High-stability direct methanol fuel cell membrane electrode based on CNT material

A methanol fuel cell, high-stability technology, used in fuel cells, battery electrodes, fuel cell components, etc., can solve problems such as hindering oxygen transmission, limiting battery energy density and service life, and reducing catalyst utilization. Solve the effect of cathode flooding, improve long-term discharge stability, and improve drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

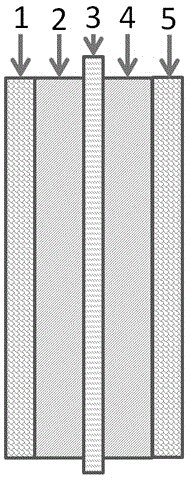

[0014] Specific implementation mode one: as figure 1 As shown, the direct methanol fuel cell membrane electrode of this embodiment is composed of an anode diffusion electrode (anode diffusion layer 1, anode catalyst layer 2), a proton exchange membrane 3, and a cathode diffusion electrode (cathode catalyst layer 4, cathode diffusion layer 5), The left side of the proton exchange membrane 3 is the anode catalyst layer 2 and the anode diffusion layer 1 in sequence; the right side of the proton exchange membrane 3 is the cathode catalyst layer 4 and the cathode diffusion layer 5 in sequence. The anode diffusion electrode is a commercial anode diffusion electrode, and the cathode diffusion layer 5 is made of CNT (carbon nanotube) material, and the above two stages are also used as mass transfer barrier layers for methanol aqueous solution (anode) and liquid water (cathode) respectively.

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment provides a method for preparing a direct methanol fuel cell membrane electrode, the steps of which are as follows:

[0016] (1) Preparation of cathode catalyst layer slurry:

[0017] Weigh 30~50mg of Pt / C (a mixture of Pt and C, wherein the content of Pt is 40wt.%) catalyst, add 0.1~0.5mL deionized water to mix, shake with an ultrasonic oscillator for 5~10 minutes, until the catalyst is Fully submerged. Then add 0.15-0.3ml of Nafion solution with a concentration of 5wt.% and 0.7-1.5mL of isopropanol, then vibrate with an ultrasonic oscillator and fully stir with a magnetic stirrer for 1-2 hours to prepare a cathode catalyst slurry.

[0018] (2) Preparation of cathode diffusion electrode:

[0019] Rinse the CNT material paper with ultrapure water ultrasonically, dry it at room temperature, and make a cathode diffusion layer; cut about 2cm×2cm cathode diffusion layer CNT material paper, fix it and evenly brush about 12~40mg of cathode c...

specific Embodiment approach 3

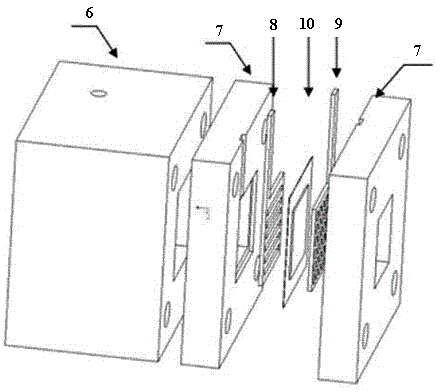

[0023] Specific implementation mode three: as figure 2 As shown, first, the new membrane electrode 10 is clamped and fixed by the anode current collector plate 8 and the cathode current collector plate 9 . Then use two plexiglass end plates 7 with rectangular openings in the middle to fix the anode current collector 8, the new membrane electrode 10 and the cathode current collector 9 together, and finally connect the liquid storage chamber 6 to the anode The side plexiglass end plates 7 are connected together.

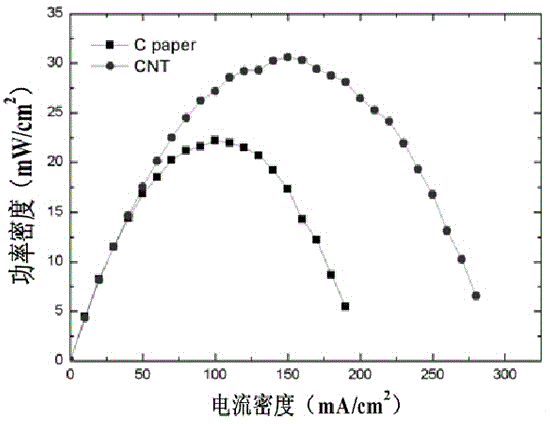

[0024] After the packaging is completed, the battery is activated and preliminary tests show that the direct methanol fuel cell with the new membrane electrode has higher performance and long-term working stability than the battery using the traditional membrane electrode, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com