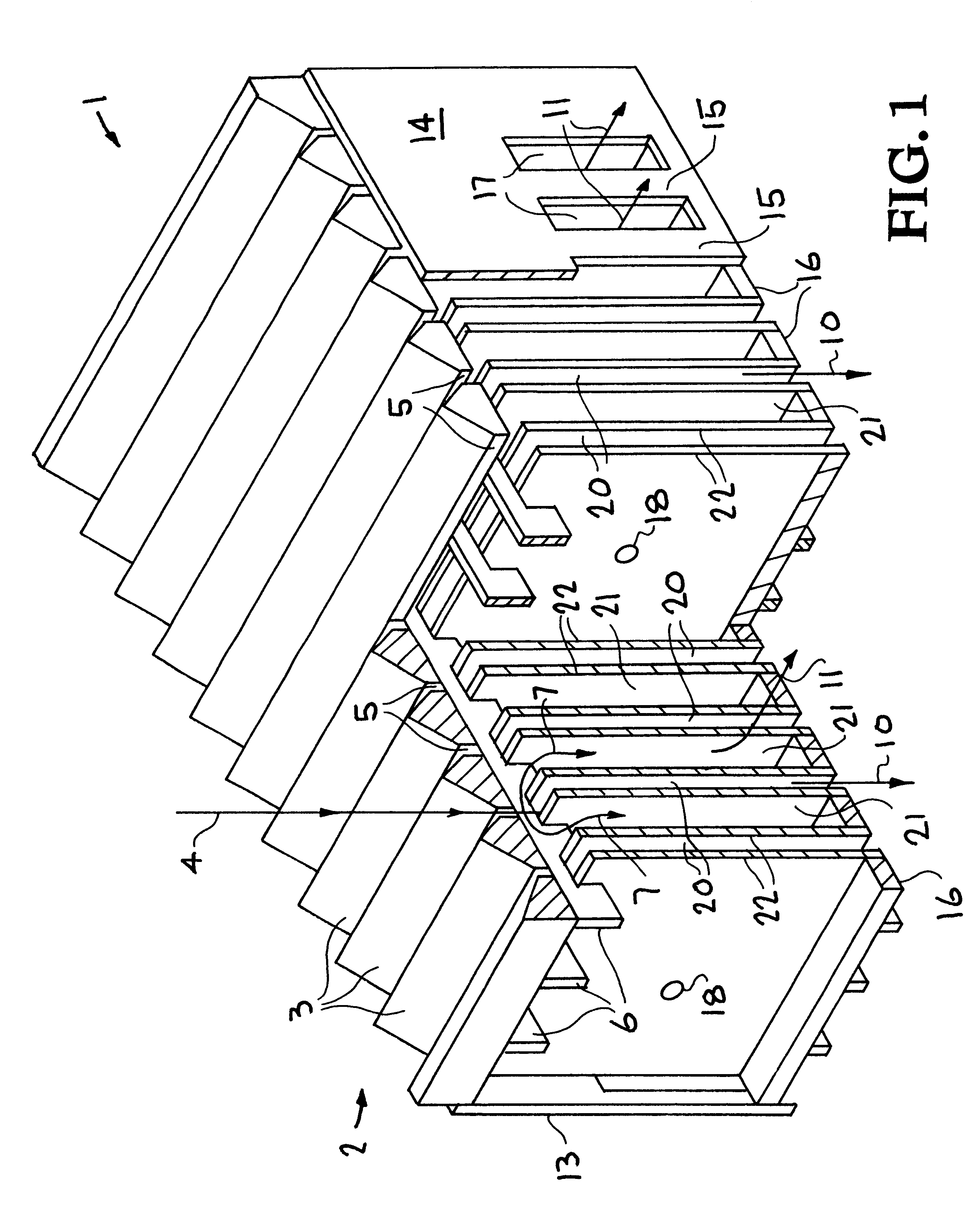

Lateral temperature equalizing system for large area surfaces during processing

ActiveUS7195693B2Rapid temperature stabilizationLittle changeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyShortest distance

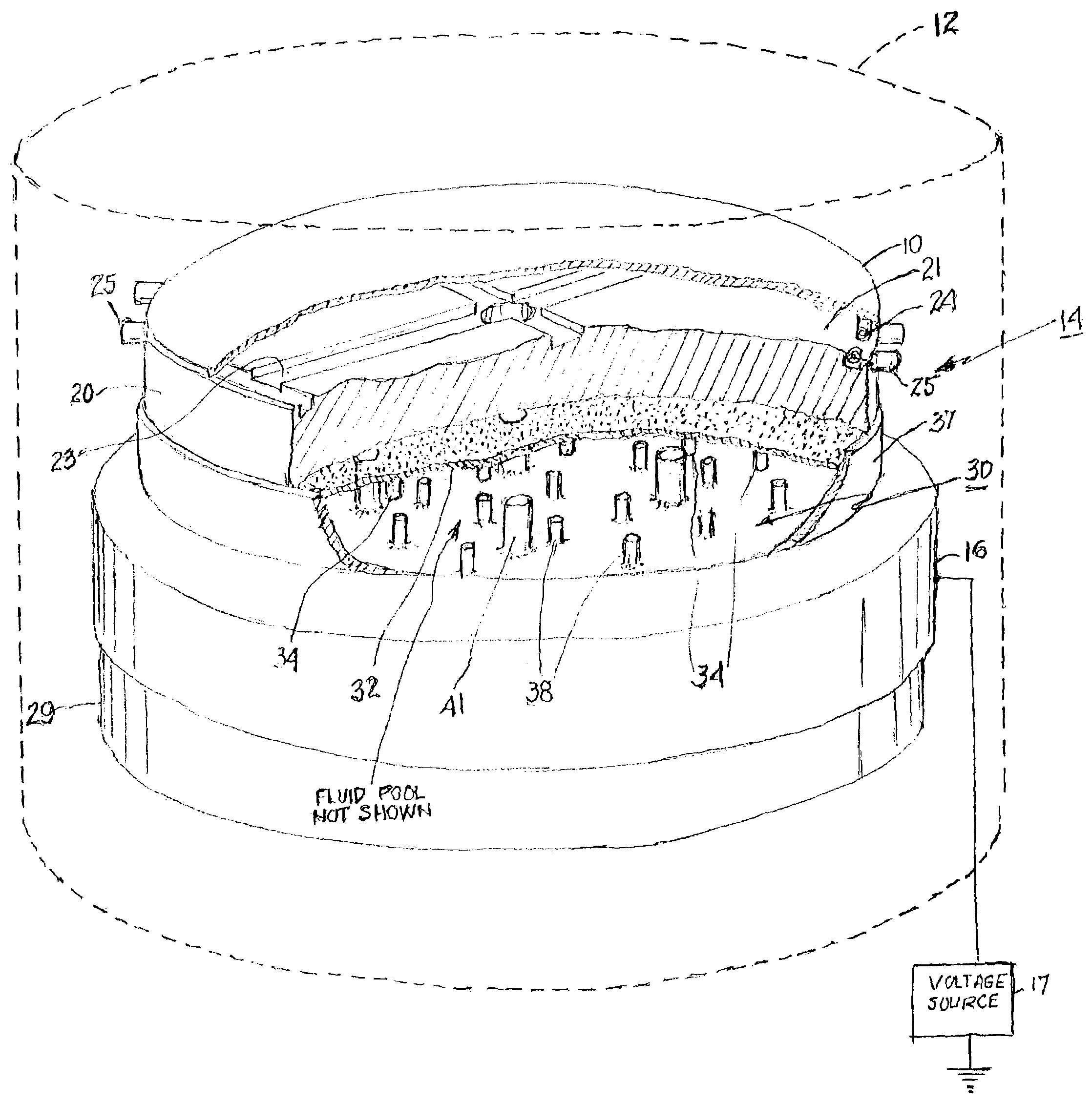

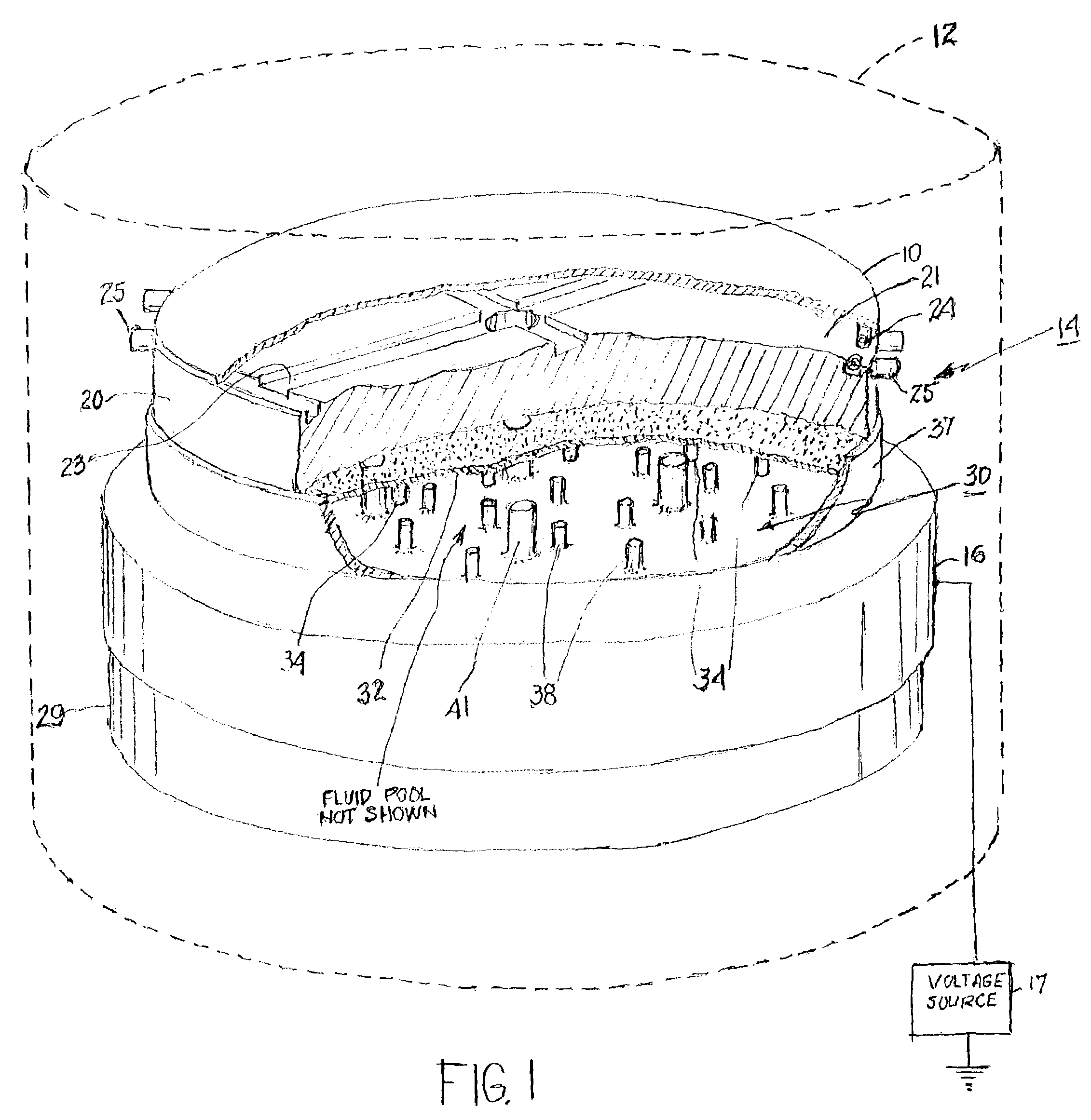

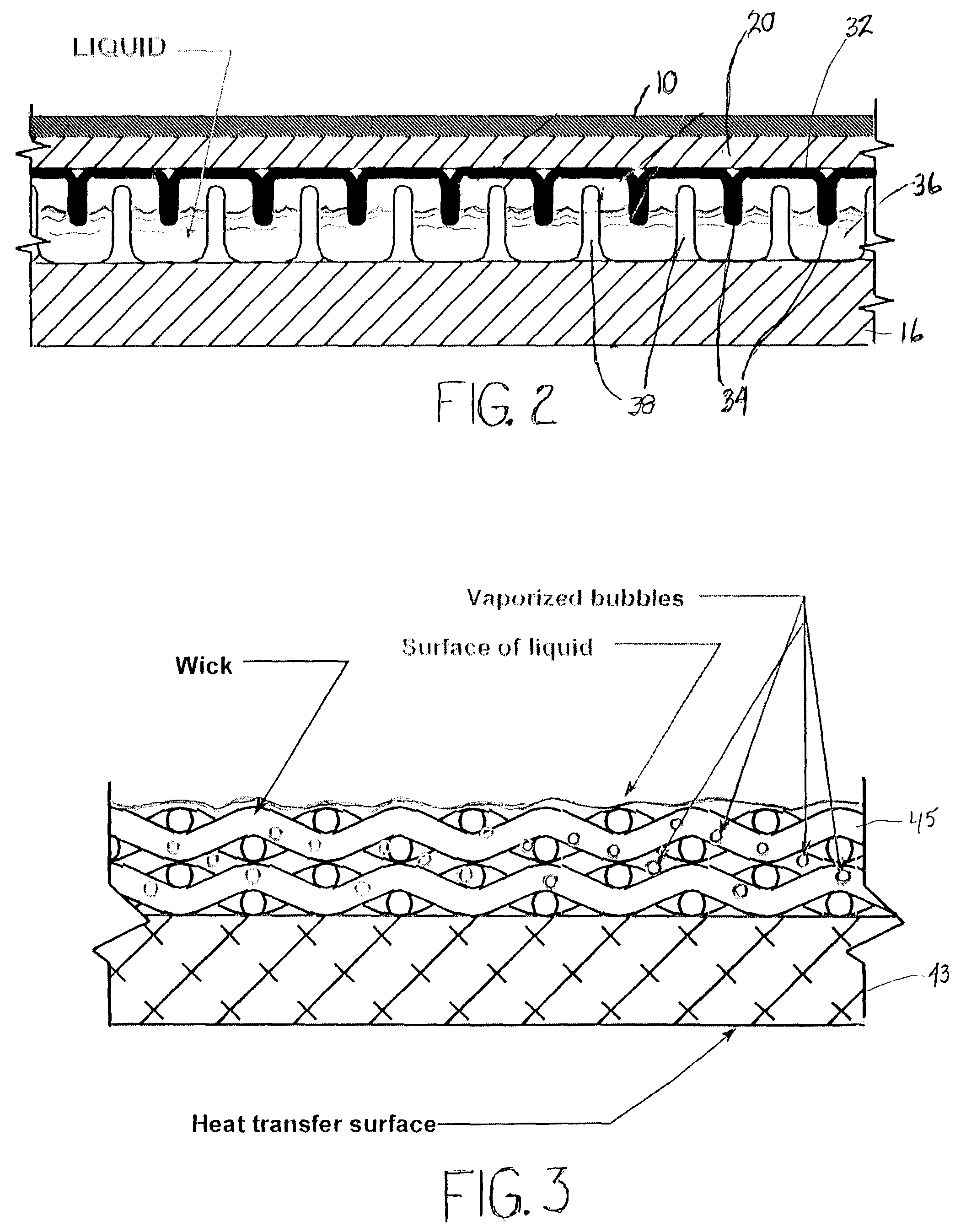

In many processes used in fabricating semiconductors the wafer is seated on the top surface of a pedestal and heated in a high energy process step, such as plasma etching. The pedestal, chuck or platen may be cooling but the wafer gradually heats until the process can no longer continue. Where large, e.g. 300 mm diameter, wafers are being processed the temperature level across the wafer is difficult to maintain substantially constant. In this system and method the lateral temperature distribution is equalized by a heat sink structure in a chamber immediately under the wafer support on top of the pedestal. A number of spatially distributed wicking posts extend downwardly from a layer of wicking material across the top of the chamber, into a pool of a vaporizable liquid. At hot spots, vaporized liquid is generated and transported to adjacent condensation posts extending up from the liquid. The system thus passively extracts heat to equalize temperatures while recirculating liquid and assuring adequate supply. The free volume above and within the liquid, and the short distances between posts, assure adequate heat transfer rates.

Owner:BE AEROSPACE INCORPORATED

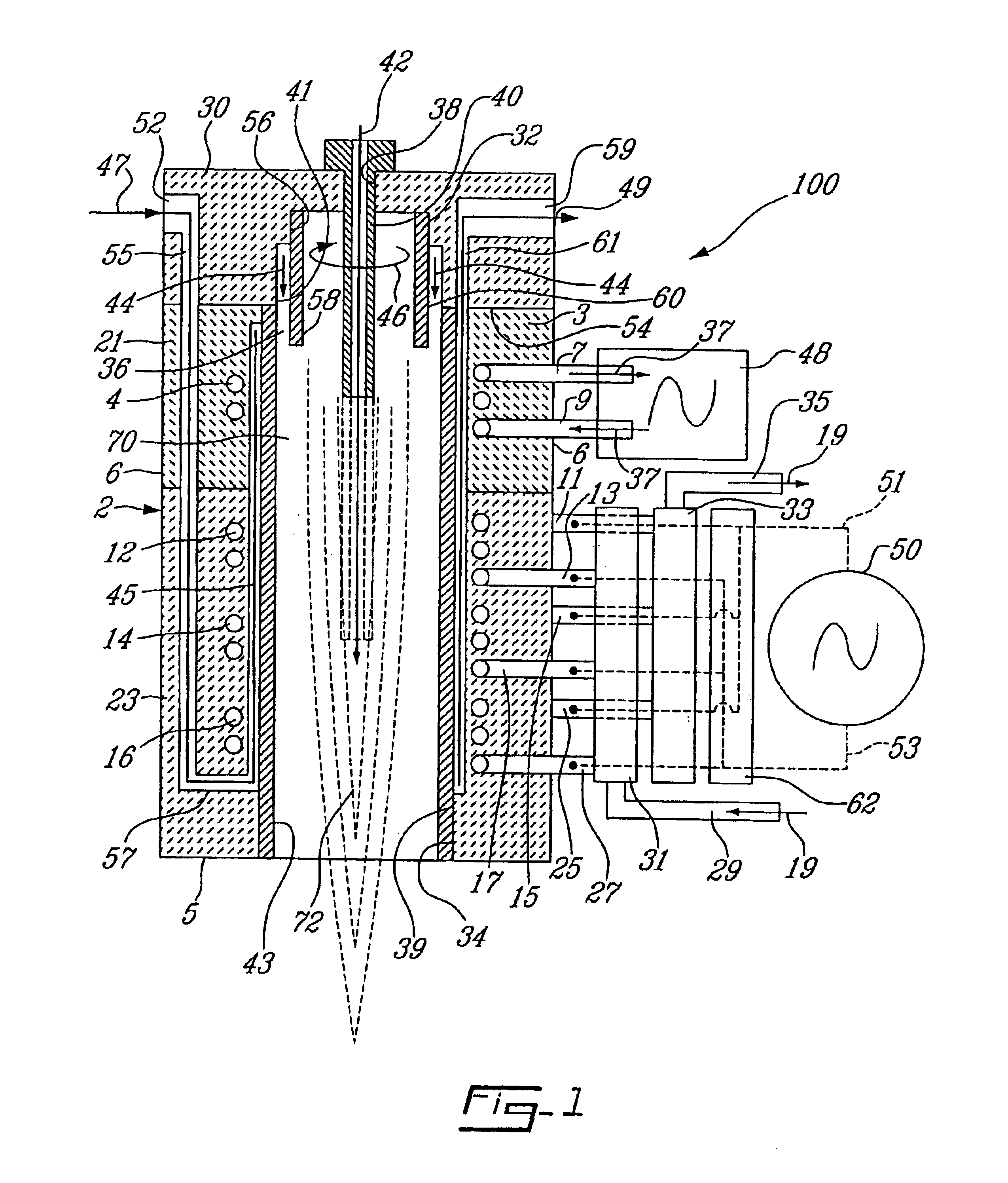

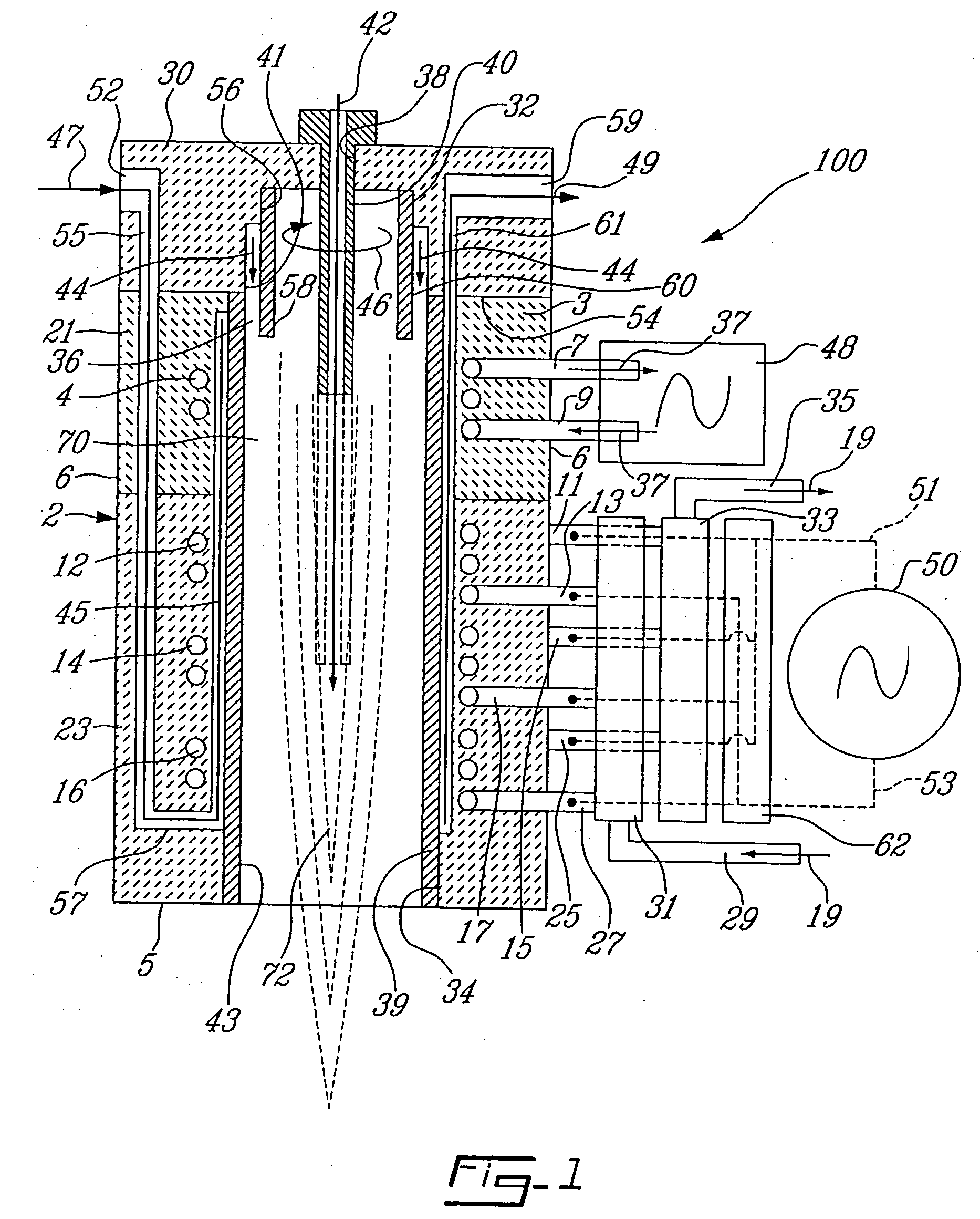

Multi-coil induction plasma torch for solid state power supply

InactiveUS6919527B2Efficient heatingImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

Owner:TEKNA PLASMA SYST INC

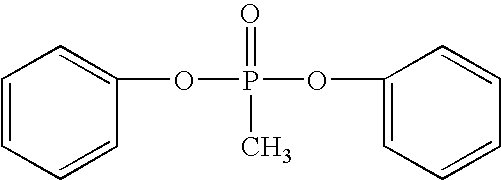

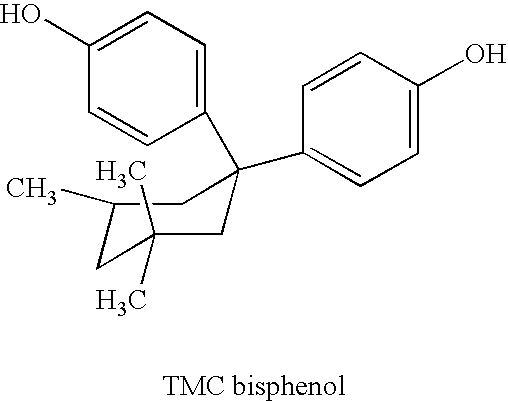

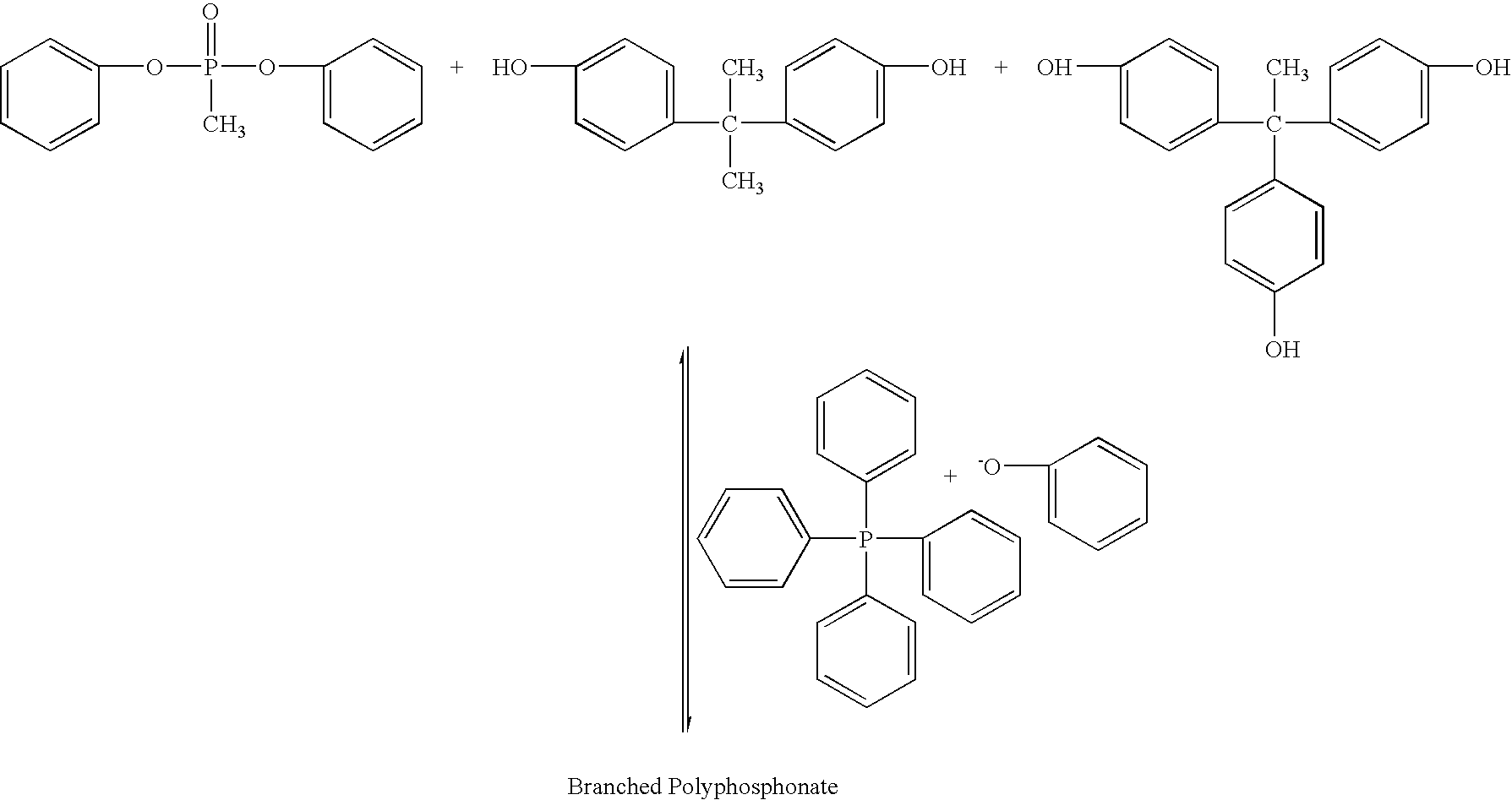

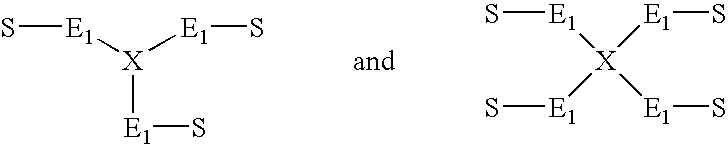

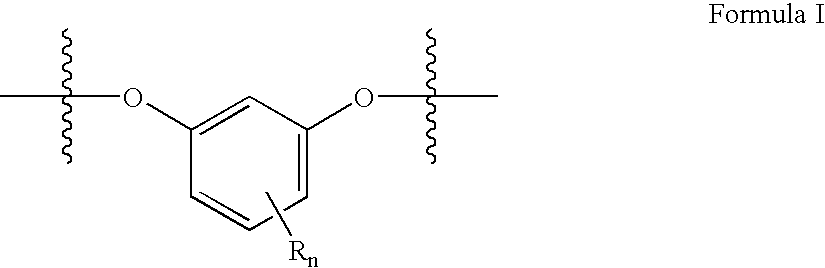

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

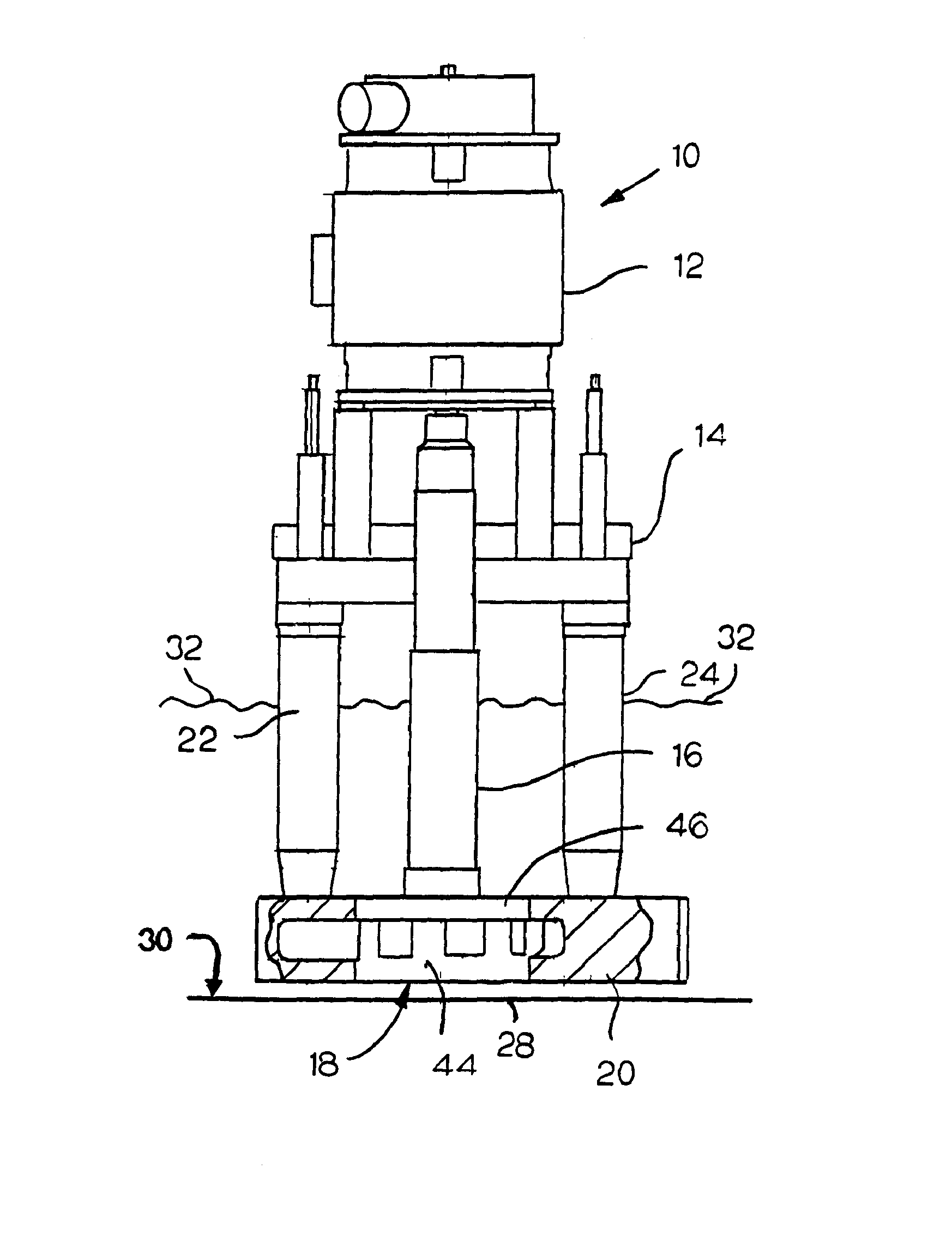

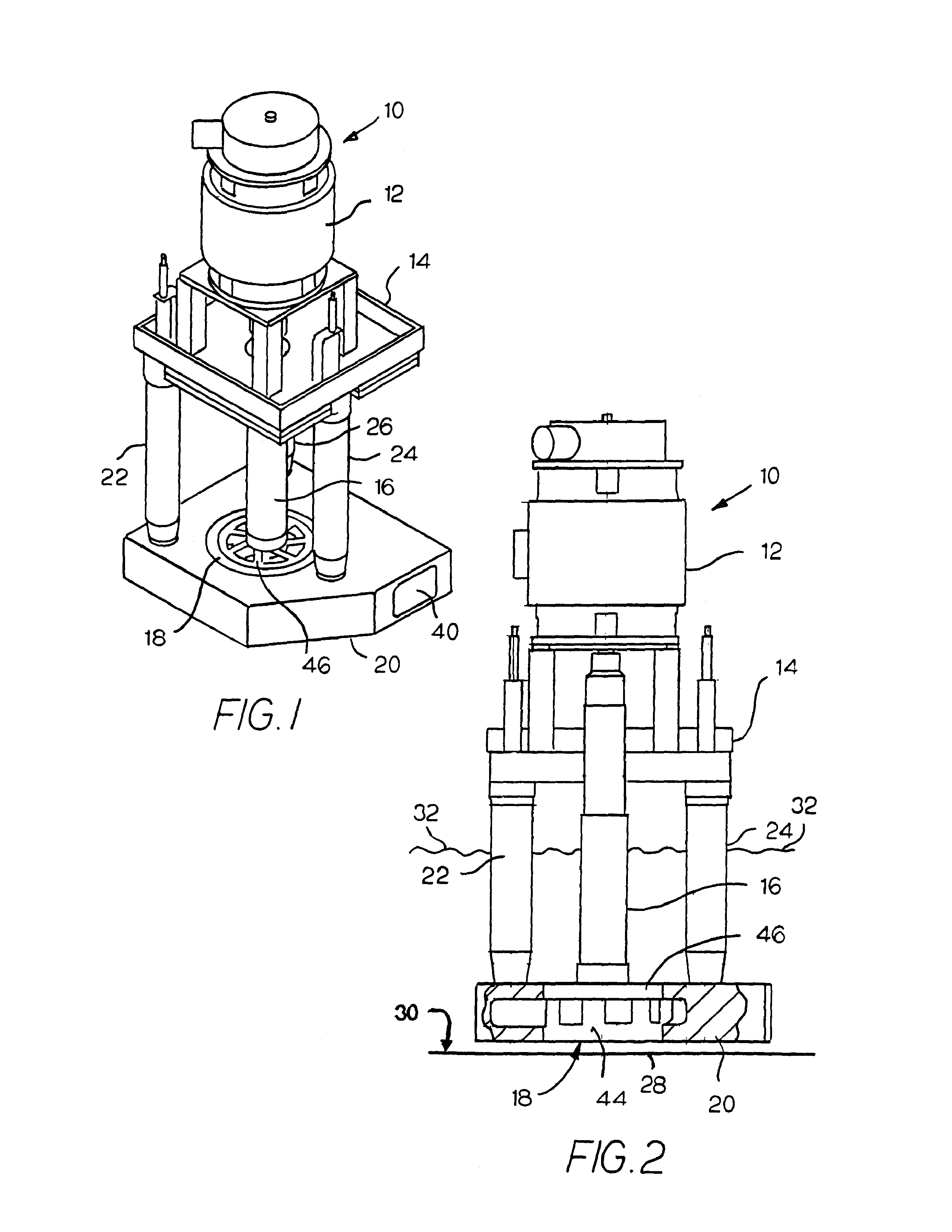

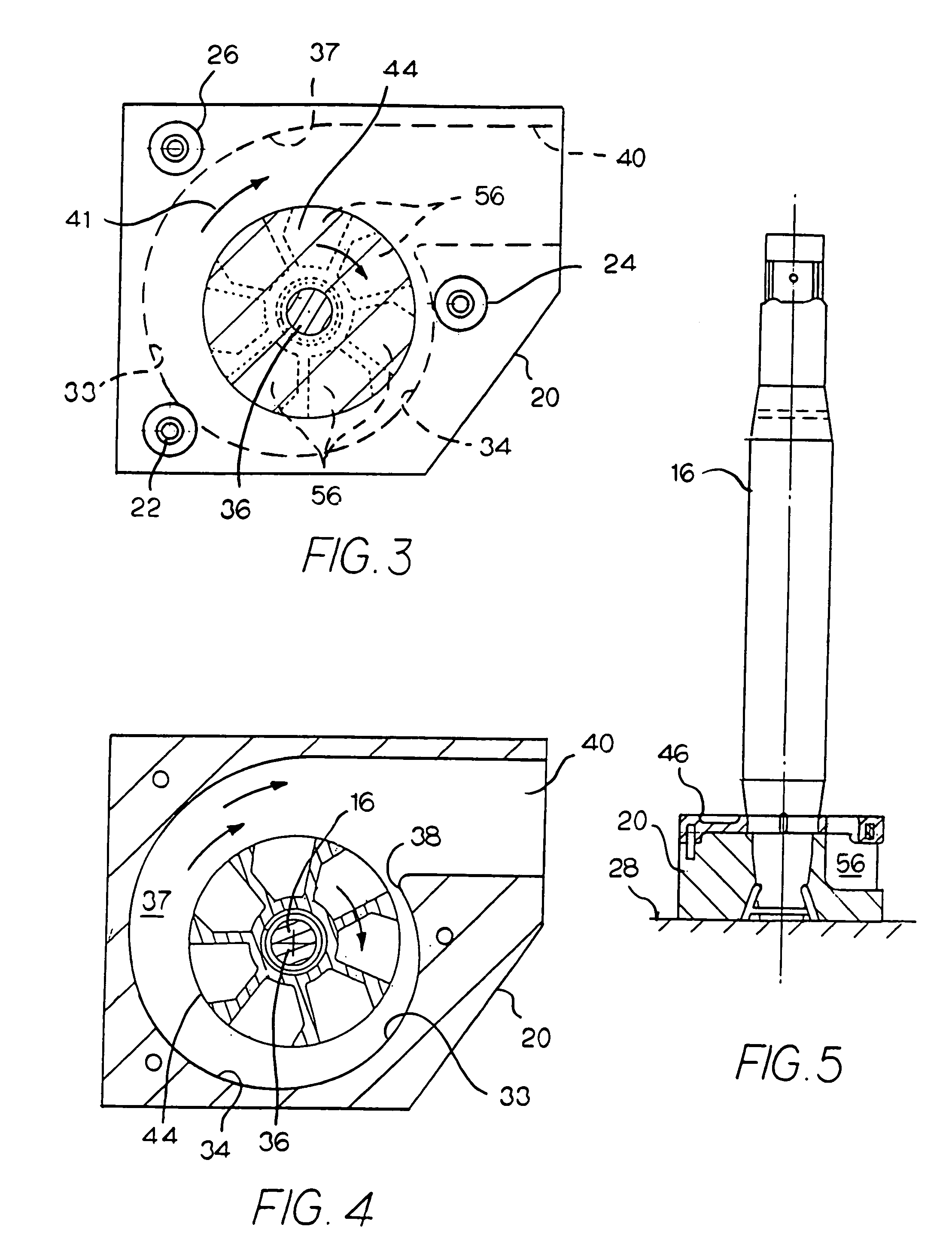

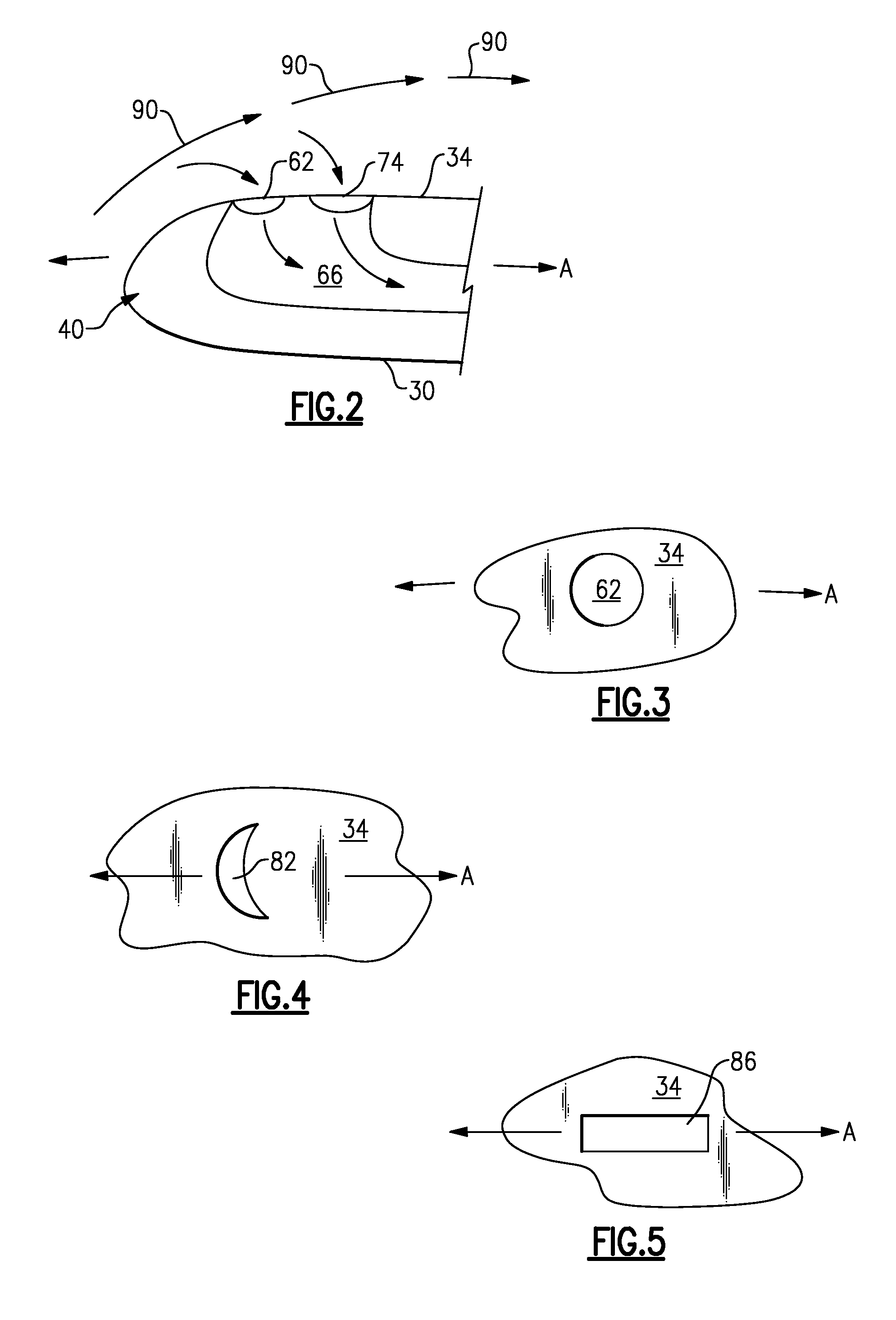

High flow/dual inducer/high efficiency impeller for liquid applications including molten metal

A centrifugal pump has a pump base with inlet inducer openings that receive molten metal into an impeller chamber. An impeller structure in the impeller chamber passes the metal in a radial direction through an outlet inducer opening into a volute passage for discharge into the pool of metal in which the pump is located.

Owner:MORANDO JORGE A

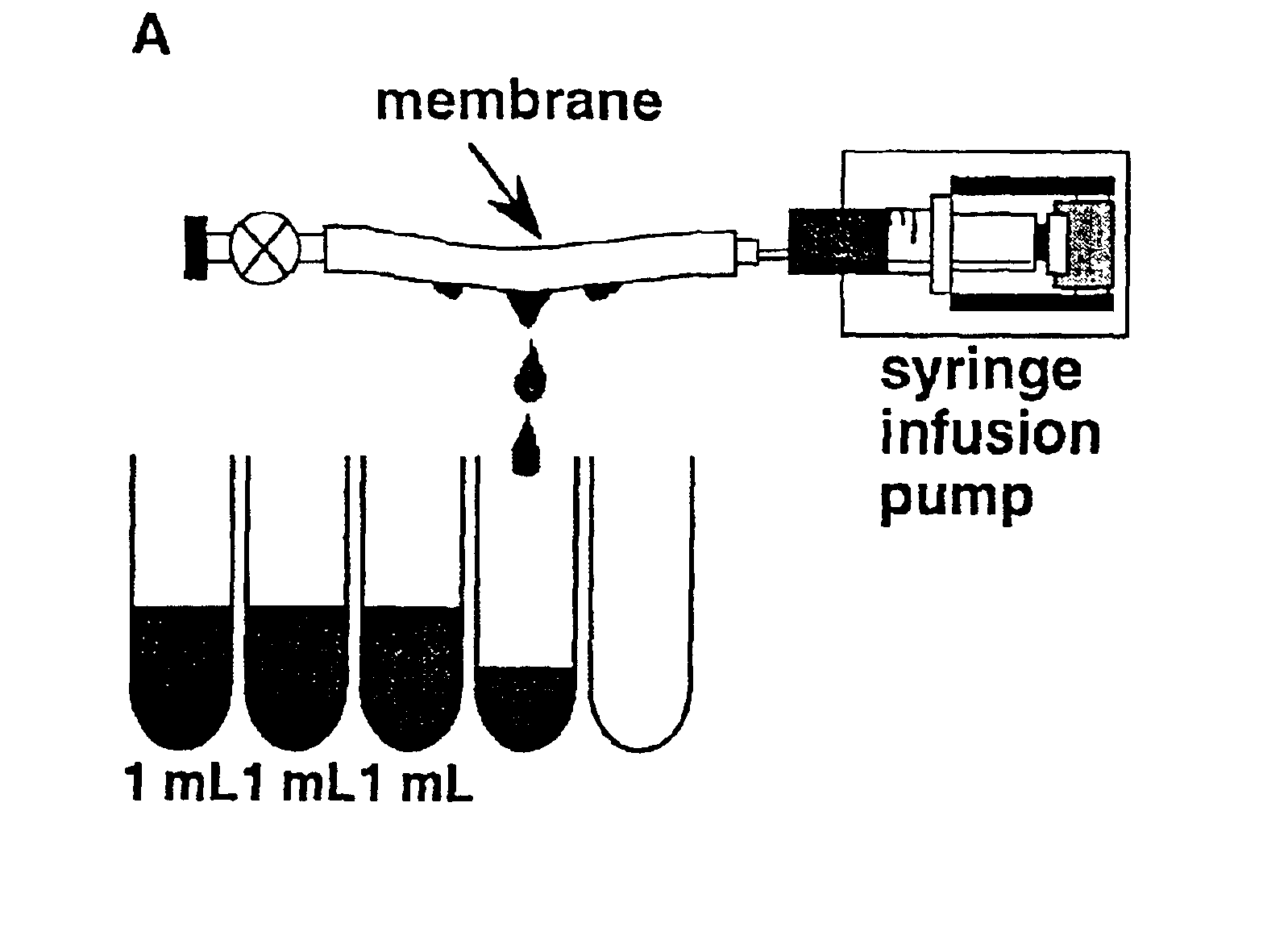

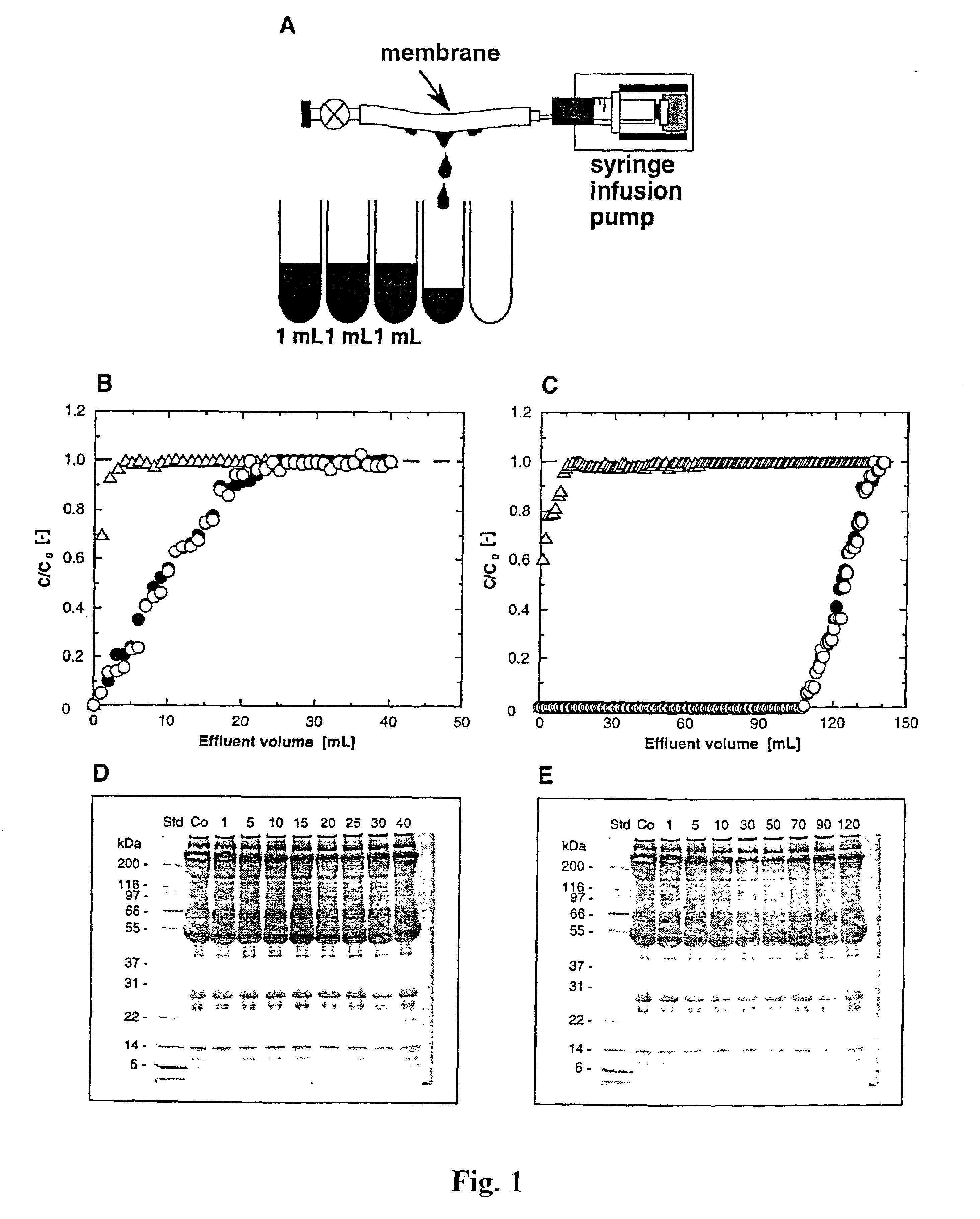

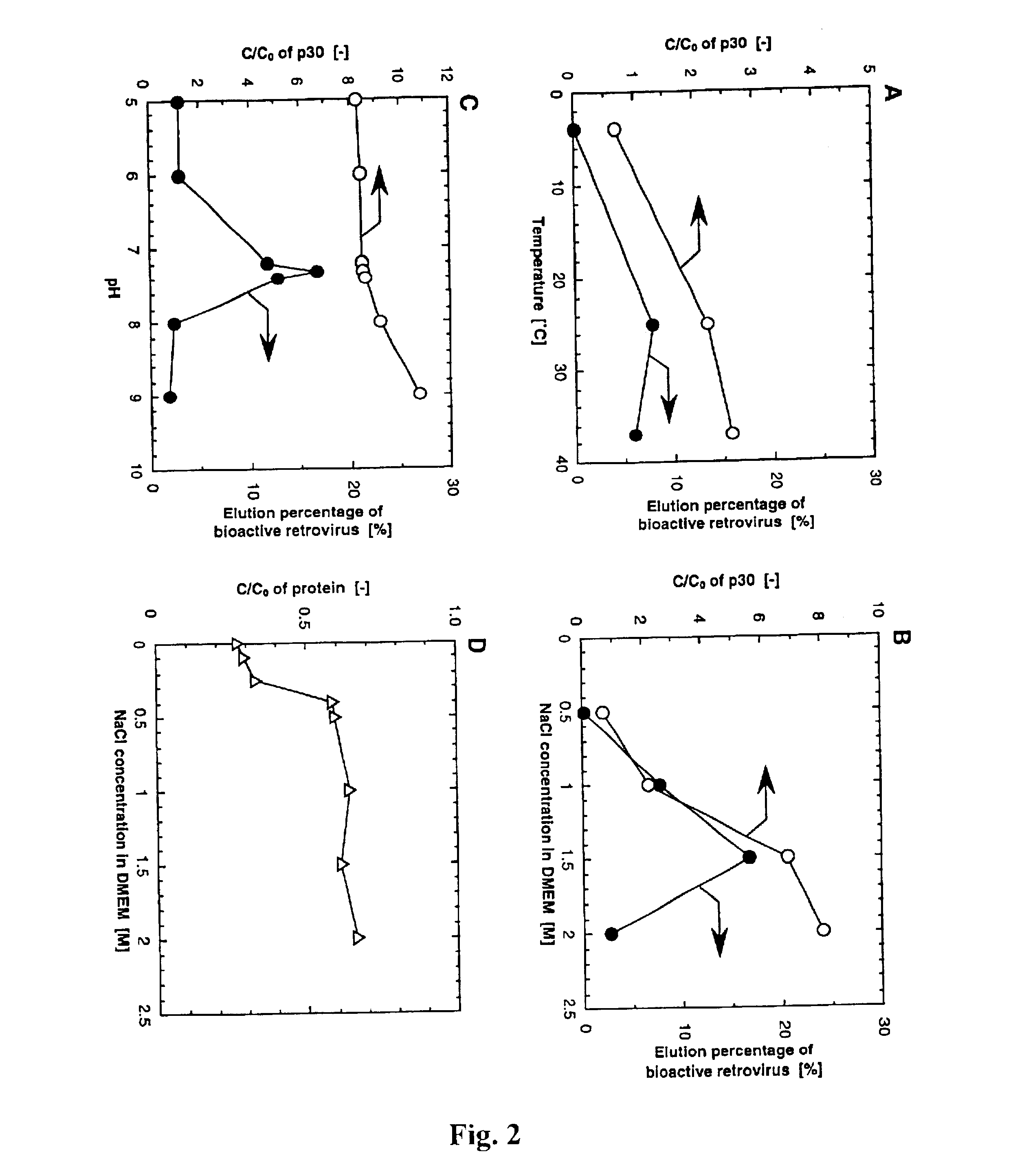

Methods for removal, purification, and concentration of viruses, and methods of therapy based thereupon

InactiveUS6861001B2Effect clotting timeEasy to zoom inBioreactor/fermenter combinationsBiological substance pretreatmentsSide chainBlood plasma

The invention is based on the discovery that certain membranes, which include side chains or molecular “brushes” having, for example, tertiary amino functional groups, can be used as highly effective filters to capture viruses / virus particles from liquids without removal of proteins. New methods based on this discovery include removing viruses from liquids such as blood or plasma, removing viruses from pharmaceuticals, concentrating and / or purifying viruses, e.g., for use in gene therapy, and producing recombinant viruses in new bioreactors. The invention also includes new methods of therapy or adjunct therapy for viral infections, in which a patient's blood or plasma is filtered through the membranes to remove viruses to reduce the viral load. The invention also includes new bioreactors and viral filters containing the membranes.

Owner:THE GENERAL HOSPITAL CORP

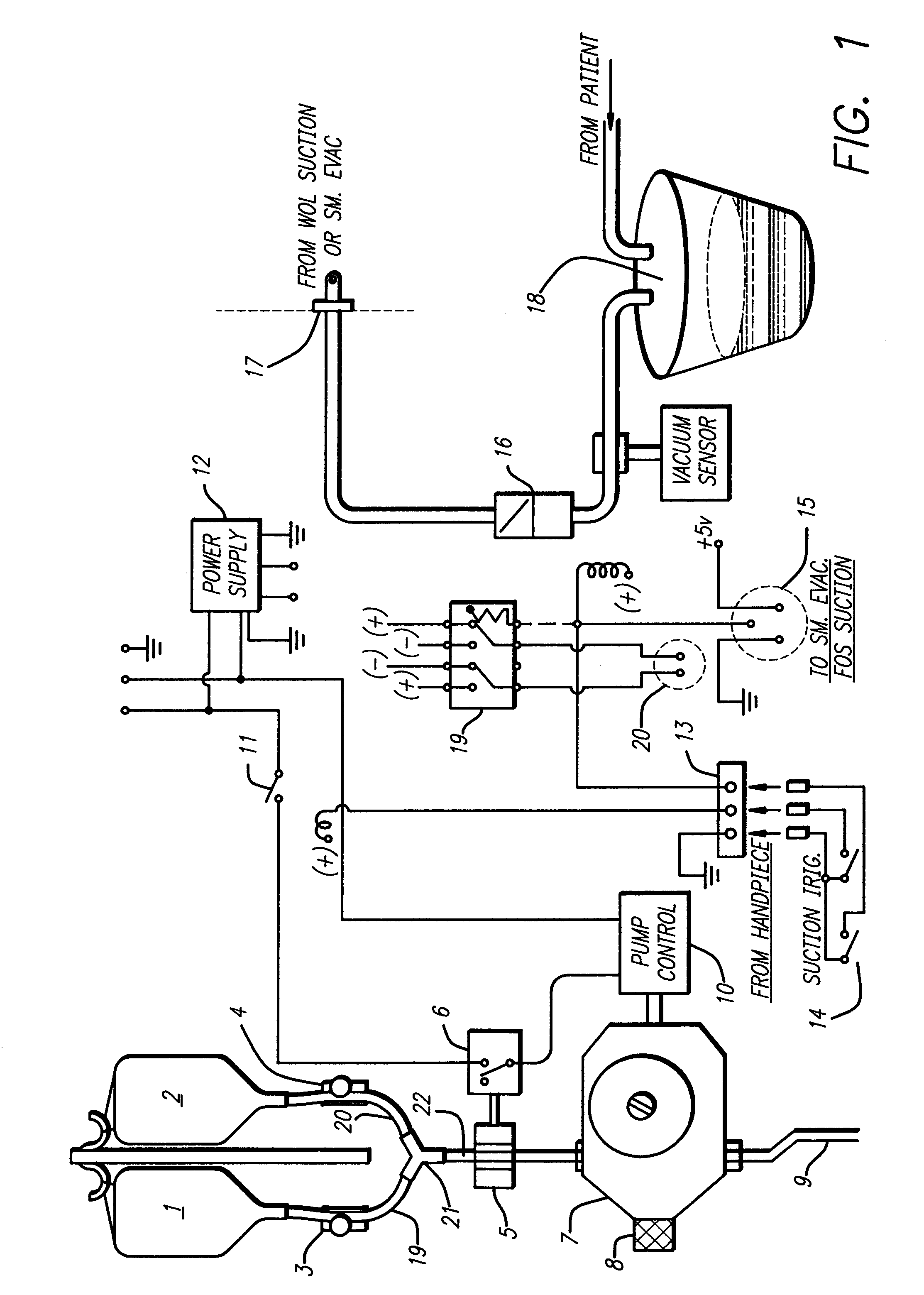

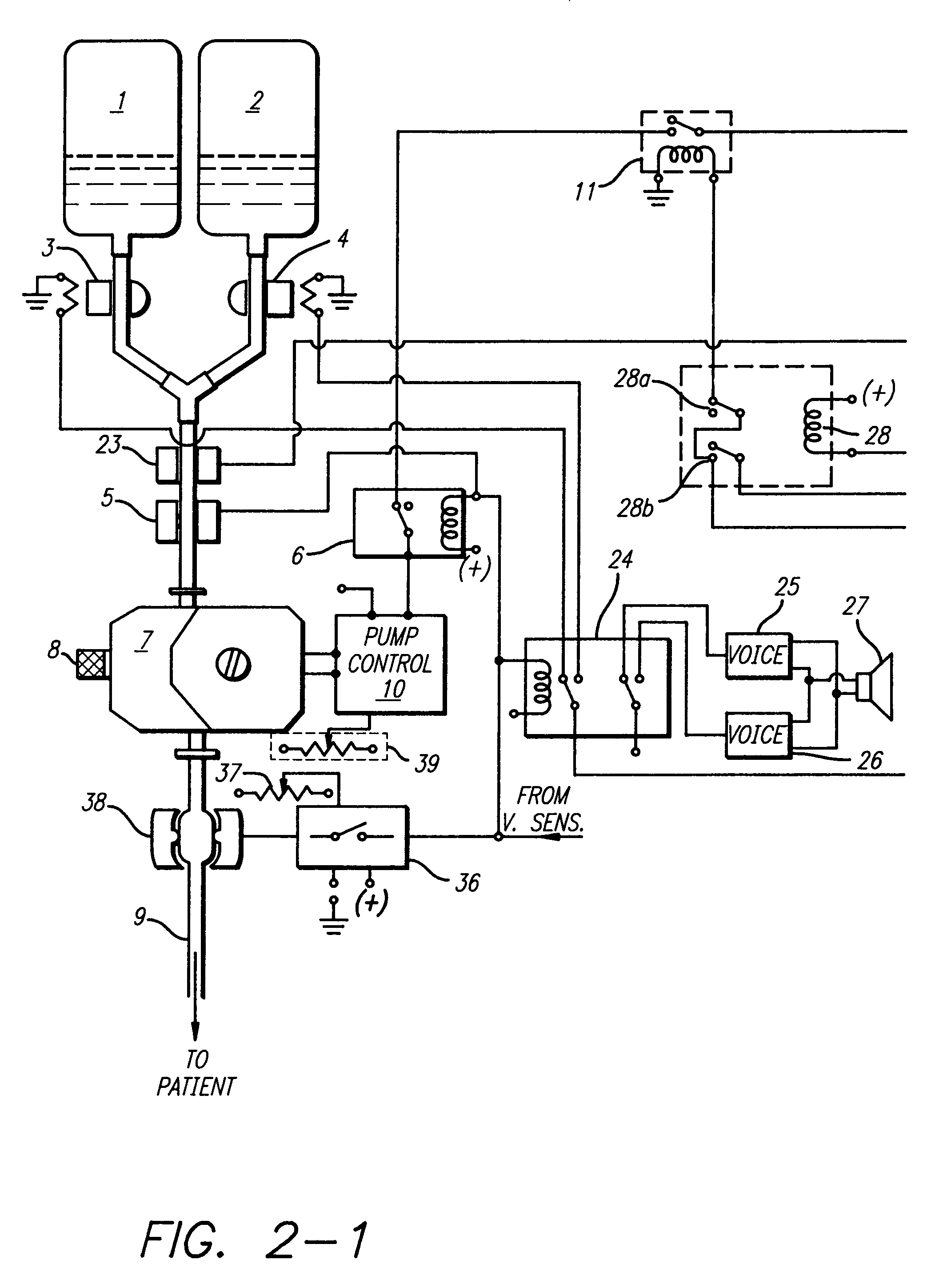

Automatic fluid control system for use in open and laparoscopic laser surgery and electrosurgery and method therefor

InactiveUS7083601B1Increase pressureImprove liquidityEnemata/irrigatorsChiropractic devicesAutomatic controlFluid control

A manual and automatic fluid control system and method for use in open and laparoscopic laser surgery and electrosurgery is disclosed. The system includes a manual mode along with several automatic modes which can effectuate both suction and irrigation, either individually or simultaneously. In the various automatic modes, the suction and / or irrigation is automatically activated during activation of a medical apparatus for laser surgery or electrosurgery without requiring separate activation from the surgeon or operating room staff. Several safety features for monitoring the fluid control system are also incorporated within the system such as fluid sensors for detecting the absence of irrigation fluid, pressure sensors and vacuum systems for monitoring fluid pressure, fluid sensors for monitoring fluid volume, and warning signals for detecting empty containers. All of the safety features are designed to automatically deactivate suction and / or irrigation means contained within the fluid control system upon detection of unsafe levels. Finally, specially designed suction / irrigation hand pieces are disclosed for use in connection with the fluid control system.

Owner:IC MEDICAL

High flux, microporous, sieving membranes and separators containing such membranes and processes using such membranes

InactiveUS20060201884A1Easy to implementReduced membrane surface areaSemi-permeable membranesMembranesHigh fluxChemistry

A sieving membrane comprises a thin, microporous barrier to provide a high flux. The membrane structure can tolerate defects yet still obtain commercially-attractive separations.

Owner:UOP LLC

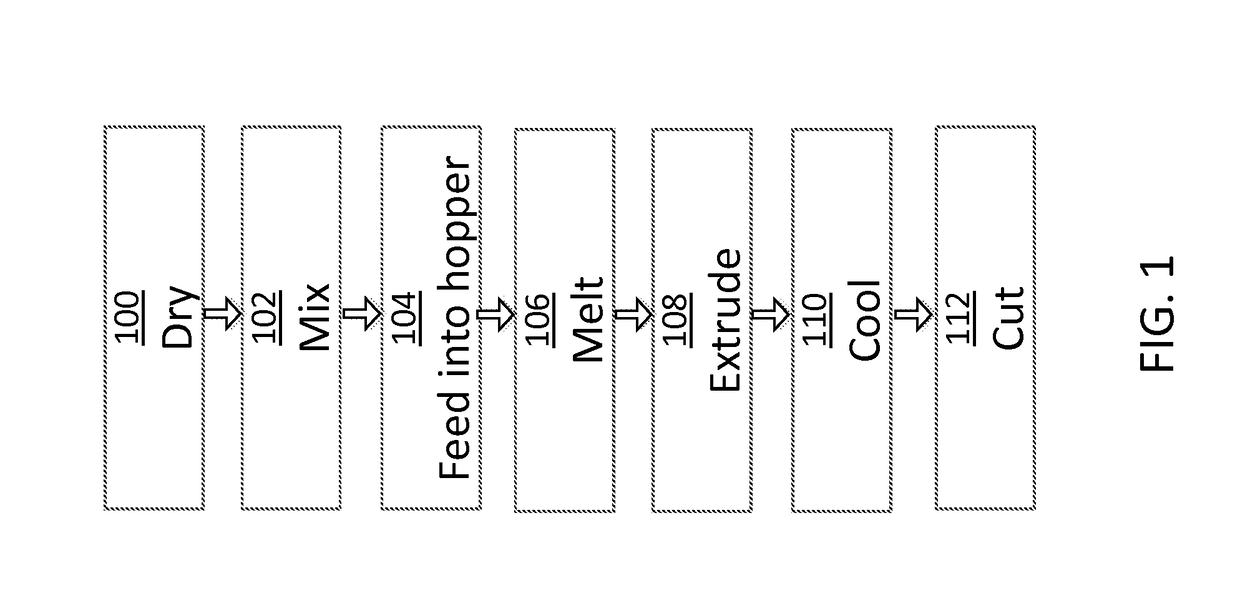

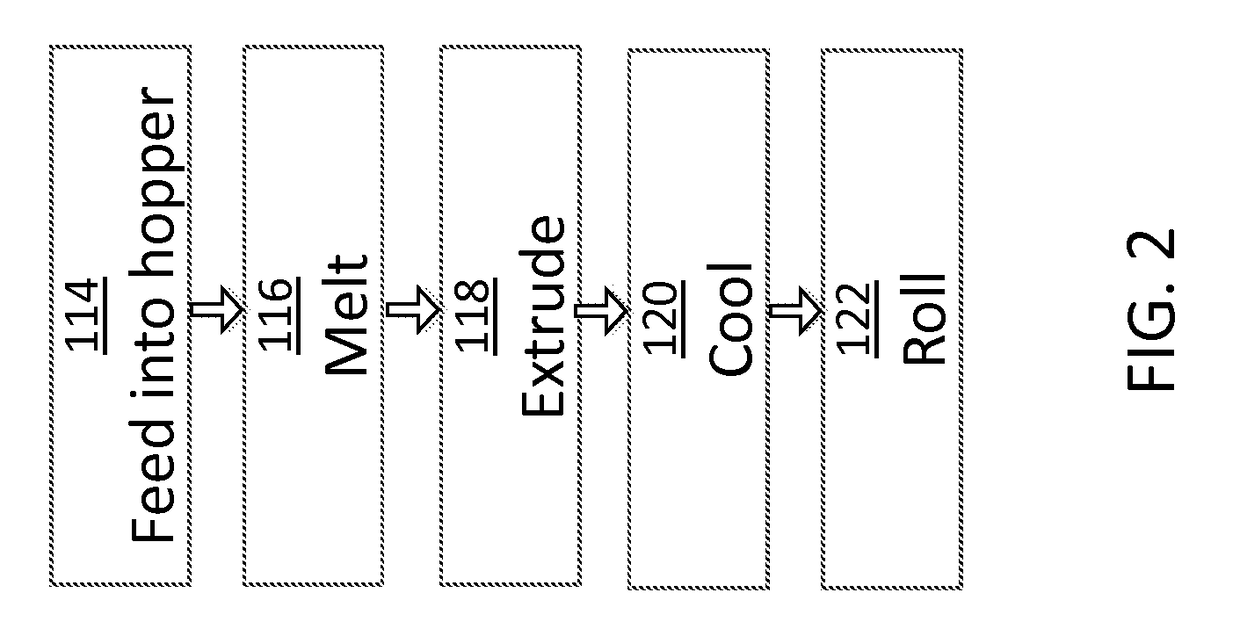

Elastomeric bicomponent fibers comprising block copolymers having high flow

InactiveUS20070004830A1Strong flow abilityIncrease chanceWorking-up pitch/asphalt/bitumen by chemical meansSynthetic resin layered productsElastomerFiber

Bicomponent fibers comprising a thermoplastic polymer and an elastomeric compound are made which can be continuously extruded from the melt at high production rates. The elastomeric compound has high flow and consists essentially of a selectively hydrogenated block copolymer and a tackifier resin, an alpha-olefin copolymer, an alpha-olefin terpolymer, a wax or mixtures thereof. In one embodiment the block copolymer has at least one polystyrene block of molecular weight from 5,000 to 7,000 and at least one polydiene block of molecular weight from 20,000 to 70,000 and having a vinyl content of greater than 60 mol %. In a second embodiment the block copolymer has a vinyl content of less than 60 mol %. The bicomponent fibers are useful for the manufacture of articles such as woven fabrics, spun bond non-woven fabrics or filters, staple fibers, yarns and bonded, carded webs.

Owner:KRATON POLYMERS US LLC

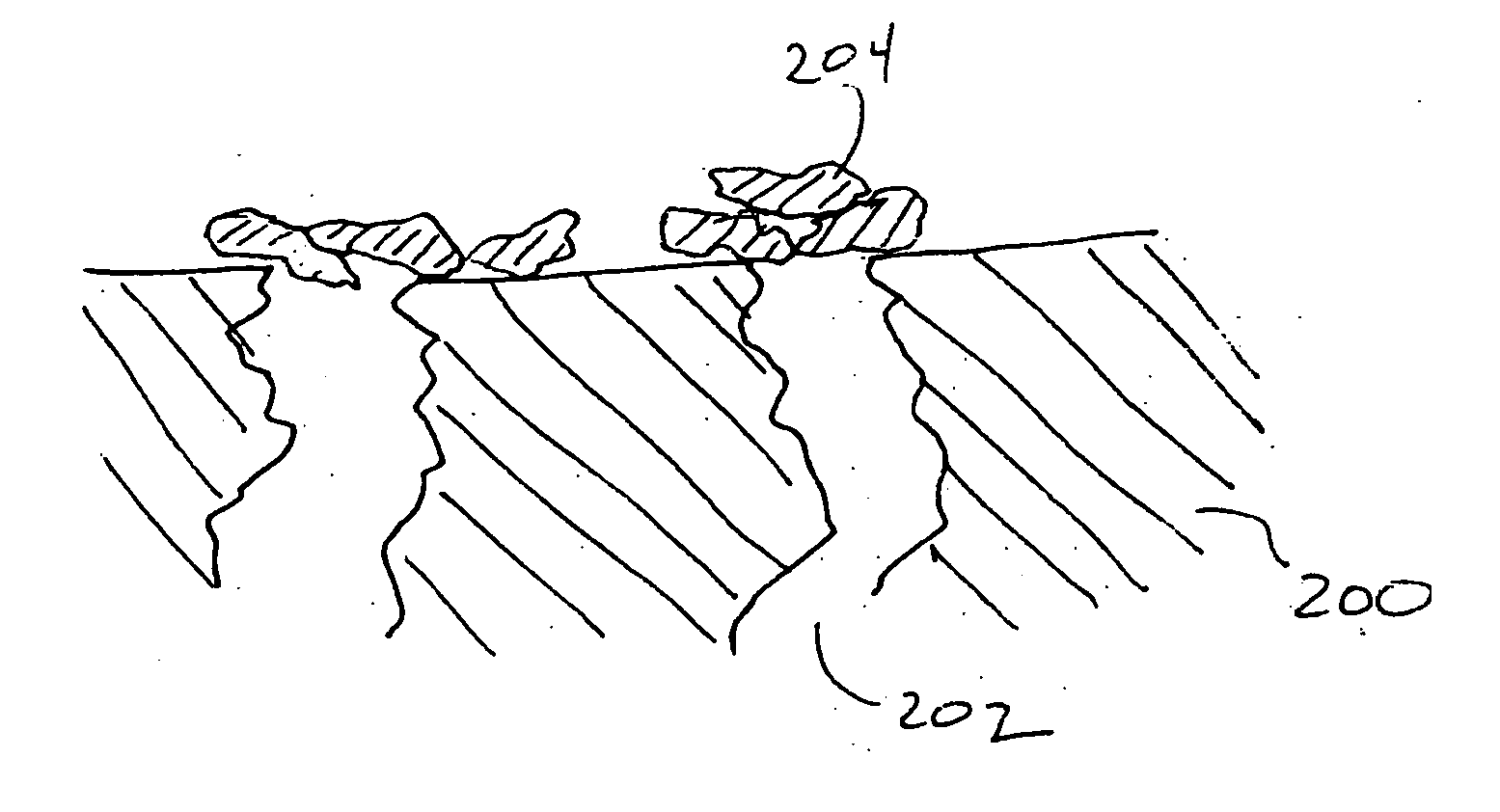

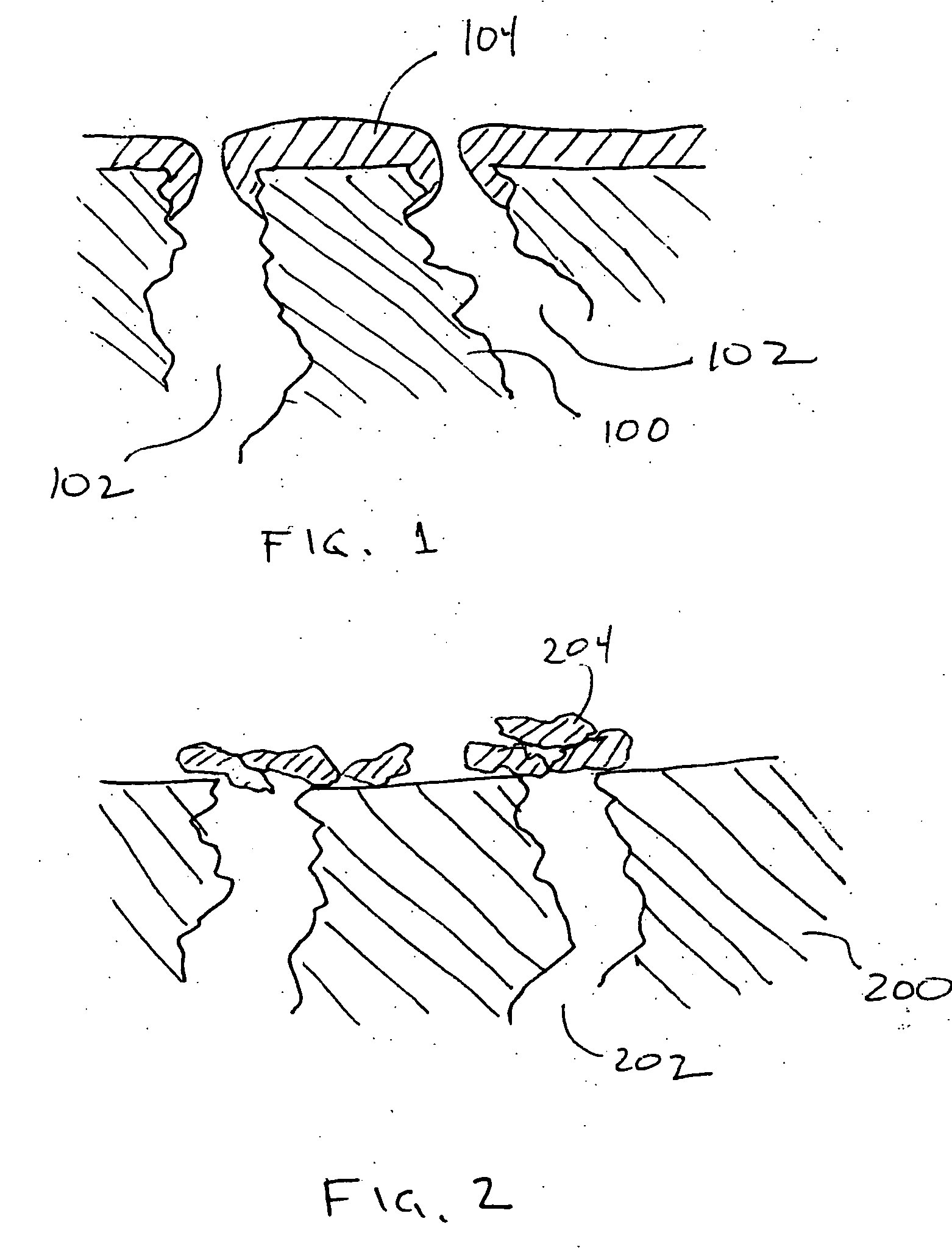

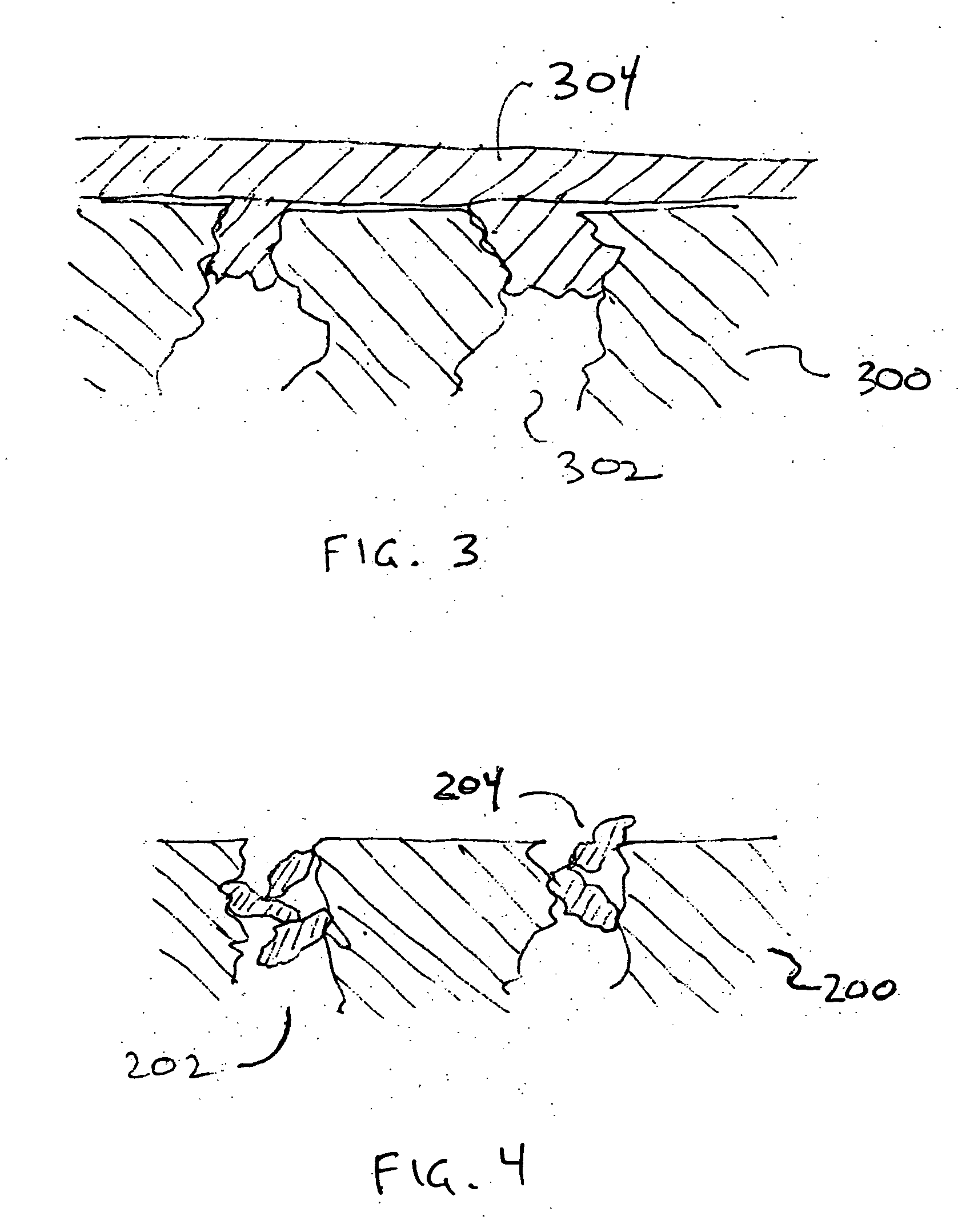

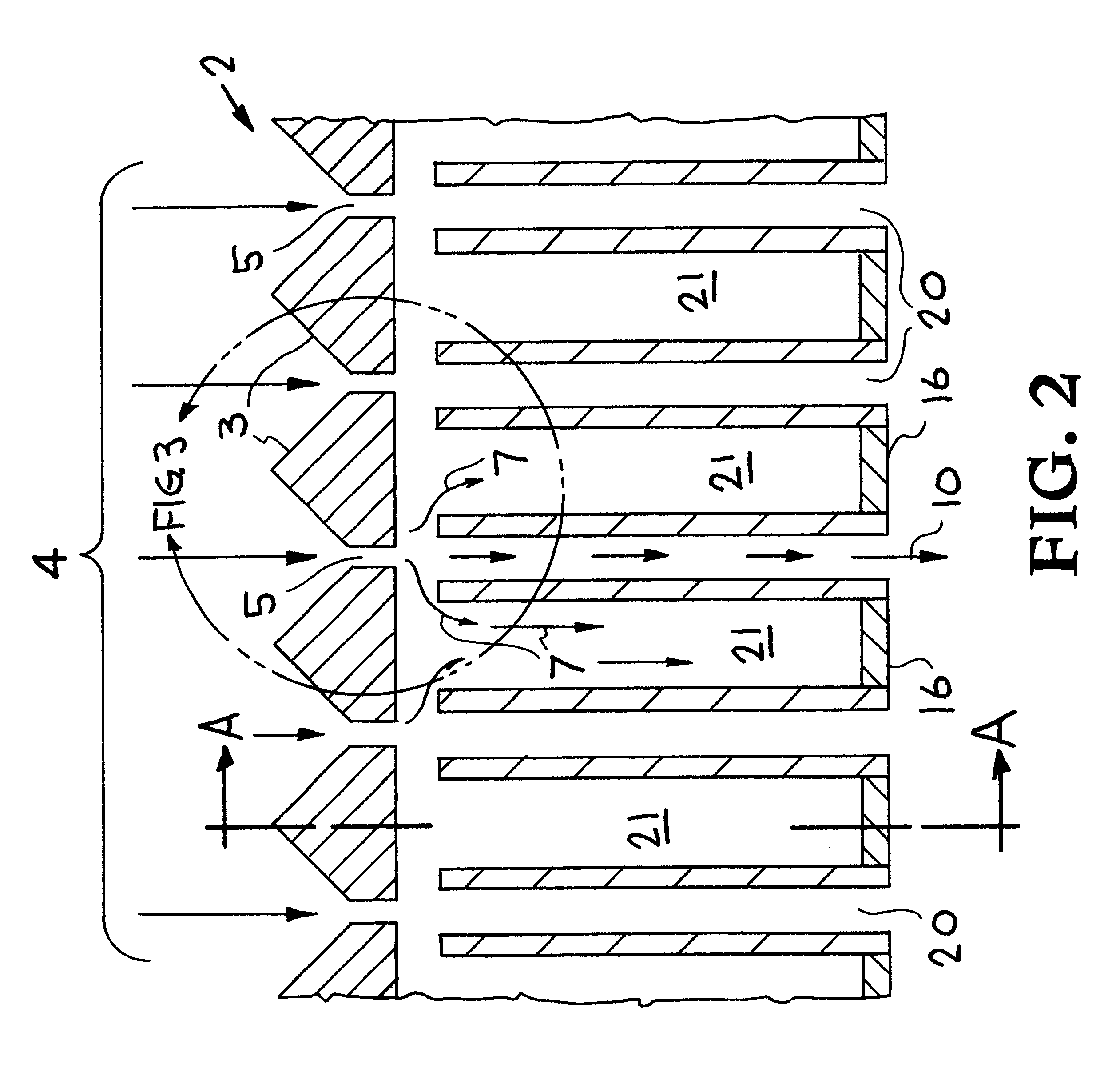

Pleated filter made of a multi-layer filter medium

InactiveUS6488731B2Improve suction capacityHigh of circulationCleaning filter meansCombination devicesFilter mediaEngineering

The present invention relates to a pleated filter made of a multi-layer filter medium, including at least one filter paper layer having area weights of 30-100 g / m2, a microfiber nonwoven fabric layer having area weights 5-120 g / m2 and a support nonwoven fabric layer made of synthetic, polymeric fibers having area weights of 10-120 g / m2. The layers of the pleated filter contain fused polymer areas by which the fabric layers are bonded to the paper layer, and by which the fabric layers are made firmer within themselves. When subject to a fractional efficiency test at an initial pressure difference of at most 180 Pa, at a boundary speed of approximately 2.62 m / s and a flow speed through the filter medium of approximately 0.13 m / s, the pleated filter is able to separate at least 90% of particles greater than 0.3 mum, at least 92% of particles greater than 0.5 mum, at least 93% of particles greater than 1 mum, and at least 97% of particles greater than 3 mum, as measured using the standard method DIN EN 60312 (IEC 60312) § 5.1.2.5.

Owner:CARL FREUDENBERG KG

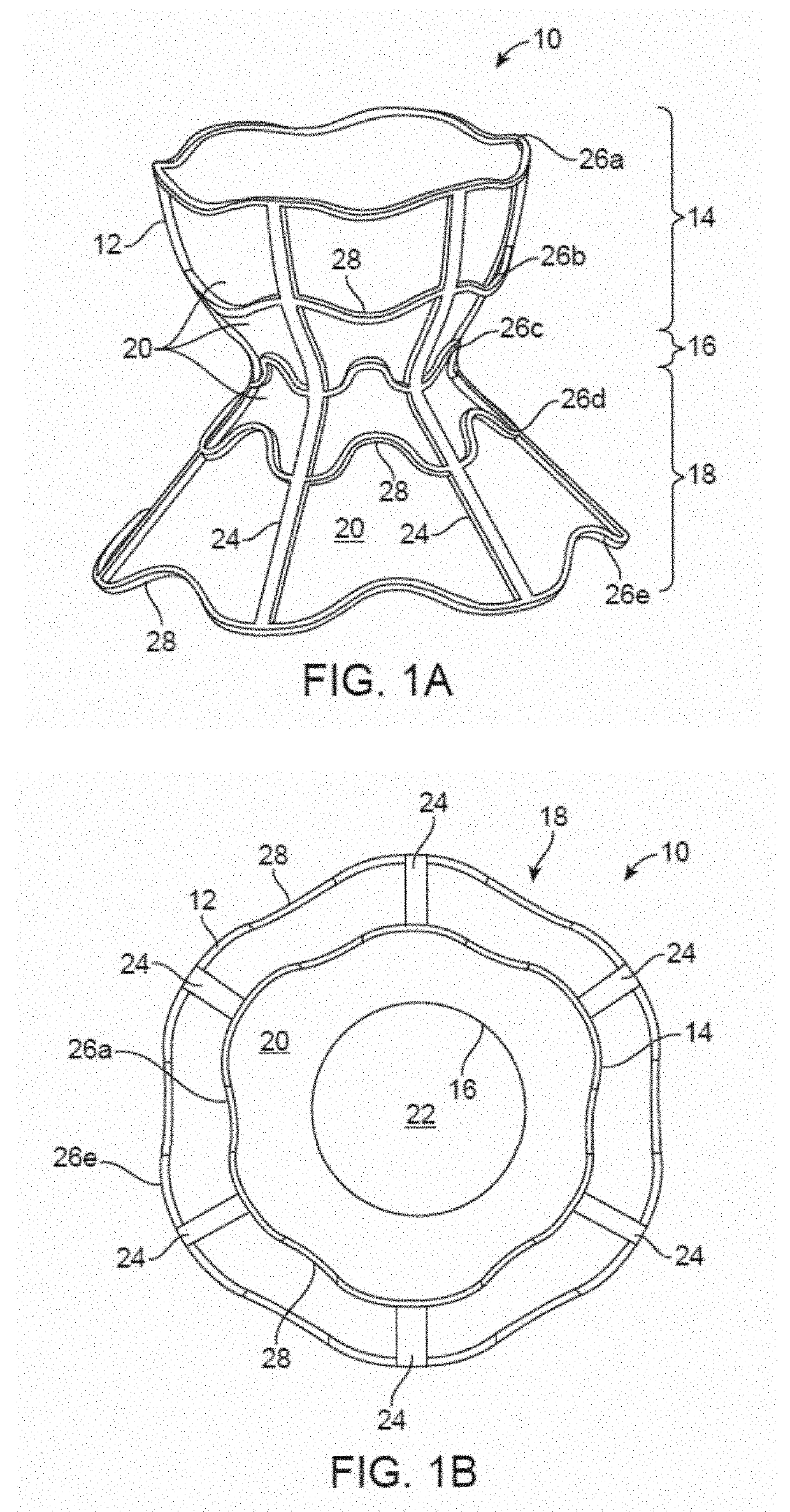

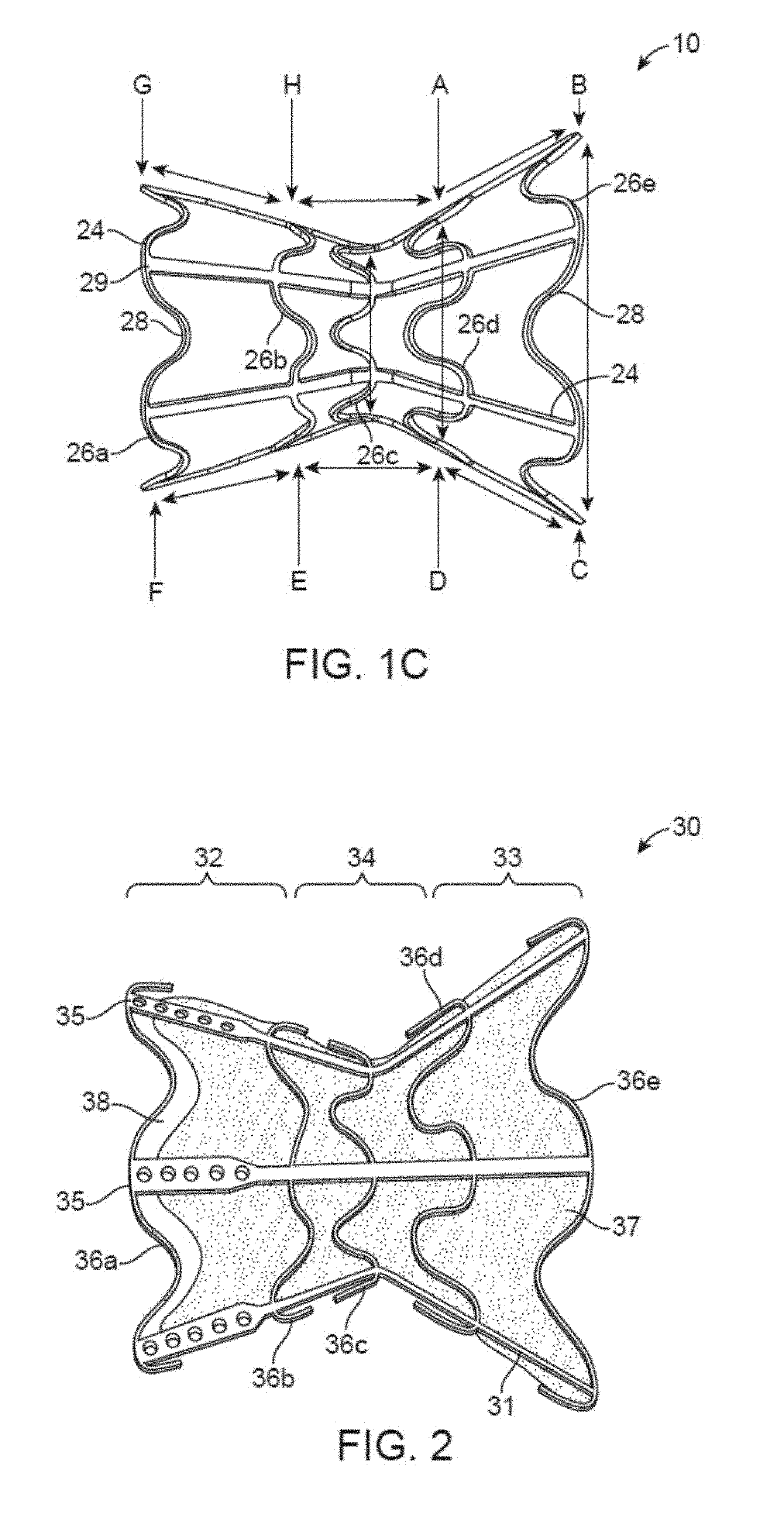

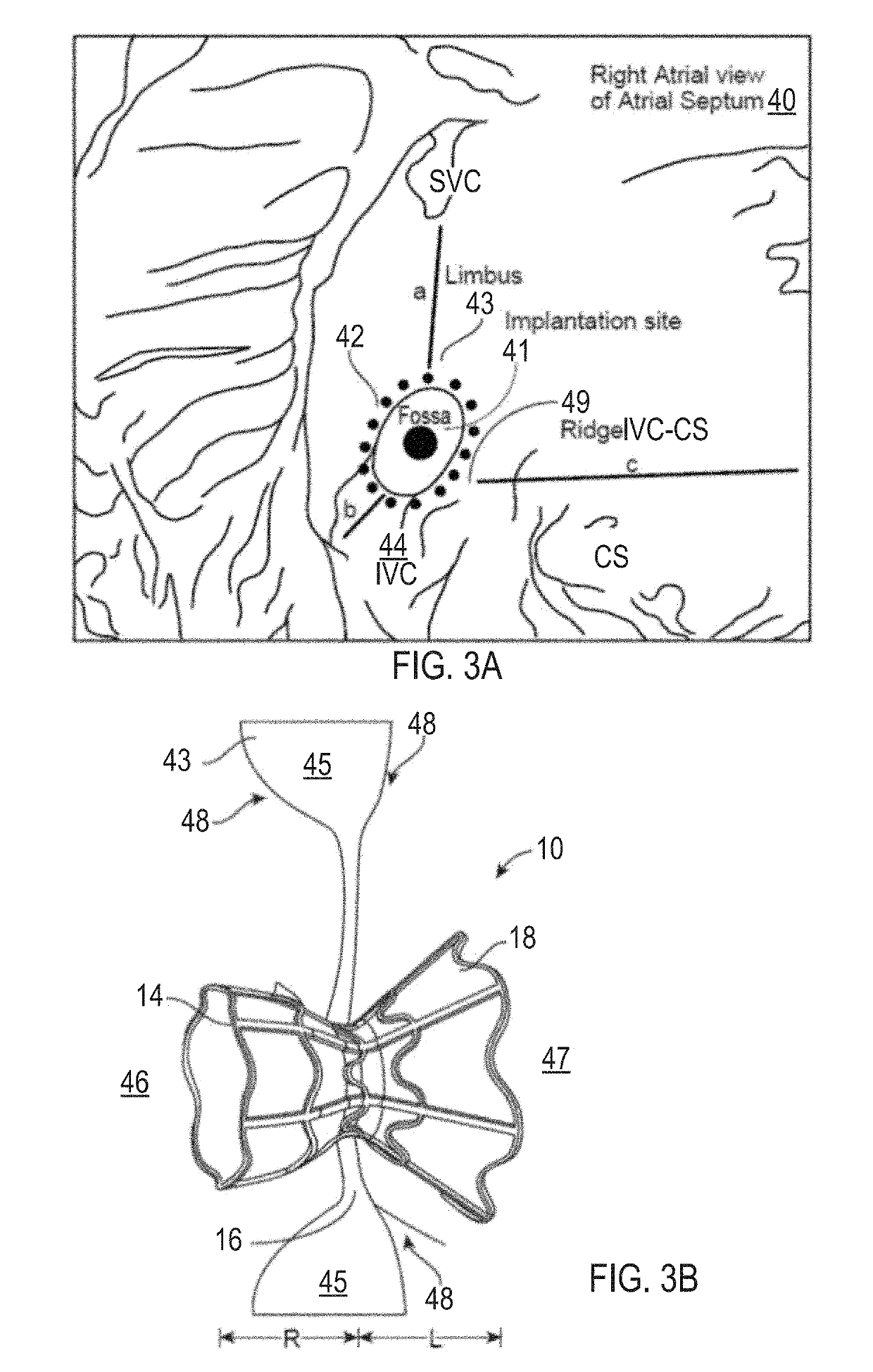

Asymmetric shunt for redistributing atrial blood volume

ActiveUS20190262118A1Maintains luminal patencyReduce riskStentsHeart valvesNormal blood volumeRight atrium

An asymmetric device for regulating blood volume distribution across a patient's atrial septum having a first expandable end region and a second expandable end region. The first expandable end region is transitionable from a contracted delivery state to an expanded deployed state in which the first expandable end region extends into the patient's left atrium and an inlet end of the first expandable end region is in a first plane. The second expandable end region is transitionable from a contracted delivery state to an expanded deployed state in which the second expandable end region extends into the patient's right atrium and an outlet end of the second expandable end region is in a second plane, such that the first plane intersects the second plane. The device further includes a neck region joining the first expandable end region to the second expandable end region, wherein the neck region is sized and shaped for placement in the patient's atrial septum.

Owner:WAVE LTD V

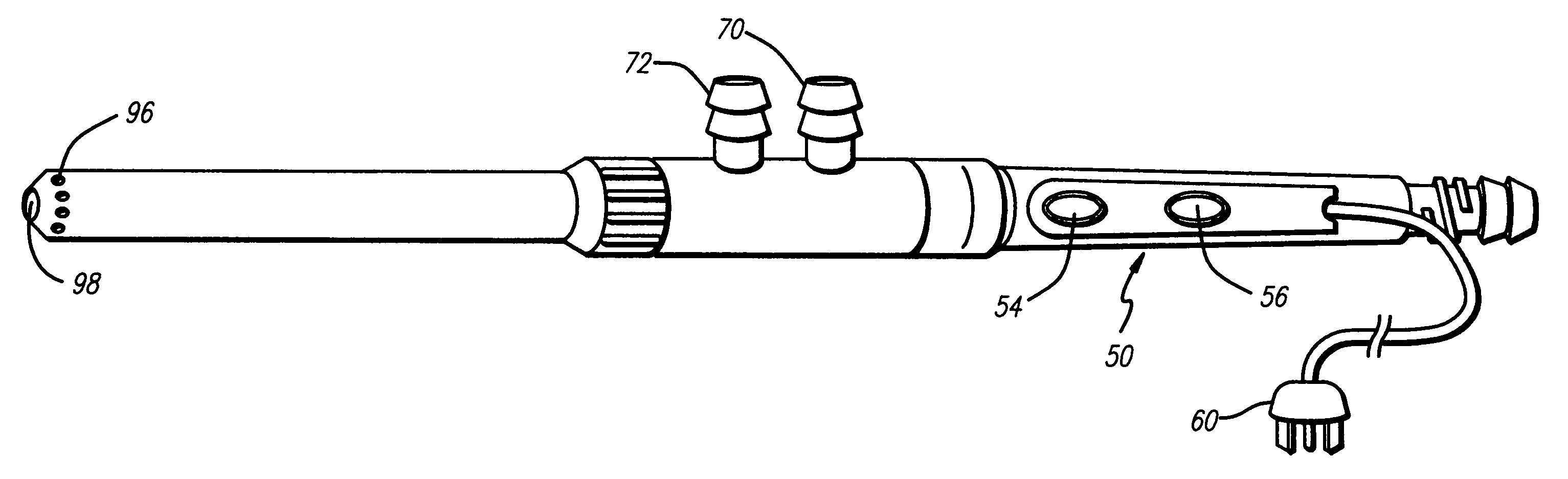

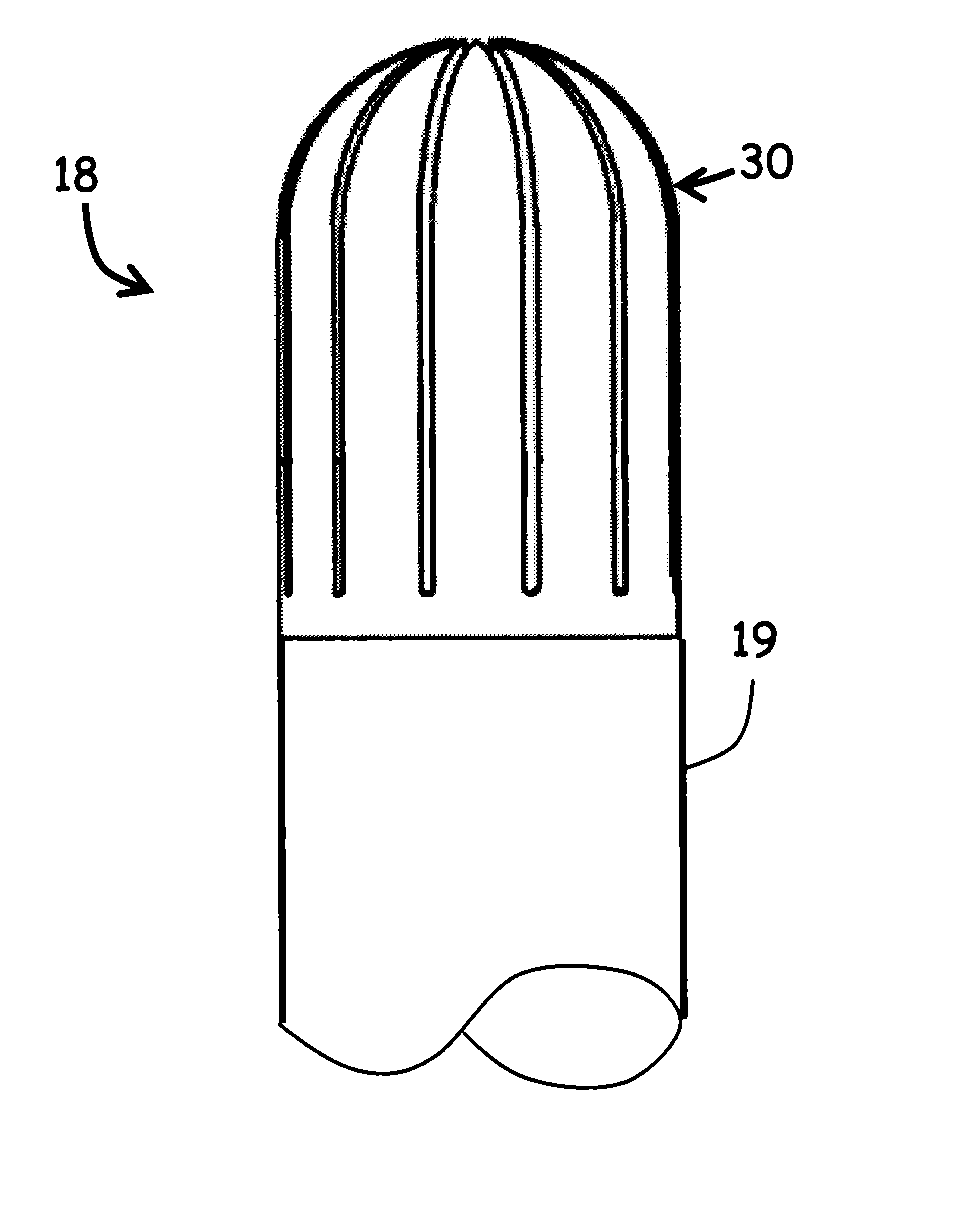

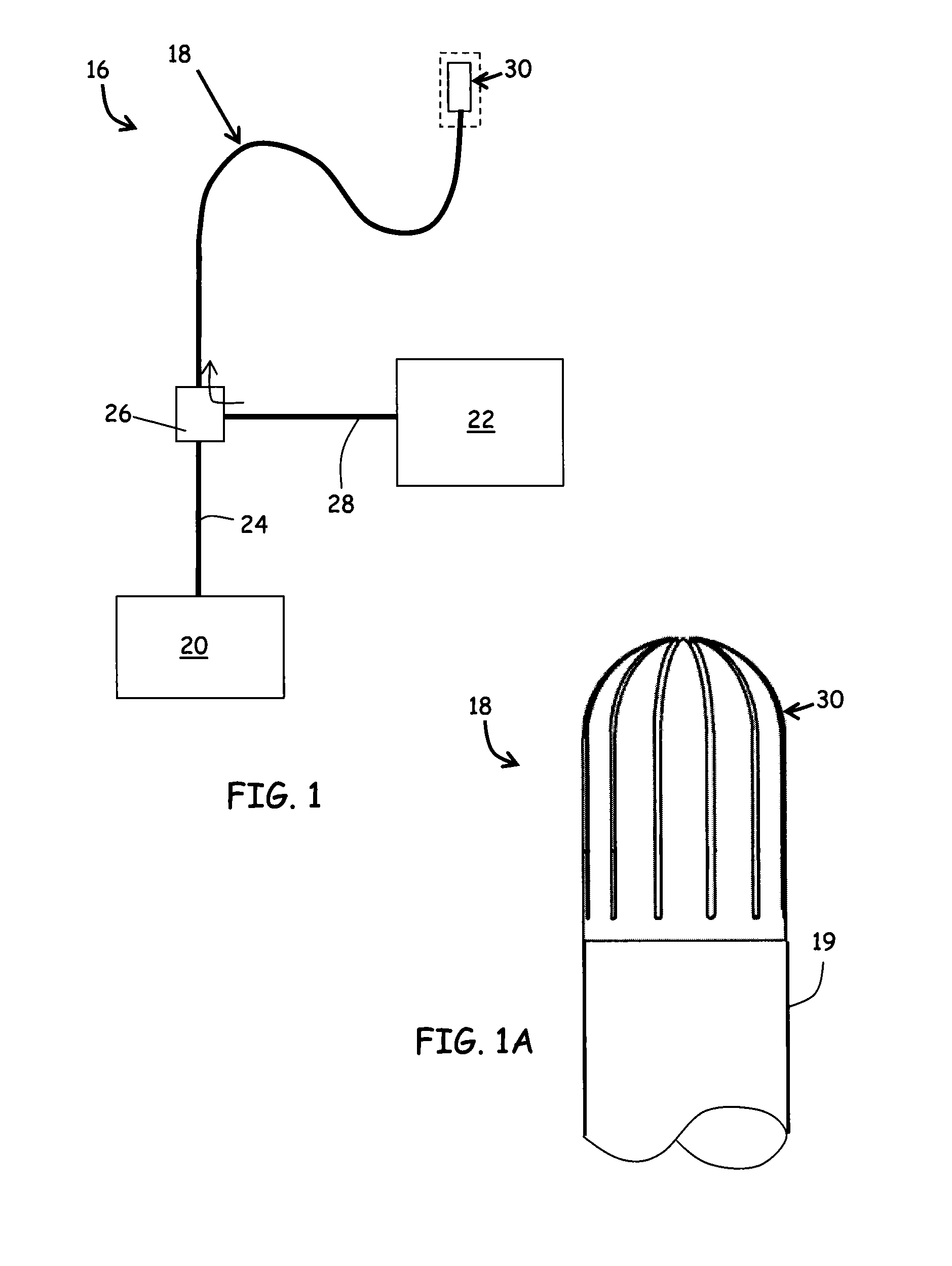

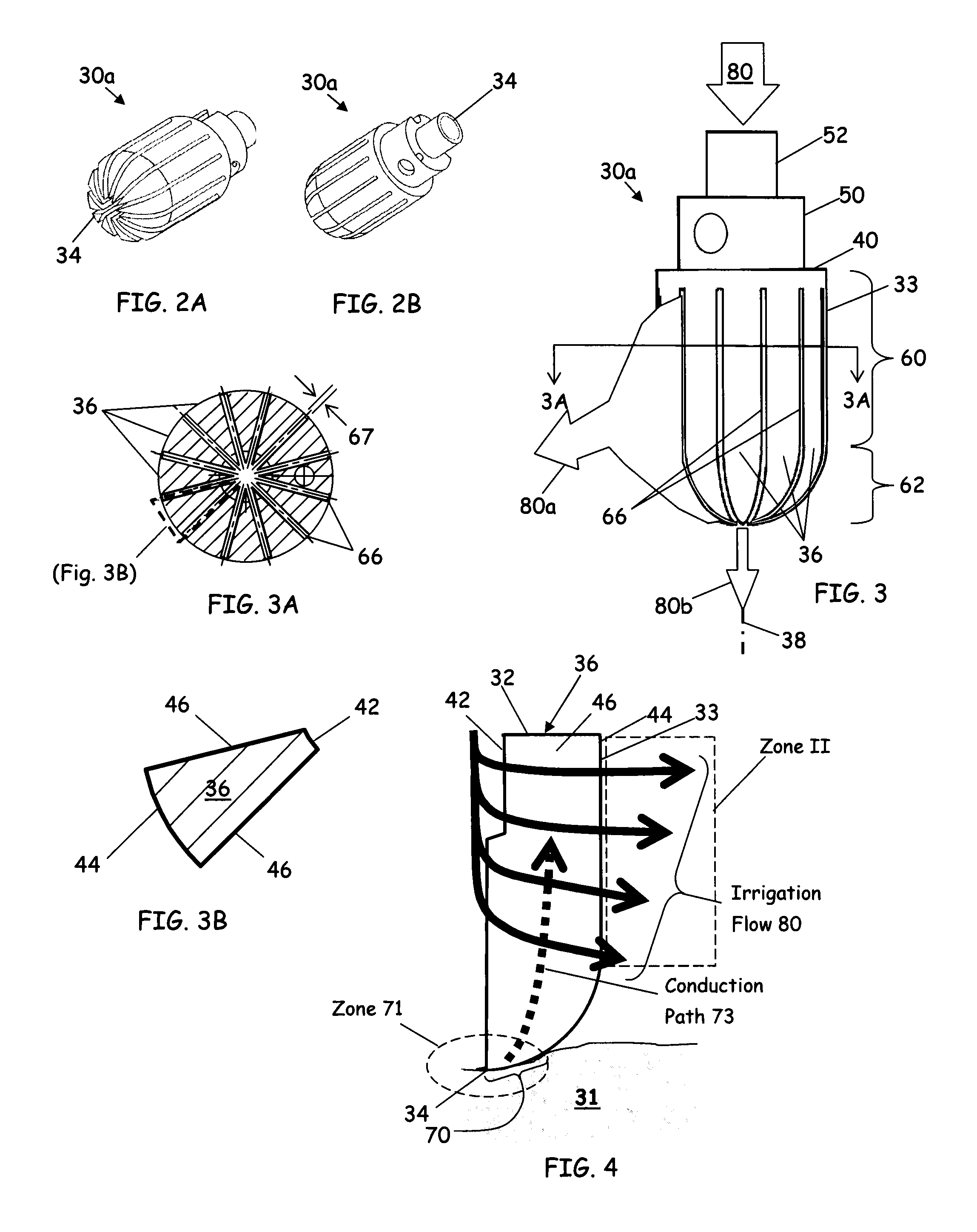

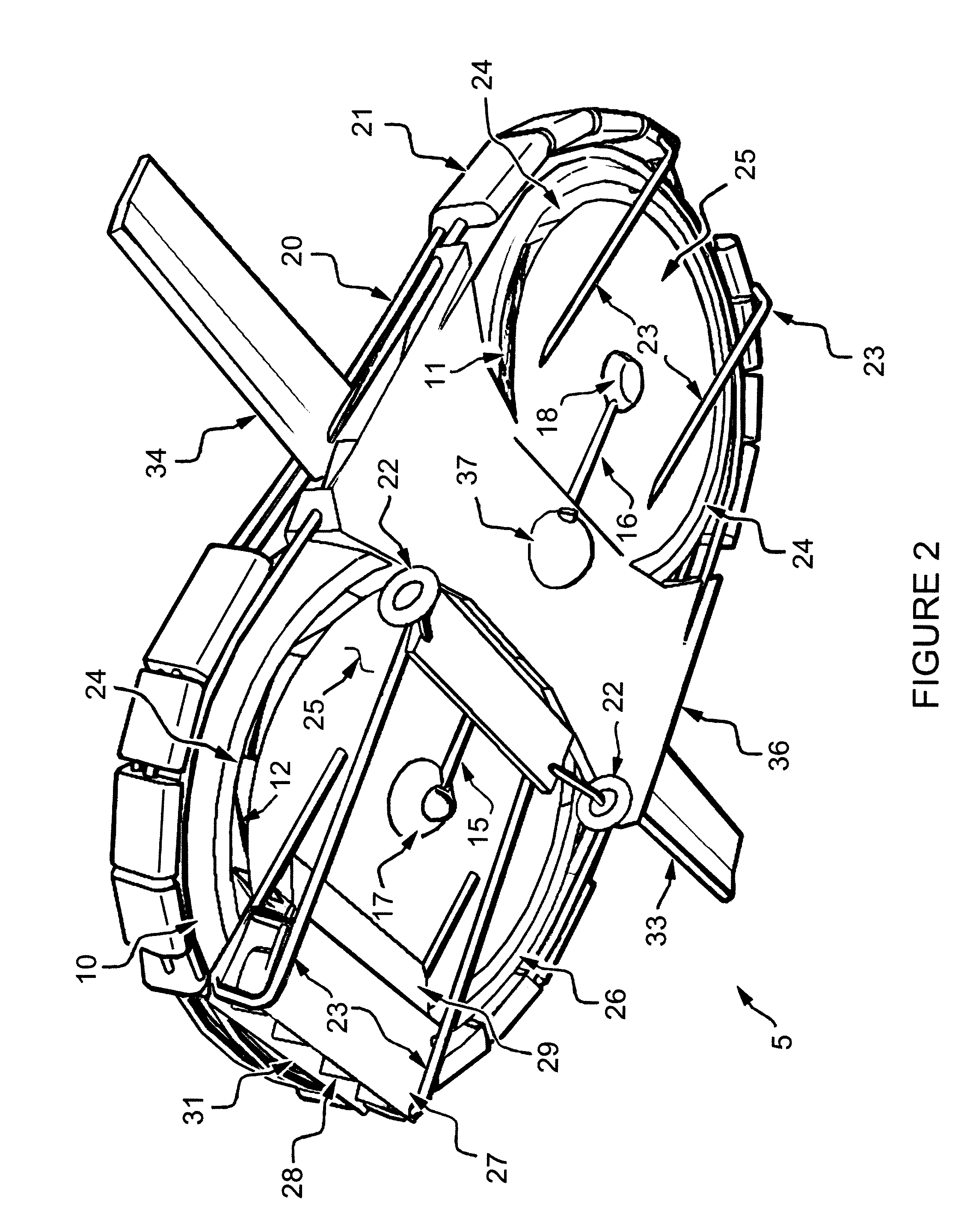

Irrigated finned ablation head

ActiveUS20110282342A1Easy to moveReliable purificationSurgical instruments for heatingSurgical instruments for irrigation of substancesDistal portionBiomedical engineering

An irrigated finned ablation head that provides enhanced cooling. The irrigated finned ablation head comprises a plurality of radial fins that are distributed about a central axis and that extend axially from a common base. The plurality of fins are arranged to define a central passageway along the central axis, as well as a plurality of slots therebetween, the slots extending in an axial direction along the irrigated finned ablation head. In one embodiment, the central passageway extends through the irrigated finned ablation head, defining an opening at the distal extremity, with the slots extending from the base to the opening. In another embodiment, the irrigated finned ablation head includes a cap portion at a distal portion that is common to all the radial fins, so that the slots are terminated at the distal portion of the irrigated finned ablation head. The radial flow distribution along the central axis can be tailored by the configuration of the central passageway.

Owner:ST JUDE MEDICAL INT HLDG SARL

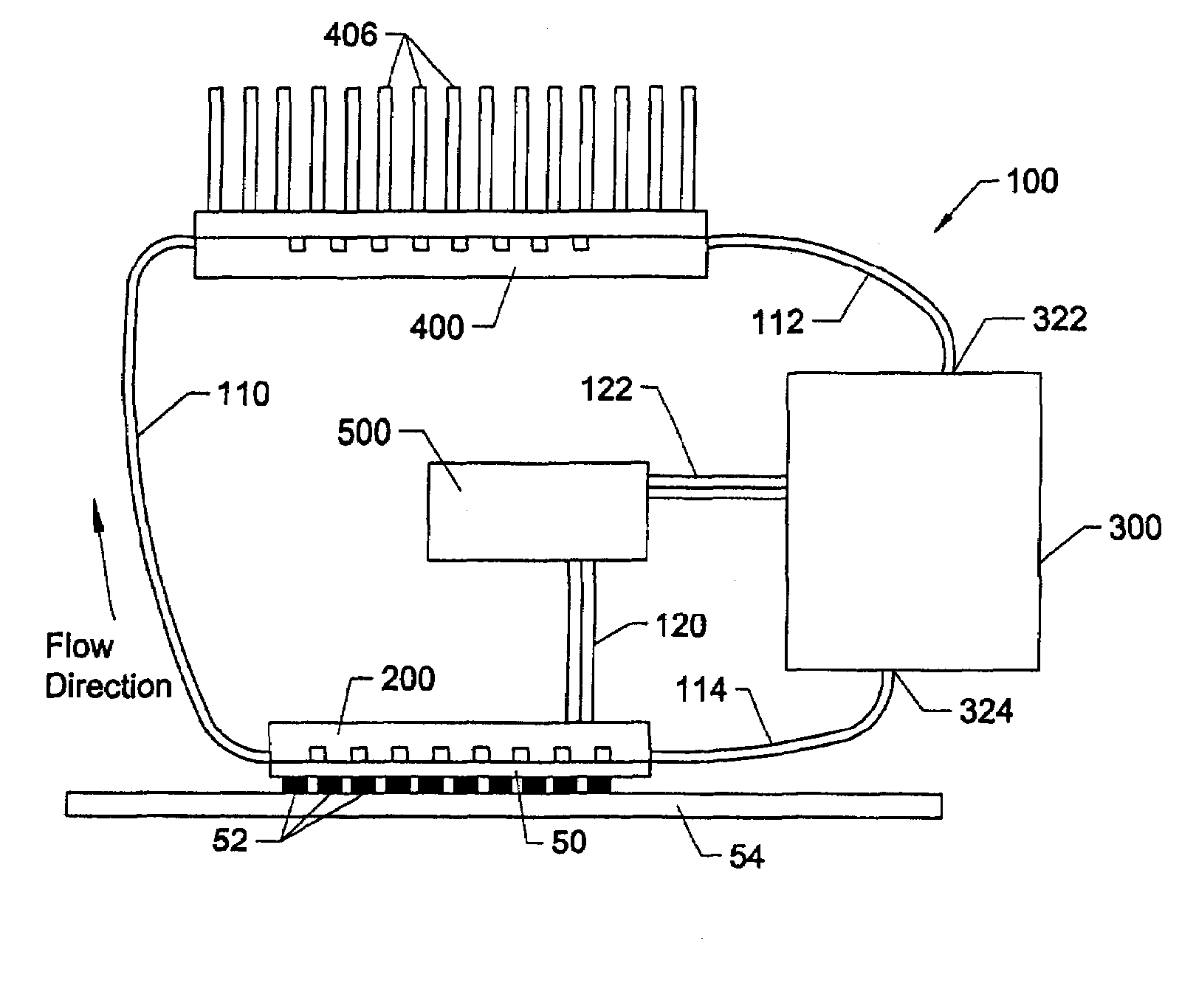

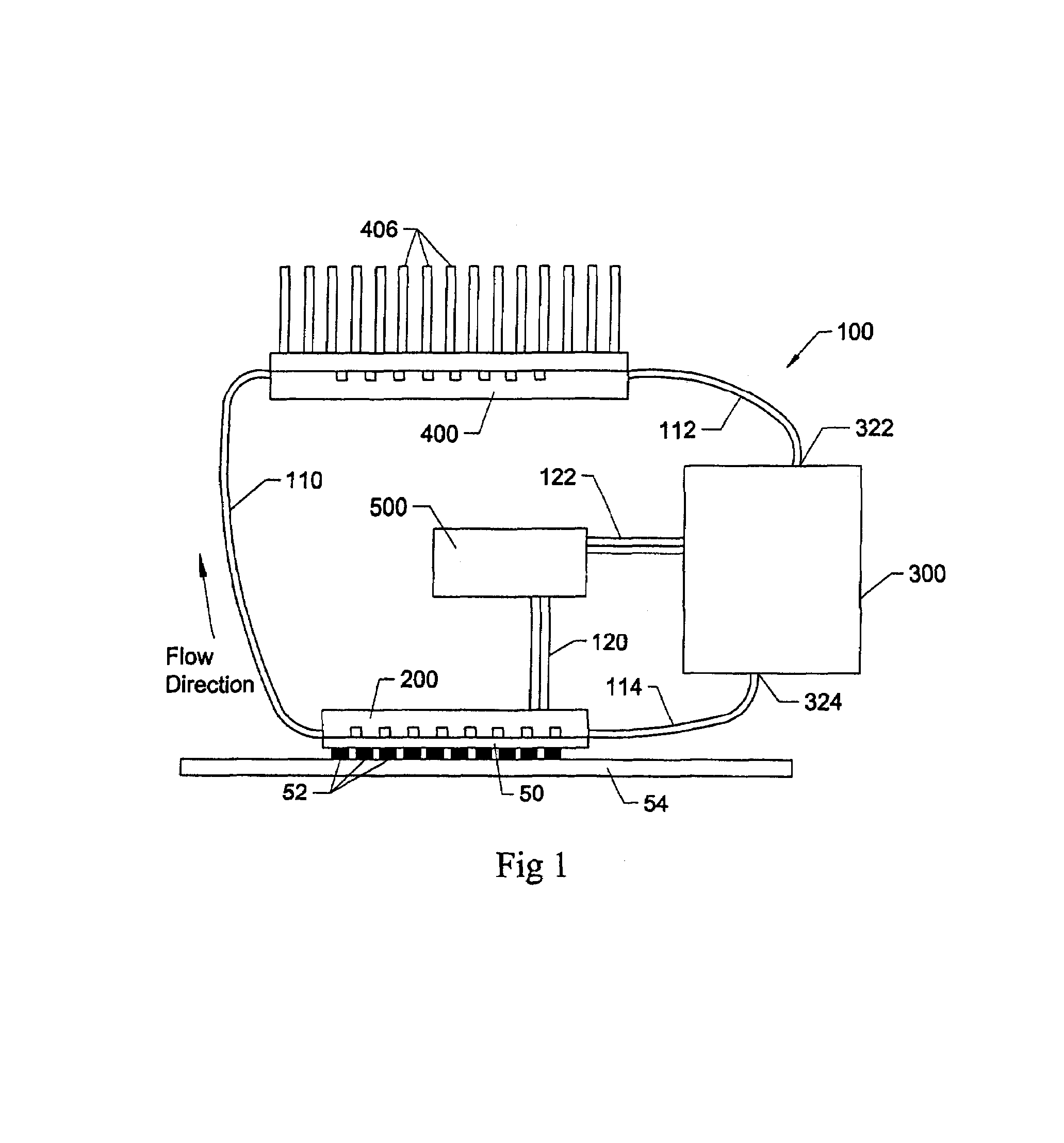

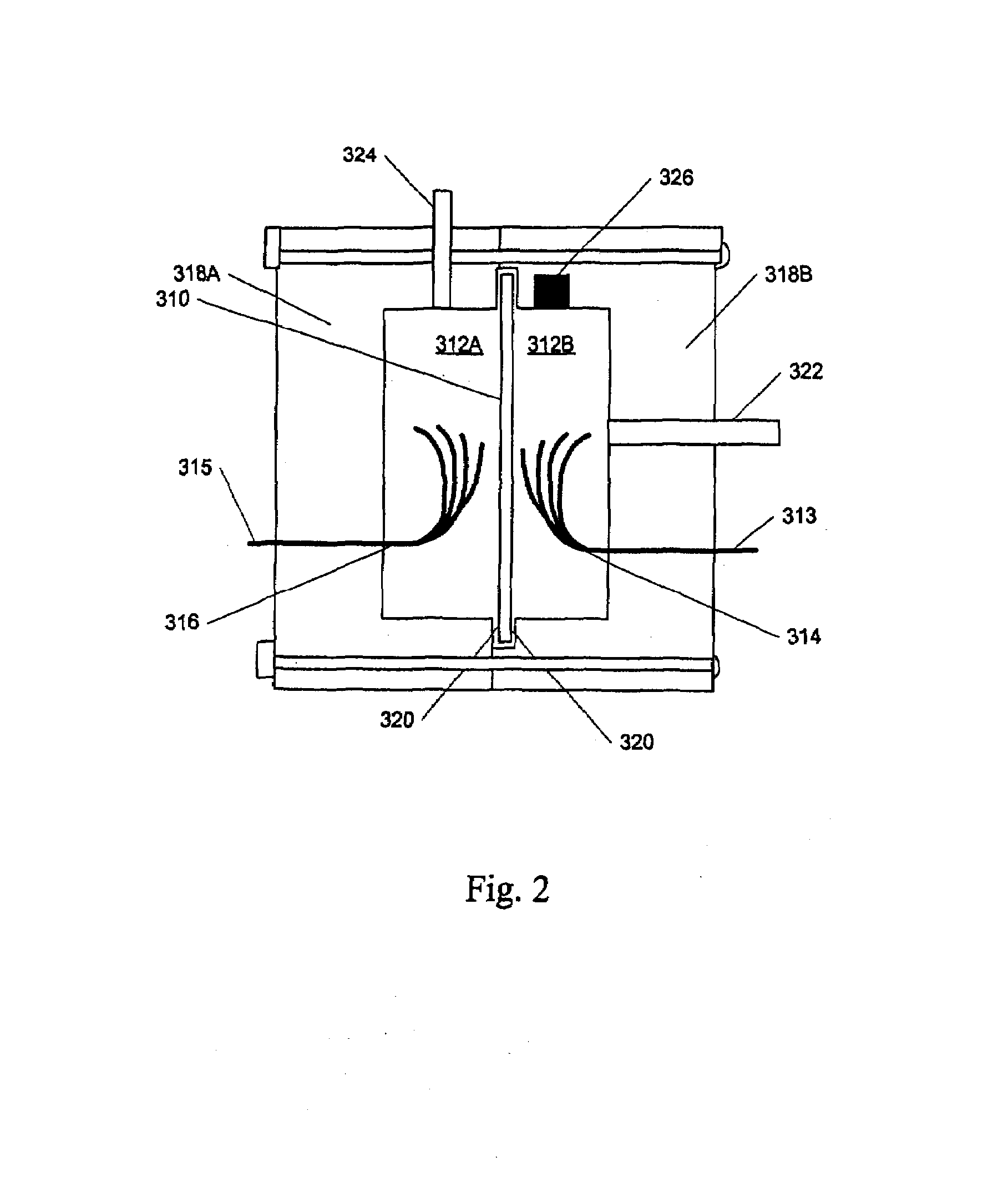

Control of electrolysis gases in electroosmotic pump systems

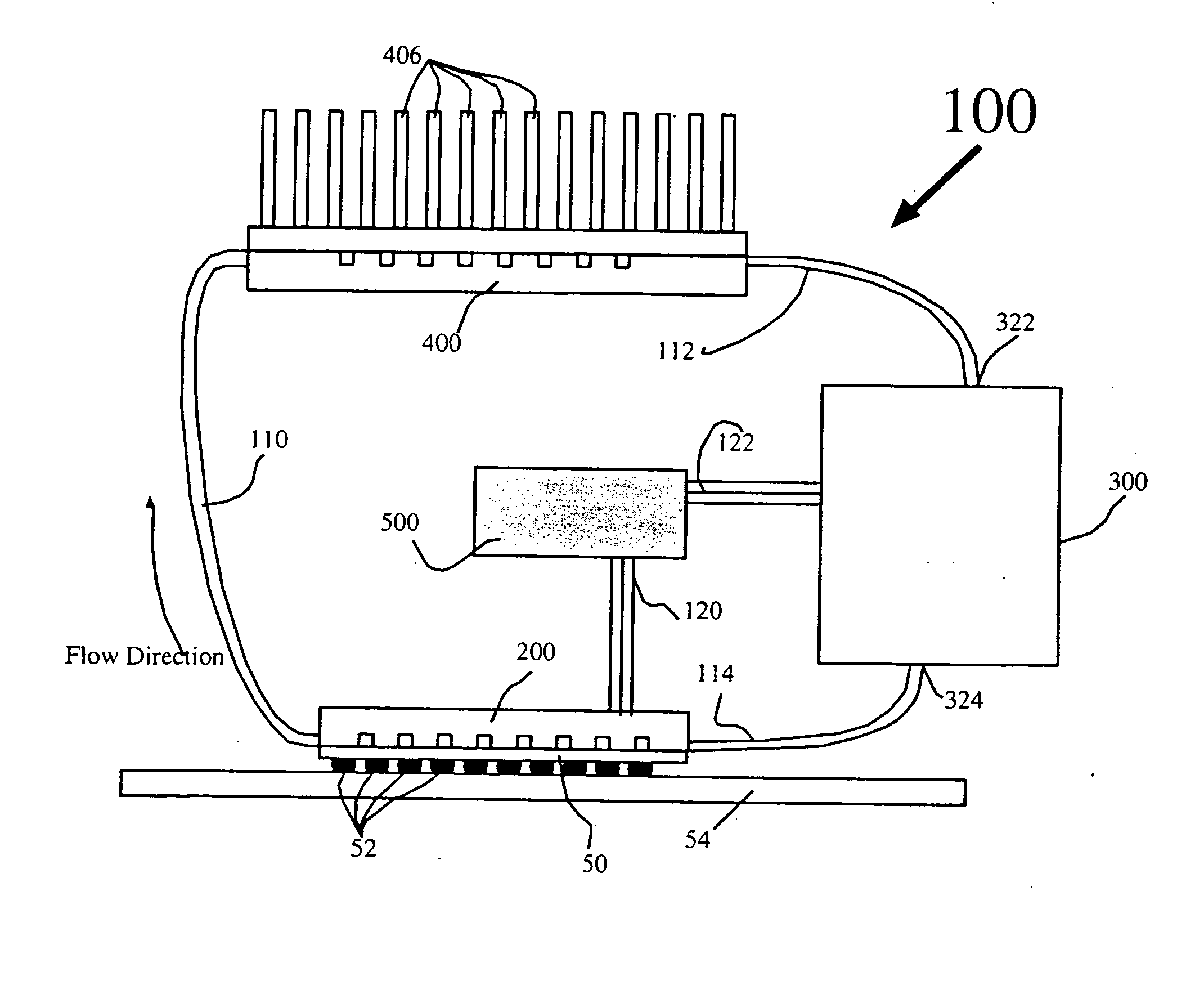

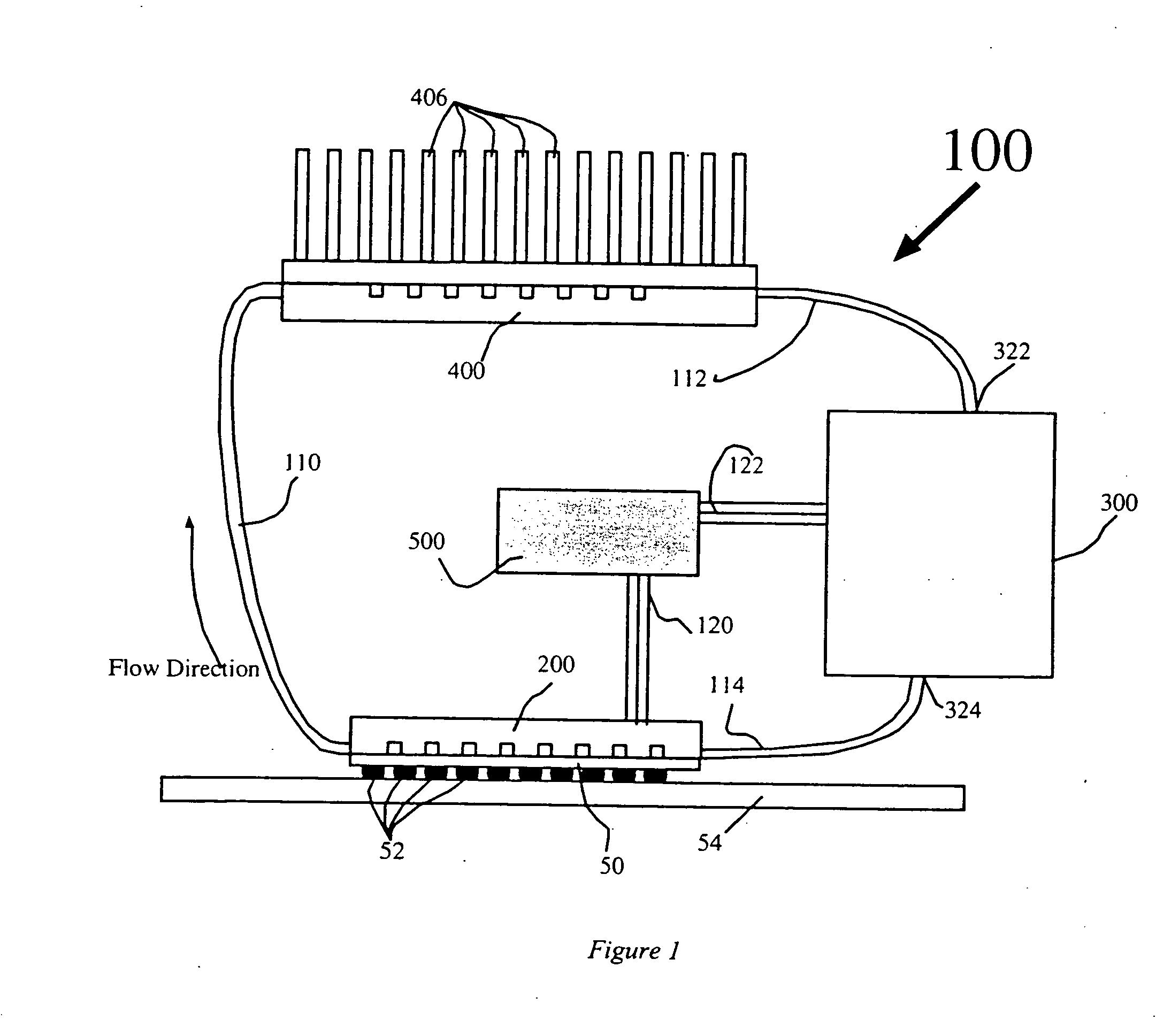

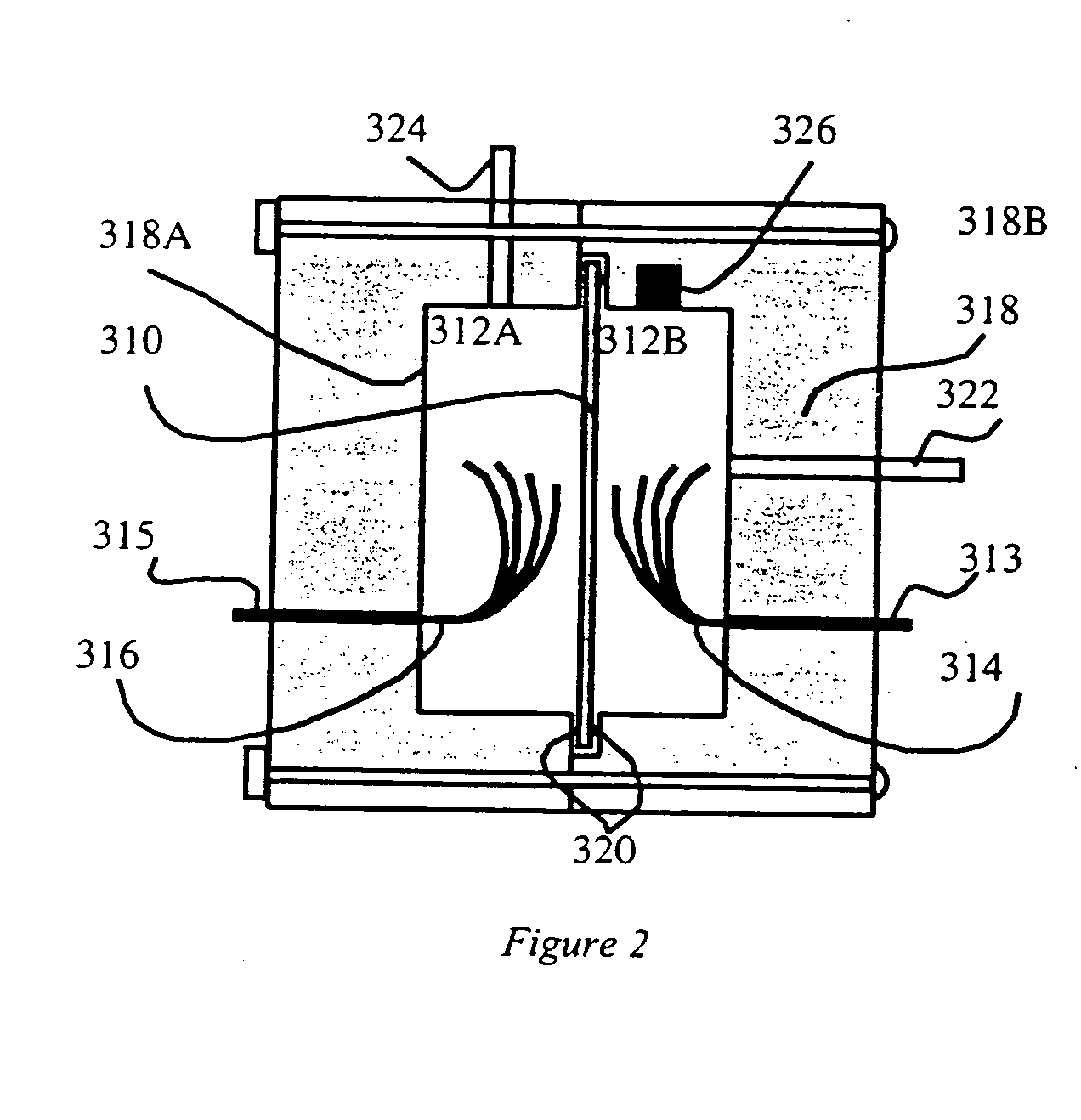

InactiveUS7134486B2Easy to shapeOptimize distributionFixed microstructural devicesSemiconductor/solid-state device detailsElectricityRe entry

Apparatus and methods according to the present invention preferably utilize electroosmotic pumps that are capable of generating high pressure and flow without moving mechanical parts and the associated generation of unacceptable electrical and acoustic noise, as well as the associated reduction in reliability. These electroosmotic pumps are preferably fabricated with materials and structures that improve performance, efficiency, and reduce weight and manufacturing cost relative to presently available micropumps. These electroosmotic pumps also preferably allow for control including venting or recapture of evolved gases and deposited materials, which may provide for long-term closed-loop operation. A gas permeable membrane removes and vents electrolytic gasses generated within the fluid chamber of the electroosmotic pump to ambient. A catalyst can be used to recombine electrolytic gases to form a vapor product that can be vented or condensed into a liquid state. An osmotic membrane provides for re-entry of condensed fluid to the fluid chamber.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

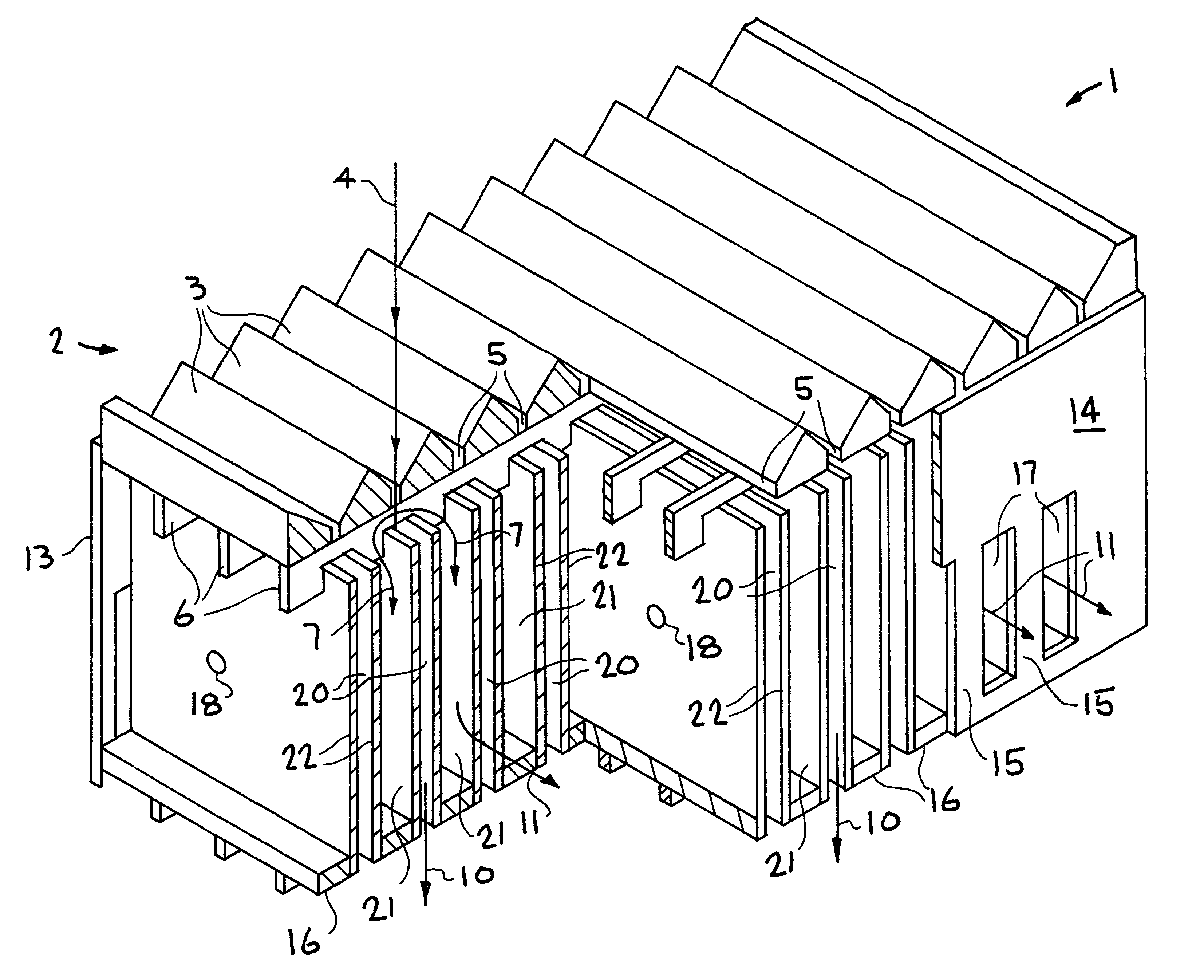

Electroosmotic microchannel cooling system

InactiveUS20050098299A1Easy to shapeOptimize distributionPump componentsDomestic cooling apparatusElectricityClosed loop

Apparatus and methods according to the present invention preferably utilize electroosmotic pumps that are capable of generating high pressure and flow without moving mechanical parts and the associated generation of unacceptable electrical and acoustic noise, as well as the associated reduction in reliability. These electroosmotic pumps are preferably fabricated with materials and structures that improve performance, efficiency, and reduce weight and manufacturing cost relative to presently available micropumps. These electroosmotic pumps also preferably allow for recapture of evolved gases and deposited materials, which may provide for long,-term closed-loop operation. Apparatus and methods according to the present invention also allow active regulation of the temperature of the device through electrical control of the flow through the pump and can utilize multiple cooling loops to allow independent regulation of the special and temporal characteristics of the device temperature profiles. Novel microchannel structures are also described.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

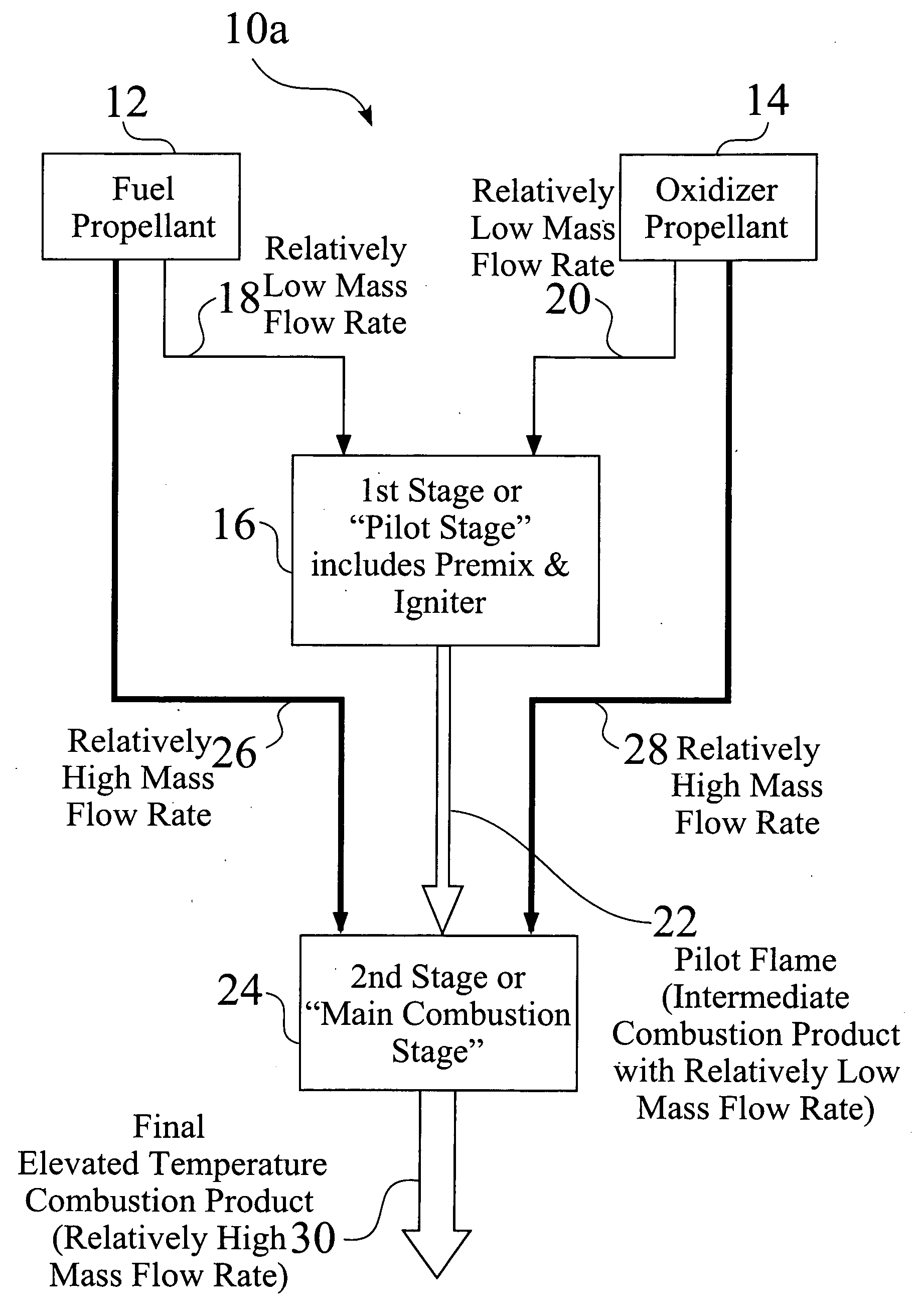

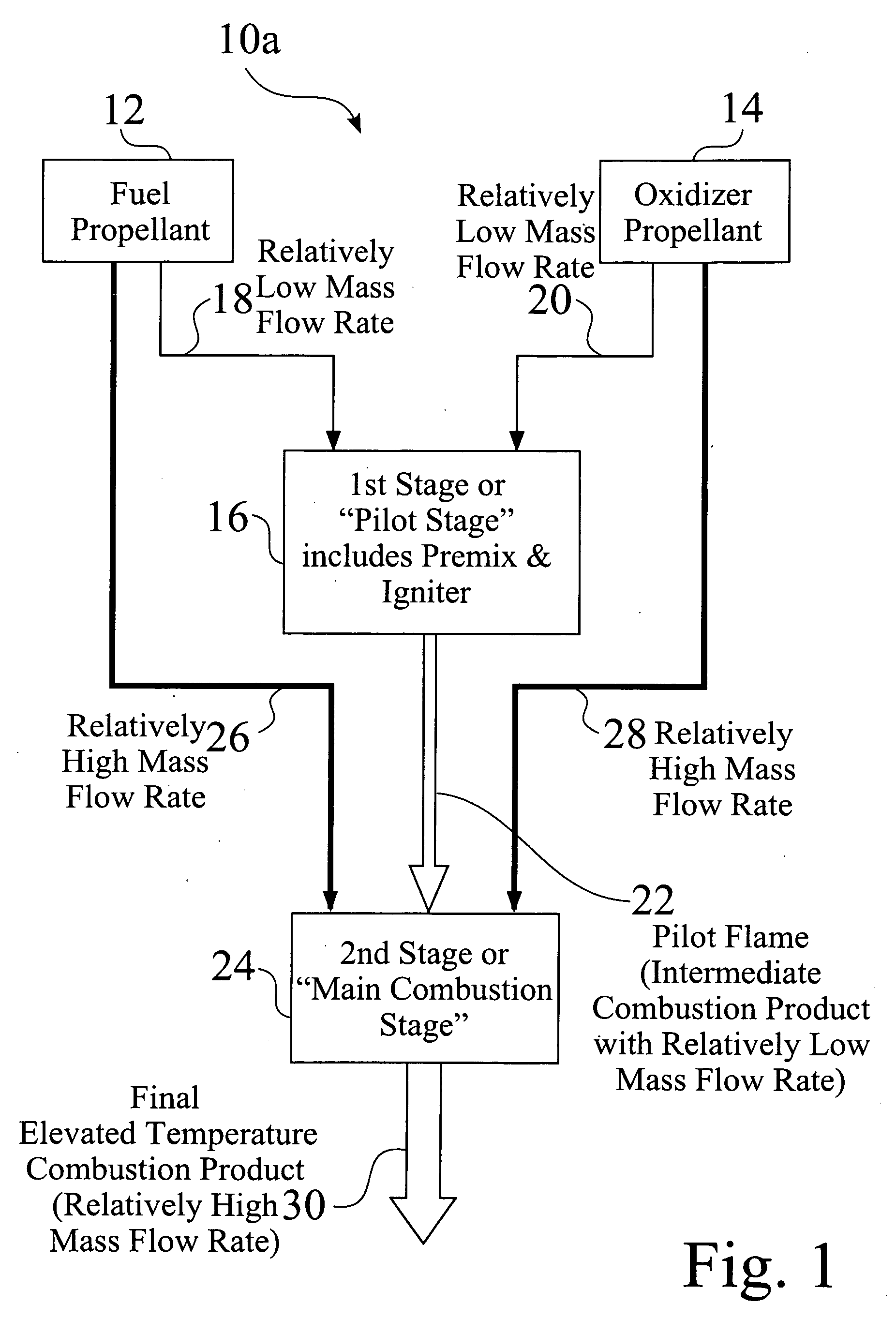

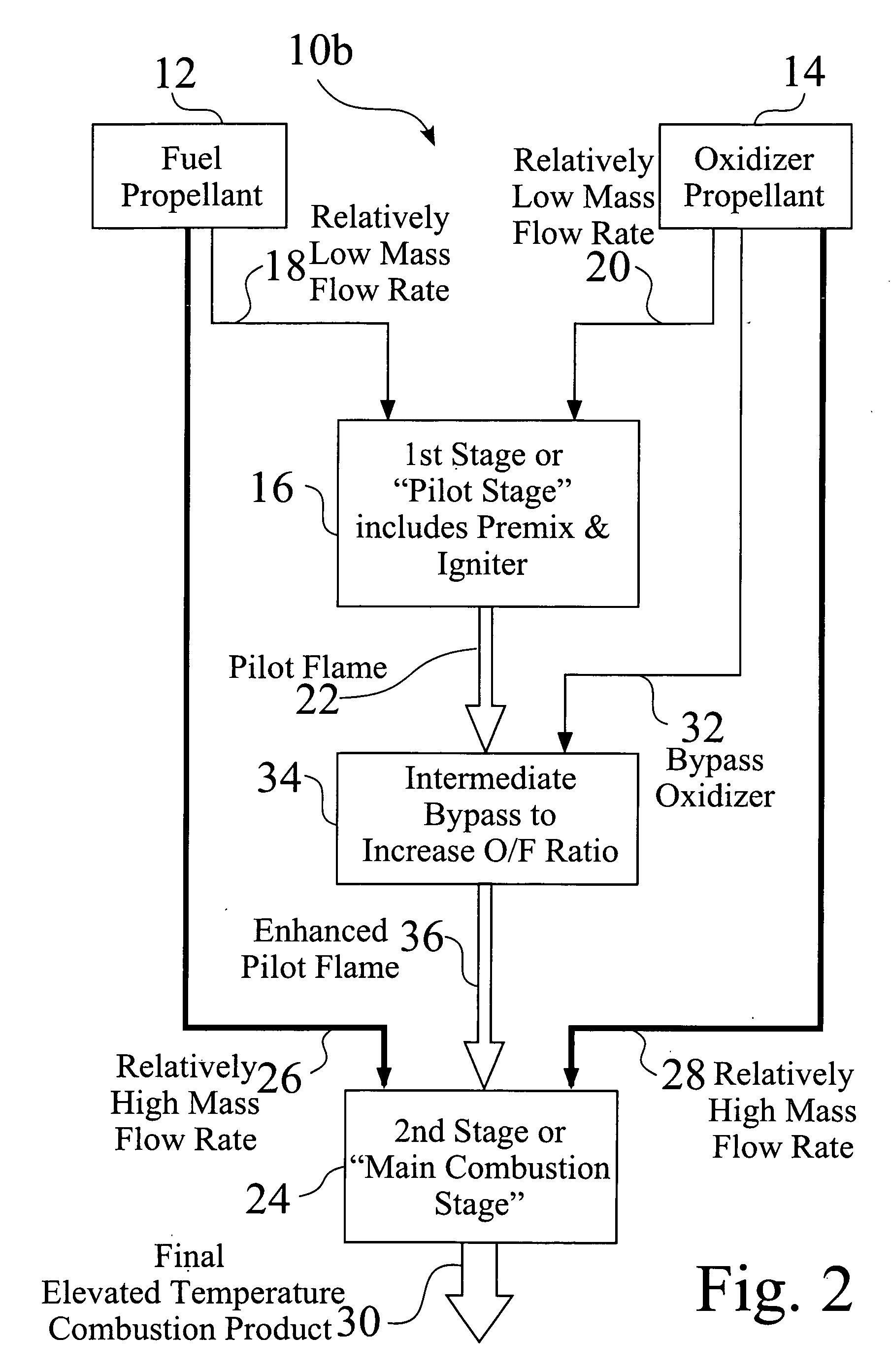

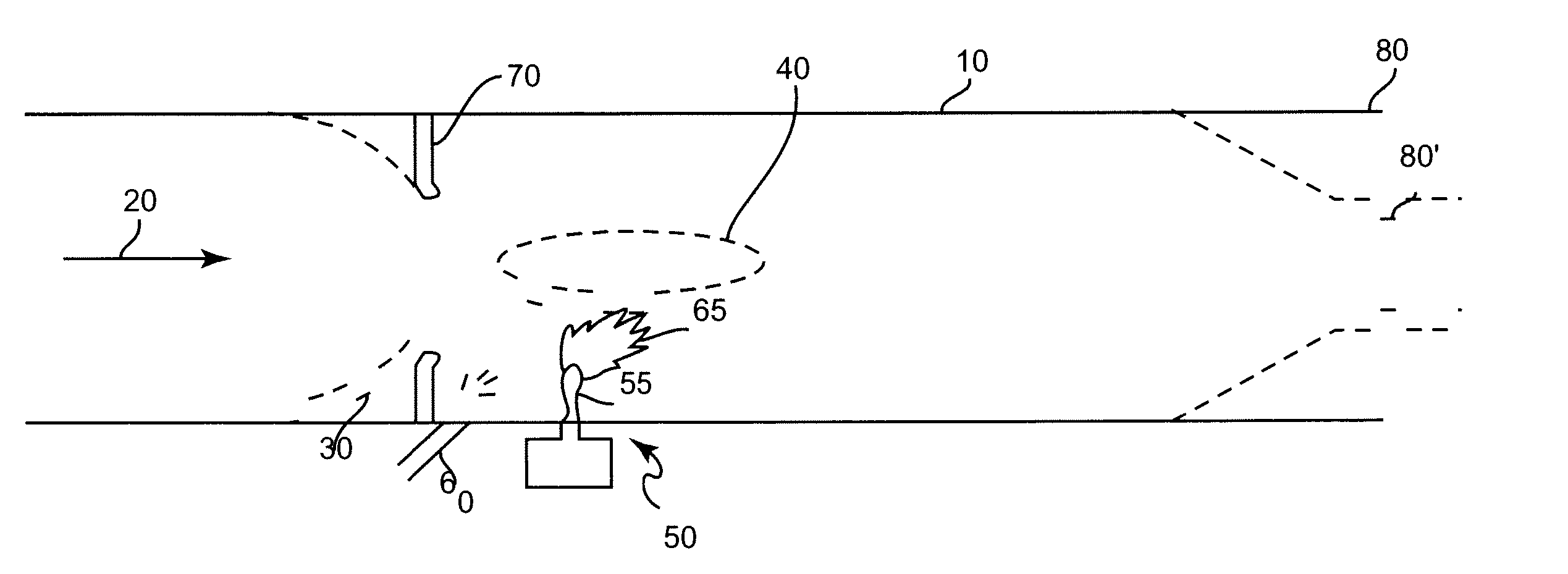

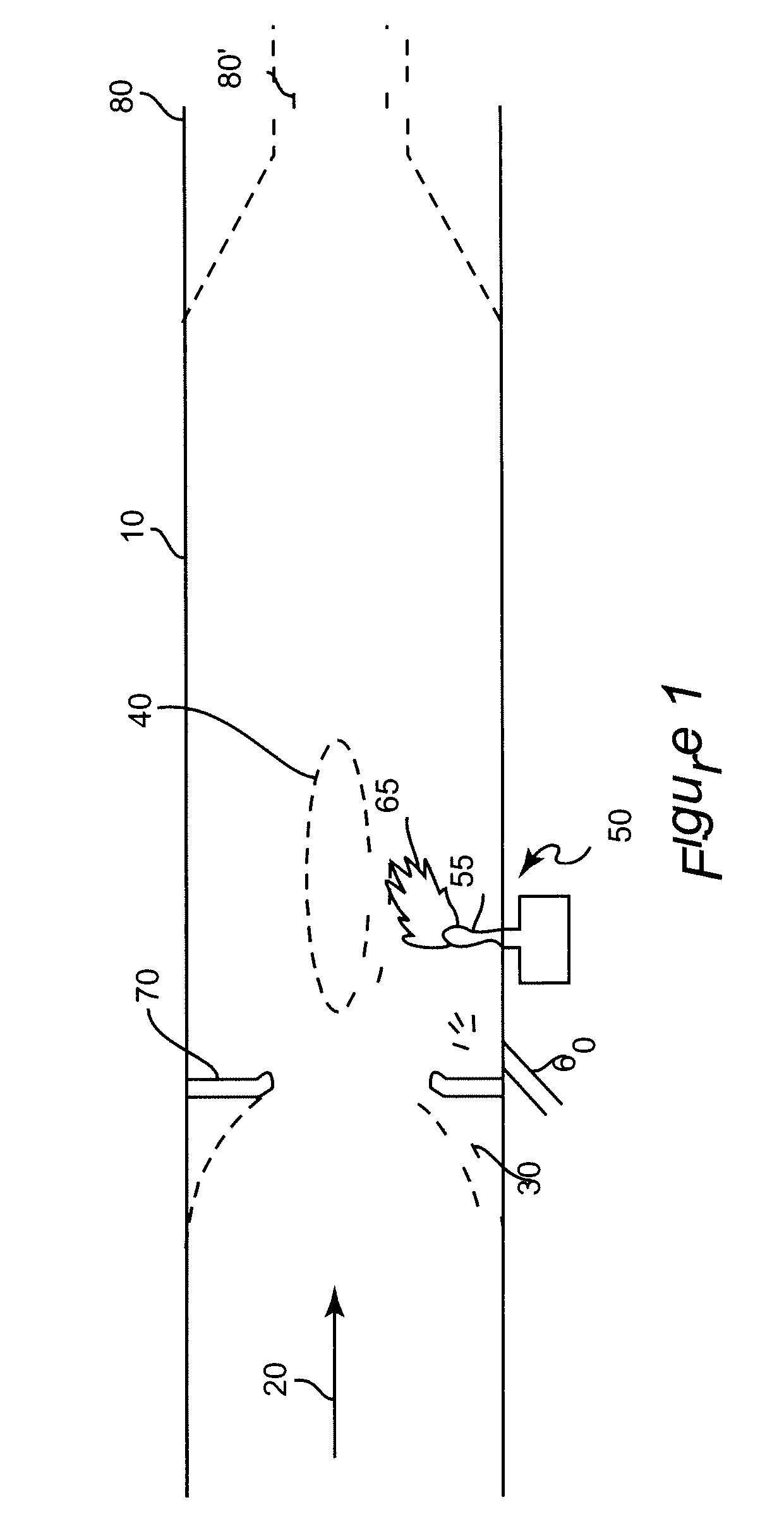

Two-stage ignition system

InactiveUS20080264372A1Relieve pressureExtended service lifeFlame ignitionElectric ignition installationCombustionPropellant

Methods and apparatus for providing a Two-Stage Ignition System are disclosed. In one embodiment of the invention, a pilot stage (16) is employed to ignite a plurality of propellants (12, 14) and to create a pilot flame (22). The plurality of propellants (12, 14) are ignited in the main combustion stage (24) using the pilot flame (22), and a flow of an elevated temperature combustion product (30) is produced.

Owner:KTE ENG

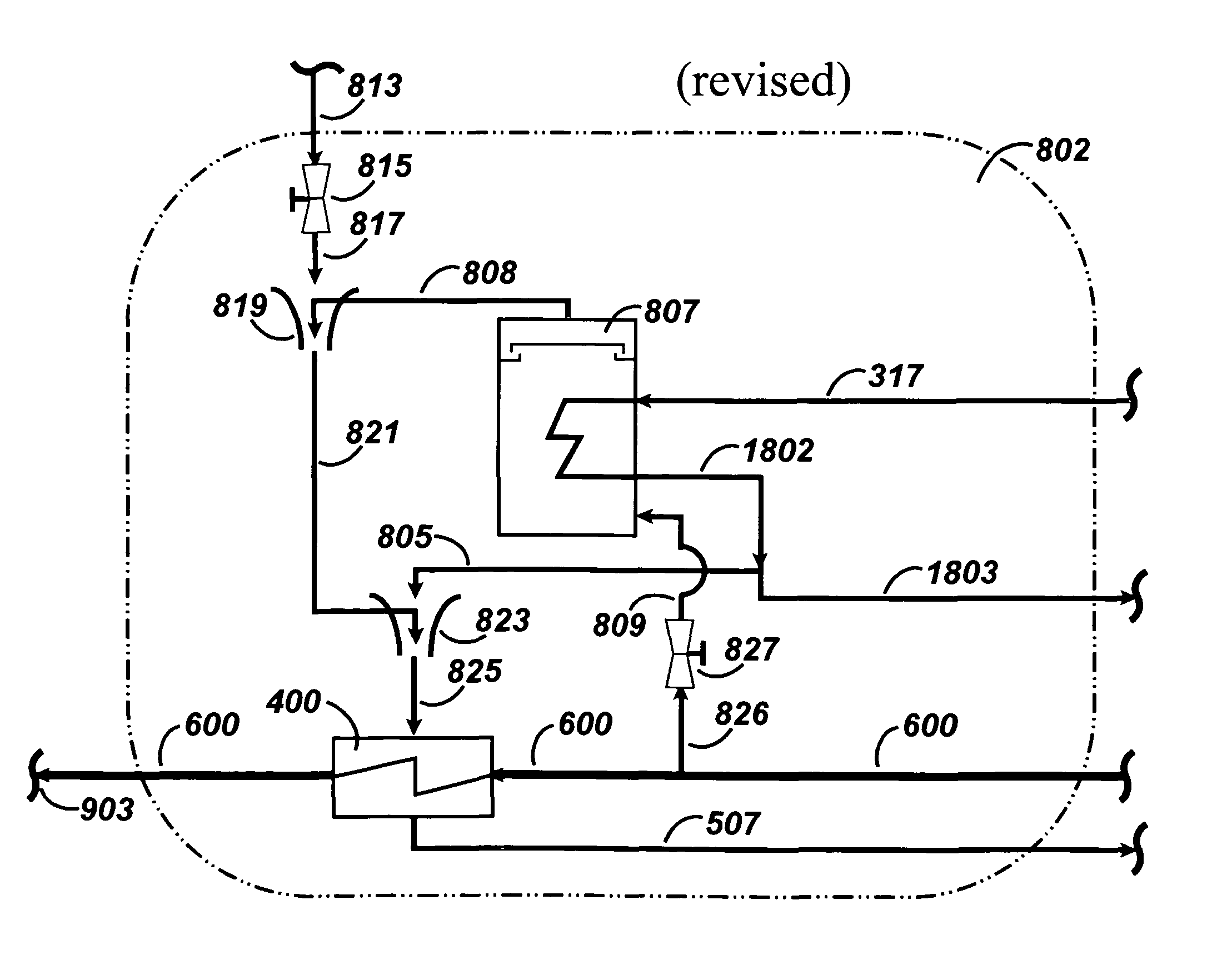

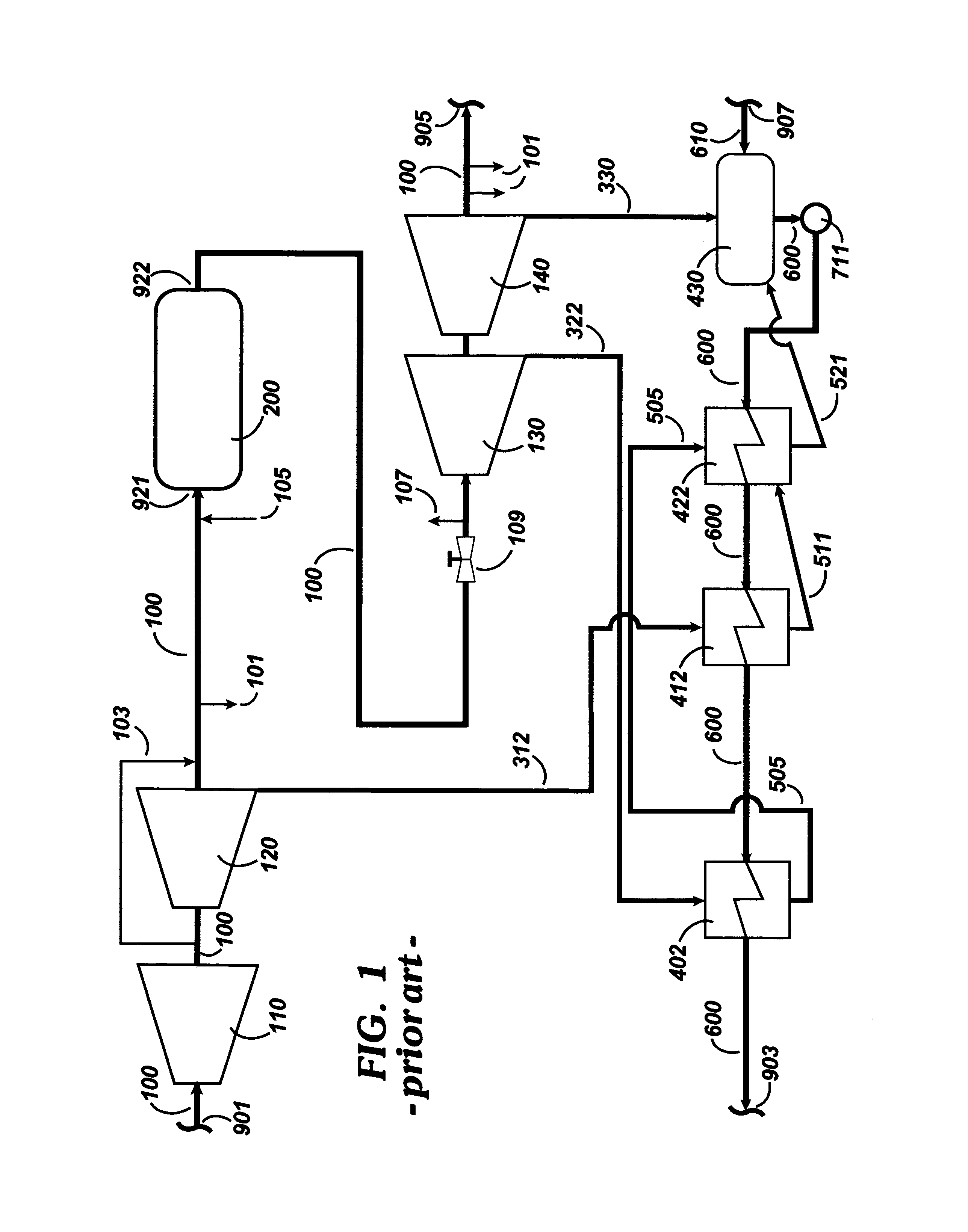

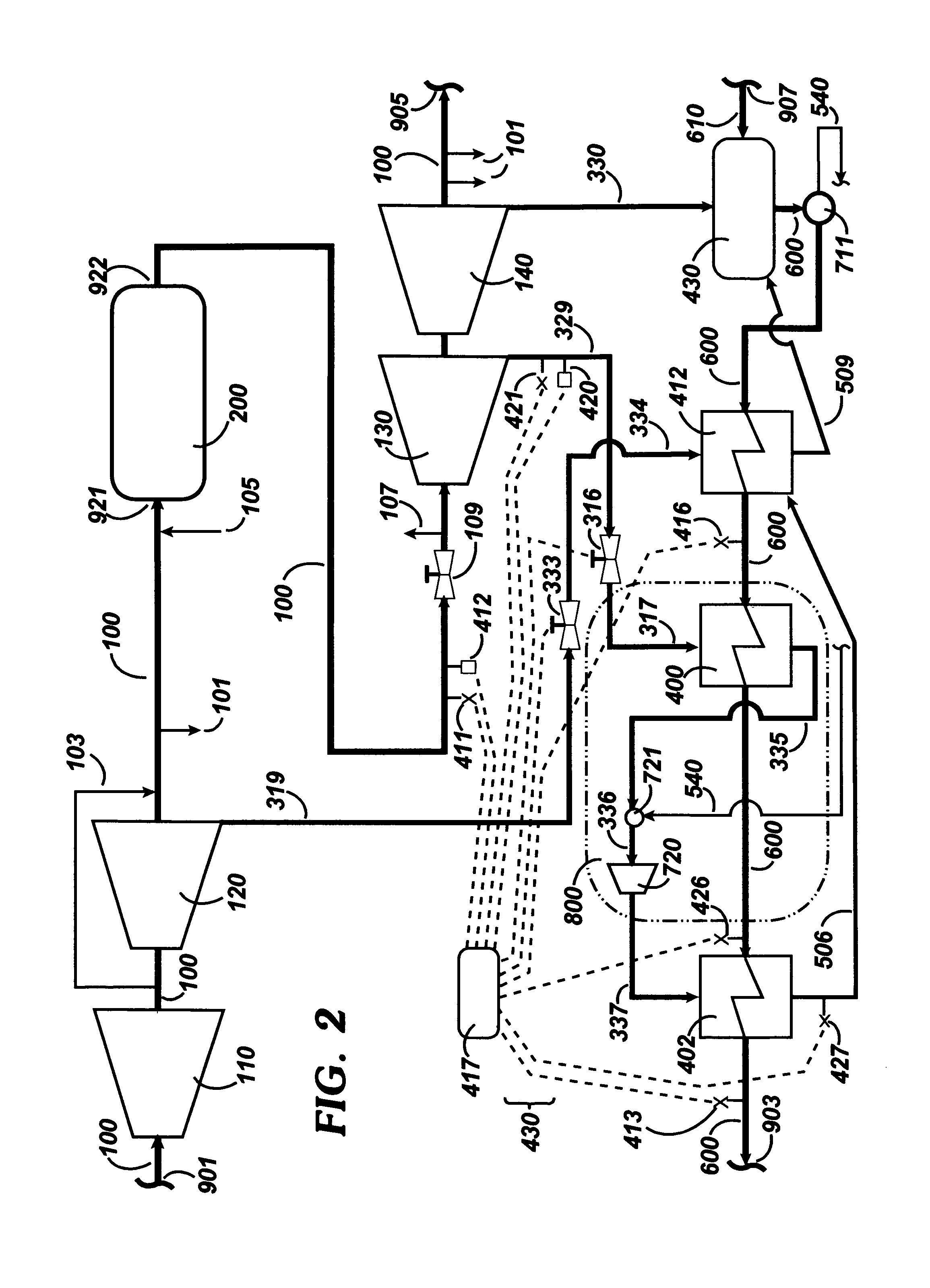

Method and apparatus for controlling the final feedwater temperature of a regenerative Rankine cycle using an exergetic heater system

ActiveUS8091361B1Power Loss MinimizationImprove system reliabilitySteam regenerationSteam useWorking fluidPower station

This invention relates to a method and apparatus for increasing the final feedwater temperature associated with a regenerative Rankine cycle, said cycle commonly used in thermal systems such as conventional power plants, whose steam generators are fired with a fossil fuel and whose regenerative Rankine cycle employs a reheating of the working fluid. This invention involves the placement of an Exergetic Heater System in the feedwater path of the regenerative Rankine cycle. The Exergetic Heater System conditions and heats feedwater such that the temperature of the cycle's final feedwater as it enters the steam generator has reached a desired value. The Exergetic Heater System receives its driving steam from an Intermediate Pressure turbine extraction.

Owner:EXERGETIC SYST

Elastomeric fibers comprising controlled distribution block copolymers

InactiveUS20070055015A1High melt flowIncrease chanceWoven fabricsConjugated synthetic polymer artificial filamentsProduction rateYarn

Bicomponent fibers comprising a thermoplastic polymer and an elastomeric compound are made which can be continuously extruded from the melt at high production rates. The elastomeric compound comprises a selectively hydrogenated block copolymer having a controlled distribution elastomeric block which has a mono alkenyl arene blockiness index of less than 40 mol % and high flow. Elastomeric fibers are also provided which comprise a controlled distribution block copolymer and a slip agent. The fibers are useful for the manufacture of articles such as woven fabrics, spunbond non-woven fabrics or filters, staple fibers, yarns and bonded, carded webs. The bicomponent fibers can be made using a process comprising coextrusion of the thermoplastic polymer and elastomeric compound to produce fibers at spinning speeds of at least 1000 mpm and having a denier from 0.1 to 50 g / 9000 m.

Owner:KRATON POLYMERS US LLC

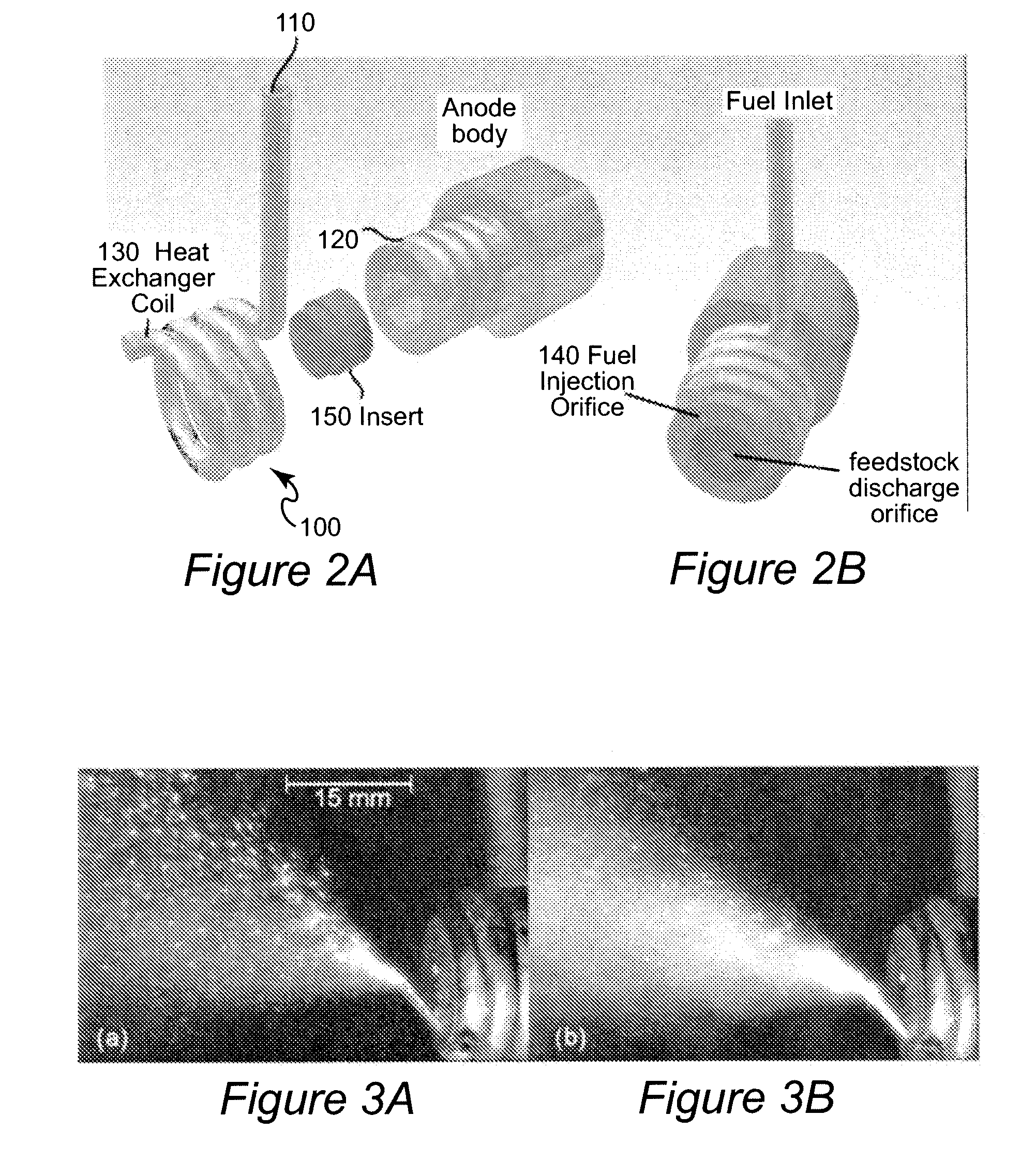

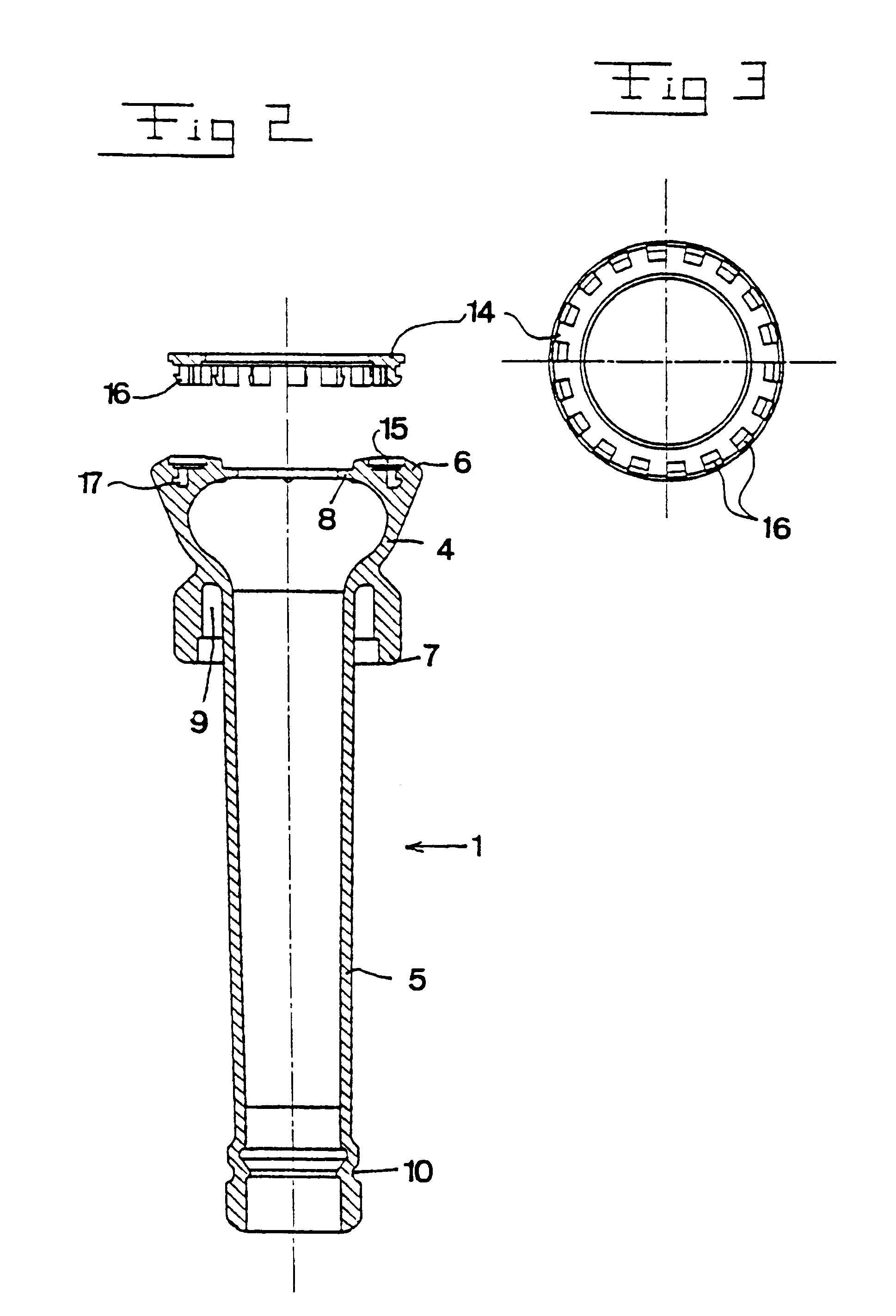

Improved Plasma Torch for Ignition, Flameholding and Enhancement of Combustion in High Speed Flows

InactiveUS20070044449A1Improves fuel mixingEnhances combustion reactionContinuous combustion chamberGas turbine plantsCombustionNitrogen

Preheating of fuel and injection into a plasma torch plume fro adjacent the plasma torch plume provides for only ignition with reduced delay but improved fuel-air mixing and fuel atomization as well as combustion reaction enhancement. Heat exchange also reduced erosion of the anode of the plasma torch. Fuel mixing atomization, fuel mixture distribution enhancement and combustion reaction enhancement are improved by unsteady plasma torch energization, integral formation of the heat exchanger, fuel injection nozzle and plasma torch anode in a more compact, low-profile arrangement which is not intrusive on a highspeed air flow with which the invention is particularly effective and further enhanced by use of nitrogen as a feedstock material and inclusion of high pressure gases in the fuel to cause effervescence during injection.

Owner:VIRGINIA TECH INTPROP INC

Block copolymers having high flow and high elasticity

ActiveUS20050197465A1High melt flowLow in contaminantWoven fabricsConjugated synthetic polymer artificial filamentsExtrusionPolymer science

Disclosed is an elastomeric hydrogenated block copolymer capable of being directly extruded or molded with a minimum of additives and having both high elasticity and low permanent set. The hydrogenated block copolymers have high melt flows allowing for ease in processing the hydrogenation block copolymers in melt processes such as extrusion and molding.

Owner:KRATON POLYMERS US LLC

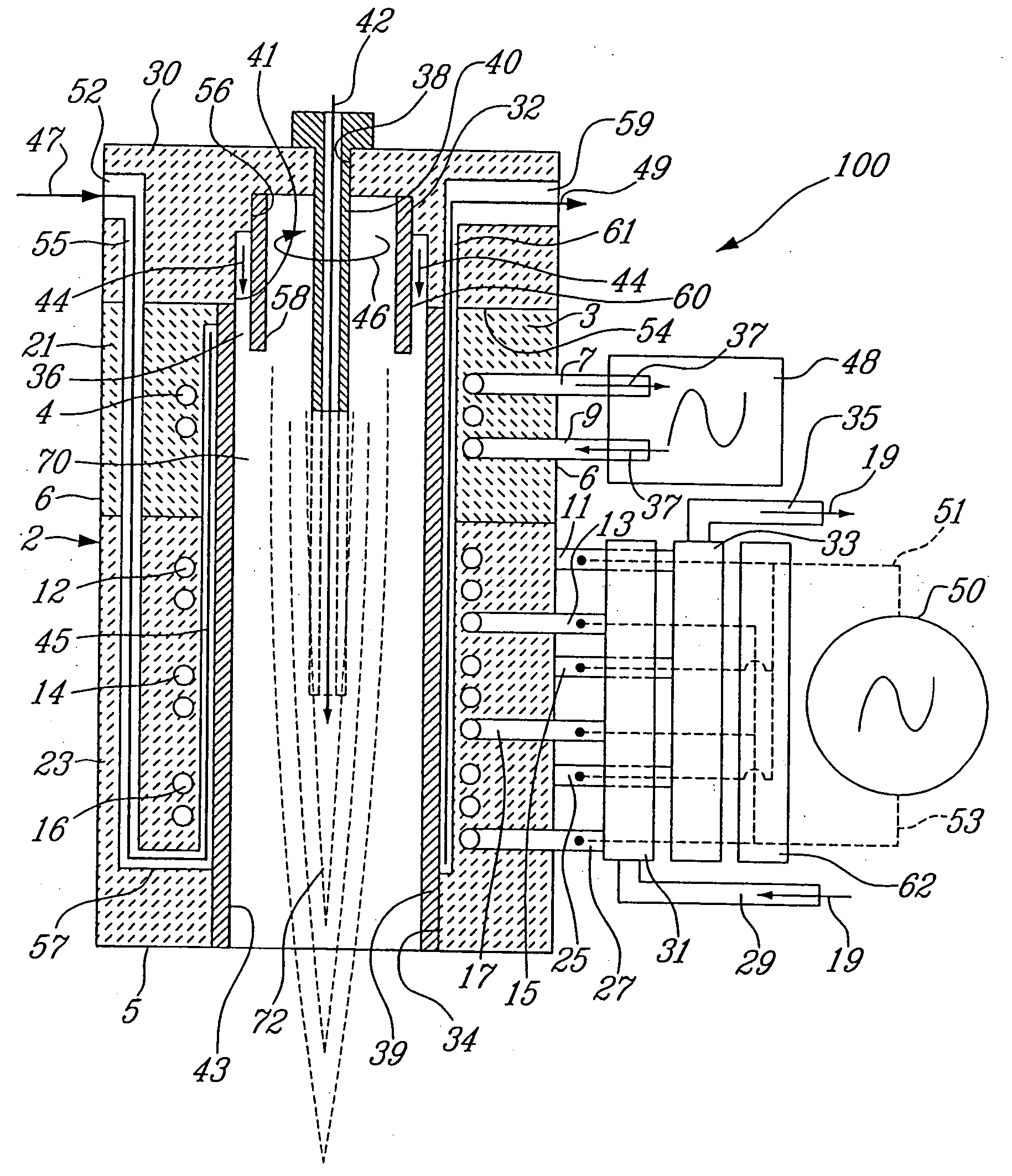

Multi-coil induction plasma torch for solid state power supply

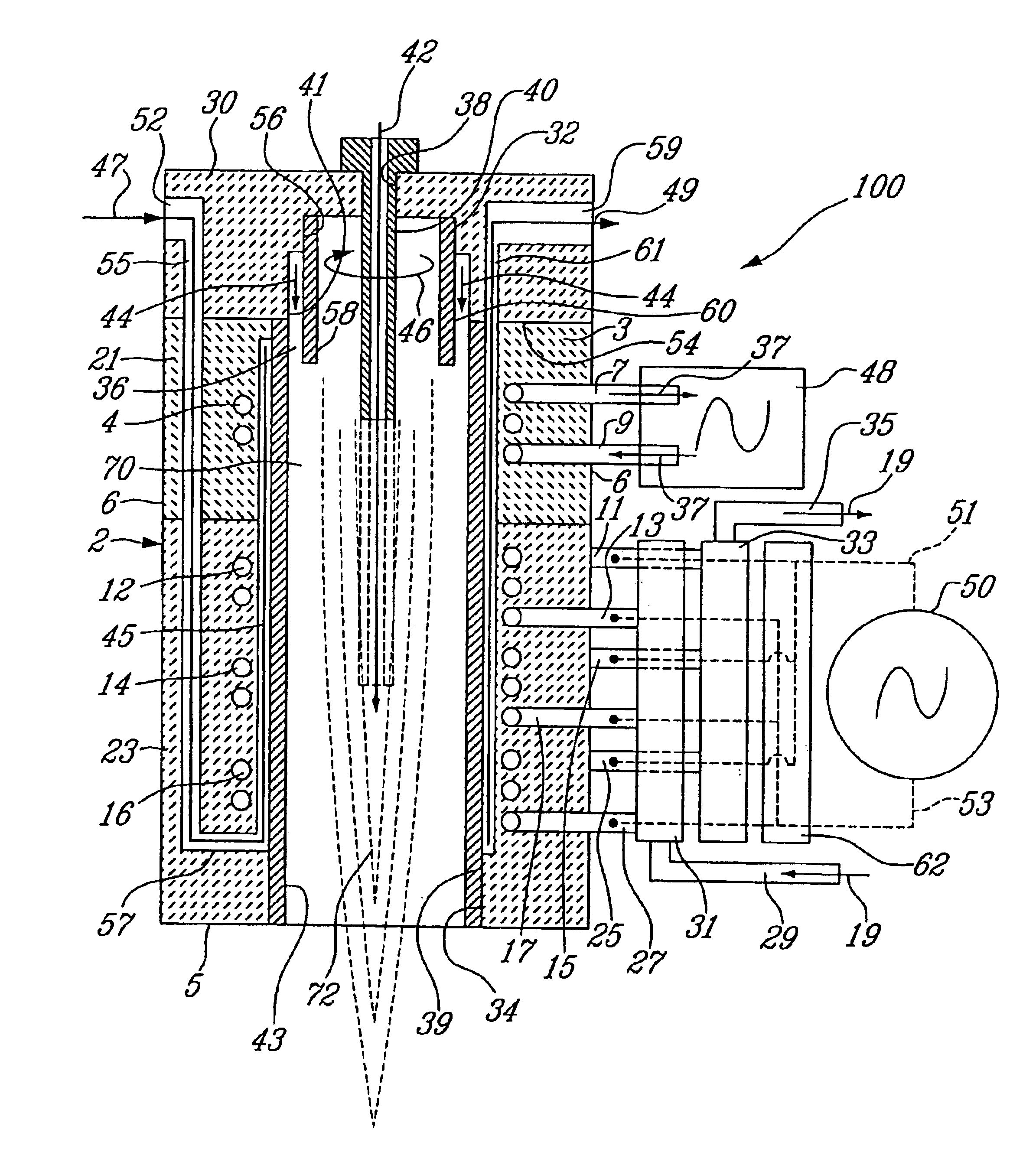

InactiveUS20050017646A1Efficiently transfer heatImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

An induction plasma torch comprises a tubular torch body, a gas distributor head located at the proximal end of the torch body for supplying at least one gaseous substance into the chamber within the torch body, a higher frequency power supply connected to a first induction coil mounted coaxial to the tubular torch body, a lower frequency solid state power supply connected to a plurality of second induction coils mounted coaxial to the tubular torch body between the first induction coil and the distal end of this torch body. The first induction coil provides the inductive energy necessary to ignite the gaseous substance to form a plasma. The second induction coils provide the working energy necessary to operate the plasma torch. The second induction coils can be connected to the solid state power supply in series and / or in parallel to match the impedance of this solid state power supply.

Owner:TEKNA PLASMA SYST INC

Amorphous polyaryletherketone and blends thereof for use in additive manufacturing

ActiveUS20170096576A1High melt flowHigh viscosityAdditive manufacturing apparatusAdditive manufacturing with liquidsFused filament fabricationAdditive layer manufacturing

A material for use in a fused filament fabrication (FFF) printer comprises a polyaryletherketone (PAEK) having an amorphous morphology. In some embodiments, the material also includes a PAEK having a semi-crystalline morphology.

Owner:AREVO INC

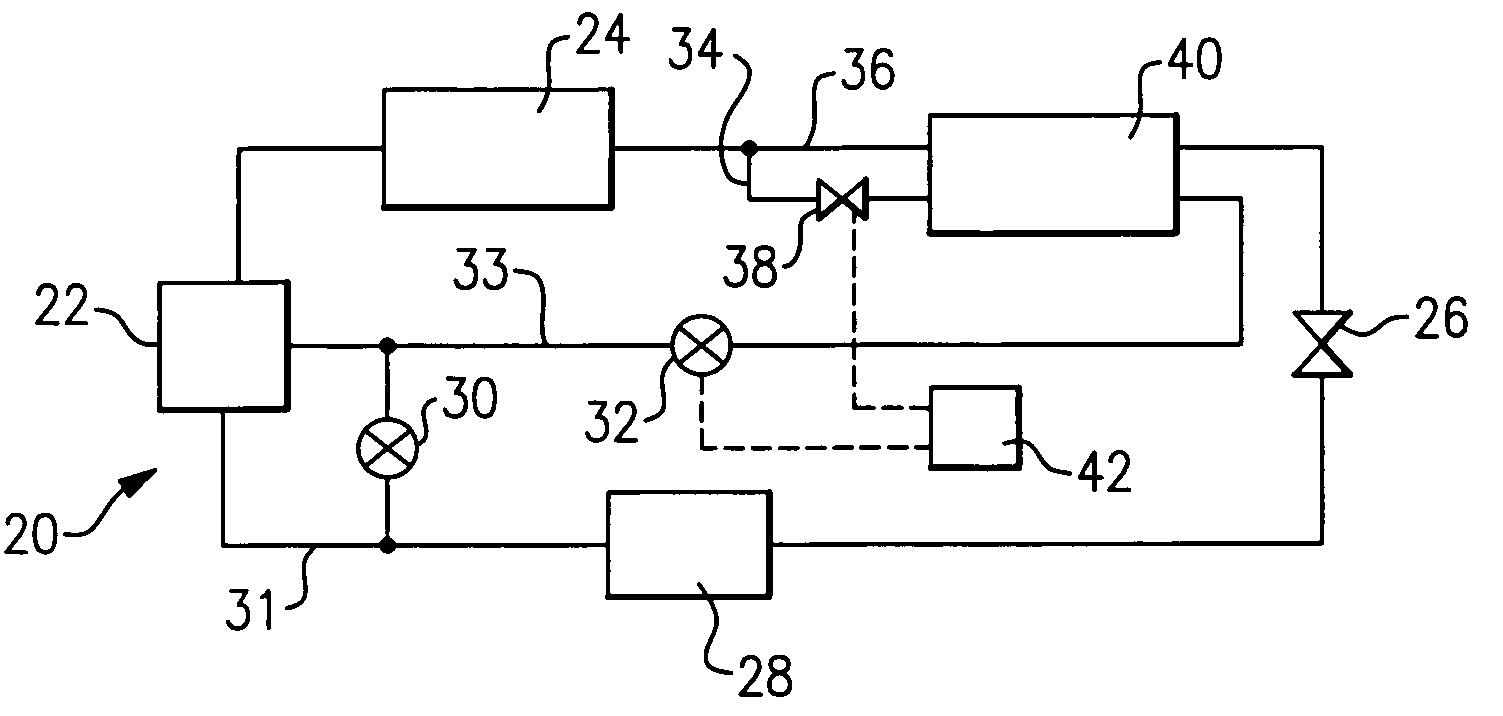

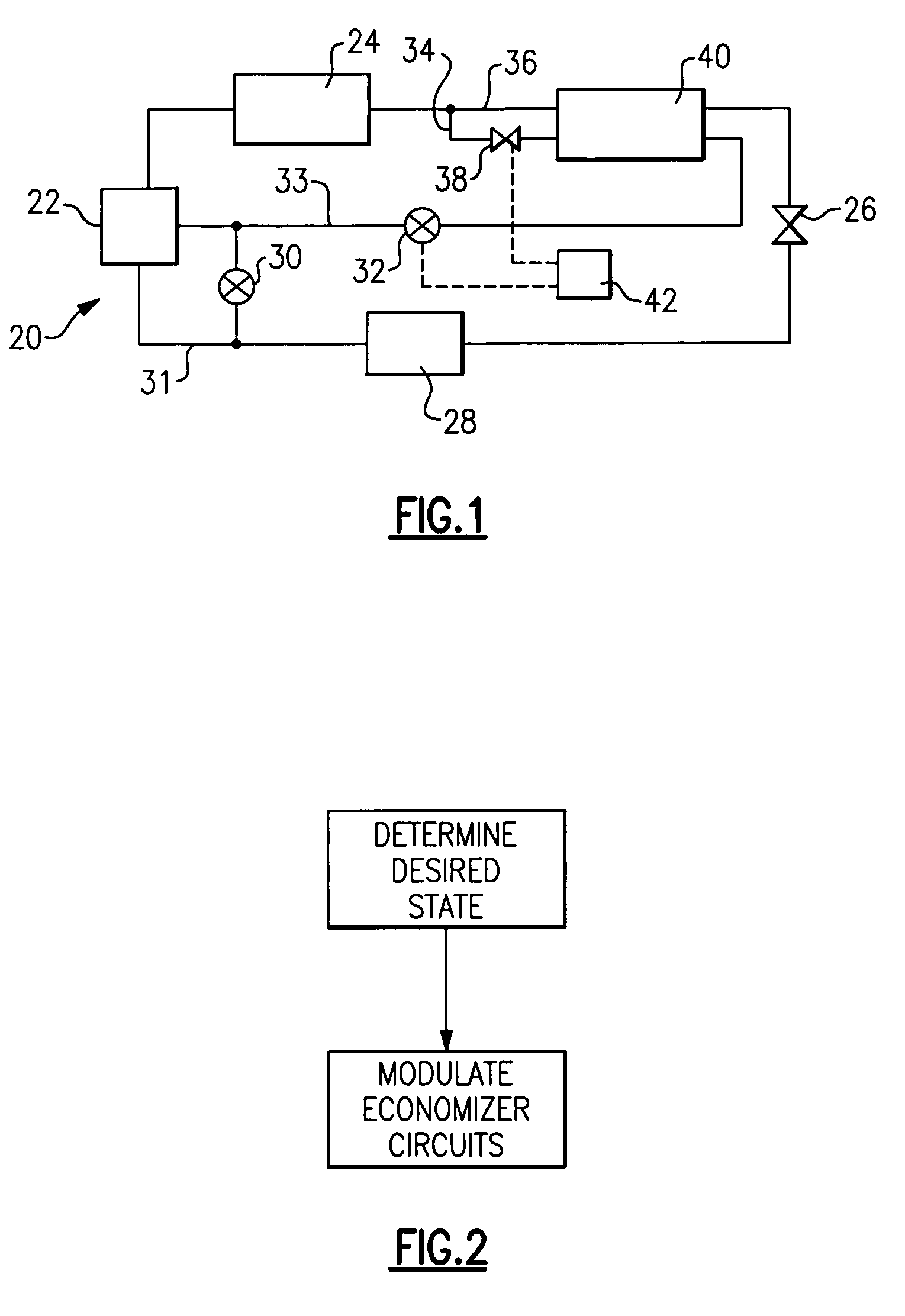

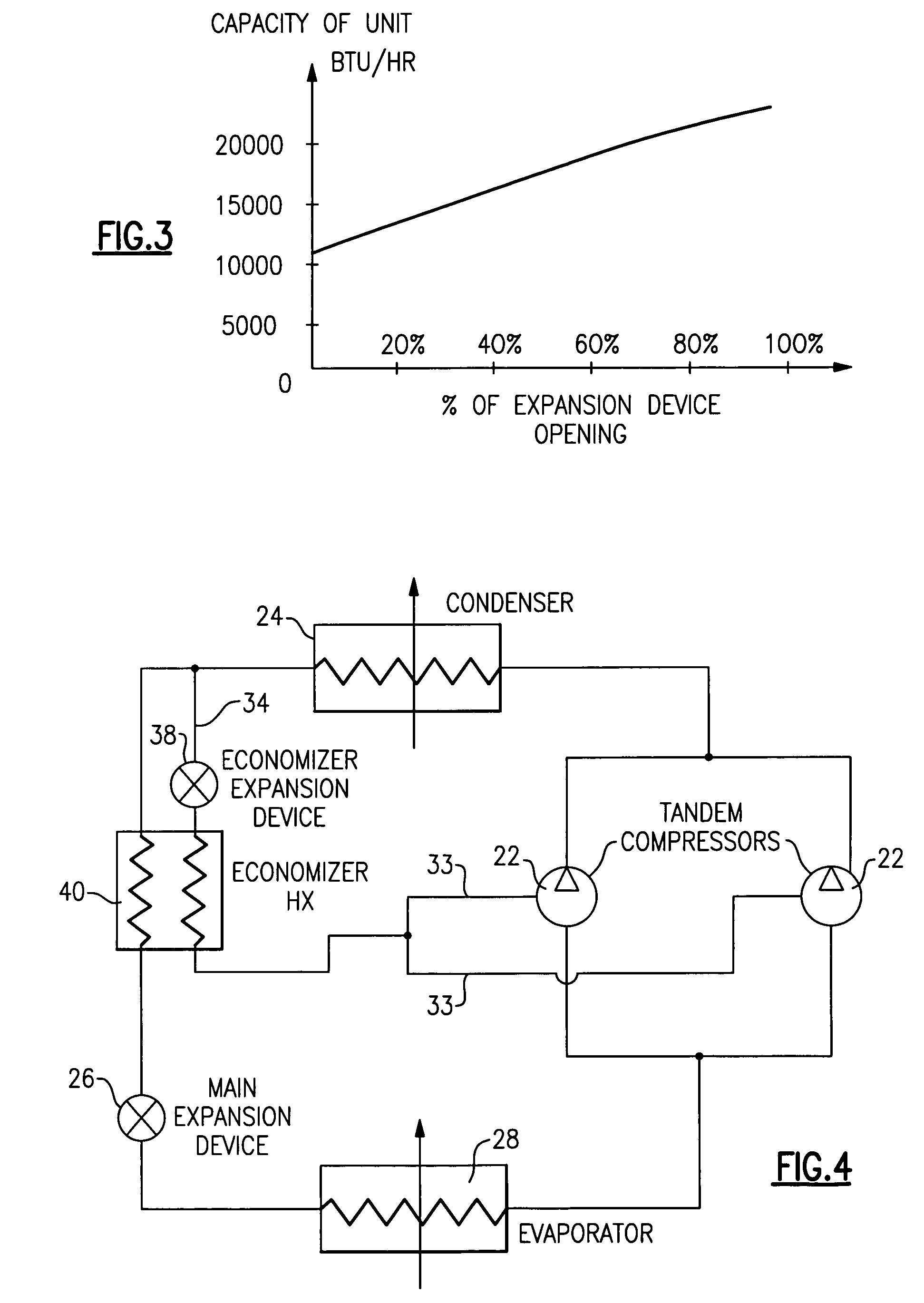

Control scheme for multiple operating parameters in economized refrigerant system

InactiveUS20050235689A1Reduce the amount requiredReduced mass flowFluid circulation arrangementRefrigeration safety arrangementTemperature controlControl theory

A refrigerant cycle is provided with an economizer circuit. The amount of refrigerant passing through the economizer circuit can be gradually modulated by an expansion device whose position can be easily adjusted from fully open to fully closed or disengaged. In the past, economizer circuits have either been fully engaged or fully disengaged. Modulation of economizer flow allows for variable capacity operation. This improves unit operating efficiency, minimizes unit cycling and prevents compressor overloading at extreme of operating conditions. It also allows for head pressure and discharge temperature control.

Owner:CARRIER CORP

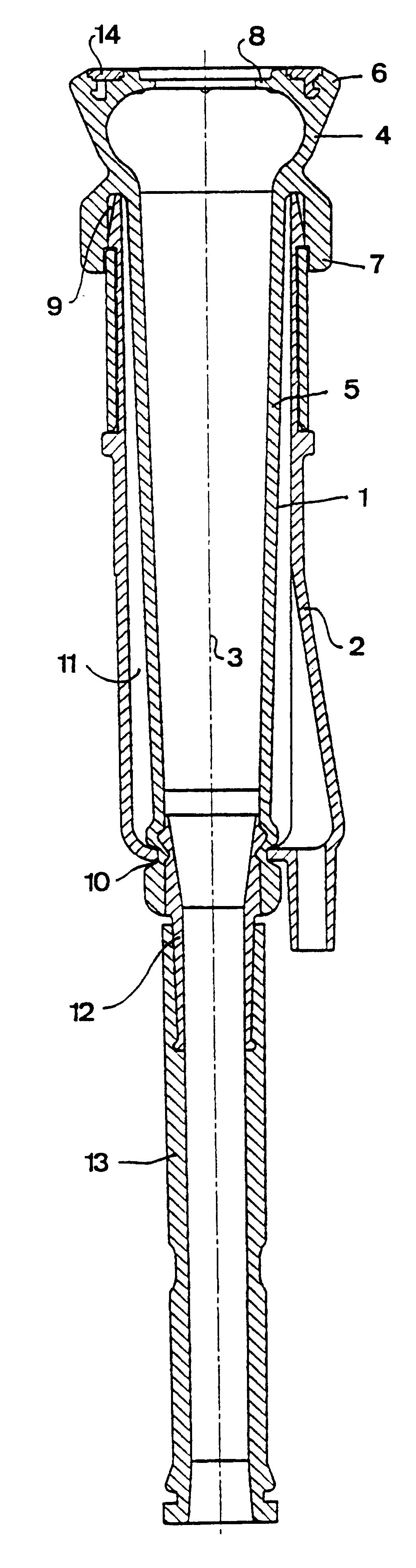

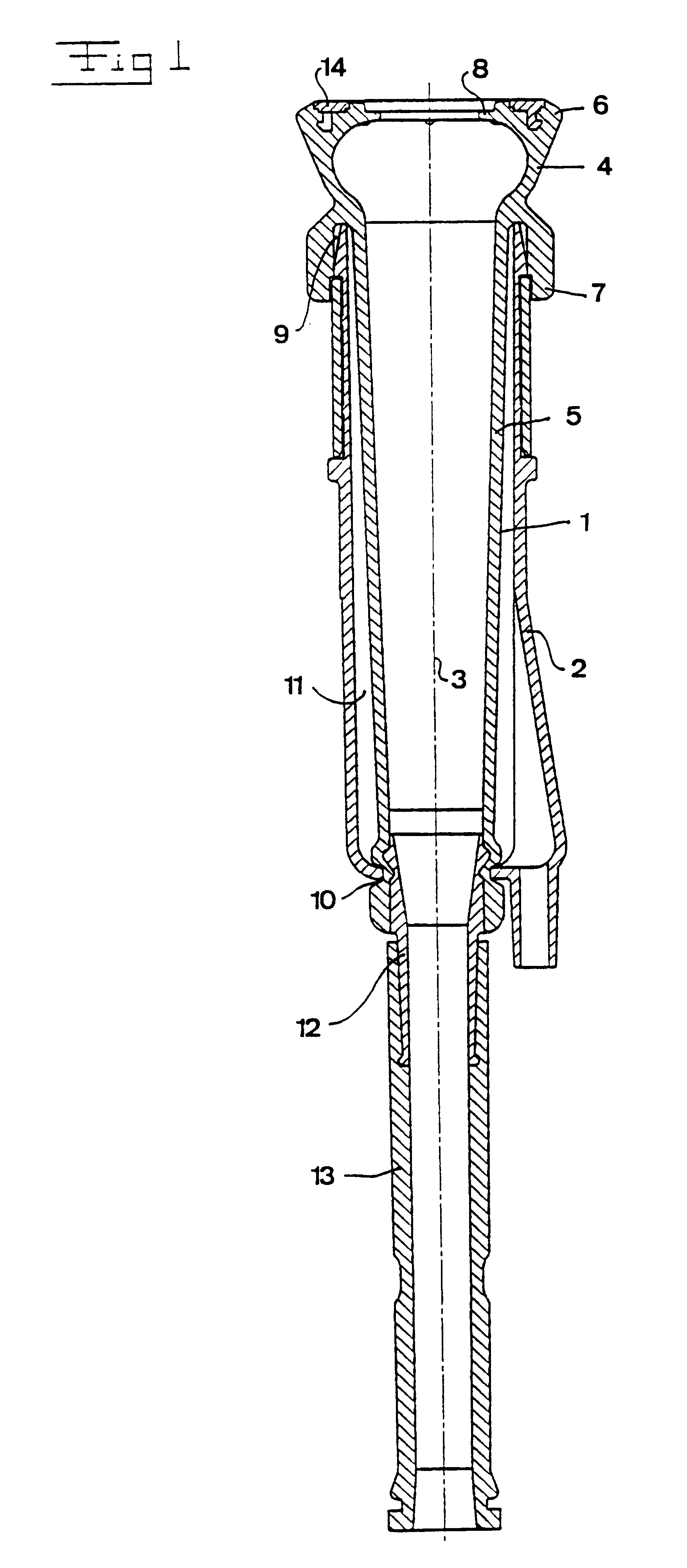

Teatcup liner and a method of manufacturing a teatcup liner

Owner:DELAVAL HLDG AB

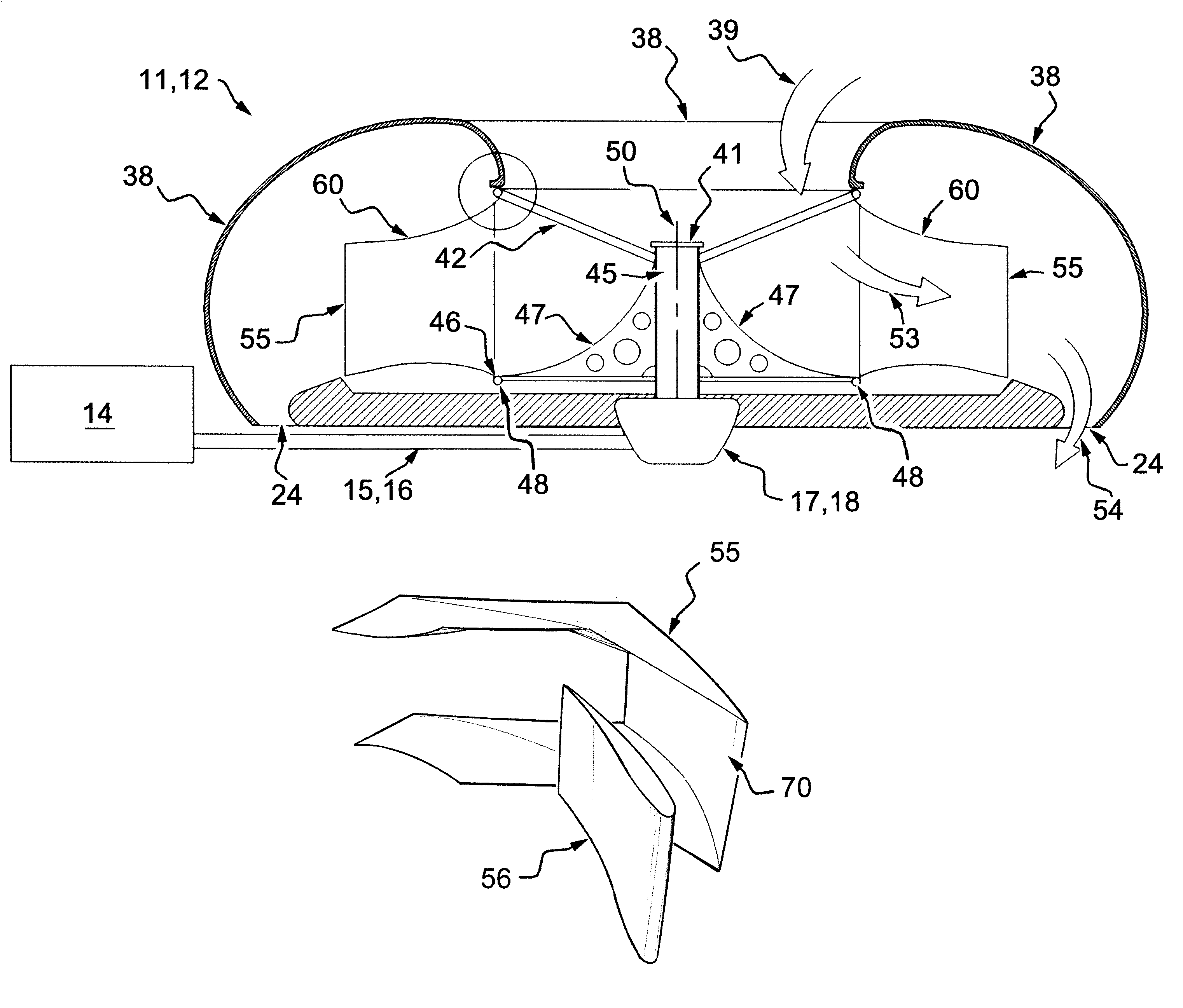

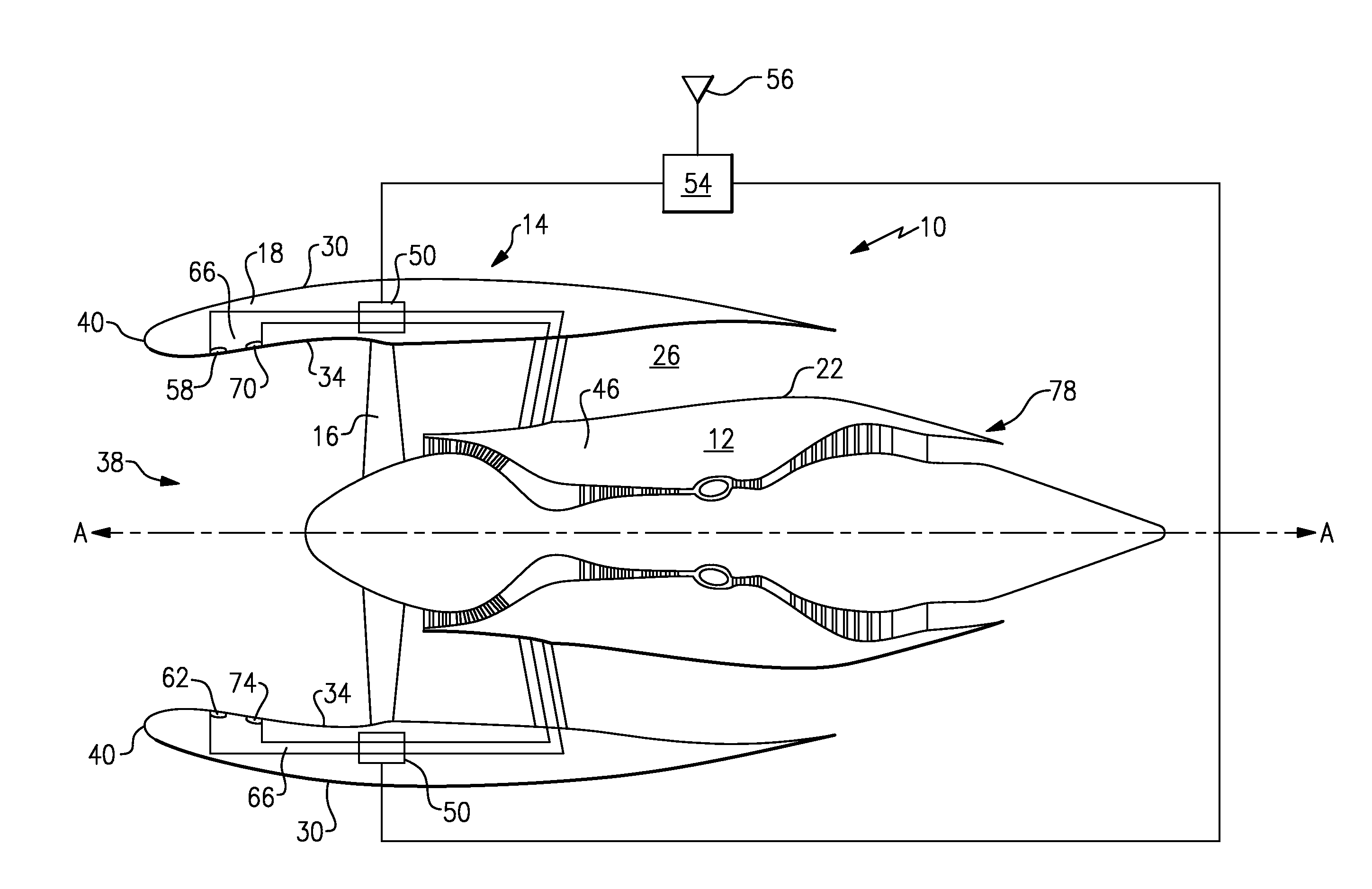

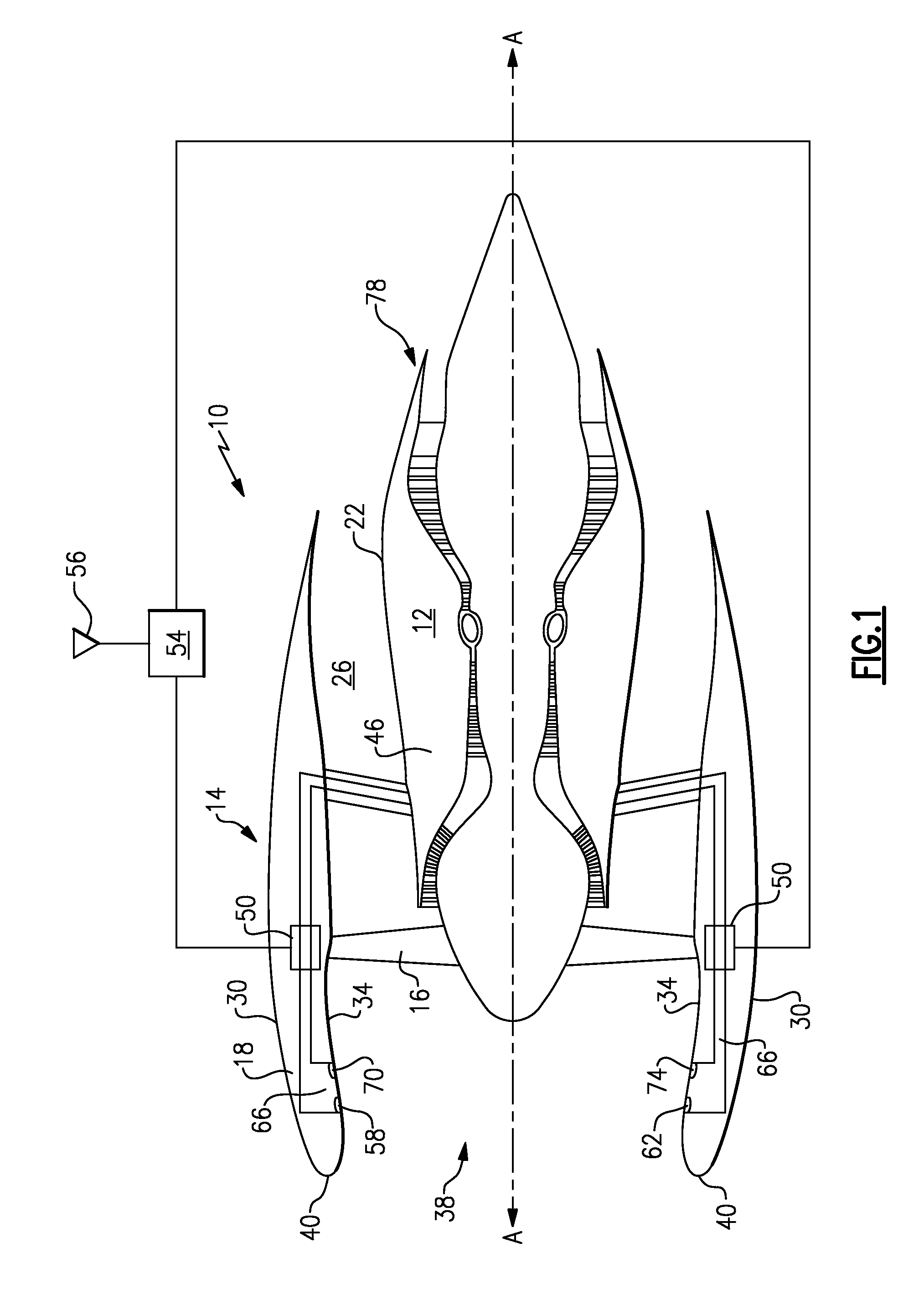

Aircraft vehicle centrifugal fan apparatus

InactiveUS8596570B1Increase volumeSuperior low-noise operationAircraft navigation controlPropellersFlight vehicleTail rotor

An aircraft provides hovercraft power via fabric fans that produce lift for supporting the craft above an underlying support surface. Fabric fans are specially configured for maximum efficiency. In one embodiment, a helicopter utilizes the fan as part of a tail rotor assembly.

Owner:CARAMBAT DAVID

Low pressure drop, multi-slit virtual impactor

InactiveUS6402817B1Increase fluid flowLower overall pressure dropWithdrawing sample devicesDispersed particle separationParticle flowEngineering

Fluid flow is directed into a multiplicity of slit nozzles positioned so that the fluid flow is directed into a gap between the nozzles and (a) a number of receiving chambers and (b) a number of exhaust chambers. The nozzles and chambers are select so that the fluid flow will be separated into a first particle flow component with larger and a second particle flow component with the smaller particles.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

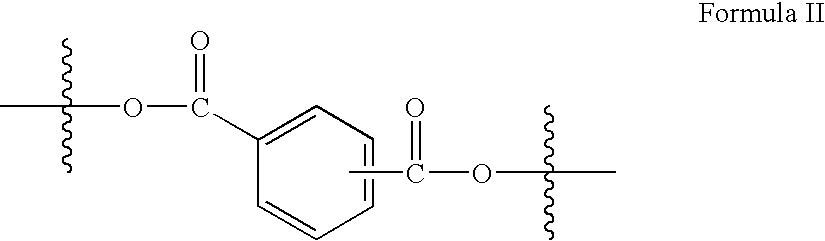

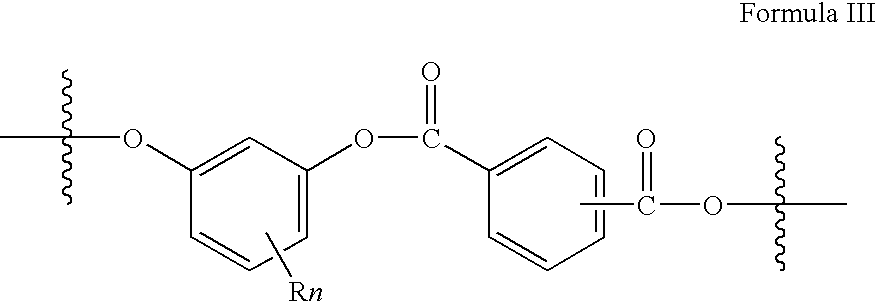

Release agent for transparent polymide blends

Compositions made from a polyarylate or polyester carbonate containing greater than about 50 mole % resorcinol based ester linkages give miscible blends with polyimide resins, addition of alkyl amide compounds improves mold release and melt flow while maintaining transparency. The blends also have high refractive index and low haze.

Owner:SHPP GLOBAL TECH BV

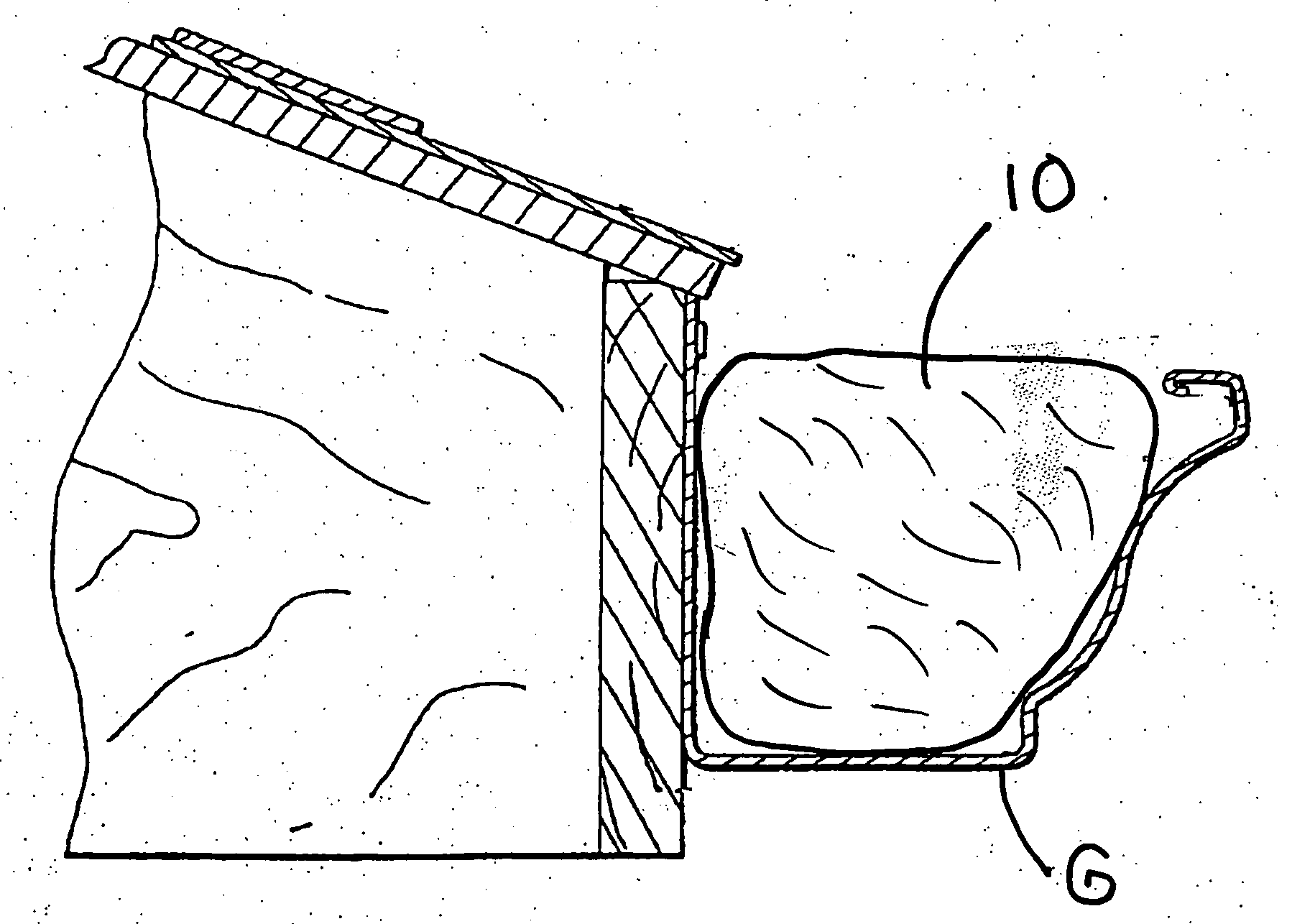

Gutter fillers and packs with enhanced fluid flow

A filler or pack material composed of homocomponent or multi-component fibers comprising various polymers with varying melting behavior. Most suitably, the filler fabric's volume fraction is between 10% and 70%. The filler can be cut, shaped, molded and fitted into the gutter. Additionally, single component or multi-component fibers can also be used together with other solids such as foam to form filler.

Owner:UNIV NORTH CAROLINA STATE

Nacelle assembly having inlet bleed

Owner:RTX CORP

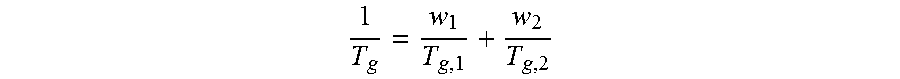

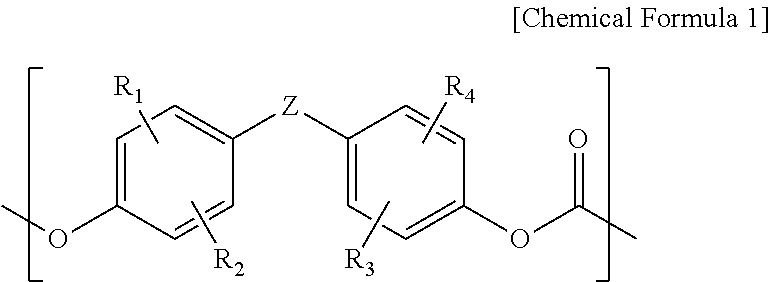

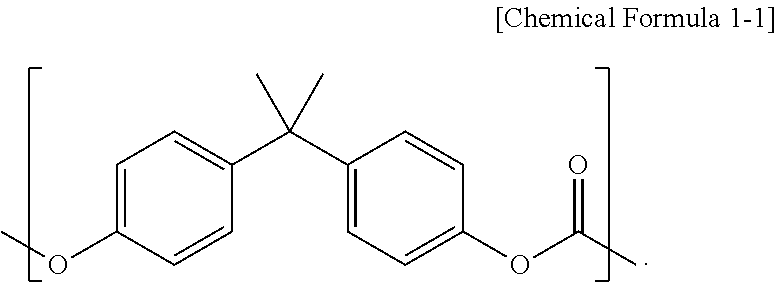

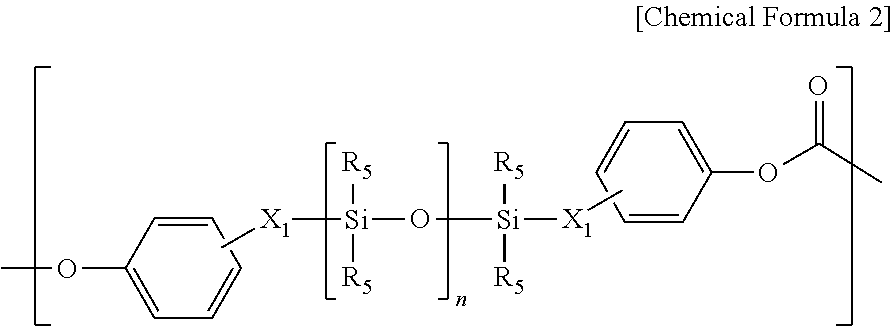

Copolycarbonate and composition containing the same

The present invention relates to a copolycarbonate and a composition comprising the same. The copolycarbonate according to the present invention has a structure in which a specific siloxane compound is introduced in a main chain of the polycarbonate, and thus exhibits an excellent transparency and a high spiral flow while having a high impact strength at room temperature and a low melt index.

Owner:LG CHEM LTD

High-cleaning silica materials made via product morphology control under high shear conditions

InactiveUS20070224133A1Desirable abrasiveIncrease brightnessCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

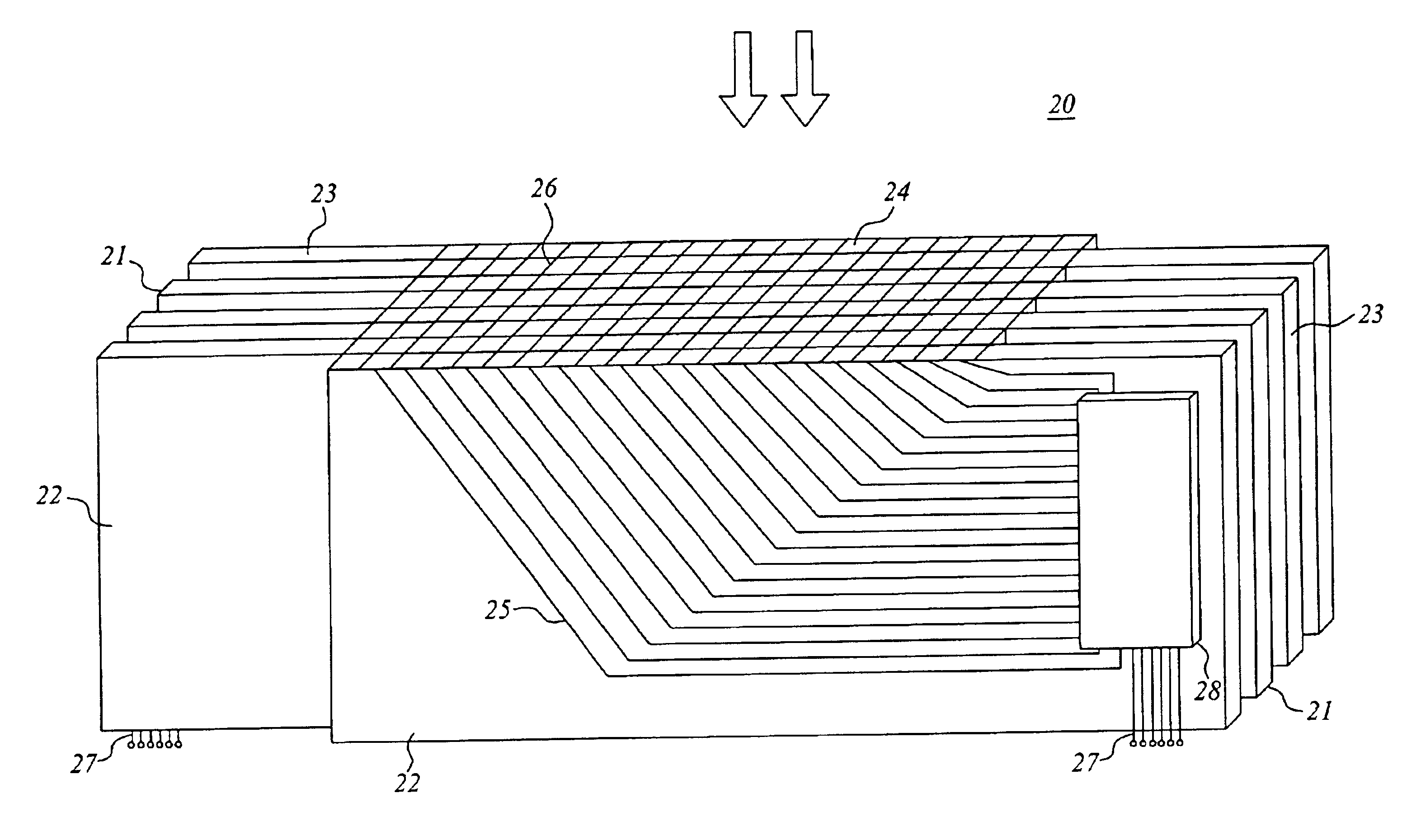

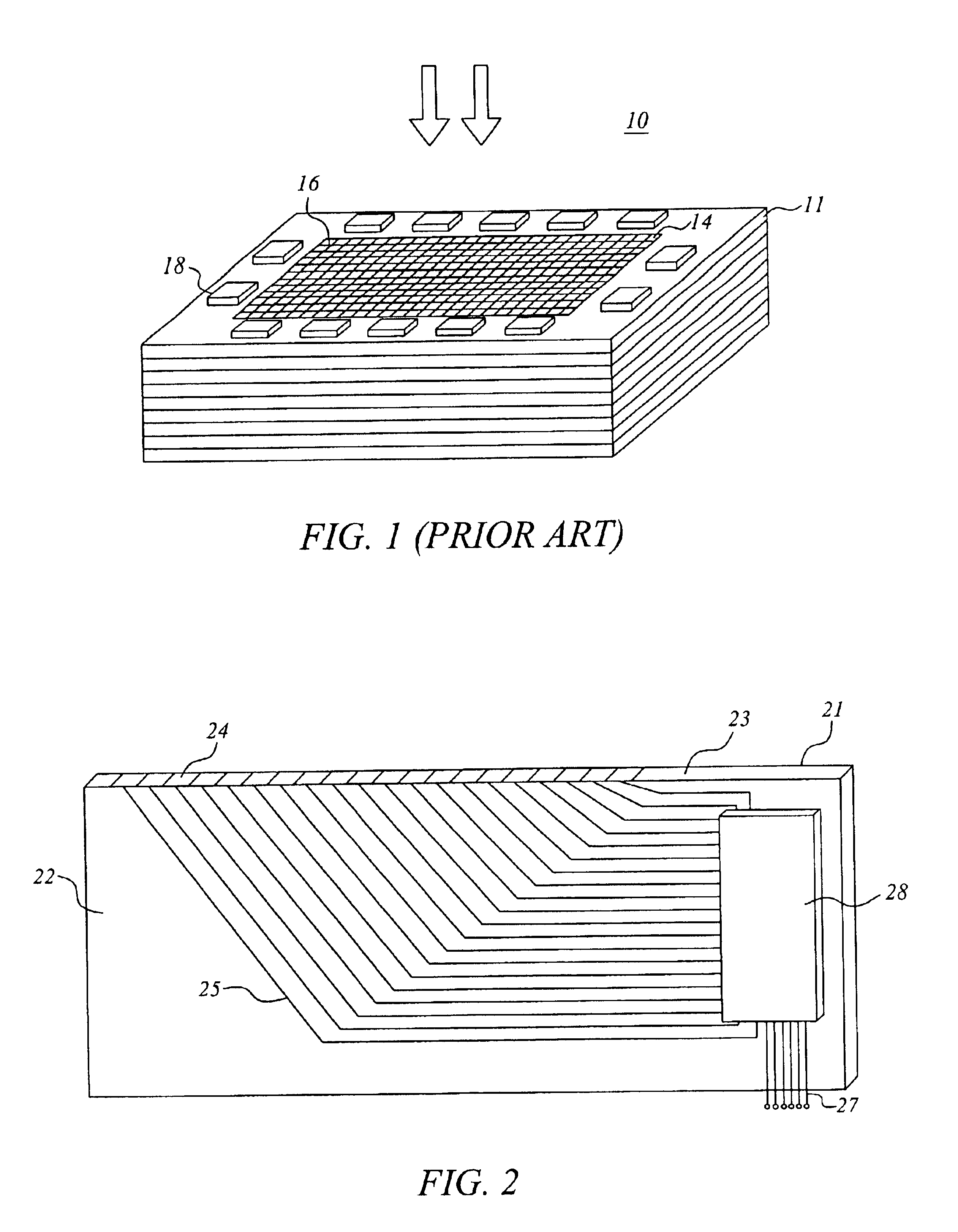

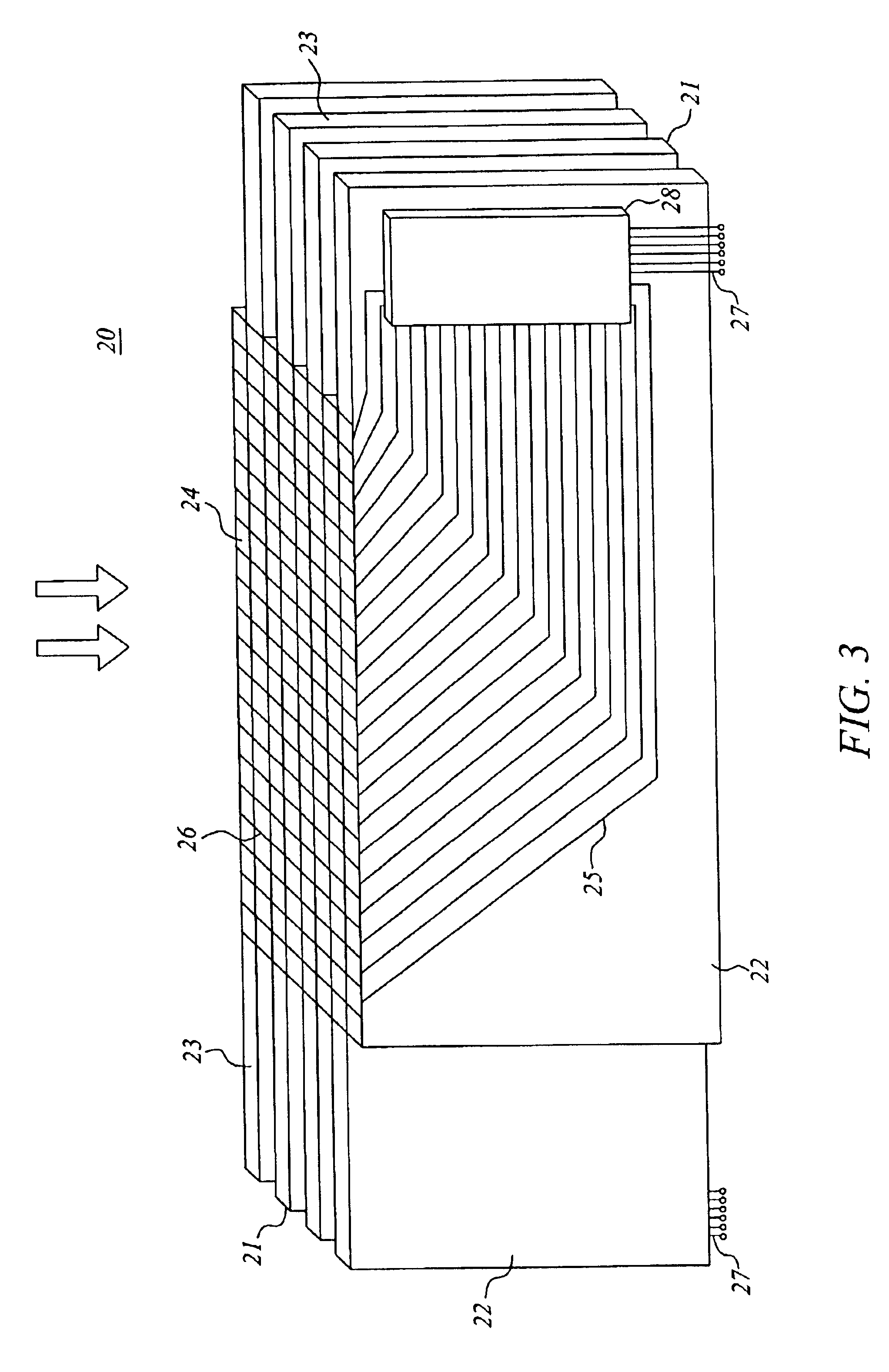

Radiation sensor device

InactiveUS6841784B2Improve imaging resolutionSimple and comparatively inexpensive to manufactureSolid-state devicesMaterial analysis by optical meansAudio power amplifierImage resolution

A radiation sensor device (20) for detection of radiation. A sensor device with an array of radiation sensitive elements (24) forming a sensor surface (26) is provided. The device comprises a number of circuit boards (21), each with a row of radiation sensitive elements, such as X-ray sensitive charge collectors, provided at the edge portion. The radiation sensitive elements are each connected to signal processing means (28), e.g. ASICs with amplifiers, outside the radiation field by a respective connection line (25) arranged on a main surface (22) of the circuit board. A number of circuit boards are arranged adjacent to each other with the main planes substantially perpendicular to the sensor surface. By using the circuit card depth the invention easily provides surfaces with a very large number of individually connected radiation sensitive elements, resulting in improved image resolution.

Owner:C RAD IMAGING AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com