Method for preparing porous organic semiconductor film by using solution method and application thereof

A technology of organic semiconductors and semiconductors, applied in measuring devices, instruments, and material analysis through electromagnetic means, to achieve the effects of easy operation, simple methods, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

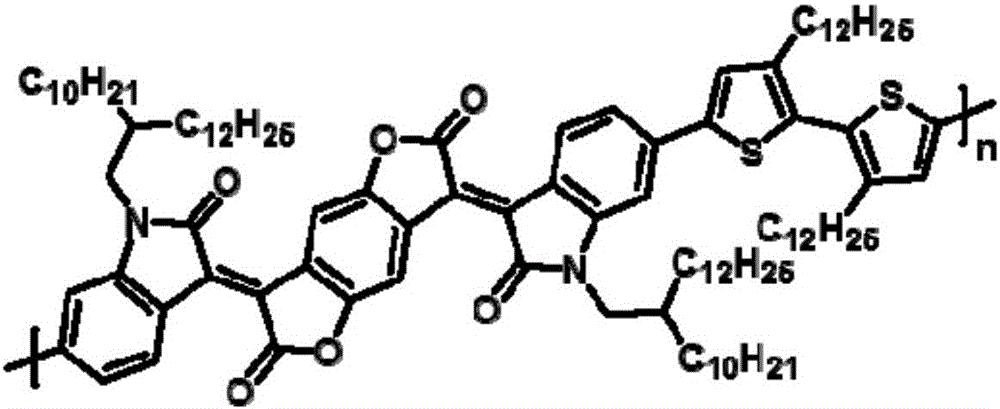

[0048] The present embodiment is based on isoindigo polymer isomer derivative PBIBDF-BT (structural formula such as figure 1) is a high-molecular-weight organic semiconductor (its weight-average molecular weight is 58852), with poly(1,4) butanediol adipate (PBA) (structural formula as shown in formula (16)) as a blended low-molecular-weight Oligomers (with a weight-average molecular weight of 2000), on Cytop-modified SiO 2 Porous PBIBDF-BT films were prepared on the substrate.

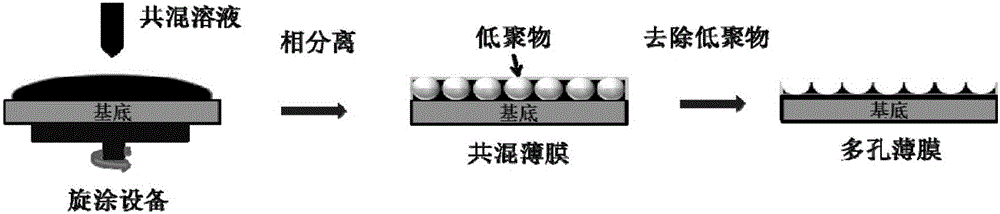

[0049] Such as figure 2 As shown, the preparation steps of the porous PBIBDF-BT film of the present embodiment are as follows:

[0050] with 300nm SiO 2 The heavily doped silicon wafer of the first layer is used as the substrate, which is washed with acetone, ethanol, and deionized water for 15 minutes in sequence, and then treated with ozone for 15 minutes. Subsequently, the Cytop solution was spin-coated on the substrate at a speed of 3000r / min for about 1min, and then placed on a hot stage at 1...

Embodiment 2

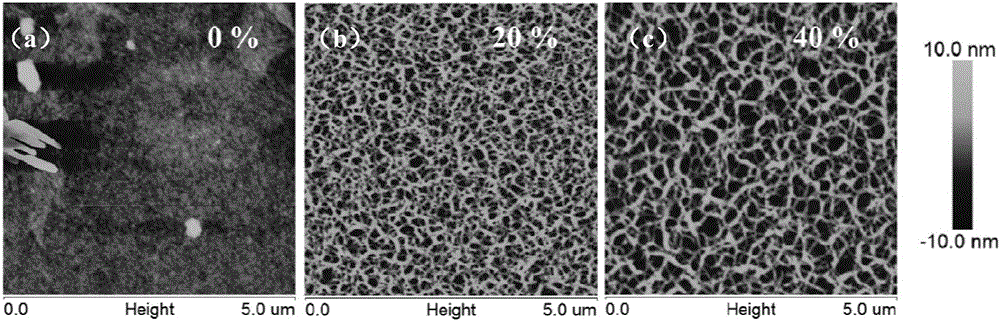

[0054] In this embodiment, the isoindigo polymer isomer derivative PBIBDF-BT (its weight average molecular weight is 55200) is a high molecular weight organic semiconductor, and polydimethylsiloxane (silicon oil for short, its structural formula is as formula (18) ) shown) as a blended low molecular weight oligomer (its weight-average molecular weight is 3000), a porous PBIBDF-BT film is prepared on a silicon substrate modified by octadecyltrichlorosilane (OTS), and by adjusting The content of oligomers is used to control the pore size in porous membranes. Specific steps are as follows:

[0055] Place the silicon substrate in H 2 SO 4 / H 2 o 2 (Volume ratio 7:3) was washed in the mixed solution at 150°C, and then the substrate was soaked in 20mL dry toluene dripped with 0.05mL OTS for 20min, so that the surface self-assembled a layer of hydrophobic OTS modified layer to obtain OTS-modified Silicon substrate.

[0056] PBIBDF-BT and silicone oil were weighed according to 1...

Embodiment 3

[0059] This embodiment prepares the porous organic semiconductor film in the same manner as in Example 1, the only difference is that PBIBDF-BT is replaced by PIID-BT polymer (its molecular formula is as follows: Figure 5 , its weight-average molecular weight is 65560), obtains the porous PIID-BT thin film.

[0060] The AFM figure of the porous PIID-BT film obtained in this embodiment is as follows Figure 6 As shown, it can be seen from the figure that a porous membrane is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com