Gutter fillers and packs with enhanced fluid flow

a technology of fluid flow and gutter filler, which is applied in the direction of roof covering, roof construction, roofs, etc., can solve the problems of gutters still being exposed to debris, wire meshes deformation, and debris entering gutters, etc., and achieves the highest flow rate, high porosity, and high flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

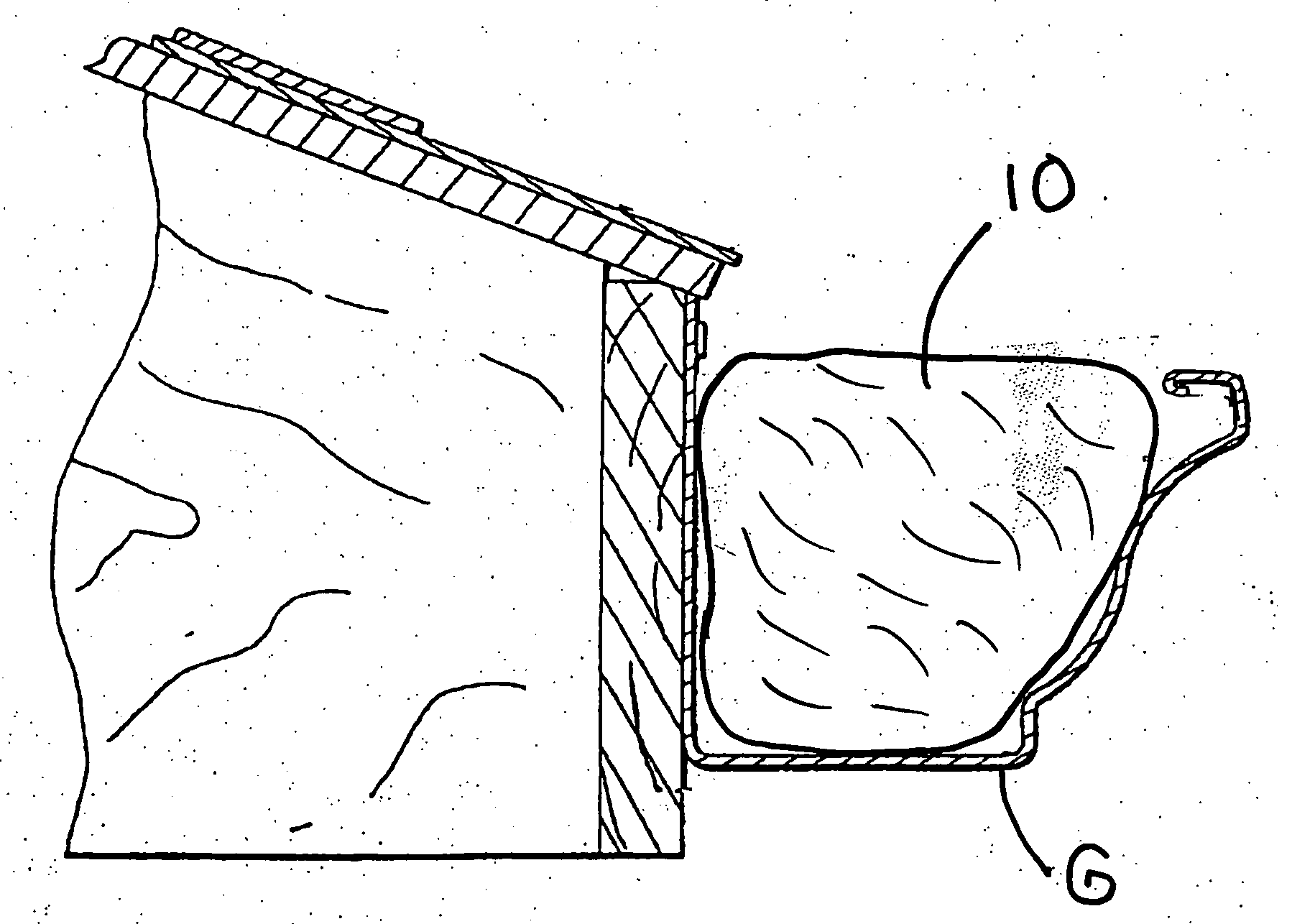

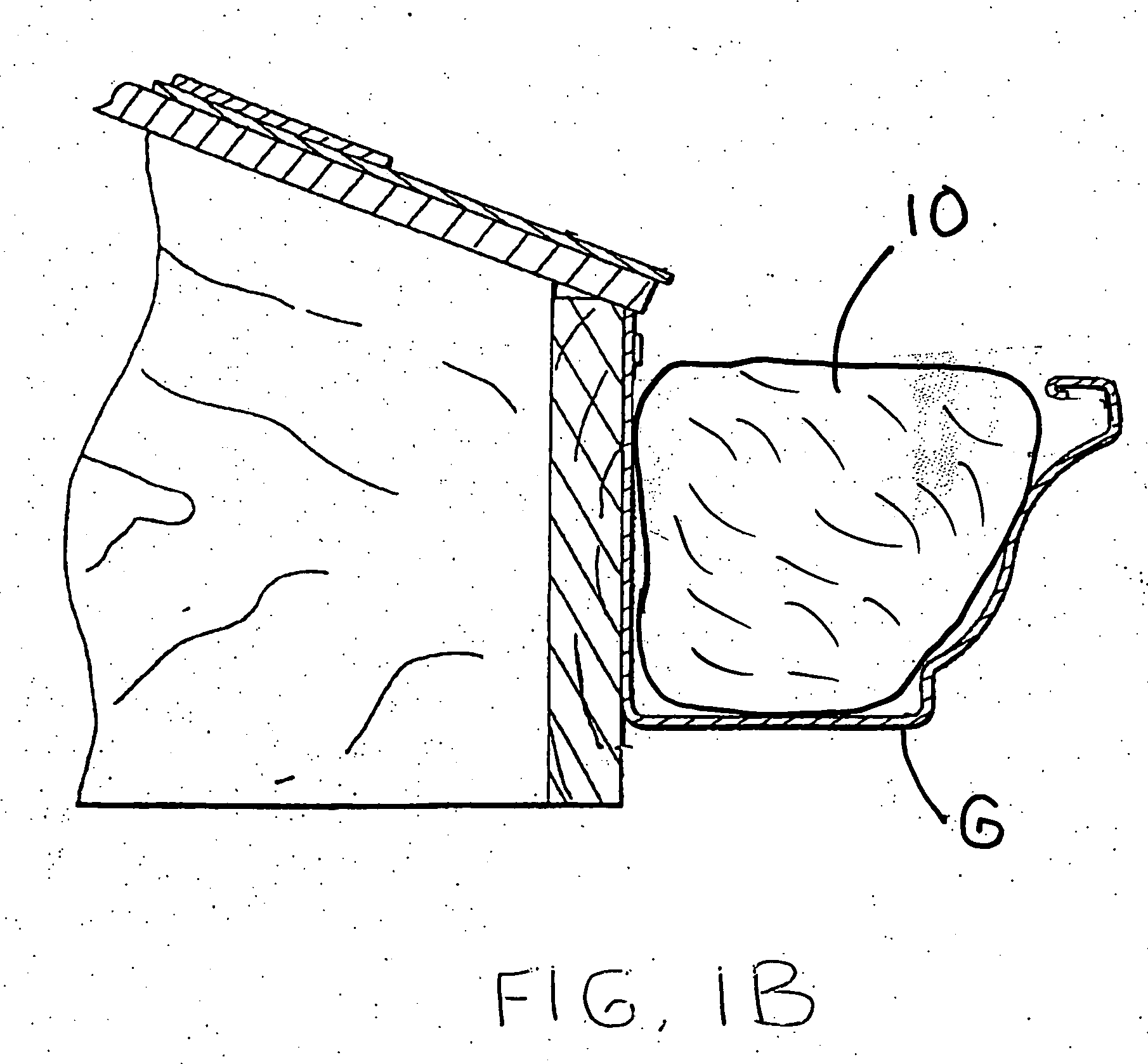

One embodiment of the subject filler material described herein is a high loft and low density (<10%-70% volume fraction) structure that can be easily cut or molded into the right shape to pack a gutter. FIG. 1A illustrates a preferred embodiment of such a product 10, and FIG. 1B shows product 10 packed into a gutter G in accordance with the invention.

A number of structure variables can be controlled to form the desired structure for product 10. In particular, fiber orientation distribution, fiber crimp and fiber diameter are the controlling elements. The ODF ψ is a function of the angle θ. The integral of the function ψ from an angle θ1 to θ2 is equal to the probability that a fiber will have an orientation between the angles θ1 to θ2. The function ψ must additionally satisfy the following conditions: ψ(θ+π)=ψ(θ)∫0πψ(θ)ⅆθ=1

To describe the alignment of the fibers, one uses a ratio known as the Anisotropy Ratio, fp defined as: fp=2〈cos2θ〉-1〈cos2θ〉=∫0πψ(θ)cos2(θr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com