Patents

Literature

240results about How to "Low requirements for process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

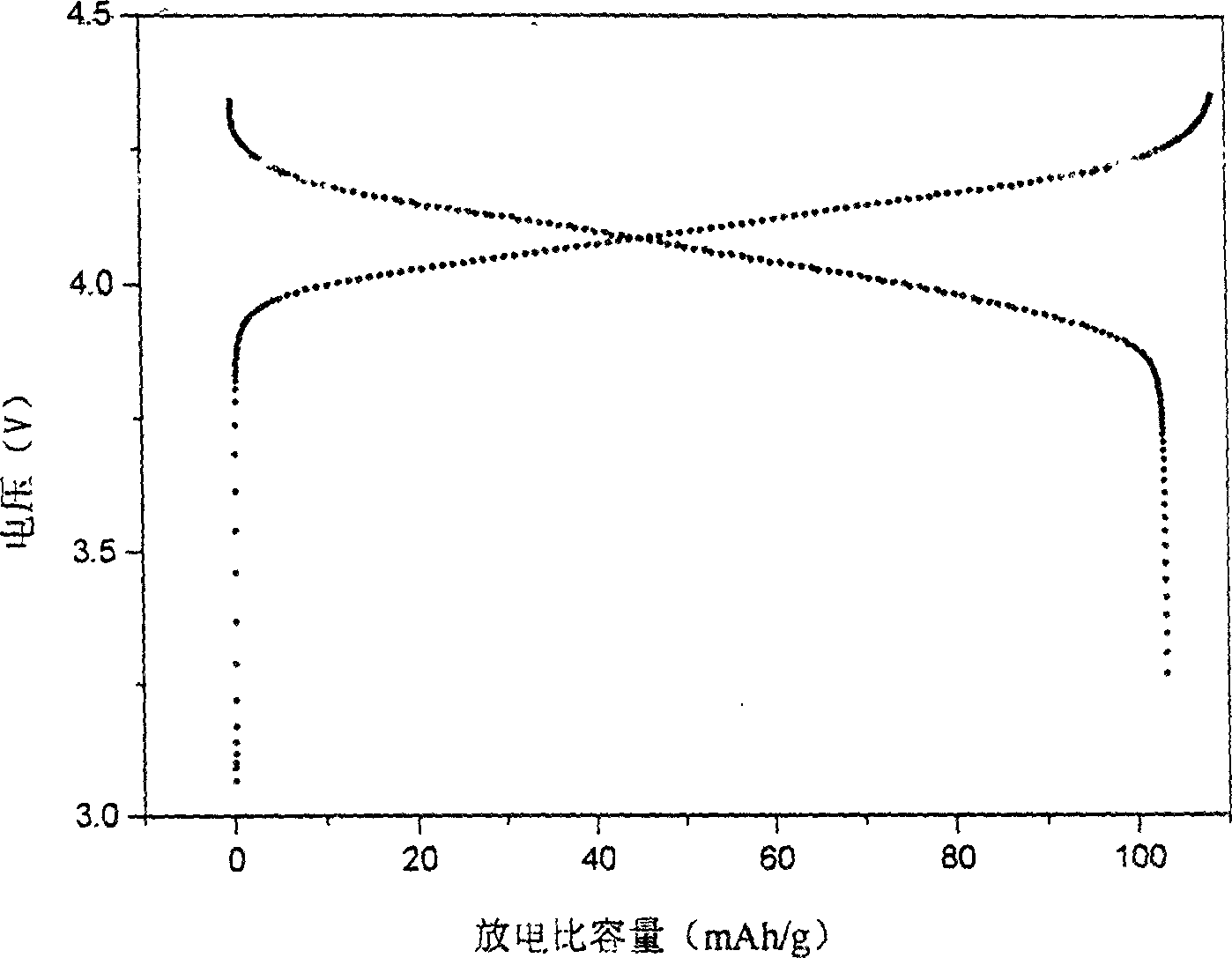

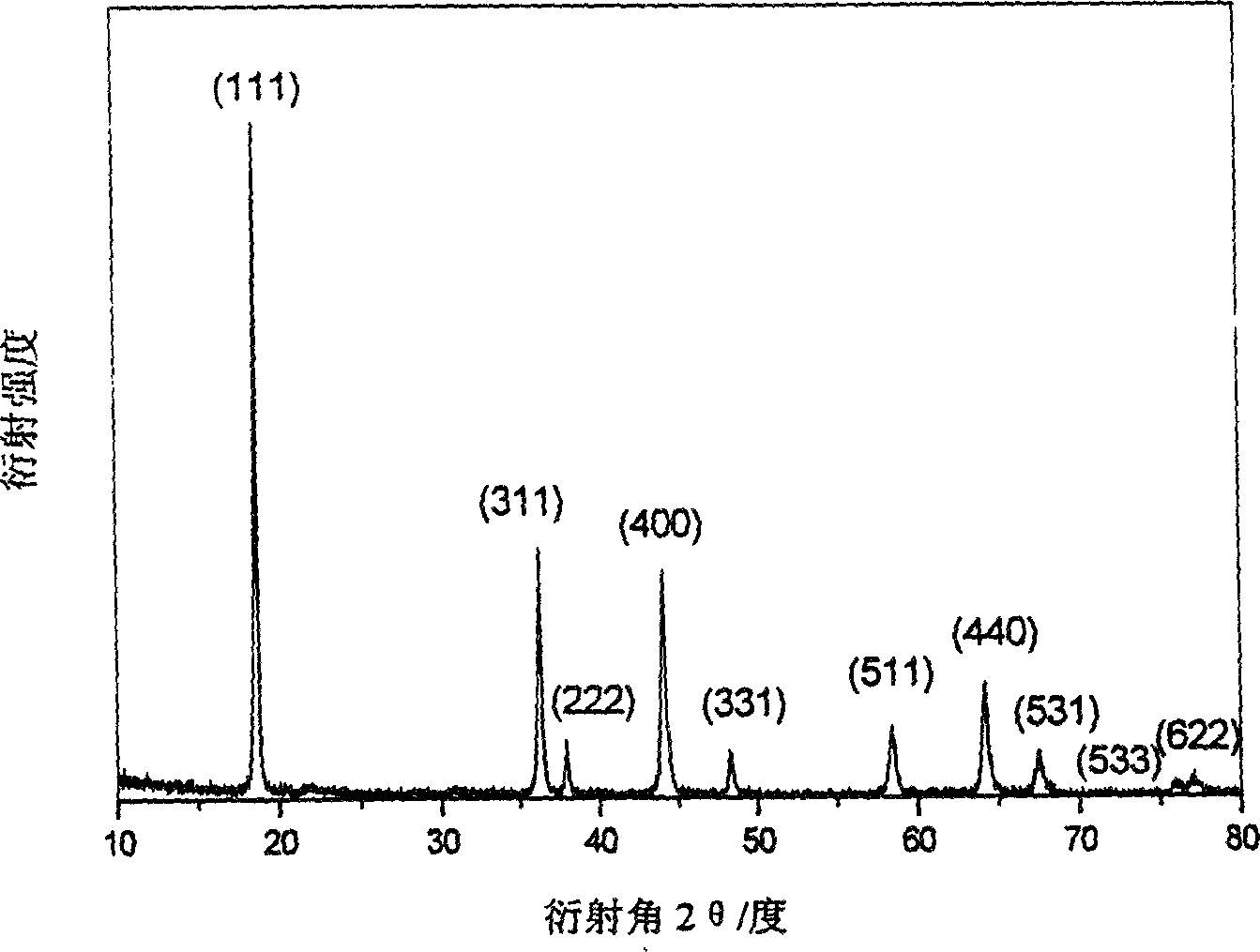

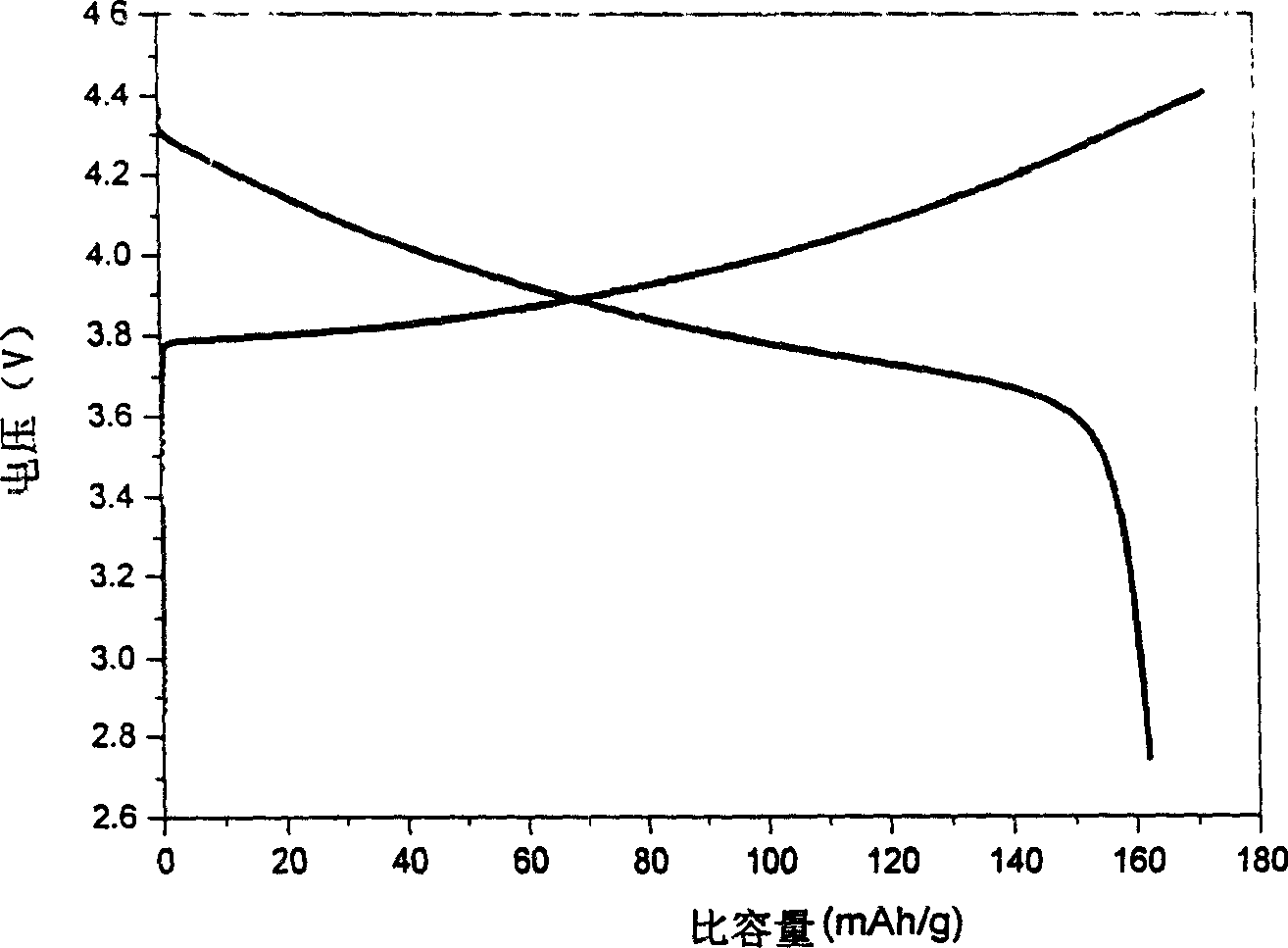

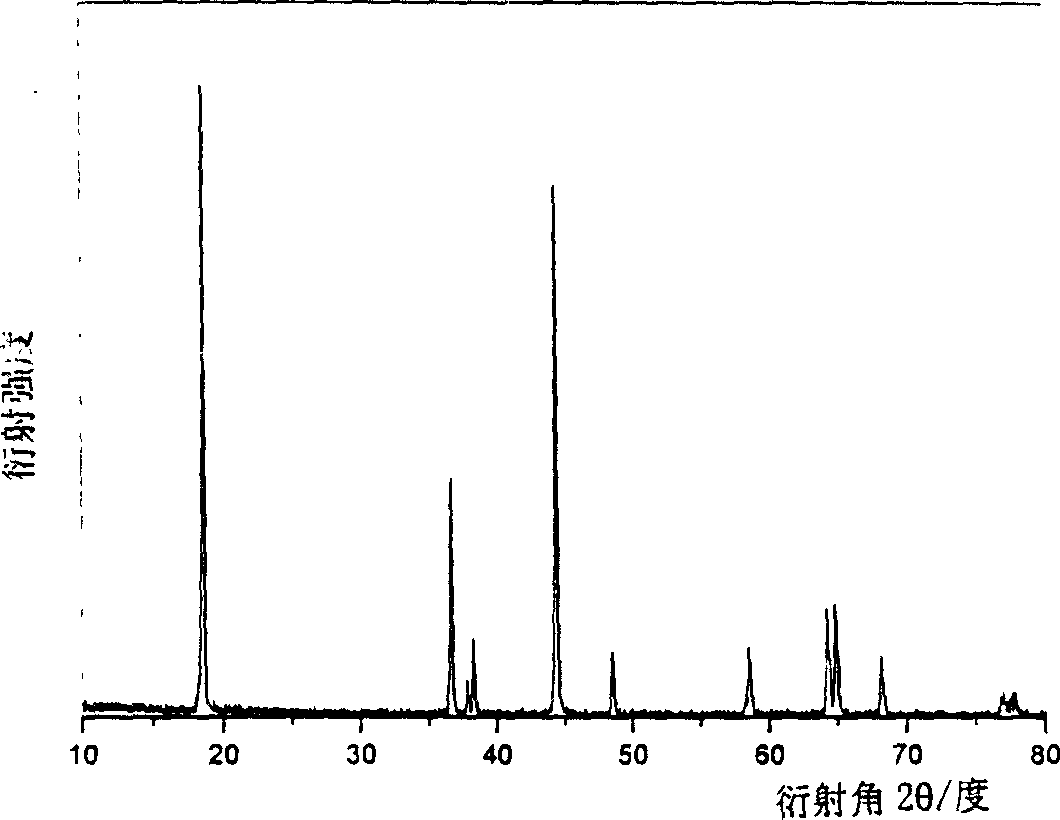

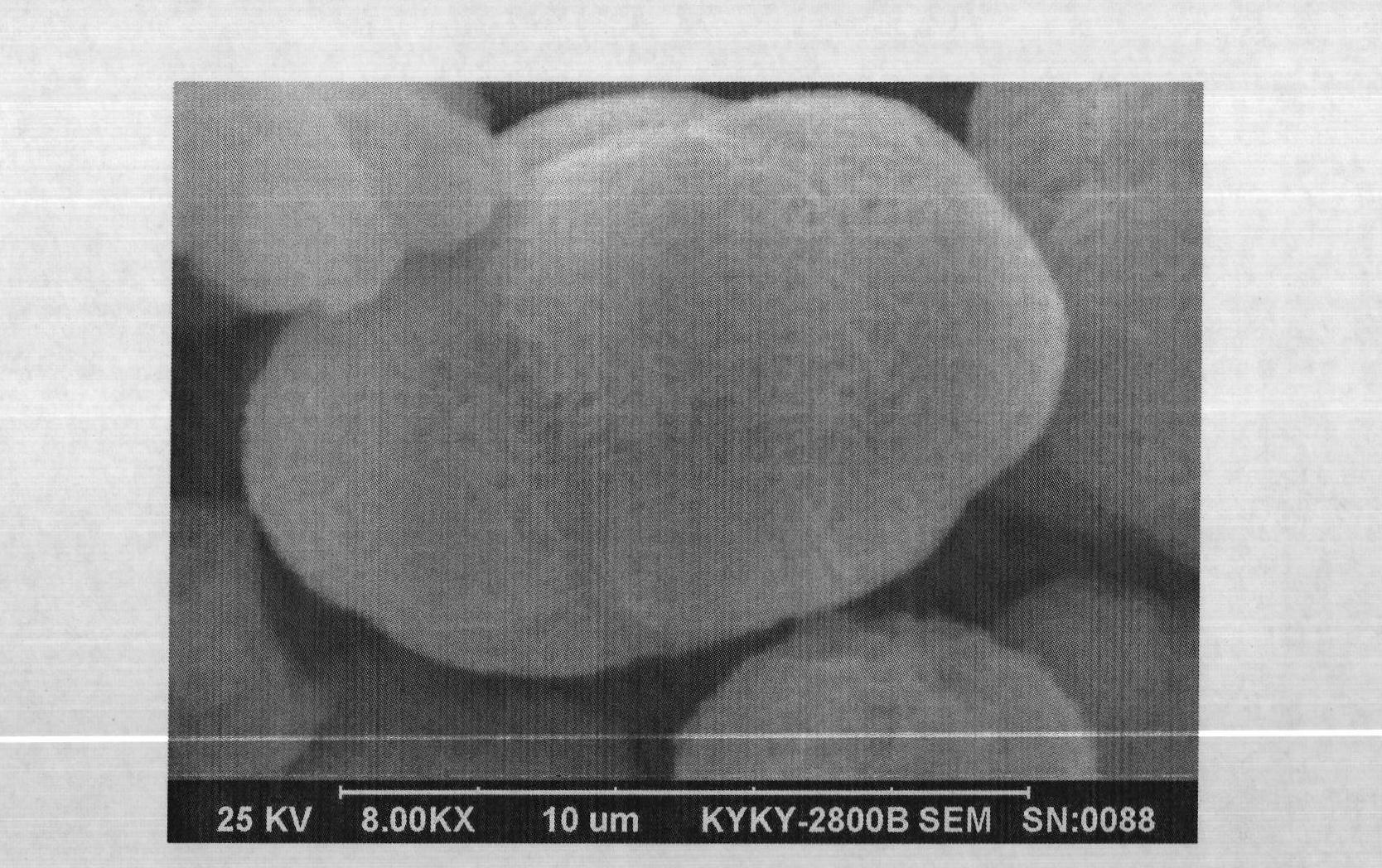

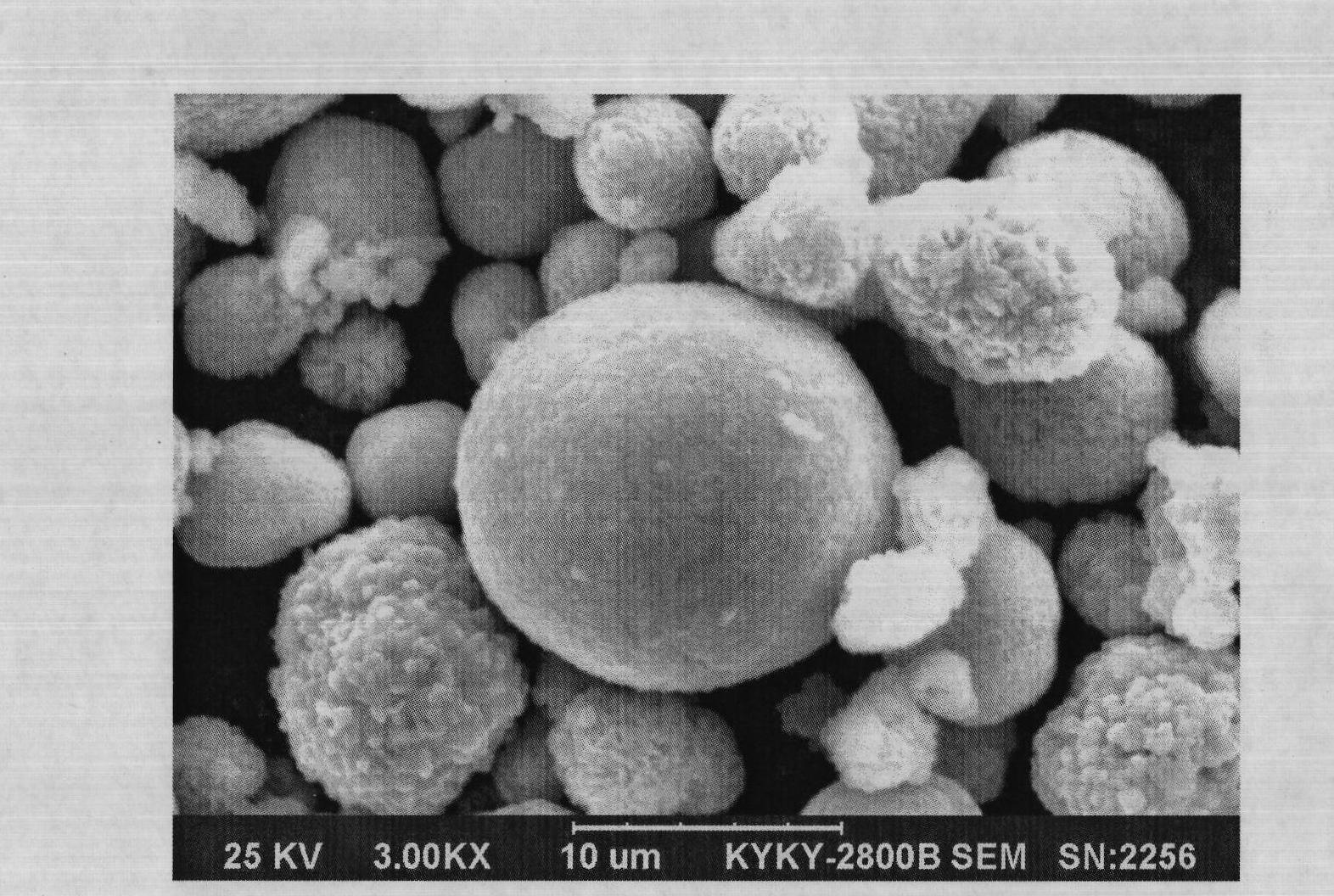

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Positive electrode material of manganese series, and preparation and usage thereof

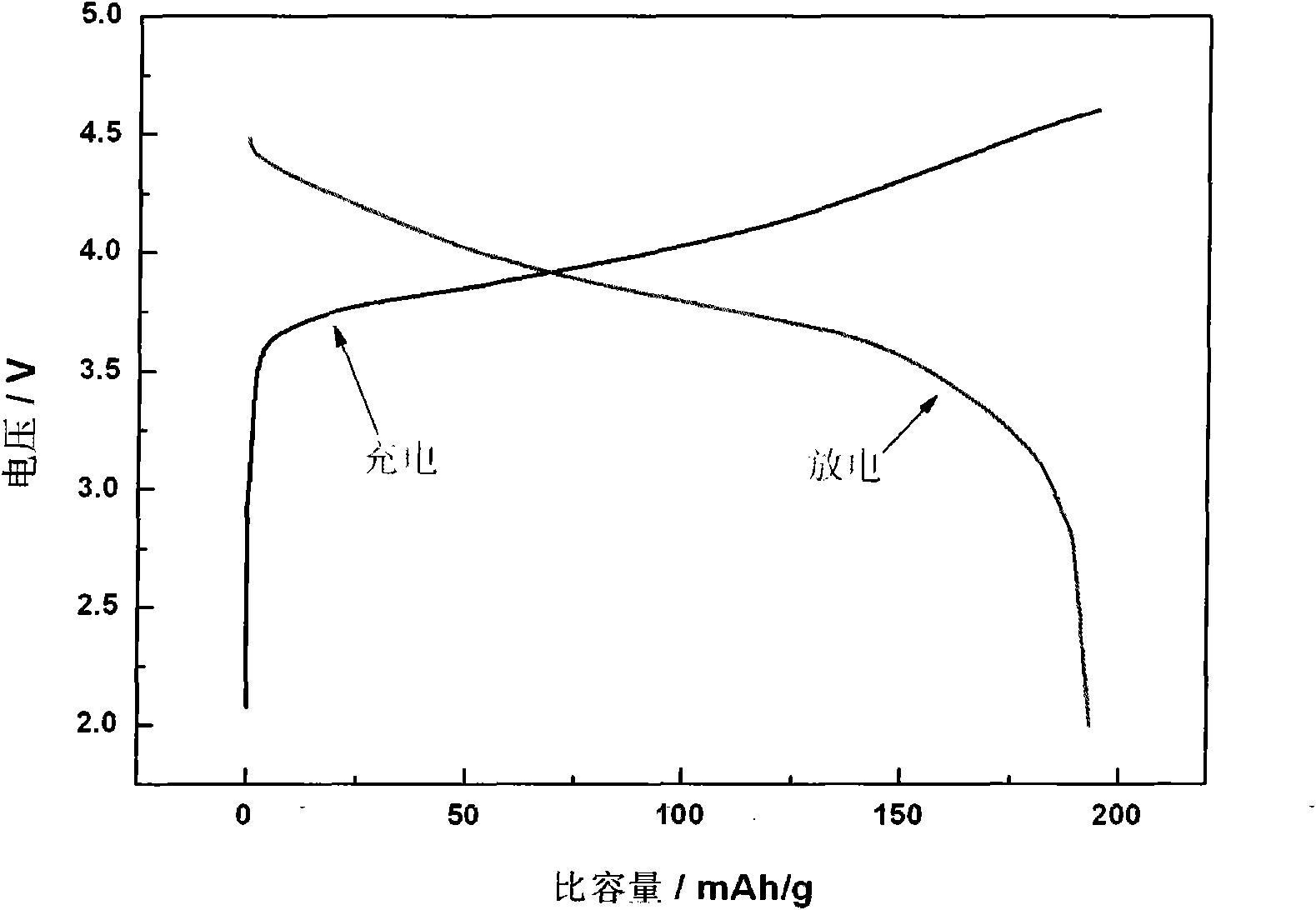

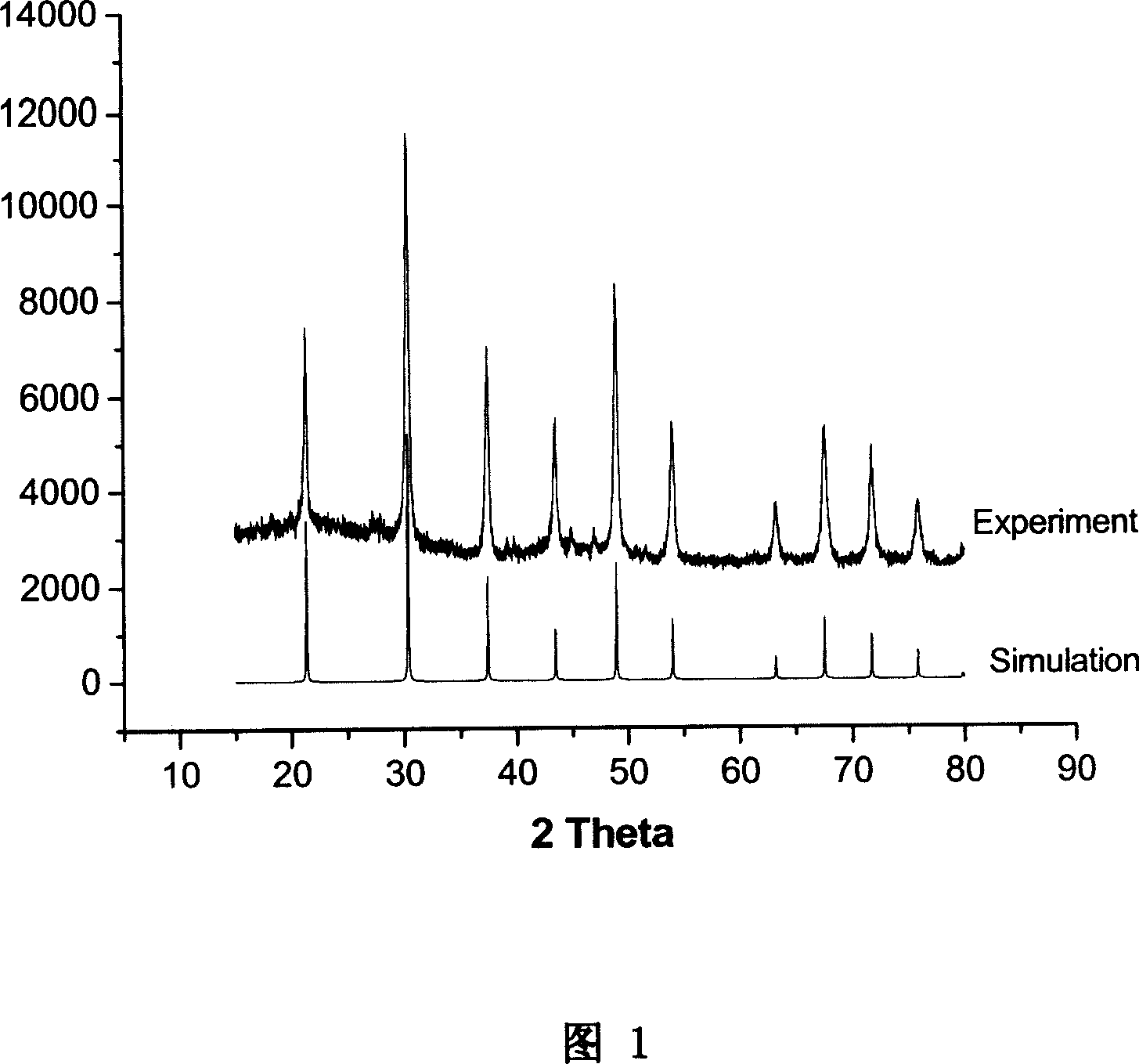

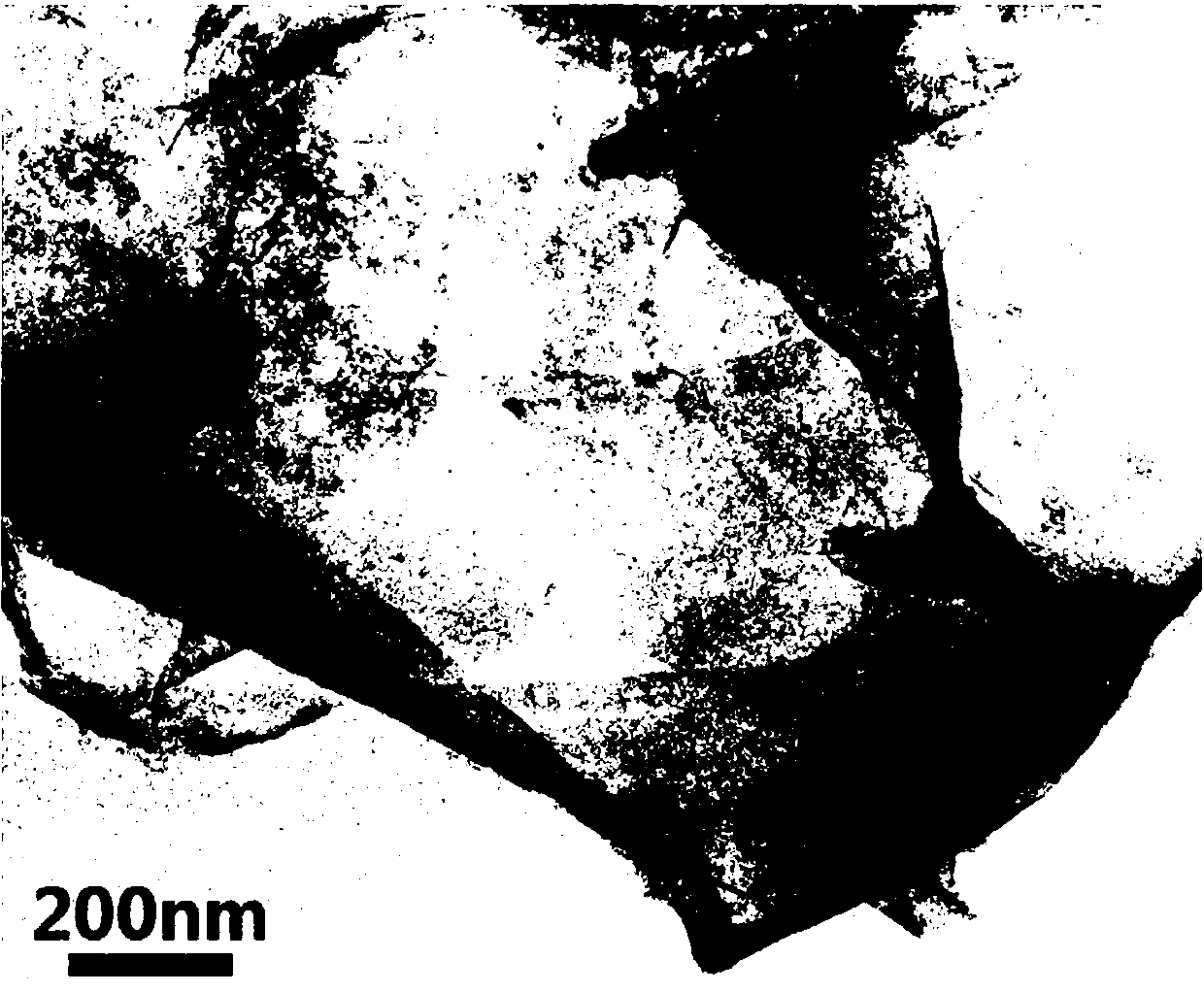

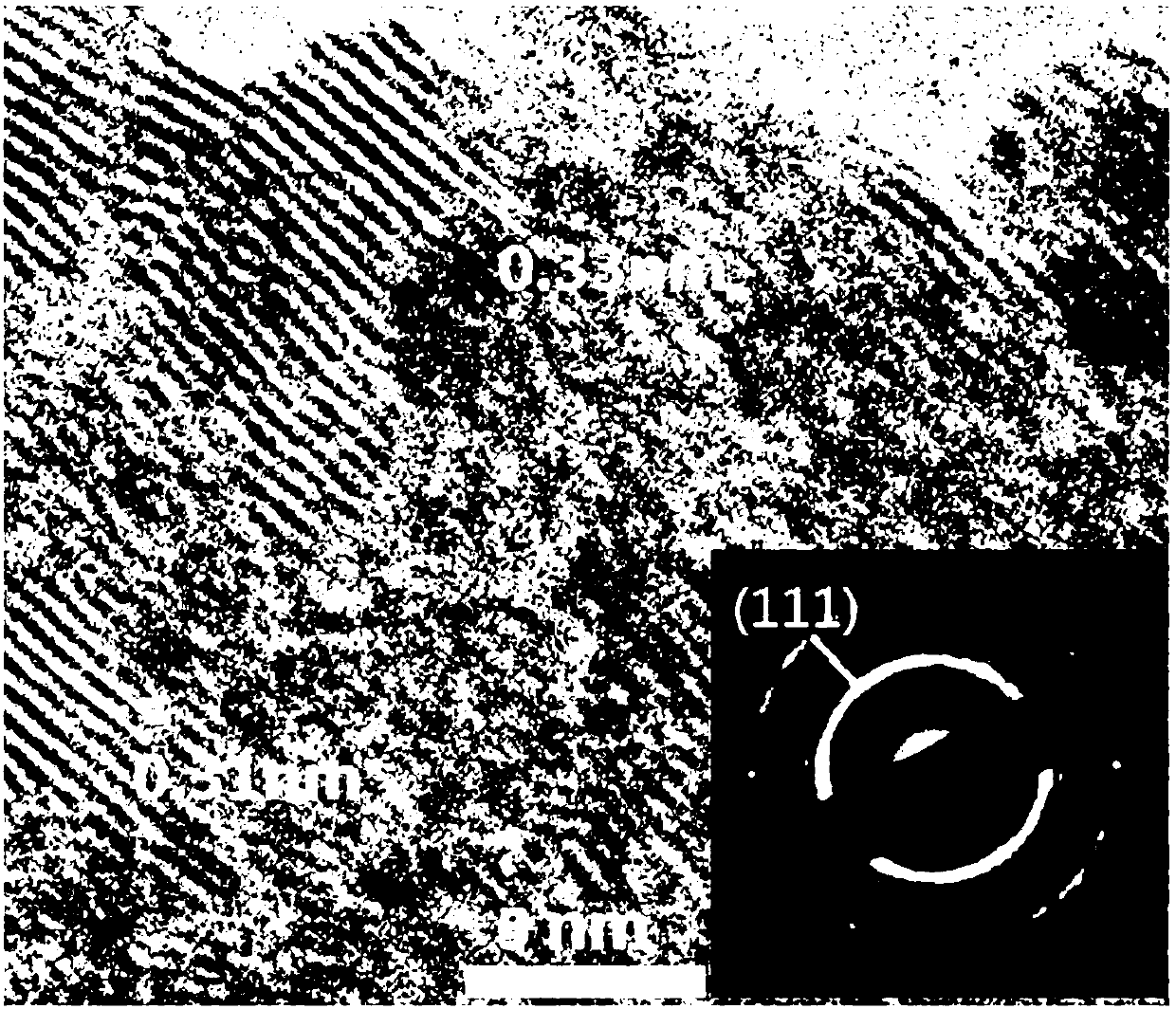

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

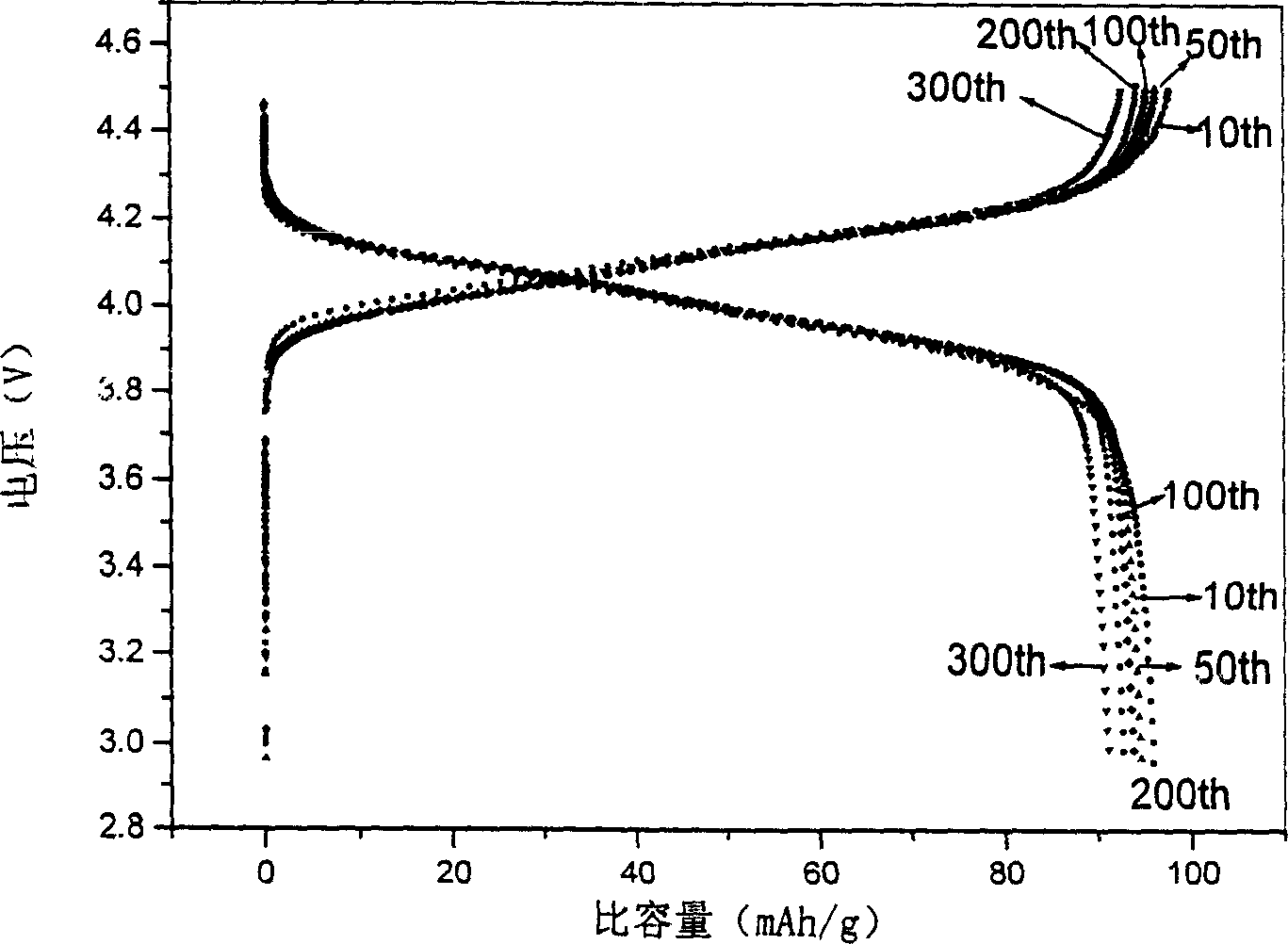

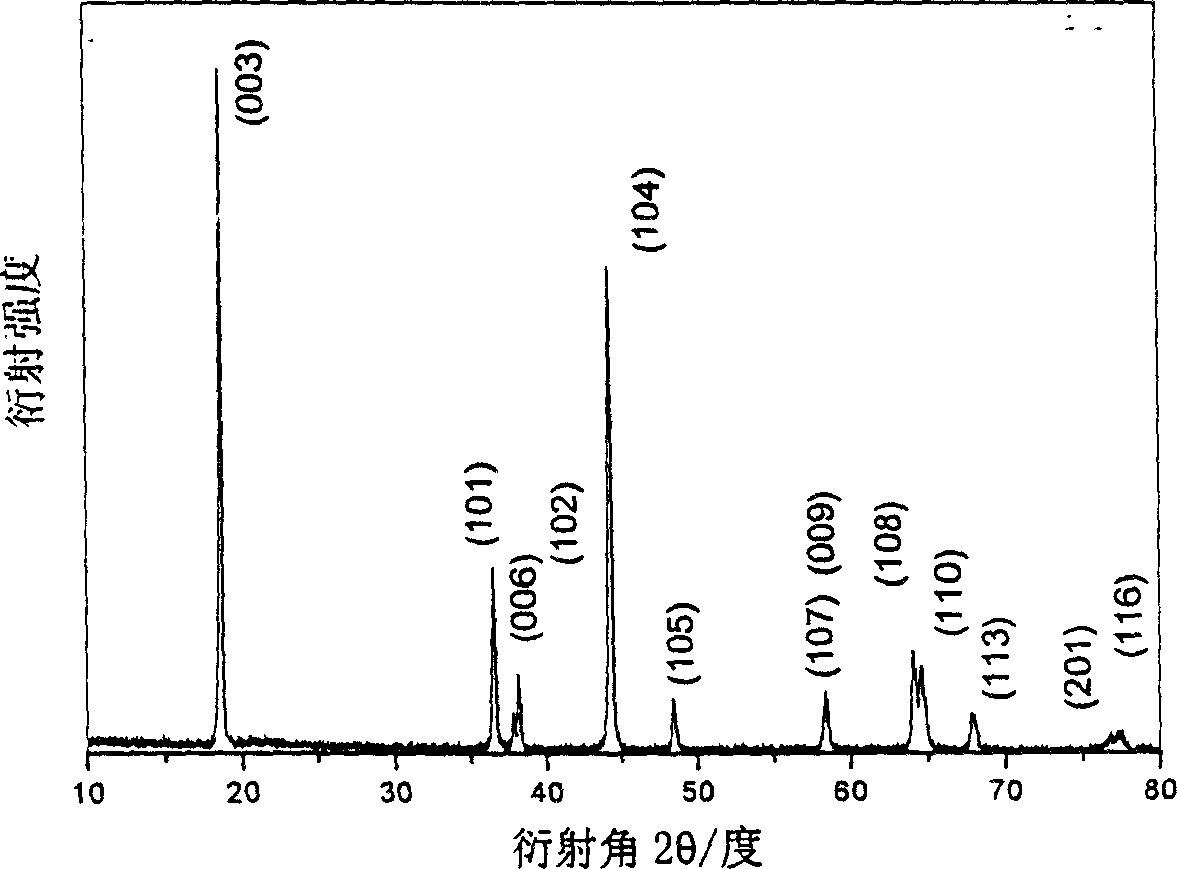

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Laminated ternary positive material and preparation method thereof

The invention provides a laminated ternary positive material and a preparation method thereof. The chemical formula of the laminated ternary positive material is aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 / M, wherein a is more than 0 and less than 1; x is more than 0 and less than 1; y is more than 0 and less than 1; and M is aluminium oxide (Al2O3), titanium dioxide (TiO2), zirconium oxide (ZrO2), lanthanum oxide (La2O3), zinc oxide (ZnO) or magnesium oxide (MgO). The preparation method comprises the following steps of: preparing a precursor mixture; sintering the precursor mixture in a sintering furnace to synthesize a aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 positive material; and performing compounding to obtain the aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 / M material. The laminated ternary positive material has high energy density, a stable high-voltage charging and discharging structure, a simple preparation process and low production cost.

Owner:BTR NEW MATERIAL GRP CO LTD

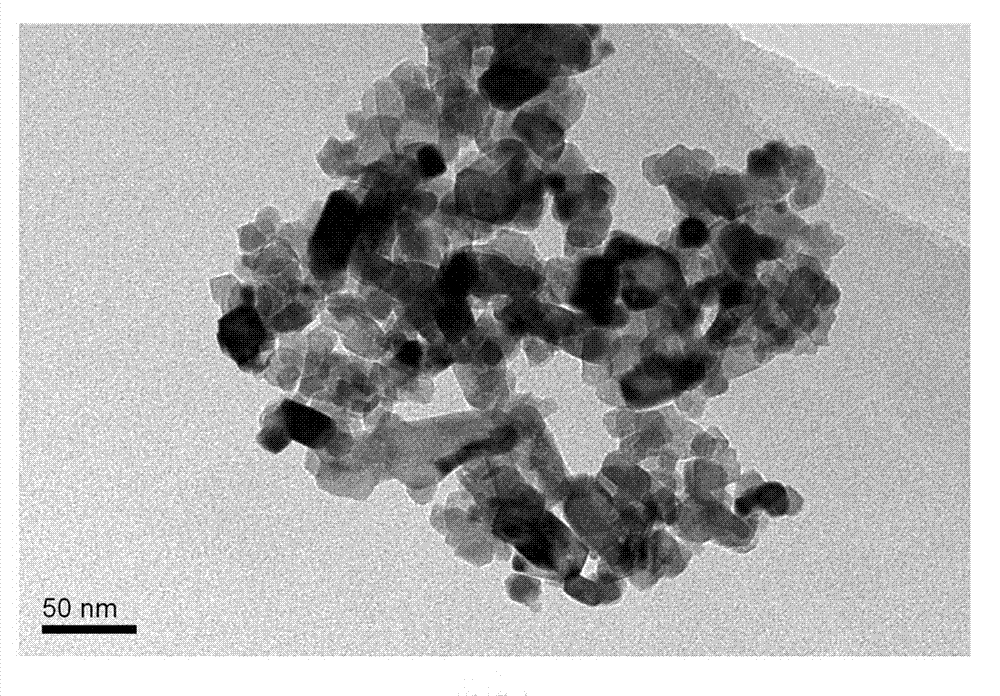

Synthesis method of nano hexaboride

InactiveCN1923686AReduce manufacturing costLow reaction temperatureMetal boridesSynthesis methodsRare earth

The invention discloses a synthesizing method of nanometer hexaboride (RB6), which comprises the following steps: adopting chloride of random one or two combinations of 57-71 rare earth metal elements, metal Y, alkaline earth Ba, Sr and Ca as raw material; making NaBH4 or KBH4 as reducer; reacting under low-temperature condition at 500-600 deg.c; washing; filtering; drying to obtain high-purity RB6 nanometer crystal powder.

Owner:HANGZHOU DIANZI UNIV

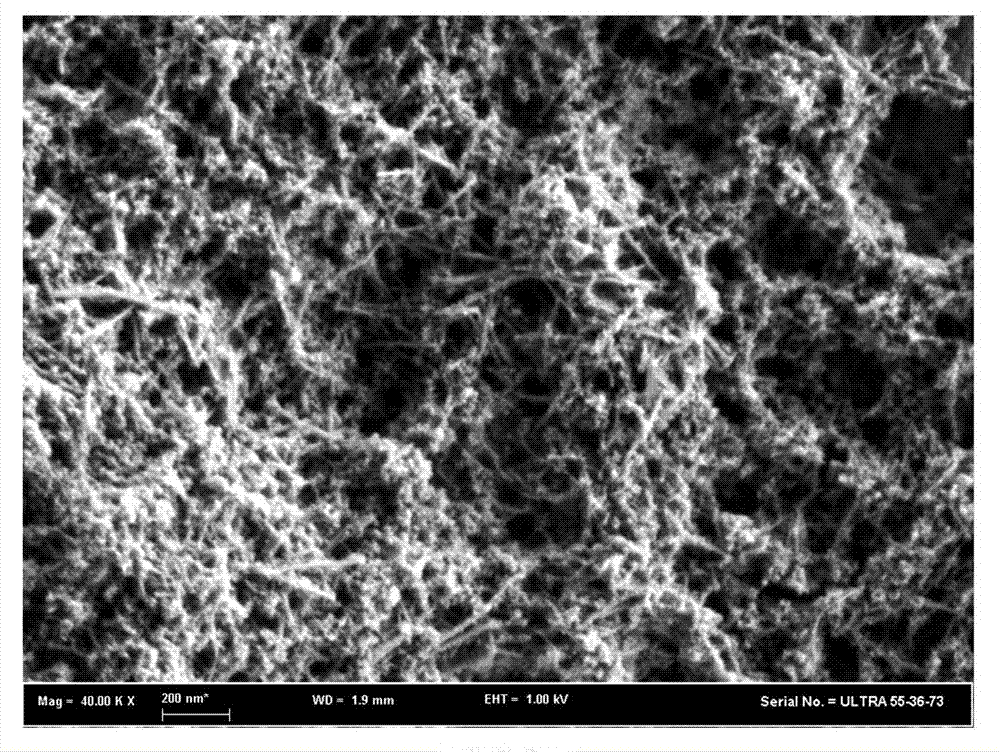

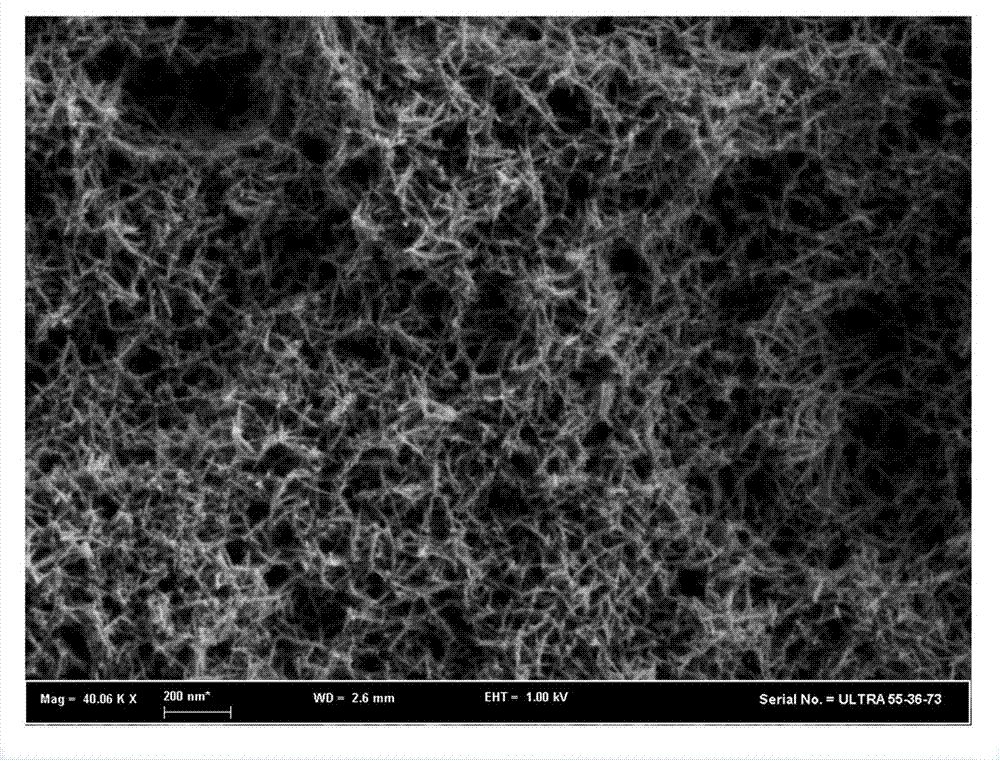

Method for preparing nanoscale sheet cerium oxide by hydrothermal method

InactiveCN103274441ASimple preparation processLow requirements for production equipmentMaterial nanotechnologyRare earth metal compoundsOrganic solventRoom temperature

The invention discloses a method for preparing nanoscale sheet cerium oxide by a hydrothermal method. The method comprises the following steps of: 1) preparing a 0.01-0.05mol / L Ce<3+> ion aqueous liquor at room temperature; preparing an ammonia water liquor at room temperature, wherein pH value of the ammonia water liquor is greater than 11; 2) placing the ammonia water liquor in a reaction kettle in a temperature range from -10 DEG C to 20 DEG C, taking the Ce<3+> ion aqueous liquor, and slowly dropping to excessive ammonia water liquor while stirring; and 3) stirring the mixed liquor obtained in the step (2) at constant temperature for reacting for 2-24 hours, centrifugalizing after reaction, removing the supernatant liquid, washing the powder obtained by centrifugalization and drying to obtain the solid sheet cerium oxide. According to the method disclosed by the invention, the nanoscale sheet cerium oxide is synthesized by one step by the hydrothermal method. The method is simple in preparation process, and low in demand on production and process conditions. No template materials are required and no organic solvents are added. The method is basically free from pollution and very environmental-friendly.

Owner:ZHEJIANG SCI-TECH UNIV

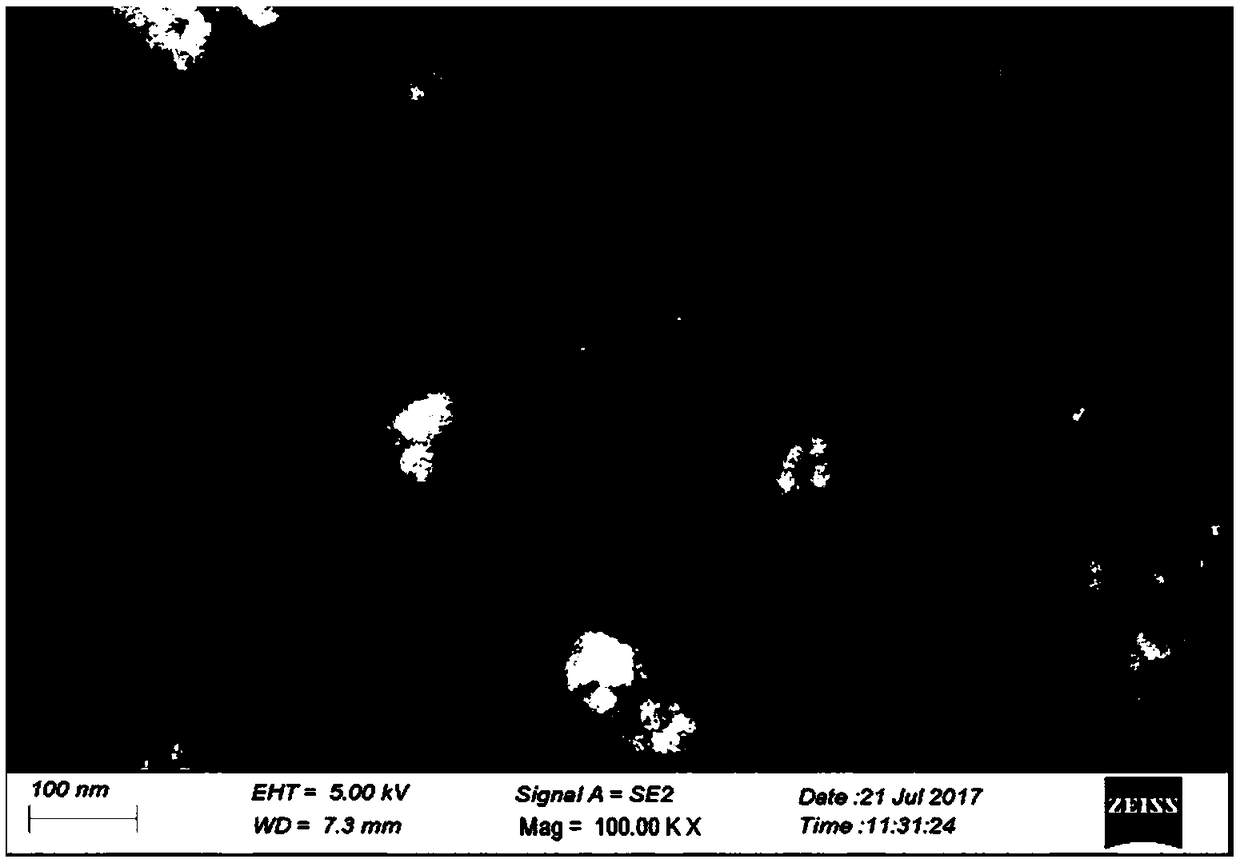

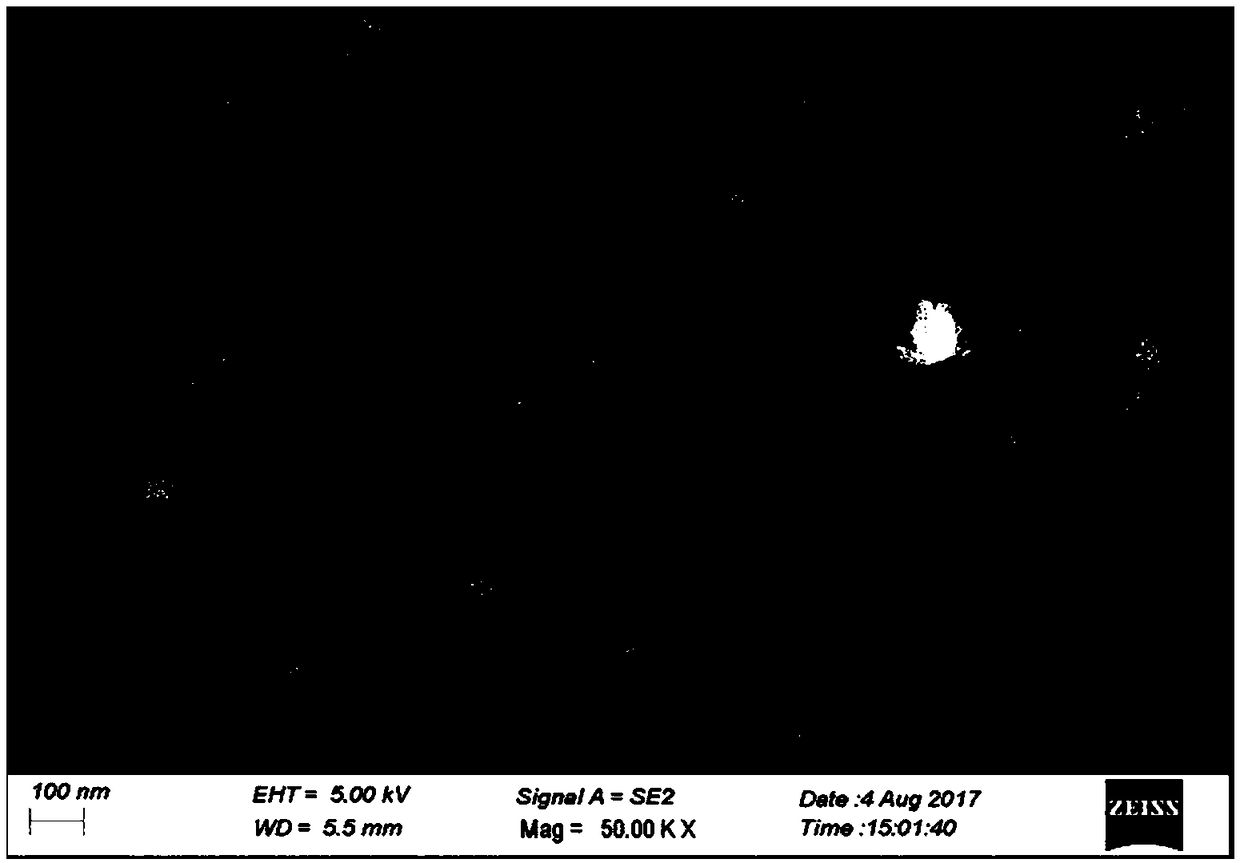

Nano silver-polyvinylidene fluoride composite separation membrane and preparation method thereof

InactiveCN102302903AIncrease water fluxHigh retention rateSemi-permeable membranesNanoparticlePolyvinylidene difluoride

The invention discloses a nano silver-polyvinylidene fluoride composite separation membrane and a preparation method thereof. The separation membrane is obtained by modifying a polyvinylidene fluoride membrane with nano silver. According to the invention, two dispersion methods namely a physical method and a chemical method are simultaneously adopted in the preparation process, so that nano particle reaches an ideal dispersion effect in the polyvinylidene fluoride separation membrane and a reliable guarantee is provided for the excellent property of the membrane. In the invention, a noble metal nano silver the price of which is relatively low is added, and the amount of nano silver is regulated, so that the mechanical property, antibiotic property and pollution resistance of the polyvinylidene fluoride separation membrane are greatly improved, the water flux and trapping rate of the polyvinylidene fluoride separation membrane are also improved, the service life of the membrane is prolonged, and the membrane has high performance-to-price ratio.

Owner:UNIV OF JINAN

Novel wood-plastic composite material

The invention discloses a novel wood-plastic composite material, which is prepared from a wood meal raw material, waste fiber textiles, solid wastes and thermoplastics by the processes of crushing, blending, granulation, extrusion molding and the like. According to the novel wood-plastic composite material, waste mushroom stems, the waste fiber textiles, the solid wastes and the like can be comprehensively utilized, and the wood-plastic composite material prepared from the waste mushroom stems, the waste fiber textiles and the solid wastes is low in cost and high in mechanical performance and service performance, and has the characteristics of low cost and strong strength; in addition, a production method is easy to operate, has lower requirements on a process condition and production equipment, and has broad market application prospect, and large-scale production can be implemented.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

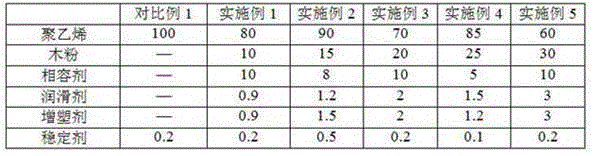

Polyethylene/wood powder composite wire for fused deposition modeling, and preparation method thereof

InactiveCN105295175APrevent crystallizationSmall shrinkage deformationAdditive manufacturing apparatusPlasticizerProcess conditions

The invention discloses a polyethylene / wood powder composite wire for fused deposition modeling, and a preparation method thereof. Raw materials and assistants used by the polyethylene / wood powder composite wire for fused deposition modeling comprise 70-90 parts of polyethylene, 10-30 parts of wood powder, 5-10 parts of a compatilizer, 0.9-3 parts of a lubricant, 0.9-3 parts of a plasticizer and 0.1-0.5 parts of a stabilizer. Addition of the wood powder to the polyethylene / wood powder composite wire inhibits crystallization of polyethylene, reduces shrinkage deformation of a fused deposition modeled product, and improves the modeling precision of the product. The fused deposition modeled product has the advantages of good toughness, improved mechanical performances and strong practicality. The invention also provides the making method of the polyethylene / wood powder composite wire. The method has the advantages of easy operation, low technological conditions and production device requirements, realization of large-scale popularization and production, wide market prospect and extremely good market benefits.

Owner:HENAN INST OF ENG

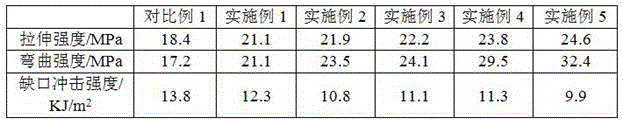

Cleaner production method for preparing superfine powder through self-propagating metallurgy method

ActiveCN103466648ALow raw material costReduce energy consumptionMaterial nanotechnologyBoron/boridesHydrogen chlorideCleaner production

A cleaner production method for preparing superfine powder through a self-propagating metallurgy method is carried out according to the following steps: (1) mixing and conducting ball-milling on the powdery oxide and magnesium powder, then compacting into a blank, putting the blank into a self-propagating reaction furnace to cause a self-propagating reaction, and naturally cooling to the room temperature to obtain a coarse product; (2) using hydrochloric acid to leach and separate magnesium oxide in the coarse product after breaking, and filtering to obtain a solid phase and a leaching agent; (3) washing and drying the solid phase and making the solid phase into ultrafine powder; (4) processing the leaching agent through a spray-pyrolysis mode to obtain a nanoscale magnesium oxide and pyrolysis tail gas, wherein the hydrogen chloride in the pyrolysis tail gas is absorbed to form hydrochloric acid and is circularly used back in the leaching process. The cleaner production method producing the ultrafine powder through the self-propagating metallurgy mode has the characteristics of low material cost, low energy consumption, simple operation, low requirement on process conditions and the like, and the product is high in purity, small in particle size and high in powder activity.

Owner:NORTHEASTERN UNIV

Preparation method of flaky nano-cerium oxide

InactiveCN103991891ANo pollution in the processEasy to prepareNanotechnologyRare earth metal compoundsStationary conditionsCerium

The invention relates to a preparation method of flaky nano-cerium oxide, comprising the following steps: preparing an aqueous solution of water-soluble cerium salt and an aqueous solution of a precipitant carbonate; adding the aqueous solution of carbonate into the aqueous solution of cerium salt within the temperature range of 0-50 DEG C under the condition of stirring; continuously stirring to react for 0.2-2 h so as to obtain a precipitate solution; aging the precipitate solution for 0-48 h under stationary condition and at the temperature of 0-50 DEG C; collecting a precipitate from the precipitate solution; and washing, drying and roasting to obtain flaky nano-cerium oxide. Hydrothermal / alcohol-thermal processes are not required. Flaky nano-cerium oxide is synthesized at one step of solution precipitation reaction at low temperature. Problems of many required raw materials, complex process, harsh production conditions and the like by a hydrothermal / alcohol-thermal method, sol-gel method, micro-emulsion method or traditional liquid phase method are avoided. Technological conditions are mild and easy to control, and the preparation method is environmentally friendly and pollution-free.

Owner:EAST CHINA UNIV OF SCI & TECH

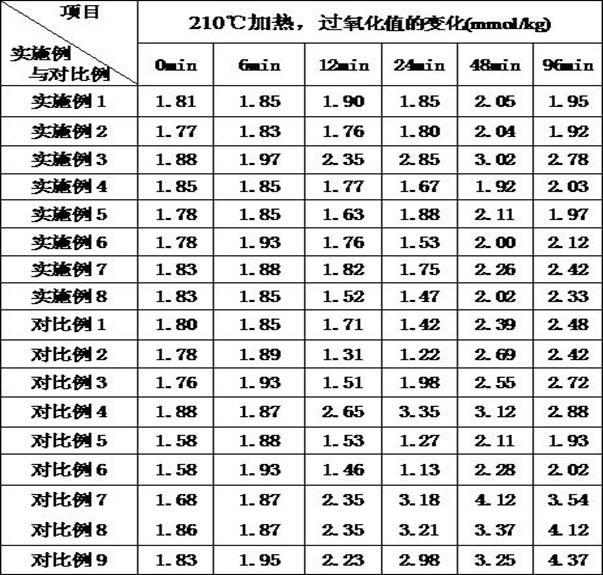

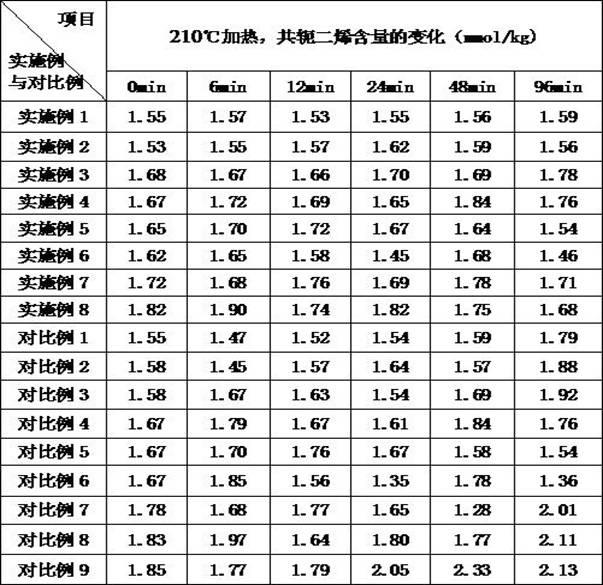

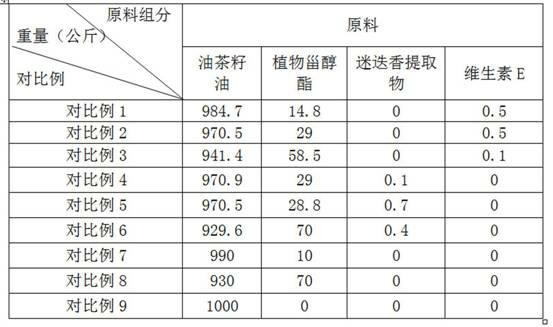

Functional camellia oil and manufacture method of functional camellia oil

InactiveCN102613320AImprove oxidation stabilityExtended shelf lifeEdible oils/fatsBiotechnologyCamellia oleifera

The invention discloses functional camellia oil, which is obtained by mixing, stirring and filtering raw materials comprising the following ingredients in parts by mass: 928.8 to 989.3 parts of camellia oleifera seed oil, 10 to 70 parts of plant sterol ester, 0.1 to 0.7 part of rosemary and 0.1 to 1 part of vitamin E. The functional camellia oil has the advantages that the stability is good, the shelf life is long, the effect of obviously reducing blood cholesterol, triglyceride and low-density lipoprotein cholesterin is realized, the cardiovascular and cerebrovascular diseases can be effectively prevented, and good stability is realized during high-temperature cooking.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

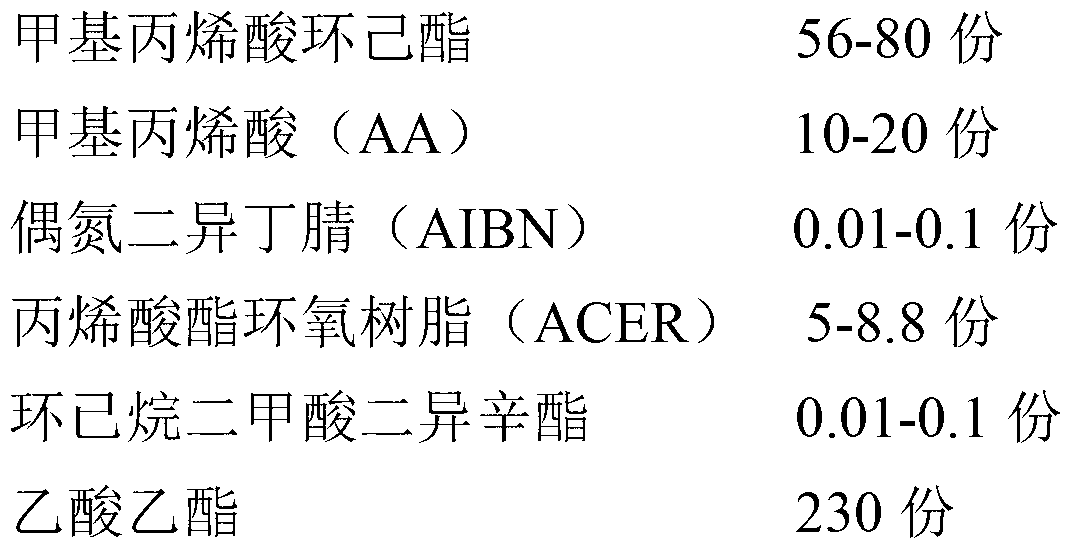

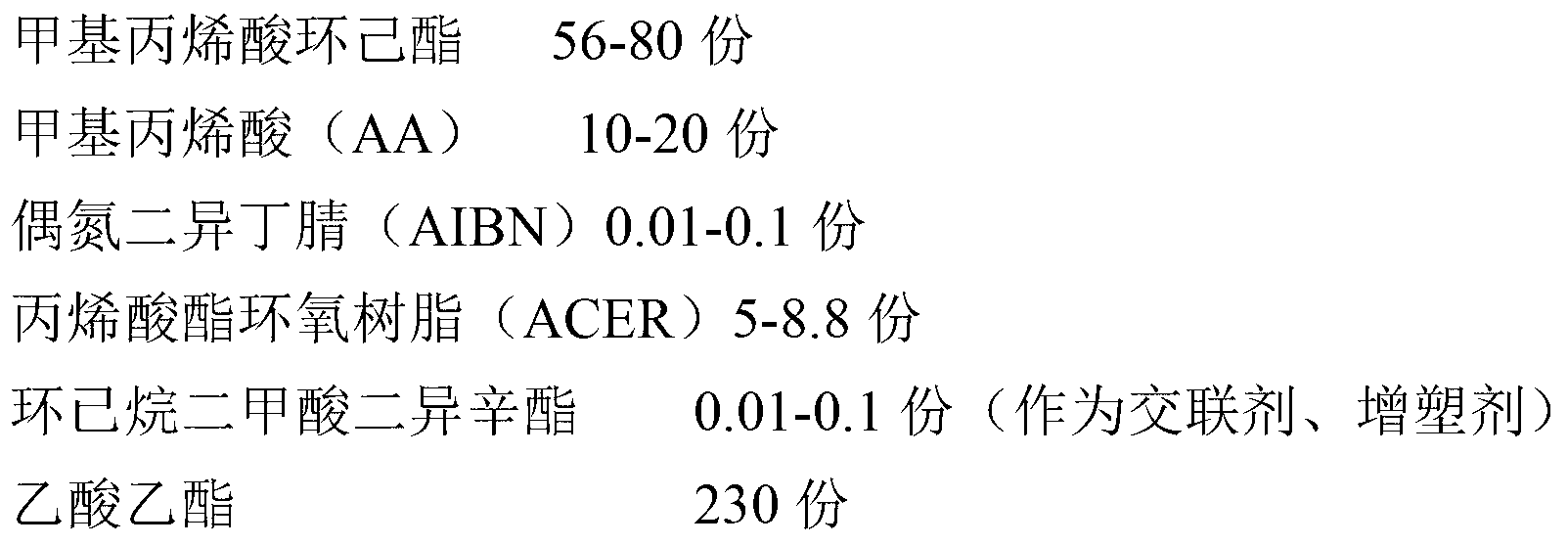

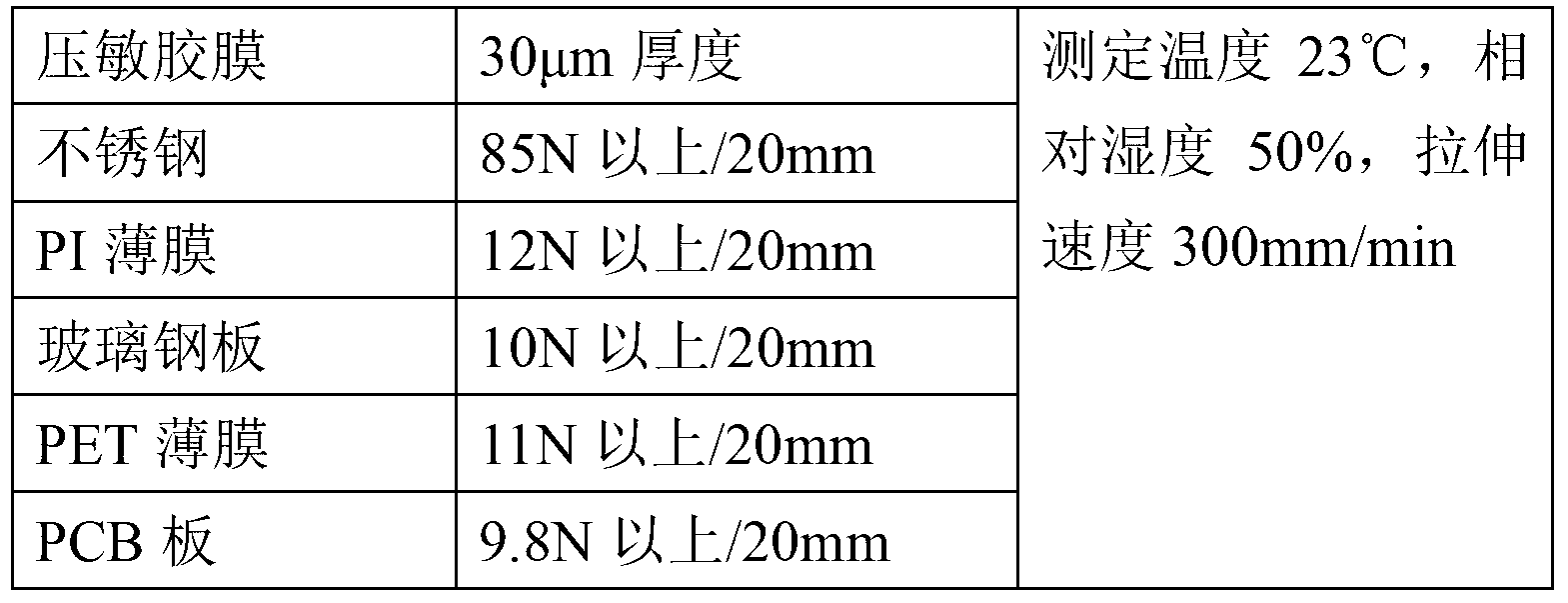

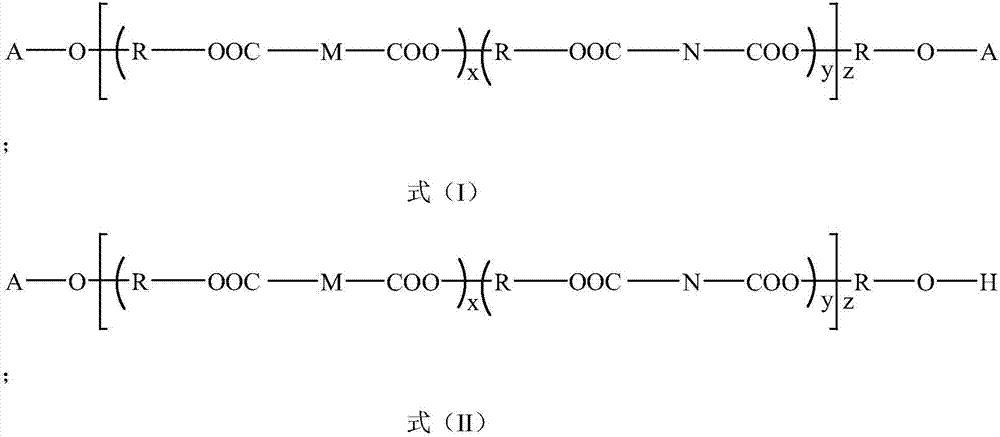

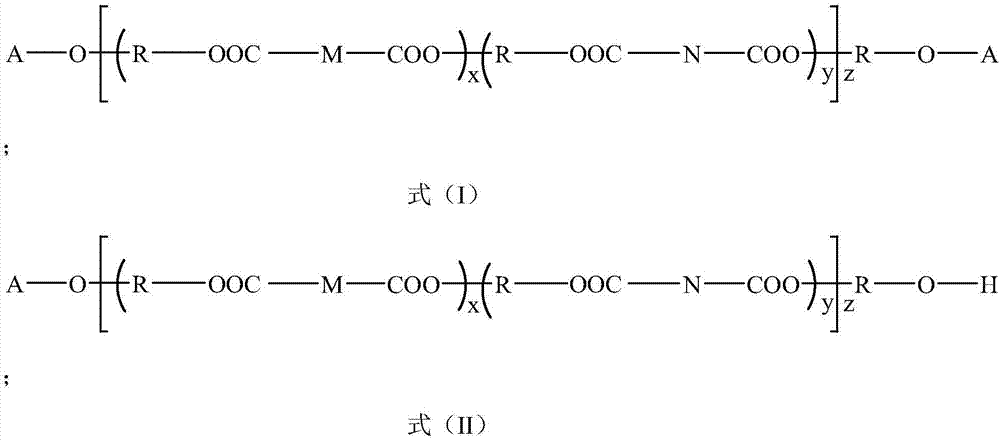

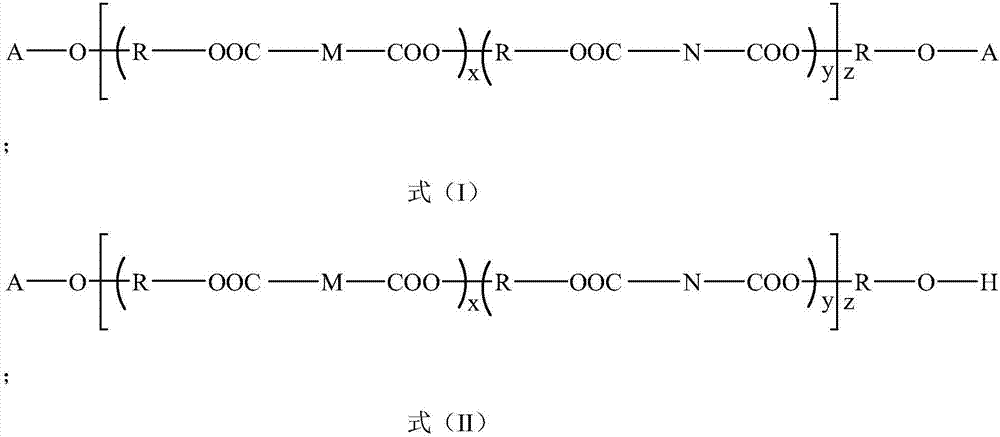

High-temperature-resistant pressure-sensitive adhesive-film for COF and preparation method thereof

InactiveCN103289593ALow costLow requirements for process conditionsFilm/foil adhesivesEster polymer adhesivesHeat resistanceBound property

Provided is a high-temperature-resistance pressure-sensitive adhesive-film for COF, and the high-temperature-resistance pressure-sensitive adhesive-film is formed by a glue solution containing a copolymer of thermoplastic polyimide and an acrylic polymer. Further provided is a preparation method of the high-temperature-resistance pressure-sensitive adhesive-film for COF, and the method comprises the following steps of: preparing the glue solution containing a copolymer of thermoplastic polyimide and an acrylic polymer, and forming the pressure-sensitive adhesive-film by employing the glue solution. The high-temperature-resistance pressure-sensitive adhesive-film has characteristics of high binding property, adaptability, cohesion property and heat resistance property.

Owner:SHENZHEN DANBOND TECH

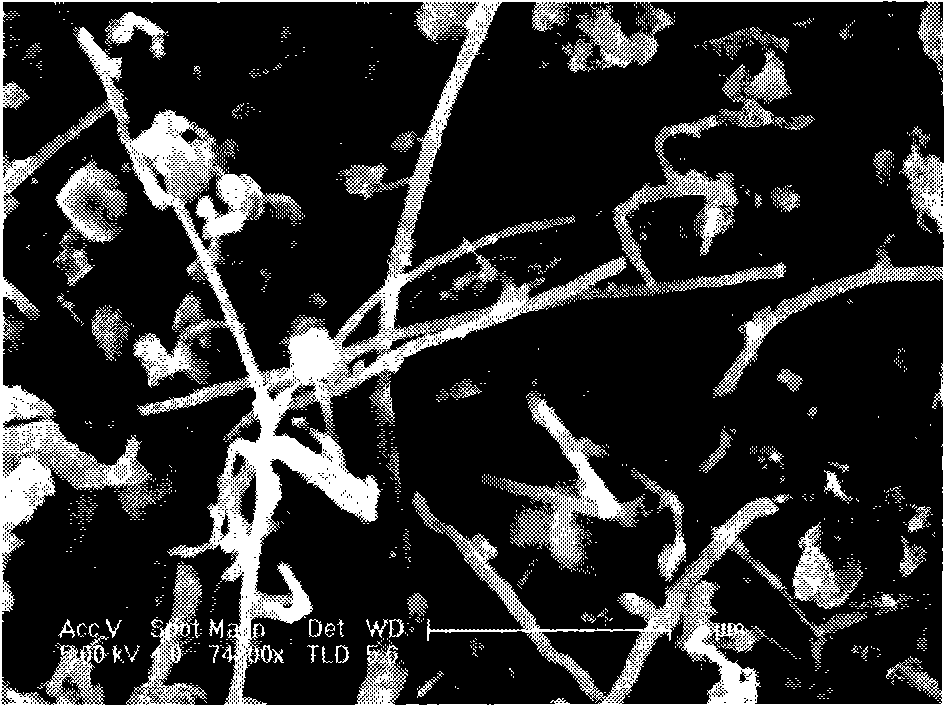

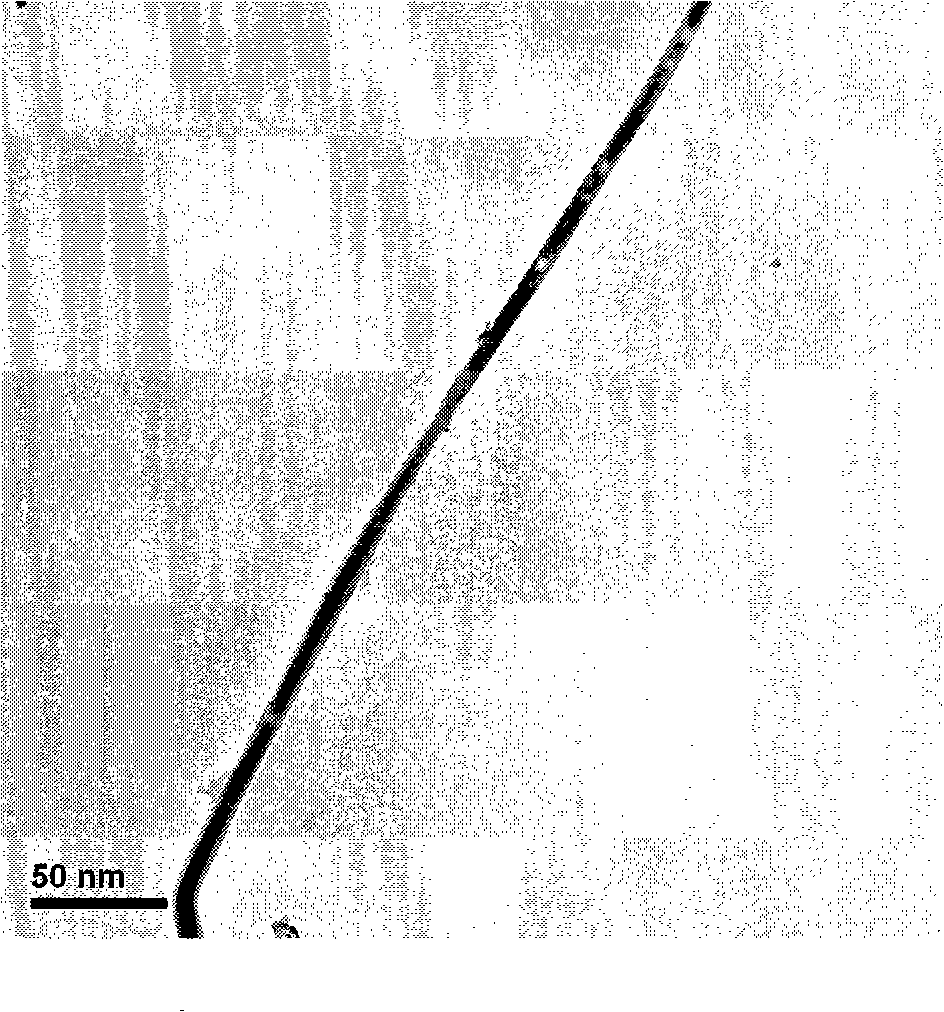

Method for rapidly preparing SiC nanowire

The invention relates to a method for rapidly preparing a SiC nano-wire belonging to the nano technology field comprising the steps: a. mixing the 33.3%-66.7% SiO powder and the 33.3-66.7% coke according to the weight ratio; b. milling the mixture in a ball mill to prepare reacting materials; c. arranging the materials in a crucible made by graphite in a sealed quartz tube and vacuuming with a vacuum pump; d. introducing argon or nitrogen into the quartz tube and adjusting the intake flow to control the tube pressure within 0.02-0.04 MPa; e. heating the graphite crucible using a high frequency induction power wire winding around the outside of the quartz tube to 1600 DEG C in three minutes and maintaining the temperature; f. cooling the materials and the tube to the room temperature under the protection of argon or nitrogen to obtain the SiC nano-wire. The method solves the problems of complicated technology, high cost, long period, and difficult control condition in the prior art of SiC nano-wire preparation.

Owner:SHANGHAI JIAO TONG UNIV

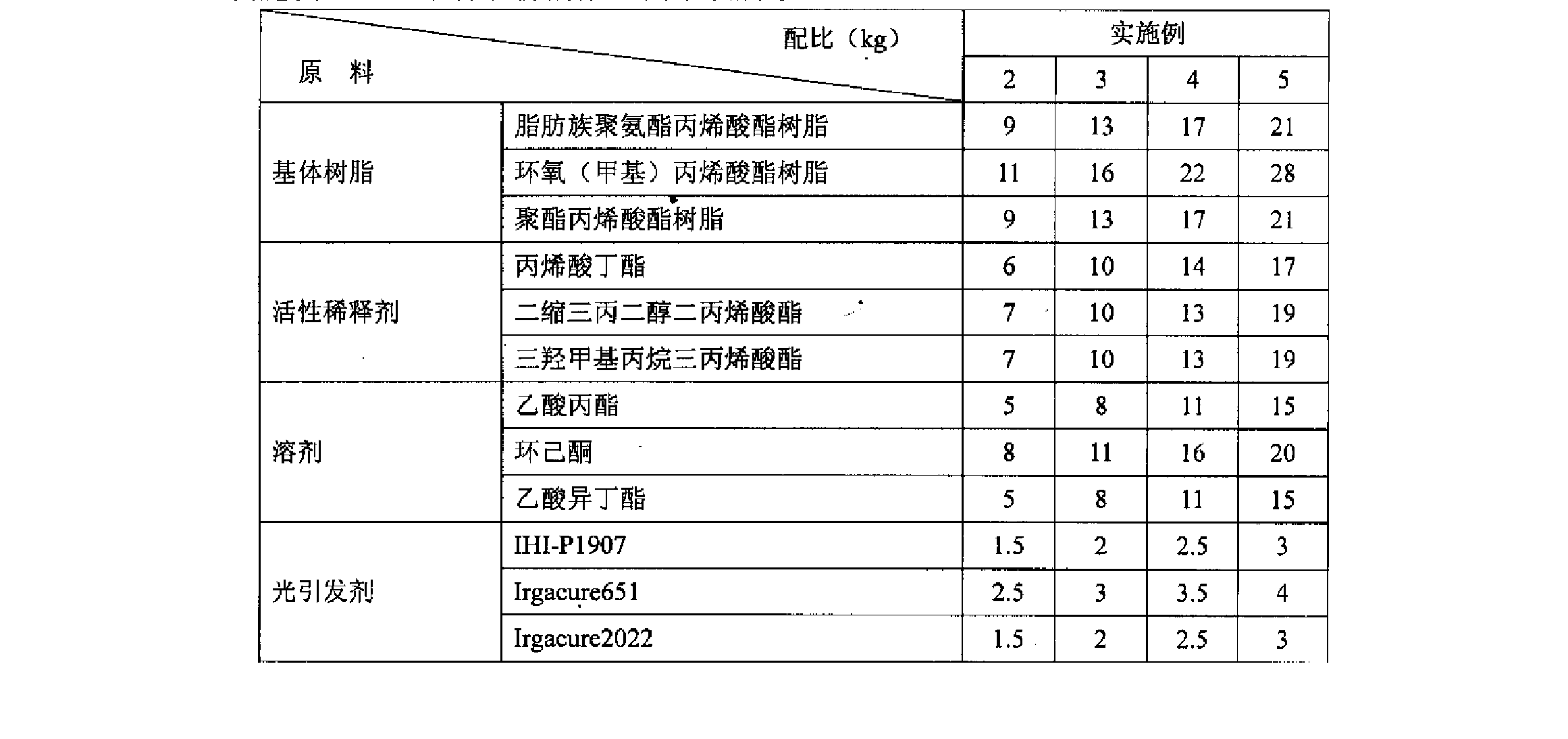

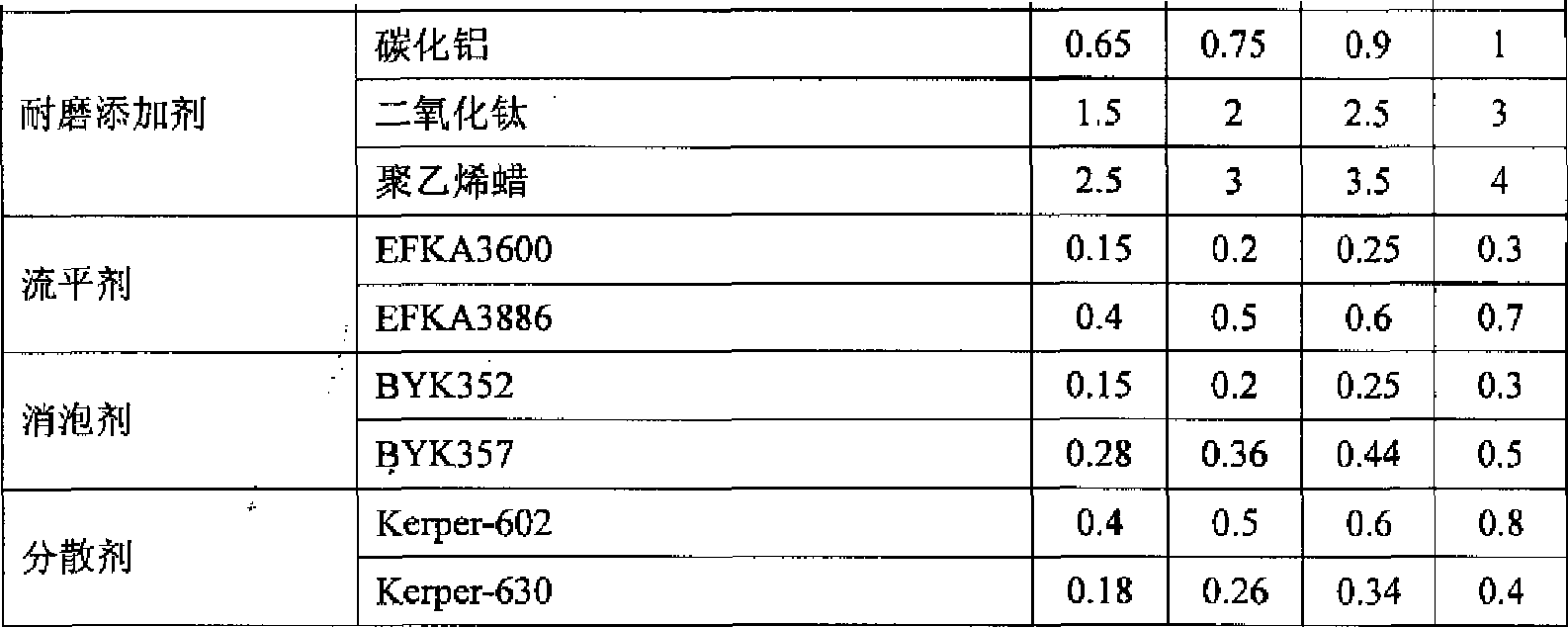

Acrylic ester modified high-weatherability paint and preparation thereof

InactiveCN101412889ALow requirements for process conditionsEasy to operatePolyurea/polyurethane coatingsEpoxy resin coatingsSolventDefoamer

The invention relates to paint for a surface coating of a section, in particular to acrylic ester modified high weather resistance paint and a preparation method thereof. The paint consists of the following raw materials in weight portion: 16 to 70 portions of matrix resin, 10 to 55 portions of active diluent, 9 to 50 portions of solvent, 0.3 to 0.8 portion of foam suppressor, 4 to 10 portions of light initiator, 3.5 to 8 portions of anti-wear additive, 0.4 to 1 portion of flatting agent, 0.4 to 1.2 portions of dispersing agent, and proper amount of pigment. The paint improves the quality of a PVC plastic colorful section and enlarges the application range of the material. The method reasonably prepares the acrylic ester modified high weather resistance paint used on the surface of the section by using a unique acrylic ester modified high weather resistance paint formulation. The invention provides the acrylic ester modified high weather resistance paint with new formulation to solve the problems of poor weather resisting property of the product and poor adhesive force of the paint during stamping after the product is stamped. The application of the paint successfully realizes high quality and high taste of the colorful section, and realizes technical renovation and great-leap-forward development of the industry of PVC colorful section.

Owner:湖南平桂制塑科技实业有限公司

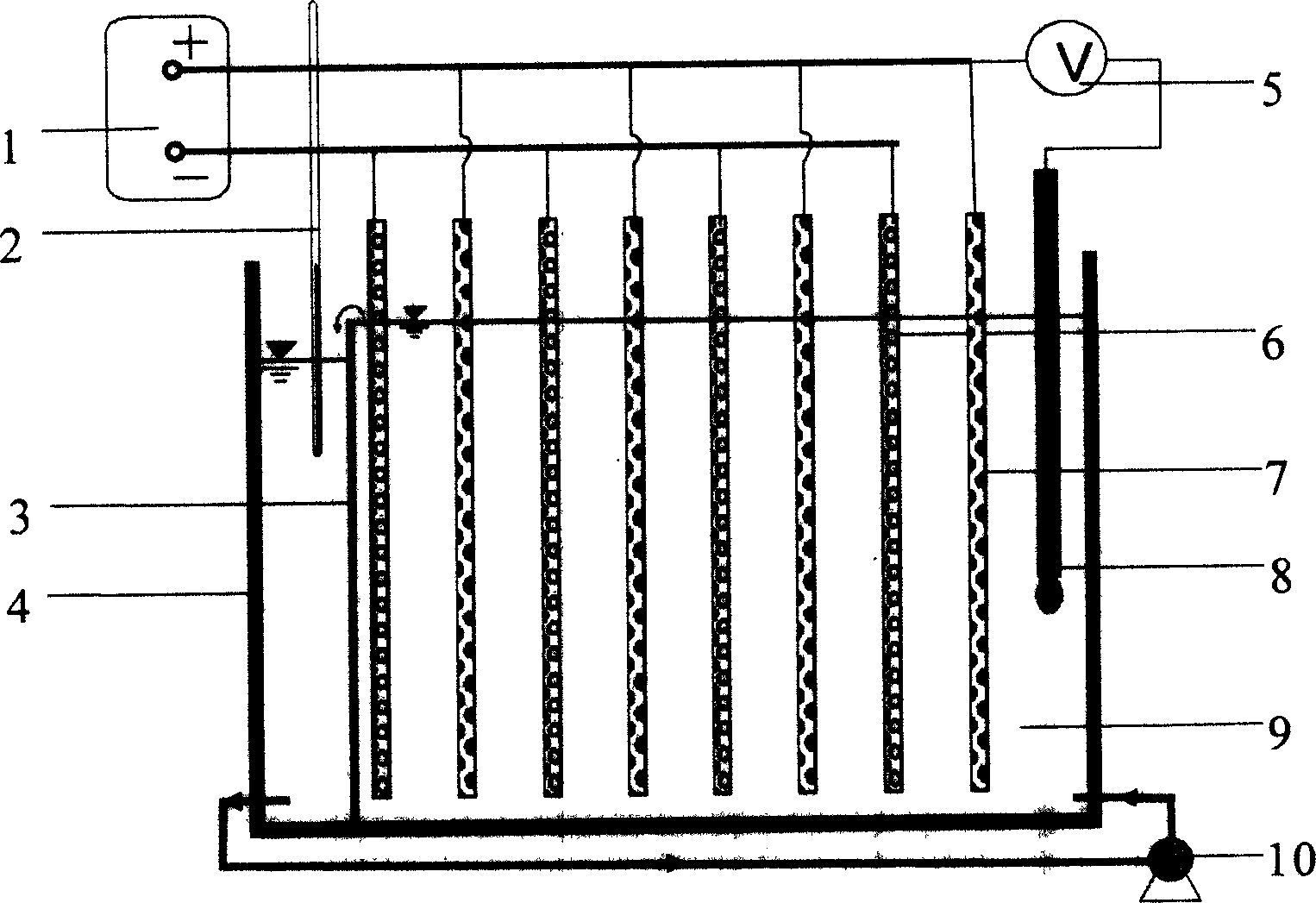

Process for preparing polymeric aluminium chloride through dimensionally stable anodes

The invention discloses a process for preparing high grade polymeric aluminium chloride through electrolysis of shape stable anode, wherein aluminium chloride is used as electrolyte, shape stable anode is used as the anode, titanium as cathode, appling DC electricity for a predetermined period of time, and circulating the electrolyte.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

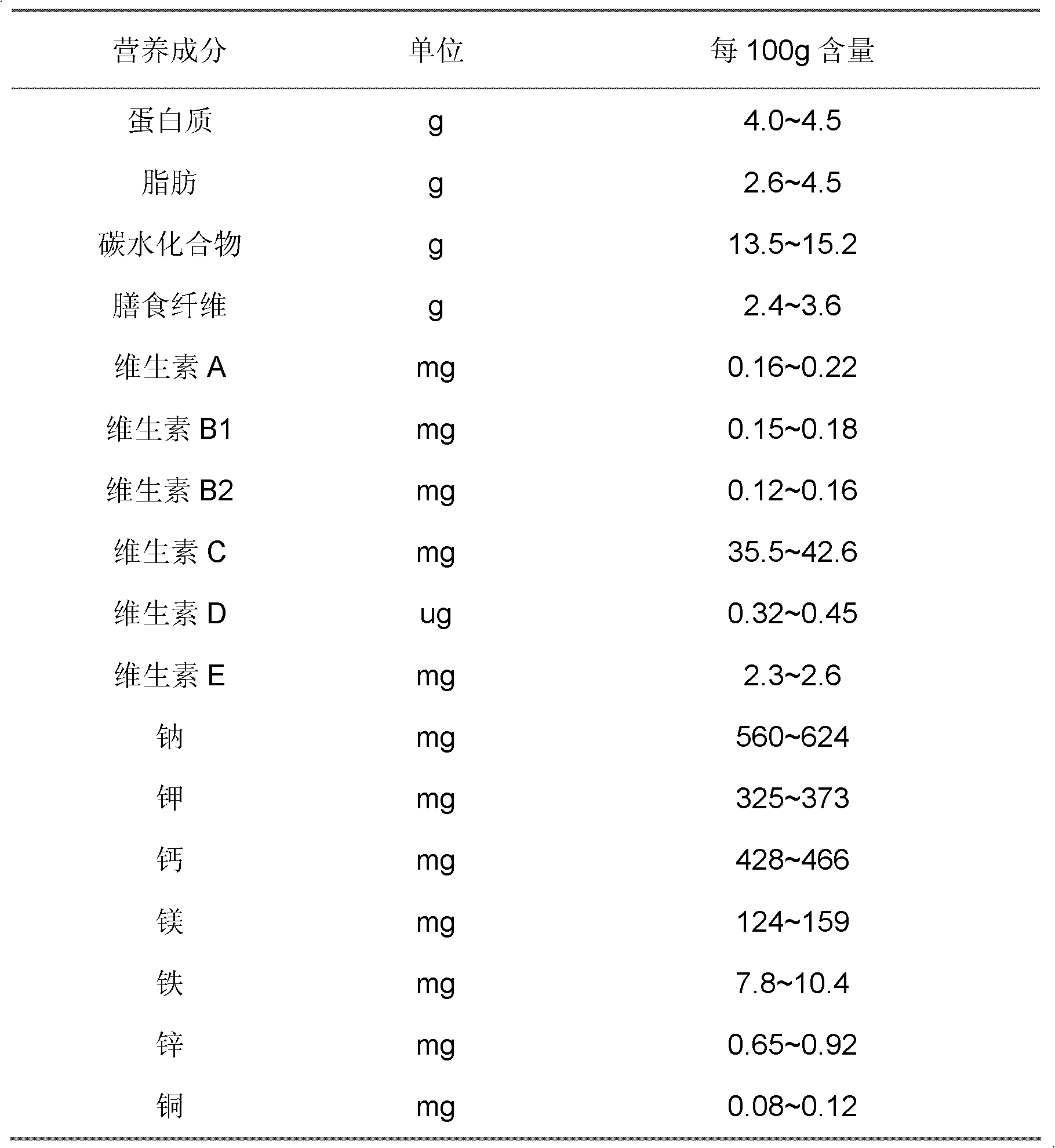

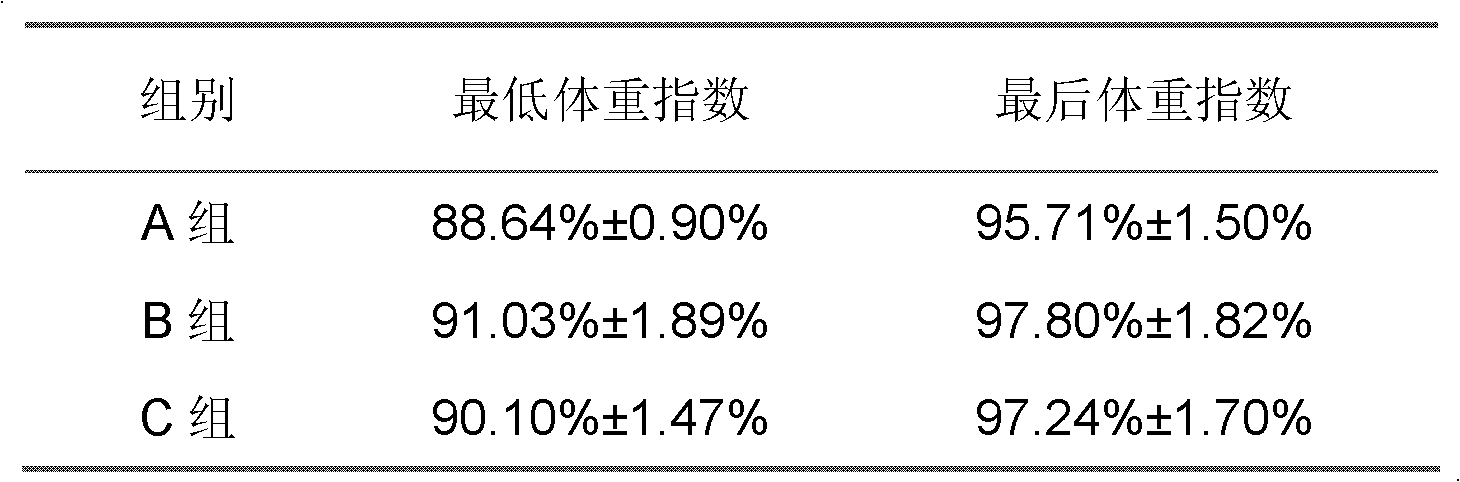

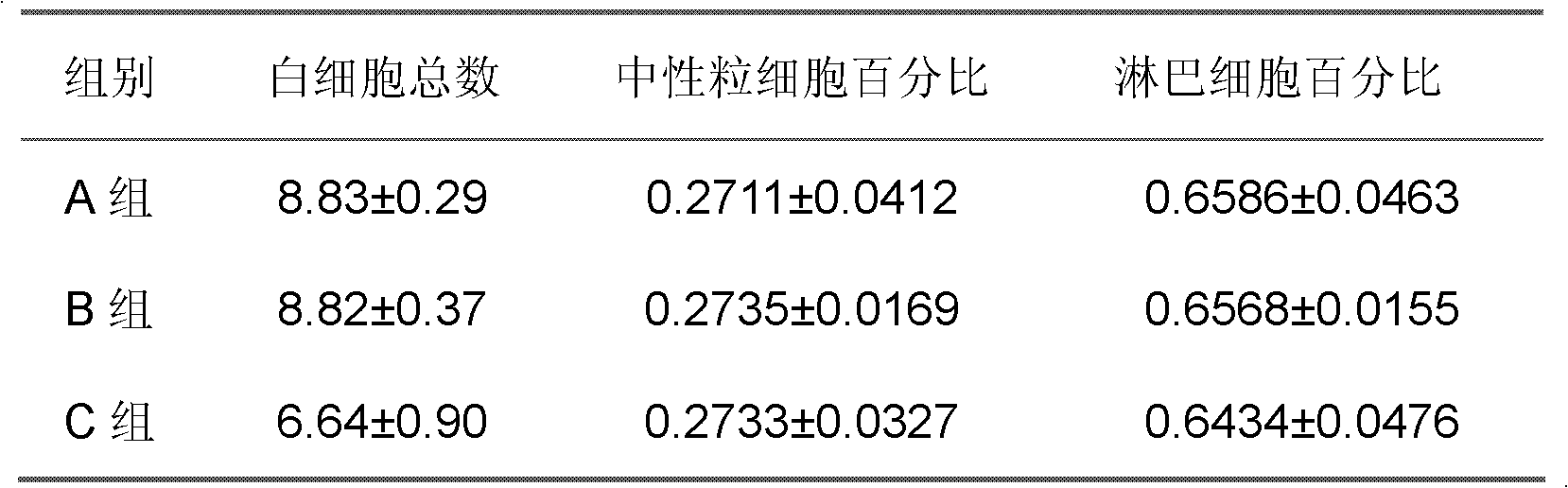

Salted egg white protein polypeptide containing enteral nutrition and preparation method thereof

InactiveCN102429149AHigh in nutrients and very comprehensiveRich in nutrientsFood preparationWater bathsAnimal science

The invention provides a salted egg white protein polypeptide containing enteral nutrition and a preparation method thereof, belonging to the field of nutritious foods. The enteral nutrition comprises the following components in percentage by mass: 2-5% of salted egg white protein polypeptide powder, 9-10% of fat, 15-20% of soy protein, 45-50% of maltodextrin, 5-10% of fruit and vegetable powder,2-5% of arginine, 7-12% of konjaku flour and 2-5% of oligosaccharide. The preparation method mainly comprises the following steps of: preparing salted egg white protein polypeptide powder, preparing salted egg white powder into an aqueous solution with pH of 7-9, heating for pretreating; adding protease, carrying out constant-temperature water bath enzymolysis on a condition of stable pH value; and finally, carrying out boiling water bath, cooling and centrifuging, treating supernate with activated carbon, and drying. The salted egg white protein polypeptide containing enteral nutrition provided by the invention has comprehensive nutrients, can be digested and absorbed easily, and can remarkably enhance immunity; the utilization value of salted egg white protein is realized completely. The effect of environment protection is realized and the processing cost of salted egg foods is reduced.

Owner:JILIN UNIV

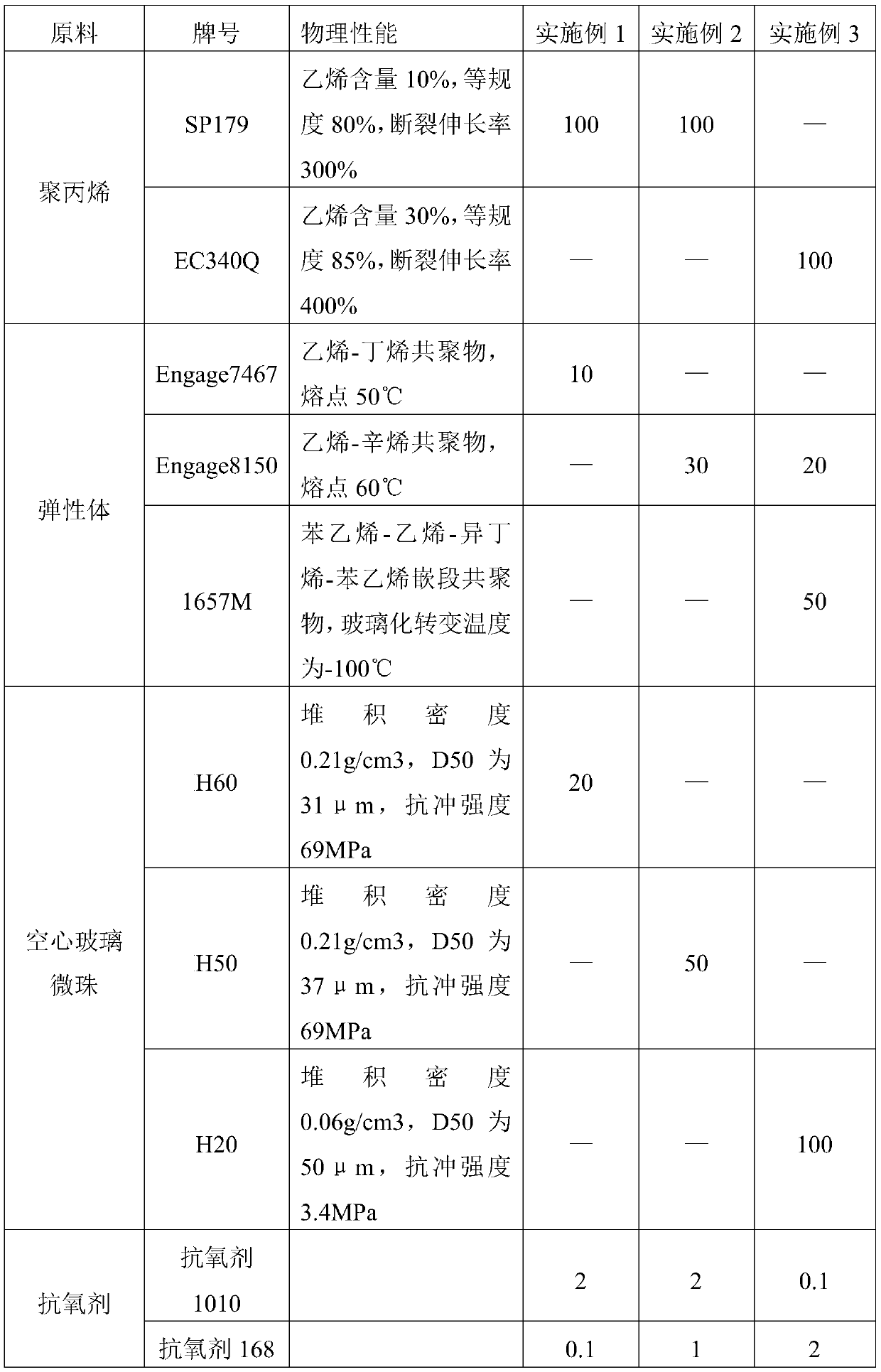

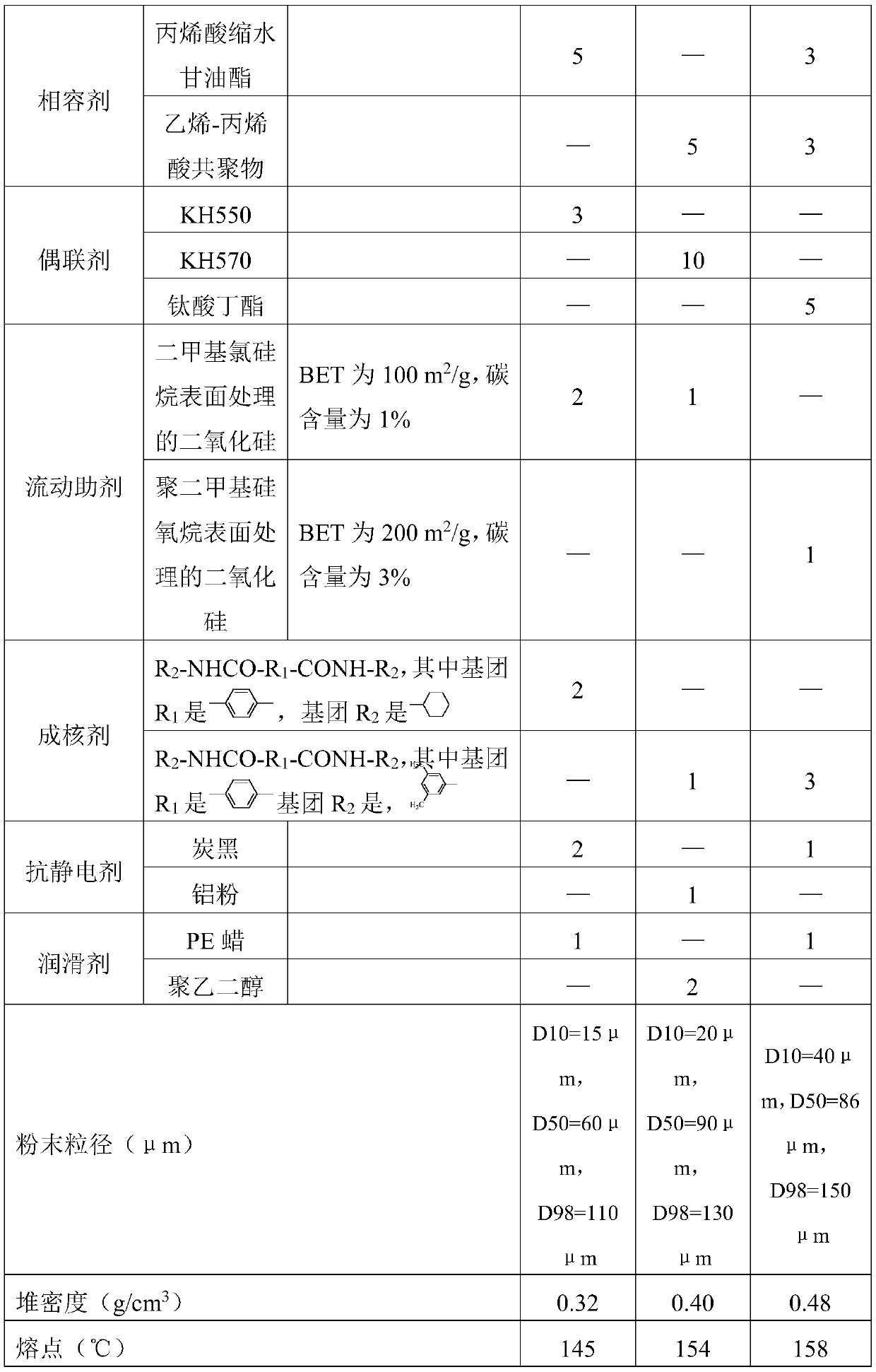

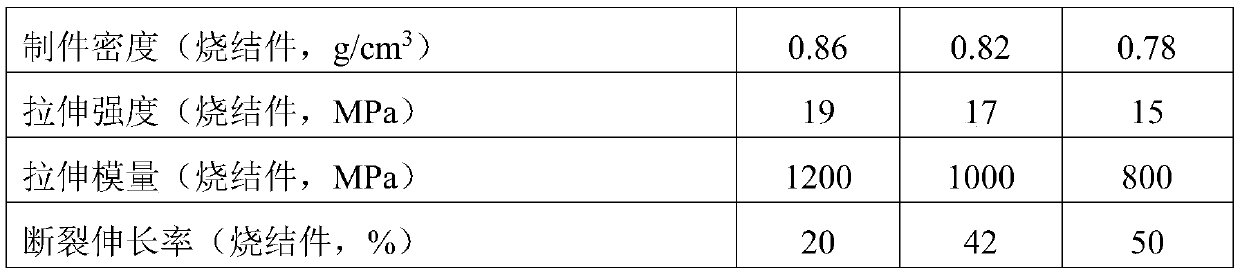

Polypropylene powder product for selective laser sintering and preparation method of polypropylene powder product

ActiveCN110746693ANarrow particle size distributionHigh sphericityAdditive manufacturing apparatusSelective laser sinteringPolypropylene

The invention provides a polypropylene powder product for selective laser sintering and a preparation method of the polypropylene powder product. Polypropylene powder has narrow particle size distribution, high sphericity and good fluidity, has no warping deformation after selective laser printing, and has excellent performance of selective laser sintering and high forming accuracy. Printing of hollow glass bead filled polypropylene powder is implemented by using a selective laser sintering process, hollow glass beads in the obtained part are not crushed, the density of the part can be greatlyreduced, and lightweight of a material can be effectively achieved; by using a coupling agent and a compatibilizer provided by the invention, the compatibility between the hollow glass beads and polypropylene can be well improved; and due to a special powder mixing process, the hollow glass beads can be tightly combined with the polypropylene after laser sintering, mechanical properties, particularly the rigidity, can be greatly improved, and the polypropylene powder product has great application values in the field of mechanical parts.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

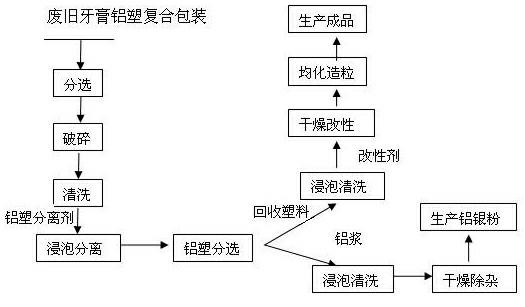

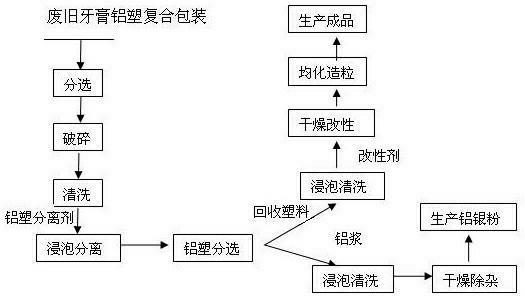

Process for recycling waste toothpaste aluminum-plastic composite packaging material

InactiveCN102151686AImprove the efficiency of the separation reactionReduce energy consumptionSolid waste disposalToothpasteProcess conditions

The invention discloses a process for recycling waste toothpaste aluminum-plastic composite packaging material. The process is characterized by comprising the following steps: (1) treating crushed materials; (2) separating aluminum and plastics; (3) granulating plastics and producing a finished product; and (4) producing aluminum-silver powder. In the process, the toothpaste aluminum-plastic composite packaging material is used as a raw material, and reagents are all non-toxic, therefore the high-quality polyethylene plastic product and aluminum powder can be produced; and the whole process for recycling the waste toothpaste aluminum-plastic composite packaging material does not generate any industrial pollution. The process is simple to operate and environmentally friendly and has the characteristics of low cost, high benefit, no toxicity, low process condition requirement and the like.

Owner:MILUO TONGYI RENEWABLE RESOURCES TREATMENT

Night-gloss glass printing ink, preparation method and printing method on glass product

ActiveCN101974264AGood luminous effectMaintain luminous performanceInksOther printing apparatusPrinting inkDefoaming Agents

The invention discloses night-gloss glass printing ink, a preparation method and a printing method on a glass product. The night-gloss glass printing ink is prepared from long afterglow fluorescent powder, light-transmitting glass pigment, a suspensoid agent, a solid dispersion agent and a defoaming agent. The night-gloss glass printing ink is prepared by uniformly mixing the long afterglow fluorescent powder with the light-transmitting glass pigment, adding the mixture in the fused supensoid agent, solid dispersion agent and defoaming agent, and stirring and cooling. The printing method is realized by the following steps of: silk printing night-gloss patterns on the glass product with the night-gloss ink; raising the temperature of the glass product to 520-650DEG C; and maintaining the temperature for 20-30 minutes and then cooling to obtain the finished product. The night-gloss glass printing ink is roasted silk printing ink for resisting the high temperature of 520-650DEG C and being applied to the glass product and is ink which can be quickly cured and has remarkable night-gloss effect, strong adhesive force and friction resistance; and the preparation method has simple process, and is convenient to operate and suitable for industrial production.

Owner:SHENZHEN HUAXI BIO TECH LTD

High-flexibility polyester epoxy impregnated resin and preparation method thereof

InactiveCN107459797AHigh mechanical flexibilityGood high and low temperature impact cracking resistancePolyesterEpoxy

The invention discloses a high-flexibility polyester epoxy impregnated resin and a preparation method thereof. According to the high-flexibility polyester epoxy impregnated resin, non-flexible unsaturated resin and non-flexible epoxy resin commonly used in the polyester epoxy system impregnated resin of the prior art are replaced by flexible unsaturated polyester resin and flexible type pliable epoxy resin, and by adopting monobasic acid terminated and synthesized flexible unsaturated polyester resin and combining the flexible type pliable epoxy resin with excellent flexibility, the remarkable toughness effect can be achieved, the impregnated resin has excellent mechanical flexibility and good high-low-temperature impact and anti-cracking performance, so that the viscosity of the high-flexibility polyester epoxy impregnated resin can achieve 386mPa.s at 25 DEG C, has good permeation property and can be impregnated by sinking, dripping or VPI, and the resin has excellent electrical insulating performance, wet-heat-resistant performance and chemical-resistant performance.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Precision forming method of straight/helical tooth cylindrical gear

ActiveCN102764847AIncrease in sizeReduce volumeMetal-working apparatusWheelsEngineeringProcess conditions

The invention relates to a precise forming method of a straight / helical tooth cylindrical gear. The precise forming method disclosed by the invention is characterized by being realized by the following two steps while a 'diameter-increasing half long ridge-tooth space splitting' way is adopted: firstly, closed die forging is carried out on cylindrical blank to form a pre-formed part, wherein one end of the pre-formed part is larger in radial dimension, sectional area and edge axial dimension and the other end of the pre-formed part is equal to the required value of the sectional area and has slightly smaller radial dimension, the two ends transit in a bevel angle manner, and a cylindrical surface is in a 'diameter-increasing half long ridge' state; and secondly, the pre-formed parts penetrate through a final forming die each tooth space of which is correspondingly provided with a splitting wedge in a sequence from big end to small end, wherein a splitting edge and a working surface of the splitting wedge are in a tilted state, a rim is split, extruded and deforms, and each slot base is deepened and the top of each ridge is lifted, thus a gear tooth with complete tooth profile is obtained. The gear tooth / tooth space obtained by the invention is clear and full, a required forming force is relatively small, an equipment action is simple, a structure of a die is not complex, a workpiece is easy to demould, requirement to technological conditions is low, and adaptability is wide.

Owner:SHENZHEN AIDELI ELECTROMECHANCIAL

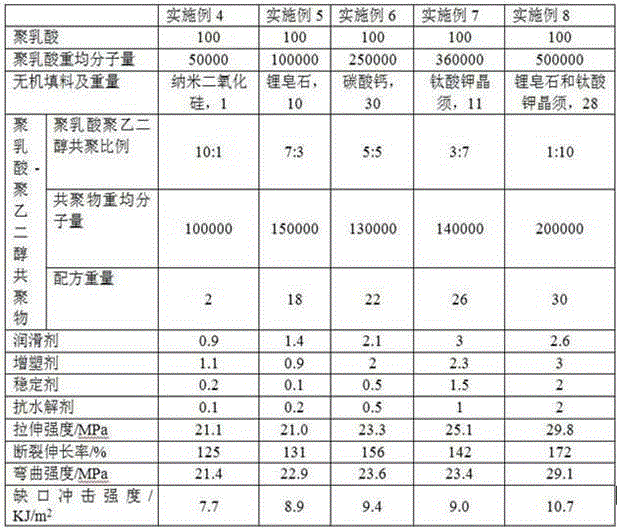

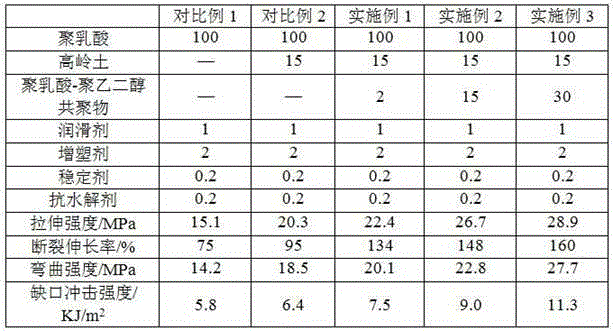

Polylactic acid material for fused deposition molding and preparation method of polylactic acid material

The invention discloses a polylactic acid material for fused deposition molding and a preparation method of the polylactic acid material. The polylactic acid material for fused deposition molding is prepared from the following raw materials and auxiliaries: 100 parts of polylactic acid, 1 to 30 parts of inorganic filler, 2 to 30 parts of polylactic acid-polyethylene glycol copolymer, 0.9 to 3 parts of lubricating agent, 0.9 to 3 parts of plasticizer, 0.1 to 0.5 parts of stabilizer and 0.1 to 2 parts of hydrolysis resistant agent. According to the polylactic acid material, due to the addition of the polylactic acid-polyethylene glycol copolymer, the inorganic filler is dispersed more uniformly in the polylactic acid, the mechanical property of a fused deposition molding workpiece is promoted, and the practicability is higher. In addition, the invention also provides the preparation method of the polylactic acid material, the preparation method is easy to operate, and low in requirements on technological conditions and production equipment without adding other equipment to promote the dispersion of the inorganic filler; large-scale promotion and production can be realized, the market prospect is wide and the market benefit is extremely excellent.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

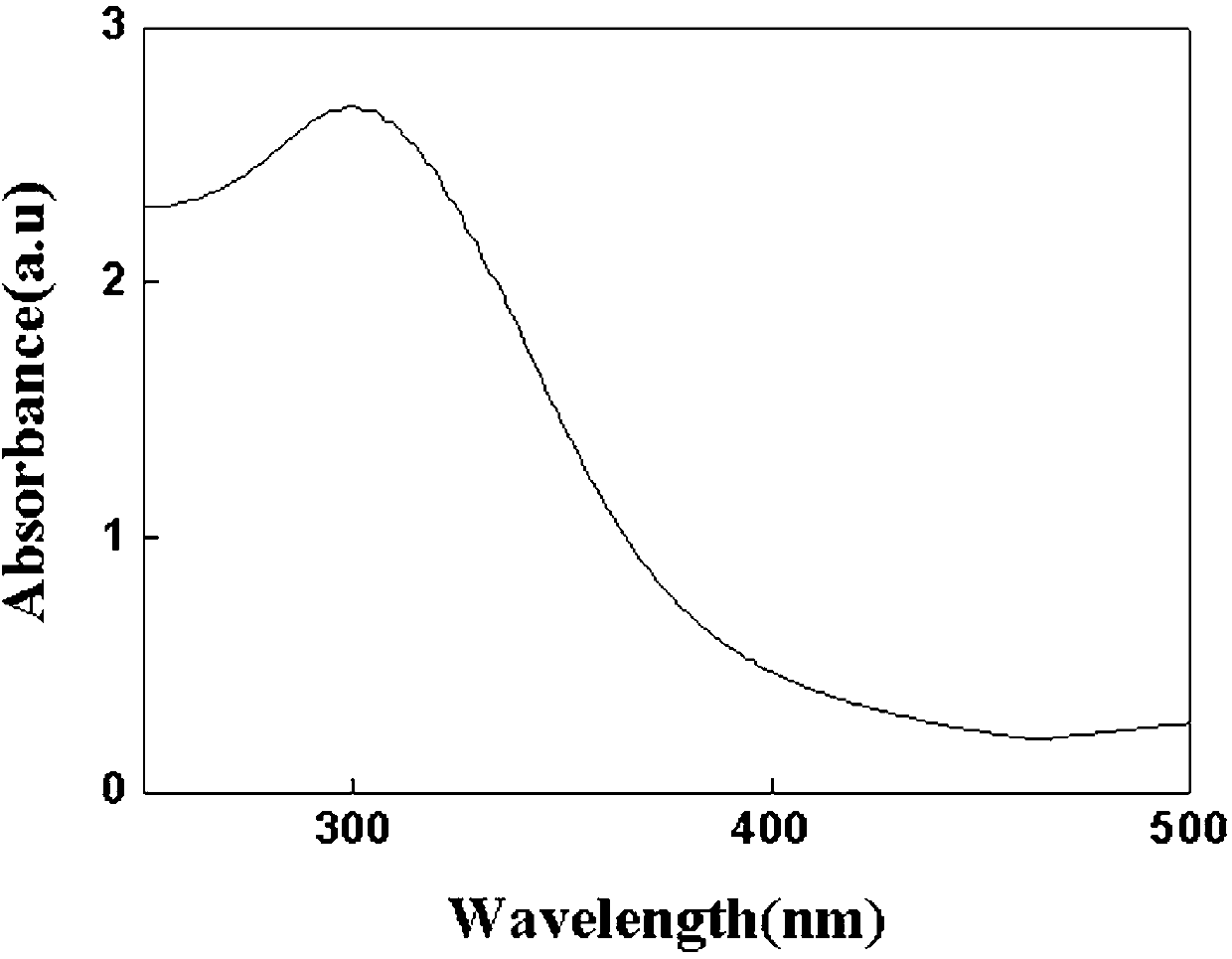

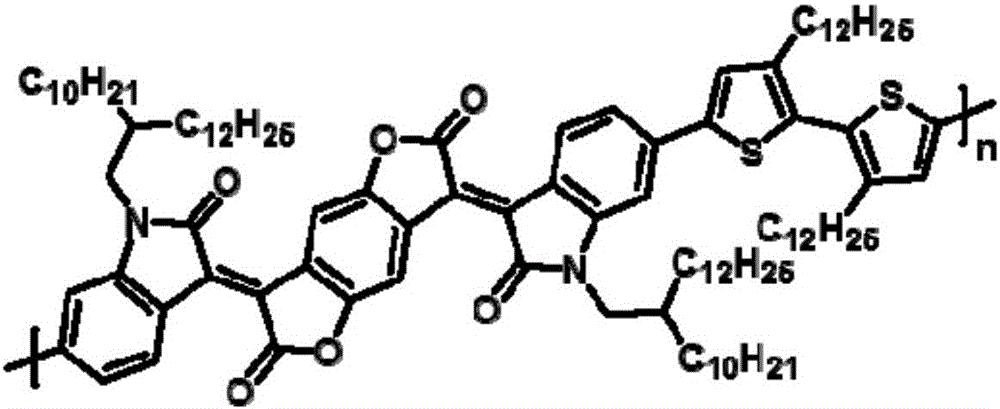

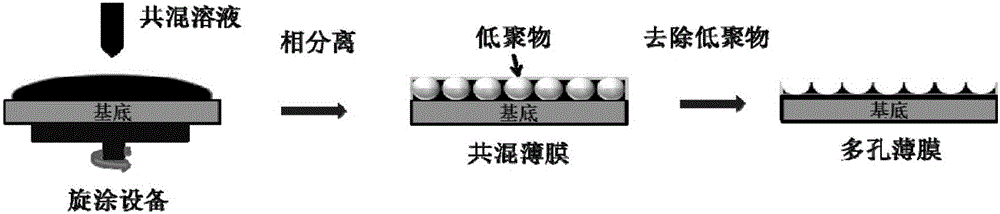

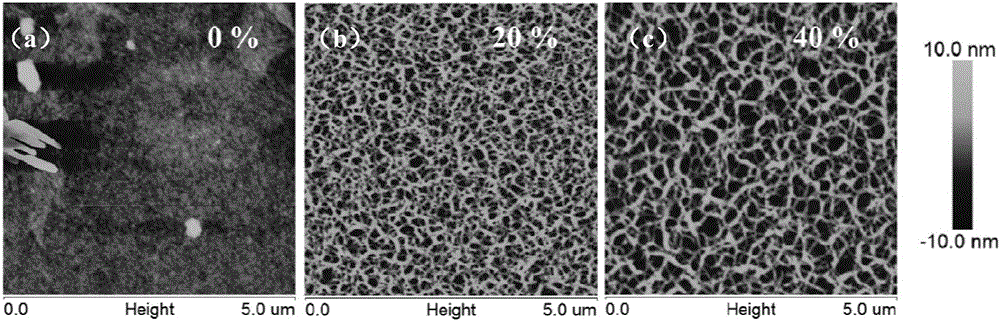

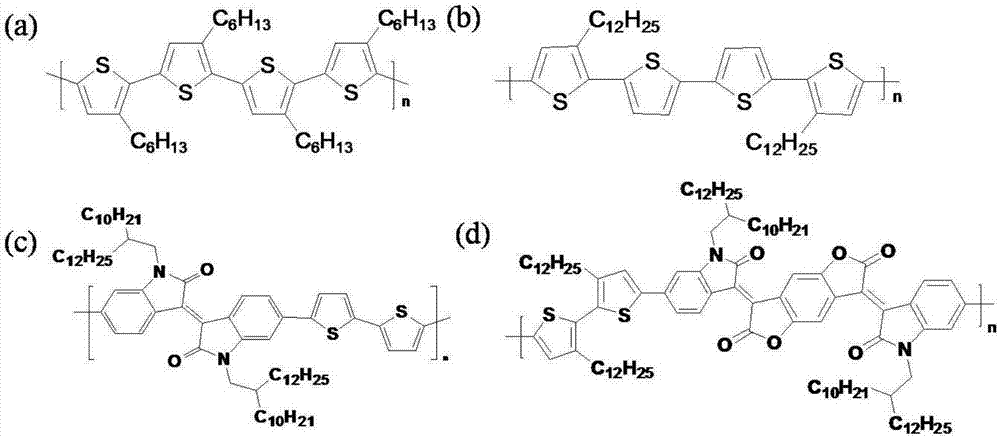

Method for preparing porous organic semiconductor film by using solution method and application thereof

ActiveCN105842302ASolve problems that are not suitable for evaporation processesSimple methodMaterial resistanceOligomerMolecular semiconductor

The invention discloses a method for preparing porous organic semiconductor film by using a solution method and application thereof. The method is characterized by including: dissolving organic semiconductor with high molecular weight and oligomer with low molecular weight in an organic solvent to obtain a blending solution; spin-coating the blending solution on the substrate to form a blending film by a solution spin-coating method, and using an appropriate solvent to dissolve and remove the oligomer with low molecular weight in the blending film to obtain the porous organic semiconductor film. The porous film is prepared by the solution method, and the method is simple, has good repeatability, has low requirements of the device and technology condition, and is suitable for preparing most of the high-molecular semiconductor porous films. The porous organic semiconductor film prepared by the invention can be used for the gas phase sensor, and can significantly improve the detection effect of the organic semiconductor material on the corresponding gas analyte by means of providing an effective gas dispersion channel.

Owner:黄山市开发投资集团有限公司

Method for preparing nanometer cerium oxide by hydrothermal method

InactiveCN102849774ASimple preparation processLow requirements for production equipmentNanotechnologyRare earth metal compoundsActive agentNanoparticle

The invention provides a method for preparing nanometer cerium oxide. The invention adopts the following technical scheme that the method comprises the following steps: 1) preparing a Ce(NO3)3.6H2O aqueous solution with a concentration of 0.05-0.1 mol / L at room temperature; 2) taking a certain volume of the Ce(NO3)3.6H2O aqueous solution at room temperature, dropwisely adding undiluted commercially-available 25% ammonia water into the Ce(NO3)3.6H2O aqueous solution according to a volume ratio of 10:1-3; 3) allowing the mixed solution to react for 2-24 hours, after the reaction, performing centrifugation, removing the liquid at the upper level, washing the powder obtained after centrifugation, and drying to obtain solid powder. The invention realizes one-step synthesis of nanometer cerium oxide by a hydrothermal method; the preparation process is simple, and the requirements for production equipment and process conditions are low; no organic solvent is added, which is basically free of pollution, and is quite environment-friendly; no macromolecular surfactant is added, which prevents posttreatment process such as washing and the like; the kinds of the required raw materials are few, and when compared with traditional process, the method of the invention is quite low in production cost; the method cam prepare uniform and pure cerium oxide nanoparticles, cerium oxide nanorods, and mixtures of the above two.

Owner:ZHEJIANG SCI-TECH UNIV

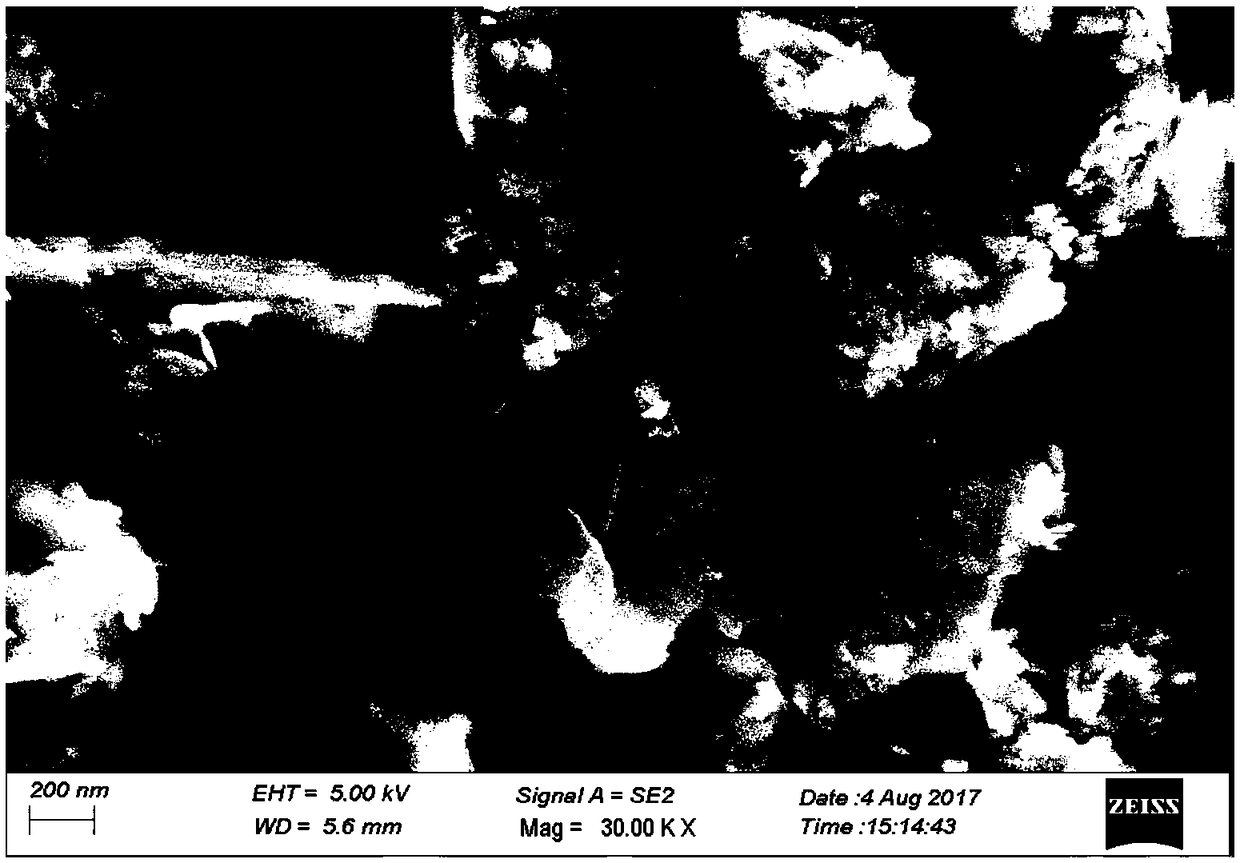

Production method of nano rare earth oxide powder

ActiveCN109019656AAchieve recyclingLow costRare earth metal oxides/hydroxidesMaterial nanotechnologyRare earthSlurry

The invention discloses a production method of nano rare earth oxide powder, comprising: preparing a rare earth salt solution, adding an ammonium hydrogen carbonate solution into the rare earth salt solution for precipitation reaction, and performing crystal form conversion on slurry obtained by the precipitation reaction at 90 to 130 DEG C under the condition of 0.2 to 0.6 MPa, and calcining obtained crystal to obtain the nano rare earth oxide powder. The production method has the advantages of low process conditions, low equipment dependence and low cost, and is suitable for industrialization.

Owner:BAOTOU RES INST OF RARE EARTHS +1

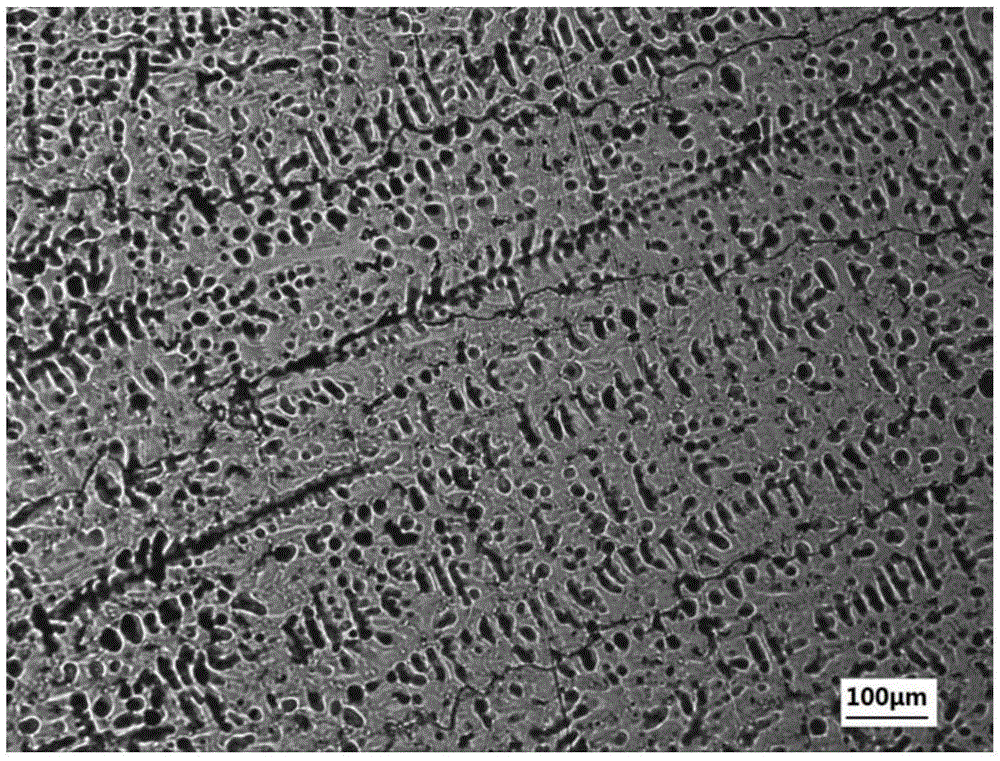

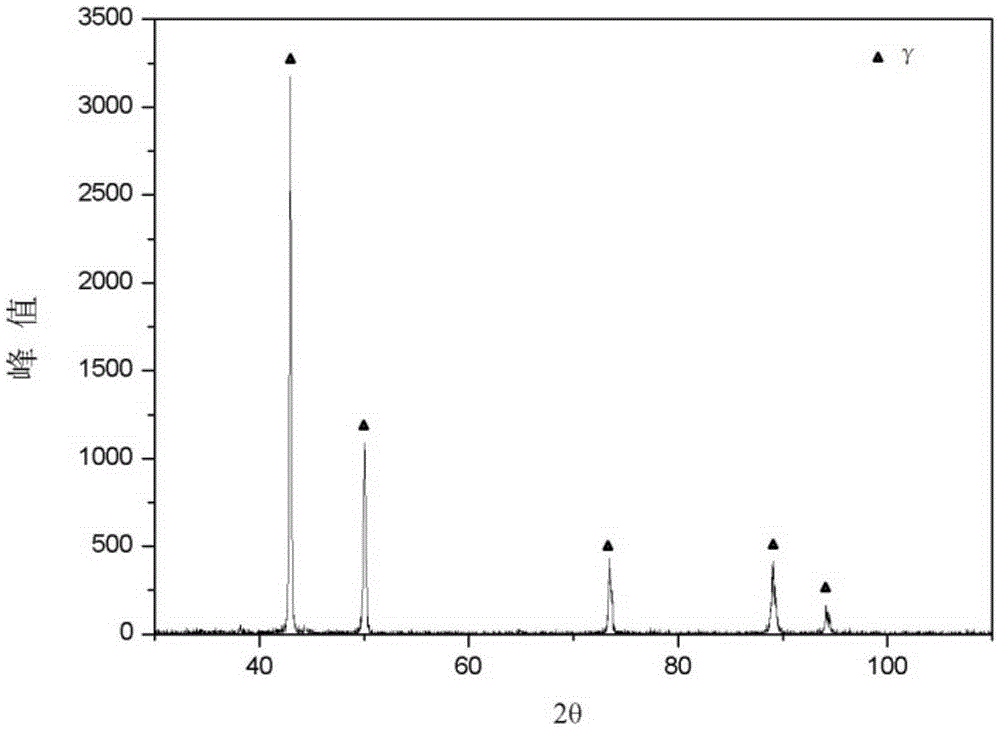

Method for smelting high-nitrogen steel at normal pressure by two steps

ActiveCN105385931AImprove mechanical propertiesLow requirements for process conditionsSolid state diffusion coatingElectro-slag remeltingProcess conditions

The invention belongs to the field of steel smelting and making and particularly relates to a method for smelting high-nitrogen steel at the normal pressure by two steps. The method comprises the first step of iron alloy nitrogenization and the second step of smelting at the normal pressure. The first step includes powder preparation and nitrogenization treatment. The second step includes heating for smelting at the normal pressure, deslagging, final deoxidization, final deslagging and pouring. In order to meet the requirement for further refining, secondary normal-pressure smelting is conducted on a steel ingot obtained after primary normal-pressure smelting is completed in the normal-pressure condition, and a refined steel ingot is obtained through an electroslag remelting technique. By the adoption of the method, the high-nitrogen steel can be smelted at the normal pressure, the nitrogen content high enough and sufficient alloy elements are guaranteed, and thus the nitrogen content of alloy can be controlled more easily; technological conditions and operation requirements are lowered, and the production cost is controlled.

Owner:CHANGCHUN SHIYUE ENERGY SAVING MATERIAL CO LTD

Method for manufacturing propeller casting for high nitrogen austenite stainless steel vessel

InactiveCN105562644ALow requirements for process conditionsGuaranteed Component Nitrogen ConcentrationFoundry mouldsFurnace typesPropellerWax

The invention relates to a method for manufacturing a propeller casting for a high nitrogen austenite stainless steel vessel. The method comprises the following seven steps: design of a propeller or paddle casting and a pouring system for the propeller or paddle casting; modeling and production preparation; wax molding; shell molding; smelting and pouring; post-treatment; and inspection. In the shell molding process, after a model shell is put into a case for sufficient roasting, the temperature of the model shell is controlled to be 650-1000 DEG C for pouring preparation. The smelting and pouring process comprises the following steps: carrying out smelting under the condition of ordinary pressure; regulating the heating power; after melting as well as deslagging and smelting are performed, quickly adjusting to reach pouring temperature and controlling the pouring temperature to be 1480-1590 DEG C; starting pouring within 90 s and finishing the pouring of all molten steel within 5 min; and after the pouring is finished, delaying solidification and sealing at a pouring gate by adopting the hot gating technology. By adoption of the method, no bubble is generated during pressure sealing and remains in the manufactured casting, and the difficult problem about unqualified high nitrogen austenite stainless steel propeller castings is solved.

Owner:CHANGCHUN SHIYUE ENERGY SAVING MATERIAL CO LTD

Method for preparing high-purity rare earth boride 6 (REB6) nano-powder

The invention discloses a method for preparing high-purity rare earth boride 6 (REB6) nano-powder. The method comprises the following steps of: (1) mixing rare earth oxide, boric oxide and magnesium powder, performing high-energy ball-milling on the mixture, pressing the mixture into a block blank, putting the blank into a self-propagation reaction furnace for heating and triggering a self-propagation reaction so as to obtain an intermediate product, which is dispersed in an MgO substrate, of REB6; and (2) leaching the intermediate product in an enclosed autoclave by taking dilute sulphuric acid as a leaching agent to obtain leacheate, removing lixivium to obtain filter residue and washing and drying the filter residue to obtain the high-purity REB6 nano-powder. The method has the advantages of low raw material cost, simple operation, low requirement on technological conditions and capability of laying the foundation for industrial production. The obtained REB6 powder has the advantages of high purity, small particle size, high powder activity and the like.

Owner:NORTHEASTERN UNIV

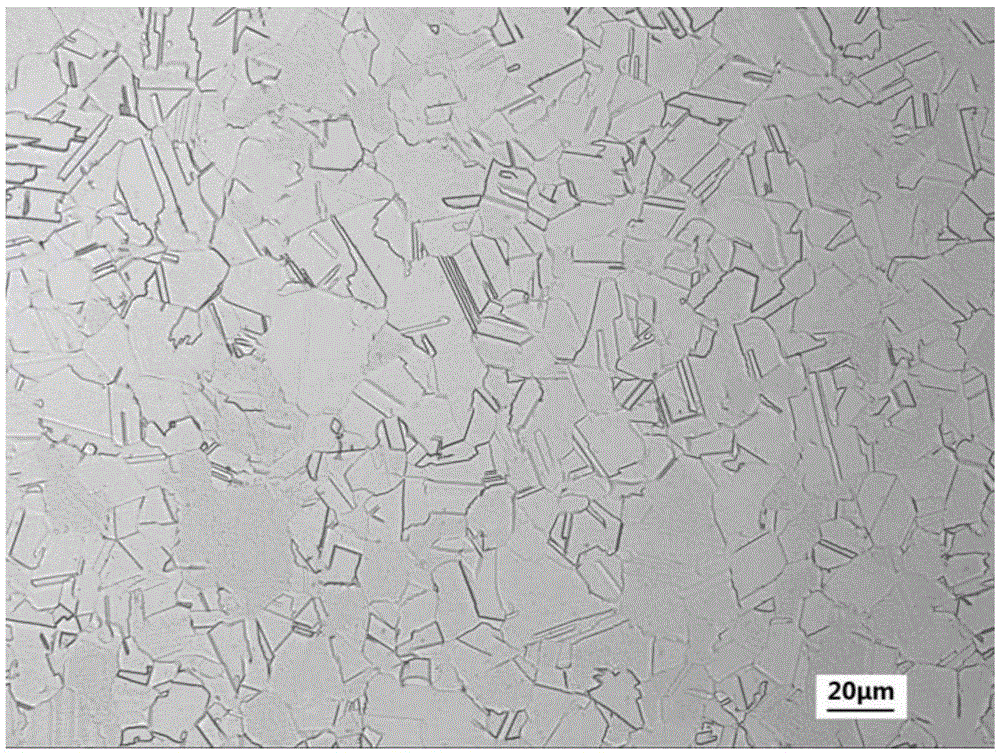

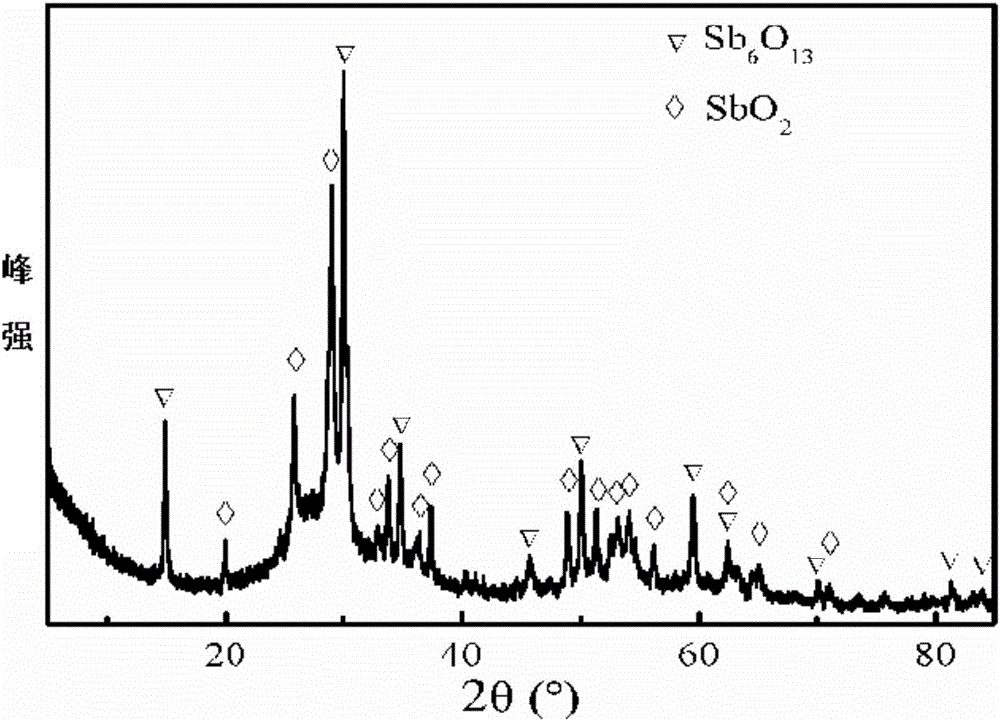

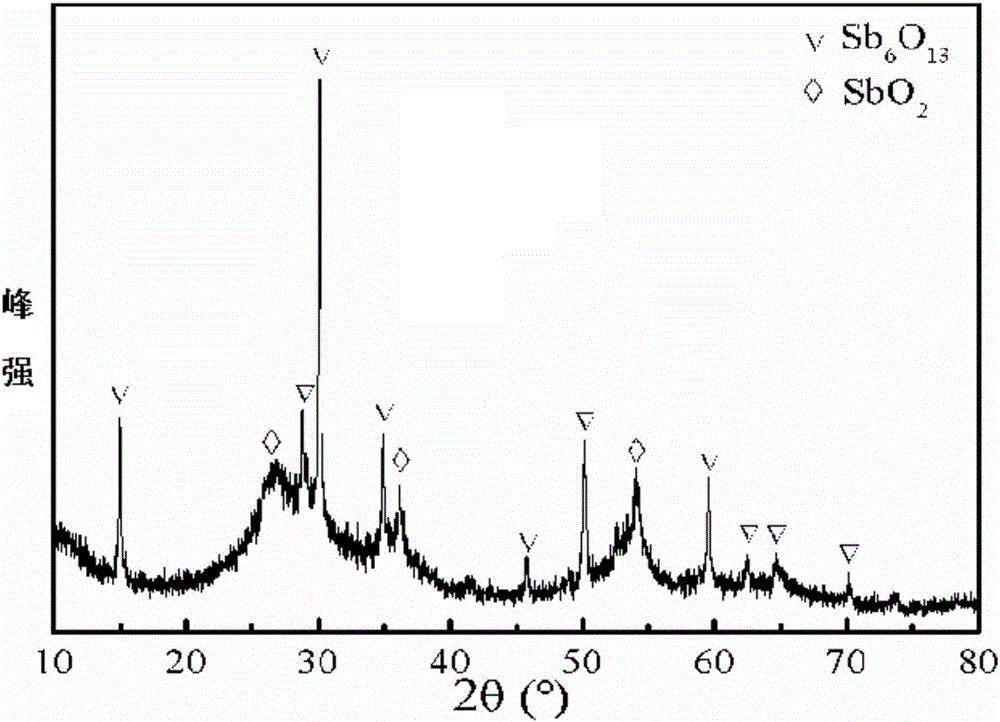

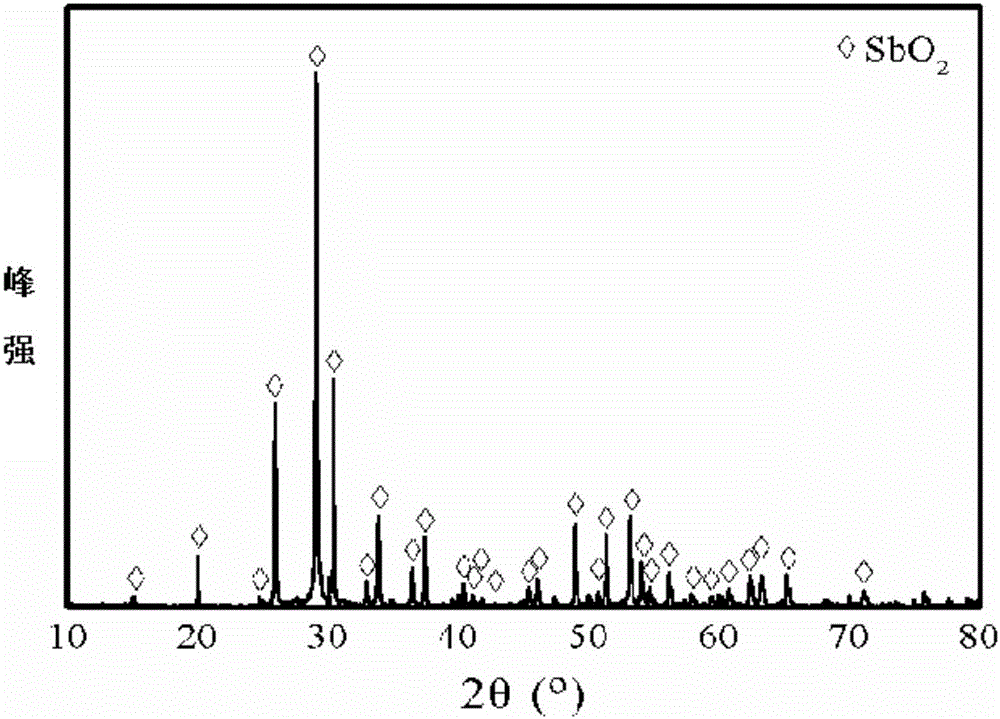

Method of using solution atomization method to prepare superfine Sb oxide

ActiveCN105858724ASimple processShort manufacturing processAntimony oxides/hydroxides/oxyacidsMaterials preparationSpray pyrolysis

The invention discloses a method of using a solution atomization method to prepare superfine Sb oxide. The method comprises the following steps: (1) trivalent Sb is added into a hydrochlric solution to prepare a Sb solution with the molar concentration of 0.05-0.8 mol / L; (2) clean oxidant is used to oxidize the solution obtained in step (1), and a pentavalent Sb solution is obtained; (3) Sb oxide powder is obtained after spray pyrolysis of the pentavalent Sb solution is obtained in step (2). According to the invention, trivalent Sb solution is used as a raw material, superfine Sb oxide powder materials are directly prepared through oxidization and spray pyrolysis, and the technological process is simple. Alternatively, lixivium from the conventional process of using an acid method in antimony smelting is directly used as the raw material. Therefore, the process of preparing the superfine Sb oxide powder materials is shortened; the conventional metallurgical process and the material preparation process are effectively combined; added value of products from conventional non-ferrous metal metallurgy is significantly increased; recycling of hydrochloric acid from lixivium is realized.

Owner:CENT SOUTH UNIV

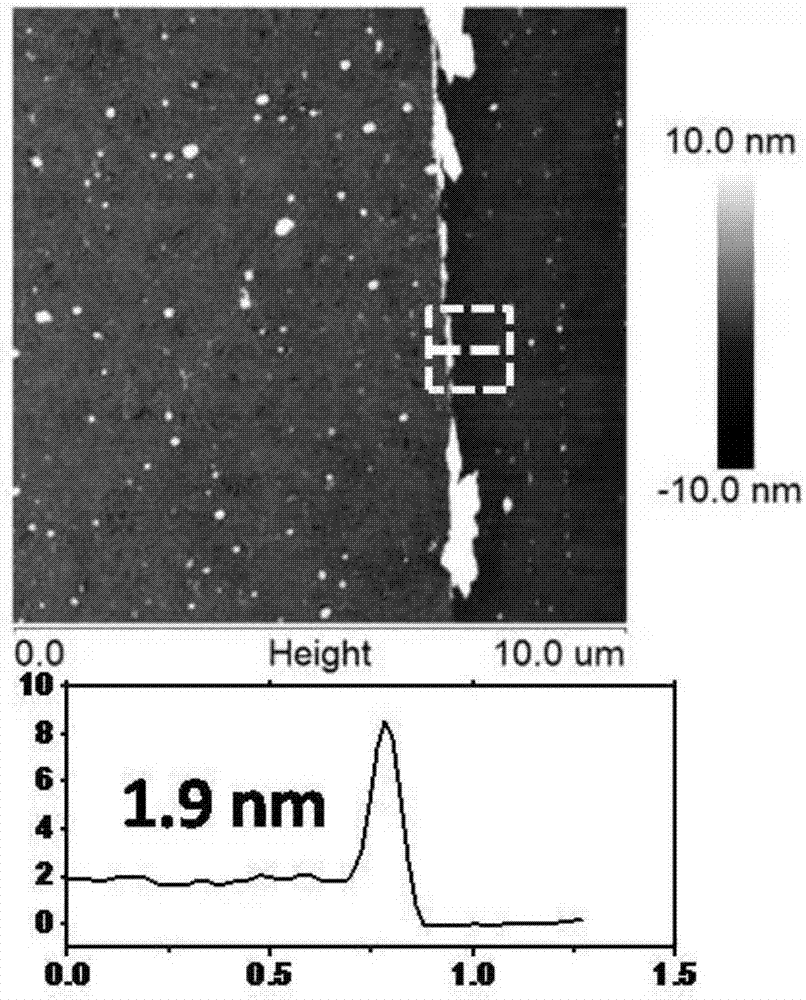

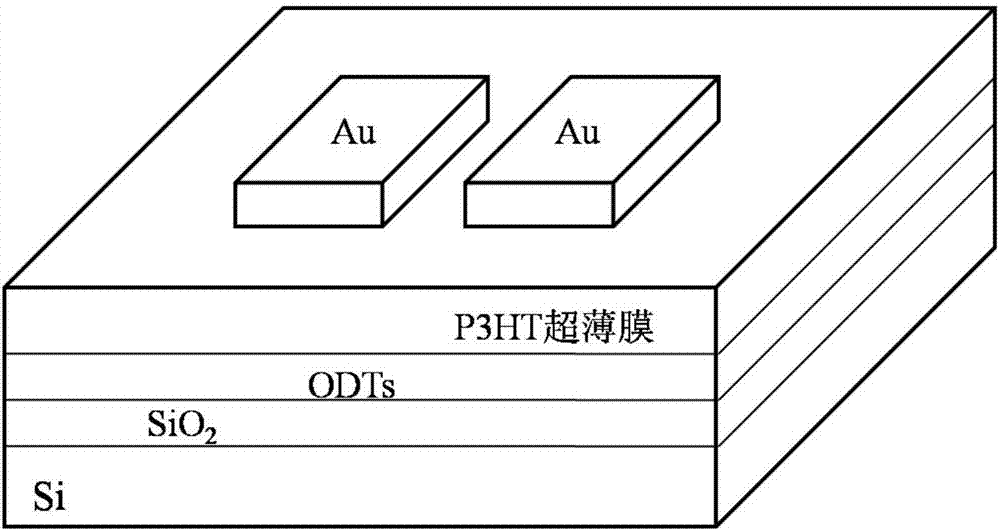

Ultrathin film and preparation method of organic field-effect transistor sensor based on ultrathin film

ActiveCN107192755ADifferent thicknessEasy to operateMaterial analysis by electric/magnetic meansOrganic solventOrganic field-effect transistor

The invention discloses an ultrathin film and a preparation method of an organic field-effect transistor sensor based on the ultrathin film. The preparation method is characterized by comprising the following steps: blending a polymer semiconductor material and a polymer insulating material in an organic solvent, and performing spin-coating to form a double-layer film; dissolving to remove the polymer insulating material film by adopting a good solvent, and obtaining the ultrathin film of the polymer semiconductor material; evaporating an electrode on the film, thereby obtaining the organic field-effect transistor sensor. The ultrathin film disclosed by the invention has the advantages of simple operation, high repeatability, low requirements on equipment and process conditions, no need of large precise instruments and equipment and the like; because the active layer has ultrathin thickness, the obtained sensor in the invention has the advantages of high sensitivity, high selectivity, low detection limit and the like, and has an important application prospect in the aspect of improving the sensing property of a gas sensor.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com