Rowed pile box culvert structure and construction method thereof

A construction method and technology of pile boxes, which are applied to special box culvert structures and their construction fields, can solve problems such as uneven settlement at the bottom of box culverts, unsuitability for use, and too thick soft foundation, so as to avoid uneven settlement, Avoid waste and reduce the effect of construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment discloses a pile-row box culvert structure, which is a single-hole box culvert structure.

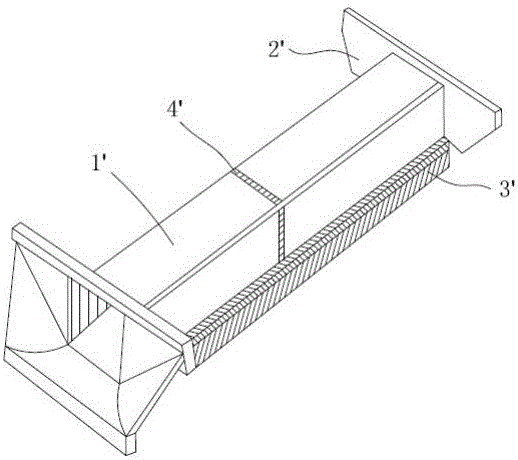

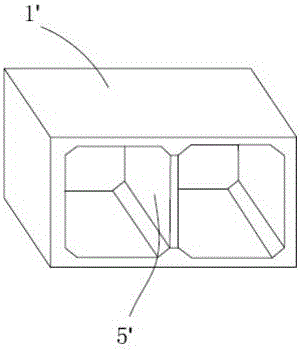

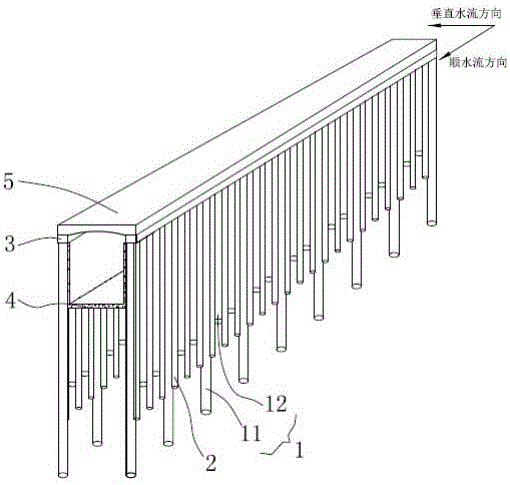

[0049] Such as Figure 3-5As shown, the single-hole box culvert structure of this embodiment includes side column row piles 1, high-pressure jet grouting piles 2, side crown beams 3, U-shaped bottom plate 4 and top plate 5. The side column row piles 1 are divided into two groups, which are arranged symmetrically on both sides, and high-pressure rotary jetting piles 2 are arranged between the two side column row piles 1 on each side to form a water-stop curtain. The side column pile 1 includes a long irrigation column pile 11 and a short irrigation column pile 12, and two short irrigation column piles 12 are arranged between the two long irrigation column piles 11, and the long irrigation column pile 11 is embedded in a moderately weathered rock formation or has a sufficient anchorage length Bearing layer plays the role of supporting the whole structure; the heigh...

Embodiment 2

[0061] This embodiment discloses a pile-row box culvert structure. The span of the box culvert is 9×8.8×9m, the clear height is 5.2m, the total length is about 81m, the thickness of the mud at the bottom of the box culvert is about 20m, and the elevation of the top plate of the box culvert is about 4.3m. The design elevation of the pavement is 8m, and the top elevation of the box culvert floor is -2.5m. According to needs, this embodiment is provided with three holes, which is a three-hole box culvert structure.

[0062] Such as Figure 9 As shown, the three-hole box culvert structure includes a row of side column piles 1, a central column 7, a high-pressure jet grouting pile 2, a side crown beam 3, a middle crown beam 6, a U-shaped bottom plate 4, and a top plate 5.

[0063] Such as Figure 11-12 As shown, the side column row piles 1 are divided into two groups, which are arranged symmetrically on both sides. High-pressure rotary spray piles 2 are arranged between the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com