Method for treating spiral oil-extruding filling pile composite foundation in stratum containing soft clay

A technology of composite foundation and treatment method, which is applied in the field of treatment of composite foundation of spiral squeezed soil grouting piles, can solve problems such as construction and structure damage, limited engineering application, engineering pile offset, etc., and achieve accelerated consolidation and pore water pressure. Dissipates, strengthens the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

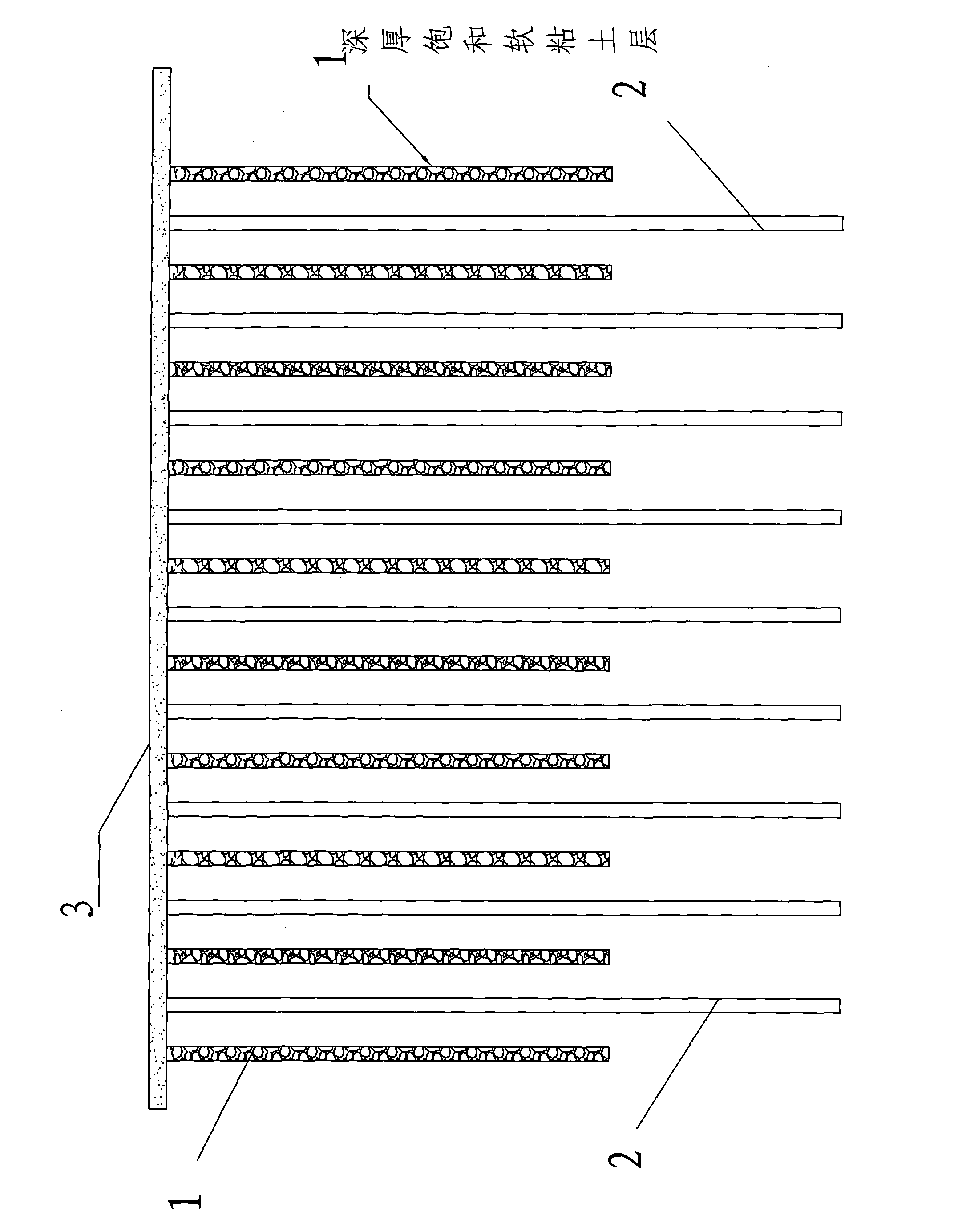

[0031] The method for treating the composite foundation of the screw-squeezed cast-in-place pile in the soft clay stratum of the present invention comprises the following steps:

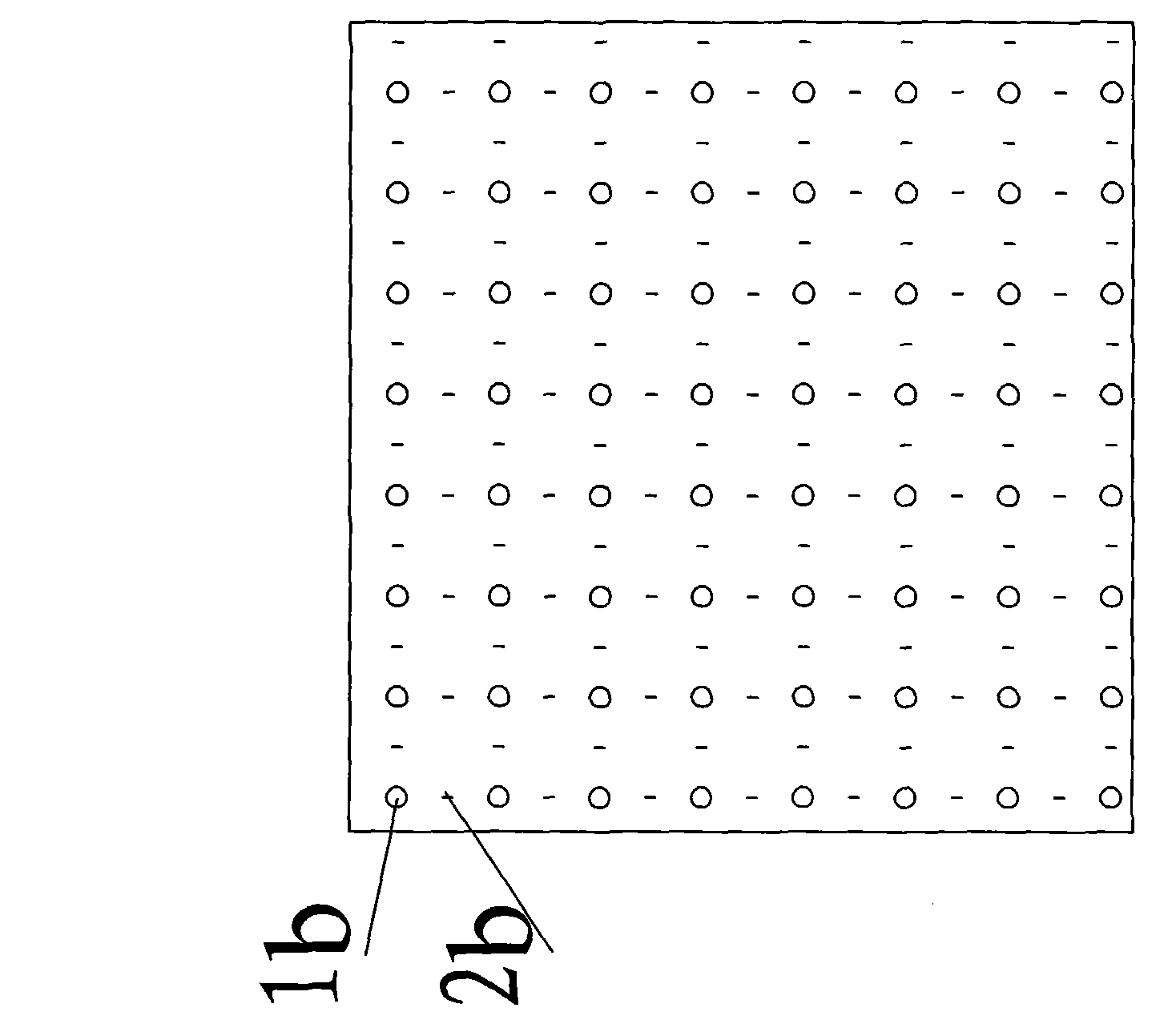

[0032] A) According to the engineering situation and stratum conditions, determine the composite foundation scheme of the spiral soil-squeezing grouting pile, including the pile diameter, pile length, pile spacing and pile position layout scheme of the spiral-squeezing soil grouting pile;

[0033] B) Arrange and implement a vertical drainage well in the middle of every two adjacent spiral soil-squeezing piles in the design. The vertical drainage well can be a sand well, a bagged sand well or a drainage board. If drainage is used The height of the upper part of the drainage board extending into the drainage cushion is 150-200mm, and the depth of the drainage well is determined according to the stratum conditions;

[0034] The above-mentioned sand wells and bagged sand wells can be made into holes by i...

Embodiment 2

[0040] Project Overview

[0041] The complex foundation treatment project of a container yard in a port has a lacustrine sedimentary stratum, which is mainly composed of deep lacustrine clay, including silty soil. The soil layer is thick, weak and loose, and belongs to saturated soft clay. It has the following characteristics:

[0042] (1) The natural water content is high, the void ratio is large, the water content is between 39% and 72%, and the void ratio is between 1.4 and 1.9;

[0043] (2) Poor water permeability, the permeability coefficient of most soft clay is 1×10 -5 ~1×10 -7 cm / s;

[0044] (3) High compressibility, the compression factor is 0.5-2.0MPa -1 , is highly compressible soil;

[0045] (4) The shear strength is low, the cohesion of the foundation soil fast shear test is about 10kPa, and the internal friction angle is between 5° and 9°.

[0046] Design and construction plan

[0047] In order to solve the problems of excessive settlement, uneven settlemen...

Embodiment 3

[0055] Project Overview

[0056] For an expressway, the width of the subgrade base is 50 meters, and the designed height of the embankment is 5 meters. The foundation soil composition of this road section is as follows:

[0057] The first layer, the cultivated soil layer, is 1.5 meters thick, loose, and contains plant roots;

[0058] The second layer, the silty clay layer is 11 meters thick, saturated, soft plastic-flow plastic, rich in organic matter, partially silt sandy, high water content, low water permeability, large void ratio, high compressibility, low strength, is the foundation The main object of reinforcement;

[0059] The third layer is an alternating layer of silty sand and fine sand, with a thickness of 17.5 meters. The sand in this layer is medium-dense and has good permeability, with a permeability coefficient of 10. -3 -10 -4 cm / s;

[0060] Design and construction plan

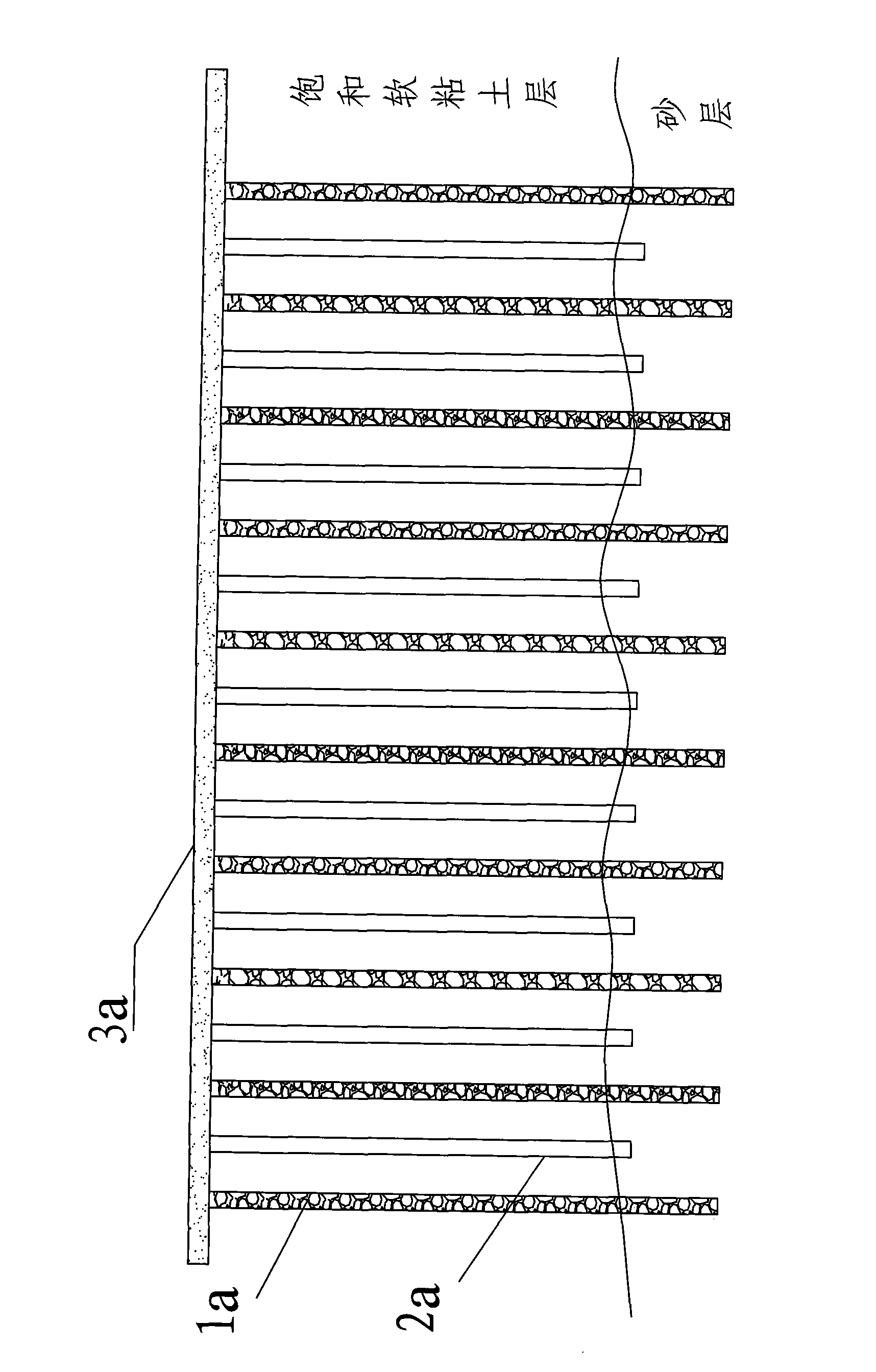

[0061] The design adopts a composite foundation treatment method combining bagged san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com