Foam fire preventing and extinguishing material, and preparation method and application thereof

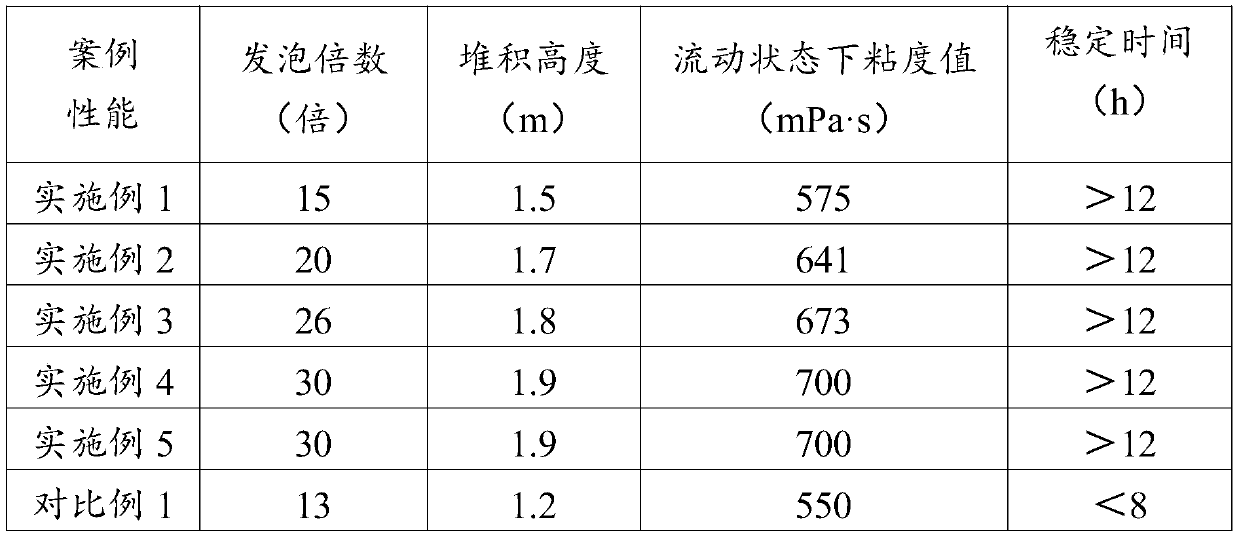

A fire prevention and foam technology, applied in fire prevention equipment, fire rescue, etc., can solve the problems of inability to prevent coal spontaneous combustion, poor foam stability, low foaming multiple, etc., and achieve enhanced fire prevention effect, enhanced strength, increased The effect of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides the preparation method of the foam fire-proofing material described in the above-mentioned technical solution, comprising the following steps:

[0034] Mix part of the water, foam stabilizer and expandable graphite, and perform the first stirring to obtain a thickened solution;

[0035] Mix the remaining water and foaming agent, and perform the second stirring to obtain a foam system;

[0036] The thickened solution and the foam system are mixed, and the third stirring is carried out to obtain the foam fire-proofing material.

[0037] In the invention, part of the water, the foam stabilizer and the expandable graphite are mixed, and the first stirring is performed to obtain a thickened solution. In the present invention, the stirring speed of the first stirring is preferably 900-1100 r / min, more preferably 1000 r / min, and the stirring time is preferably 3-5 min, more preferably 4 min. In the thickened solution, the foam stabilizer is dis...

Embodiment 1

[0044] Raw materials for the preparation of foam fire extinguishing materials: 1 kg of sodium α-olefin sulfonate, 1 kg of sodium dodecylbenzene sulfonate, 2.5 kg of sodium alginate, 10 kg of expandable graphite, and 100 kg of water.

[0045] Add 30kg of water, 2.5kg of sodium alginate and 10kg of expandable graphite into container A, and stir at a speed of 1000r / min for 4min to obtain a thickened solution;

[0046] Add 70 kg of water, 1 kg of sodium α-olefin sulfonate and 1 kg of sodium dodecylbenzene sulfonate into container B, and stir at a speed of 2000 r / min for 5 minutes to obtain a foam system;

[0047] The thickened solution was added to the foam system, and stirred at a speed of 2000 r / min for 5 minutes to obtain a foam fire extinguishing material.

Embodiment 2

[0049] Raw materials for the preparation of foam fire-resistant materials: 1.5 kg of sodium α-olefin sulfonate, 1.5 kg of sodium dodecylbenzene sulfonate, 3 kg of sodium alginate, 13 kg of expandable graphite, and 100 kg of water.

[0050] Add 30kg of water, 3kg of sodium alginate and 13kg of expandable graphite into container A, and stir at a speed of 1000r / min for 4min to obtain a thickened solution;

[0051] Add 70kg of water, 1.5kg of sodium α-olefin sulfonate and 1.5kg of sodium dodecylbenzenesulfonate into container B, and stir at a speed of 2000r / min for 8 minutes to obtain a foam system;

[0052] The thickened solution was added to the foam system, and stirred at a speed of 2000 r / min for 8 minutes to obtain a foam fire extinguishing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Expansion multiple | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com