Elastomeric dispensing pump that can be made with as few as two components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

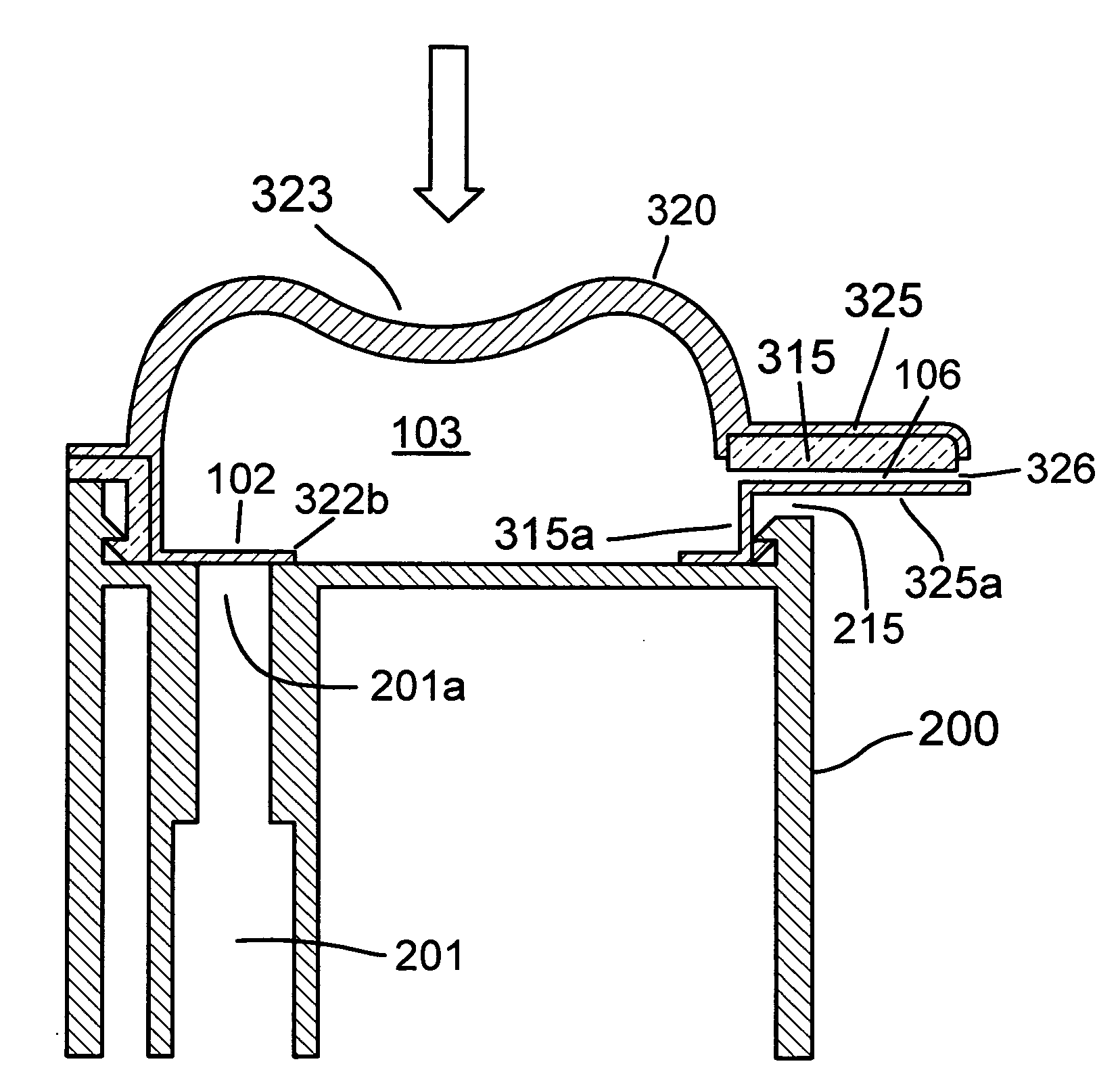

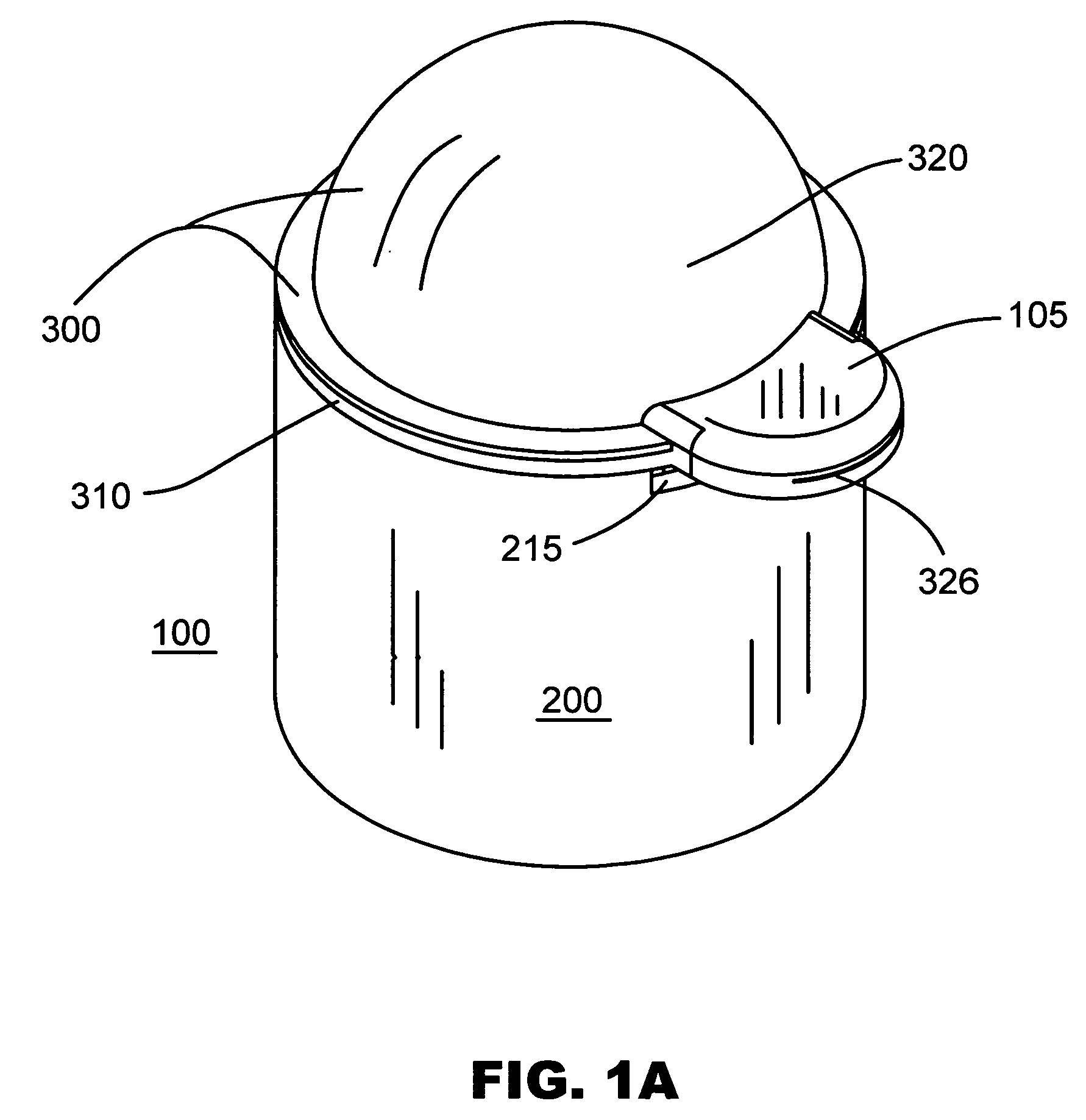

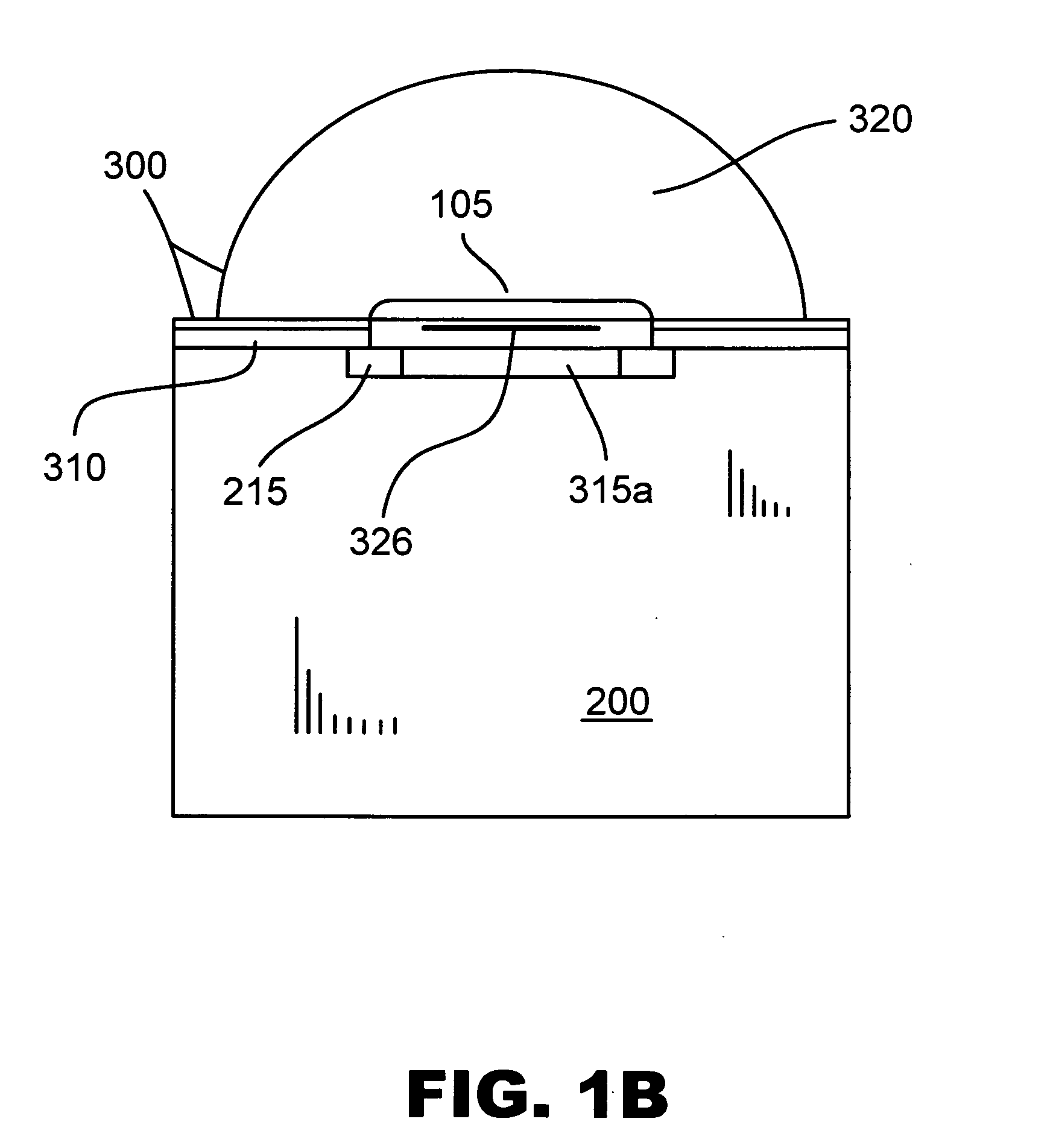

[0066]The present invention relates to a fluid dispensing pump that can be fabricated with as little as two easily assembled separate parts: a pump base part and an integral pump top part that is securely attached to the pump base in a fluid-tight manner, the pump top part having a rigid core and a self-restoring resilient layer. The two parts of the pump top can be made by multi-material molding in the same mold or over-molding whereas the core is made first and then placed in a mold again to over-mold the elastomeric layer.

[0067]The rigid core and the elastomeric layer may be joined through: 1) a mechanical binding such as groves, asperities, holes or other surface means 2) a chemical bind such as interface solidification of melted portions of the two materials. 3) or they may just overlay in a weak binding. Some embodiments of the present invention do not require a particularly strong binding because the elastomeric layer is self-sealing; however, embodiments that have rotating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com