Synthesis method of nano hexaboride

A synthesis method and hexaboride technology, which is applied in the field of synthesis of nano-hexaboride materials, can solve the problems of high cost, complex process, and high energy consumption, and achieve the effects of reducing energy consumption, reducing reaction temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

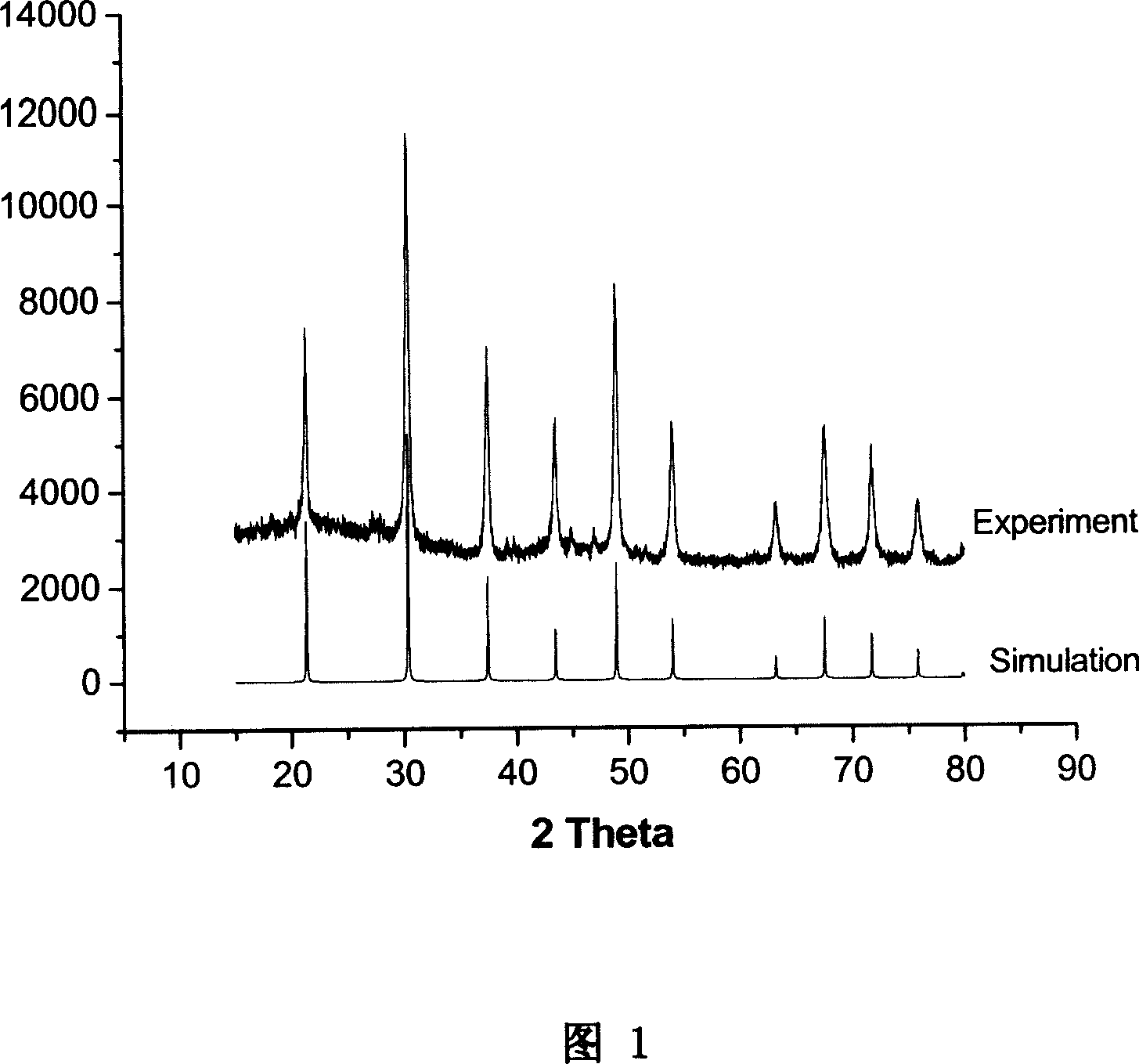

[0026] Proportional ingredients weigh analytically pure raw materials, LaCl 3 (2.326g) and NaBH 4 (2.1527g), mixed thoroughly and placed in a quartz tube reaction vessel. Put the quartz tube reaction vessel into a stainless steel autoclave and seal it; heat the autoclave to 550°C, keep it warm for 6 hours to fully proceed the reaction, and then cool it to room temperature; after collecting the product, use distilled water, 5% hydrochloric acid and distilled water in sequence Cleaning, and then drying the product obtained after filtration in a vacuum oven to obtain nano boride LaB 6 .

[0027] As can be seen from Figure 1, the resulting product is LaB 6 .

Embodiment 2

[0029] Proportional ingredients weigh analytically pure raw materials, CeCl 3 (2.1854g) and NaBH 4 (2.0126g), mixed well and placed in a quartz tube reaction vessel. Put the quartz tube reaction vessel into the stainless steel autoclave and seal it; heat the autoclave to 600°C, keep it warm for 3 hours to make the reaction fully proceed, and then cool it to room temperature; after collecting the product, use distilled water, 5% hydrochloric acid and distilled water in sequence Cleaning, and then drying the product obtained after filtration in a vacuum oven to obtain nano boride CeB 6 .

Embodiment 3

[0031] Proportional ingredients weigh analytically pure raw materials, CaCl 2 (1.2011g) and KBH 4 (3.5024g), fully mixed and then put into a stainless steel autoclave and then sealed; the autoclave was heated to 500 ° C, kept warm for 10 hours to allow the reaction to fully proceed, and then cooled to room temperature; Wash with hydrochloric acid and distilled water, and then dry the product obtained after filtration in a vacuum oven to obtain nano boride CaB 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com