Horizontal drainage plate-vacuum preloading combined electroosmosis system and sludge treatment method thereof

A technology of horizontal drainage boards and drainage boards, which is applied in soil protection, construction, and infrastructure engineering, etc., and can solve the problems of easy bending of drainage boards, poor reinforcement effect, and inability to discharge polar water molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

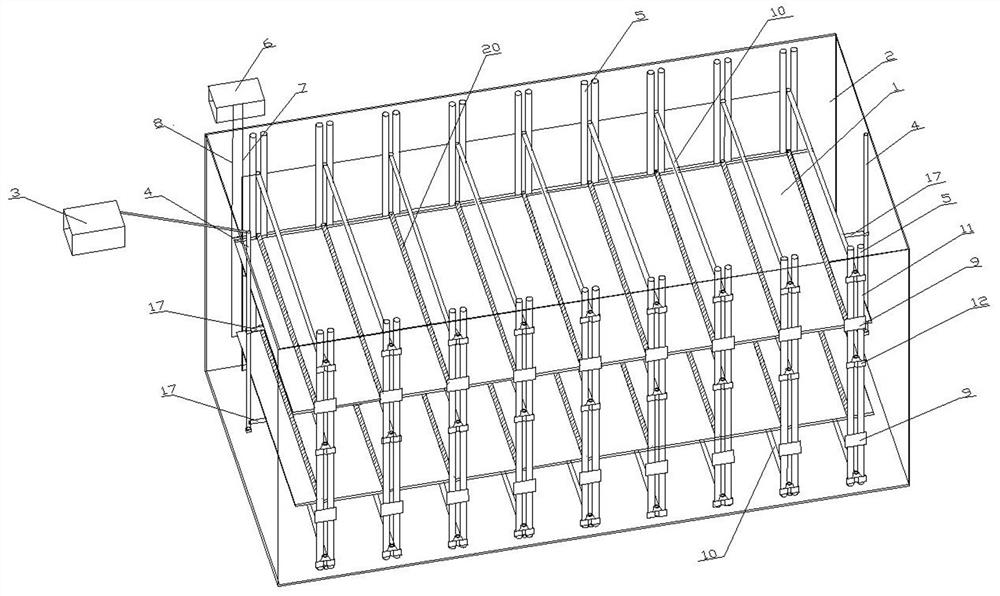

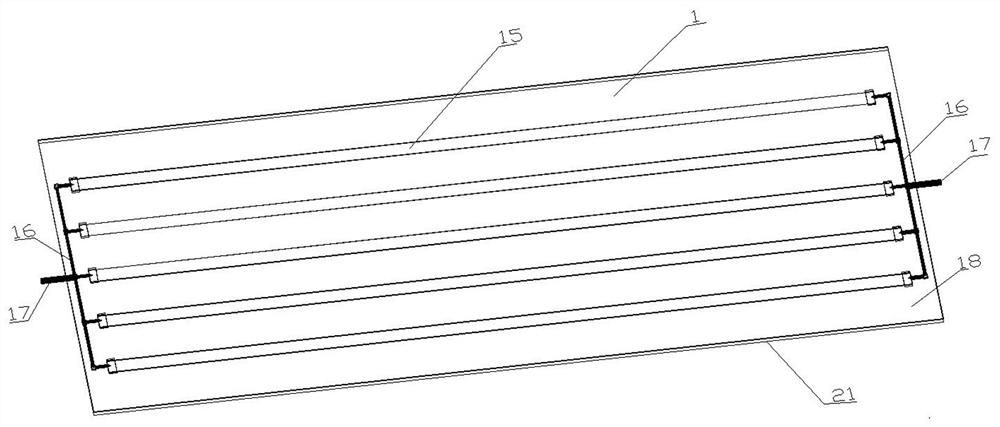

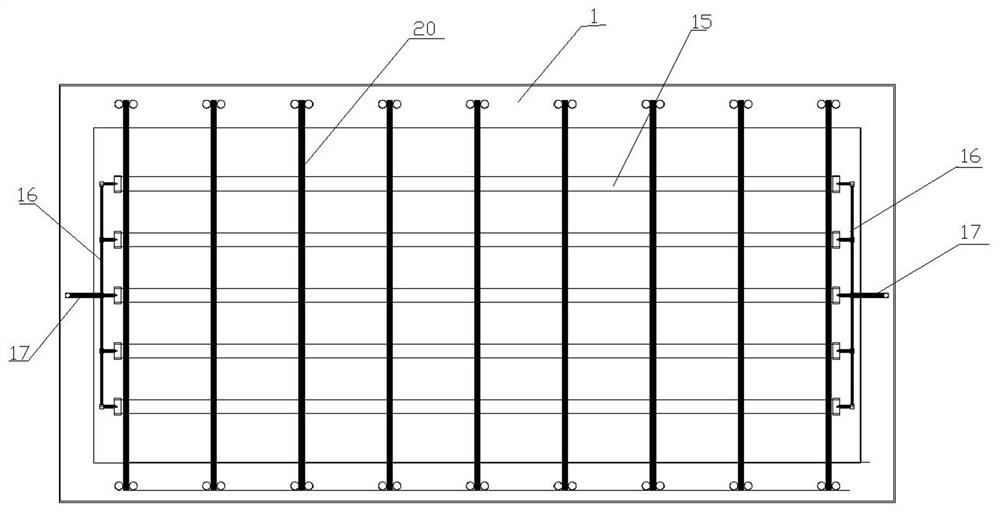

[0021] refer to Figure 1-Figure 5 As shown, a horizontal drainage board-vacuum preloading combined electroosmosis system provided by Embodiment 1 of the present invention includes a horizontal drainage board system 1, an electroosmotic system, and a vacuum preloading system. The vacuum preloading system includes a vacuum preloading system. Tank 2, vacuum pump 3 and vertical manifold 4 connected to the vacuum pump, the electroosmotic system includes a plurality of vertical insulation components 5, multi-layer anode reinforcement layers, wires and power supply 6, the wires include positive wire 7 and negative wire 8. The plurality of vertical insulating components are vertically distributed at the lateral edges of both sides of the vacuum preloading tank 2, and the insulating components 5 are vertically fixed at the lateral edges of the vacuum preloading tank 2 through a plurality of triangular support brackets 9 , the triangular support 9 is fixed at a certain height, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com